Desalination Plants

Water Sector Expertise

SAVENER is a benchmark in desalination engineering, developing innovative solutions that ensure safe and sustainable access to drinking water. Our approach covers the entire desalination cycle, from the design of intake and treatment infrastructure to process optimization to maximize efficiency and minimize environmental impact.

Each desalination project requires a comprehensive vision, combining advanced engineering, operational efficiency, and sustainability. That is why SAVENER develops solutions tailored to the specific conditions of each site, considering factors such as source water quality, client requirements, economic feasibility, and environmental context.

The challenges of climate change, population growth, and the increasing demand for water have driven the need for increasingly advanced desalination infrastructure. SAVENER has the knowledge, experience, and technical capacity to tackle these challenges, providing large-scale desalination solutions that ensure a reliable and efficient water supply.

Desalination is not just about removing salts from seawater but a strategic process for economic, industrial, agricultural, and urban development. The key lies in designing highly efficient and sustainable desalination plants, optimizing every stage of the process to guarantee both technical and financial viability.

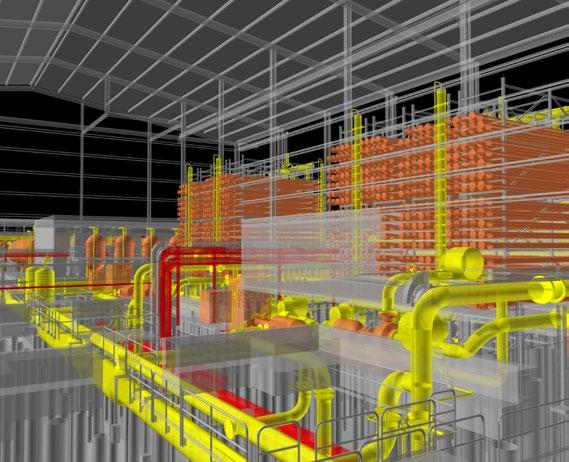

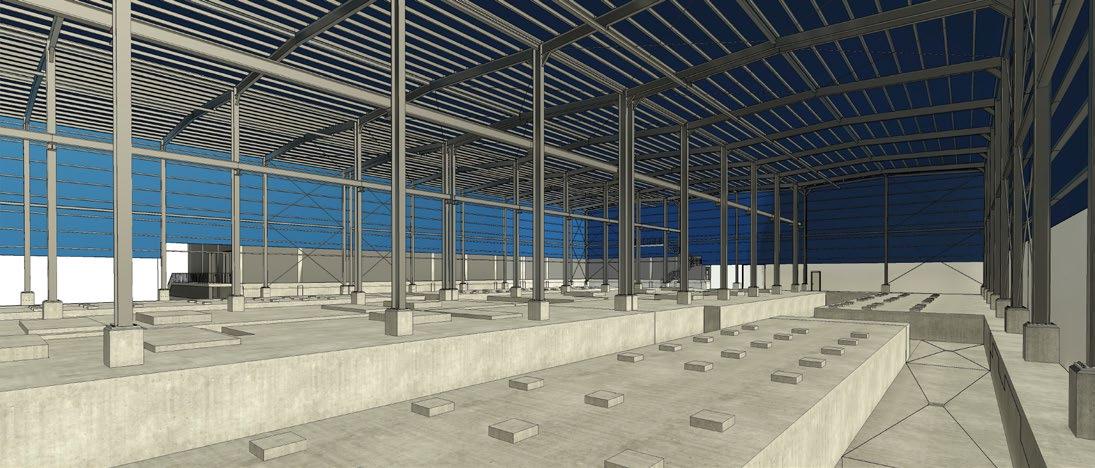

SAVENER has been involved in the design and development of some of the world’s largest and most innovative desalination plants, contributing expertise in process optimization, 3D modeling, mechanical and electrical engineering, piping, instrumentation and control, HVAC, and treatment processes.

Our technical team has designed and implemented pioneering solutions that have redefined industry standards in the desalination sector. Our adaptability and knowledge of the EPC market allow us to integrate into any development team, ensuring efficient collaboration with the world’s leading contractors and engineering firms.

The geographic diversity of desalination projects has led SAVENER to develop in-depth knowledge of international regulations, as well as to employ advanced simulation and modeling tools to ensure compliance with the most stringent technical requirements.

Our goal is not just to act as an engineering provider but to become a strategic partner, offering technical consulting, cost optimization, and operational efficiency at every stage of the project, from design to commissioning and maintenance.

Services

Capabilities Summary

SAVENER is a leading provider in the design and development of seawater reverse osmosis (SWRO) desalination plants, working with some of the largest global EPC contractors and operators.

Among our most recent projects are:

∙ Engineering and detailed design of the Barka V Desalination Plant in Oman, with a capacity of 100,000 m³/day.

∙ Detailed design of the Ghubrah III Desalination Plant, with a capacity of 300,000 m³/day, the largest in Oman.

Over the past five years, SAVENER has conducted preliminary studies, feasibility assessments, and conceptual designs for desalination plants ranging from 100,000 to 800,000 m³/day, solidifying its leadership in the sector.

Our expertise covers all disciplines required for the development of large-scale desalination projects, including:

∙ Civil Engineering, Architecture, Marine Works, Structural Engineering, Mechanical, Electrical, Instrumentation and Control, Piping, and Process Engineering.

∙ Hydraulics, Oceanographic Studies, and Environmental Assessments.

∙ Safety and reliability analysis, including CHAIR, HAZOP, HAZID, HAZCON, HACCP, and SPoF.

∙ SIL (Safety Integrity Level) studies, noise analysis, and design optimization.

∙ Site evaluations, environmental permitting, and stakeholder management.

∙ Development of national desalination strategies, advising governments and organizations on water resource planning and management.

The projects in which SAVENER has participated span various regions worldwide, particularly in the Middle East, where desalination has become a key element in sustainable development and potable water supply. In addition to full engineering services for these projects, SAVENER has conducted research and preliminary analyses for multiple facilities, serving both public and private clients.

The following chapters present the most significant desalination projects in which SAVENER has been involved, highlighting their impact on the industry and their contribution to innovation in desalination engineering.

Services

Innovative Solutions for Optimal Performance

Process optimization is a key factor in the design of desalination systems, especially in membrane pretreatment and post-treatment phases. Effective pretreatment not only protects membranes and extends their lifespan but also improves operational efficiency and reduces costs.

At SAVENER, we have developed advanced Process Optimization strategies for desalination plants, conducting bench-scale and pilot-scale testing to evaluate alternatives that enhance overall performance. Thanks to this methodology, we have achieved:

∙ Reduction in capital costs, by designing more efficient systems adapted to the characteristics of the feedwater.

∙ Operational cost savings, through energy consumption optimization, minimized chemical cleaning requirements, and reduced waste production.

SAVENER’s approach in every project is to fully understand the needs of all stakeholders involved, from engineering designers to plant operators. Our extensive experience in desalination plants allows us to develop solutions tailored to each specific context,

ensuring optimal integration of all process units within the facility. Among our solutions are:

∙ Advanced pre-treatment systems to ensure high-quality feedwater for membranes, reducing biological, colloidal, and scaling fouling.

∙ Filtration optimization, utilizing dual-stage filtration, multimedia filtration, or ultrafiltration systems, depending on the feedwater quality.

∙ Ultraviolet (UV) disinfection, minimizing the use of biocides and controlling microbial growth within the plant.

∙ Energy recovery strategies to reduce power consumption in reverse osmosis processes.

With an approach based on innovation and efficiency, SAVENER ensures that each desalination project achieves maximum performance with minimal operational and environmental impact.

Value Engineering in Desalination

At SAVENER, we apply Value Engineering (VE) principles to maximize the efficiency and sustainability of desalination projects, optimizing every phase of the process without compromising plant quality or operability. Our multidisciplinary team has a solid track record in conducting VE studies for desalination plants, ensuring innovative solutions that reduce costs, improve performance, and guarantee operational reliability.

Through our experience, we have developed optimization strategies for desalination projects of various scales, from small facilities to large infrastructures exceeding $900 million. SAVENER’s Value Engineering is based on:

∙ Detailed pre-treatment analysis, selecting technologies that reduce suspended solids and minimize membrane fouling.

∙ Optimization of reverse osmosis design, balancing energy efficiency, water recovery, and equipment longevity.

∙ Comprehensive economic evaluation, considering the total cost of ownership (CAPEX + OPEX) to ensure long-term cost-effective solutions.

∙ Use of advanced modeling and simulation tools, enabling predictive plant behavior analysis and anticipating potential optimizations.

∙ Efficient planning and scheduling, ensuring smooth project execution from conception to commissioning.

Through our Value Engineering approach to desalination, SAVENER delivers sustainable, efficient, and tailored solutions that maximize investment and guarantee optimal performance for each desalination plant.

