MASTER 2023

UNITING MATERIALS, TECHNOLOGY AND

DESIGN

Transforming Interior Spaces.

High quality fnishes on MONARC composite wall panels for use in the design of bath & shower enclosures, kitchens, living rooms, and other interior spaces. Premium properties of MONARC ensure an extremely fat, light weight, waterproof panel that offers easy installation & delivers a striking visual appearance inspired by natural elements such as wood, marble, tile, and other variations of stone & metal.

For more information or to order samples, scan QR code with mobile camera or email us: info.usa@3acomposites.com

3ACOMPOSITESUSA.COM/MONARC

Calacatta Gold

Fire & Electrical Rated Lightweight Composite Material Low Maintenance Easy Installation Added Value High Quality Appearance

Superior coating technology on TFL Manufactured in North America

PERFECT MATT - HIGH GLOSS tafisa.ca

Outstanding anti-fingerprinting

Highly scratch resistant

Watchmoreonline tafisa.ca

MASTERS OF THE INDUSTRY

51 A comprehensive listing and directory of the providers of materials and services in the panel processing industry.

SPECIAL SECTION

141 DISTRIBUTION MATTERS

Highlighting NBMDA (North American Building Material Distribution Association).

142 Interview With Matt Huber President of NBMDA.

144 Reuniting Under One Roof NBMDA's Annual Convention was back home in Chicago in 2022.

148 Not Your Father’s Shop Class Fostering future woodworkers at the high school level.

152 Industry Stakeholders Promote Woodwork

The "YouWood" campaign is dedicated to spreading the word about professional opportunities in the woodworking trades.

154 Conversation With Kevin Gammonley NBMDA – 70 years of providing valued resources to the distributor community.

156 2023 NBMDA Member Director y

EDITORIAL FEATURES

49 Formaldehyde Certifcation Deadline Looms A description and timeline of EPA’s formaldehyde emission standard rulings.

DEPARTMENTS

8 From the President Patrick Adams points out how things may be simple, but not easy.

162 AD INDEX

526 Media and Surface & Panel magazine thank the following organizations who contributed images for the publication of this issue: Arauco, Arclin, BEHR, Bierson, Burkle, Cambrio, Canon, Cefla, Christian Chernock Properties, Dackor, DVUV, EGGER, Eureka, Formica, Franklin, Funder, Grass, Häfele, Hettich, IKEA, istock.com, Jowat Adhesives, KCD Software, Kleiberit, Kronospan, LamWorks, Leuco, LP Building Solutions, Maibeck Canexel, Mirlux, Modway, NBMDA, New Leaf Performance Veneers, Olon, Omnova, Palram, Panel Processing, Richelieu, Schattdecor, ShopBot, Stiles Machinery, Striebig, swissQprint, THDP, Thermwood, Titus, Toppan, UCS, United Finishers, Swiss Krono, Venjakob, and Wilsonart.

CONTENTS MASTER • 2023 UNITING MATERIALS, TECHNOLOGY AND DESIGN PRODUCTS/MANUFACTURERS 10 PLYWOOD PRODUCTS 12 Softwood Plywood 13 Hardwood Plywood 14 Aircraft & Marine Plywood 15 ENGINEERED WOOD SIDING & TRIM (EWST) 16 FIBERBOARD PRODUCTS 17 Hardboard/HDF 18 Medium Density Fiberboard (MDF) 21 Particleboard 24 LAMINATES 25 High Pressure Laminate (HPL) 26 Thermally Fused Laminate (TFL) 28 Specialty Laminates & Films 30 DECORATIVE FOILS & LIGHTWEIGHT PAPERS 31 COATINGS 32 Liquid & Powder Coatings 34 VENEER 36 EDGE TREATMENTS 37 ADHESIVES 39 TECHNOLOGY 40 Software 41 Digital Printing & Screening 42 Processing Technolgy 45 HARDWARE & FASTENERS 47 TOOLS & MACHINERY 4 SURFACEANDPANEL.COM ON THE COVER:

With EGGER’s Decor Match System, fabricators, architects and designers can find ideally matched thermally fused laminate (TFL), laminates and edge banding, all manufactured from a single source.

GENESISPRODUCTSINC.COM | 877.226.8292 Where all the pieces come together YOUR Panel | Component | Drawer | Door | TFL | Moulding SOURCE

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735

padams@526mediagroup.com

VICE PRESIDENT

Shelly Adams

PUBLISHER EMERITUS

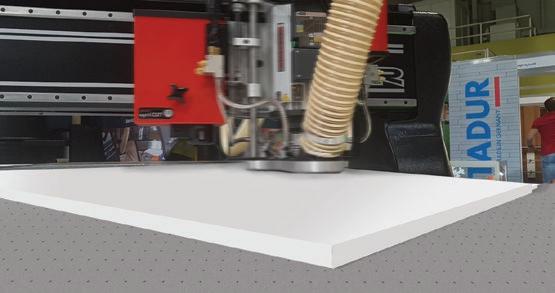

John Aufderhaar

PH: 920-206-1766

john@bedfordfallsmedia.com

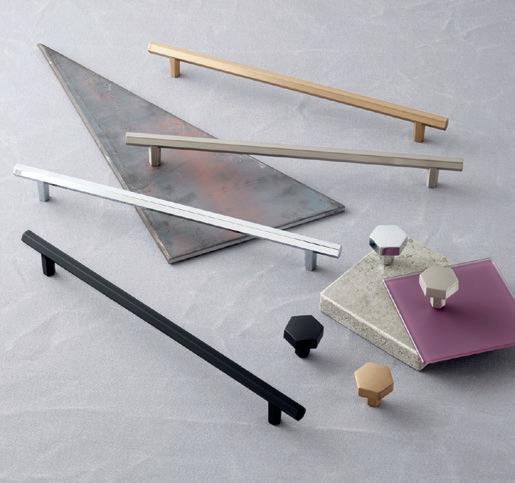

MANAGING EDITOR

Jennifer Williams

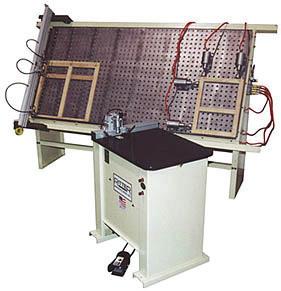

PH: 714-486-2735

jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL

Sara Graves, SENIOR EDITOR

CONTRIBUTORS

Kevin Gammonley, Denise Williams

SALES

Nick Kosan

PH: 714-486-2735

nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735

ccasey@526mediagroup.com

GRAPHIC DESIGN

Karen Leno

VIRTUAL EVENTS

Alekxandr Olson

PH: 920-261-1947

aolson@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735

info@526mediagroup.com

Never Miss aBeat.

SUBSCRIBE

TO THE SURFACE & PANEL NEWSLETTER FOR NEW STORIES EVERY WEEK

Costa Mesa, CA 92626, telephone 714-486-2735. © 2023 by 526 Media Group. Patrick Adams, President. All rights reserved. No part of this publication may be reproduced or transmitted in any form, electronic or mechanical without written permission from the publisher. Subscription policy: Individual subscriptions are available, without charge, to manufacturers who engage in panel processing, qualifed service providers and suppliers. Publisher reserves the right to reject non-qualifed subscribers. One year subscription to non-qualifed individuals: U.S. $50, Canada/ Mexico $75, all other countries $100, payable in U.S. funds. Single issues are $15, and must be prepaid. 526 Media Group does not assume and hereby disclaims any liability to any person for any loss or damage caused by errors or omissions in the material contained herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. Printed in the U.S.A. Postmaster: Send address changes to Surface & Panel, 526 Media Group, 151 Kalmus Drive, Ste. E200, Costa Mesa, CA 92626. Please direct all subscription questions to: Surface & Panel, 526 Media Group, 151 Kalmus Drive, Ste. E200, Costa Mesa, CA 92626 or email info@526mediagroup.com.

6 SURFACEANDPANEL.COM

SURFACEANDPANEL.COM/SUBSCRIBE

526 MEDIA GROUP 151 Kalmus Drive, Ste. E200 Costa Mesa, CA 92626

714-486-2735 Surface & Panel is published quarterly by 526 Media Group, 151 Kalmus Drive, Ste. E200,

PH:

SURFACE & PANEL MASTER SIMPLE, BUT NOT EASY

The mission statement here at 526 Media Group is, “Relentlessly serving working class heroes.” It sounds simple, but it’s not easy. Serving is not easy. It requires hard work, selflessness and constant attention to the needs of those you serve. Given that we have publications that have been continuously serving their audience for more than 100 years, we must be doing something right.

However, every so often you are able to create something that ends up being bigger than you planned—it does more than you intended and is valued in a greater way than you imagined. I recently was walking through the IWF tradeshow in Atlanta and was reminded of this several times. It was amazing catching up with readers and advertisers alike after our two-year COVID “pause.” Outlooks were positive and discussions were full of new ideas and fresh perspectives gained from their time spent in nontraditional ways.

Walking up and down the aisles in our Surface & Panel corporate shirts, we constantly were being stopped by those walking by. Some had ideas of things to cover and some recounted stories they enjoyed from past issues. But more than anything else, they simply said, “Thank you.” As a publisher, there is no greater compliment than hearing those simple two words from a reader. In the sea of so-called, agenda-driven “media,” along with the flood of infomercials and junk mail, it is those two words that confirm you are indeed serving an industry.

What really stood out, however, were the handful of times that we saw our own publication in the hands of those walking through the aisles. I stopped one person and asked, “Why are you carrying the 2022 Surface & Panel Master? It was released back in January and we are not circulating it here at the show.” The reply was the dream of every publisher: “I keep it and refer to it all year. I thought it would be a good guide for me of who to see at IWF.” Simple as that. And—even better—we spotted the 2022 Master several times more on the show floor.

