Saskatchewan

SK (306) 721-2666

Saskatoon, SK (306) 934-3555 Swift Current, SK (306) 773-2951 www.redheadequipment.ca

Manitoba

Ontario NORS

Stittsville, ON (613) 836-6633

Sudbury, ON (705) 692-0552

Thunder Bay, ON (807) 475-3052 www.nors.com

Top Lift Enterprises, Inc. Bolton, ON (905) 857-5200

In fire-prone regions across the country, landowners and mulching professionals are often faced with the daunting task of cleanup and recovery.

When wildfires affect these landscapes, the immediate focus for operators must be on clearing hazardous debris, stabilizing the land, and ensuring damaged areas do not become even more vulnerable to erosion and invasive species.

Mulching stands out as a critical part of this process, offering a controlled and eco-conscious approach to rehabilitating fire-damaged areas and making them more resilient. With the right equipment, landowners can efficiently restore their prop-

erties while also reinforcing their landscapes against imminent risks.

Whether you’re facing forest fires in the West, brush fires in the South, or prairie fires in the Midwest, the experts at Diamond Mowers offer the following tips for effective post-fire cleanup and future fire defense.

Fires affect landscapes differently depending on the region. Understanding these distinctions can help land

contractors choose the right methods and equipment for recovery.

• Forest Fires: Since these fires typically involve dense, woody debris, an open drum mulcher is best for removing large trees in forested areas.

“Our new Drum Mulcher OD Pro X2 features durable carbide teeth to handle thick vegetation, making it ideal for forest fire recovery where clearing large remnants quickly is essential for land restoration,” said Nate Cleveringa, vice president of engi-

neering and product management at Diamond Mowers.

• Brush Fires: Brush fires tend to occur in scrubland environments and leave behind tangled, low-lying greenery. The sharp, powerful blades of a brush cutter enable it to efficiently cut through weeds and shrubs a regular mower or trimmer might struggle with and restore land to its natural state.

• Prairie Fires: These fires move quickly across grasslands and can leave debris that contributes to erosion and invasive plant growth. Here, again, a drum mulcher is the best choice for processing thick patches of tough vegetation. Diamond’s Drum Mulcher DC Pro X2 features proprietary Edge Hardened Steel Teeth, which have taller “paddles” to ingest more material for a more comprehensive and cleaner mulch on the first pass. Meanwhile, a brush cutter offers thorough treatment for more delicate areas. Together, these attachments can help maintain the soil and promote healthy regrowth of native plants.

Post-fire landscapes present unique dangers and hazardous conditions that need to be addressed carefully. Taking the right precautions helps to ensure the safety of

EXCAVATORS

2022 YANMAR SV08-1D 2'3"-2'9" WIDE, DIG BKT, 2 BKTS, Q/C, 106 HRS $26,900

2025 YANMAR SV08-1D RUBBER, 2'3"-2'9"WIDE CALL (2) YANMAR VIO17-A, RUBBER, CANOPY, 2 BKTS, HYD THUMB, 165-534 HRS CALL

NEW YANMAR VIO17-1E, CANOPY, 2 BKTS, HYD THUMB, AUX HYD CALL

2015 BOBCAT E20, 12" DIG, 39" CLEAN UP, HYD THUMB, 2,595 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, BLADE, 2 BKTS, HYD THUMB, 378 HRS CALL

2025 YANMAR VIO25-6B, CAB HEAT, BLADE, 2 BKTS, HYD THUMB, 24 HRS CALL

2017 DEERE 26G, CANOPY, 2 BKTS, HYD THUMB, 2,455 HRS CALL

2022 YANMAR VIO35-6A, CANOPY, RUBBER, 2 BKTS, HYD THUMB, 481 HRS CALL

2023 YANMAR VIO35-6A, CANOPY, BLADE, 2 BKTS, HYD THUMB, 319 HRS $48,900 (6) YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 120-695 HRS CALL

NEW YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB CALL

(3) YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 431-790 HRS CALL

NEW YANMAR SV40, 6 WAY BLADE, HYD Q/C, 2 BKTS, HYD THUMB CALL

2021 HITACHI ZX50U-5N, CAB AIR, 2 BKTS, THUMB, WRIST BKT, 1,838 HRS CALL (4) YANMAR VIO50-6A, CAB, 2 BKTS, HYD THUMB, AUX, 103-468 HRS $74,900

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX HYDS, 109 HRS CALL

(7) YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 500-1,024 HRS CALL

NEW YANMAR VIO55-6A, CAB AIR, RUBBER, 2 BKTS, HYD THUMB, AUX CALL

2016 KOMATSU PC78US-10, 18" PADS, BLADE, AUX PIPING, 3,698 HRS CALL

2019 HITACHI ZX75US-5B, 18" PADS, BOR, BLADE, ONLY 1,131 HRS SOON

2020 HITACHI ZX75US-5B, 18" BOR, BLADE, 4,273 HRS CALL

2019 CAT 308E2 CR 18" BOR, BLADE, AIR, 520 HRS SOON

2019 CAT 308CR-07A, 18" PADS, BLADE, AUX PIPING, ONLY 2,054 HRS $78,900 (5) YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB, 212-1,033 HRS CALL

2024 YANMAR VIO80-7, RUBBER, CAB AIR, 2 BKTS, HYD THB, AUX, 188 HRS CALL (6) YANMAR SV100-2A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 762- 1,330 HRS CALL