Disciplines

Engineering Parter of the most important EPC Companies of the world, supporting from the areas:

∙ PM (Project Management & Coordination)

∙ Design (3D Modelling)

∙ Civil/Structures

∙ Architecture

∙ Mechanical

∙ Piping

∙ Process

∙ Marine Works

∙ I&C

∙ Electricity

∙ Auxiliaries

PM (Project Management & Coordination)

• Engineering projects procedure methodology

• General conditions document for the project and site

• Battery limits - Project General Design

• Project Management Plan

• Engineering Management Plan

• Coding criteria

• Engineering Communication Plan

• Engineering Document List (EDL)

• General arrangement

• Preliminary general design

• Spare, lubricant, chemicals, special tools manual

• Interface design

• Permit List

Civil/Structures

• Basic Structural Calculation Criteria Document

• BOQ - Administration Building r.c. structure + architectural

• BOQ - Cartridge Filters r.c. structure

• BOQ - Cartridge Filters Steel Structure

• BOQ - Chemical drainage pits r.c. structure

• BOQ - Chemical Post-treatment Reinf. Concrete + Architectural

• BOQ - Chemical Post-treatment Steel Structure

• BOQ - Chemical Pre-treatment Reinf. Concrete + Architectural

• BOQ - Chemical Pre-treatment Steel Structure

• BOQ - Chillers Building r.c. structure

• BOQ - Chillers Building steel structure

• BOQ - Chillers Electrical Building r.c. structure + architectural

• BOQ - CIP System r.c. structure + Architectural

• BOQ - CIP System Steel Structure

• BOQ - CO2 Dosing System Reinf. Concrete + Architectural

• BOQ - CO2 Dosing System Steel Structure

• BOQ - DAF Electrical Building r.c. structure + architectural

• BOQ - DAF Reinf. Concrete + Architectural

• BOQ - DAF Staircase r.c. foundations

• BOQ - DAF Staircase Steel Structure

• BOQ - DAF Steel Structure

• BOQ - Diesel Fuel Oil shelter r.c. foundations

• BOQ - Diesel Fuel Oil shelter steel structure

• BOQ - Electrical pits r.c. structure

• BOQ - Emergency Diesel Generator Building Reinf. Concrete + Architectural

• BOQ - Filtered Water Pumping Station Reinf. Concrete + Architectural

• BOQ - Filtered Water Pumping Station Steel Structure

• BOQ - Filtered Water Tanks Reinf. Concrete

• BOQ - Filters Backwash Dirty Water Tanks r.c. structure + Architectural

• BOQ - Filters Backwash Dirty Water Tanks steel structure

• BOQ - Filtration Electrical Building r.c. structure + architectural

• BOQ - Fire-Fighting System Reinf. Concrete + Architectural

• BOQ - Flushing Tanks r.c. foundations

• BOQ - GF Reinf. Concrete + Architectural

• BOQ - GF Steel Structure

• BOQ - Gravity Sludge Thickeners r.c. structure

• BOQ - Guardhouse Building Reinf. Concrete + Architectural

• BOQ - HVAC ground basements r.c. structure

• BOQ - Incoming Power Transformers r.c. structure

• BOQ - Lime Storage Area Reinf. Concrete + Architectural

Disciplines

• BOQ - Lime Storage Area Steel Structure

• BOQ - Limestone Blowers r.c. structure + architectural

• BOQ - Limestone Blowers steel structure

• BOQ - Limestone Filters Building Reinf. Concrete + Architectural

• BOQ - Limestone Filters Building staircase r.c. foundations

• BOQ - Limestone Filters Building staircase steel structure

• BOQ - Limestone Filters Building Steel Structure

• BOQ - Main Electrical Building Reinf. Concrete + Architectural

• BOQ - MEB staircase r.c. foundations

• BOQ - MEB staircase steel structure

• BOQ - Neutralization pits r.c. structure + architectural

• BOQ - Neutralization pits steel structure

• BOQ - Oily Water Chamber pits r.c. structure

• BOQ - Oily Water drainage network

• BOQ - Oily Water drainage pits r.c. structure

• BOQ - Outfall Pit Reinf. Concrete + Architectural

• BOQ - Pipe Supports r.c. foundation

• BOQ - Pipe Supports r.c. foundations

• BOQ - Pressurization Pumping Station Reinf. Concrete + Architectural

• BOQ - Pressurization Pumping Station Steel Structure

• BOQ - Product Water Flowmeter Reinf. Concrete + Architectural

• BOQ - PW Reservoir Civil Works

• BOQ - PW Reservoir Electrical Underground System Civil Work

• BOQ - PW Reservoir Fence and Gates

• BOQ - PW Reservoir Main Process Pipes Underground Earthworks

• BOQ - PW Reservoir Pavement and Sidewalks

• BOQ - PW Reservoir Steel Stairs, ladders and platforms

• BOQ - PW Reservoir Steel Pipe Rack

• BOQ - PW Reservoir Strom Water Drainage System

• BOQ - RO Building Reinf. Concrete + Architectural

• BOQ - RO Building Steel Structure

• BOQ - RO Terminal Drainage Pit Reinf. Concrete

• BOQ - Screening Chlorination Pumps r.c. foundations

• BOQ - Sewage drainage pits r.c. structure

• BOQ - Sewage lifting pits r.c. structure

• BOQ - Sewage Treatment System Reinf. Concrete + Architectural

• BOQ - Sewage Treatment System Steel Structure

• BOQ - Sludge Recirculation Pumps r.c. foundations

• BOQ - Sludge Silos Reinf. Concrete

• BOQ - Sludge Silos Steel Structure

• BOQ - Sludge Treatment Building r.c. structure + Architectural

• BOQ - Sludge Treatment Building Steel Structure

• BOQ - STB staircase r.c. foundations

• BOQ - STB staircase steel structure

• BOQ - Stoplog Storage r.c. foundations

• BOQ - Storm Water drainage network

• BOQ - Storm Water drainage pits r.c. structure

• BOQ - Storm Water Terminal Pit r.c. structure

• BOQ - Street Light poles r.c. foundations

• BOQ - SWI & Pumping Station Steel Structure

• BOQ - SWI Chemicals Reinf. Concrete + Architectural

• BOQ - SWI Chemicals Steel Structure

• BOQ - SWI Electrical Building r.c. structure + architectural

• BOQ - SWI Reinf. Concrete + Architectural

• BOQ - Valve Pits r.c. structure

• BOQ - Waste Water Treatment Plant r.c. structure

• BOQ - Workshop & Warehouse Reinf. Concrete + Architectural

• BOQ - Workshop & Warehouse staircase r.c. foundations

• BOQ - Workshop & Warehouse staircase steel structure

• BOQ - Workshop & Warehouse Steel Structure

• BOQ - WWT Plant staircase r.c. foundations

• BOQ - WWT Plant staircase steel structure

• Calculation Report - Administration Building r.c. structure

• Calculation Report - Cartridge Filters r.c. structure

• Calculation Report - Cartridge Filters steel Structure

• Calculation Report - Chemical Posttreatment Reinf. Concrete Structure

• Calculation Report - Chemical Posttreatment Steel Structure

• Calculation Report - Chemical Pretreatment Reinf. Concrete Structure

• Calculation Report - Chemical Pretreatment Steel Structure

• Calculation Report - Chillers Building r.c. structure

• Calculation Report - Chillers Building steel structure

• Calculation Report - Chillers Electrical Building r.c. structure

• Calculation Report - CIP System Reinf. Concrete

• Calculation Report - CIP System Steel Structure

• Calculation Report - CO2 Dosing System Reinf. Concrete Structure

• Calculation Report - CO2 Dosing System Steel Structure

• Calculation Report - DAF Electrical Building r.c. structure

• Calculation Report - DAF Reinf. Concrete Structure

• Calculation Report - DAF Staircase Steel Structure and r.c. foundations

• Calculation Report - DAF Steel Structure

• Calculation Report - Diesel Fuel Oil shelter steel structure and r.c. foundations

• Calculation Report - Emergency Diesel Generator Building Reinf. Concrete Structure

• Calculation Report - Filtered Water Pumping Station Reinf. Concrete Structure

• Calculation Report - Filtered Water Pumping Station Steel Structure

• Calculation Report - Filtered Water Tanks r.c. Structure

• Calculation Report - Filters Backwash Dirty Water Tanks r.c. structure

• Calculation Report - Filters Backwash Dirty Water Tanks steel structure

• Calculation Report - Filtration Electrical Building r.c. structure

• Calculation Report - Fire-Fighting System Reinf. Concrete Structure

• Calculation Report - Flushing Tanks r.c. foundations

• Calculation Report - GF Reinf. Concrete Structure

• Calculation Report - GF Steel Structure

• Calculation Report - Gravity Sludge Thickeners r.c. structure

• Calculation Report - Guardhouse Building Reinf. Concrete Structure

• Calculation Report - Incoming Power Transformers r.c. structure

• Calculation Report - Lime Storage Area Reinf. Concrete Structure

• Calculation Report - Lime Storage Area Steel Structure

• Calculation Report - Limestone Blowers r.c. structure

• Calculation Report - Limestone Blowers steel structure

• Calculation Report - Limestone Filters Building Reinf. Concrete Structure

• Calculation Report - Limestone Filters Building staircase steel structure and r.c. foundations

