8,120

8,120

The Atlantic Heavy Equipment Show is back and bigger than ever, marking 40 years of driving heavy industry in Atlantic Canada.

Since its inception, this powerhouse event has been the region’s premier showcase for the heavy equipment and forestry sectors - bringing together the biggest players, the boldest machines, and the brightest innovations.

Attend the show March 26–27, 2026 at the Moncton Coliseum Complex, where more than 200,000 square feet of indoor and outdoor exhibits will feature the lat-

est equipment, services, and technology designed to tackle the toughest jobs with ease.

This milestone edition is more than a trade show - it’s a celebration of Atlantic Canada’s industrial strength. With a SOLDOUT show floor in 2024 and more than 10,000 qualified professionals in attendance, booth space for 2026 is already surging – more than 80% sold!

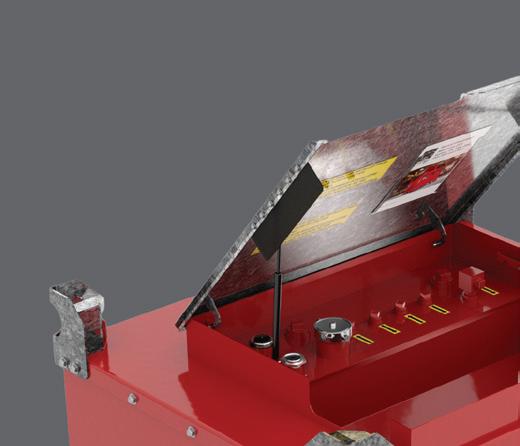

MB Crusher units take on a unique range of materials, from potatoes, glass, and even hay!

Summer is in full swing in many corners of the world: long days, blue skies, and plenty of sunshine. While construction sites slow down during the hottest weeks, MB Crusher’s machines don’t hang up their boots completely – they just take on a new perspective. Even on holiday, they never really stop being useful… they simply switch roles.

This time of year, MB Crusher equipment dives into more unconventional (but

no less essential) tasks, from farming to recycling and even some unexpected – yet surprisingly clever – collaborations. Here’s a peek at a few of their more unusual summer adventures.

From site to spuds

The Netherlands — famous for tulips, windmills and… potatoes? Here, an MB-HDS314 padding bucket took on a rather curious task: separating potato waste from

Power Up Your Presence

Don’t miss your chance to drive your business forward and connect with decisionmakers, buyers, and industry leaders. Whether you’re in construction, forestry, road building or other industries, this is the place to get your product seen.

For full event details and updates, follow us on Facebook or Instagram, or visit the website at: www.ahes.ca

Booth spaces are selling fast—secure your spot today. For booth quotes or media inquiries contact:

• Andrew Burns, Exhibit Sales – andrewb@ mpeshows.com

• Mark Cusack, National Show Manager – markc@ mpeshows.com SP

Source: Marketplace Events

soil, stones and roots. Thanks to MB Crusher’s rotary shaft system, the job was done in no time. It even crushed the damaged spuds to make composting more efficient. The result? Total independence in waste management and a sharp cut in disposal costs.

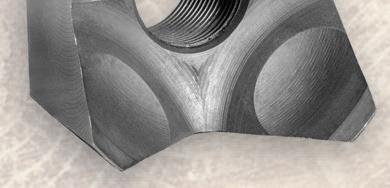

Smashing glass

Even crusher buckets like to take it easy in the summer. Case in point: glass crushing. One customer needed to recycle thin window glass and turned to the BF80.3 – the perfect partner for the job. Mounted on a CAT 320 GC excavator and set to the closed jaw setting, it produced a clean, uniform crushed material, ready to be reintroduced into the glass production cycle. Clean, efficient, and sustainable.

Summer’s hottest duo

What’s summer without a new friendship? The MBG600 sorting grapple teamed

up with a Merlo telehandler for a dynamic duo that’s as unexpected as it is effective. With the telehandler’s reach and agility and the grapple’s 360° rotation and secure grip, they made light work of moving everything from logs to concrete blocks. The perfect pair for getting the job done swiftly – and leaving time for a cheeky afternoon nap.

Old MacDonald had a grapple

Out in the countryside, there’s no such thing as a summer break. With hay bales to shift and animals to feed, the MB-G500 sorting grapple proves to be a trusty ally. Compact, precise, and tireless, it helps move fodder and farm materials with ease, simplifying the day-to-day and lightening the load for farmers.

A summer well spent… gearing up for autumn

So, while construction sites might be catching their breath, MB Crusher attachments are still on the move. Different setting, unexpected challenges – same unbeatable versatility. Even under the August sun, they show that being multi-talented isn’t just useful… it’s a way of life. SP

Source: MB Crusher

2022 YANMAR SV08-1D 2'3"-2'9" WIDE, DIG BKT, 2 BKTS Q/C, 106 HRS $26,900

2025 YANMAR SV08-1D RUBBER, 2'3"-2'9" WIDE CALL

2023 YANMAR VIO17-A CANOPY, 2 BKTS THUMB, AUX HYDS, 612 HRS $29,900

2023 YANMAR VIO17-A CANOPY, 2 BKTS HYD THUMB, 534 HRS CALL

2024 YANMAR VIO17-1E CANOPY, 2 BKTS HYD THUMB, 308 HRS CALL

NEW YANMAR VIO17-1E, CANOPY, 2 BKTS HYD THUMB, AUX CALL

2015 BOBCAT E20, 12" DIG, 39" CLEAN UP, HYD THUMB, 2,595 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, BLADE, 2 BKTS HYD THUMB, 378 HRS $49,900

2025 YANMAR VIO25-6B, CAB BLADE, 2 BKTS HYD THUMB, 24 HRS CALL

2025 YANMAR VIO25-6B, CAB BLADE, HYD Q/C CALL

2017 DEERE 26G, 17" DIG, 30" CLEAN UP, HYD THUMB, 2,455 HRS CALL

2023 YANMAR VIO35-6A, CANOPY, BLADE, 2 BKTS HYD THUMB, 319 HRS $48,900

2023 YANMAR VIO35-6A, CANOPY, 2 BKTS HYD THUMB, AUX, 481 HRS CALL

2023 YANMAR VIO35-6A, CAB AIR HYD Q/C, 2 BKTS HYD THUMB, 431 HRS CALL

2024 YANMAR VIO35-6A, CAB AIR HYD Q/C, 2 BKTS HYD THUMB, 695 HRS $59,900

2024 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 120 HRS CALL

NEW YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB, 291 HRS CALL

NEW YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB, 192 HRS CALL

NEW YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB CALL

2023 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB, 790 HRS CALL

2023 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB, 613 HRS $69,900

2023 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB, 431 HRS CALL

2025 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS HYD THUMB CALL

2025 YANMAR SV40, 6 WAY BLADE, RUBBER, HYD Q/C CALL

2021 HITACHI ZX50U-5N, CAB, 2 BKTS, THUMB, +WRIST BKT, 1,838 HRS CALL

2024 YANMAR VIO50-6A, CAB AIR, 2 BKTS HYD THUMB AUX, 468 HRS $74,900

2024 YANMAR VIO50-6A, CAB AIR, 2 BKTS HYD THUMB, 2ND PTO, 378 HRS CALL

2024 YANMAR VIO50-6A, CAB AIR, 2 BKTS HYD THUMB, AUX HYDS, 103 HRS CALL

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS HYD THUMB, AUX HYDS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 1,024 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 1,000 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 772 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 751 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB AUX, 571 HRS CALL

2024 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 502 HRS CALL

2025 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX, 500 HRS CALL

2025 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB AUX, 31 HRS CALL

2025 YANMAR VIO55-6A, CAB AIR, 2 BKTS HYD THUMB, AUX CALL

2016 KOMATSU PC78US-10, 18" PADS, BLADE, AUX PIPING, 3,698 HRS CALL

2020 HITACHI ZX75US-5B, 18" BOR, BLADE, 4,273 HRS CALL

2019 CAT 308CR-07A, 18" PADS, BLADE, AUX PIPING, 2,054 HRS $78,900

2023 YANMAR VIO80-1A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 1,033 HRS CALL

2023 YANMAR VIO80-1A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 786 HRS CALL

2023 YANMAR VIO80-1A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 659 HRS CALL

2023 YANMAR VIO80-1A, STEEL CAB AIR, 2 BKTS HYD THUMB, 423 HRS CALL

2023 YANMAR VIO80-1A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 212 HRS CALL

2024 YANMAR VIO80-7, RUBBER CAB AIR, 2 BKTS HYD THUMB, 188 HRS CALL

2023

YANMAR SV100-2A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 1,330HRS CALL

2023 YANMAR SV100-2A, STEEL CAB AIR, HYD THUMB 2 BKTS, 1,215 HRS $109,900

2023 YANMAR SV100-2A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 1,058 HRS CALL

2023 YANMAR SV100-2A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 1164 HRS CALL

2023 YANMAR SV100-2A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 738 HRS CALL

2023 YANMAR SV100-2A, RUBBER CAB AIR, 2 BKTS HYD THUMB, 762 HRS CALL

2024 YANMAR SV100-7, RUBBER CAB AIR, 2 BKTS HYD THUMB CALL

2025 YANMAR SV100-7, STEEL CAB AIR, HYD THUMB, 2 BKTS AUX CALL

2025 YANMAR SV100-7, RUBBER CAB AIR, PTO2 HYD Q/C CALL

2019 CAT 311FL RR 20" PADS, BLADE, PIPING, 4,392 HRS CALL

2017 CAT 312F GC, 20" PADS, AIR, ONLY 2,868 HRS $67,500

2019 CAT 312F GC, 20" PADS, AIR, ONLY 2,168 HRS $74,900

2008 CAT 313D CR 20" PADS, AIR, BLADE, PIPED, 6,555 HRS CALL

2008 HITACHI ZX135US-3, Q/C HYD THUMB, DIG BKT, NEW U/C, 8,900 HRS CALL

2011 HITACHI ZX135US-3, 20" PADS, 2 BKTS HYD THUMB, 8,136 HRS CALL

2014 KOMATSU PC138US-10 20" PADS, AIR, BLADE, ONLY 3,779 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS HYD THUMB, 2,451 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS HYD THMB, AUX, 3,596 HRS $135,900