2025 YANMAR SV100-7, RUBBER, CAB AIR, HYD Q/C, 2 BKTS, HYD THB, AUX CALL

NEW YANMAR SV100-7 RUBBER, CAB AIR, PTO2, HYD Q/C CALL

2017 CAT 312F GC, 20" PADS, AIR, ONLY 2,868 HRS $67,500

2019 CAT 312F GC, 20" PADS, AIR, ONLY 2,168 HRS $74,900

2008 CAT 313D CR 20" PADS, AIR, BLADE, PIPED, 6,555 HRS $49,900

2019 HITACHI ZX120-6, 24" PADS, AIR, ONLY 1,887 HRS SOON

2008 HITACHI ZX135US-3, 20" PADS, Q/C, DIG, THB, 8,971 HRS, NEW U/C CALL

2014 KOMATSU PC138US-10 20" PADS, AIR, BLADE, ONLY 3,779 HRS CALL

2016 HITACHI ZX135USBL-5 20" BOR, BLADE, 4,865 HRS SOON

2017 HITACHI ZX135US-6, 20" PADS, BOR, AIR, ONLY 2,768 HRS SOON

2017 HITACHI ZX135USBL-6, BLADE, 2 BKTS, HYD THUMB, 3,596 HRS $135,900

2017 HITACHI ZX135USBL-6, 20" PADS, BLADE, 2 BKTS, Q/C, THB, 2,073 HRS CALL

2018 HITACHI ZX135USBL-6, 20" PADS, BLADE, 8,503 HRS SOON

2018 HITACHI ZX135US0S-6, 20" BOR, BLADE, BOOM, 1,551 HRS, 2 BKTS $89,900

2020 HITACHI ZX135USBL-6 CABGUARD, BLADE, THB, 2 BKTS, 2,487 HRS $159,900

2023 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT, 360 HRS CALL

2024 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT, NEW CALL

2017 CAT 907M, CAB AIR, HYD Q/C, GP BKT, 3,798 HRS SOON

2021 CAT 910 - 14A, CAB AIR, 3,981 HRS SOON

1993 DEERE 544G, Q/C, BKT/FORKS, 5,282 HRS ON METER, CLEAN UNIT CALL

2013 KOMATSU WA380-7 CAB AIR, HYD Q/C, BKT & FORKS, 8,350 HRS $94,900

2004 YANMAR C12R, RUBBER, DUMPER, TAILGATE, ONLY 1,046 HRS $8,900

2022 YANMAR C50R-5AR, AIR, SWIVEL DUMP, 8,379 LB, 733 HRS $109,900

2023 YANMAR C50R-5AR, AIR, SWIVEL DUMP, 8,379LB,1,087 HRS $109,900

2021 MOROOKA MST1500VDR 360 SWING DUMPER, 17,637 LB & 6.5 CU YD CAP, 1,392 HRS CALL

2021 MOROOKA MST2200VDR 360 SWING DUMPER, 24,000 LB & 8 CU YD CAP, 877 HRS CALL

2002 CAT 725, AIR RIDE SEAT, TAILGATE, 23.5X25 TIRES, 11,800 HRS $109,900

2011 KOMATSU D51EX-22, CAB AIR, PAT BLADE, MS RIPPER, 3,814 HRS CALL

2019 CAT D6T LGP, PAT BLADE, MS RIPPER, GUARDING, 7,430 HRS $239,900

SKID STEERS/COMPACTORS

2016 BOBCAT S70, HLA 36" GP BKT, AUX HYDS, ONLY 748 HRS $15,900

2015 BOBCAT S590, HYD Q/C, A/C CAB, 2 SPEED, 1,859 HRS $49,900

2013 BOBCAT S650, CAB AIR, BKT & FORKS, HYD Q/A, 3,383 HRS CALL

2015 BOBCAT T590, CAB AIR, SJC CONTROLS, 2,444 HRS CALL

2022 KUBOTA SVL65-2, CAB AIR, HYD Q/C, ONLY 266 HRS, 66" GP BKT CALL

2022 KUBOTA SVL65-2, HYD Q/C, 68" HD LO PRO BKT, 1,012 HRS CALL

2022 KUBOTA SVL65-2, HYD Q/C, 68" HD LO PRO BKT, 1,246 HRS CALL

2023 KUBOTA SVL75-3, AIR, HI FLOW, 74" HD BKT, 875 HRS CALL

2021 BOBCAT T76 R SERIES, CAB AIR, HYD Q/C, 74" BKT, 2 SPD, 2,000 HRS $49,900

2025 YANMAR TL65RS, 67" BKT, 67 HP, 2100 LB ROC, CAB AIR, HI FLOW, RVC CALL

2025 YANMAR TL75VS, 67" BKT, 74 HP, 2555 LB ROC, CAB AIR, HI FLOW, RVC CALL

2025 YANMAR TL80VS, 72" BKT, 74 HP, 2,900 LB ROC, CAB AIR, HI FLOW, RVC CALL

2006 ING RAND SD70D TF, 66" SMOOTH DRUM, SHELL KIT, EXC COND $36,900

2013 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1713 HRS CALL

2014 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1,744 HRS CALL

2016 VOLVO SD75B, 66" DRUM, CANOPY, ONLY 2078 HRS CALL

2021 SAKAI SV544DC, 84" SMOOTH DRUM, CAB AIR, 3,500 HRS CALL

2020 HITACHI ZX135USBL-6, BLADES, FROM 1,226 - 1,862 HRS CALL

2020 HITACHI ZX135USBL-6 20" PADS, BLADE, CABGUARDS, ONLY 2,040 HRS, 2 BKTS, Q/C, PRO LINK HYD THUMB $169,900 (4)

2022 HITACHI ZX135USBL-6, 28" PADS, AIR, BLADE, AUX HYDS, 1,490 HRS CALL

2024 HITACHI ZX135USK-6, 20" PADS, AIR, 'K' MODEL, NEW, ONLY 5.1 HRS CALL

2022 CAT 315 GC BLADE, 2 BKTS, HYD THUMB, ONLY 249 HRS CALL

2022 CAT 315 GC BLADE, 2 BKTS, Q/C, ONLY 319 HRS CALL

2018 HITACHI ZX200-6, 24" PADS, AIR, Q/C, 2 BKTS, ONLY 5,182 HRS $89,900

2021 HITACHI ZX200-6, 24" PADS, AIR, AUX HYDS, ONLY 1,296 HRS CALL

2021 CAT 323, AIR, HYD THUMB, 2 BKTS, HYD Q/C, 529 HRS CALL

2012 HITACHI ZX200LC LR, 18M SUPER LONG REACH, ONLY 3,551 HRS $119,900

2018 HITACHI ZX200LC-5, 2 BKTS, Q/C, HYD THUMB, ONLY 3,690 HRS, CABGUARD, SIDE GUARDING, NO DEF/NO REGEN $154,900

2021 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, 1,000 HRS CALL

2022 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, 999 HRS CALL

2020 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, ONLY 80 HRS SOON

2011 HITACHI ZX225USR-3, 24" PADS, AIR, Q/C, 2 BKTS, 9,640 HRS CALL

2020 HITACHI ZX225USR-6, 24" PADS, AIR, 2 BKTS, Q/C, HYD THUMB, ONLY 2,803 HRS $154,900

2020 HITACHI ZX225USRK-6, 24" AUX HYD PIPING, 8,253 HRS SOON

2015 HITACHI ZX245USLC-5, Q/C, 2 BKTS, PL THB, GUARDING, 8800 HRS $119,900

2021 HITACHI ZX245USLC-6, 32" PADS, Q/C ,2 BKTS, THB, 3,347 HRS CALL

2018 HITACHI ZX345USLC-6N, HYD WEDGE Q/C, HYD THUMB, 2 BKTS, CABGUARD, 4,500 HRS CALL

2019 CAT 330 07A 24" PADS, AIR, 2 BKTS, HYD THUMB, ONLY 2,454 HRS CALL

2021 CAT 336 07C, 28" PADS, AIR, ONLY 778 HRS, 2 BKTS, HYD THUMB, CATWALKS CABGUARD, 2D EQUIPPED CALL

2020 HITACHI ZX490LCR-6, Q/C, DIG & CLEAN UP BKTS, ONLY 996 HRS CALL

LIFTS & LIFT TRUCKS

2008 GENIE GTH-5519, CAB, AIR RIDE SEAT, 19' LIFT, 5,500 LB CAP, 48" FORKS CALL

2014 GENIE Z34/22 4X4, KUBOTA, 34' LIFT, 4' JIB, 5,611 HRS CALL

2012 GENIE Z60/34 4X4, DIESEL, 3,250 HRS CALL

WATER TRUCKS

2019 KOMATSU HM400-5 ARTICULATED WATER TRUCK, RETARDER, RVC, EMERG STEER, PAS, REAR SPRAY, 29.5R25 TIRES, 10,137 HRS CALL

2009 INTERNATIONAL 8600 CUMMINS 6 CYL, 10 SPEED, FRONT/REAR/DUAL SIDE SPRAY, 2,500 GALLON TANK CALL

2005 FREIGHTLINER M2 106, CAT C7 ENG, ALLISON AUTOMATIC, 2,500 GAL SUPREME TANK, PUMP, FRONT, REAR, SIDE SPRAY, 251K MILES CALL