Disciplines

• Calculation Report - Limestone Filters Building Steel Structure

• Calculation Report - Main Electrical Building Reinf. Concrete Structure

• Calculation Report - MEB staircase steel structure and r.c. foundations

• Calculation Report - Neutralization pits r.c. structure

• Calculation Report - Neutralization pits steel structure

• Calculation Report - Oily Water Chamber r.c. structure

• Calculation Report - Oily water drainage network

• Calculation Report - Outfall Pit Reinf. Concrete Structure

• Calculation Report - Pressurization Pumping Station Reinf. Concrete Structure

• Calculation Report - Pressurization Pumping Station Steel Structure

• Calculation Report - Product Water Flowmeter Reinf. Concrete Structure

• Calculation Report - PW Reservoir Concrete

• Calculation Report - PW Reservoir Electrical Underground System Civil Work

• Calculation Report - PW Reservoir Steel Pipe Rack

• Calculation Report - PW Reservoir Steel Stairs, ladders and platforms

• Calculation Report - PW Reservoir Storm Water Drainage System

• Calculation Report - RO Building r.c. structure

• Calculation Report - RO Building Steel Structure

• Calculation Report - RO Terminal Drainage Pit r.c. structure

• Calculation Report - Roads design

• Calculation Report - Sewage Treatment System Reinf. Concrete Structure

• Calculation Report - Sewage Treatment System Steel Structure

• Calculation Report - Sludge Silos Reinf. Concrete Structure

• Calculation Report - Sludge Silos Steel Structure

• Calculation Report - Sludge Treatment Building r.c. structure

• Calculation Report - Sludge Treatment Building Steel Structure

• Calculation Report - STB staircase steel structure and r.c. foundations

• Calculation Report - Storm Water Drainage Network

• Calculation Report - Storm Water Terminal Pit r.c. structure

• Calculation Report - SWI & Outfall Pit Reinf. Concrete Structure

• Calculation Report - SWI & Pumping Station Steel Structure

• Calculation Report - SWI Chemicals Reinf. Concrete Structure

• Calculation Report - SWI Chemicals

Steel Structure

• Calculation Report - SWI Electrical Building r.c. structure

• Calculation Report - Valve Pits r.c. structure

• Calculation Report - Waste Water Treatment Plant r.c. structure

• Calculation Report - Workshop & Warehouse Reinf. Concrete Structure

• Calculation Report - Workshop & Warehouse staircase steel structure and r.c. foundations

• Calculation Report - Workshop & Warehouse Steel Structure

• Calculation Report - WWT Plant staircase steel structure and r.c. foundations

• Concrete structures BoQ

• Drainage System Philosophy

• Drainage System Philosophy Technical Specification

• General Design Criteria for Architectural Standard Details

• General Design criteria for civil works

• Pipes Underground Earthworks BoQ

• Reservoir Civil Works BoQ

• Reservoir Electrical Underground System Civil Work BoQ

• Reservoir Fence and Gates BoQ

• Reservoir Pavement and Sidewalks BoQ

• Reservoir Steel Stairs, ladders and platforms BoQ

• Reservoir Steel Pipe Rack BoQ

• Reservoir Storm Water Drainage System BoQ

• Technical Specification for Climatic Study

• Technical Specification for Onshore Civil Works for Subcontracting

• Technical Specification for Temporary Facilities

• Techcnical Specification for Topografic Survey of Existing Roads

• Vendor Documents Reviews Mechanical

• Agitation and neutralization CIP pumps Data Sheet

• Agitation and neutralization CIP pumps Tabulation

• Agitation and neutralization CIP pumps Technical Specification

• Air compressor Data Sheet

• Air compressor Technical specification

• Blowers (Filters & Limestone beds) Data Sheet

• Blowers (Filters & Limestone beds) technical specification

• Blowers Tabulation

• Cartridge filters Data Sheet

• Cartridge filters Tabulation

• Cartridge filters technical specification

• Chemical loading pumps Data Sheet

• Chemical loading pumps Tabulation

• Chemical loading pumps Technical specification

• CIP heater Data Sheet

• CIP heater Tabulation

• CIP Heater Technical Specification

• CIP pumps Data Sheet

• CIP pumps Tabulation

• CIP pumps Technical Specification

• DAF AIR compressor Data Sheet

• DAF recirculation pumps Data Sheet

• DAF recirculation pumps Tabulation

• DAF recirculation pumps Technical Specification

• DAF-Air compressor Tabulation

• DAF-Air compressor Technical specification

• Data sheets Hoist & cranes Data Sheet

• Diesel oil system Data Sheet

• Diesel oil system Tabulation

• Diesel oil system Technical Specification

• Dispersant dosing skid Data Sheet

• Dispersant Dosing skid Tabulation

• Dispersant dosing skid Technical Specification

• Eff Sludge Thickener Technical Specification

• Effluent Sludge Thickener Data Sheet

• Engineering HVAC System Technical Specification

• ERD booster pump Data Sheet

• ERD booster pump Technical Specification

• ERD Booster pumps Tabulation

• Ferric chloride dosing skid Data Sheet

• Ferric Chloride Dosing skid Tabulation

• Ferric chloride dosing skid Technical Specification

• FFS&FFD System Engineering information List

• FFS&FFD System Technical Specification

• FFS&FFD System Calculation

• FFS&FFD System Engineering information Equipment Data Sheet

• FFS&FFD System Tabulation

• Filtered water pumps Data Sheet

• Filtered water pumps Tabulation

• Filtered water pumps Technical Specification

• GRP Covers Tabulation

• GRP tanks Data Sheet

Disciplines

• GRP tanks Technical Specification

• GRP tanks Calculations

• GRP tanks Tabulation

• High Pressure Pumps Data Sheet

• High pressure pumps Tabulation

• High Pressure Pumps Technical Specification

• Hoist & cranes Tabulation

• Hoist & cranes Technical Specification

• HVAC System Calculation

• HVAC System Engineering information Equipment Data Sheet

• HVAC System Engineering information List

• HVAC System Engineering Tabulation

• Installation & Erection for Mechanical Data Sheet

• Installation & Erection for Mechanical equipment Tabulation

• Installation & Erection for Mechanical Technical Specification

• Lamelar Sludge scrapers Data Sheet

• Lamelar Sludge scrapers Tabulation

• Lamelar Sludge scrapers Technical Specification

• Lubricant list

• Mechanical Calculation of RO Racks

• Mechanical design criteria

• Mechanical equipment General specification

• Mechanical Equipment List

• Mechanical Spare parts List

• Mechanical workshop equipment Data Sheet

• Mechanical workshop equipment Tabulation

• Mechanical workshop equipment Technical Specification

• Metallic Tanks Calculation

• Metallic Tanks Data Sheet

• Metallic Tanks Tabulation

• Metallic Tanks Technical Specification

• Miscellaneous Mechanical Elements (inyection quills, silica gel, eyectors) Data Sheet

• Miscellaneous Mechanical Elements (inyection quills, silica gel, eyectors) Technical Specification

• Miscellaneous Mechanical Elements Tabulation

• Mixers WWT Data Sheet

• Mixers WWT Tabulation

• Mixers WWT Technical Specification

• Oils & Lubricants Data Sheet

• Oils & Lubricants Tabulation

• Oils & Lubricants Technical Specification

• Painting Technical specification

• Penstocks (others) Data Sheet

• Penstocks (others) Tabulation

• Penstocks (others) Technical Specification

• Performance Guarantee Pumps

• Pneumatic/Aircompress Elements (filters, dryers, valves and tanks...) Data Sheet

• Pneumatic/Aircompress Elements (filters, dryers, valves and tanks...) Tabulation

• Pneumatic/Aircompress Elements (filters, dryers, valves and tanks...) Technical Specification

• Polypacks Data Sheet

• Polypacks Tabulation

• Polypacks Technical specification

• Pressure Groups (Service & Potable Water) Data Sheet

• Pressure Groups (Service & Potable Water) Tabulation

• Pressure Groups (Service & Potable Water) Technical Specification

• Process elements Covers Data Sheet

• Process elements Covers Technical Specification

• Product water pump Data Sheet

• Product water pump Technical Specification

• Product water pumps Tabulation

• RO Pressure vessels Data Sheet

• RO Pressure vessels Tabulation

• RO Pressure vessels Technical Specification

• Safety Showers & Safety Elements Data Sheet

• Safety Showers & Safety Elements Tabulation

• Safety Showers & Safety Elements Technical Specification

• Sample panels Data Sheet

• Sample panels Tabulation

• Sample panels Technical Specification

• Scissor lifts Data Sheet

• Scissor lifts Tabulation

• Scissor lifts Technical Specification

• Screen cleaning pumps Data Sheet

• Screen cleaning pumps Tabulation

• Screen cleaning pumps Technical Specification

• Seawater Intake Screening Data sheets (penstock and stoplog included) Tabulation