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS Q/C HYD THUMB, 2,073 HRS CALL

2018 HITACHI ZX135US0S-6, BLADE, OFFSET BOOM, 1,551 HRS, Q/C 2 BKTS$89,900

2018 HITACHI ZX135USBL-6 20" PADS, BLADE, ONLY 2,541 HRS CALL

2020 HITACHI ZX135USBL-6 CABGRD, BLADE, PL THB, 2 BKTS, 2,487 HRS $159,900

2020 HITACHI ZX135USBL-6, CABGRD, BLADE, PRO LNK THMB, 2 BKTS, 2,047 HRS $169,900

2020 HITACHI ZX135USBL-6, BLADE, AUX HYD PIPING, 1,451 HRS CALL

2020 HITACHI ZX135USBL-6, BLADE, AUX HYD PIPING, 1,565 HRS CALL

2020 HITACHI ZX135USBL-6, BLADE, 2 BKTS Q/C, HYD THUMB, 1,226 HRS CALL

2022 HITACHI ZX135USBL-6, AIR, BLADE, AUX HYDS, ONLY 1,490 HRS CALL

2024 HITACHI ZX135USK-6, AIR, 'K' MODEL NEW ONLY 5.1 HRS CALL

2021 CAT 315, GC BLADE, Q/C 2 BKTS, HYD THUMB, 1,368+ HRS $187,500

2022 CAT 315, GC 20" PADS, BOR, BLADE, 2 BKTS HYD THUMB, ONLY 249 HRS

2022 CAT 315, GC 20" PADS, BOR, BLADE, 2 BKTS Q/C, ONLY 227 HRS CALL

2018 HITACHI ZX200-6, 24" PADS, AIR, Q/C DIG & CLN UP BKT, 5,182 HRS $89,900

2021 HITACHI ZX200-6, 24" PADS, AIR, AUX HYDS, ONLY 1,296 HRS CALL

2021 CAT 323, 24" PADS, AIR, AUX HYDS, 2D, ONLY 529 HRS CALL

2012 HITACHI ZX200LC LR 32" PADS, AIR, 18M REACH, Q/C DIG BKT, 3,551 HRS $124,900

2018 HITACHI ZX200LC-5, 2 BKTS Q/C HYD THUMB, CABGUARD, SIDE GUARDING, NO DEF/NO REGEN, ONLY 3,690 HRS $154,900

2021 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, 1,000 HRS CALL

2022 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, 999 HRS CALL

2011 HITACHI ZX225USR-3 24" PADS, AIR, Q/C 2 BKTS, 9,640 HRS $49,900

2022 HITACHI ZX225USRLC-6, 24" PADS, AIR, ONLY 3,354 HRS SLIDE ARM CALL

2015 HITACHI ZX245USLC-5N, Q/C 2 BKTS, PRO LINK HYD THUMB, CABGUARD CATWALKS, 8,808 HRS

$119,900

2021 HITACHI ZX245USLC-6, Q/C 2 BKTS HYD THUMB, 3,347 HRS CALL

2025 KOMATSU PC238USLC-11 32" PADS, Q/C 2 BKTS HYD THUMB 3DMG CALL

2018 HITACHI ZX345USLC-6N, HYD THUMB, 2 BKTS, CABGUARD,4,250 HRS CALL

2019 CAT 330 07A 24" PADS, AIR, AUX HYDS, ONLY 2,454 HRS CALL

2021 CAT 336 07C, 28" PADS, AIR, 2 BKTS HYD THUMB, CATWALKS CABGUARD, 2D EQUIPPED, 778 HRS CALL

2020 HITACHI ZX490LCR-6, Q/C DIG & CLEAN UP BKTS ONLY 996 HRS CALL LOADERS/DUMPERS/DOZERS

2023 YANMAR V4-7 CAB AIR, HYD BOBTACH Q/C, 360 HRS CALL

2024 YANMAR V4-7 CAB AIR, HYD BOBTACH Q/C, 56 HRS CALL

2024 YANMAR V4-7 CAB AIR, HYD BOBTACH Q/C, NEW CALL

2019 CAT 910M CAB AIR, HYD Q/C, GP BKT & BLADE, ONLY 384 HRS CALL 2023 CANYCOM SC75PDH PIVOT DUMP CARRIER W/2,200 LB CAP, 350HRS CALL

2004 YANMAR C12R RUBBER, DUMPER, TAILGATE, ONLY 1,046 HRS $8,900

2022 YANMAR C50R-5AR CAB AIR, SWIVEL DUMP, 8,379LB CAP, 733 HRS $109,900

2023 YANMAR C50R-5AR CAB AIR, SWIV. DUMP, 8,379LB CAP, 1,087 HRS $109,900

2021 MOROOKA MST1500VDR 360 SWING DUMPER, 6.5 CU YD CAP, 1,392 HRS CALL 2021 MOROOKA MST2200VDR 360 SWING DUMPER, 8 CU YD CAP, 877 HRS CALL

2002 CAT 725 AIR RIDE SEAT, TAILGATE, 23.5X25 TIRES, 11,800 HRS CALL

2011 KOMATSU D51EX-22 CAB AIR, PAT BLADE, MS RIPPER, 3,814 HRS CALL SKID STEERS/COMPACTORS

2016 BOBCAT S70, HLA 36" GP BKT, AUX HYDS, ONLY 748 HRS $15,900

2015 BOBCAT S590, HYD Q/C, A/C CAB, 2 SPEED, 1,826 HRS $49,900

2013 BOBCAT S650 CAB AIR, BKT & FORKS, HYD Q/A, 3,383 HRS CALL

2015 BOBCAT T590 CAB AIR, SJC CONTROLS, 2,351 HRS CALL

2022 KUBOTA SVL65-2 CAB AIR, HYD Q/C, ONLY 266 HRS, 66" GP BKT CALL

2022 KUBOTA SVL65-2, TRACK SKID, HYD Q/C, 68" HD LO PRO BKT CALL

2022 KUBOTA SVL65-2, TRACK SKID, HYD Q/C, 68" HD LO PRO BKT CALL

2023 KUBOTA SVL75-3, TRACK SKID, AIR, HI FLOW, 74" HD BKT CALL

2021 BOBCAT T76 R SERIES, CAB AIR, JOYSTICK, HYD Q/C, 74" BKT 2 SPEED, 1,912 HRS, BRAND NEW ENGINE JUST INSTALLED (WARRANTY) CALL

2025 YANMAR TL65RS 67" BKT 67 HP, 2100LB ROC, CAB AIR HI FLOW, RVC, 128 HRS CALL

2025 YANMAR TL75VS 67" BKT, 74 HP, 2555LB ROC, CAB AIR HI FLOW, RVC, 250 HRS CALL

2025 YANMAR TL75VS, 67" BKT, 74 HP, 2555LB ROC, CAB AIR HI FLOW, RVC, 84 HRS CALL

2025 YANMAR TL80VS, 72" BKT, 74HP, 2,900LB ROC, CAB AIR HI FLOW, RVC CALL

2024 YANMAR TL100VS, 84" BKT, 104HP, ROC 3,600LBS, 349+ HRS CALL

2018 SAKAI SV204TF, 54" BOLT ON SHELL KIT, CANOPY, 616 HRS CALL

2006 ING RAND SD70D TF 66" SMOOTH DRUM, SHELL KIT, CANOPY $37,900

2013 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1713 HRS CALL

2014 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1,744 HRS CALL

2016 VOLVO SD75B, 66" DRUM, CANOPY, ONLY 2078 HRS CALL

2014 SAKAI SV513D, 84" SMOOTH DRUM, CAB AIR COND, 1,771 HRS $104,900

2021 SAKAI SV544DC 84" SMOOTH DRUM, CAB AIR COND, 3,201 HRS CALL ATTACHMENTS AND MISC

2008 GENIE GTH-5519 CAB, AIR RIDE SEAT, 19' LIFT, 5,500LB CAP 48" FORKS CALL

2019 KOMATSU HM400-5 ARTICULATED WATER TRUCK, RETARDER, RVC, EMERG STEER, PAS, REAR SPRAY, 29.5R25 TIRES, 10,137 HRS CALL

2019 MULTIQUIP WT5CSG 7K GVWR, NEW HONDA ENGINE & NEW 2" PUMP, 525 GAL POLY TANK, 7,000 LB GVWR 9,900

2025 SUP 200 LONG REACH 16M BOOM/STICK TO FIT ZX200/210LC CALL 2025 SUP 290 LONG REACH 18M BOOM/STICK TO FIT ZX250/290/300 CALL

2 HITACHI ZX345USLC-6, 2 BKTS, HYD THUMB, CABGUARD

6 HITACHI ZX330/ZX350LC-6, 2 BKTS, HYD THUMB

DOZERS

CAT D3K2 LGP, 6 WAY DOZER, CAB AIR, 80HO, 20K LBS

2 KOMATSU D39/RIPPER, 6 WAY, CAB AIR KOMATSU D71PXI PAT/RIPPER, 6 WAY DOZER, MS RIPPER, “I” MACHINE

LOADERS

2 YANMAR V4-7, CAB AIR, BOBTACH Q/C, .91 CU YD BKT

8 KOMATSU WA200/250/270/320, 2.5-3.75 YD KOMATSU WA380-8, FORKS, BKT

CAT 950K, FORKS, BKT GRADERS/COMPACTORS

2 CORNIVER CT40 40” SMOOTH DRUM, KUBOTA ENG

8 CORNIVER CT48 48” SMOOTH DRUM, KUBOTA ENG

8 SAKAI SV204/VOLVO SD45, 45” SMOOTH DRUM, CANOPY

8 SAKAI SV414/VOLVO SD75, 67”/66” DRUM, CAB AIR

4 SAKAI SV544, 84” SMOOTH DRUM, CAB AIR CAT 140M, 14 TIRES, SCARIFIER, CAB AIR

Vermeer introduces a limited release of electric tree care concepts including brush chippers, a stump cutter and a mini skid steer to partner with professionals and validate the technology in the field.