ATTACHMENTS AND MISC

2017 BOBCAT 68" BROOM ANGLE BROOM, MADE IN USA CALL

2019 BOBCAT 84" BROOM ANGLE BROOM, MADE IN USA CALL (2) SUP 200 & 290 LONG REACH BOOM/STICK, TO FIT ZX200 & 290LC CALL

2025 SUP 35/55/80 TILT BUCKETS TO FIT VIO35/40/50/55/80/100 CALL

DOZERS

CAT D3K2 LGP, 6 WAY DOZER, CAB AIR, 80HO, 20K LBS

2 KOMATSU D39/RIPPER, 6 WAY, CAB AIR KOMATSU D71PXI PAT/RIPPER, 6 WAY DOZER, MS RIPPER, “I” MACHINE

LOADERS

2 YANMAR V4-7, CAB AIR, BOBTACH Q/C, .91 CU YD BKT

8 KOMATSU WA200/250/270/320, 2.5-3.75 YD KOMATSU WA380-8, FORKS, BKT CAT 950K, FORKS, BKT GRADERS/COMPACTORS

2 CORNIVER CT40 40” SMOOTH DRUM, KUBOTA ENG

8 CORNIVER CT48 48” SMOOTH DRUM, KUBOTA ENG

8 SAKAI SV204/VOLVO SD45, 45” SMOOTH DRUM, CANOPY

8 SAKAI SV414/VOLVO SD75, 67”/66” DRUM, CAB AIR

2 HITACHI ZX345USLC-6, 2 BKTS, HYD THUMB, CABGUARD

6 HITACHI ZX330/ZX350LC-6, 2 BKTS, HYD THUMB

4 SAKAI SV544, 84” SMOOTH DRUM, CAB AIR CAT 140M, 14 TIRES, SCARIFIER, CAB AIR

workers and the effectiveness of cleanup efforts.

• Assess for Hidden Hazards: Unstable trees and smoldering vegetation can compromise operator safety or cause further damage if left unattended.

• Use Appropriate Protective Gear: Operators should be equipped with helmets, gloves, and safety

glasses to protect against flying debris, sharp objects, or accidental contact with machinery. “A minimum half-inch thick polycarbonate operator protection is required, and some applications may require additional safeguards,” added Cleveringa.

• Work in Stages: Address high-risk areas first, es-

pecially near buildings or infrastructure, to eliminate immediate threats. Prioritizing these zones also allows for emergency repairs or access to critical areas sooner.

When tackling post-fire cleanup, it’s important to start with more perilous areas where erosion or regrowth

pose significant risks.

• Stabilize Slopes: Slopes are particularly vulnerable to landslides or soil erosion after a fire, so stabilizing them can lead to longterm land integrity. With its extended reach, an excavator drum mulcher is an ideal option for accessing burnt vegetation in hard-to-reach areas and creating a protective layer over the soil on steep terrains.

Cleveringa explained. “Its carbide teeth can withstand extreme abrasion and won’t spark in rocky environments – an essential feature in fireprone areas.”

Cultivating Resilience

An important aspect of post-fire recovery is prepar-

• Incorporate Firebreaks: Establish defensible zones that minimize ladder fuels and help contain future fires. Well-maintained firebreaks safeguard homes, buildings, and utility infrastructure from spreading fires and protect valuable property in highrisk zones.

Komatsu PC350LC-8, 3 bkts, thumb, cabguard, catwalks, exc. cond. 4,415 hrs.

Komatsu PC200LC-8, 3 bkts, Q/C, thumb, cabguard, catwalk, exc. cond., 1,772 hrs.

Komatsu PC170LC-10, 3 bkts, thumb, cabguard, exc. cond., 2,725 hrs.

Komatsu PC138USLC-II, 2 Bkts, Hyd. Q/C, Thumb, Exc. Cond., 2,300 Hrs. P.O.R.

Komatsu PC88MR-8, 2 bkts, hyd. Q/C & thumb, swing boom and blade, 2,400 hrs.

Komatsu D65EX-17, sigma blade, ripper & forestry guarding, 75% U/C, exc. cond., 6,050 hrs.

Komatsu D39 PX-24, 6-way blade, winch, forestry guarding, 3,100 hrs.

Hamm H13iX, 84” smoothdrum packer w/cab, A/C, low hrs, exc. cond.

Hamm 3307, 66” smoothdrum packer w/shell kit, cab, A/C, exc. cond. FOR RENT bkts, EQUIPMENT FOR RENT OR SALE

• Protect Waterways: Burnt debris and loose soil can wash into streams or rivers, impacting water quality and local ecosystems.

A brush cutter excels at clearing smaller vegetation around tight waterways, which contributes to a reduction in runoff contamination.

24” 3-bar pads

• (3) Cat D6H,R,T Idlers P/N 395-4325 - Like New!

• Create and Maintain Defensible Spaces: Thin vegetation to create firebreaks and protective buffers around homes, businesses, utility poles, and other infrastructure.

“Engineered for heavy ground engagement and processing harsh materials, the Drum Mulcher OD Pro X2 is the perfect ‘go-to’ tool for large-scale tasks like this,”

ing for future disasters and cultivating long-term resilience. Landowners can support these goals by incorporating mulching as part of their ongoing land management efforts and following these strategies:

• Track Regrowth: Conduct land assessments on mulched areas to identify invasive species that can outcompete native grasses and disrupt the ecosystem. Regular checks allow for timely intervention and promote a more balanced landscape where native and fire-adaptive plants can thrive.

• Enhance Soil Health and Biodiversity: Mulching returns organic material to the soil, enriching it with nutrients that promote native plant regrowth. The protective mulch layer helps retain moisture and prevent soil erosion, which is crucial for rehabilitating fire-damaged areas. Recovering from wildfires is as much about rebuilding the land as it is about preparing it for what’s ahead. By integrating mulching into routine maintenance, landowners and professionals can strengthen ecosystems, reduce long-term risks, and turn vulnerable terrain into resilient landscapes. Visit www.diamondmowers.com to learn more. SP

Source: Diamond Mowers

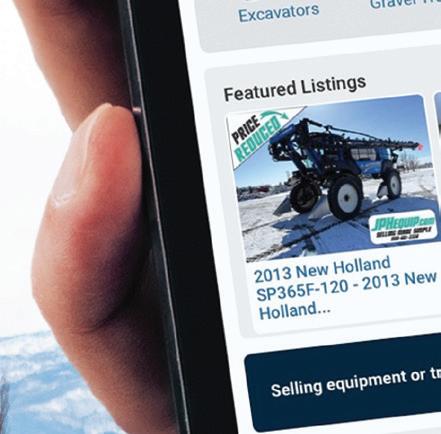

New Holland Construction is elevating the way its customers manage their equipment with the launch of myNewHollandConstruction.

This digital platform marks the next generation of telematics and fleet management technology to enhance operators’, fleet managers’ and owners’ abilities to conveniently and effectively track and manage their connected machines.

myNewHollandConstruction is now officially available to access and download for all New Holland Construction customers who have a machine set up with connectivity. To increase accessibility to telematics, fleet management data and myNewHollandConstruction, all New Holland Construction machines, beginning with Model Year 2026, will come telematicsready with a CM1X or P&CM modem and a standard sevenyear connectivity subscription.

“Telematics is an essential component for construction fleets and operations, as well as farmers, ranchers and

producers,” says Jake Sickels, product manager for New Holland Construction North America. “Knowing where your machines are, when they’re being used and how they’re performing provides peace of mind to operators and fleet managers alike. myNewHollandConstruction puts that information, and other critical insights, in your hands anytime, anywhere.”

fully in-house by CNH and New Holland Construction to create an easy-to-use operator interface and allow flexibility in the backend system around customer-specific needs. The platform is available on desktop as well as a mobile app for Android and iOS, meaning operators and fleet managers can access real-time data on the go.

tools help compare active versus idle time, monitor fault codes and evaluate overall job site efficiency to maximize productivity and reduce downtime.

