TAKTL Qualifications

CAPACITY

206,000 SQ FT

TOTAL FACILITIES

ANNUAL CAPACITY

1,000,000 SQ FT

DAILY CAPACITY

4,000+ SQ FT

206,000 SQ FT

TOTAL FACILITIES

ANNUAL CAPACITY

1,000,000 SQ FT

DAILY CAPACITY

4,000+ SQ FT

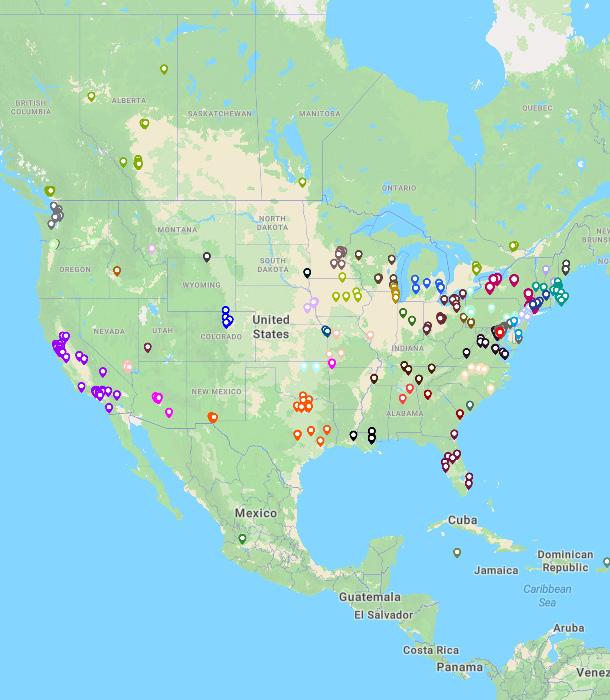

TAKTL is a family-owned business, headquartered in Pennsylvania, where 100% of our manufacturing occurs. We comply with both “Buy America” and “Buy American” requirements, and are proud to keep our manufacturing local to the United States.

Panels are cast on urethane mold forms, which are manufactured at the TAKTL factory for maximum precision and control.

Mixing and dosing systems are automated for precision control of mix properties.

Casting is machine-controlled for thickness and surface appearance.

Optimized curing conditions ensure long-term performance of the material.

CNC cutting equipment is specially programmed for each project to ensure tight dimensional tolerances and coordination with fabrication drawings.

TAKTL® Qualifications

High flexural and anchor pullout strength means fewer anchor points and lower hardware and subframe costs relative to comparable materials.

ASTM C1629 Level 3 Impact Resistance (highest level).

Panels are watertight with extremely low absorption compared to GRFC, fibercement, or traditional precast concrete. This improves durability because panels are not permeable to water and water-borne contaminants (like chlorine or salts).

Panels maintain strength through repeated freeze/thaw cycles and have therefore been chosen for extreme environments like Alaskan winters.

TAKTL panels are non-combustible, and have also been tested to the NFPA 285 standard.

TAKTL maintains a Notice of Acceptance from Miami Dade County and a Florida Product Approval for designing and using panels in hurricane zones.

Every TAKTL panel is cast with two layers of high performance, alkali-resistance glass mesh. These layers act as a safety net to greatly reduce the chance of panel failure in the event of an extreme impact (like a swing stage, a vehicle, or hurricane storm debris).

TAKTL offers a standard 20-year warranty at no added cost. TAKTL panels are engineered to last for the lifetime of the underlying structure.

TAKTL has matched hundreds of colors, to coordinate with everything from limestone to metal panel. In most cases, custom color is offered at no additional charge and will not affect the delivery schedule for the project.

TAKTL standard textures combined with the options for finishes (Colorseal, Cast, or Mediablast) mean a wide range of visual effects that can be achieved within the standard line. Custom textures are also available, however, and we are happy to work with design teams to craft something unique.

TAKTL’s professional team includes trained architects, designers, and manufacturing experts. Our technical support team is committed to the successful delivery of every project, and will work to manage foreseen and unforeseen challenges along with our customers.

TAKTL’s offices are adjacent to the manufacturing facility, and we do not sell through distribution so every project has the benefit of direct-to-factory information transfer and coordination.

We are committed to the final outcome of the project, not just to delivering our product on time. So our team will be invested in the process until the punch list is complete and the building is turned over.

TAKTL® Qualifications

THIRD

EIGHT CHECKPOINTS

TAKTL maintains a third-party certified Quality Management System under the International Code Council (ICC-ESR 3899).

Material and panels are checked at eight different points in the process, starting from raw materials and ending with final inspection prior to crating.

APPEARANCE

Panels are reviewed for visual appearance and color.

DIMENSIONS

Panel size, thickness, and anchor locations are all controlled to within +/- 1/16”.

PERFORMANCE

Panels are tested daily for strength performance.

TAKTL scheduling systems allow for planning well in advance, to accommodate demanding schedules and delivery requirements.

The team at TAKTL will be actively engaged in the submittals process to help the entire project team stay on track with finalizing details and approvals in advance of production release.

For large projects, TAKTL will dedicate production capacity well in advance to lock in a timeline that supports project requirements. Provided the project team stays on schedule with submittals and production release, this allows us to comfortably supply aggressive timelines and installation schedules.

TAKTL® Qualifications