Making something is simple. Calling it “valuable” is marketing speak and that also is simple. Creating a publication that is valued and used by an industry year after year is not simple, nor is the work that each of you do to build your brand and win and keep your clients. This is where our missions align. Our mission is to help make sure that you accomplish your mission. When you do, we both win.

This is the 2023 Surface & Panel Master. Like every year, we talked to you about what you need and what would best serve you, which is simple. But what was not easy was then packaging that new content into something we hope is even better than in years past.

Having this information at your fingertips has proven to be valuable, as it often is easier to navigate information and resources in a print format. We put extra attention into the enhanced digital edition that can be accessed anywhere, anytime. We also have invested in expanding our audience even more, which continues to be the largest, most qualified group of stakeholders throughout our industry segment of any publication or organization.

Simply put, we did not take the “easy road.” For many years now, when your requested issue of Surface & Panel shows up, you know that we take our reputation, and your mission seriously because it is full of the industry’s most trusted information, news and trends. This year is no different!

From the entire team at 526 Media Group, and the team responsible for the Surface & Panel Master, thank you for your support and for the privilege of serving you, your team and your mission.

Patrick Adams, President | 526 Media Group, Inc.

8 SURFACEANDPANEL.COM 2023

FROM THE PRESIDENT Send your thoughts and messages on this issue and article to Patrick at padams@526mediagroup.com

Creating a publication that is valued and used by an industry year after year is not simple, nor is the work that each of you do to build your brand and win and keep your clients.

uniboard.com

Special moments make memories!

Our modern and high quality TFL and HPL collection o ers the most progressive decorative solution in the market. As a Leader in Design and Decorative Surfaces, Uniboard® o ers the broadest color palette and a complete co-product program ranging from edgebanding and moldings to five-piece doors. Building functional and on-trend kitchens, closets and bathrooms has never been easier!

PROUDLY MADE IN NORTH AMERICA.

PLYWOOD PRODUCTS

SOFTWOOD PLYWOOD

HARDWOOD PLYWOOD

AIRCRAFT PLYWOOD

MARINE PLYWOOD

Often referred to as the “Granddaddy of engineered wood products,” plywood originated and later standardized the creation of a composite wood paneling unit stronger than the sum of its parts. And as one of the first such products to be made by bonding together pieces of wood, plywood has been around in one form or another for more than a thousand years.

Ancient Greeks and Egyptians used thinly cut wood and glued it into layers to help conserve their wood supplies, and in China, shaved wood was glued together to make furniture more than a thousand years ago. More modern iterations of plywood were used by the English, French and Russians.

Early plywood from the 19th and 20th centuries was typically made from hardwood for furniture and cabinet production. A patent for “plywood” was issued to John K. Mayo of New York City in 1865. The patent was reissued in 1868 and describes the product as “[consisting of] cementing or otherwise fastening together a number… of sheets, with the grain of the successive pieces, or some of them, running crosswise or diversely from that of the others…”

A few decades later, the World Fair came to Portland, Oregon, in 1905 to celebrate the 100th anniversary of the Lewis and Clark Expedition. Gustav Carlson, part owner and plant manager for the Portland Manufacturing Company, developed a technique making laminated panels from Pacific Northwest softwoods. His “3-ply veneer work” on display prompted orders from several cabinet, trunk and door manufacturers, and by 1907, Portland Manufacturing was producing more than 400 panels a day.

At first, the burgeoning industry served mainly door manufacturers, but in 1920, that focus shifted to the automobile market, and plywood was used for vehicle running boards. By 1929, 17 plywood mills dotted the Pacific Northwest, producing more than 350 million square feet of plywood that year. The rapid weathering of plywood running boards and subsequent drop in demand led to a 1934 breakthrough with the addition of a waterproof adhesive, which set up a new era and possible markets for plywood.

Standardizing the quality of plywood products led to the organization of the Douglas Fir Plywood Association in 1933. The improved quality and standardization of plywood helped boost sales and established the material as a mainstay in construction use. This continued through World War II, which saw plywood used for building everything from barracks to boats.

Post-War demand only increased, and plywood production mills spread from the Pacific Northwest into Canada and down to southern pine forests to meet the growing need.

10 SURFACEANDPANEL.COM

The Douglas Fir Plywood Association evolved into the American Plywood Association in 1964 and later into today’s APA—The Engineered Wood Association, a nonprofit trade organization based in Tacoma, Washington, that serves the U.S. and Canadian engineered wood products industry.

Technological advances fueled by increasing demand for replenishable and reliable building products has only boosted plywood’s popularity and appeal to plywood manufacturers. It was found that the cross-lamination of wood veneer layers improve the inherent structural advantages of wood by distributing along-the-grain strength of wood in both directions. This idea of “reconstituting” wood fiber to produce better-thanwood building materials has led in more recent times to a technological revolution and the rise of a whole new engineered wood products industry, according to the APA. These products not only yield superior performance properties, but also make better use of precious forest resources.

PLYWOOD VARIETIES

Today’s plywood is manufactured by assembling thin layers or plies of wood glued and pressed together using powerful adhesives, with adjacent layers having their wood grain rotated up to 90 degrees to one another, which increases the product’s strength and durability. Lower-quality or thinner plywoods may only have their plies arranged at right angles to each other, while some higher-quality products can feature five plies with staggered rotations (0, 45, 90, 135, and 180 degrees), offering even greater strength using the graduated steps. Typical plywood panels use face veneers of a higher grade than the core veneers. The core layers are mainly used to increase the separation between the outer layers where the bending stresses are highest, thus increasing the panel's resistance to bending. So thicker panels can span greater distances under the same loads. In bending, the maximum stress occurs in the outermost layers, one in tension, the other in compression. Bending stress decreases from the maximum at the face layers to nearly zero at the central layer. Shear stress, by contrast, is higher in the center of the panel, and at the outer fibers.

By utilizing wood scraps, so to speak, rather than solid, whole boards, plywood can be made with less impact on the environment. Today’s plywood is an economical, factory-produced sheet of wood with precise dimensions that does not distort or crack with changes in atmospheric moisture.

Because of this, plywood is widely used for diverse applications ranging from making designer furniture or wall and floor coverings to packaging—and even for making boats and airplanes. There are various specialty plywood materials available to serve these and many other markets

And it all began with plywood.

SURFACE & PANEL - MASTER 2023 11 CONTINUED ON PAGE 12

PLYWOOD IS WIDELY USED FOR DIVERSE APPLICATIONS RANGING FROM MAKING DESIGNER FURNITURE OR WALL AND FLOOR COVERINGS TO PACKAGING.

SOFTWOOD PLYWOOD

Softwood plywood is a plywood made utilizing softwood for the faces, or outer layers. These woods are typically from coniferous or evergreen trees, including cedar, fir, spruce and pine (collectively known as spruce-pinefir or SPF). It is relatively inexpensive and is available in a wide variety of thicknesses and grades for uses both inside and outside.

Softwood plywood has emerged as the most popular type of plywood used in the U.S., due to its cost, durability, flexibility in applications and its sustainability—trees used for softwood plywood production tend to grow more rapidly than hardwood trees. Softwood plywood is available in different grades for its various intended applications, and is used extensively for construction and structural projects, from exterior home sheathing to home flooring and roofing underlayment. It is also very popular with homeowners or hobbyists for projects including sheds, doghouses and even skate or bike ramps.

The most common size of softwood plywood is a 4x8-foot sheet, available at home improvement centers and manufacturers across the country. Sheets can vary in thickness, most commonly from 1/16 inch to about an inch. The number of plies, which is always odd, depends on the sheet’s thickness and grade. For example, sheets for roofing can be 5/8-inch thick while subflooring is required to be at least ¾-inch thick, depending on the distance between floor joists. n

SOFTWOOD PLYWOOD MANUFACTURERS

Aspen Planers

www.aspenplaners.ca

Merritt, BC Canada (250) 378-9266

Boise Cascade

www.bc.com

Boise, ID (208) 384-6161

Canoe Forest Products

www.canoefp.com

Canoe, BC, Canada (250) 833-1200

Eagle Plywood Specialties

www.eagleplywood.com

Grants Pass, OR (800) 547-5991

Freres Lumber

www.frereswood.com

Lyons, OR (503) 859-2121

GP Wood Products

www.buildgp.com

Atlanta, GA (866) 249-3639

Hardel Mutual Plywood

www.hardel.com

Chehalis, OR (800) 562-6344

Hood Industries

www.hoodindustries.com

Hattiesburg, MS (601) 264-2962

Hunt Forest Products www.huntforpro.com

Ruston, LA (318) 255-2245

LP Building Solutions

www.lpcorp.com

Nashville, TN (888) 820-0325

Murphy

www.murphyplywood.com

Rogue River, OR (541) 582-3288

Pacific Wood Laminates

www.socomi.com

Brookings, OR (541) 469-2136

PotlatchDeltic

www.potlatchdeltic.com

St. Maries, ID (509) 328-0930

Richmond Plywood Corp.

www.richply.com

Richmond, BC, Canada (604) 278-9111

Roseburg

www.roseburg.com

Springfield, OR (800) 245-1115

RoyOMartin

www.royomartin.com

Alexandria, LA (800) 299-5174

Scotch Plywood

www.scotchplywood.com

Fulton, AL (800)-936-4424

SDS Lumber

www.sdslumber.com

Bingen, WA (509) 493-2155

Southern Veneer Products

www.southernveneerproducts.com

Fitzgerald, GA (229) 424-0294

Swanson Group

www.swansongroup.biz

Roseburg, OR (800) 331-0831

Timber Products Co. www.timberproducts.com

Springfield, OR (800) 557-5131

Tolko www.tolko.com

Vernon, BC, Canada (250) 550-2512

Westlam Industries www.westlam.com

Langley, BC, Canada (604) 888-2894

Weyerhaeuser www.weyerhaeuser.com

Seattle, WA (800) 525-5440

CONTINUED FROMPAGE 11 12 SURFACEANDPANEL.COM

HARDWOOD PLYWOOD MANUFACTURERS

Besse Forest Products Group

www.bessegroup.com

Gladstone, MI (906) 528-3113

Buffalo Veneer & Plywood www.buffaloveneerandplywood.com

Buffalo, MN (763) 682-1822

Columbia Forest Products www.columbiaforestproducts.com

Greensboro, NC (800) 627-1609

Commonwealth Plywood Inc. www.cpiwhitehall.com

Whitehall, NY (518) 499-0099

Darlington Veneer

www.dvcplywood.com

Darlington, SC (800) 845-2388

Eastern Panel Manufacturing

www.easternpanel.com

Chatham, VA (434) 432-3055

HARDWOOD PLYWOOD

Hardwood plywood is plywood in which the outside layers, or faces, are made from hardwood dicot trees, including oak, maple, cherry, walnut, beech and mahogany. It is known for its excellent durability, strength and stiffness, along with its damage- and wear-resistance. It also is used for its resistance to creep, also known also as cold flow, which is the permanent deformation that increases with time under constant load or stress .