Vermeer is taking a significant step in the electrification of tree care equipment by introducing a new

line of models. This initial, limited release of electric tree care equipment includes the BX1000XL electric brush chipper for the North American market, the BC200 electric brush chipper for the European market, the SC30TX electric stump cutter and the S450TX electric mini skid steer. These machines will be made available to a

select group of customers globally as part of a strategic field validation program.

The program is designed to gather direct customer feedback on the performance of these electric models in real-world applications. This initiative will help guide future tree care and landscaping product development and refinement.

Komatsu PC350LC-8, 3 bkts, thumb, cabguard, catwalks, exc. cond. 4,415 hrs.

bkts,

Komatsu PC200LC-8, 3 bkts, Q/C, thumb, cabguard, catwalk, exc. cond., 1,772 hrs.

Komatsu PC170LC-10, 3 bkts, thumb, cabguard, exc. cond., 2,725 hrs.

Komatsu PC138USLC-II, 2 Bkts, Hyd. Q/C, Thumb, Exc. Cond., 2,300 Hrs. P.O.R.

Komatsu PC88MR-8, 2 bkts, hyd. Q/C & thumb, swing boom and blade, 2,400 hrs.

Komatsu D65EX-17, sigma blade, ripper & forestry guarding, 75% U/C, exc. cond., 6,050 hrs.

Komatsu D39 PX-24, 6-way blade, winch, forestry guarding, 3,100 hrs.

Hamm H13iX, 84” smoothdrum packer w/cab, A/C, low hrs, exc. cond.

Hamm 3307, 66” smoothdrum packer w/shell kit, cab, A/C, exc. cond. FOR RENT

2024 Komatsu PC238LC-11, Zero tail swing, 3

“This lineup is a critical step in our electrification journey,” said Josh Vrieze, senior product manager for Vermeer. “By working directly with tree care professionals in the field, we can better understand the realworld performance of these machines and refine them to meet the challenges of tomorrow’s jobsites. This is about practical innovation, driven by the needs of our customers.”

The introduction of these electric tree care equipment models addresses growing industry needs for quieter, zero-emission and low-maintenance equipment. As global regu-

lations evolve and customers increasingly prioritize sustainability, Vermeer is proactively developing solutions. This concept lineup, featuring electric brush chippers, a stump cutter and a mini skid steer, is a direct response to market drivers. By electrifying these proven platforms, Vermeer will demonstrate how this new power source

can enhance productivity and create a better operator experience. At the same time, the equipment will deliver the reliability and performance customers expect from Vermeer.

Field validation with industry professionals

This initiative creates a partnership with

adopters to help shape the future of Vermeer electricpowered equipment. Feedback from operators using the new electric brush chippers, stump cutter and mini skid steer in the field will directly influence the next generation of machines. This collaborative approach focuses on developing solutions that are practical, efficient and ready for the demands of real-world jobsites.

Addressing jobsite needs with electric power

The benefits of electric tree care equipment address key challenges on modern jobsites. The new Vermeer electric concepts are designed to help contractors

work more efficiently and in more places than before.

The quiet operation of a machine like the SC30TX electric stump cutter allows for longer operating hours and work in noise-sensitive areas. The zero emissions from an electric mini skid steer or brush chipper help contractors meet strict environmental standards, a key advantage when bidding on certain municipal or corporate contracts. Furthermore, the simplified design of electric power systems reduces many common maintenance tasks, helping to maximize uptime and lower long-term operating costs. SP

Source: Vermeer

Ensuring the safety, productivity, and proper maintenance of equipment can be a challenge on many job sites. ALLU Tracker is designed to make this easier by giving customers real-time visibility into their equipment – anytime, anywhere.

With GPS location, usage logging, and smart notifications, the Tracker helps contractors and rental companies improve efficiency, reduce downtime, and prevent misuse.

The Tracker’s built-in GPS ensures accurate location tracking. Customers can quickly check the latest position of their equipment via the mobile app or web portal. Past routes can also be traced, while geofencing adds an extra layer of security against theft and unauthorized use.

“Accurate location and geofencing features bring additional peace of mind for the customer,” said Jouko Ylitalo, Support Manager, ALLU. “They can see the latest location of the equipment easily via the app or website portal. Also, past routes of equipment

cations can be tailored for each device. Whether it’s a low battery alert, equipment leaving a set area, or reaching a 500-hour maintenance milestone, customers receive updates instantly via email, text message, or both.

can be traced.”

The Tracker logs daily working hours, giving customers reliable data for rental billing, service planning, and wear part replacement. By scheduling maintenance based on real usage, operators can reduce unexpected breakdowns and costly service interruptions.

All the data in the world is only useful if it can be acted upon. With ALLU Tracker, alarms and notifi-

Thanks to its heavy-duty magnetic mount, installation is quick and requires no modifications to the bucket structure. The Tracker can also be moved easily between buckets when needed.

Compact in size, rugged in design, and with up to five years of battery life, the Tracker is engineered to withstand the toughest site conditions.

Installation of the Tracker has proven to be quick and hassle-free, requiring minimal effort. Ozzies also found the web portal user-friendly and easy to navigate, making it simple to access essential data and generate reports for internal use.

“For the price its cheap insurance for our rental equipment and trusted mobile app feature is a bonus,” said Rob Khaler, Ozzies. SP

Ozzies, one of ALLU’s partners, uses the Tracker to improve fleet control and sees it as a practical, cost-effective solution. A key advantage for Ozzies is the ability to monitor equipment movement via GPS tracking, giving them better visibility and control across work sites. They also benefit from detailed utilization reports and rental time data.

Source: ALLU

Electrified backhoe and mini excavator, nimble compact equipment and other heavy-hitting iron - CASE will display how they’re delivering reliability, productivity and innovation for utility professionals.

CASE Construction Equipment is heading to The Utility Expo 2025, October 7-9, to showcase a full lineup of proven machines built to help utility crews take on their toughest jobsite challenges. From zeroemissions electric models to highly compact equipment and heavy-duty workhorses, CASE will feature solutions that help teams work smarter, swifter and more profit-

ably at booth K277.

“Utility professionals face unique challenges daily. Working in narrow urban spaces, meeting environmental regulations, maintaining aging infrastructure and maximizing throughput under tight timelines — they have their work cut out for them,” said Terry Dolan, head of CNH Construction Brands, North America. “At CASE, helping teams meet those challenges head-on with versatile, reliable and efficient machines is what wakes us up each morning. We’re here to make it easier for them to get the job done right.”

Municipal crews, maintenance teams and utility contractors often work in special environments where noise and emissions need to be kept to a minimum. Whether maintaining infrastructure in residential neighborhoods, trenching for pipes in indoor environments or operating in environmentally sensitive areas, CASE’s wide-ranging EV lineup gives teams smarter ways to work while meeting complex jobsite requirements.

For larger tasks in urban or sensitive environments, the four-wheel-drive, 580EV electric backhoe loader combines strength with sustainable, emissions-free operation. With the same performance and breakout forces as the popular 97-horsepower CASE 580SN diesel model, the 580EV provides productivity-boosting capabilities along with all the advantages of electrification — clean, quiet operation, instant torque and lower daily operating costs. The 14-foot electric backhoe is also compatible with many of the same attachments the 580SN supports and includes an Extendahoe to boost reach. Features like ProControl swing dampening, PowerLift/PowerBoost and electrohydraulic controls improve precision and ease of use.

For tight jobsites or indoor work, the compact, 1.5 metric-ton CX15EV mini excavator gives contractors more power and capabilities on the job with a minimal footprint. At less than 32 inches wide, this unit can fit through almost any doorway and is

compatible with numerous attachments, including various buckets, augers and hydraulic hammers, making it an extremely handy tool for getting more work done efficiently.

Utility work often demands flexibility and precision for working in confined areas. CASE’s display of compact equipment at The Utility Expo 2025 will feature a collection that rises to the challenge while also delivering enhanced power and workflow.

Previewing at the expo ahead of its official release is the upcoming 24-horsepower CX34D mini excavator, which pairs precision and performance for crews that work regularly in cramped spaces. The true zero-tail swing design lets operators work close against walls or structures, while three power modes and proportional hydraulic controls make it easier to dial in performance.