• Seawater Intake Screening System Data Sheet

• Seawater Intake Screening Technical specification (penstock and stoplog included) Technical Specification

• Sludge and Sumps Pumps Data Sheet

• Sludge and Sumps Pumps Tabulation

• Sludge and Sumps Pumps Technical Specification

• Sludge silo Data Sheet

• Sludge silo Tabulation

• Sludge silo Technical specification

• Sodium Bisulphite dosing skid Data Sheet

• Sodium Bisulphite dosing skid Technical Specification

• Sodium Bisulphite Dosing skid Tabulation

• Sodium Hydroxide dosing skid Data Sheet

• Sodium Hydroxide Dosing skid Tabulation

• Sodium Hydroxide dosing skid Technical Specification

• Sodium Hypochlorite dosing skid Data Sheet

• Sodium Hypochlorite Dosing skid Tabulation

• Sodium Hypochlorite dosing skid Technical Specification

• Sodium Silicofluoride Dosing skid Tabulation

• Sodium Silicofluoride dosing skid Technical Specification

• Sulfuric Acid dosing skid Data Sheet

• Sulfuric Acid dosing skid Technical Specification

• Sulphuric acid Dosing skid Tabulation

• SWI pumps Data Sheet

• SWI pumps Tabulation

• SWI pumps Technical Specification

• Tabulation –Effluent Sludge Thickener Tabulation

• Weirs & Chanels Data Sheet

• Weirs & Chanels Tabulation

• Weirs & Chanels Technical Specification

• WWT Plant pumps Data Sheet

• WWT Plant pumps Tabulation

• WWT Plant pumps Technical Specification Piping

• Air valves Data sheet

• Air valves Tabulation

• Air valves Technical Specification

• Ball valves Data sheet

• Ball valves Tabulation

• Ball valves Technical Specification

• Butterfly valves Data sheet

• Butterfly valves Tabulation

• Butterfly valves Technical Specification

• Check valves Data sheet

• Check valves Tabulation

• Check valves Technical Specification

• Control valves Data sheet

• Control valves Tabulation

• Control valves Technical Specification

• Counterbalanced valves Data sheet

Disciplines

• Counterbalanced valves Tabulation

• Counterbalanced valves Technical Specification

• Data Sheet GRP Aboveground Supply Data sheet

• Data Sheet GRP Underground Supply Data sheet

• Diaphragm valves Data sheet

• Diaphragm valves Tabulation

• Diaphragm valves Technical Specification

• ERD Racks Data sheet

• ERD racks Tabulation

• Expansion and Dismantling joints Data sheet

• Expansion and Dismantling joints Tabulation

• Expansion and Dismantling joints Technical Specification

• Flexible Groove couplings Technical Specification

• Gate valves Data sheet

• Gate valves Tabulation

• Gate valves Technical Specification

• Groove couplings Data sheet

• Groove couplings Tabulation

• GRP Above Ground Supply Technical Specification

• GRP Aboveground Supply Tabulation

• GRP Stress Aerial Pretreatment

• GRP Stress Calcite Beds area

• GRP Stress CediI area

• GRP Stress Intake area

• GRP Stress Calculation Cartridge filters

• GRP Stress Calculation CIP & Flushing System

• GRP Stress Calculation DAF System

• GRP Stress Calculation Gravity filters area

• GRP Stress Calculation Intermediate pumps

• GRP Stress Calculation Limestone filters

• GRP Stress Calculation Potable Water Pipeline

• GRP Stress Calculation Potable Water Pump Station

• GRP Stress Calculation RO System

• GRP Stress Calculation Waste water treatment system

• GRP underground Supply Tabulation

• GRP Underground Supply Technical Specification

• HDPE pipes supply Data sheet

• HDPE pipes supply Tabulation

• HDPE pipes supply Technical Specification

• Inline Element List

• Isometrics Chemical dosing area

• Isometrics Drawings

• Isometrics. Calcite Beds

• Isometrics. Cedi System

• Isometrics. CIP and remineralization dosing storage Area

• Isometrics. CIP system

• Isometrics. Compressed air system

• Isometrics. DAF System

• Isometrics. Flotation area

• Isometrics. Gravity filters area

• Isometrics. GRP above ground piping

• Isometrics. GRP and plastic pipes. Reverse osmosis system

• Isometrics. GRP underground piping

• Isometrics. Interconnecting Area SWI/Plant

• Isometrics. Limestone area

• Isometrics. Metallic pipes. Reverse Osmosis Area

• Isometrics. Outfall

• Isometrics. Potable water distribution

• Isometrics. Sea water intake system

• Isometrics. Waste water treatment area

• Knife valves Data sheet

• Knife valves Tabulation

• Knife valves Technical Specification

• Needle valves Data sheet

• Needle valves Tabulation

• Needle valves Technical Specification

• Others Plastic pipes and fittings Data sheet

• Others Plastic pipes and fittings Technical Specification

• Piping class. Guide (including piping design criteria)

• Plastic pipes and fittings Tabulation

• Plastic valves Data sheet

• Plastic valves Tabulation

• Plastic valves Technical Specification

• Plug valves Data sheet

• Plug valves Tabulation

• Plug valves Technical Specification

• Preliminary Lay Out Piping Routing

• Pressure relief valves Data sheet

• Pressure relief valves Tabulation

• Pressure relief valves Technical Specification

• Puddle flange Data sheet

• Puddle flange Tabulation

• Puddle flange Technical Specification

• PVDF pipes and fittings Data sheet

• PVDF Pipes and fittings Tabulation

• PVDF pipes and fittings Technical Specification

• RO Racks Data sheet

• RO Racks Tabulation

• Rupture disc Data sheet

• Rupture disc Technical Specification

• Rupture discs Tabulation

• SS & duplex Stress Calculation

• Static mixers Data sheet

• Static mixers Tabulation

• Static mixers Technical Specification

• Superduplex & SS pipes and fittings Tabulation

• Superduplex & SS pipes Technical Specification

• Supports for GRP pipes Data sheet

• Supports for GRP Pipes Tabulation

• Supports for GRP pipes Technical Specification

• Supports for minor pipes Tabulation

• Supports for minor pipes Technical Specification

• Supports for Superduplex & SS pipes Tabulation

• Supports for Superduplex & SS pipes Technical Specification

• Supports list for Calcite Beds

• Supports list for Cartridge filters

• Supports list for Cedi System

• Supports list for Chemical dosing area

• Supports list for CIP and Flushing system

• Supports list for Compressed air system

• Supports list for DAF System

• Supports list for Flotation area

• Supports list for Gravity filters area

• Supports list for GRP and Plastic. Reverse osmosis system

• Supports list for Interconnecting Area SWI/Plant

• Supports list for Intermediate pumping station

• Supports list for Limestone area

• Supports list for Potable water distribution system

• Supports list for Reverse Osmosis Area

• Supports list for Sea water intake system

• Supports list for Waste water treatment area

• Valve design criteria

• Wall thickness Calculation for GRP pipes

• Wall thickness Calculation for metallic pipes

• Wall thickness Calculation for Plastic pipes

• Wall thickness Calculation for Superduplex pipes

Disciplines

Process

• Auxiliary systems. Hydraulic calculations

• Auxiliary systems. Surge Analisys

• Calcite beds internals Data Sheet

• Calcite beds internals Technical Evaluation

• Calcite beds internals Technical Specification

• Centrifuge Decanter Data Sheet

• Centrifuge Decanter Technical Evaluation

• Centrifuge Decanter Technical Specification

• CFD simulation Technical Specification

• Chemical Consumption List

• CO2 System Data Sheet

• CO2 System Technical Evaluation

• CO2 System Technical Specification

• Commissioning & Start Up Procedure

• DAF Data Sheet

• DAF Technical Specification

• DAF Technical Evaluation

• Data sheets ERDs Data Sheet

• Drainage and overflows. Hydraulic calculations

• Energy consumption

• EPC Contract & OTS Review

• ERD Technical Evaluation

• ERDs Technical Specification

• Filter Media Material Data Sheet

• Filter Media material Technical Evaluation

• Filter Media Material Technical Specification

• Functional Description - Chemical System

• Functional Description - Posttreatment

• Functional DescriptionPretreatment

• Functional Description - RO

• Functional Description - Waste Water

• General description of the plant

• General Process Flow Diagram

• Laboratory Equipment Technical Specification

• Laboratory Equipment Data Sheet

• Laboratory Technical Evaluation

• Lamellas WWT Data Sheet

• Lamellas WWT Technical Evaluation

• Lamellas WWT Technical Specification

• Line List

• Main systems. Hydraulic calculations

• Main systems. Surge Analisys

• Mass balance Calculation

• Nozzles Data Sheet

• Operation Modes

• P&ID Symbology

• P&ID. Antiscalant dosing system. Storage and dosing system

• P&ID. Cartridge Filtration

• P&ID. CO2 dosing system

• P&ID. DAF - Auxiliaries

• P&ID. DAF system

• P&ID. Drinking water pressurization and distribution

• P&ID. Effluents neutralization and drainages

• P&ID. Ferric Chloride dosing system. Dosing system

• P&ID. Ferric Chloride dosing system. Storage

• P&ID. FFS. Fire fighting system

• P&ID. Filtration. DMGF. General Pipes

• P&ID. Gravity Sand Filters

• P&ID. Intermediate pumping station

• P&ID. Limestone filters

• P&ID. Marine works, Intake tower

• P&ID. Outfall pit

• P&ID. Permeate Water Facilities.

