SSPC-AB1 Certified & CARB Approved

Stocking Locations

Houston Baltimore Los Angeles

13040 Market St Houston, TX 77015

1205 68th St Baltimore, MD 21237

14445 Alondra Blvd. La Mirada, CA 90638

36 30/60 50 80 120 3.3 ~ 3.8 mil 2.8 ~ 3.2 mil 2.7 ~ 2.8 mil 2.3 ~ 2.7 mil 1.8 ~ 2.2 mil

Garnet

Size Typical Mil Profile

Fused Aluminum Oxide

Sizing

• Sizes from 10 to 1200 grit

• ANSI B74.12 Table 2

• ANSI B74.12 Table 3

• Customer Specific Standards

Certifications

• ANSI and FEPA

• Agency & Mil-Specs (such as A-A-59316 & MIL-A-22262B)

• Pratt & Whitney, Rolls Royce, Praxair, Stryker, etc

Typical Chemistry

Aluminum Oxide

Titanium Dioxide (TiO2)

Silicon Dioxide (SiO2) Iron

(Fe2O3)

(MgO, CaO, Cr2O3)

Oxide

96.69 % 2.52 % 0.44 % 0.10 % < 0.1 % Mineral Brown White 99.78 % < 0.1 % < 0.1 % < 0.1 % Sodium Oxide (Na2O) < 0.1 % < 0.1 % 0.16 %

Others

Steel Shot

RockRidge proudly offers both high carbon and low carbon steel shot in all SAE sizes and hardness ranges.

High carbon steel shot is available in:

• Standard hardness 40-51 HR C

• L hardness 54-61 HR and H hardness 60 HR C Min.

Steel Shot Sizing

Shot Product S70 S110 S170 S230 S280 S330 S390 S460 S550 S660 S780 Screen Size 40-120 30-50 20-40 18-35 16-30 14-25 12-20 10-18 10-16 8-14 7-12