Maintenance is proactive and streamlined with this platform. Operators can establish customizable alerts to help them plan and schedule maintenance activities like oil changes, air filter replacements, tire rotations and other routine services.

myNewHollandConstruction is a platform developed

The platform works by delivering real-time telematics monitoring of machine utilization, performance and geolocation for instant visibility across fleets. Operators and fleet managers gain access to detailed machine metrics, including hours worked, productivity, fuel consumption and job site cost figures. Users can track fuel usage at varying engine loads to forecast annual fuel expenses or assess leased equipment based on actual hours worked rather than fixed schedules. Reporting

myNewHollandConstruction also acts as a centralized hub for customers to engage with their New Holland Construction dealers when it comes to maintenance. Through the platform, dealers can provide easier, more proactive communication and service, from deploying predictive service alerts and software updates to

scheduling maintenance. This ensures the right parts and support are available when needed to keep fleets up and running efficiently. Another important aspect of myNewHolland-

Construction is machine location tracking. Users can locate machines left on remote job sites, verify machine assignments or quickly respond if a unit is moved unexpectedly. Notifications can also be set up for security alerts. Additionally, geofencing and job site assignments allow machines to be linked to specific projects to establish security and operational oversight. Rolebased logins are available to ensure fleet managers, operators and service personnel see only the data relevant to their responsibilities.

myNewHollandConstruction builds on the trusted functionality of FleetForce, which was New Holland Construction’s original telematics platform offering, while offering a more modern, user-friendly and convenient interface. The current FleetForce platform will remain active until December 19, 2025, allowing existing users to make the platform migration. Machines will appear on both FleetForce and myNewHol-

landConstruction until year-end as users transition platforms. Each New Holland Construction machine comes with a seven-year telematics subscription, with data retained for three additional years after expiration, if not renewed.

“Fleet management at your fingertips – that’s what myNewHollandConstruction delivers. Every machine tells a story, from utilization and fuel consumption to maintenance needs,” Sickels says. “This platform empowers our customers to turn that data into action, improving efficiency, reducing downtime and lost revenue opportunities and keeping projects on track.”

The myNewHollandConstruction system is available now and accessible through local North America New Holland Construction dealerships. Current FleetForce users will receive an email with system onboarding instructions, while new customers will gain access to the portal and app at the point of purchase through the dealer. SP

Source: New Holland Construction

Environmental clean-up in the morning, laying bed prep in the afternoon, quarry material sorting in the evening. With the MB Crusher screening bucket, the work never stops – just changes tune.

You wouldn’t expect a kaolinite quarry in sunny Spain and the snowy slopes of the French Alps to have much in common. But they do share one smart solution: the MB Crusher padding bucket. Different materials, different challenges – one bit of kit. One tool, multiple tasks. The result? Greater efficiency, less waste, and more control.

Because let’s be honest –every site is asking the same question: “How can I do more with less?” Where there’s material to process, there’s an MB Crusher padding bucket ready to roll.

Spain: Where kaolin is no longer ran over

In one Spanish quarry, kaolinite – that chalky white mineral used in everything from porcelain to paper –used to be crushed under the tracks of excavators or smashed up with the bucket. Crude, inefficient, and costly. Now? It’s extracted, stored,

dried, and processed with an MB-HDS323. The result: consistently high-quality material, neatly sorted and ready to go. Quicker, cleaner, and a whole lot smarter.

Meanwhile, high in the Alps…

Ski resorts don’t just come alive when the snow falls – they’re hard at work even in the off-season. On one French mountainside, a team laying pipes for snowmaking systems faced a logistical nightmare: how do you refill a trench in a remote spot without hauling materials in and out at great cost (and environmental impact)?

The solution? An MBHDS320, mounted on a CAT320, screened and prepped excavated material on site – then reused it to fill the trench. Uniform, ready-to-use backfill in minutes. No transport, no fuss. And the mountain kept its peace.

One machine for two sites.

The common denominator? That ingenious shaft system. MB’s patented design lets you swap rotors in minutes – right there on site. No need to pop down to the workshop. It’s as simple as changing TV channels.

One moment it’s soil. The next? Sand. Then glass, then green waste. That’s versatility with a capital V.

In France, at ENEDIS AUVERGNE’s power line construction sites, a padding bucket helps separate spoil from reusable backfill, all while ensuring only top-grade soil goes near the cables. Normally this means trips to the tip, buying in fresh materials – the usual faff. Here, it’s all done on site.

In Germany, on the island of Sylt – a protected area with tricky access and tight environmental rules – an MBHDS320 made it possible to screen sand, peat and soil on location. No need to ship it off to the mainland for processing. Every journey saved means money saved – and less impact on delicate landscapes.

Real versatility? It’s hanging off your excavator arm. That’s what the MB-HDS line is all about. Equipment that adapts to your site – not the other way round. Wet or dry, soft or tough, urban or rural. From compact backhoes to beastly excavators, MB Crusher has 13 models – and every one can handle shaft swaps in minutes. This year, the range just got bigger:

• MB-HDS407 – a nimble, ultra-compact padding bucket for 3.5 to 9 ton excavators and backhoes. Lightweight, precise, and perfect in tight spots.

• MB-HDS533 – the heavyweight champion: a 3.4-metre-wide powerhouse for 50 to 80 ton excavators. Made for big jobs and difficult materials.

From Spanish quarries to Alpine peaks, from backfilled trenches to underground cables, MB Crusher’s padding bucket are changing the game.

No longer “a machine for every job” – now it’s “one machine for all jobs.” SP

Source: MB Crusher

Get ready for two of the biggest heavy equipment shows in the country—both happening Spring 2026!

Celebrating 40 years, the Atlantic Heavy Equipment Show will gather thousands of industry professionals from across the Maritimes and beyond. Taking place March 2627 at the Moncton Coliseum Complex, this event brings networking and sales to a whole new level. Representing the following industries all in one place:

• Heavy equipment

• Roadbuilding, earthmoving, and material handling

• Logging and forestry operations

• Snow and ice removal

• Aggregates, screening, and

crushing

• Jobsite safety, support, and tools

• And much more!

Discover the latest innovations, technologies, machinery and trends up close! This show spotlights everything you need to get the big jobs done – with dozens of cutting-edge machines on display with both indoor and outdoor exhibits. With nearly 11,000 attendees and a SOLD-OUT show floor at the latest edition in 2024, this event continues to impress year after year. Booth spaces are available now and already

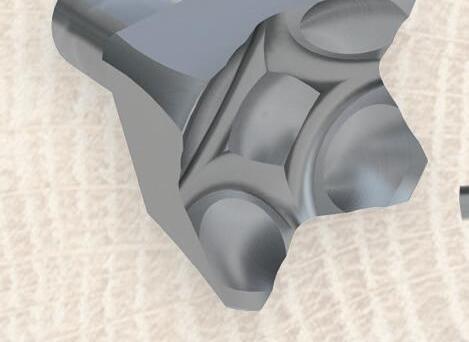

Waratah Forestry Equipment has launched two new harvester heads — the H427 and the H427X.

The new harvester heads deliver powerful, durable and reliable solutions for today’s toughest forestry applications. Built to handle large timber, the H427 offers high productivity and precision, while the H427X extends that performance with heavy-duty features, purpose-built for tracked machine applications.

“As the largest heads in our 400 Series lineup, the H427 and H427X are built to give loggers the confidence

they need in the forest,” said Brent Fisher, product marketing manager for Waratah. “Whether it’s the versatility of the H427 or the heavy-duty capabilities of the H427X, both models are designed to enhance performance, durability, productivity and reliability in demanding environments.”