For crews who need more muscle in constricted workspaces, the burly 58-horsepower CX50D mini excavator yields a strong punch in

a compact design, with high lifting capacity and precise digging capabilities. The CX50D offers standard multifunction hydraulics and a second auxiliary. For advanced attachments, an optional third circuit is available.

The CX90E midi excavator also raises the bar on performance with a 72-horsepower engine, minimal tail swing for close-quarters operation and compatibility with multiple attachments. The perfect balance of size and power gives crews the ability to take on larger tasks in spaces where bigger machines simply can’t fit.

For jobs big and small, the 90-horsepower TV450B compact track loader brings strength and stability for

utility crews tackling tough workloads. Sporting industry-leading breakout force and high-flow hydraulics, the TV450B is engineered for demanding attachment work — whether it’s heavyduty grading, loading or material handling. Its intuitive controls boost precision, output and operator comfort and the loader’s extensive selection of attachments make it a true utility workhorse for a broad scope of tasks.

Rounding out the compact lineup, the TL100 mini track loader offers more functionality in a very small package. With convenient stand-on operation, a rated operating capacity of 1,000

lbs. and more than 40 different attachment options, this stand-on unit is an easy-touse jack-of-all-trades for light utility work.

For larger utility projects that call for more brawn, CASE’s featured array of heavy-duty machines produces. Leading the pack is the multifunctional and impressively powerful 580SV Construction King side shift backhoe loader. With a 97-horsepower engine, fourwheel drive drivetrain and a

wide range of attachment options, this double-duty rig can handle almost any workload. It also features an innovative side shift design that enables rectangular trench digging without repositioning and working up against buildings with ease.

For rugged roadwork and urban jobsites, the WX175E SR wheeled excavator is designed for versatility on the move. With industry-leading hydraulics and compatibility with attachments like tilt rotators, pallet forks and grapples, the WX175 can adapt to multiple roles while providing superior precision and control.

It can also reach speeds of 22 mph, letting crews transition between sites quickly, making it a go-to choice for complex urban projects that call for muscle and speed. Attendees can see the machine’s versatility in action with a tiltrotator and multiple attachments.

CASE will also be featuring the 96-horsepower 750M dozer, which boasts best-inclass drawbar pull of 41,000 lbs., no DEF required, and EH blade controls as standard.

With a robust undercarriage design that reduces vibration and an advanced load management system that adjusts track speed to match the load, this powerhouse streamlines site prep and precision grading on utility infrastructure projects.

Experience CASE Equipment at The Utility Expo 2025

Attendees can see CASE’s latest innovations firsthand and learn how the company’s offering can meet the toughest utility challenges by visiting booth K277 at The Utility Expo 2025, October 7-9 at the Kentucky Exposition Center in Louisville. SP

Source: CASE CE

With

Finance

Brandt

LBX Company is pleased to announce JT Equipment as an authorized dealer for Link-Belt Excavators.

This new partnership will see JT Equipment offer rentals, sales, and support for Link-Belt Excavators across South Alberta, Canada.

“We look forward to working with the team at JT Equipment to grow our presence in the Calgary and the southern Alberta market,” says Kevin Roberts, LBX Director of North American Sales.

Matthew Cox, Vice President of JT Equipment, explains, “We’re proud to become the official LinkBelt Excavator dealer for Southern Alberta. This partnership marks a significant milestone for our company, reflecting our commitment to providing top-quality equipment and service to our customers. Link-Belt’s reputation for innovation and reliability aligns per-

fectly with our values, and we’re excited to bring their world-class machines to our region.”

This partnership enables JT Equipment to offer a broader range of heavy equipment, catering to the diverse needs of the construction, forestry, landscaping, and municipal sectors in Alberta. The company’s inventory includes excavators, skid steers, loaders, dump trucks, telehandlers, woodchippers, and stump grinders. SP

Source: LBX Company

Since 2023, Quadco has been the exclusive North American distributor of Bracke Forest AB products. Now Quadco has added the Bracke T26.b Disc Trencher, designed to excel in the toughest terrains.

“We were very excited to showcase the T26.b as well as other Bracke attachments at DEMO International,” said Mark Boisvert, Business Development Manager at Quadco. “These forestry attachments will help customers who are dedicated to creating and keeping healthy forests.”

The Bracke T26.b Disc Trencher is engineered for exceptional scarification, creating ideal soil conditions

for seeds and plants to thrive, even in demanding environments. Its innovative design ensures maximum productivity and consistent results in forestry site preparation.

Equipped with eight programmable operating modes, the T26.b allows operators to seamlessly adapt to changing site conditions from the cab. Its cuttingedge sensor system provides real-time data on key pa-

rameters, including base machine speed, disc angles, and arm positioning, enabling precise adjustments for optimal performance. Features like adjustable ground pressure, customizable arm angles, and float mode ensure uninterrupted, efficient operation tailored to any terrain.

The T26.b’s flexible design offers configurations with two, three, or four rows, making it ideal for a wide range of forestry applications. Whether your operation requires continuous or intermittent functionality, the T26.b delivers versatility and consistent results to meet your needs.

Maintenance is straightforward with the T26.b, featuring easy access to components and the use of readily available parts. This minimizes downtime and keeps your operations running smoothly, ensuring optimal productivity. SP

Source: Quadco

WBM

grapple 18,350 hrs, service rec. avail. from new CALL

2013 Hitachi ZX290F-3 Heel Boom, c/w: Pierce M55 grapple, 24,434 hrs, service records available from new CALL

2010 Caterpillar 330DFMLL Heel Boom, c/w: T-Mar 60” log grapple $64,500

1998 Madill 4800 Heel Boom, T-Mar log grapple $274,500

2001 Madill 124 Swing Yarder, Recent major work orders, can be viewed working $1,395,000

1993 Madill 144 Swing Yarder, $84,500

1989 Madill 123 Swing Yarder, Recent $250K in work orders $839,500

1988 Cypress 7280C Swing Yarder $649,500

2 X Madill 044 Grapple Yarders, c/w: Series 60 or Cummins power CALL

Rotair HR-1000 Hyd. Rock Drill, c/w: Atlas Copco 1238 hammer $89,500

Morgan Power Apparatus M40-F Tank Drill, c/w: PR66 hammer, GD 3800 or 4800 boom $39,500

PROCESSORS

2015 Hitachi ZX290F-3 Log Loader, c/w: 2014

Southstar QS605 processing 10,904 hours CALL

2011 Hitachi ZX290F-3 Log Loader, c/w: 2010

Waratah HTH623C proc. head, 13,858 hrs.. $164,500

2003 Caterpillar 330C Processor, c/w: 2004 Waratah HTH626 processing head. CALL WHEEL LOADERS

2017 Caterpillar 988K “Millyard Machine,” c/w: Cat Millyard

Bobcat Company, a global compact equipment, innovation and worksite solutions brand, is set to make a powerful impact at The Utility Expo 2025.

From October 7-9, attendees are invited to visit Bobcat at booth K129 at the Kentucky Exposition Center in Louisville, Kentucky.

Alongside its trusted lineup, Bobcat will showcase some of its most recent additions—including the MT120 mini track loader and the land management package, exclusive to the T86 compact track loader. Visitors can also explore an expansive product and attachment lineup on display and with hands-on demonstrations showcasing end-to-end solutions for the most demanding job sites.

The MT120 boasts a classleading 1,200-pound rated operating capacity and an impressive 88.2-inch lift height and reach. At just 36 inches wide, the MT120 excels in tight spaces while its smooth, precise pilot controls and pre-

mium ride-on platform ensure operator comfort. With more than 20 compatible attachment categories, operators can use their MT120 for digging, ground preparation, utility installation, breaking up and removing concrete, trenching and much more.

The land management package, an exclusive offering for the T86 compact track loader includes premium features like a rearview camera, reversing fan, advanced 7-inch touch display, and a dedicated land management door. Additional top-of-theline performance features include a Level II FOPS, headlight/taillight and exhaust guards, tubeline covers, and polycarbonate rear and side windows. The T86 land management package combines power, technology, and pro-

tection to optimize your land management operations.

For jobs that require operators to haul more materials, tow heavier loads and transport more people, the Bobcat UV34XL utility vehicle is an ideal solution. The 39.9-hp utility vehicle offers seating for six people and includes a 1,000cc, two-cylinder SOHC engine that delivers high-performance power, maximum reliability and durability. The UV34XL will be shown with the Limited accessory package and SP9 boxspreader.

The 60” disc mulcher is a powerful land-clearing attachment that utilizes a flywheel design to store kinetic energy, allowing it to effortlessly cut down trees up to 14 inches in diameter and shred them into mulch. This versa-

tile tool is ideal for a variety of tasks, including utility line and right-of-way maintenance, site preparation, and general vegetation management. With its hardened-steel knives and multiple operating techniques, the disc mulcher is a highly effective tool for clearing land.

The 86” landplane is a versatile attachment designed for grading, leveling, and preparing surfaces. It can easily break up hard ground, pulverize soil clods, and sift out large rocks, whether moving forward or in reverse. This tool is also ideal for peeling sod, aerating soil for seeding, and transporting materials around a worksite, making it a highly effective and multi-functional land preparation tool.

Also on display in the Bobcat booth will be the T76 compact track loader, UW56 Toolcat utility work machine, PA425v portable air compressor, PA185vp portable air compressor, PG40 portable generator, R68P rammer, Trench roller, and attachments including 84” angle broom, NB140 nitrogen breaker, VP12 vibratory plow, and Root Grapple.