Hardwood plywood is used in millwork and in building furniture, cabinets, doors, musical instruments and sporting equipment. Most hardwood plywood is made with formaldehyde-free glues, which are not moistureresistant, limiting its uses to interior locations. There are specialty plywoods designed and created for exterior uses, including marine- and airplane-grade products.

Baltic Birch plywood is a European-specialty hardwood variety made from birch trees near the Baltic Sea. It is made up of an inner void-free core of cross-banded birch plies with an exterior grade adhesive, and is known for its excellent stability and durability. n

Formwood Industries www.formwood.com

Jeffersonville, IN (812) 458-2118

Genesis Products www.genesisproductsinc.com

Goshen, IN (877) 266-8292

GL Veneer www.glveneer.com

Huntington Park, CA (800) 588-5003

Husky Plywood www.huskyplywood.com

Ste.-Therese, QC, Canada (866) 414-8759

Manthei Wood Products www.mantheiwoodproducts.com

Petoskey, MI (231) 347-7040

Murphy www.murphyplywood.com

Eugene, OR (541) 582-3288

Premwood www.premwoodllc.com

Grand Rapids, MI (616) 667-9500

Roseburg

www.roseburg.com

Springfield, OR (800) 245-1115

S.J. Morse Co.

www.sjmorse.com

Capon Bridge, WV (304) 856-3423

States Industries

www.statesind.com

Eugene, OR (800) 626-1981

Swanson Group

www.swansongroup.biz

Roseburg, OR (800) 331-0831

Timber Products Co.

www.timberproducts.com

Springfield, OR (800) 557-5131

The Wood Gallery Inc.

www.woodgallery.biz

Dallas, TX (972) 869-9161

SURFACE & PANEL - MASTER 2023 13 CONTINUED ON PAGE 14

THE WALL PANEL IN THIS LIVING ROOM CAN BE CONFIGURED WITH SHELVING AND DESK UNITS. CONSTRUCTED OF BALTIC BIRCH, IT

IS EXTREMELY DURABLE, DIMENSIONALLY STABLE AND CAN HANDLE HEAVY LOADS.

High-strength plywood, also known as aircraft Plywood, is made from mahogany, spruce and/or birch using adhesives with an increased resistance to heat and humidity. It was used mainly for an aircraft’s wing surfaces, the flat, bulkhead sections and the webs of the wing spars. This specialty plywood was used in the construction of air assault gliders during World War II and to build several fighter aircraft. It also was used to make Howard Hughes' enormous H-4 Hercules, known as The Spruce Goose— although it was made almost entirely from birch, not spruce. Aircraft plywood is still used today, mostly made up of three or more plies of birch for its lightweight strength. Uses include any application requiring lightweight structural integrity, and water- and fire resistance, such as making musical instruments, toys and puzzles. It also is used in making roller coasters, race cars, drones and experimental aircraft. n

AIRCRAFT PLYWOOD MARINE PLYWOOD

MARINE PLYWOOD MANUFACTURERS

Anderson Plywood

www.andersonplywood.com

Culver City, CA (855) 424-9663

Chesapeake Plywood, LLC

www.chesapeakeplywood.com

Baltimore, MD (410) 224-0055

Homestead Hardwoods

www.marine-plywood.us

Vickery, OH (419) 684-5275

J. Gibson McIlvain

www.mcilvain.com

White Marsh, MD (800) 638-9100

Plywood Logistics

www.plywoodlogistics.com

Westlake Village, CA (424) 367-8374

Seacoast Hardwood

www.seacoasthardwood.com

Sanford, ME (207) 324-1078

Toledo Plywood

www.toledoplywood.com

Toledo, OH (800) 686-1684

Weber Plywood

www.weber-plywood.com

Tustin, CA (949) 979-6490

AIRCRAFT PLYWOOD MANUFACTURERS

Aircraft Plywood Manufacturing

www.aircraftplywood.com

Highland, IL (618) 514-3955

Aircraft Spruce & Specialty Company

www.aircraftspruce.com

Corona, CA (877) 477-7823

Thomas Canada LTD

www.thomescanada.com

Bowmanville, ON, Canada (905) 623-9888

Wicks Aircraft

www.wicksaircraft.com

Highland, IL (618) 654-7447

Marine plywood is manufactured mainly from durable hardwood face and core veneers, with few defects so it performs longer in both humid and wet conditions and resists delaminating and fungal attacks. Its thin layers are usually set up perpendicularly as part of a process called cross-lamination that helps strengthen the material. Marine plywood is superior-quality hardwood plywood that is specially treated using paint, preservatives, or varnish to resist water damage. Marine plywood is constructed out of the finest grade of naturally water-resistant tropical hardwoods, including mahogany and teak.

Other types of specialty plywood include those treated with special chemicals or coatings to make them fire or moisture resistant. Pressure-treated plywood is included in this category with its pressurized production process that increases its durability and resistance to rot and insect damage. Each type of specialty plywood has been designed and produced to fill an industry need, and innovations continue. n

14 SURFACEANDPANEL.COM

CONTINUED FROMPAGE 13

©ISTOCKPHOTO.COM / VOVASHEVCHUK

ENGINEERED WOOD SIDING & TRIM EWST

Engineered wood siding and trim composite panels are made of wood fiber strands, such as plywood, particleboard, mediumdensity fiberboard (MDF) or oriented strand board (OSB), that are heat bonded together with resin and finished. The heat-bonding process creates a stronger and more durable panel. Resembling wood, and available in an array of finishes, colors and textures, these panels are treated with water-resistant waxes and zinc borate to create a final product that is cheaper than traditional wood panels, designed to resist moisture, and protect against fungal decay and termites in both interior and exterior environments.

These highly versatile products are finished in embossed finishes and realisticlooking wood grains to match the aesthetics of where the finished product is placed. For commercial and residential interior applications, the paneling is frequently used in cabinetry, walls and floors and is considered easy to work with. n

Collins Products

www.truwoodsiding.com

Klamath Falls, OR (541) 884-2241

Kaycan

www.kaycan.com

Williston, VT

KWP

www.kwpproducts.com

Terrebonne, QC, Canada (450) 964-5786

LP Building Solutions

www.lpcorp.com

Nashville, TN 1-888-820-0325

Maibec Canexel

www.maibec.com/en/canexelf

Trespa

www.trespa.com

Weert, The Netherlands (31) 495-458-358

ENGINEERED WOOD SIDING & TRIM MANUFACTURERS

SURFACE & PANEL - MASTER 2023 15

HARDBOARD/HDF

MEDIUM DENSITY FIBERBOARD

FIBERBOARD PRODUCTS W

(MDF)

PARTICLEBOARD (LDF)

ith solid wood becoming more scarce and expensive to use in recent years, and the increased emphasis on using more sustainable and environmentally friendly materials, fiberboard has rapidly grown in popularity and has replaced many solid timber products in the building and construction industries.

Made from the leftovers and byproducts of working with wood, the more-affordable fiberboard has also found a place in budget-conscious projects both large and small. Fiberboard products have changed the entire industry.

These fiberboard products are most often used as substrates and a basis for various surfaced panels. Fiberboard can be coated in a wide variety of materials, colors and patterns. The most popular coating traditionally has been that of a wood-look veneer, but recent advances in technology, scanning and printing have opened the world to limitless surfacing possibilities.

The use of fiberboard is very popular in construction and various other applications, from ready-to-assemble furniture to boat building.

Some form of fiberboard has been around for more than a century, but a happy accident led to a standardized method of creating the material. William Mason, an inventor and friend of Thomas Edison, sought a way to utilize the huge amounts of wood chips and shavings left over and discarded by booming lumber mills. The story goes that one evening in 1925, he forgot to shut down his equipment and the next morning, he discovered a thin, durable sheet had been created. He then played with the method, using pressure, heat and resin and patented what became known as Mason’s Method to create this thin, durable product—a method still used today.

Mass production of fiberboard took a few more decades to establish, but today, manufacturers continue to innovate and find new ways to create and use this product.

Traditionally, the resin and binders used to create fiberboard contained formaldehyde, but manufacturers today are increasingly finding alternative methods and materials to make the products.

Some manufacturers now offer no-added formaldehyde (NAF) products for customers who want to minimize their exposure to the potential volatile organic compounds (VOCs) that can “off-gas” out of wood panels into the breathable air.