• P&ID. Polyelectrolite dosing system. Clarification WW

• P&ID. Polyelectrolite dosing system. Pretreatment/Waste Water Treatment

• P&ID. Polyelectrolite dosing system. Sludge dehydratation

• P&ID. Product water system

• P&ID. RO CIP and flushing system

• P&ID. RO System

• P&ID. Sea water intake

• P&ID. Service water pressurization and distribution

• P&ID. Sludge deshidratation

• P&ID. Sodium Fluorosilicate dosing system. Storage and dosing system

• P&ID. Sodium Hydroxide dosing system. Dosing system

• P&ID. Sodium Hydroxide dosing system. Storage

• P&ID. Sodium hypochlorite dosing system. Intake dosing system

• P&ID. Sodium hypochlorite dosing system. Storage

• P&ID. Sodium hypochlorite dosing. Post-treatment. Dosing system

• P&ID. Sodium hypochlorite dosing. Post-treatment. Storage

• P&ID. Sodium metabisulphite. Storage and dosing system

• P&ID. Sulphuric Acid dosing system. Pretreatment. Dosing system

• P&ID. Sulphuric Acid dosing system. Pretreatment. Storage

• P&ID. Tanker filling

• P&ID. Waste Water Treatment and Effluent Tank

• P&ID. Waste Water Treatment Clarifiers

• P&ID. Waste Water Treatment Sludge Thickener

• Pneumatic calculations

• Power Consumption Calculation

• Process Design Criteria

• Process O&M Manual

• Process Spare parts List

• RO Membranes Data Sheet

• RO Membranes Technical Specification

• Seawater analysis Technical Specification

• Underdrain system (Filters ) Technical Evaluation

• Underdrain system (Filters ) Technical Specification

• Underdrain system (Filters) Data Sheet

• Valves List

Marine Works

• Ballasting Calculation

• Climatic Study, Meteoceanographic and Marine Engineering Technical Evaluation

• Earth Movements and Shore Protection BoQ

• Geotechnical & Bathymetric Survey Offshore Technical Evaluation

• Intake Towers BoQ

• Intake Towers Calculation

• Marine Works Basis of Design

• Marine Works Construction Technical Evaluation

• Marine Works Construction Technical Specification

• Marine Works Engineering Technical Specification

• Meteoceanographic Study Technical Specification

• Offshore Earthworks/Rocks Calculation

• Offshore Pipes Site Works BoQ

• Offshore Pipes Supply BoQ

• Offshore Pipes Supply Technical Evaluation

• Offshore Pipes Supply Technical Specification

• Offshore Pipes Technical Specification

• Offshore Pipes Technical Specification

• Pipe Mechanical Calculation

• Recirculation Study Technical Evaluation

• Recirculation Study Technical Specification

• Rock Material Technical Specification

• Rock Material Technical Specification

• SW Intake Transient Analysis Technical Specification

Disciplines

I&C (Instrumentation and Control)

• Actuators BoQ

• Actuators Data Sheet

• Cable Trays Datasheets

• Cable Trays Layout

• Cable Trays Technical Specifications

• Cable Trays Technical Tabulations

• Cables Datasheets

• Cables Technical Specifications

• Cables Technical Tabulations

• CCTV, Security and Megaphone Technical Specification

• CCTV, Security and MegaphoneLayout

• Control valve actuators Technical Specifications

• Control Valves Data sheet

• Control Valves Layout

• Control Valves List

• DCS Architectural Drawing

• DCS Datasheet

• DCS Technical Evaluation

• DCS Technical Specifications

• Electrovalves Cabinets BoQ

• Electrovalves Cabinets Data Sheet

• Electrovalves Cabinets Technical Specification

• Electrovalves Island Layout

• Electrovalves Island List

• I&C Assembly MTO

• I&C Cable List and routing

• I&C Cable Trays list and routing

• I&C Cables Data sheet

• I&C Cables Technical Specification

• I&C Wiring Diagrams

• Instrumentation Assembly Hook-Ups

• Instrumentation Datasheets

• Instrumentation Layout

• Instrumentation Technical Specifications

• Instrumentation Technical Tabulations

• Instruments BoQ

• Instruments Data Sheet

• Instruments List

• Instruments Technical Specification

• Junction Boxes Data sheet

• Junction Boxes Layout

• Junction Boxes List

• Junction Boxes Technical Evaluation

• Junction Boxes Technical Specification

• Pneumatic Consumers List

• Signal List

• Vendor Documents Review

Electricity

• ASI

• Cable trays

• Cables and Cable Supporting System

• Cables and cables ways (underground raceways, trays and conduits systems).

• CC System

• DC and Safe AC System and Associated Equipment

• Earthing and Lightning Protection

• Earthing System and bonding/ grounding cables and connections.

• Emergency Power Supply

• Grounding

• High Voltage Indoor Substation

• HV/MV main transformers

• Lighting and Small Power

• Lighting System (General and Emergency)

• Lightning Protection System

• Low Voltage AC Switchgear

• Low Voltage Capacitor Banks

• Low Voltage Distribution Panels and Motor Control Centers

• Low Voltage Emergency Diesel Generators

• Low Voltage Lighting & Small Power Auxiliary Distribution Panels

• Low voltage panels CCM & TGBT

• Low Voltage Small Power Distribution

• Low Voltage Variable Frequency Drives and Soft Starters

• LV/LV auxiliary transformers

• Medium voltage cables

• Medium Voltage Capacitor Banks

• Medium Voltage Soft Starter Drives

• Medium Voltage Switchgear

• Medium Voltage Variable Frequency Drives

• MV and LV Power Busbars

• MV/LV auxiliary transformers

• Rectifier-charger plus batteries

• Transformers

• Underground pipelines

• UPS System

Software

• 3DS MAX

3D Graphics and Animations

• ACSOL

DHW Solar Installation Modelling

• ALLPLAN

BIM (Building Information Modelling)

• Ansys Fluent

Fluid simulation

• Ansys

FEM Structural Calculation

• Assemble

Collaboration Manager

• AutoCAD 2018 Design

• AutoCAD 2020 Design

• AutoCAD PLANT 3D

3D Facilities Modelling

• AutoPIPE

Piping design, modelling & analysis

• Autoturn

Vehicle Path Design

• AVEVA

Plant Design & Modelling

• AVIPlan Turn Pro

Aircraft Taxiway & Runaway

Movement Analysis & Simulation

• BIM 360

Common Data Environment

• BimCollab

Collaboration Manager

• BTwin

Low voltage

• CADWorx P&ID

Plant Plant Diagram Design

• CADWorx Plant

Plant Design & Modelling

• CAEPIPE

Pipe flexibility analysis

• CAESAR II

Pipe flexibility analysis

• Caneco BIM

Caneco and Revit integration

• Caneco BT

Low voltage electrical calculations

• Caneco IMPLANT

Caneco and Autocad integration

• CDEGS

Current Distribution,

Electromagnetic Interference, Grounding and Soil Structure Analysis

• CE3X

Buildings Energy CertificationSpain

• CFwin

Cold rooms design

• CIVIL 3D

Civil Engineering design and documentation

• CUwin Light steel covers

• Cwin

Water Supply Networks

• Cyclone REGISTER

Points Cloud Process and Register

• CYPE 3D

Structural calculation

• CYPETHERM HE Plus

Buildings Energy CertificationSpain

• DAISALUX

Emergency Lighting Modelling

• DAwin Air Distribution

• Design Builder

Thermal Modelling, Facilities, CFD

• DIALux evo

Lighting Simulation

• DIALux

Lighting Simulation

• DMELECT

Low voltage electrical calculations

• DOE-2

Building Energy Analysis

• DYNAMO 0.9.1

Batch-type Graphic Interface for BIM

• EAwin

Steel structure

• EHwin

Reinforced concrete structures

• ENERGY PLUS

Thermal Modelling

• EPLAN

Planning, documentation and management of automation projects

• ESwin

Three-dimensional structures

• ETABS

Structural calculation

• ETAP

Analysis, simulation, monitoring, control, optimization and automation of electric power systems.