Big-Timber Harvesting: H427

The rugged H427 is

85% SOLD, secure your spot today by requesting a booth quote online or by contacting the show team.

• Mark Cusack, National Show Manager – markc@ mpeshows.com

• Andrew Burns, Exhibit Sales – andrewb@mpeshows.com

Want to attend? Keep an eye on the show’s Facebook page (@AtlanticHeavy) for upcoming registration info and full show details.

Supply Post is proud to partner with the event and Logging and Sawmilling Journal to produce the official show guide. Mark your calendars for March 26-27 at the Moncton Coliseum. See you there! www.ahes.ca

On the National front

Canada’s largest Heavy Equipment Show is celebrating its 30th anniversary. The National Heavy Equipment Show will once again take over Mis-

built for big timber and demanding applications from late thinning to the final cut. Featuring a strong frame, high-performance saws including an optional top saw and HD tilt frame, it delivers durability, feed force and cut capacity needed for reliable productivity. Its saws are a standout feature, providing fast, precise cutting even in the toughest conditions.

With an operating weight of 1,655 kg (3,649 lb.), the H427 balances strength and stability in rugged forestry conditions. The latest measuring system design improves length and diameter accuracy, while an efficient control valve and optimized four-roller feed arm geometry ensure consistent performance on wheeled and tracked carriers. A four-knife delimbing system and streamlined service access further enhance uptime, making the H427 a high-output solution for loggers.

Weighing in at 1,853 kg (4,085 lb.), the H427X delivers the same performance benefits as the H427 but is purpose-built for heavy-duty tracked machine applications. The H427X features a standard, heavy-duty tilt frame and heavy-duty feed motor

sissauga’s International Centre for the largest event of its kind on April 23 and 24.

Since its debut, the National Heavy Equipment Show has stood as the largest indoor event in Canada for industry professionals to discover the latest equipment, technology, and services for the roadbuilding, heavy construction, land improvement, screening & crushing, municipal, and infrastructure sectors. With a sold out show floor, over 13,000 attendees

covers for added durability and protection. This helps provide operators with the toughness and responsiveness required with tracked applications, hardwood and large timber.

and an expansion to include Hall 4 at the last edition in 2024, this event promises to impress. Put your brand, equipment and skills in front of thousands of industry pros at this can’t-miss event. Those interested in exhibiting at the show are encouraged to request a booth quote online or contact a member of the show team to book their spot, as exhibit space is already 75% sold and likely to sell out.

• Mark Cusack, National Show Manager – markc@

mpeshows.com

• Andrew Burns, Exhibit Sales – andrewb@mpeshows.com

Interested in attending? Keep an eye on the show’s Facebook page (@NationalHeavyEquipmentShow) for upcoming registration info and full show details.

Mark your calendars and be sure to visit the Supply Post booth, April 23-24, 2026. www.nhes.ca. SP

Source: MPE Shows

Backed by easily accessible dealer support, genuine Waratah parts and an industry-leading warranty, the H427 and H427X heads are available to customers across the United States, Canada, Europe, Australia, New Zealand, Africa, Brazil and Latin America. SP

Source: Waratah Forestry Equipment

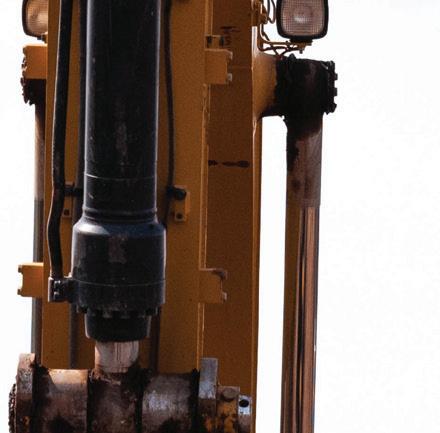

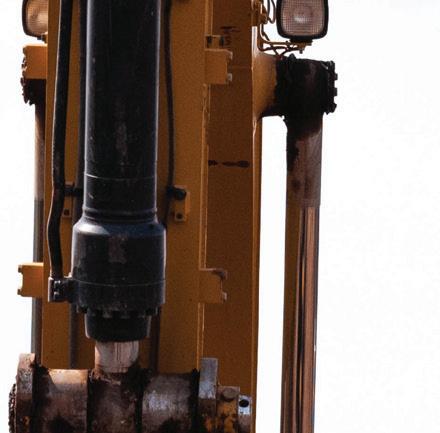

The next generation compact radius Cat 303.5 CR Mini Hydraulic Excavator features a significant software update designed to improve transient speeds up to 25% compared to previous 303.5 CR next gen models.

“While the top end speed hasn’t changed, how the machine gets from ‘0 to 60’ has. It’s much faster from the start,” says Greg Worley, market professional for Cat mini excavators.

The 303.5 CR’s more dynamic design with quick transient speeds helps to reposition the excavator in a shorter period, limiting the time the machine is not working. This results in contractors being up to 35% more productive at the jobsite, depending on application and conditions.

The update is compatible with all next generation builds dating back to the first production models in 2021. The current software version is available on the excavator’s operating monitor, and customers can get the latest update from their Cat dealer.

Key features of the 303.5 CR include:

Heavy lifting and performance

• Capable of lifting, swinging and carrying a standard 2,450 lb (1111 kg) street plate.

• Trenching productivity and controllability of the angle blade in Stick Steer mode.

Comfort and industry-first features

• Sealed and pressurized operating cab with adjustable operator settings.

• Exclusive Cat Stick Steer joystick control to enhance machine travel and cruise control.

Simplified service

• Easily accessible checkpoints from ground level and a unique tilt-up cab/ canopy to reach additional service areas.

Compact radius swing

• Reduces overhang when working to the side, allowing machines to deliver high performance in confined spaces.

The updates will be installed on the Cat 303.5 CR at the Utility Exposition, October 7-9, and Equip Exposition, October 21-24, in Louisville, Ky. and are available to operate. SP

Source: Caterpillar

and even golf courses.

When it comes to maintaining green spaces and clearing ground, Indeco IMH hydraulic mulching heads offer a highly efficient, versatile and hard-wearing solution.

The IMH forestry mulching heads are ideal for removing trees, undergrowth, land-

Designed for installation on excavators, mini loaders and 3 to 49-ton skid steers, these hydraulic mulching heads for forestry and agricultural work adapt to all kinds of operational needs, transforming your worksite machine into a powerful environmental management tool.

clearing and creating fire breaker lines, as well as periodically clearing public and private green spaces. Their efficiency is showcased in a variety of areas, such as pipelines, ski slopes, railway lines, motorways, electricity pylons

But it isn’t just a question of cutting, IMH mulching heads can also be used to shred branches, bushes, roots and tree trunks, turning them into material for reuse as natural mulch. This helps to make the soil more fertile, reduces erosion and limits the use of chemical fertilisers, resulting in both economic and environmental benefits.

Indeco mulching heads for excavators guarantee high productivity and savings on operating costs. The multiple or direct V-belt transmission, combined with fixed or variable displacement hydraulic motor units, ensure excellent power control and easy maintenance.

The versions with VD piston motors automatically adapt to the machine’s hydraulic characteristics, thus optimising torque and rotor speed. This system reduces the risk of overheating and improves performance during continuous work.

The use of HARDOX steel for the machine body and anti-wear skids, together with the Heavy Duty rotor, ensure exceptional durability even in the harshest of conditions. The interchangeable teeth and “bite limiter” profiles result in powerful, uniform mulching, improving operating continuity.