16 SURFACEANDPANEL.COM

HARDBOARD/HDF

HARDBOARD, FREQUENTLY PRODUCED AS HIGH-DENSITY FIBERBOARD (HDF), IS AN ENGINEERED WOOD PRODUCT USED PRIMARILY IN THE CONSTRUCTION AND FURNITURE-MAKING INDUSTRIES. PEGBOARD IS A TYPE OF PERFORATED HARDBOARD.

Hardboard, also called high-density fiberboard (HDF), is an engineered wood product used primarily in the construction and furniture-making industries.

As its name suggests, it is harder, stronger and more dense than related particleboard and medium density fiberboard (MDF), but does not require any additional adhesive in its production, as the lignin present in the wood fibers bonds the materials together. Some manufacturers today also add resin to their production of HDF, to increase its durability and versatility.

It can be produced in a wet (HDF) or dry process. The dry process results in a smooth texture on both sides, while the wet process—the Mason Method—results in one finished smooth side and one textured side.

The first hardboard products can be traced to England in 1898, when a manufacturer hot pressed waste paper into a usable board. Manufacturers continued to manipulate the process and materials and by the 1920s, a high-density product was created by compressing wet wood pulp at high temperatures.

The most popular applications of HDF can be found in the construction, flooring, furniture and cabinetry industries, but it is also used in automobile production and in the art world as a painter’s canvas or in creating scenery for the theater.

Pegboard is a type of perforated hardboard and is very popular in shops and design for its flexible usage for organization.

Coating hardboard with linseed oil and baking it creates “tempered hardboard,” which offers more water and impact resistance and makes for a stronger end product than regular HDF. Tempered hardboard is often used in construction siding. n

HARDBOARD/HDF MANUFACTURERS

CalPlant 1, LLC

www.eurekamdf.com

Willows, CA (530) 361-0003

D&M Lumber Products

www.dmlumber.com

Brooklyn, NY (718) 386-6119

Decorative Panels International

www.decpanels.com

Toledo, OH (800) 529-4301

Kronospan LLC

www.kronospan-express.com

UK (256) 741-8755

Premwood

www.premwoodllc.com

Grand Rapids, MI (616) 667-9500

Stimson Lumber Co.

www.stimsonlumber.com

Portland, OR (503) 295-0951

Uniboard www.uniboard.com

Montreal, QC (877) 864-8641

West Wood Products

www.west-wood.net

Rancho Dominguez, CA (310) 631-8978

PRODUCTS SURFACE & PANEL - MASTER 2023 17 FIBERBOARD PRODUCTS

MEDIUM DENSITY FIBERBOARD

Medium Density Fiberboard (MDF) is an engineered wood product made from wood fibers compressed and bonded with a synthetic adhesive. As a thin, strong panel, it is the most versatile of the fiberboard products, and has become known as the go-to, low-cost alternative to solid timber products in the manufacturing and building industries.

MDF lacks a wood grain and features a smooth finish, making it notoriously easy to work with. Most MDF starts as sawdust and wood shavings and is mostly composed of softwood. Some brands do contain a higher percentage of hardwood—it really depends on what is most readily available to the manufacturer.

Wood chips and sawdust are the basic materials that are compressed to make MDF panels. Some manufacturers even include waste paper, which helps repurpose and reuse additional waste materials. These fibers are cleaned and processed to remove any impurities, then refined further so that all of the particles are small and consistent. MDF products are processed with a resin (often, formaldehyde-based), which bonds the fiber particles when they’re compressed.

FIBERBOARD PRODUCTS

18 SURFACEANDPANEL.COM

The most common binder for boards intended for dry environments is ureaformaldehyde. Other binders may be used depending on the grade of board and its intended end-use. For example, melamine urea-formaldehyde, phenolic resins and polymeric diphenylmethane diisocyanate (PMDI) are generally used in boards that require an improved moisture resistance. PMDI binder is not formaldehyde-based and consequently does not emit any formaldehyde. The exact makeup of an MDF board will vary from product to product.

Additives may be used to impart MDF with special characteristics for specific applications.

The density of MDF can vary greatly—from about 14 pounds per cubic foot (pcf) up to 80 pcf. The density affects the sturdiness of the panel and how it needs to be sanded. The higher density panels are very strong but are typically more difficult to sand and stain or paint. The average MDF density ranges from about 20-40 pcf. n

COMPLYING WITH THE EPA

According to the Environmental Protection Agency (EPA), composite wood panels and finished products containing such composite wood panels that are manufactured in the United States or imported into the United States must be certified as compliant with either the TSCA Title VI or the California Air Resources Board (CARB) Airborne Toxic Control Measures (ATCM) Phase II emission standards—which are set at very similar levels—by a Third-Party Certifier (TPC) approved by CARB and recognized by EPA. And all TPCs first must be authorized and approved by an Accreditation Body (AB). But how can a manufacturer or distributor determine if a TPC or AB is EPA-approved?

Third-Party Certifiers (TPCs) are laboratories conducting independent third-party formaldehyde emissions testing of regulated composite wood products to comply with the updated EPA rules and regulations.

For an updated list of recognized Third-Party Certifiers (TPCs) under the Formaldehyde Emission Standards for Composite Wood Products Rule, visit the EPA website at www.epa.gov/formaldehyde/recognizedthird-party-certifiers-under-formaldehydeemission-standards-composite-wood Accreditation Bodies (ABs) include product accreditation bodies and laboratory accreditation bodies. To become recognized as an EPA TSCA Title VI AB, an organization must apply through the EPA Central Data Exchange (CDX) at https://cdx.epa.gov

The EPA says ABs may choose to apply to be recognized as one or both types of ABs (product or laboratory only, or product and laboratory AB). The CDX online application will allow selection of either one or both AB types and will provide the information required in the sections.

An updated list of EPA-approved Accreditation Bodies (ABs) can be found at www.epa.gov/formaldehyde/recognizedaccreditation-bodies-under-formaldehydeemission-standards-composite-wood

For more on formaldehyde emissions compliance and the EPA, see page 49.

SURFACE & PANEL - MASTER 2023 19

MDF IS THE MOST VERSATILE OF THE FIBERBOARD PRODUCTS, AND HAS BECOME KNOWN AS THE GO-TO, LOW-COST ALTERNATIVE TO SOLID TIMBER PRODUCTS IN THE MANUFACTURING AND BUILDING INDUSTRIES.

ON PAGE 20

CONTINUED

MDF

FIBERBOARD PRODUCTS

MEDIUM DENSITY FIBERBOARD MANUFACTURERS

Arauco North America

na.arauco.com

Chile/Atlanta, GA (800) 261-4890

Buffalo Veneer & Plywood

www.buffaloveneerandplywood.com

Buffalo, MN (763) 682-1822

CalPlant 1, LLC

www.eurekamdf.com

Willows, CA (530) 361-0003

D&M Lumber Products

www.dmlumber.com

Brooklyn, NY (718) 386-6119

Duraplay de Parral SAPI

www.duraplay.com.mx

Mexico (52) 627-523-9800

EGGER Wood Products

www.egger.com

Lexington, NC (844) 977-0053

Genesis Products

www.genesisproductsinc.com

Goshen, IN (877) 266-8292

GP Wood Products

www.buildgp.com

Atlanta, GA (866) 249-3639

Great Plains MDF

www.greatplainsmdf.com

Calgary, Alberta (587) 897-2362

Kronospan LLC

www.kronospan-express.com

UK (256) 741-8755

Langboard

www.langboard.com

Quitman, GA (912) 534-5959

Maderas Conglomeradas SA

www.macosa.com.mx

Mexico (52) 55-5715-5870

Pan Pacific Products

www.panpacificproducts.com

Broken Bow, OK (580) 584-6247

Premwood

www.premwoodllc.com

Grand Rapids, MI (616) 667-9500

Roseburg

www.roseburg.com

Springfield, OR (800) 245-1115

Swiss Krono USA

www.swisskronousa.com

Switzerland (866) 334-9923

Timber Products Co.

www.timberproducts.com

Springfield, OR (800) 557-5131

Ultrapan

www.ultrapan.net

Coral Springs, FL (754) 702-2632

Uniboard

www.uniboard.com

Montreal, QC (877) 864-8641

Unilin MDF

www.unilin.com

Belguim (32) 56-66-7021

West Fraser

www.westfraser.com

Vancouver, BC (901) 620-4200

West Wood Products

www.west-wood.net

Rancho Dominguez, CA (310) 631-8978

Weyerhaeuser MDF

www.weyerhaeuser.com

Seattle, WA (800) 525-5440

20 SURFACEANDPANEL.COM FIBERBOARD PRODUCTS MDF

CONTINUED FROM PAGE 19

PARTICLEBOARD

Particleboard, or Low Density Fiberboard (LDF), is the least expensive fiberboard option, offering a smooth surface for veneer faces.

Particleboard can be produced to precise thicknesses in a variety of panel sizes and is relatively heavy. Despite its heft, particleboard has the least amount of structural strength compared to the other fiberboard options and is subject to the greatest amount of expansion if exposed to moisture.

Today’s particleboard gives users the consistent quality and design flexibility needed for fast, efficient production lines and quality consumer products. Particleboard panels are manufactured in a variety of dimensions with a wide range of physical properties, providing maximum design flexibility.

Particleboard is used extensively in today’s popular Ready-to-Assemble furniture industry. It also is widely used in manufacturing countertops, kitchen cabinets, shelving, store fixtures, underlayment, door core and stair treads— often covered with a sealant or other coating to help with moisture resistance.

