12 minute read

Taking the plunge for a king-size

New challenges for historic newbuild yard

Alberto Perrone, refit sales director at large-yacht builder Lürssen, explains why the company is now embracing complex rebuild projects – and how the changing global energy sector could work to the advantage of the industry.

BY MAX STOTT

Lürssen has a 147-year-old history that proves its commitment to breaking records in the new-build sector. On its website, the company claims to have built the first motor boat in 1886, the world’s fastest commuter yacht in 1927, the longest yacht in the world in 2015 and the biggest yacht in the world in 2016. Therefore, as reputations in the new-build sector go, it’s not a bad one. But now, Lürssen is also starting to gain a significant reputation in multiple sectors of the market, especially refit.

“A refit is not just about necessary maintenance, it can also be a way to completely transform a yacht,” says Alberto Perrone, refit sales director at Lürssen. While the shipyard is known globally for its many new-build superyachts, the refit side of the business is just as exciting and challenging for its skilled workforce. “We enjoy the very complex rebuilds and refits. We like it when owners come to us with problems to solve, we want to do the things that other yards steer clear of,” says Perrone.

The past few years have seen some very notable yachts enter one of the many shipyards Lürssen has to offer, with 12 yachts between 70 metres and well over 100 metres undergoing work last year alone. Lürssen comprises a total of five shipyards in northern Germany, an array of covered sheds and drydocks and a manpower of more than 1,800 including over 450 engineers and naval architects.

This enables the company to build new yachts and transform existing ones alongside each other, using the same skilled workers and machinery, and dedicating the same facilities and expertise as they would to a brand new vessel.

“We know it’s quite unusual for a large-yacht builder to also dedicate its time to refit operations, but it’s actually a big advantage for our clients,” says Perrone. “Our workforce is used to extremely complex and time-consuming builds, so we are much better prepared to overcome any surprises.

“Our time management is worldrenowned, and the workforce is very disciplined in the practice of finding the right solutions, of doing things the right way, which is a crucial advantage when it comes to problem-solving on refits, where there will likely be unknowns.”

There are also five- and ten-year-old Lürssen yachts needing to undergo their scheduled surveys, and being able to take them back to the high-performance workforce that built them has obvious advantages.

One such recent success story was the colossal refit of the 110-metre Kaos, which enjoyed a substantial refit on both

HEALTH CARE CENTRE

REFIT & REBUILD REFIT CONSULTANCY

Kaos, ex Jubilee, which had up to 150 people at a time working on the refit.

CREW SERVICES

Photos: Klaus Jordan

SPARE PARTS SUPPLY

the interior and exterior after passing into new ownership. During busy periods, there were around 150 people at a time working on Kaos.

“In order to strengthen our service and refit activities, we founded our own refit company, Lürssen Yacht Refit & Services, so we can ensure our yachts achieve their full potential and life expectancy over the years,” says Perrone. “It enables us to meet our clients’ needs better, look after the yachts like we know how, and it has the added benefit of enabling us to improve and expand our service business.”

The past two years have seen record yacht sales, both in new build and brokerage, and many shipyards are now unable to provide a new-build slot for up to six or seven years. This leaves a large gap in the market for owners who are looking to purchase a boat but don’t want to wait to set sail for several years.

“If there is a yacht out there that broadly works for someone, then we have the capabilities to make it their perfect yacht,” explains Perrone. “Whether it’s cosmetic interior changes, paint jobs, hull extensions or complete rebuilds, we can do it all in a fraction of the time it would take them to build a new yacht. For some people, it’s the fastest route to getting a new yacht.

“The yacht conversion potential is huge and untapped. Many commercial boats are built on amazing platforms. For example, the oil-drilling vessels are incredibly stable even in big seas because they had to be in their previous lives.” Many of these vessels are only a couple of years old but have been taken out of service due to the changing energy sector and demand for oil in the North Sea.

“Many commercial vessels are large, extremely stable and comfortable and already come with diesel-electric propulsion, so the potential if someone wanted to transform one of these boats is definitely worth exploring, and it’s a challenge that Lürssen would be excited to take on,” says Perrone.