One of the strong points of IMH mulchers is their ease of use and maintenance. Direct access to the internal components, like the shaft and hydraulic connections, ensures

the risk of faults and increase the reliability of the equipment.

The mulching heads can also be quickly and safely installed on different models of excavators thanks to the interchangeable assembly points, thus avoiding errors that could affect productivity.

A broad range for all needs

The IMH Series is divided into three types to cover all needs:

• For compact excavators: seven models from IMH 3 to IMH 14, with a maximum mulching capacity from 75 mm to 380 mm in diameter.

• For excavators: IMH 20 and IMH 30, up to 410 mm as the maximum mulching diameter.

• For skid steers: models from IMH 3.2 SS to IMH 5.2 SS, with a maximum mulching diameter between 180 mm and 250

work, from straightforward residential green space maintenance to intensive operations in forests and along railway lines.

Sustainability and savings

In addition to the technical benefits, IMH green space maintenance equipment actively contributes to environmental sustainability. The mulched material can be left in place as natural ground cover, thus reducing the need for transport and disposal while improving the condition of the soil.

In conclusion, Indeco hydraulic mulching heads are reliable, durable and sustainable tools for anyone who uses machines to maintain green spaces. Whether it’s equipment for land clearing or machines to eliminate vegetation, the IMH Series is the professional equipment of choice in terms of efficiency,

Reaching new heights of safety and ensuring shorter downtimes: operators can now use the FAE App to reposition RCU vehicles if remote-control signal is lost.

The FAE App now boasts a function of particular importance to owners of RCU55, RCU75 or RCU120 remote-controlled tracked carriers. If the remote control cannot be used, it is now possible to move the vehicle using only the FAE App. This function allows tracked carriers to be moved safely and quickly, as external equipment is no longer required to transport the vehicle in the event of a block.

Specifically, the new function makes it possible to:

• Switch the diesel engine on and off and manage its rotation speed.

• Drive and steer the vehicle, including in reverse.

• Raise or lower the attachment.

• Make the undercarriage, and therefore the track width, wider or smaller. All movements are made at limited speed, in order to maximize operator safety.

This new function will come standard on all new RCU55, RCU75 and RCU120 vehicles. It is also backward compatible upon request, subject to an update to the vehicle’s software.

This new app control option comes in addition to the already robust functionality available for the RCU on the FAE App.

Real-time information: The app’s interface makes it possible to monitor machine operation data, like the diesel engine’s load percentage, instant fuel economy and working pressure, as well as to receive malfunction alerts.

Diagnostics: The FAE app displays failures, with a description of the malfunction and the parts involved. It also allows users to export problem reports to facilitate repairs.

Scheduled maintenance: Users receive required maintenance alerts, including the number of hours remaining until the next scheduled maintenance and a list of required maintenance work.

The FAE App is available for iPhone and Android OS. SP

Source: FAE

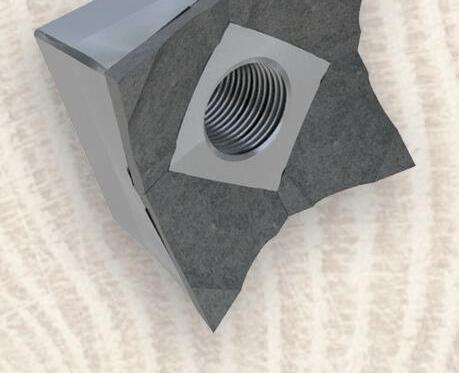

The Vermeer RH9 rock drill head is the newest addition to the rock tooling lineup for dual rod horizontal directional drills.

The RH9 rock drill head is a specialty tool designed for installing small diameter utilities including single fiber conduit lines, compatible with Vermeer D23x30DR S3 and D40x55DR S3 horizontal directional drilling (HDD) equipment. The RH9’s precision-engineered design helps reduce the overall footprint of HDD installations while maintaining reliable performance in rock drilling applications with its field-rebuildable components.

“The RH9’s compact design is ideal for contractors working with smaller diameter and shallow bore applications,” said Cody Mecham, product manager at Vermeer. “This specialty tool functions like a scalpel for precise rock drilling projects that don’t require larger diameter holes. Its lighter weight and shorter profile give crews better handling in the field with less equipment needed, making

it particularly valuable for telecom installations in rock conditions.”

The RH9 features a twodegree bend near the front of the tool for responsive steerability, similar to other Vermeer rock drill heads. It comes with multiple configuration options to meet diverse operational needs, including both direct connect and starter rod options. Contractors can choose between a smaller unit with 8-in (20.32-cm) sonde housing or the standard 15-in (38.1-cm) configuration to match their specific requirements. While the 15-in sonde configuration is common in the US market, the smaller unit provides international contractors with a more compact solution for shallower telecom work where depth capabilities of larger sondes aren’t required.

The RH9 drill head is compatible with tricone and PDC (polycrystalline dia-

mond compact) bits for various rock formations. Along with the established RH10 and RH15 models, the RH9 joins the rock drill head product line from Vermeer, giving contractors a comprehensive range of options to match their specific drilling requirements. SP

Source: Vermeer

Loading and unloading trucks is now safer for customers of VDL Container Systems, thanks to Tele Radio.

VDL Container Systems is a leading manufacturer of demountable container handling systems and spreaders, with more than 25 years in the industry. Based in the Netherlands, it has a global customer base and is a market leader in the Benelux region. Its truck product range includes hooklifts, cable systems and chain systems for container handling, as well as skip loaders.

The company’s customers required a remote-control so-

lution to help improve safety when loading or unloading.

“We were looking for a partner that could address three key challenges: visibility, precision, and reliability,” said Paul van der Loo, product manager at VDL Container Systems.

When using cab-based controls, operators face restricted sight lines around hooklifts, skip loaders and chain systems. This can make it hard to judge swing radius or tip risk. Precision via pro-

portional controls is also vital as two- or three-position systems can jolt loads, leading to unpredictable movements or even vehicle rollover.

For the same reason, uninterrupted performance is vital. One broken link between transmitter and receiver can have costly, potentially fatal consequences. In addition, VDL’s customers operate in extreme environments from working near industrial ovens to sub-zero Nordic yards. Its

controllers need to withstand heat, cold and debris.

After searching the market for the right solution, VDL invested in the Tiger T14-7 and T15-7 remote controls from Tele Radio. Tiger is a robust radio control system adaptable to standard and complex applications. SIL3 and PLe certified, it is available in several radio bands with frequency-hopping technology. Designed for harsh environments, the push button transmitters are rated to either IP65 or IP66.

$36,500

2004 Hitachi ZX230LC Excavator. Machine comes with quick change Rotobec hydraulic grapple and heel, cleanup bucket. This machine is fully guarded with 32” triple bar pads and shows 11,089.0 hrs on the meter $48,900 Road Building Package. John Henry Drill (new Cat 3054 compressor engine) on Cat315 Excavator, Cat 330L Hoe drill (1238 Atlas Copco hammer and valve resealed), (2) M40 Tank Drills, Hitachi EX270LC Excavator, Kobelco 350-9 Excavator (new undercarriage), Hitachi EX300-3 parts machines, Terex TA27 Rock Truck, 2001 Terex TA30 Rock Truck, 2004 TerexTA30 Rock Truck (low hr transmission), 2008 Ford F350 Dually Powder Truck, Powder Mags, 1996 Western Star 4964S Tractor with Tandem step deck and Tridem lowbed, (2) Tandem axle water trucks, LW Kenworth with 13,500L Diesel tank and pump mounted on it, 5000L Diesel Tank, 1200L gas tank, (3) shop trailers loaded with parts, Genset trailer with 45Kw & 13 Kw single phase gensets with a dry

GMC cab over flat deck, GMC welding truck with Hiab,

3500 dually shop truck, Tandem axle off-highway lowbed

Pacific 40 Ton Log Trailer,

Nose Line Lugging Added, All New Lines & Turnbuckles on the Comp. Snorkel & a Rebuilt Esco Grapple, Unit has Not Worked Since the

Crucially for VDL, they also provide millimetrelevel proportionality. The pressure-sensitive buttons modulate hydraulic flow in real time, eliminating load jerk. And the secure, failsafe connection maintains control even in the most extreme circumstances. With up to 1,000m working range, operators can step well clear of heat, noise, or swinging objects while maintaining full visibility of the lift.