SURFACE & PANEL - MASTER 2023 21 FIBERBOARD PRODUCTS

CONTINUED ON PAGE 23

PARTICLEBOARD

PARTICLEBOARD MANUFACTURERS

Arauco North America

na.arauco.com

Chile/Atlanta, GA (800) 261-4890

BestBoard Impulsora SA

www.bestboard1.com

Mexico/Chula Vista, CA (619) 819-6064

Buffalo Veneer & Plywood

www.buffaloveneerandplywood.com

Buffalo, MN (763) 682-1822

Collins Products

www.collinswood.com

Portland, OR (800) 329-1219

D&M Lumber Products

www.dmlumber.com

Brooklyn, NY (718) 386-6119

Duraplay de Parral SAPI

www.duraplay.com.mx

Mexico (52) 627-523-9800

EGGER Wood Products

www.egger.com

Lexington, NC (844) 977-0053

Florida Plywoods

www.fply.com

Greenville, FL (850) 948-2211

Forestal Terranova Mexico SA

www.masisa.com

Mexico

Genesis Products

www.genesisproductsinc.com

Goshen, IN (877) 266-8292

GP Wood Products

www.buildgp.com

Atlanta, GA (866) 249-3639

Kronospan LLC

www.kronospan-express.com

UK (256) 741-8755

Maderas Conglomeradas SA

www.macosa.com.mx

Mexico (52) 55-5715-5870

Masonite Corp.

www.masonite.com

Tampa, FL (800) 663-2667

Panel Processing, Inc.

www.panel.com

Alpena, MI (800) 433-7142

Panolam Industries

www.panolam.com

Shelton, CT (877) 726-6526

Plummer Forest Products

www.plummerforest.com

Post Falls, ID (208) 457-8703

Premwood www.premwoodllc.com

Grand Rapids, MI (616) 667-9500

Roseburg

www.roseburg.com

Springfield, OR (800) 245-1115

Tafisa Canada

www.tafisa.ca

Lac-Megantic, QC (819) 583-2930

Timber Products Co.

www.timberproducts.com

Springfield, OR (800) 557-5131

Uniboard www.uniboard.com

Montreal, QC (877) 864-8641

West Wood Products

www.west-wood.net

Rancho Dominguez, CA (310) 631-8978

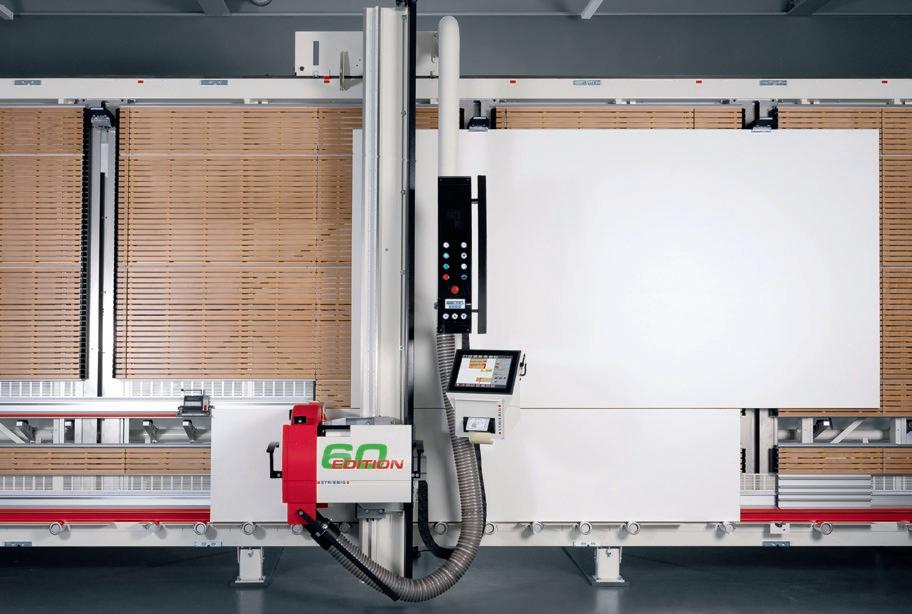

Woodgrain Composites

www.woodgraincomposites.com

Fruitland, ID (888) 783-5485

FIBERBOARD PRODUCTS

The first known particleboard was made in Germany in the late 1880s, made from wood flour and adhesive under high heat and pressure and molded into what was called “artificial wood.” Commercial applications began during World War II when it was advantageous to produce from wood waste products including off-cuts, shavings and sawdust. These materials were processed into small pieces and screened before being mixed with various resins and adhesives once it was found that the more uniform pieces made for a better, more streamlined product.

Three-layer particleboard is made up of the finely ground materials placed in layers on either side of a coarser core layer while graded-density particleboard is made up of particles that gradually become smaller as they get closer to the surface.

Particleboard rose in popularity in residential applications in kitchens during the 1950s housing boom, but in many cases, it remained more expensive than solid wood. Technological advances helped streamline the production process and the “artificial wood” products became much more economical. Today’s panel production can include the addition of materials to help make the final product more resistant to water, insects or even fire. n

SURFACE & PANEL - MASTER 2023 23

FIBERBOARD PRODUCTS PARTICLEBOARD

CONTINUED FROMPAGE 21

PARTICLEBOARD IS WIDELY USED IN MANUFACTURING COUNTERTOPS, KITCHEN CABINETS, SHELVING, STORE FIXTURES, UNDERLAYMENT, DOOR CORE AND STAIR TREADS.

HIGH PRESSURE LAMINATE (HPL)

LAMINATES W

THERMALLY FUSED LAMINATE (TFL)

SPECIALTY LAMINATES (2D & 3D LAMINATES & FILMS)

hat began as a product to insulate radio equipment has evolved into one of today’s most popular decorative surfaces. Laminates are a popular material for home interiors and commercial spaces, due in large part to their versatility and affordability.

Lamination refers to the process of manufacturing a multiple-layer material, often combining various base components to create an end product with enhanced qualities, including those offering sound or fire insulation, UV-resistance and antibacterial or electrostatic dissipative properties. Laminates utilize heat, pressure, welding or adhesives to create the product fusing thin sheets onto a substrate.

Laminates are classified into different categories based on their how they are manufactured and their finish usage and properties. These categories include highpressure and low-pressure laminates and specialty laminates.

Laminates are often associated with the clean designs from the 1950s, 60s and 70s, but have actually been around since 1909, when plastic laminates were invented for use as insulation for electronics and wiring. The first laminates were made of canvas and paper covered with phenolic resin and were first made into laminate sheets in 1913. Phenolic resin was useful but could produce only a brown finish for the laminate material, so decorative uses were still a few years away.

In 1927, the Formica Insulation Company filed a patent for the first decorative plastic laminate, using colored paper for their top layer and offering 13 different colors. The company continued to add colors, textures and patterns to their laminate materials and in 1938, with the invention of melamine—made by adding a hard, clear topcoat finish by baking the product—a wide variety of durable, stain-resistant laminate surfaces were available to general consumers by the end of the 1940s.

First seen mainly in commercial buildings including iconic American diners, laminate surfaces made their way into the booming housing market in post-war America with their shiny, modern look. Consumers loved the clean look for their cabinets, countertops and even furniture including kitchen tables. Technological advances and chemical innovation led to more realistic laminates, and the new exotic patterns and colors helped grow the market, along with the burgeoning home renovation market through the 1960s, 70s and 80s.

A focus on the environment saw a renewed look at laminates, which do not produce harmful fumes, and the decorative surface became more practical for many commercial spaces, including hospitals, restaurants and offices. The paper-to-polymer ratio in today’s laminates help make a stronger, more durable material than ever—it has been said that laminate can be as strong as steel, when compared by weight.

Laminates continue to be popular due to their easy installation on any wood surface like plywood and MDF panel, their relatively low cost, durability, low maintenance and vast choice or finishes, including matte, glossy, metallic, solid, textured and even leather.

24 SURFACEANDPANEL.COM

HIGH-PRESSURE LAMINATE (HPL)

High-pressure laminate (HPL) was the original and most widely used laminate surface, and is known for being easy to work with and very durable. It can be fabricated on-site, differentiating HPL from many other laminate products. Because it is so easily fabricated, different core or substrate options can be used for many purposes.

As the name suggests, high-pressure laminates are produced by bonding the layer of the laminate with the substrate (typically plywood or MDF) at very high pressure. Considered to be one of the most durable decorative surfaces, HPL offers a wide variety of surface designs, including digital prints and can withstand heavy loads, making it a favorite for countertops and flooring.

In a single pressing cycle, several different HPL designs can be produced at one time, making its production particularly efficient.

HPL panels can easily be cut into unique shapes, and narrow strips of HPL can be cut from a panel to use on raw edges—often on-site and as-needed. Special postforming grades of the material can form specialty edges, as well.

HPL is often used as a more economical, durable alternative to veneer and stone surfaces in high-use applications, with its ability to create realistic textures through its pressing process. It can be seen extensively in commercial settings, including in fast food restaurants, offices and hotels.

HPL is formed and cured at more than 1,000 pounds per square inch—most commonly between 1,200 and 2,000 pounds per square inch. It is 60-70 percent paper, saturated with different kinds of plastic resins for various applications.

In contrast, low-pressure laminates are adhered to substrates under low pressure (generally around 400 pounds per square inch) and are commonly used as a finishing layer for particleboard or fiberboard (MDF). n

CT (877) 726-6526 Stevens

IL (217) 857-7100 Tafisa Canada, Inc.