Whatever the challenge, Bobcat is ready to meet it. Put your skills to the test and see how the Bobcat lineup empowers you to confidently conquer any job with unmatched versatility and power.

• MT100 and MT120 Mini Track Loaders: See the different lift heights of our mini track loaders by dumping material over the limbo bars, demonstrating their lift height and agility in tight spaces.

• T66 Compact Track Loader: Experience the T66’s impressive controllability and precision

by using a 74” industrial bucket grapple to stack tires in a challenging pyramid or tower.

• E20 Compact Excavator: Discover how “big performance comes in small packages” as you maneuver the E20’s retractable undercarriage through a gate.

• E38 Compact Excavator: Test your precision on the E38 equipped with a trenching bucket’s and enhanced Depth Check System, using the display screen to achieve pre-defined dig depths. The Utility Expo takes place October 7-9, in Louisville, Kentucky. SP

Source: Bobcat Company

VMAC, the leader in compressed air innovation, is excited to announce its participation in The Utility Expo 2025 (Booth No. S3526), taking place October 7-9, 2025 at the Kentucky Exposition Center in Louisville.

As North America’s largest biennial event dedicated to utility and construction professionals, The Utility Expo offers industry professionals an unparalleled opportunity to engage with the latest equipment, tools, and solutions across electric, gas, water, and telecom sectors.

“We understand the demands placed on modern utility fleets – from tight timelines to rugged reliability, and no room for failure. VMAC’s newest products are aimed at delivering even greater integration, power, and performance for utility, construction, and service fleets,” said Tod Gilbert, VMAC President.

VMAC will showcase multiple new products at the

Expo, reinforcing its reputation for innovation in mobile compressed air solutions. Among its announcements, VMAC will be releasing the new G90 with FlexDrive AMS, a gas-driven air compressor boasting up to 90 CFM at 100 psi continuously and up to 50 CFM at 170 psi for high-pressure applications with one system.

Building on its history of unveiling transformative technologies, VMAC will also showcase its new battery electric powered rotary screw air compressor, the VMAC e30 with Stealth Power, the world’s most compact, lightweight, and intelligent battery electric powered 30 CFM rotary screw air compressor.

VMAC’s new 6-in-1 Mul-

tifunction Power System, powered by Honda, is the only gas-powered multifunction system with built-in hydraulics, giving operators the freedom to do more in the field without hauling multiple machines. With six power sources packed into one compact, gas-driven machine with 40 CFM compressed air, 8 kW of electric power, up to 250 A of welding capability, 12V and 24V battery charging, 300 A boosting, and 8 GPM of hydraulic power – operators will have everything needed to tackle the toughest jobs, anywhere.

VMAC will also be unveiling its advanced Multi-Port Air Manifold, engineered to transform service trucks and vans into highly efficient and organized pneumatic workstations.

VMAC looks forward to demonstrating its expertise in mobile power and air systems while offering hands-on opportunities for The Utility Expo attendees to experience new equipment and learn directly from VMAC product experts. SP

Source: VMAC

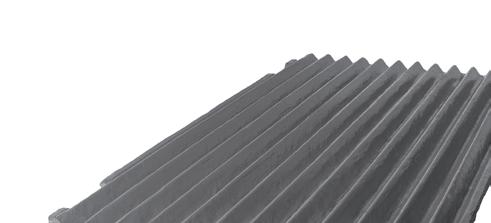

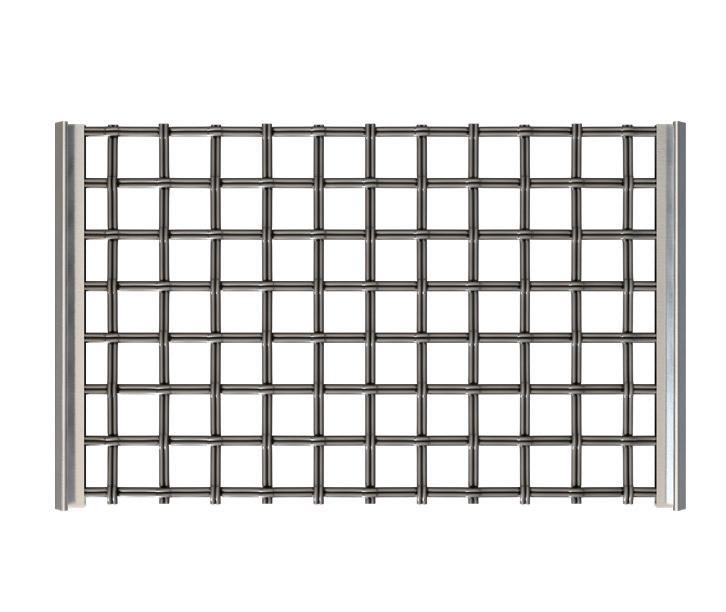

Two new add-on compactors from Ammann are more compact and yet deliver more powerful torque.

The Ammann APA 90/110 and the APA 110/110 feature improved compatibility with tilt rotators on excavators. Instead of hydraulic rotators, the new add-on tools utilise a worm gearbox to provide the rotational movement. Worm gear boxes are more compact than hydraulic rotators and provide more powerful torque, too.

Three widths are available: 800 mm, 940 mm and 1100 mm. These add-on compactors are compatible with all standard adapters on the market. The quick coupling system allows them to be connected and ready for

action within seconds.

Add-on compactors reach locations that are unsafe for machines and operators, including steep slopes and trenches. They provide high compaction power and quickly process multiple material types. The attachments are powered by host machines, most often excavators.

These two APA Add-On Compactors are built for the 12-tonne to 40-tonne excavator class and for applications where a strong compaction performance is required. Layers as thick as 1 metre can be compacted, providing significant time savings when compared to traditional vibratory plates.

Applications include pipeline construction, residential and industrial developments, backfill, confined workspaces, slope and hillside compaction, cable construction, dumpsite construction and railway work.

Construction crews appreciate the hazard-free operation of the add-on compactors, which allows work from a safe distance. The excavator’s cabin structure provides additional reinforcement, shielding the operator from any falling debris.

The compactors utilize Ammann’s innovative tripleshaft exciter system, which directs vibratory forces toward the ground and away from the machine. Highly durable rubber shock mounts absorb the vibration to protect the excavator and ultimately the operator.

The attachments’ robust design enables compaction of thick layers. High output quickens the process.

The APA 90/110 and the APA 110/110 have two modes: high amplitude, or low amplitude, that can be adjusted based on whether they are working on thick or thin layers.

The compactor can be equipped with worm gearbox or with a stiff system, where there is no rotation. SP

Source: Ammann

Strong stable, with eight wheels: the new Eco Log 688 takes the step into the next generation and joins the pendulum arm harvesters in the G series.

The new 688G also comes with several other improvements. With a new hydraulic system, new pumps and naturally equipped with Eco Log’s modern harvester cabin, the 688G now offers an even higher tractive force and strength than before –in the machine as well as in the already strong harvester crane that has now been lifted to yet another level.

The development team at Eco Log, under the leadership of Emil Forsblom – Head of

Product Development, has since the launch of the G series had a dedicated focus on further developing the eightwheeled harvester – the next machine in the product program to be upgraded.

“In the development of our 688G we have introduced a lot of new technology – an updated transmission, a new hydraulic system and a new generation of pumps,” said Emil. “That is big updates that generate both high tractive force

and performance to the machine. Thanks to a new crane valve and an electrically controlled crane pump, we get more power to the crane that can work efficiently even on full reach. As a customer, you get a really strong all-round machine in the same class as the largest machines on the market, a machine that can be used for everything from bigger thinnings to clear cuts.”

To achieve maximum traction force, the transmis-

sion and powertrain have been developed by equipping the machines with a completely new transmission pump and motor. Depending on the conditions in the forest and what the operator prefers, you can

choose between different selectable driving modes where there is also a boost function for the situations when you need that extra power.

New on the eightwheeled harvesters is also

variable pressure levels, which means that the pressures to crane and harvester head is automatically calibrated and adjusted. Emil Forsblom explains that this results in several advantages. ATTACHMENTS

FAE is broadening the fields of application for its RCU75 remote-controlled tracked carrier. With the introduction of the SAE universal attachment plate, the vehicle is now compatible with a range of equipment which was previously exclusive to the skid steer segment.

This universal attachment plate allows FAE’s RCU75 vehicle to be equipped not only with FAE attachments — such as forestry mulchers, swinging hammer mulchers, stump cutters, stone crushers and road planers — but also with third-party equipment designed for skid steers, such as chippers, sprayers, forestry

winches, sweepers, mixing buckets, lifting forks, dozing blades, disc trimmers, trenchers and more.

The RCU75 is designed to work in hard-to-reach areas or on steeply sloping terrain where operator safety and operating efficiency are a concern. This vehicle is excellent for working in hilly

and wooded areas and near railroad tracks, power lines, gas and oil pipelines, gardens, roads, highways, canals, rivers and lakes.

The FAE tracked carrier relies on the compact and powerful Rehlko (Kohler) 74 hp common rail electronic fuel injection engine, a fuelefficient option that complies

with the most stringent emission standards. The heavyduty undercarriage has a variable hydraulic design with independent rollers and an automatic tensioning system. High profile rubber tracks, with 86 mm spacing and 320 mm width, and idler wheels, enable the RCU75 to handle even the most challenging conditions. High-tech solutions give the RCU75 unbeatable traction, making it possible to work on steep slopes up to 55°. Additionally, a steel track option is available, ensuring outstanding traction on particularly challenging terrain.