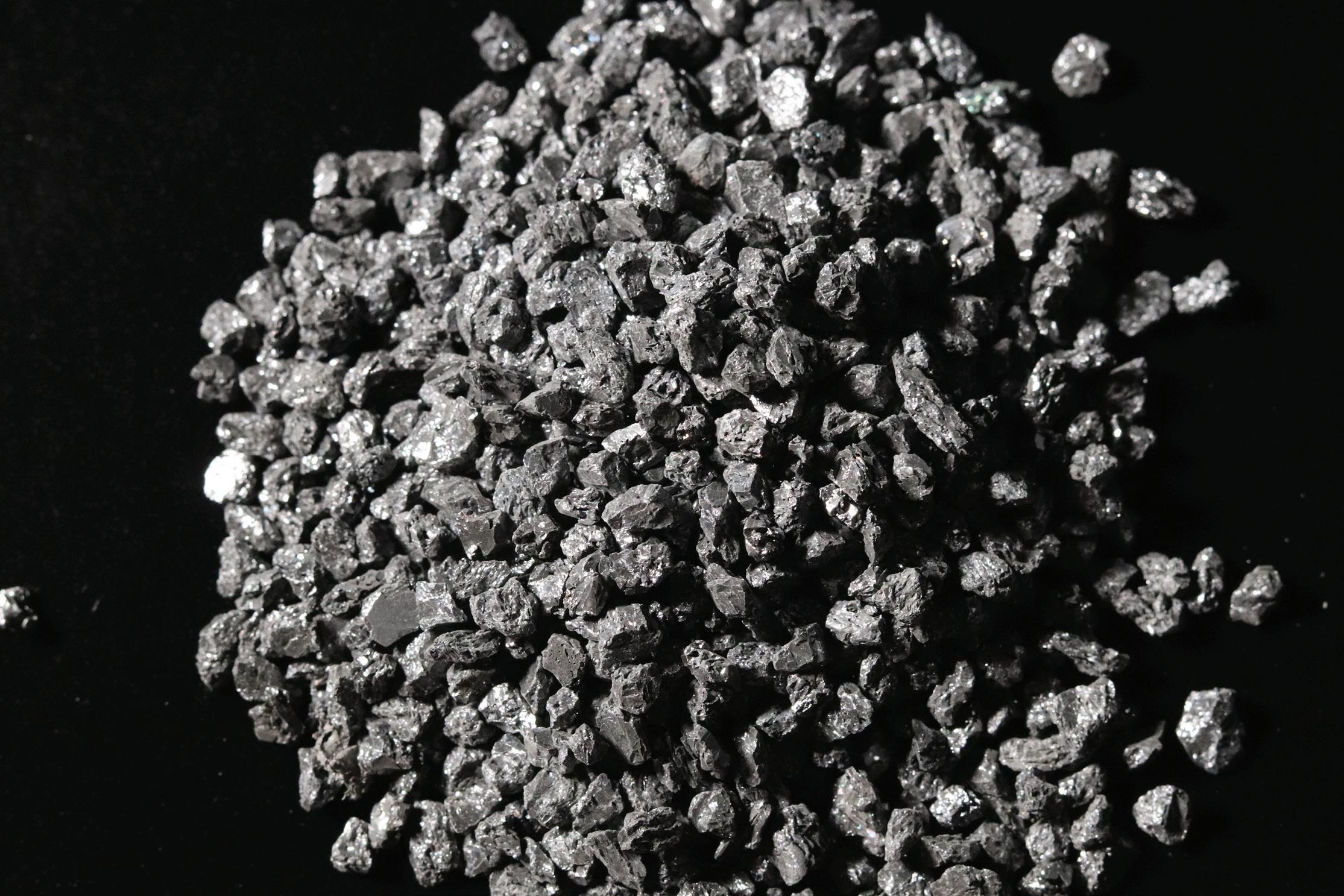

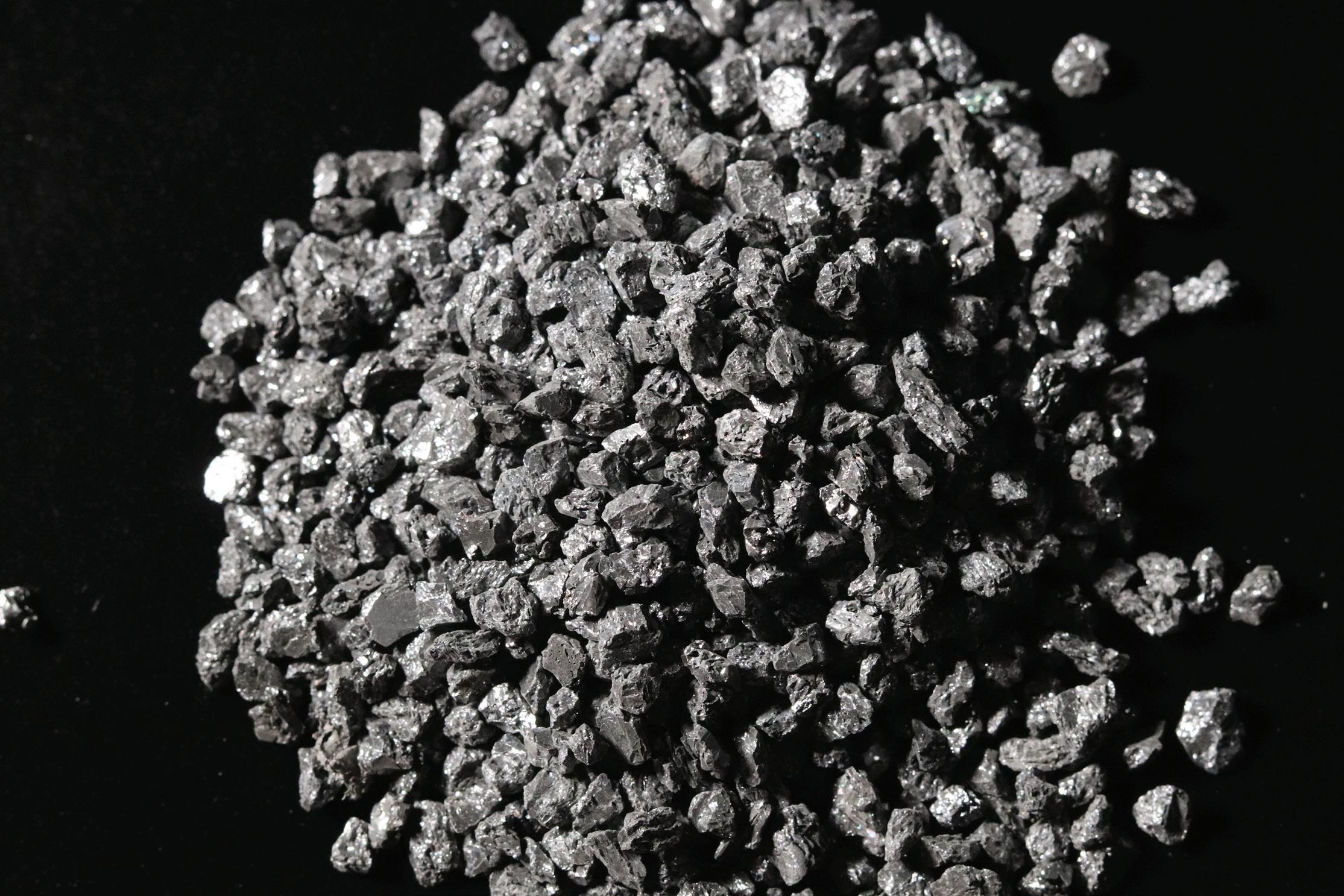

Steel Grit

RockRidge Steel grit is manufactured to SAE J444 and J1993 specifications and is manufactured in a state-of-the-art facility where quality is the top priority.

RockRidge steel grit is manufactured in 3 different hardnesses SG 40-51 HR C, LG 54-61 HR C, and HG 60 HR C Min. and has minimal stress cracks which helps to improve durability in service.

Each size of grit is manufactured from specific grades of steel shot in order to generate angular blocky particles that will impart maximum transmitted energy onto the work pieces being cleaned.

RockRidge Steel shot and grit is available in 55-gallon drums on pallets, 50lb bags or super sacks to suit every blast cleaning operation.

Steel Grit Sizing

SAE Size No. G12 G14 G16 G18 G25 G40 G50 G80

