11 minute read

Huisfit transforms 62-metre S/Y Athos

HUISFIT TRANSFORMS 62M S/Y ATHOS

This conversion project regularly employed up to 50 skilled workers for more than a year …

BY MAX STOTT

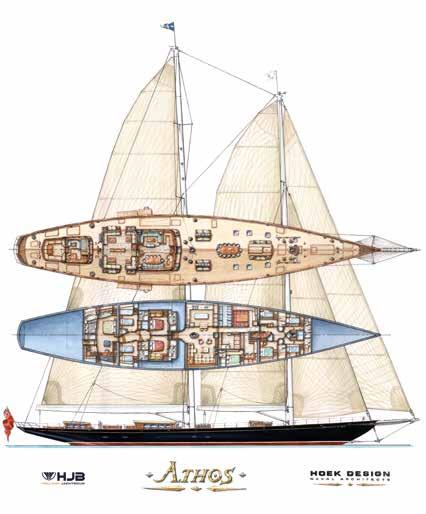

Before acquiring the 62m Hoekdesigned, Holland Jachtbouwbuilt Athos (2010), the new owner had chartered the vessel for around a year. Although he’d enjoyed the yacht, he saw many ways in which it would be possible to optimise and enhance the amenities and user experience.

As the project evolved in his mind, the refit list grew, and what started as a large refit project soon came to embrace all aspects of the Huisfit proposition: Refit, Rebuild and Renewal.

The stern overhang needed to be extended and, on deck, cockpit layouts had to be redesigned and a new forward navigation deckhouse had to be added. New booms, new sails and carbon rigging would ensure improved sail management and performance. All systems were to be updated and a considerable amount of the interior was to be replaced or reconfigured and updated.

Hoek Design was, once again, involved in all naval architecture work to accommodate these changes as well as the interior styling and layout of the new owner’s cabin, one of the guest cabins, the main salon, the new crew service area and the navigation deckhouse. Peter Mikic Interiors was responsible for the layout and styling of the main deckhouse and for the overall guest interior decoration.

Athos’s stern has been extended by 1.25 metres, a seemingly modest size increase, yet the concave and convex curves of the new section called for exceptional skills in the design and build of the aluminium structure in order to fit it perfectly into the aluminium hull. The extension, with a relocated pushpit, provides a new two-metre area for sunbeds behind the owner’s private cockpit.

The cockpit itself has been reconfigured for easier access and now features extra amenities, including a fridge and icemaker. The interior layout and furnishing of the owner’s deckhouse have been updated and, as a finishing touch, the new stern section has been complemented by a fine teak transom.

The main cockpit and deckhouse, aft of the mainmast, have been extensively modified to offer a true social hub for meeting and greeting, al-fresco dining and relaxed leisure activity. The new cockpit is wider and longer and can comfortably provide dining for 12 people. There’s also informal seating for guests to meet in smaller groups or find a quiet corner to enjoy a read.

Coffee tables are flexibly designed to adjust to also becoming dining tables. A bar with a fridge and icemaker has been installed. Just aft of the main cockpit, redesigned dashboard consoles sit on the port and starboard of the ship’s wheel.

The main deckhouse floor has been raised to one level and provides an enhanced outlook. The entire interior, including the navigation station, was taken out and a new design was installed. The deckhouse looks much larger, the traffic flow is better and the natural light has improved. A new classic-looking bar has been built on the portside and a couch occupies the space of the navigation station, while smaller dining tables and casual seating maximise flexibility.

More forward, the former crew companionway, which gave access to the crew quarters, has been replaced by a larger, third deckhouse, crafted in the same style as the other deckhouses. This encompasses a new navigation and secondary steering station and provides additional social space for the crew and access below. At the same time, the new design of the crew deckhouse improved the flow of the engine-room ventilation system and reduced the subsequent noise considerably.

The owner’s suite has been totally stripped out, redesigned and refitted. An additional porthole was made on either side and wasted space was eliminated to make full use of idle space. There are now two bathrooms in place of one and a new walk-in closet. Hard panelling has been replaced by subtle fabrics and the plank flooring has been carpeted to create a warm and tranquil ambience.

Just forward of the owner’s suite,

Photo: Wynne Projects

Photo: Wynne Projects

Athos before refit (top left), the stern (top right), interior during refit (middle) and forward deckhouse (bottom).

Photo: Wynne Projects Photo: Wynne Projects

Photo: Huisfit

Athos’s layout and sailplan after refit (right) and in 2010 (below).

Photo: Tom van Oossanen

a day head has been removed. The space subsequently obtained has been incorporated into the aft port guest cabin, where a fixed queen bed and a sofa have been added. Along with the three other guest cabins, the floor has been carpeted and the fielded panels have been upholstered.

Everything inside the corridor that connects the guest cabins has been renewed – new walls, new flooring, new carpets and even a new chandelier. The biggest change in this area was the replacement of the original curved staircase to the main deckhouse with a new stairway.

From the main deckhouse, stairs forward previously gave access to a lower salon in an open-plan setting with a showpiece galley. A fireplace was removed and a wall was built between the two areas to create a cosy and intimate media room to starboard. A long bookcase built cross-ships and luxurious new furniture complete the scene.