For many years, Lürssen has been developing and including sustainable options on its new builds, such as reducing emissions through intelligent energy management thanks to an artificial intelligence system that analyses the yacht’s usage, monitors and visualises the power supply and energy consumption and even performs automated power-management tasks.

Making a yacht more energyefficient can be as simple as changing fluorescent lights to LEDs or as complex as installing a heat-recovery system that saves energy by using the heat loss from the generators to heat the pool. Other successful solutions in the past have included introducing motion sensors to reduce light consumption and installing heat-insulating, foil-coated windows to keep the yacht cool and reduce AC usage. Innovations such as these were highlighted and broadcasted by Lennart Pundt, Lürssen’s head of project development, at The Superyacht Forum 2021.

Over the past few years, refit has quietly developed into a core part of the business for Lürssen. Although refit projects will always differ in size and style, the ultimate outcome will always be the same: that the yacht’s life expectancy and performance will be undeniably increased and comparable to that of a new build, and that the core value – whatever that may be for the owner – will be enhanced. MS

YACHT MANAGEMENT

SUPERYACHT LIFE SUPPORT

ADVERTISING

ADVERTISING

Spanning every sector of the superyacht sphere, SuperyachtNews is the industry’s only source of independent, thoroughly researched journalism. Access real-time news stories, market intelligence, on-demand videos and our dynamic network of live and virtual events delivered directly to your device.

SEEK ADVENTURE. BE VIGILANT.

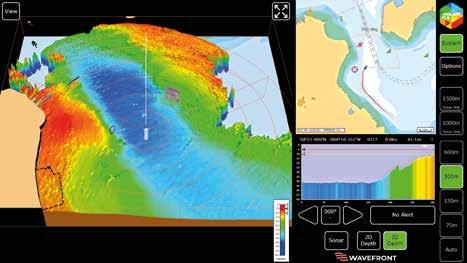

Vigilant, our Forward Looking Sonar (FLS), alerts s you to threats below the surface, so you have the time to take action and your guests can focus on the adventure.

VIGILANT - A WAVEFRONT PRODUCT www.wavefront.systems

Future focus on forward-looking sonar systems

Situational awareness for navigation and manoeuvring takes on a new dimension with Wavefront.

Real-time, high-resolution forward-looking sonar (FLS) provides an unparalleled tool for a superyacht. Any vessel navigating in poorly chartered areas, Polar regions or through debris fields is significantly disadvantaged without some form of FLS system.

There have been various iterations of sonar systems available on the wider market for a generation, but few could provide the level of detail that would inspire real confidence from a watchkeeper. The main drawbacks of these early generations of the technology were a lack of resolution and range. When using a sonar system that was limited by these factors, a vessel is forced to move cautiously, despite the read-outs ostensibly displaying the foreground of the vessel.

The technology has come a long way since its inception, as has the number of yachts venturing further afield and into less chartered waters. As any watchkeeper can attest after cruising the Pacific or Polar regions, many of the charts that support these voyages are outdated and inaccurate. Safe and environmentally conscious anchoring requires a detailed understanding of the depths and composition of the sea floor – details that were, in many cases, at best implied by limited and analogue data inputs.

Although FLS systems have been a more common feature for offshore supply, exploration cruising and naval applications, the superyacht industry has been slower to integrate them. Now leading the field, Wavefront has redefined the outermost limits for these technologies, designing systems that can meet the next generation of challenges specific to the yachting industry.

Wavefront’s solution is set apart by its high definition and range, which can allow relatively high-speed manoeuvring with confidence. From a performance perspective, Wavefront is pushing the boundary of the technology as far as it will go. The Vigilant Forward-Looking Sonar provides real-time 3D images of the seabed and water column ahead of the vessel.

The 1.5km range of the Vigilant 1500 system provides an unrivalled level of resolution at such a range, and detailed 3D resolutions at 600m provide a bridge team with valuable data streams for safe manoeuvring, anchoring and navigation. Having these data input in sufficient time allows the vessel to maintain sufficient speed and, in turn, water over rudders to maintain effective steering.

