4 minute read

How Oceanco restored the charms of Lucky Lady

Photo: © Francisco Martinez

A 20-year-old yacht returns home for a makeover

We speak with life-cycle support manager Anton Smit about how the Dutch yacht builder reconstructed the 20-year-old vessel.

BY MAX STOTT

When 63-metre motoryacht Lucky Lady returned home to Oceanco for a rebuild, the mission was to turn the 20-year-old vessel into a ‘future-proof’ superyacht. It would be fair to assume this would be a slightly daunting task for any shipyard, but for the owners of this particular vessel, some comfort was taken from the fact that the yacht was coming back to its original creators.

Lucky Lady was almost completely gutted and then put back together, and, for this reason, it can be considered a rebuild rather than a refit. Alongside the yacht’s 20-year Lloyd’s Class survey, the work undertaken included complete overhauls of the main engine, steering unit and gearbox, while a new powermanagement system and exhaust filters were installed on the gensets.

The propeller shafts were replaced and a new chiller plant was also installed on board. To make Lucky Lady more operationally efficient, 820 metres of LED lights were fitted to her interior and exterior, while the exterior paintwork was upgraded to give it a fresh, contemporary look.

This may sound very achievable on paper, but the actual complexities and challenges that crop up with projects of this magnitude are often overlooked. Anton Smit, Oceanco’s life-cycle support manager who played an integral handson role in this project, says that while everything did eventually go to plan, it was by no means a walk in the park.

Refit yards are almost always looking for two important scarcities – time and space. Space is less of a problem for Oceanco considering that just a few years ago the company acquired a 28acre facility close to its headquarters at Alblasserdam in the Netherlands. However, time can still be a problem even for the most reputable and experienced shipyards, so how did Smit manage to complete such a major rebuild on schedule?

“At this scale of maintenance work, time is of the essence,” says Smit. “At Life Cycle Support we always seek to minimise the downtime of a yacht so she can return to her cruising programme as soon as possible.

“Upon arrival of a yacht to the Oceanco facilities, we inspect all its critical equipment such as the propulsion system, generators and tanks. This allows us to rule out any major repairs that have not been factored into the original brief in order to avoid surprises at the final stages of the refit.”

The responsibility of the project rests on the shoulders of the refit yard, but the client can also do things to make the process smoother and ultimately more cost-effective. Smit adds, “Involve us from the very start of your discussions. With current supply-chain issues, we will be able to plan ahead and avoid costly acceleration fees. Having access to the right materials, at the right time, has a positive impact on the budget.”

The superyacht industry tends to struggle with accurate and up-to-date terminology, and there is clearly more room for differentiation within the market without necessarily needing to adopt irrelevant terminology. So this project begs the question: Is it a refit or a rebuild?

If you ask Oceanco, they will say that

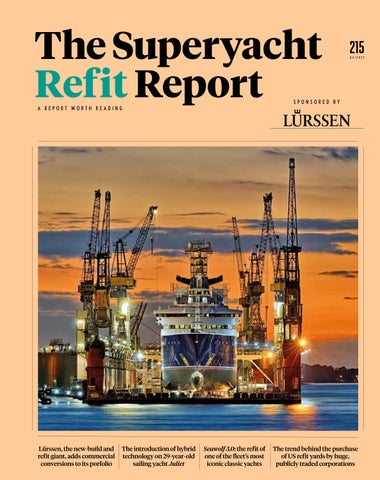

Lucky Lady returns to Oceanco.

it’s a rebuild, but surely if that were true the actual physical structure of the ship would have to be modified somewhat. With Lucky Lady, the majority of the modifications and upgrades involve the mechanics and technology of the vessel.

Smit says, “The way we approach the rebuild process at Oceanco is similar to that of a new build, only with a large part of the project already completed at the starting point. For any significant refit or rebuild project, it’s crucial to have a clear agreement between the yard, Classification society and Flag registry so we have an exact understanding of where original rules are applicable and where new rules should be implemented. For example, with installing a new luxury or crew interior, we should comply with the latest rules for Flag and Class.”

One of the biggest selling points for new-build yards that offer refitting services is that their vessels are ‘returning home’. With Lucky Lady, the original team involved in the construction of the yacht was available for the rebuild project. This allowed the yard to save time and money without any vital information getting lost in translation.

“We have many long-term employees at Oceanco who bring many years, or even decades, of experience with us to the table,” says Smit. “It is fair to say that engineering has come a long way over the past 20 years, across the whole industry, and having many members of the original team who built her involved in the refit was key as they know her by heart.”

Smit concludes, “Oceanco’s strategy is to work hand in hand with our comakers from the start of any project. Together with these co-makers and the owner’s team we determine the priorities and set the milestones of the project well in advance of the vessel arriving at our facilities.

“Progress is proactively monitored by a dedicated planning manager and production team throughout, so we can identify the critical path and mitigate risks for delays. Time and again, this method has proven effective to ensure redelivery within the scope of a life-cycle support project’s contract.” MS