Glass Beads

RockRidge Glass Bead media breaks down at a slow rate and can survive multiple impacts. This allows for continuous recycling and extended blasting time. Glass beads are chemically inert and will not leave any residue on the surface of the work-piece. RockRidge is partnered with Potters to bring our clients the leading U.S. made materials for their application

Sizing

#5 #6 40/60 50/80 #3 #4 # 20/40 30/50 Mesh #8 #9 #10 # #7 70/120 80/140 100/200 Mesh 60/100 #11 #12 # 120/230 140/325 Mesh # Mesh # Mesh

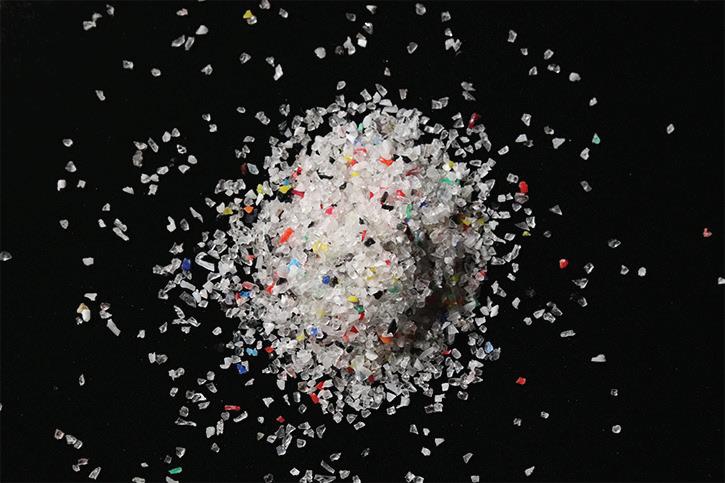

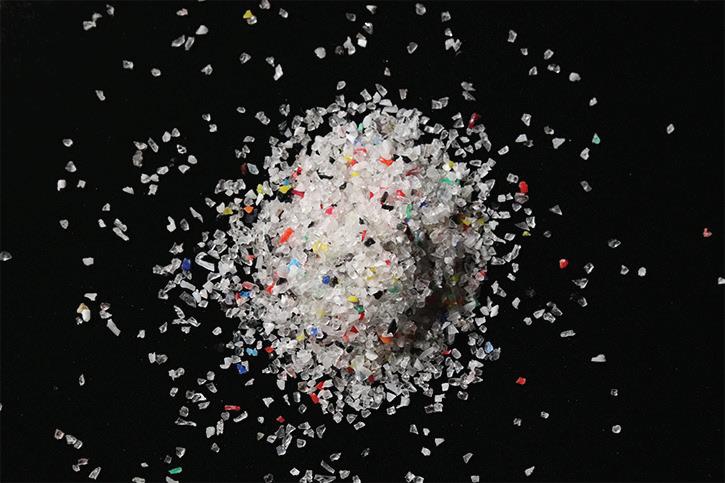

Plas�c Blas�ng Media

RockRidge Abrasives supplies type 2 and type 3 plastic blasting media for use as a blasting media for the removal of coatings from aluminum and composite components without damaging the substrate.