Lac-Mégantic, QC, Canada (819) 583-2930

Laval, QC, Canada (800) 263-5240

Wilsonart www.wilsonart.com

Temple, TX (800) 433-3222

SURFACE & PANEL - M ASTER 2023 25

HIGH PRESSURE LAMINATE MANUFACTURERS AICA Group www.aica-al.com/aica_group Nagoya, Aichi, Japan (81) 52-533-3156 CEI Materials www.ceimaterials.com Manchester, MI (734) 212-3006 Dackor www.dackor.com Winter Garden, FL (407) 654-5013 EGGER Wood Products www.egger.com Lexington, NC (844) 977-0053 Formica Corp. www.formatop.com Kitchener, ON, Canada (888

2

Formica Corp. www.formica.com Cincinnati, OH (800) 367-6422 Lamitech www.lamitech.co Cranbury,

Merino Laminates www.merinolaminates.com Moti Nagar,

Panolam Industries

www.panolam.com

www.stevensadvantage.com

www.tafisa.ca

THE PROPERTIES OF HPL CREATE OPPORTUNITIES FOR BOTH VERTICAL AND HORIZONTAL SURFACE TREATMENTS.

)

37-0037

NJ (800) 320-7456

New Delhi, India (011) 45557000

International, Inc.

Shelton,

Advantage

Teutopolis,

Uniboard www.uniboard.com

THERMALLY FUSED LAMINATE (TFL)

Thermally fused laminates (TFLs), also known as melamine panels, combine the top layers of HPL or LPLs and thermally fuses them to the surface of a composite substrate. The paper-based surface layers are saturated with melamine resin and treated with a special thermosetting system, bonding the layers to the substrate (typically composite wood or particleboard) under heat and pressure for a clear, durable finish. The product remains very popular for use with ready-toassemble or flat-pack furniture products but has also emerged as a durable supplement to HPL products.

TFLs were relatively limited in design finishes when first created nearly three decades ago, and were used mainly for the interior of cabinets and other cost-effective practical uses. TFL designs evolved through the 1990s to help create products, including decorative molding, that matched other laminate surfaces, offering a way to incorporate seamless design in projects in a cost-effective manner.

Woodgrain design TFLs have become increasingly popular, particularly where veneer or solid wood may be too fragile or expensive. Manufacturers claim that TFL is very efficient to produce and are made with “climate-positive” composite wood cores that utilize wood fiber that is otherwise discarded.

TFLs are used in many different applications, from architectural wall panels to commercial spaces and residential cabinet faces. And because the decorative faces are thermally fused, rather than glued, to the panel core, TFLs offer high wear-, moisture- and scratch-resistance. Special cores, surfaces or resins are available to enhance certain desirable properties, including fire resistance.

Another advantage of TFL products is that they can be matched to various other materials, including HPL, 3DL, decorative foils and edge treatments. n

26 SURFACEANDPANEL.COM

THERMALLY FUSED LAMINATE MANUFACTURERS

AICA Kogyo

www.aica.co.jp/english

Nagoya, Aichi, Japan (81) 52-533-3156

American Laminates, Inc.

www.americanlaminates.com

Riverbank, CA (800) 800-2536

Arauco North America

na.arauco.com

Atlanta, GA (800) 261-4890

Arclin

www.arclin.com

Roswell, GA (877) 689-9145

Dalbac Manufacturing Co., Inc.

www.dalbac.com

Forney, TX (972) 564-6200

Dongwha Malaysia

www.dongwha.com/myen/main/main.asp

Kedah Darul Aman, Malaysia (606) 799-3000

EGGER Wood Products

www.egger.com

Lexington, NC (844) 977-0053

Fiberesin Industries

www.fiberesin.com

Oconomowoc, WI (262) 567-4427

THERMALLY FUSED LAMINATE

Formatop

www.formatop.com

Kitchener, ON, Canada (888) 237-0037

Funder America, Inc.

www.funderamerica.com

Mocksville, NC (336) 751-3501

KML Corp.

www.kmldesignerfinishes.com

Klamath Falls, OR (877) 958-9990

Kronospan, LLC.

www.kronospan-express.com

Eastaboga, AL (256) 741-8755

MJB Wood Group

www.mjbwood.com

Dallas, TX (972) 401-0005

Panel Processing, Inc.

www.panel.com

Alpena, MI (866) 794-1441

Panolam Industries International, Inc.

www.panolam.com

Shelton, CT (877) 726-6526

Premier Eurocase

www.premiereurocase.com

Denver, CO (303) 373-9718

Purbanchal Laminates Pvt. Ltd.

www.purbanchallaminates.com

Gandhidham, Gujarat, India (91) 2836-231468

Roseburg www.roseburg.com

Springfield, OR (541) 679-2614

Specialty Laminates

www.specialtylaminates.com

Eugene, OR (541) 343-5383

Stevens Industries, Inc.

www.stevens-wood.com

Teutopolis, IL (217) 857-7100

Swiss Krono Group

www.swisskrono.com/global-en

Barnwell, SC (866) 334-9923

Tafisa Canada, Inc.

www.tafisa.ca

Lac-Mégantic, QC, Canada (819) 583-2930

Texas Wooden Solutions, Corp.

www.melaminetex.com

Humble, TX

Timber Products Co. (VALUE ADDED DIVISION)

www.timberproducts.com

Springfield, OR

Uniboard

www.uniboard.com

Laval, QC, Canada (800) 263-5240

Wilsonart

www.wilsonart.com

Temple, TX (800) 433-3222

FUN FACT

Melamine is an organic compound that contains 67% nitrogen by mass, offering flame retardant properties. Melamine resins are created when the compound is combined with formaldehyde and other agents. Melamine foam is used as insulation, soundproofing material and in polymeric cleaning products, such as Magic Eraser.

SURFACE & PANEL - MASTER 2023 27

SPECIALTY LAMINATES & FILMS

There are a growing number of specialty laminates & films these days, but the three main categories are 3D Laminates (3DL), 2D Laminates (2DL) and Cast Polypropylene Laminating Film (Cast PP Film). Each offers its own benefits in manufacturing and design.

3D LAMINATE (3DL), also known as rigid thermoformable foils (RTF), decorative vinyl or vinyl foil is made by overlaying and laminating thin, decorative thermoplastic material onto (typically) MDF panels. A thin sheet of rigid thermosetting PVC or PET (polyethylene terephthalate) polymers is manufactured with a lacquer on top for scratch resistance, and a primer on the back to improve adhesion.

3DL overlays are available in solid colors, woodgrains, metallics and other designs, using rotogravure systems using water-based or solvent-based inks. Textures including woodgrain, stone and even brushed aluminum can be applied to the overlay with embossing rolls.

The 3DL fabrication process wraps the material around panel edges and helping to seal it against moisture and bacteria. This “self-edging” also reduces the need for additional edgebanding or finishing. 3DL surfaces wrap five of six panel sides, and offer soft, rounded edges unique to the product, and countless uses for carved or shaped products, including molding.

MDF is the most common substrate used for 3DL, offering a sought-after better-than-carbon-neutral material for today’s projects. 3DL offers a higher scratch resistance than HPL and a higher impact resistance than HPL or TFL.

The option for seamless faces, along with the advanced mimicry of hardwood or exotic woods and other patterns makes 3DL popular in both commercial and residential projects. Kitchen and bath cabinet doors are the most popular use of 3DL in residential spaces, but it is commonly found in furniture and closet systems

as well. Office furniture is widely made from 3DL, and it also is used for textured architectural features in hotels, restaurants and other commercial spaces.

2D LAMINATES (2DL) are versatile surfacing products suitable in a broad range of decorative and functional applications. They can be flat-laminated or profile-wrapped to wood substrates, using a process similar to that of 3DL, but as the name suggests, minus the embossing step. 2DL is often used on flat surfaces, while 3DL is used on more intricate projects, including specialty molding.

2D Laminates are engineered to be scratch, abrasion and stain resistant. A high-performance coating provides an added degree of protection, durability and easy clean-up when compared to paper laminates or painted surface treatments. Many companies also offer custom color, design, coatings and constructions.

Two popular types of laminate today offering a sleek look are acrylic laminates, made from polymer fiber with similarities to lacquer, and PVC laminates, which are multi-layered preprocessed materials that are made based on polyvinyl chloride and multi-layered pre-processed materials that are made based on polyvinyl chloride. Both are typically available in thin sheeting and sold in rolls.

Fire-rated laminates are created using fire-resistant resin, and other specialty laminates include those with anti-bacterial/antifungal properties used in hospitals and outdoor UV-resistant laminates used for billboards and siding.

CAST POLYPROPYLENE LAMINATING FILM , also known as Cast PP Film, eliminates the need for a decorative paper layer while offering an economical thermoplastic of high clarity, high gloss, and good tensile strength. It is easy to print and can offer a higher level of water and chemical resistance than other laminates.

Cast PP Film is PVC-free and is fully recyclable and fully customizable, offering a wide selection of colors, finishes and textures. Special UV coatings can also be applied on both smooth and embossed surfaces. It is used in both residential and commercial applications, including RV walls and ceilings, shelving and flooring.