The galley to port, behind the new wall, has been custom-rebuilt and all equipment updated for modern haute cuisine practices. A stewardess station has been added, meaning that there’s more room in the galley for the chef. In the crew quarters, the laundry has allnew appliances, the crew cabins have new floors and the crew mess enjoys the benefit of new worktops.

Other enhancements include allnew navigation, alarm and safety systems and new lighting throughout. All programmable logic controllers (PLCs) have been changed and pumps upgraded. All guest spaces benefit from a state-of-the-art communications and entertainment package. The main tender has been completely rebuilt and there’s a new second tender. The bottom of the hull was blasted to bare aluminium before a full respray.

This conversion project regularly employed up to 50 skilled people for more than a year. Project manager Bear Wynne, from Wynne Projects Ltd, says, “The new Athos looks amazing. The multiple modifications have been beautifully done. The attention to detail and finish is excellent. The additions and modifications have not only improved the functionality of the yacht, but they have also enhanced its appearance. The quality of Huisfit’s work is exceptional.” MS

Athos will be available to charter, through Y.CO, in the Caribbean and Bahamas for this winter season.

Oceanco’s quest to transform its fleet

We speak with Paris Baloumis, group marketing manager at Oceanco, about the yard’s ambition to make the existing fleet more sustainable.

BY MAX STOTT

It’s no secret that Oceanco has had a record-breaking year in the newbuild sector, with many exciting projects for very high-profile clients. Some of the shipyard’s recent deliveries feature the most innovative green technology in the entire maritime sector: the likes of Black Pearl, Bravo Eugenia and Project Y721 have been written about extensively over the past few years.

The actual facilities at Oceanco have also been invested in massively; the Alblasserdam headquarters feature electrically driven heat pumps, reducing gas consumption by 50 per cent, and solar panels covering 10 per cent of the annual energy consumption.

This is all well and good, but Oceanco has been building superyachts since the 1990s, and if the company really wants to improve its green credentials it is going to have to start focusing on transforming its existing fleet.

Since 1993, Oceanco has built 38 yachts and, as it stands, not all of them are exactly futureproof. That’s why, in 2019, the shipyard acquired a 28-acre facility close to its Albasserdam headquarters in a bid to expand its capacity for maintenance, refit and lifetime extension work. The site includes a dedicated 132m x 38m space that is known as the home of Oceanco’s Life Cycle Support team. Even though this space is a new addition, it has already produced some exciting refit case studies.

Paris Baloumis, group marketing manager at Oceanco, explains the company’s vision. “Following on from a record-breaking year is both a challenge and a motivation to keep doing what we are doing,” says Baloumis. Oceanco has had three high-profile deliveries this year, and they currently have five superyachts under construction, all over 100 metres.

Baloumis adds, “That wasn’t the only busy part because we also had some high-profile refits with our Life Cycle Support team. We had the 82-metre Alfa Nero, which is an icon in the market, and that came for a refit and an upgrade. Then we had an old yacht, the 62m Lucky Lady, and we had Limitless, which is a beautiful yacht, but the one very fundamental project is the 20-year-old Oceanco [Lucky Lady] that came back for a total transformation, and we don’t call that a refit because it’s really a rebuild.”

Lucky Lady (see pages 53-55) has been described as a ‘catalyst case study’ by Oceanco. The vessel previously featured two 1,650hp Caterpillar diesel engines and a relatively traditional layout. However, this all changed. Baloumis says, “We brought it back to Oceanco and

Paris Baloumis, group marketing manager, Oceanco.

Oceanco’s facilities.

we took everything out, the engine, the gearbox, all the technology, everything, and we brought it all back up to modern standards."

There are more than 6,000 active yachts over 30m in the world that still rely on fossil fuels and they will eventually either need to be refitted and become a part of the energy transition or they will become relics of a bygone era. Oceanco has a fleet of 38 superyachts, so it’s entirely possible to imagine a future where every yacht ever built by Oceanco is running on sustainable fuels. This is not just a fantasy for Oceanco, but a genuine target they would like to reach.

“The energy transition is actually the most important focus for us because it’s all about how we can decrease our dependence on fossil fuels,” says Baloumis. “The interesting thing about this is that we all talk about it in the industry but no one has the magic formula, nobody can say it’s going to be this or it’s going to be that. So we are moving forward and we are making sure that everything we’re building now becomes future-proof. That means that with the way we build yachts now, we are going to be able to refit the vessels to accommodate future fuels, whether it is synthetic fuel or methanol or batteries.”

While it’s vital that more businesses focus on making the existing fleet more sustainable, the fact is that the majority of these yachts were not built with refit in mind. This means that the yard not only has to cope with the inevitable challenges that come with trying to incorporate new technology on an old vessel, but also that the actual physical refit process will be long, expensive and not very environmentally friendly. Fortunately, new-build yards are now taking this into further consideration – even if it does come at a price.

Baloumis adds, “We want owners of Oceanco yachts to be able to upgrade their vessels. That does mean it is more expensive to build initially because you have to think about denser fuels, bigger tanks, different kinds of insulation and different safety regulations for possible future fuels. At the same time, we think that this is the right way to go because new technologies are coming and you need to anticipate them and have a yacht that will be suitable in a new era.”

Oceanco turning a sharp focus towards sustainability and the refit sector is good news for the entire industry. The company has a vision that stretches across decades, and a chat with Baloumis is enough to convince anyone that while much of the competition is playing checkers, Oceanco is playing chess. MS