In order to maintain perfor-

mance while using the tracks and the attachment simultaneously, the RCU75 makes use of a dual hydrostatic transmission. This integrated technological system consists of electronically controlled piston pumps combined with a dedicated electronic control unit. The result is high performance and reliability that lasts, plus simple and intuitive operation. The RCU75 is operated using a remote control, with a large 4.3” display and customizable function keys for superior management of all vehicle and head functions. A 2.4 GHz transmission frequency ensures reliable communication.

Optimally laid out and com-

prehensive controls, together with a balanced shoulder strap, make the FAE remote control unit ergonomic and easy to use.

The FAE RCU75 can be paired with the FAE app, allowing you to access real time operational data, diagnostic notifications, and scheduled maintenance indications on your smartphone.

The RCU75 will not be the only product to benefit from this exciting new option. The SAE attachment plate will also be available for FAE’s most powerful remote-controlled tracked carrier: The RCU120. SP

Source: FAE

“It means that the machine is working with different pressure levels depending on the situation and external conditions,” Emil explained. “You get plenty of power in both machine and crane when needed but can also operate with significantly lower pressure and save fuel when possible. Since the pump pressure calibration is automatic, it also makes servicing easier, and you never have to control the pressure on the crane or harvester head pumps. The machine takes care of that.”

Facts – Eco Log 688G

• Entirely reworked hy-

draulic system with new intelligent EoC pumps and valves. Automatic pump pressure calibration — no more manual fine-tuning.

• Fully redesigned transmission and driveline for improved traction.

• Selectable drive modes: Comfort, Balanced, Dynamic + Boost

• Valbara körlägen: Comfort, Balanced, Dynamic + Boost.

• Stronger crane with higher lifting force

• Smarter and stronger oscillation frame lock with dynamic performance

• Significantly improved tilt angles

Associated Auto Auction and its specialist collector car auction brand, Coast2coast, have become the latest auction house to join the Euro Auctions Group.

• Optional hydraulic cabin damping for premium ride comfort

Other improvements that have been made on the machine are, amongst others, better tilt angles on the crane base and a stronger oscillation frame lock that adapts automatically to both speed and crane position. Also, the machine’s design has been given a boost.

“I think it looks really nice. Now, we look forward to the next step – to deliver the machines to our customers and see them work out there in the forests,” Emil concluded. SP

Source: Eco Log

by Michener Allen making this one of the biggest auction houses for collector and cherished cars in Canada.

Leadership Commentary

Effective immediately, AAA becomes the fourth Canadian auction house in the Euro Auctions network, alongside Michener Allen Auctioneering, Jardine Auctions Inc and the recently acquired North Toronto Auction.

All AAA employees will be retained, the company will transition to operate under the Michener Allen brand from its facility in Headingley Manitoba, on the periphery of

Winnipeg. Craig and Janelle Collingridge will remain in leadership positions within the business.

The acquisition further enhances Euro Auctions’ ability to serve customers across Canada, as it will enrich the customer offering in Winnipeg. Michener Allen will now relocate its operations to the Headingley site. The specialist collector cars auctions held in Winnipeg will complement the collector car auction held

“Becoming the latest Canadian auction house to join Euro Auctions Group marks exciting times for Associated Auto Auction,” said Craig Collingridge, of Associated Auto Auction. “Partnering with a global leader will only enhance what we deliver to our customers and I’m very much looking forward to working alongside the Michener Allen Team. The acquisition not only enhances the auction offering here in Manitoba with increased focus on industrial assets but also provides a national platform for Collector car auctions across Canada.”

“We’re excited to welcome Craig, Janelle and his team into the Euro Auctions family and incorporate them into our strong Canadian group,” stated Derek Keys, Founder and Managing Director of Euro Auctions Group. “The addition of Associated Auto Auction enhances our customer offering and provides the required footprint we need to provide a service to our customers in Manitoba and on a national level across Canada.”

“We’re delighted to welcome another respected Canadian auction into the wider Euro Auctions group, and to integrate their operations with Michener Allen as we continue to strengthen our presence in Manitoba,” added Ian Michener, CEO Michener Allen. SP

Source: Euro Auctions Group

OZ Lifting Products LLC demonstrated its first stainless steel davit crane at the WEFTEC this September.

The Winona, Minnesota-based manufacturer returned to the WEFTEC show floor, with a 20 ft. by 20 ft. booth, having exhibited on four prior occasions. At the center of its exhibit was a prototype of its first ever stainless steel davit crane — suited to environments where corrosion resistance is of the utmost importance.

The product, which is available in 500 lb. and 1,000 lb. capacities, meets the unique material, dimension, and lifting requirements of these markets. The water and wastewater sector typically specifies type 304 and 316 stainless steel; the latter is a requirement in coastal and marine applications.

Richard Miller, sales manager at OZ Lifting, said: “The latest addition to our product range has its perfect launchpad — WEFT-

EC — where water quality professionals gather to find material handling and other solutions for the special demands of their work. The stainless steel davit crane will be of interest to many markets, but it will be especially relevant to the wastewater industry.”

Full-scale production is expected to commence in time for OZ Lifting to deliver stock to its distribution network prior to Q1 2026. The stainless steel davit crane will be compatible with the pedestal, socket, wall mount, and wheel bases for ultimate flexibility when looking to install the system in a variety of locations and applications.

Already familiar to WEFTEC attendees is the Tele-Pro davit crane range,

which is available in 500 lb., 1,200 lb. and 2,500 lb. capacities, and allows users to leverage the benefits of the company’s other davits, while telescoping the boom in and out under load. The series remains an excellent fit for wastewater and water treatment applications, where operators often encounter varying lift points, obstructions, or changing reach requirements during maintenance.

Miller said: “This feature allows plant personnel to fine-tune the boom length mid-lift, without having to stop and re-rig, improving efficiency and reducing downtime. It’s particularly useful for tasks like pulling pumps, mixers, or screens from wet wells or clarifiers, where conditions can change quickly and precise positioning is

critical.”

Also popular among wastewater professionals are the CompOZite and CompOZite Elite davit cranes. The 1,200-lb. capacity CompOZite davit crane is renowned for being ultra-lightweight and having exceptional corrosion resistance. It is made from advanced composite material and weighs only 83 lb. The carbon fiber CompOZite Elite, meanwhile, is the world’s most innovative davit crane, offering the same capacity as the CompOZite, but with a total crane weight of only 37 lbs.

Miller added: “All of our

davit cranes are designed for quick, tool-free assembly and can be used across multiple interchangeable bases installed throughout a facility, making it easy to service pumps, mixers, and equipment in different locations. The advanced composite material and carbon fiber are not only incredibly strong but also corrosionresistant, ensuring long service life even in harsh, highmoisture, or chemical-rich environments, typical of wastewater plants.”

OZ Lifting also showed its complete stainless series, including push beam trolleys, beam clamps, chain hoists, lever hoists, and

winches. All manual winches displayed can be drill driven and include a drill drive adapter, making the job easier and more efficient for the operator. Like the new stainless davit, these solutions are engineered for corrosion resistance, low maintenance, and long service life in harsh water environments. They are compact, lightweight, and durable, making them ideal for confined spaces and demanding lift points. Together, they combine to give operators a versatile, site-ready arsenal to handle virtually any lifting requirement. SP

Source: OZ Lifting Products

If you work in forestry, you already know what kind of abuse a machine takes in the woods.

Productivity depends on durability, a real hydraulic system and a machine built to run hard while keeping its cool. That is exactly why more contractors are taking a second look at SANY excavators.

These machines feature reinforced structures, heavyduty undercarriages and no shortcuts on steel or strength. The chassis is robust, the frames are overbuilt and the focus is on long-term reliability in rough terrain. Under the hood, every machine is powered by Yanmar, Isuzu or Cummins engines known for field-proven dependability.

SANY offers excavators for every scale of forestry work. The SY80U, SY95C, SY135C and SY155U are ideal for smaller clearing projects, roadside vegetation work, and jobs that demand maneuverability without sacrificing attachment power. Models like the SY215C, SY225C and SY265C balance power

and versatility for mulching, thinning, and moderate land clearing. When the job calls for horsepower and highflow attachment support, the SY335C and SY385C deliver for mass clearing and heavy land development. Wide track configurations come standard on small and large excavators for better flotation and traction in soft or uneven terrain without the need for aftermarket upgrades.

SANY also offers OEM forestry cab guarding for operators who need extra protection in dense brush or debris-heavy environments. These kits are engineered by SANY to fit properly and protect the cab without limiting visibility or service access. They are available for multiple models and can be tailored to your specific applications.

Hydraulics are another area where SANY machines stand apart. Forestry attach-

ments put serious demands on a hydraulic system, especially when running highflow multi-function tools all day. SANY machines come from the factory with dual auxiliary circuits, a case drain, and full plumbing for quick couplers. Several models include a dedicated gear pump for rotate functions, providing consistent flow without starving other systems. Combined flow capabilities support high-demand attachments, and larger cooling packs on next-generation models keep oil temperatures under control during extended use. Flow and pressure are fully adjustable from the cab so you can fine-tune performance for each attachment.

Operator comfort and control are essential when you spend long hours in remote locations. Every SANY excavator features a ROPS-certified cab (FOPS-certified with cab guarding), high-output

HVAC and a multifunction monitor that puts hydraulic settings and diagnostics within easy reach. Air-suspension seating, USB and 12V outlets, smart storage, and intuitive controls make the cab a place where you can work comfortably and efficiently. Rearview cameras are standard on

most models, and some of the newest models offer a full 360° camera system for better awareness in tight or cluttered work zones.