The film can be easily laminated or wrapped onto a wide range of substrates, including MDF or plastic and composite layers. It is created in a continuous or static press, where the surface is bonded to the substrate with a heat-activated adhesive under heat and pressure. n

28 SURFACEANDPANEL.COM

SPECIALTY LAMINATES & FILMS MANUFACTURERS

Dackor

www.dackor.com

Winter Garden, FL (407) 654-5013

Decotone Surfaces

www.decotonesurfaces.com

Garwood, NJ (908) 301-0600

DNP America, LLC

www.dnpamerica.com

New York, N Y (212) 503-1060

Interprint, Inc.

www.interprint.com

Arnsberg, Germany (49) 2932-950 0

Klockner Pentaplast

www.kpfilms.com/en/

Buenos Aires, Argentina (54) 11-5365-6969

Omnova

www.omnova.com/laminates

Beachwood, OH (216) 682-7000

SPECIALTY LAMINATES & FILMS

Paladin Ind., Inc.

www.paladinind.com

Kentwood, MI (616) 698-7495

Premier Eurocase

www.premiereurocase.com

Denver, CO (303) 373-9718

Profol

www.profol.com

Cedar Rapids, IA (319) 365-0599

Renolit Corp.

www.renolit.com

LaPorte, IN (219) 344-5684

Riken U.S.A. Corp.

www.riken-usa.com

Novi, MI (248) 513-3511

Sekisui Kydex Llc.

www.kydex.com

Bloomsburg, PA (800) 325-3133

SSI North America

www.ssinorthamerica.com

Randolph, NJ (973) 598-0152

Synergy Thermal Foils

www.synergythermofoils.com

Coral Springs, FL (954) 420-9553

Tafisa Canada, Inc.

www.tafisa.ca

Lac-Mégantic, QC, Canada (819) 583-2930

Taghleef Industries

www.syndecor.com

Newark, DE (302) 326-5500

Toppan Interamerica, Inc.

www.toppaninteramerica.com

Tokyo, Japan (83) 3835-5111

UFP Industrial

www.inbound.ufpindustrial.com

Grand Rapids, MI (800) 598-9663

Vekaplan

www.vekaplan.co.uk

Leeds, UK (44) 113-273-6281

SURFACE & PANEL - MASTER 2023 29

DECORATIVE FOILS & LIGHTWEIGHT PAPERS

DECORATIVE FOILS & LIGHTWEIGHT PAPERS

MANUFACTURERS

Ahlstrom-Munksjö

www.ahlstrom-munksjö.com

Helsinki, Finland (920) 766-4611

(North America Sales Office)

American Adhesive Coatings LLC.

www.aacchotmelts.com

Lawrence, MA (978) 688-7400

Dawei Decorative

www.dawei-decor.com

Hong Zhou City, Zhe Jiang province, China (86) 18668216300

Decorative Panels Group

www.decorativepanels.co.uk

Elland, West Yorkshire, UK (44) (0) 1484-658341

Interprint, Inc.

www.interprint.com

Arnsberg, Germany (49) 2932-9500

Pittsfield, MA (413) 443-4733

LamiGraf

www.lamigraf.com

Barcelona, Spain (34) 93-8431888

Olon Industries

www.olon.ca

Georgetown, ON, Canada (800) 387-2319

Omnova

www.omnova.com/laminates

Beachwood, OH (216) 682-7000

Panel Processing Inc.

www.panel.com

Alpena, MI (866) 794-1441

Schattdecor, Inc.

www.schattdecor.com

Lexington, SC (803) 957-3377

Surteco North America

www.surteco.com

Buttenwiesen, Germany (49) 8274-51-0

Toppan Interamerica Inc.

www.toppaninteramericainc.com

Tokyo, Japan (81) 3-3835-5111

Yodean Décor

www.yodean-decor.com/product/

Hangzhou City, Zhejiang Province, China

(86) 18668216300

Decorative Foils & Lightweight Papers, also known as finish foils and top-coated papers, are thin, paper-based decorative surfaces bonded onto a smooth substrate—typically MDF. They are very popular in the design world for their flexible, economic applications, as they offer a limitless array of printed designs and variations that mimic other materials.

These thin coatings are easily wrapped around shapes and substrate edges, and are widely used in cabinet interiors, and as contoured edges matching TFL panels. While both are paper-based overlays printed on rotogravure presses, decorative foils are impregnated with resins and do not require a topcoat (although topcoats can be applied for desired applications) and lightweight papers require a top coating of polyurethane or other resins.

These coatings provide a realistic representation of wood grain or other patterns, and typically cost less than most other decorative surfaces. They are widely used in vertical applications, including decorative flat wall panels and architectural mouldings and trim. Another advantage is the reproducibility of the designs—a panel can be duplicated exactly years later, unlike with wood and veneers.

As these coatings are very thin, the usual embossing process used for TFL and HPL won’t work. Instead, small areas are printed with inks that resist the topcoat layer, resulting in visual variations that closely mimic finished wood or other designs. Foils and lightweight papers are often matched with TFL, HPL and 3DL to maintain a seamless design on projects. n

30 SURFACEANDPANEL.COM

LIQUID COATINGS

POWDER COATINGS

COATINGS

The variety of coatings available for today’s surfaces is extensive. As its name implies, a coating is a covering applied to the surface of an object, for decorative and/or functional uses. Coatings can be applied to a substrate as solids, liquids or gases. Coatings also come in other forms, including decorative foils and lightweight papers

Many industrial coating processes involve the application of a thin film of the coating material onto a substrate, finishing the substrate for residential or commercial uses. If the substrate being used starts and finishes the process wound onto a roll, the process is called “roll-to-roll” or “web-based” coating. This roll of this substrate is called a “web.”

Coatings including paint and lacquer can offer the added advantage of both protecting the substrate while being decorative, while other functional coatings may be applied to improve the surface properties of the substrate, such as wear, water or corrosion resistance and adhesion. Other coatings can add a completely new property, such as magnetism or electrical conductivity, to the substrate.

SURFACE & PANEL - MASTER 2023 31

CONTINUED ON PAGE 32

LIQUID & POWDER COATINGS

Now Powder Coating BIRCH PLYWOOD

Liquid and powder coatings need to be applied carefully to control the amount and thickness of the material being used. This can be accomplished in various manners, from using simple applications to using more complex, automated systems and specialized machinery.

Automated air gun spray systems are used to cover larger surfaces with an even coating of liquid paint or polymer, and is typically very fast and efficient, even collecting excess coating material for reuse. The machines used work with both waterand solvent-based liquid coating materials. As this technique is limited to lower levels of layer deposition, some applications require multiple passes through the machine to build up the final coating product.

The extrusion coating technique uses molten web of synthetic resin to coat a substrate material. It is an economic way to apply various plastics onto substrates including fiberboard.

Thermal spraying techniques spray heated materials onto a substrate, offering a thicker possible coating over large areas at a high deposition rate when compared with other liquid coating processes.

A single coat clear coating for Birch in only 20 minutes? YES! You send us the drawings, we send you a fnished part.

Supplying components for the contract furniture, hospitality, retail, healthcare and other industries.

Request a sample at www.dvuv.com

Unlike conventional liquid paint coatings, powder coatings are typically applied electrostatically as free-flowing dry powder and cured with heat or ultraviolet light. The powder coating is usually a thermoplastic or a thermoset polymer, which creates a hard finish generally tougher than that of conventional paint coatings.

The powder coating process was invented by Daniel Gustin in the 1940s and involved coating an item electrostatically then applying heat to cure it. Advancements in powder coating technology, including UV curable powder coatings, have allowed for a greater variety of substrate materials to be used, due to the minimum heat and oven dwell time required to process the materials.

32 SURFACEANDPANEL.COM

CONTINUED FROM PAGE 31

Sample

Request

ADVANCEMENTS IN POWDER COATING TECHNOLOGY, INCLUDING UV CURABLE POWDER COATINGS, HAVE ALLOWED FOR A GREATER VARIETY OF SUBSTRATE MATERIALS TO BE USED, DUE TO THE MINIMUM HEAT AND OVEN DWELL TIME REQUIRED TO PROCESS THE MATERIALS.

LIQUID & POWDER COATINGS

Because powder coating does not utilize a liquid process for application, it can produce thick coatings without running or sagging, and minimal appearance differences between horizontally coated surfaces and vertically coated surfaces. And this coating process emits very few volatile organic compounds (VOCs), since there is no carrier fluid to evaporate.

Another advantage to powder coatings is that several powder colors can be applied before curing, allowing color blending and special effects in a single layer. And while it is easier to apply thick coatings that cure to a smooth finish, it is not as easy to apply smooth, thin films using powder coatings. It is, however, easier to create a wide range of specialty effects that are not possible with other coating processes.

LIQUID & POWDER COATINGS MANUFACTURERS

AKZO Nobel Coatings, Inc.

www.akzonobel.com

Amsterdam, The Netherlands (31) 88-9697809

Arauco North America

na.arauco.com

Atlanta, GA (800) 261-4890

Arkema

www.arkema.com

King of Prussia, PA (310) 214-5327

Asian Paints PPG PVt. Ltd.

www.asianpaintsppg.com

Mumbai, Maharashtra, India (91) 22-6218-2700

Axalta Coating Systems

www.axaltawoodcoatings.com

Glen Mills, PA (855) 547-1461

BASF (North America)

www.basf.com

Florham Park, NJ (973) 245-6000

Benjamin Moore & Co. Inc.

www.benjaminmoore.com

Montvale, NJ (855) 724-6802

DVUV, LLC

www.dvuv.com

Cleveland, OH (216) 741-5511

Eastman Chemical Co.

www.eastman.com

Kingsport, TN (800) 327-8626

Funder America, Inc.

www.funderamerica.com

Mocksville, NC (336) 751-3501

Hempel, Inc. (North America)

www.hempel.com

Conroe, TX (936) 523-6000

Indigo Paints

www.Indigopaints.com

Boranada, Rajasthan, India (02931) 281-162

IVM Chemicals/Milesi Wood Coatings

www.milesi.us

Charlotte, NC

Jotun

www.jotun.com

Sandefjord, Norway (713) 860-8241 (NA)

Kwality Paints and Coatings Pvt. Ltd.

www.kwalitypaints.co.in

Bhosari, Pune, India (91) 20-46780905

PPG Industries, Inc.

www.ppg.com

Pittsburgh, PA (412) 434-3131

RPM International Inc.

www.rpminc.com

Medina, OH (330) 273-5090

Sherwin-Williams

www.sherwin-williams.com

Cleveland, OH (216) 566-2000

Stahl

www.wendelgroup.com

Wooster, OH (330) 202-4215

Tafisa Canada, Inc.

www.tafisa.ca

Lac-Mégantic, QC, Canada (819) 583-2930

Teknos

www.teknos.com

Helsinki, Finland (358) 9-506-091

Tiger Drylac U.S.A., Inc.

www.Tiger-coatings.com

St. Charles, IL (800) 243-8148

Worthen Industries

www.worthenind.com/adhesives

Nashua, NH (800) 967-8436

SURFACE & PANEL - MASTER 2023 33

n

VENEER V

eneer typically is a very thin sheet of hardwood—generally thinner than 1/8 of an inch—cut and matched in a pattern that then can be applied to a more durable, less expensive surface.