The simplest solution is to install a Wavefront system, such as Vigilant, into a bulbous bow, as seen in the graphic. Retrofitting these systems during a refit is also relatively easy. Measuring 300mm by 300mm, the projector unit fits into a sea chest, which in turn only needs a power cable and a connection to the ethernet.

As well as off-the-shelf systems, a custom project that the team is currently developing requires a forward-looking system that can detect semi-submerged containers while travelling at 26 knots. Wavefront has created a system that will detect a container 1.5km away, giving a high-speed yacht the vital minutes to adjust course.

The software is designed to integrate with existing on-board navigation equipment such as ECDIS, and via a standalone display can produce a highly detailed three-dimensional field view ahead of the vessel. With full adjustable limits and ranges imputable, vessel-specific UKC (under keel clearance) and contours colorations can be set.

Along with the Vigilant 1500 and 1000, Wavefront is developing a smaller unit, the Vigilant 500, with a significantly smaller footprint. The 500 is designed for smaller non-displacement superyachts, where technical space is at a premium. Although designed for a shorter maximum range of sonar capabilities, none of the Vigilant models will compromise the resolution or range of the 3D modelling.

THE NEW LUSBEN

BY MAX STOTT

Details have emerged that reveal the significance of Lusben’s three-year investment project …

Lusben, Azimut|Benetti Group’s Refit Division, is gearing up to tackle a new challenge that will see major investments over the next three years, with a massive expansion of the Livorno site. It’s an ambitious project that aims to give the brand a stronger international identity, but there will also be a huge upgrade in terms of facilities, technology, services and on-shore and quayside space, with the inclusion of hospitality areas for clients.

Lusben, which began life in Italy in 1956 in its renowned Viareggio headquarters, was taken over 22 years ago by Azimut|Benetti Group. The Livorno site was added in 2004, followed by Varazze in 2019, with the aim of ensuring a convenient offering for the potential market on the French Riviera.

Today, Lusben has a number of major initiatives underway that will ultimately lead to global expansion. The Livorno yard, which handles all the Refit Division’s largest superyachts, is just the starting point for this relaunch project.

The amount of space that is being added is monumental. Lusben recently received the final approval of the drydock area concession, which increases the total surface area from 100,000 to 220,000 sqm (a rise of 120 per cent), with yard space increasing from 55,000 to 90,000 sqm (64 per cent) and the water surface from a highly respectable 45,000 sqm to 130 sqm (190 per cent).

As part of the concession, the yard has also acquired a 180-metre-long floating dock with a capacity of 18,000 tonnes. The number of dry berths will increase from 25 to 35 (40 per cent) and in-water moorings from 20 to 32 (60 per cent).

The expansion plan continues at the Varazze production site, where a comprehensive redevelopment project is being finalised. The site has 15 dry berths plus a technical marina with 12 in-water moorings, and after the redevelopment it will also offer guest facilities and a crew area. Rounding out the facilities is a 400-tonne travel lift, while the site’s accommodation capacity is supplemented by availability at the adjacent Marina di Varazze, its natural extension.

The historic Viareggio yard has a 600-tonne travel lift and a pressurised, ventilated and heated (up to 70C) paint booth for boats up to 50 metres in length, a 30,000sqm marina, 34 yacht berths, a helideck and crew accommodation.

A challenge that has such ambitious goals requires the solidity of a wellorganised and highly motivated team. Today, the programme to expand the refit division, under the leadership of general manager Giorgio Casareto (appointed a few months ago), sees operations director Alessandro Lazzerini managing operating sites with a view to increasing the quality of services offered to clients, standardising and integrating processes between the various sites and improving the efficiency of the facilities. Working with him are Paolo Simoncini, Lusben Viareggio and Varazze site director, and Alessio Centelli, Lusben Livorno site manager.

“We’re implementing an exciting project full of new prospects that will lead to major new developments,” says Casareto. “By implementing a development strategy characterised by targeted investments, we want to create a company that can provide an even quicker response to our clients’ needs, supported as ever by our suppliers, who have always delivered the highest levels of quality.” MS

L-R: Alessandro Lazzerini, Paolo Simoncini, Giorgio Casareto and Alessio Centelli.