Typical Grades

• 12/16

• 12/20

• 16/20

• 20/30

• 20/40

• 30/40

• 40/60

• 60/80

• Custom sizes available upon request

Typical Physical Characteristics

Type Plastic (Urea) Physical Characteristics Type 2 Type 3 Density Bulk Density Hardness Friability Recyclability Dust Levels Shape 1.5 g/cm3 0.7 g/cm3 3.3 Mohs Medium

Very

Angular, Semi-Cubical Plastic (Melamine) 1.5 g/cm3 0.7 g/cm3 3.5-4

Angular,

Abrasive

High

Low

Mohs Medium High Very Low

Semi-Cubical

Coated Abrasives

Belts

Discs

Sheets

Rolls

Flap Discs

Flap Wheels

Specialty Products

The term “coated abrasive” indicates how the abrasive is bonded to each product. Coated abrasives consist of a backing material such as paper, cotton or polyester cloth, film, or vulcanized fiber.

RockRidge is here to assist you in finding the best solution for your finishing application.

Equipment

Wide Belt Sanders

Backstand Grinders

Stroke Belt Sanders

Belt Grinders

RockRidge offers a broad array of other surface finishing equipment.

Most manufactured metal parts need to be touched with a grinding, buffing, or polishing process at some point. There are a multitude of options available on the market to best tailor to your application needs.

Non-Woven Abrasives

Discs Belts

Hand Pads

Non-woven abrasives consist of a web of nylon fibers impregnated with abrasive grains bonded with synthetic resins. Non-Woven products are ideal for cleaning, blending, deburring, stripping, finishing and surface prep.

The Best Brands

RockRidge partners with the best brands on the market to bring you the highest quality products.

Project Specific

Our Sales Representatives are equipped to determine the best solution for your application.

Safety Focused

RockRidge is committed to providing you with the best materials to ensure a safe working environment.

Here For You

With state-side and international locations RockRidge is able to deliver quality service in your backyard!

Silicon Carbide

RockRidge Silicon Carbide, also referred to as SiC, is comprised of Silicon and Carbon. It is an extremely hard abrasive grain. Silicon Carbide’s hardness falls around 9 on the Mohs scale. RockRidge Silicon Carbide is available in black and green compositions.

Black Sizing

• Sizes 10 to 1200

• FEPA F Standard 42-1:2006

• FEPA P Standard 43-1:2006

• ANSI B74.12-2003

• Customer Specific Standards

Green Sizing

• Sizes 10 to 1200

• FEPA F Standard 42-1:2006

• FEPA P Standard 43-1:2006

• ANSI B74.12-2003

Typical Chemistry

Carbide (SiC) 98.00

Black Green

Carbon (C) Silicon Dioxide (SiO2) Free Silicon (Si) Iron (Fe2O3) 0.25 % 0.70 % 0.80 % 0.10 % 99.10 % 0.10 % 0.50 % 0.15 % 0.10 %

Silicon

%

Free

Mass Finishing Media

Plastic Media

Media Type

AFPP

AFBC

AFMC

AFAC

AFHC

Description

Intended for preparing surfaces requiring a plating surface finish - super fine and smooth surface finishes on ferrous and non-ferrous materials.

Excellent deflashing media with excellent wear - gives reasonably smooth finish while providing good paint and powder coat surface preparation

Mid-range cutting media, popular for non-ferrous finishes or anodizing of parts

Faster cutting ability - best general deburring media, excellent for non-ferrous, yet still enough power to cut steel and stainless steel

Popular media for extreme cutting, especially for harder materials such as stainless steel, titanium, and other materials

Ceramic Media

Media Type

AF-P

AF-HD

AF-LC

AF-MC

AF-XF

AF-X

AF-SIC

AF-XX

Description

Porcelain fused media with no abrasive additives, for ultimate high luster

High density media for polishing or heavier deburring in high energy units

Light cutting ceramic, longer life, minimal aluminum oxide for minimal deburring, smoother finishes

General deburring medium cut ceramic media with good life

Good cutting media with good finish and good wear and life - slightly higher cut than AF-MC

Most popular high cutting ceramic media offers, good deburring, decent life, and good finish

Higher cutting silicon carbide infused media used in sintering and brazing applications

Highest cutting media available, comes with high wear rates

YOUR ABRASIVE SPECIALISTS

RockRidge was created by a collective of abrasive specialists who wanted to supply our customers with high-quality abrasives that we have hand-selected and thoroughly tested. We have dozens of distributor locations across the U.S., U.K., and Canada, all of which provide reliable product knowledge and loyal service.

www.rockridgeabrasives.com