“Container handling operators face multiple, high-stake hazards every shift,” said van der Loo. “Operators require precise control. Tele Radio provides both the connection and precision we require.”

Fundamentally, Tele Radio helps to ensure the safety of VDL’s customers. “Operators gain perspective on their surroundings when using a remote control,” he added. “They can distance themselves from the intense heat of an industrial oven or a precariously balanced offloading truck.

“Imagine transporting a load of molten metal, an

offloading garbage truck that tips backward to the point it could turn over, or an innercity delivery amidst bustling traffic. Tele Radio provides end-users with the ability to take a step back and gain a full overview of the situation.”

The company’s clients operate in the harsh conditions found in industries such as mining, agriculture, and construction, as well as extremely cold weather in the north of

Europe and very hot temperatures in the south.

“Tele Radio is unmatched in establishing a secure connection, ensuring our users’ safety,” he added. “We have a great working relationship with Tele Radio. They listened closely to what we needed, making them a great partner for now and also to develop future products.” SP

Source: Bridger Howes

engcon, the world-leading manufacturer of tiltrotators, announces the integration of its advanced tiltrotator technology with the latest excavator models from Develon: the DX230LC-9 and DX260LC-9.

With this collaboration, the new Develon 9 series excavators will now be delivered tiltrotator-ready, setting a new standard for ease of installation and operational efficiency.

The factory-prepared solution ensures a straightforward and time-efficient installation of engcon DC3 tiltrotators, significantly re-

ducing the need for complex retrofitting. The integration supports both engcon sandwich solutions and directmounted DC3 tiltrotators, while maintaining full compatibility with Develon’s 2D machine guidance systems and aftermarket 3D machine control systems.

For rental companies, this development provides a de-

cisive advantage. Tiltrotatorready excavators allow fleets to easily equip or interchange tiltrotators as needed, maximizing machine flexibility and utilization while simplifying fleet management. End users renting these machines benefit from immediate access to tiltrotator functionality, enabling higher productivity and efficiency from day one.

– This collaboration with Develon allows us to provide a more advanced and integrated solution for our end customers, while delivering a simplified installation process for our dealers and rental partners, says Sam Ryan, Global OEM Manager at engcon. By ensuring the Develon 9 series excavators are tiltrotator-ready, we make it easier than ever to adopt tiltrotator technology on a global scale, he continues.

The partnership reflects a broader industry shift toward closer collaboration between excavator manufacturers and tiltrotator specialists, ensuring machines are designed to deliver maximum efficiency and productivity as standard. SP

Source: engcon

TO

FELLER BUNCHER

2002 Madill T2250B, c/w: Quadco QFH 22” felling head w/ 360 wrist, Series 50 engine $59,500

2019 John Deere 844K-III, c/w: Brandt log grapple, third valve, forestry guarding pkg, 7,936 hrs $474,500

LOG LOADERS

2014 John Deere 3754D Heel Boom, c/w: WBM grapple 18,350 hrs, service rec. avail. from new CALL

2013 Hitachi ZX290F-3 Heel Boom, c/w: Pierce M55 grapple, 24,434 hrs, service records available from new CALL

2010 Caterpillar 330DFMLL Heel Boom, c/w: T-Mar 60” log grapple $64,500

1998 Madill 4800 Heel Boom, T-Mar log grapple $274,500

2001 Madill 124 Swing Yarder, Recent major work orders, can be viewed working $1,395,000

1993 Madill 144 Swing Yarder, $84,500

1989 Madill 123 Swing Yarder, Recent $250K in work orders $839,500

1988 Cypress 7280C Swing Yarder $649,500

2 X Madill 044 Grapple Yarders, c/w: Series 60 or Cummins power CALL

ROCK DRILLS

Rotair HR-1000 Hyd. Rock Drill, c/w: Atlas Copco 1238 hammer $89,500

Morgan Power Apparatus M40-F Tank Drill, c/w: PR66 hammer, GD 3800 or 4800 boom $39,500

PROCESSORS

2015 Hitachi ZX290F-3 Log Loader, c/w: 2014

Southstar QS605 processing 10,904 hours CALL

2011 Hitachi ZX290F-3 Log Loader, c/w: 2010

Waratah HTH623C proc. head, 13,858 hrs.. $164,500

2003 Caterpillar 330C Processor, c/w: 2004 Waratah HTH626 processing head. CALL

The Canadian Concrete Expo, the largest trade show in Canada dedicated to concrete construction, is announcing a 20% expansion for its 2026 event, bringing the show floor to a record 400,000 square feet.

Already on track to sell out exhibit space, CCE continues to solidify its position as the premier hub for professionals, innovations, and technologies shaping the future of Canadian construction.

The expansion comes at a critical moment when Can-

ada is facing unprecedented demand for housing, sustainable infrastructure, and advanced building solutions.

From the country’s largest cities to its most remote regions, construction leaders are under pressure to deliver projects that are faster, stronger,

greener, and smarter. CCE 2026 is where those challenges meet real solutions — all under one roof.

“Construction is the backbone of Canada’s economy, and our trade show is where the industry comes together to share ideas, build partnerships, and discover innovations,” said Stuart Galloway, President of Canadian Concrete Expo.

“This 20% growth reflects the industry’s demand for a powerful platform that enables professionals from across Canada and international markets to connect and collaborate.”

addressing the skilled labor shortage.

• 400+ Exhibitors & Growing: An expanded show floor filled with handson demonstrations, large equipment, interactive displays, and access to the latest technologies from leading Canadian and international suppliers.

• Unmatched Networking: High-impact opportunities for contractors, engineers, architects, developers, and industry leaders to forge valuable relationships that turn ideas into real-world projects.

• Dynamic Conference Schedule: Expert-led sessions tackling the industry’s most urgent priorities — from meeting net-zero building targets to adopting new construction methods and

• Dedicated Demo Area: A massive 100,000+ sq. ft. space where attendees can experience tools and machinery in action, compare solutions side-by-side, and gain the insights they need to stay competitive.

The Canadian Concrete Expo is Canada’s largest and most comprehensive trade event focused on the concrete and construction industries. Bringing together over 400 national and international exhibitors and over 8,000 industry professionals, the expo serves as a platform for exploring cutting-edge technologies, sharing best practices, and fostering innovation. For exhibiting companies, CCE offers unrivaled exposure to a highly qualified audience ready to invest in the prod-

ucts and partnerships that will define the next decade of construction.

• Dates: February 11–12, 2026

• Location: The International Centre, 6900 Airport Rd, Mississauga, ON L4V 1E8

• Website: www.CanadianConcreteExpo.com.

• Find contact details online at SupplyPost.com/ news. SP

Source: Canadian Concrete Expo

Liebherr crawler dozers have always been characterized by maximum compatibility with established machine control systems.