• FloMASTER

Computational Fluid Dynamics CFD

• HAP

Thermal Loads and Energy Demand

• Hilti

Anchor calculation

• HULC

Buildings Energy CertificationSpain

• Illustrator

Vector Graphics Editor

• InDesign

Desktop Publishing & Typesetting

• InfraWorks

Civil Infrastructure Design

• Istram

Civil Engineering design

• LAwin

High voltage overhead power lines

• MDT Earthworks

• Microsoft Office

Word processor, spreadsheet editor, presentations

• MIDAS

Structural calculation

• MPwin

Bill of Quantities

• Navisworks Manage

Clash Detection

Software

• Photoshop Image Edition and Design

• Pipe Flow Hydraulic Analysis

• PipeData Pipe fittings catalog

• Plaxis

Geotechnical analysis

• Presto Bill of Quantitites

• ProntAcustic Handbook for the acoustic study

• ProntEnergy Photovoltaic energy estimation

• ProntMedAc Acoustic measurements

• PVcase Photovoltaic Analysis

• PVGIS Photovoltaics

• PVsyst

Photovoltaic Simulation & Calculation

• RAwin Water Supply Networks

• RECAP PRO Points Cloud Process and Register

• REVIT 2018

BIM (Building Information Modelling)

• REVIT 2020

BIM (Building Information Modelling)

• REVIT 2021

BIM (Building Information Modelling)

• RFEM

FEM Structural Calculation

• ROHR2 Pipe flexibility analysis

• ROwin Automatic water sprinklers

• SAFE Foundations

• SAP 2000 Structural calculation

• SCENE Points Cloud Process and Register

• SmartPlant 3D

Plant Design & Modelling

• SolidWorks FEM Analysis

• SRwin Underfloor heating

• STAAD Pro Structural calculation

• STwin

Solar Thermal Facilities

• SUwin Urban Seawage

• SYNCHRO Pro 4D Virtual Construction Scheduling and Simulation

• SYNCHRO SWP Virtual database

• Tekla

Structural design

• TeKton 3D Building and Facilities

• TK-AC

Compressed Air Facilities

• TK-CDT

Thermal Loads and Energy Demand

• TK-DAC

Air Distribution through ducts

• TK-EHU

Unified tool export. LIDER / CALENER

• TK-HE0

Limitation of Energy Consumption

• TK-HE1

Limitation of Energy Demand

• TK-HE5

Photovoltaic Solar Facilities

• TK-HR

Noise Protectionlities

• TK-HS4

Water supply

• TK-HS5

Water Evacuation

• TK-ICA

Water Air Conditioning - Hydraulic circuits

• TK-IFC IFC Exhange

• TK-IG

Gas Facilities

• TRNSYS

Transient Systems Modelling

• Vehicle Tracking

Vehicle Path Design

• Wanda Hydraulic Analysis

International Desalination Expertise World Map

Marruecos

• Agadir Omán

• Salalah

• Barka V

• Ghubrah III Arabia Saudita

• Al Khafji

• Shuaibah

• Shuaibah 5

• Kaust

• Zuluf

Túnez

• Sousse

Emiratos Árabes Unidos

• Al-Taweelah (Abu Dhabi)

• Jebel Ali (Dubai)

• Shuweihat (Abu Dabi)

Dubal

SAVENER was selected by ABENGOA to carry out the majority of the engineering for the Dubai desalination plant, located in the United Arab Emirates. This project represents a high-level technical challenge, not only due to its scale but also because of its dual function: in addition to supplying drinking water to the local population, it provides ultrapure water to the world’s largest premium aluminum producer, Emirates Global Aluminum (EGA). This particularity imposes strict requirements in terms of quality, safety, and supply reliability.

The plant is a seawater reverse osmosis (SWRO) desalination facility with a production capacity exceeding 41,000 m³/day of potable and industrial water. Its design incorporates advanced technologies to ensure optimal performance throughout the process:

∙ Efficient pre-treatment, featuring a dissolved air flotation (DAF) system and gravity filters, ensuring maximum membrane protection.

∙ High-performance reverse osmosis, utilizing five membrane stages to maximize water recovery and optimize energy consumption.

∙ Specialized post-treatment, including calcite beds and CO₂ dosing, ensuring proper chemical balance for water distribution.

∙ Continuous electrodeionization (CEDI) system, used for ultrapure water production, meeting the strict standards required by the aluminum industry.

For this project, SAVENER leveraged its extensive desalination expertise, providing a highly specialized technical team in Design, Civil Engineering, Piping, Mechanical Engineering, Instrumentation and Control, and Project Management.

The Piping and Mechanical team was responsible for the comprehensive system engineering, covering everything from initial calculations to the final design details:

∙ Stress analysis for steel and GRP (Glass-Reinforced Plastic), ensuring structural integrity.

∙ Design and calculation of supports, optimizing infrastructure stability and durability.

∙ Finite Element Method (FEM) simulation to assess mechanical behavior under static, dynamic, and fatigue conditions.

∙ Technical specifications and material lists, ensuring precise and efficient resource planning.

The integration of SAVENER’s team within the workflow alongside Abengoa specialists and the end client has been key to the project’s success. Specifically, in the Piping area, SAVENER has demonstrated exceptional flexibility, quickly adapting to technical adjustments and requirements in a timely and efficient manner, ensuring excellence in project execution.

This project reaffirms SAVENER’s position as a benchmark in engineering for desalination plants, offering innovative, efficient, and tailored solutions to meet the sector’s most demanding requirements.

Agadir

SAVENER was selected for the design of this innovative reverse osmosis desalination plant, with an initial capacity of 275,000 m³/day, thanks to its extensive experience and expertise in the desalination sector. This project not only ensures the supply of drinking water to a region with 1.5 million inhabitants, but also drives agricultural, tourism, and industrial development, guaranteeing water security and sustainable growth in the area.

High-Efficiency and Sustainable Design

This state-of-the-art facility incorporates the most advanced ultrafiltration pre-treatment, optimizing the quality of feedwater for the membranes and ensuring optimal performance of the seawater reverse osmosis (SWRO) system. To maximize energy efficiency, the plant will operate using electricity from a wind farm, minimizing its carbon footprint and promoting a sustainable desalination model.

The project includes a comprehensive hydraulic network featuring:

∙ 22 km of main pipelines for treated water transport.

∙ 490 km of distribution networks, ensuring optimal regional coverage.

∙ Multiple pumping and storage stations, designed to maintain a stable and efficient water supply.

∙ Planned expansion to 450,000 m³/day, ensuring the plant’s adaptability to future demands.

Advanced Engineering and 3D Modeling

The design and engineering of this desalination plant were developed by a SAVENER multidisciplinary team, integrating experts in Design, 3D Modeling, Piping, Mechanical Engineering, Instrumentation and Control, Irrigation, and Project Management. A key factor in the project’s success was the seamless collaboration between the Design, BIM, and 3D Modeling teams, using AutoCAD Plant 3D to maintain a real-time updated model, allowing for rapid adaptation to changes and improvements at each stage of development.

Commitment to Excellence and Global Integration

With extensive experience in desalination, SAVENER works alongside the world’s leading EPCs, ensuring that its technical team can effectively integrate into any development team and contribute to the success of large-scale projects. Our adaptability, combined with a Value Engineering-driven approach, enables us to provide innovative, sustainable, and highly efficient solutions to the challenges of the desalination sector.

This project serves as a key reference in SAVENER’s commitment to engineering excellence, desalination innovation, and global sustainable development.

Al Khafji

Located in northeastern Saudi Arabia, this is the world’s first solarpowered desalination plant, marking a milestone in desalination engineering. The integration of solar energy into a facility of this scale has redefined the approach to planning key subsystems, making energy efficiency a top priority. Every solution adopted has been designed to minimize energy consumption while ensuring maximum performance with the least environmental impact.

Innovation in Cooling and HVAC Systems

SAVENER was selected to tackle the challenge of designing the plant’s thermal control and HVAC system, ensuring the highest possible efficiency in an environment with extreme temperatures. The traditionally high energy consumption of these systems posed a key challenge, which SAVENER resolved through an innovative solution integrated within the desalination process itself.

SAVENER developed a pioneering system that uses desalination process water to condense the cooling plants. This design, the first of its kind worldwide for a desalination facility, enables:

∙ A 50% reduction in electrical power demand for the cooling system.

∙ A 60% decrease in operational electricity consumption, achieving unprecedented efficiency.

∙ Prevention of fluid mixing between the process and cooling systems, ensuring operational safety.

Additionally, a District Cooling system was designed, where condensed cooling plants utilize processed water before the reverse osmosis stage,

exchanging it in an intermediate tank. This innovative strategy maximizes thermal and energy efficiency, solidifying SAVENER as a leader in sustainable desalination plant development.

Technical Capabilities and Water Production

The reverse osmosis (SWRO) process used in this plant has a production capacity of 60,300 m³/day, ensuring a reliable and sustainable water supply. The plant is equipped with advanced pre-treatment and posttreatment technology, including:

∙ Next-generation ultrafiltration, ensuring maximum protection for reverse osmosis membranes.

∙ Dissolved air flotation (DAF) system, eliminating suspended solids and contaminants.