Forestry contractors know what works because they have seen what does not. With machines built for forestry, OEM guarding

options, high-performance hydraulics and operator-focused design, SANY excavators deliver a dependable solution for professionals who want to get the job done and move on to the next project. SP

Source: SANY

Komatsu went back to the drawing board and reimagined the cab, creating a working environment that’s comfortable, efficient and loaded with smart technology.

Komatsu is proud to announce two new gamechanging excavators. The new PC220LC-12 features a cab and controls designed for operator comfort, efficiency and productivity. The PC220LCi-12 includes the same features plus IMC 3.0, Komatsu’s latest intelligent machine control technology, incorporating automation enhancements designed to enhance operator productivity throughout each shift.

Both 21-24 ton-class hydraulic excavators are ideal for residential and commercial contractors, either performing basic land clearing and general earthwork or more advanced GPS designdriven site development.

Compared to the PC210LC-11, both excavators feature:

• A cab that is 28% larger, with 30% more legroom and 50% improved visibility;

• Up to a 20% increase in fuel efficiency due to a new electro-hydraulic system and high-output engine;

• Up to a 20% reduction in maintenance costs due to longer replacement intervals for hydraulic oil and oil filters and longer cleaning intervals for the particulate filter; and

• Significant performance upgrades including increases of up to 7% in lifting capacity and up to 8% in bucket digging force.

The PC220LCi-12 with IMC 3.0 features a construction industry first — factory-integrated 3D boundary control. With this innovative technology designed to help improve efficiency, operators can now set a work-restriction surface for height, depth, front, back and side boundaries. The machine is designed to stop automatically when it approaches a restricted zone.

3D boundary control helps operators work efficiently across the entire jobsite by remembering multiple restriction zones specific to each work area.

Several new and enhanced features are provided as standard equipment and help deliver operator comfort and convenience. Besides the spacious cab, air-suspension seat and ergonomic controls, a new operator ID system stores up to 50 profiles. Once an ID is entered, each operator has their personalized settings automatically loaded. Both models help drive toward zero harm with rollover avoidance alerts, a KomVision 360 camera for enhanced bird’s-eye views, people and object detection alert mode and many other features.

“We’ve built these excavators for the ones who need to get it done on every shift,” says Peter Robson, Senior

DEVELON announces its newest wheel material handler: the DX270WMH-7.

It’s built for tough recycling jobs and configured to conquer them. The machine is designed to elevate operator productivity, enhance safety and optimize material movement at recycling and solid waste facilities.

“A wheel material handler needs to be more than powerful — it should be smart, adaptable and a true partner to the operator,” says Brian Kim, heavy excavator product manager for DEVELON. “The DX270WMH-7 delivers on all fronts. Its exceptional versatility allows operators to complete a range of recycling tasks. And it features our -7 Series cab design and safety technologies, allowing operators to work longer, more comfortably and with greater peace of mind.”

Manufactured in-house for agility and precision, the

DX270WMH-7 wheel material handler makes light work of even the heaviest loads, such as car bodies and other bulky materials.

Utilizing a grapple or magnet attachment, the machine effortlessly moves and positions materials across recycling yards and solid waste facilities. The machine’s chassis design provides better lifting and a more durable undercarriage to minimize downtime.

With a nearly 3-foot longer reach and elevated cab, the DX270WMH-7 helps position operators for better productivity when loading trucks, containers and railcars at busy sites. Operators can work with full visibility of the site from the standard hydraulic cab riser. This feature allows an operator to safely enter the material handler’s cab at ground level. Once in-

Director, Product and Service. “That was the thinking behind the design of these next-generation machines — to empower operators to

perform at their very best, which translates into greater productivity on the jobsite. With the most advanced working environment we’ve

ever created, these are excavators your operators will love to run.” SP

side the cab, the operator can raise the cab hydraulically to the preferred height and then begin working.

The DX270WMH-7 material handler is equipped with a new virtual wall setting. The feature stops the machine’s boom and arm from hitting surrounding objects, helping the operator work confidently in tighter spaces and minimizing machine downtime.

Built with comfort in mind, the new DX270WMH-7 features a fully adjustable heated air-suspension seat and heat and air conditioning, letting operators customize their level of comfort. It also features joystick steering in addition to the standard steering wheel, giving the operator the option of steering the machine without taking their hands off the joystick.

The machine comes with

an easy-to-read 8-inch LCD monitor that displays machine diagnostics and controls to improve performance. Bluetooth® hands-free radio and MP3 audio let operators listen to their favorite content while keeping their hands free to work the controls.

Wider front and rear outriggers on the DX270WMH-7 create a larger base that improves stability, especially when operators are working with higher lifting capacities. The machine’s outriggers extend the footprint of the machine by creating a larger, wider area of contact with the ground.

A new collision prevention feature keeps the machine’s grapple attachment and cab from colliding during operation. Plus, the DX270WMH-7 is outfitted with an around view monitor (AVM) camera system that provides up to 360 degrees of visibility for a bird’s-eye view of the equipment and its surroundings. Operators can choose to only have a rearview camera to improve visibility all around.

Other key safety features include front and rear LED

working lights for enhanced visibility in low-light settings, seatbelt warning for operator safety and an alarm to identify the machine on the site.

The DX270WMH-7 wheel material handler provides operators with easy access to maintenance points and service procedures. It has an engine aftertreatment system with no diesel particulate filter (DPF) to minimize maintenance. This means the machine does not require a regeneration process to burn off accumulated soot.

The machine also features an air inlet mesh to keep fresh

air flowing to the engine and a reversible fan to keep the machine cooler and keep debris out for less maintenance.

MY DEVELON fleet management, a digital telematics platform for managing equipment, comes standard on the new machine. This powerful diagnostic tool is available on all -7 Series machines and monitors the health, location and productivity of DEVELON equipment from a user-friendly mobile app and website.

In addition to the new DX270WMH-7, DEVELON offers two tracked material handlers: the DX225MH-5 and DX300MH-5. SP

Source: DEVELON

AGGREGATE

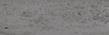

Sandvik is introducing its next generation bolter miner for longwall mining. Sandvik MB672 features the latest bolting technologies to increase productivity, improve safety and ergonomics for operators and reduce total cost of ownership.

around the globe,” said Uwe Restner, Vice President Product Line Management Underground Continuous Mining at Sandvik Mining. “The new Sandvik MB672 bolter miner is setting a new benchmark in bolting automation to accelerate mining and pave the way for future autonomous machine operation.”

Building on the proven reliability of Sandvik MB670-1, the upgraded Sandvik MB672 is purpose-engineered for longwall mining operations. As underground coal mining continues to embrace automation and digitalization to enhance safety and efficiency, Sandvik is advancing bolting technology with innovative solutions designed to automate the bolting process. These developments mark a significant step toward achieving bolting automation in the near future.

to meet specific operational needs.

Building on a long-established innovative sump frame mechanism that integrates cutting and bolting to enable simultaneous material cutting and ground support installation, Sandvik has now taken the next step toward bolting automation, advancing mining productivity while significantly improving operator safety.

“Sandvik pioneered the bolter miner concept more than 30 years ago, and we continue to strengthen our market-leading position with more than 500 bolter miners delivered to our customers

Sandvik supplies everything its customers need for longwall development — from underground excavation, ground support and material loading to transportation and logistics. Sandvik bolter miners simultaneously cut, support, gather material and convey it into vehiclebased or continuous haulage systems. This, coupled with a comprehensive parts and service offering, helps customers remove risk from their operations. Highly trained experts and engineers from Sandvik provide the right parts and services for nonstop operation, low operating costs and long service life. SP

Source: Sandvik

Furthermore, the fully-automated cutting cycle, known as Cutronic, enables consistent, faster and more accurate advancement, significantly reducing panel development time in stable ground conditions. This not only enhances operational efficiency but also reduces wear and tear on Sandvik MB672, extending its service life and reducing its operational costs. The machine, which features an optimized, ergonomic operator platform, is available in both high and low operational configurations, each designed

easy to adjust settings on the fly for peak productivity.

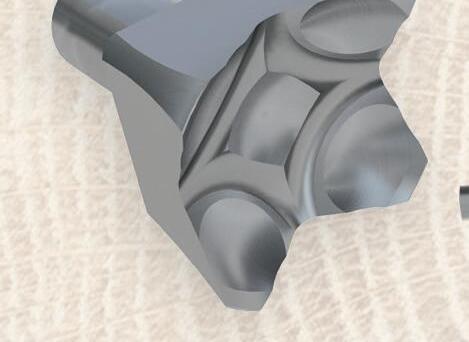

Fecon has introduced its Stone Crusher Series for skid steer and compact track loaders, giving landowners and contractors a faster way to reclaim rocky, unusable property.

The new attachments crush stones where they lie and leave a finer aggregate that improves soil structure, water retention, and access for light-duty vehicles.

“Customers have asked for a tougher, smarter attachment that minimizes passes and downtime,” said Jeff Stanley, Fecon’s Chief Commercial Officer. “The Stone Crusher Series meets that need with the industry’s widest working width, a performance feedback panel, and the heavy construction Fecon is known for.”

• SC7620 working width: 76 inches — the rotor width extends beyond a compact track loader’s tracks, crushing rocks before the tracks reach them and reducing track wear.

• SC6220 working width: 62 inches — a compact option that shares the same crushing chamber, rotor, and tooling as its larger sibling.