Using a very thin layer of the hardwood maximizes efficiency and allows for the most possible useable material from a single piece of wood. And when a veneer is applied to a substrate, it can actually increase the strength of the finished product.

Veneering dates back to ancient Egyptian times, when rare or expensive wood veneer was used over cheaper wood to create furniture and other products. Citizens of the Roman Empire also used veneering for similar reasons.

And while the idea remains the same, the process for creating veneer has evolved. Veneers originally were sawn from logs, but manufacturers today thinly slice the wood, making for less waste.

Today, the thin sheets of wood that make up veneer are harvested either by peeling or shaving the trunk of a tree or by slicing large rectangular blocks of wood, or flitches. Each slicing processes gives a very distinctive type of grain, depending upon the tree species.

The most common hardwood species used for veneer in North America include maple, cherry, red or white oak, hickory, ash, alder, walnut, and poplar. Softwood veneers from pine, fir, and other conifer species are also produced.

Each slicing process gives a distinctive type of grain depending upon the tree species. There are three main ways for slicing veneer:

• Using a rotary lathe to turn the wood against a very sharp blade and peel it in one continuous strip cuts concentric to the growth rings and is not considered to be very desirable. Veneer produced in this manner is typically used for plywood, where the wood grain and aesthetics are not as important.

• A slicing machine that raises and lowers the flitch (log) against the blade to slice the wood evenly and across the growth rings creates what is known as the “crown cut,” and mimics sawn pieces of wood.

• A half-round lathe in which the log can be positioned for the best grain looks creates a “rift cut,” which offers a more textured feel and appearance.

34 SURFACEANDPANEL.COM

©ISTOCKPHOTO.COM / SERGEYRYZHOV

VENEER OFFERS DURABLE AND AFFORDABLE VERSATILITY AS WELL AS AN ECOLOGICAL ADVANTAGE OF MAXIMIZING HARVESTED WOOD.

THERE ARE VARIOUS TYPES OF VENEER AVAILABLE:

• RAW veneer has no backing on it and can be used with either side facing up.

• PAPER-BACKED veneer is backed with paper, and is available in various sizes as needed.

• PHENOLIC-BACKED veneer is used for composite, or artificial wood veneer and is available in varying sizes.

• LAID UP veneer is made up of raw veneer that has been joined to make larger pieces.

• RECONSTITUTED veneer is cut from a log—often fast-growing tropical species—and the raw veneer can be dyed and laminated together to form a block that can then be sliced.

• WOOD ON WOOD is also known as 2-ply and features a decorative wood veneer face with a lower-grade wood backing applied in the opposite direction as the face veneer to increase its strength.

THE FACES OF VENEER ALSO VARY ACCORDING TO PRODUCTION AND ALIGNMENT METHODS:

• WHOLE PIECE VENEER is made from continuous pieces of veneer peeled from a log using a rotary process.

• BOOK MATCHED VENEER occurs when every other strip of veneer is turned over, producing a grain pattern that is mirrored and matched at the veneer joint.

• SLIP MATCHED VENEER is made when each strip is laid out side by side (without turning over), producing a repetitive pattern.

• SPLICED VENEER is made from several pieces of veneer varying in width that are glued together to form a whole sheet. The look and pattern of the grain depends on how each piece was placed.

VENEER ALSO OFFERS DIFFERENT GRADES FOR VARIOUS USES:

• SELECT VENEER is made entirely from heartwood or sapwood and is matched for grain, pattern and color.

• UNIFORM VENEER is also made entirely of heartwood or sapwood, but is matched for color only.

• NATURAL VENEER is made from both heartwood and sapwood and is generally less expensive than select or uniform veneer.

• PAINT GRADE VENEER offers a smooth finish smooth designed so that none of the grain shows through when painted.

• STAIN GRADE VENEER is designed to show the natural characteristics of the wood when given a clear or tinted stain.

Veneer offers durable and affordable versatility, and can be used to create curved surfaces, something that is much more difficult—if not impossible—to do with regular wood. That, combined with its ecological advantage of maximizing harvested wood makes it a popular choice for many of today’s projects. n

VENEER MANUFACTURERS

Atlantic Veneer Corp.

www.moehring-group.com

Newport, NC (800) 335-7723

Besse Forest Group www.bessegroup.com

Gladstone, MI (906) 528-3113

Cahaba Veneer

www.cahabaveneer.com

Centreville, AL (205) 926-9797

Columbia Forest Products www.columbiaforestproducts.com

Greensboro, NC (800) 627-1609

Commonwealth Plywood www.commonwealthplywood.com

Whitehall, NY (518) 499-0099

Danzer www.danzer.com

Austria/Edinburgh, IN (812) 526-2601

Formwood Industries www.formwood.com

Jeffersonville, IN (812) 458-2118

Freeman Corp., The www.freemancorp.com

Winchester, KY (859) 744-4311

Great Lakes Veneer www.greatlakesveneer.com

Marion, WI (715) 754-2501

Manthei Veneer www.mantheiveneer.com

Petoskey, MI (231) 347-7040

Oakwood Veneer www.oakwoodveneer.com

Troy, MI (800) 426-6018

Timber Products Co. www.timberproducts.com

Springfield, OR (800) 557-5131

Veneer Technologies www.veneertech.com

Newport, NC (800) 593-5601

SURFACE & PANEL - MASTER 2023 35

EDGE TREATMENTS

EDGE TREATMENTS MANUFACTURERS

n ABS

n ACRYLIC/PMMA

n HIGH PRESSURE LAMINATE (HPL)

n CPL

n MELAMINE

n PP

n PVC

n WOOD VENEER (EDGEBANDING)

Arborite n www.arborite.com

Montreal, QC (800) 996-0366

Cefla North America n www.ceflafinishing.com

Italy / Charlotte, NC (704) 598-0020

Crown Laminates n www.crownlam.com

India (800) 555-1234

Edgeband USA n www.edgebandusa.com

Jeffersonville, IN (812) 725-8924

Edgemate n www.edgemate.com

Roaring Spring, PA (814) 224-5717

EGGER Wood Products n n n n www.egger.com

Lexington, NC (844) 977-0053

Emco Industrial Plastics n www.emcoplastics.com

Cedar Grove, NJ (973) 239-0202

Finixia n n www.finixia.com

Spain (34) 961-93-3040

Formica Corp. n www.formica.com

Cincinnati, OH (800) 367-6422

Formwood Industries n www.formwood.com

Jeffersonville, IN (812) 458-2118

Hopewell n www.hopewellplastics.com

Hong Kong (852) 2549-3322

Olon Industries n www.olon.ca

Georgetown, ON (905) 877-7300

Panolam Industries n www.panolam.com

Shelton, CT (877) 726-6526

PRI Edgebanding n n n www.priedgebanding.com

Gurnee, IL (847) 543-0141

Rehau n n n www.rehau.com

Switzerland (49) 9283-77-0

Sonae Industria n n www.surforma.com

Portugal (351) 220-10-s6300

Surteco North America n n n n n n n www.surteco.com

Germany/Myrtle Beach, SC (800) 992-3936

Tafisa Canada n www.tafisa.ca

Lac-Mégantic, QC, Canada (819) 583-2930

Tece n n n n n n www.tece.com.tr

Turkey (90) 224-242-2100

Toppan n n www.toppan.com

Japan/Griffin, GA (770) 467-5900

Ultrapan n n n www.ultrapan.net

Coral Springs, FL (754) 702-2632

Uniboard n www.uniboard.com

Montreal, QC (877) 864-8641

Veneer Technologies n www.veneertech.com

Newport, NC (800) 593-5601

West Wood Products n n n

www.west-wood.net

Rancho Dominguez, CA (310) 631-8978

Wilsonart n n n n

www.wilsonartengineeredsurfaces.com

Temple, TX (800) 433-3222

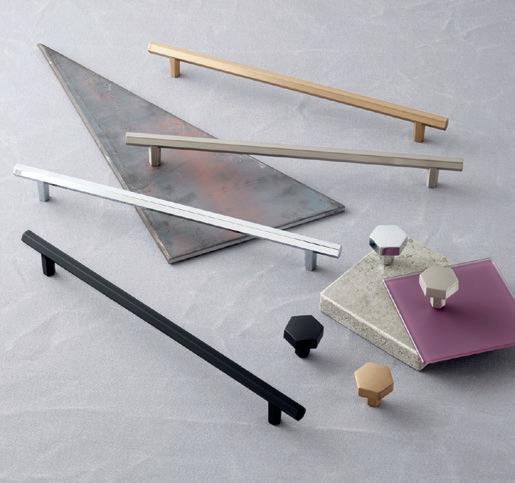

Manufactured wood cores, such as MDF, plywood and particleboard have unattractive edges that may not match the rest of the board and that can absorb moisture if left unfinished.

To resolve this, edgebanding is affixed to the edge to create a seamless edge that perfectly matches the rest of the laminate, an important consideration for finished goods, such as countertops and furniture.

At present, a range of edgebanding materials, including polyvinyl chloride (PVC), wood, and resins, are available in the market due to advancements in technology.