∙ Six reverse osmosis trains, optimizing process efficiency and water recovery.

∙ CO₂ storage tanks and chemical supply systems, maintaining an optimal chemical balance for treated water.

∙ Centralized control unit, enabling automated and highly efficient operation.

Al Khafji

Integration with Solar Energy – A Sustainability Model

The desalination plant will operate in synergy with a 15 MW solar farm, located 1 km from the facility over a 90-hectare area. The photovoltaic installation will be directly connected to both the plant and the national power grid, ensuring a stable and sustainable energy supply.

This pioneering model represents a key step in the evolution of desalination toward energy self-sufficiency, reducing reliance on conventional energy sources and minimizing the facility’s carbon footprint.

SAVENER – Leading Innovation in Desalination

Through its expertise and Value Engineering approach, SAVENER has successfully integrated highly efficient solutions into a globally recognized project. The combination of desalination and renewable energy makes this plant a model of sustainability for the future, reinforcing SAVENER’s position as a strategic partner in the development of advanced, low-impact desalination infrastructures.

«SAVENER in

Osmosis Desalination Plant in

Taweelah

This project marks a milestone in the desalination sector as the largest reverse osmosis desalination plant ever built. Its significance lies not only in its production capacity but also in its key role within the Taweelah power and water generation complex, establishing itself as a global benchmark infrastructure.

With a production capacity of 909,000 m³/day, the Taweelah plant is capable of ensuring the potable water supply for the city of Abu Dhabi for an entire year. Additionally, it is the country’s first large-scale desalination plant to integrate drinking water production with clean energy, thanks to a 40 MWp photovoltaic solar farm, reducing its carbon footprint and enhancing operational efficiency.

SAVENER – Value Engineering in a Landmark Project

In a project of this magnitude, SAVENER was selected by the leading international consortium to contribute its desalination expertise, playing a key role in various design and implementation areas. Our participation has covered the Design and 3D Modeling, Electrical, and Instrumentation & Control (I&C) Departments, contributing to the engineering of several critical plant sections.

The Instrumentation & Control (I&C) Department was responsible for the design, calculations, modeling, and implementation of a wide range of key elements in the plant’s automation, including:

∙ Field element listings, ensuring efficient integration into the control system.

∙ Technical specifications and datasheets, guaranteeing compliance with the highest engineering standards.

Taweelah

∙ Bill of Quantities (BoQ) and signal design, for detailed planning and project optimization.

∙ Integration of key components such as solenoid valves, pneumatic consumers, junction boxes, switches, and control systems.

Excellence in Integration and Execution

SAVENER’s track record in desalination projects and its ability to work in demanding EPC environments have enabled seamless integration with the consortium’s engineering teams. Effective collaboration with other specialists and the flexibility to adapt to project needs have been key to:

∙ Executing tasks smoothly, ensuring high-quality standards.

∙ Optimizing project expansion quickly and accurately, ensuring efficient execution.

∙ Harmonizing processes and methodologies with the rest of the technical team, maximizing productivity and minimizing implementation time.

The Taweelah desalination plant is a global benchmark in the application of advanced desalination technology combined with renewable energy, and SAVENER has played a fundamental role in its development, solidifying itself as a strategic partner in the engineering of large-scale desalination plants.

«Looking for Efficiency in Desalination»

Salalah

This project was developed in collaboration with Abengoa and Fisia Italimpianti as EPC partners, covering all phases of Engineering, Procurement, Construction, and Commissioning. The Salalah desalination plant, located in the Dhofar region of Oman, represents a key advancement in the country’s desalination infrastructure, with a production capacity of 113,650 m³/day.

Innovation in Water Treatment

The project included the construction of a new reverse osmosis plant, along with the seawater intake and brine outfall, incorporating advanced technologies to enhance process efficiency. Two key innovations stand out:

∙ Dissolved air flotation (DAF) pre-treatment, optimizing the removal of solids and organic matter to protect the reverse osmosis membranes.

∙ Post-treatment with gravity limestone contactors, ensuring efficient remineralization for potable water distribution.

These solutions improve water quality, extend equipment lifespan, and reduce operational costs.

SAVENER – A Strategic Partner in Engineering and Equipment Management

Offtaker:

In this project, SAVENER contributed its desalination expertise, deploying a multidisciplinary team in Design, Electrical Engineering, HVAC, Instrumentation & Control, and Project Management. Our work focused on basic engineering and procurement management of essential

«Looking for Efficiency in Desalination»

Salalah

Location: Salalah, Dhofar Governorate, Oman

Capacity: 113.650 m3/day Technology: Reverse Osmosis Desalination

Clients: Acwa Power, Veolia and Dhofar International for Investment and Development

Offtaker: Oman Power and Water Produrement Copmpany

equipment, ensuring seamless integration with Abengoa and Fisia Italimpianti.

The Electrical and Instrumentation & Control Department played a key role in the selection, acquisition, and integration of critical electrical components, such as:

∙ Power transformers and high- and low-voltage switchgear.

∙ Motor control centers (MCC) and LVS systems.

∙ Distribution panels and variable frequency drives.

∙ Uninterruptible power supply (UPS) systems and lightning protection.

The effective management of procurement and logistics optimized time and costs, ensuring that all equipment met the highest quality and reliability standards.

Integration and Flexibility in Execution

The SAVENER team integrated seamlessly with Abengoa’s engineers and the client, demonstrating strong adaptability in the project’s most critical phases. This was particularly evident in the Piping area, where swift management of variations and technical adjustments ensured uninterrupted execution, maintaining project timelines.

Commitment to Excellence in Desalination

The Salalah desalination plant is a benchmark in the application of innovative technologies to optimize water quality and operational efficiency. SAVENER’s experience in large-scale desalination projects, its flexibility in EPC environments, and its ability to integrate with international teams ensure that each solution is executed with the highest levels of quality and efficiency.

This project reinforces SAVENER’s position as a strategic partner in the engineering and development of global desalination infrastructure.

«Looking for

Shuaibah

Located 90 km south of Jeddah, this seawater reverse osmosis desalination plant was successfully commissioned in July 2019, marking a key advancement in the region’s water infrastructure. With a production capacity of 250,000 m³/day, this facility is essential for securing the water supply to Mecca, Jeddah, and Al-Baha, contributing to the water security of these major cities.

SAVENER – Value Engineering in a Large-Scale Project

In this project, SAVENER deployed its desalination expertise, providing a team of specialists in Design, Electrical Engineering, HVAC, Instrumentation & Control, and Project Management. Its participation was crucial in designing essential infrastructure to ensure the plant’s efficient and sustainable operation.

The Electrical Department was responsible for designing and calculating the indoor and outdoor lighting systems, ensuring optimal light distribution for the safety and operability of the facility.

Additionally, SAVENER designed the HVAC system, ensuring efficient thermal control with sustainability and energy efficiency criteria. The design prioritized solutions that reduced energy consumption while optimizing system performance without compromising plant comfort or operability.

Commitment to Innovation and Efficiency

Thanks to its expertise in desalination engineering, SAVENER has provided optimized solutions that ensure the plant’s operational and energy efficiency. Its focus on Value Engineering and its ability

to integrate electrical and HVAC systems with sustainability and performance criteria reinforce its role as a strategic partner in largescale desalination infrastructure.

This project strengthens SAVENER’s position as a benchmark in engineering for desalination plants, delivering innovative and sustainable solutions to secure water access in high-demand regions.

Sousse

This project aims to produce potable water from seawater, sourced from the cooling channel of the Sidi Abdelhamid power plant in Sousse, owned by the Tunisian Company of Oil and Gas (STEG). With a capacity of 50,000 m³/day, the plant features a two-stage filtration pre-treatment system and two reverse osmosis units, each with a production capacity of 25,000 m³/day, ensuring an efficient and reliable water treatment process.

This project is part of the Tunisian Government’s strategic plan to promote the use of non-conventional water resources, such as desalination, to address water scarcity and improve water quality. Additionally, it aims to meet the growing demand in the country’s main tourist destinations, supporting the region’s sustainable development.

SAVENER – Benchmark Engineering in Design and Electrical Systems

SAVENER was selected to develop key engineering packages for the project in the areas of Design and Electrical Engineering. Abengoa, responsible for the plant’s design, construction, and operation in a Joint Venture with EPPM, once again entrusted SAVENER with critical aspects of the project, including advanced electrical engineering studies.

The Electrical Department of SAVENER played a fundamental role in the project, leading the design, procurement management, and review of medium- and low-voltage electrical systems, including:

∙ Basic design of high- and low-voltage installations, ensuring a safe and efficient electrical infrastructure.

∙ Procurement management and review of essential electrical equipment, such as 11 kV transformers, 30 kV and 11 kV switchgear, motor control centers (MCC), LVS systems, distribution panels, variable frequency drives, and uninterruptible power supply (UPS) systems.

∙ Specialized electrical studies, including short-circuit analysis, power flow analysis, selectivity, and power factor correction, optimizing energy performance and the plant’s operational stability.