• Fusion smart control gives operators instant pressure feedback through an LED panel and app, making it

• Heavy-duty build — up to 3,965 pounds of highstrength steel, segmented wear liners, and singlebolt carbide tooling stand up to demanding jobs and simplify maintenance.

• Eight-inch material capacity and a 20-inch diameter rotor let both models crush larger stones in a single pass, eliminating haul-off and extra processing.

Both models run on highflow hydraulics from 30 to 50 gpm at up to 5,500 psi. A single 160cc piston motor efficiently delivers power to the crushing rotor via a 68 mm cogged belt.

Production units began coming off the line in June. SP

Source: Fecon

Collaboration to deliver step-change capabilities through software-defined vehicle and autonomy platform.

Komatsu is pleased to announce a strategic technology collaboration with Applied Intuition, a Silicon Valleybased company at the forefront of vehicle intelligence. This collaboration aims to provide cutting-edge technologies and real-time adaptability to Komatsu’s next generation mining equipment, helping customers boost productivity, reduce downtime and operate with greater precision and efficiency.

With Applied Intuition’s proven capabilities across vehicle operating systems, autonomy stacks, and tooling, and Komatsu’s extensive expertise in off-highway auton-

omy and mining applications, the companies will co-develop a unified software-defined vehicle (“SDV”) and autonomy platform that will serve as the central brain of Komatsu’s next generation of mining equipment. This collaboration represents one of the most significant technology initiatives in Komatsu’s history and signals a bold step toward a future of increasingly autonomous, software-driven mining operations.

“Komatsu is committed to creating value together with our customers, and this collaboration represents a step change in how we bring innovative, high-performance tech-

nology to their operations,” said Peter Salditt, President, Mining Business Division, Komatsu and CEO, Komatsu Mining Technologies. “By combining Komatsu’s deep mining expertise with Applied Intuition’s cutting-edge AI and SDV solutions, we’re enabling a future where our equipment continuously evolves to meet customers’ unique mine site needs.”

The jointly developed platform will introduce a new era of machine intelligence through key features such as:

• Software-defined vehicle architecture that will enable continuous feature delivery over the life of the machine, with native integration of data management, digital security and connected support.

• Flexible autonomy capabilities ranging from advanced operator assist to full autonomy on a common platform, adaptable across fleets, commodities and operational complexities.

• Embedded machine learning and AI that supports functional enhancements and continuous learning, enabling site-specific optimization as conditions

change.

We expect that mining customers will benefit from improved equipment performance, reduced downtime and increased return on investment through Komatsu’s next-generation autonomy systems. The enhanced architecture aims to enable faster deployment, simplified support and scalable solutions that extend across mine sizes and geographies. This new flexibility is critical in an industry facing labor shortages, challenging site conditions and rising demand.

“In a world where autonomy is becoming the norm, our goal is to ensure our customers don’t just keep up— they lead,” said Qasar Younis, co-founder and CEO of Applied Intuition. “The mining industry is one of the most regulated in the world, and as the bar keeps rising around emissions, human safety and geopolitics, Applied Intuition and Komatsu plan to build the next generation of mining products.”

This collaboration advances Komatsu’s vision of a fully autonomous future for mining, while helping to solve today’s pressing challenges. As mineral demand increases

alongside a decline in skilled labor entering the field, autonomy becomes an essential enabler of safer, more efficient and scalable operations. Together, Komatsu and Applied Intuition are laying the foundation for mining machines that think, learn and evolve, helping customers around the world unlock more value from their operations and build a more sustainable future. SP

Source: Komatsu

blocks dangerous movements in case of overload;

• Side tilt corrector, adapting the machine to all types of terrain;

Tyalta Industries Inc. is proud to be the new authorized dealer for Prostack in Western Canada, offering a comprehensive portfolio of innovative solutions for bulk material handling and product stockpiling. This partnership brings industry-leading equipment and support to meet the evolving needs of the region’s material handling markets.

Introducing the TW 36-150, a 150-foot radial telescopic conveyor engineered for the North American market NOW THE EXCLUSIVE

Arriving at Tyalta Industries Inc. October 28th, 2025.

Automated stockpile patterns

Extended Reach: 150-foot (46-meter) telescopic length with radial capability

Massive Capacity: Stockpile heights over 48’ 10” (14.9m) for 102,696 yd³ (78,517m³)

Tool-Free Deployment: Quick setup without additional tools or labor

Road Towable: Designed for easy transport across North America

∙ Purpose-Built: Engineered specifically for North American market demands

∙ User-Friendly Design: Quality of life improvements for enhanced reliability

In addition to the TW 36-150 Tele Stacker, the ProStack range includes Telescopic Conveyors, Tracked Conveyors, Tracked Feeders, Bulk Reception Feeders, and Port Hoppers—offering a complete bulk material handling solution for the quarrying, ports, and mining industries.

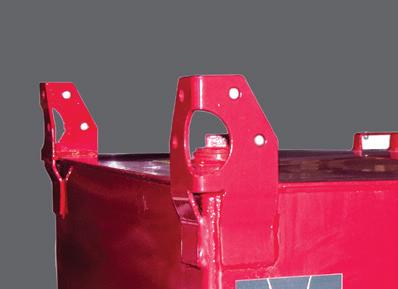

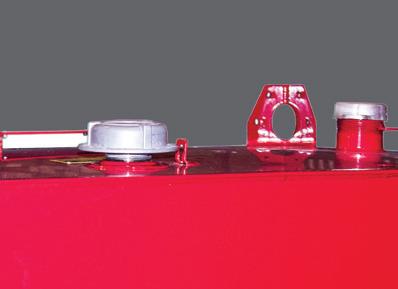

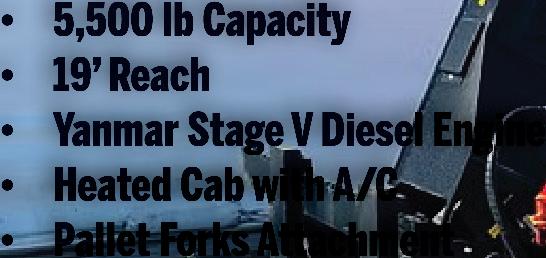

For those looking for a high-capacity telehandler, DIECI has developed the Hercules range, ideal for handling heavy and bulky loads at great heights.

Telehandlers are highperformance and versatile machines, designed to transport heavy loads and reach impressive heights. Each model stands out for its unique features, designed to simplify, speed up, and optimize every work phase on construction sites, in mines, and in emergency contexts

Hercules is the most powerful DIECI telehandler in the DIECI range and the ideal machine for moving heavy and bulky loads, even at high heights. Designed for loading and unloading containers, marble blocks, and other bulky materials, this machine offers a lifting capacity ranging from 13 to 23 tons, while ensuring fast maneuverability and the high reliability that characterizes all DIECI machines.

The Hercules heavy-duty range includes four models, each designed to meet specific lifting requirements:

• Hercules 130.10, the “smallest” in the range, with a lifting capacity of 13,000 kg and a lifting height of 9.5 meters;

• Hercules 190.10, with a maximum capacity of 19,000 kg and a maximum lifting height of 10.2 meters;

• Hercules 210.10, offer-

ing the same lift height performance, but with an increased capacity of up to 21,000 kg;

• Hercules 230.10, currently the largest model in the range, with 23,000 kg capacity and a maximum lift height of 10.15 meters.

In addition to technical capabilities, the entire range ensures the highest standards of safety, handling, and comfort. Advanced technological solutions guarantee intuitive operation, ease of use and adaptability, making these heavy-duty telehandlers the perfect solution for the most demanding and unconventional working environments.

The Hercules heavy-duty telehandler allows you to tackle the toughest jobs in the mining, emergency, port and industrial sectors with total safety, offering high power, exceptional precision, and complete control. Its reliability is enhanced by several features that increase safety and efficiency even in unusual conditions. Key features include:

• Arm too high, which automatically reduces driving speed when the boom is raised;

• Anti-Tilt System, which

• Automatic attachment recognition, configuring the machine according to the connected equipment and automatically setting the correct load chart;

• Automatic wheel alignment and steering direction indicator;

• Remote control with display, allowing the operator to control the machine from the ground, reducing risks in hazardous environments;

• Four-wheel drive and steering, for better traction and agility on all terrains;

• Single ECU, that enables continuous parameter monitoring via an advanced diagnostic system.

Each Hercules telehandler is designed to make the operator’s job easier. That’s why the cab has been carefully engineered to offer a comfortable and intuitive driving position, ready to take on any challenge. Operator experience is also enhanced on board the Hercules telehandler, thanks to several technical features that improve usability and ensure protection, including:

• ROPS-FOPS certified cab, in line with safety regulations;

• Single-lever joystick, for full control of movements;

• Dashboard with clear instruments and welldistributed controls; Continued on page 29

• Ergonomic seat, adjustable steering wheel, and sound insulation, ensuring maximum comfort;

• Display for continuous load monitoring (angle, extension, load, height).

• Various applications for a high-capacity telehandler

Strong, robust, powerful and… versatile! The Hercules heavy-duty fixed telehandler is suitable for various applications, capable of replacing other machines such as aerial platforms or forklifts. Its adaptability is guaranteed by its compatibility with a wide range of attachments like winches, booms and baskets, enhancing its performance across different work environments.

Two Hercules telehandlers are currently in operation at the Boto gold mine in Senegal, supporting the handling of 4,000 kg tires. Mining is one of the key sectors for the use of high-capacity telehandlers. Uneven, dusty, and sloping terrain demands reliable, powerful, and safe machines, while the large

volume of material on site demands highly efficient, high-performance equipment.