Sousse

Efficiency and Precision in Execution

SAVENER’s extensive experience in desalination projects, its ability to adapt to EPC processes for major companies, and its seamless integration with the project’s technical team ensured that the work was executed with:

∙ High-quality results, meeting the most demanding industry standards.

∙ Optimized execution, ensuring speed and precision at every project phase.

∙ Full synergy with Abengoa and EPPM teams, guaranteeing a smooth and efficient operation.

Commitment to Innovation and Water Security

The Sousse Desalination Plant is an example of how value engineering in desalination can contribute to improving water security and sustainable regional development. Through its participation in this project, SAVENER reaffirms its leadership in desalination infrastructure engineering, delivering innovative and efficient solutions to guarantee potable water access in high-demand areas.

«SAVENER in a key project

Barka V

SAVENER has been awarded the comprehensive design of the Barka V SWRO Desalination Plant, located in Oman. This project, developed under a contract exceeding 50,000 working hours, has been entrusted to SAVENER by the EPC consortium formed by GS Inima (Spain) and Fisia Italimpianti (Italy), further solidifying its role as a key player in largescale desalination plant engineering.

A High-Capacity Plant with Advanced Technology

With a production capacity of 100,000 m³/day, the plant represents an investment of approximately $129 million and will be located in Barka, north of Muscat, expanding the desalination complex that supplies water to residents near the capital. Its design integrates advanced technologies to ensure efficient and sustainable performance

∙ 5 reverse osmosis trains with spiral-wound membranes, optimizing process efficiency.

∙ Pre-treatment system with dissolved air flotation (DAF) and dual-media gravity filters, ensuring high-quality feedwater for the membranes.

∙ Post-treatment with upflow limestone filters, providing effective remineralization for potable water.

SAVENER – A Strategic Partner in Desalination Engineering

This project enables SAVENER to work in close coordination with specialists from GS Inima and Fisia Italimpianti, contributing expertise across all key project disciplines, including:

∙ Civil Engineering

∙ Electrical Engineering

∙ Piping

∙ Process Engineering

∙ Instrumentation & Control (I&C)

∙ Mechanical Engineering

∙ 3D Modeling

This collaboration ensures that the engineering of Barka V meets the highest standards of quality and technical excellence, reinforcing SAVENER’s reputation in the sector.

Leadership in Desalination Engineering

With the awarding of this project, SAVENER reaffirms its leadership in desalination system engineering, strengthening its international presence as a strategic and technological partner in major water infrastructure projects

The Barka V SWRO desalination plant is not only a significant step toward regional water security but also a testament to SAVENER’s commitment to innovation and engineering excellence in the water sector

Shuaibah 5

In the Shuaibah 5 desalination plant project, SAVENER has played a key role as a provider of Technical Advisory Services, focusing on the review and optimization of the piping system serving the desalination plant.

Our work has included:

∙ Comprehensive review of the hydraulic design and stress analysis of the main pipelines.

∙ Optimization analysis, proposing improvements over the existing preliminary design to maximize system efficiency.

∙ Specialized technical consulting, ensuring the correct integration of pipelines within the desalination process.

A Large-Scale Project in Saudi Arabia

The Shuaibah 5 desalination plant, with a production capacity of 600,000 m³/day, is one of the most significant infrastructures in the region’s water sector. The engineering, procurement, and construction (EPC) contract was awarded to Rawafid and Advanced Water Technology (AWT), with TUA overseeing the engineering development of the project.

SAVENER – A Benchmark in Desalination Engineering

This project is part of the strategic collaboration between SAVENER and TUA, strengthening its position in the Saudi Arabian and UAE desalination markets. SAVENER’s involvement in such initiatives cements its role as one of the leading engineering firms specializing in complex desalination systems, delivering high-value technical solutions and operational efficiency at an international level.

Kaust

The King Abdullah University of Science and Technology (KAUST) in Saudi Arabia is one of the most advanced research campuses in the world. Covering an area of 36 km² in Thuwal, near Jeddah, it operates its own desalination plant to supply water to all its facilities.

The existing desalination plant, with a capacity of 50,000 m³/day, required an upgrade to its brine rejection system to ensure operational safety and process continuity. SAVENER was selected by Nesma Partner, the project’s main contractor, through SGP, to design and develop a new emergency rejection line, thanks to its expertise in solving technological and logistical challenges in demanding climatic environments.

Technical Solution and Project Scope

The project involved the implementation of a new 1.5 km rejection line, designed to complement the existing system and provide a safer, more efficient discharge mechanism. Due to the pipeline’s dimensions and hydraulic characteristics, multiple analyses were conducted to optimize its performance and ensure its reliability, including:

∙ Transient behavior study of the pipeline, evaluating stresses generated by flow and pressure variations.

∙ Stress calculation and hydraulic analysis, ensuring stable operation without negative impacts on the existing system.

∙ Electrical and control system design, guaranteeing seamless integration with the desalination plant’s infrastructure.

∙ Engineering development using BIM methodology, enabling coordinated and efficient design and execution management.

Excellence in Engineering and Coordination

SAVENER’s design met the highest standards of optimization, efficiency, and durability, aligning with the requirements of all project stakeholders. SAVENER’s management and coordination capabilities were crucial in effectively integrating the project team and delivering a high-quality, reliable solution.

This project reinforces SAVENER’s position as a leading engineering firm in desalination infrastructure, providing advanced solutions that ensure safety, efficiency, and sustainability in critical facilities.

Shuweihat

The Shuweihat Desalination Plant, located in the western region of the United Arab Emirates, is part of the Shuweihat Power Station complex and has a production capacity of 318,225 m³/day of desalinated water. This project marks a significant milestone in the development of highcapacity desalination infrastructure, further establishing SAVENER as a key industry leader.

SAVENER’s Engineering Scope

SAVENER has provided comprehensive engineering across multiple key disciplines, including civil, structural, mechanical, and piping engineering. Its participation has ranged from the detailed design of main buildings to the calculation of pre-treatment and distribution systems, ensuring maximum operational efficiency.

Key areas of the project include:

∙ Design of the reverse osmosis building, optimizing its layout to enhance the desalination process’s quality and efficiency.

∙ Engineering and construction of storage tank foundations, designed for three tanks measuring 100 meters in diameter and 20 meters in height, essential for regulating the supply of desalinated water.

∙ Development of the electrical substation design, providing the necessary energy infrastructure for plant operations.

∙ Design and construction of the gravity filter system, critical for pretreating water before the reverse osmosis process.

Auxiliary Infrastructure and Process Optimization

Beyond the core systems, SAVENER has designed several essential auxiliary infrastructures, such as:

∙ Cartridge filter building, providing preliminary filtration to protect the reverse osmosis membranes.

∙ Rinse tank building, designated for storing permeate water after the reverse osmosis process.

∙ Dissolved air flotation (DAF) system, enhancing feedwater quality and improving process efficiency.

Innovation and Precision in Design

For this project, SAVENER employed advanced BIM modeling technologies and Artificial Intelligence (AI) tools, enabling:

Shuweihat

∙ High precision in designs, reducing errors and optimizing execution timelines.

∙ Greater efficiency in construction, minimizing unforeseen issues and enhancing system integration.

∙ Detailed analysis of pipeline flexibility and support structures, ensuring the structural integrity of the water distribution system.

SAVENER – A Leader in Desalination Engineering

The execution of the Shuweihat Desalination Plant further strengthens SAVENER’s position as a leader in desalination engineering, demonstrating its technical and operational capabilities in large-scale infrastructure development. This project exemplifies SAVENER’s commitment to excellence and innovation in desalination engineering, ensuring efficient and sustainable solutions for potable water supply in high-demand regions.

Ghubrah III

Located in Muscat, the capital of Oman, the Ghubrah III desalination plant is one of the most advanced infrastructures in the region, with a production capacity of 300,000 m³/day of potable water. This facility is crucial for ensuring the water supply to approximately 2.5 million people, setting a new benchmark in the global desalination sector.

SAVENER’s Engineering Scope

SAVENER has developed the complete engineering of the plant, covering all essential disciplines for its efficient design and operation, including:

∙ Civil and structural engineering, ensuring the stability and durability of the infrastructure.

∙ Mechanical and piping engineering, optimizing the water transport and distribution systems.

∙ Electrical and HVAC engineering, guaranteeing energy efficiency and climate control within the facilities.

The complexity and scale of this project highlight SAVENER’s ability to deliver integrated and multidisciplinary engineering solutions, meeting the highest international standards.

One of the Most Advanced Plants in the Middle East

The Ghubrah III desalination plant stands as one of the largest and most advanced facilities in the Middle East and the largest in Oman. Its design

incorporates cutting-edge technologies that maximize efficiency and sustainability in the desalination process.

This project is distinguished by the implementation of innovative solutions that enhance operational performance and minimize environmental impact, setting a new standard in the desalination industry.

SAVENER – A Benchmark in Desalination Engineering