The connection through Liebherr Unicontrol Easy

With the introduction of Liebherr Unicontrol Easy Link, customers can now benefit from the proven reliability of Liebherr machines alongside Unicontrol’s agile and accessible 3D control systems, offering a flexible solution for automated grading precision.

Link is available for both new machines and as a retrofit for already delivered G8 crawler dozers in the mentioned size classes. Integration requires activation of the corresponding software interface in the machine control system, a simple and direct electrical connection to the Unicontrol system, and preparation of the cab to accommodate the Unicontrol display.

Unicontrol, founded in 2019 and headquartered in Odense, Denmark, develops modern GPS/GNSS-based 3D control systems for construction machinery. Its solutions are primarily sold in Europe, North America, and Australia, with particular recognition in Scandinavia.

“Unicontrol is now a direct option for those looking to activate automatic grade control on their Liebherr machines,” said Martin Kirkmand, Product Development Director at Unicontrol. “It’s a significant step that reflects the industry’s move toward more accessible, flexible technology that works the way contractors need it to.” SP

Source: Liebherr

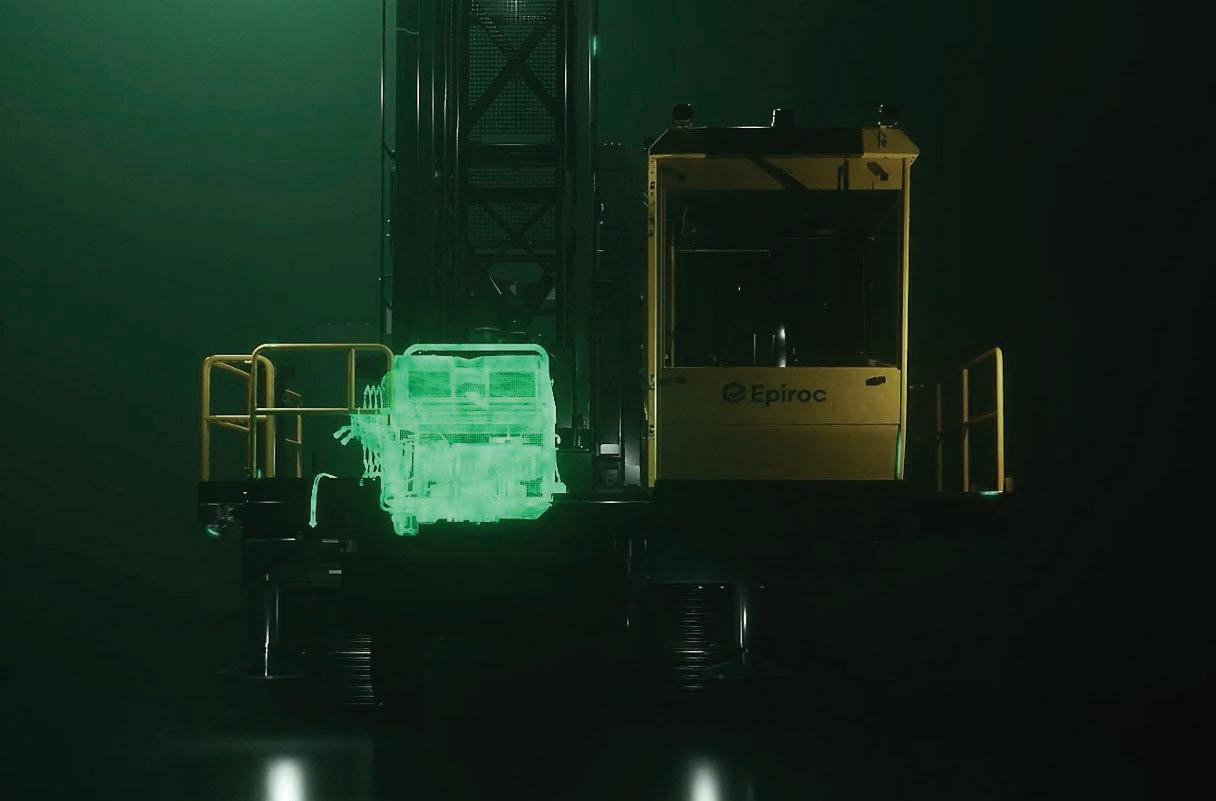

Epiroc, a leading productivity partner for the mining and infrastructure industries, introduces the Automatic Bit Changer (ABC) for hands-free bit changes on Pit Viper 270 and Pit Viper 290 series drill rigs used in rotary drilling.

of bit types and sizes from a safe distance without exposure to live work.

“Through its development and trial,” said Carla Chaname , Product Manager – Automation. “The Automatic Bit Changer has proven to be the safest and most efficient way to change bits that is currently available.”

Available for new drills and retrofit of drills already in the field, the Automatic Bit Changer is easy to maintain, and its compact, above deck design takes up less space in comparison to competitors’ designs. The above deck design ensures maintenance procedures are simpler and safer to perform, operator viewing angles are optimized and retrofits for the working Pit Viper fleet are available.

The Automatic Bit Changer option is designed to change rotary tricone bits significantly faster than manual exchanges and eliminates human interaction with the drill string for a safer, more efficient way to operate a drill fleet.

with customers and crossfunctional teams resulted in an auto bit changer that is repeatable, keeps the operator out of the line of fire, and improves machine uptime,” said Matthew Fosler, Senior Design Engineer, Surface division.

The Automatic Bit Changer makes it possible for operators to complete hands-free drill bit changes with the single touch of a button and to stay informed on their screen. Operators can make or break joints, select drill bits, and add or remove them. This can be done from either a remotelybased control room or from the comfort of the cab. The Automatic Bit Changer optimizes productivity and efficiency of the drilling operation and improves safety by eliminating exposure to live work environments.

Epiroc’s Automatic Bit Changer decreases downtime and eases operator workloads. The carousel design allows up to four bits to be easily changed significantly faster and safer than a single manual exchange. The removable bit carousel can store rotary tricone bits in varying sizes and cutting structure, for a total of four onboard bits, for flexibility and versatility on a drill site.

Customizing a Pit Viper 270 or Pit Viper 290 drill rig with the Automatic Bit Changer option offers many benefits for the operator. In addition to easing their workload, it reduces the possibility of human error, injuries related to heavy lifting, lost time on manual adjustments, accidents and exposure to dust and noise. Eliminating these live work tasks is crucial in the mining industry.

By eliminating manual drill changes, increasing machine uptime and decreasing worker injuries, Epiroc’s Automatic Bit Changer supports a more productive and profitable operation.

“It has been truly an honor to be a part of this product’s development and I cannot wait to see the impact it will make in our industry”, concluded Ms. Chaname. SP

“The early collaboration

Featured in the unique carousel design, the Automatic Bit Changer gives users the ability to safely replace the worn drill bits with a range

Source: Epiroc

The Alamo Group Snow and Ice team continues to expand its footprint with the opening of a new 15,000 sq. ft. facility in Caledon, Ontario.

This marks another major milestone for the group, following the successful launch of its 400,000 sq. ft. facility in Wooster, Ohio, earlier this year.

The Caledon facility replaces the team’s former Mississauga location, offering significantly more space and capacity. The expansion allows for:

• Increased service capabilities

• Enhanced support for the growing rental fleet

• Larger on-hand parts inventory Faster, more responsive customer support for municipalities and contractors across the Greater Toronto Area.

“This is the next big thing for Alamo Group,” said JP

Bourque, Vice President of Alamo Group Snow & Ice.

“We’re investing in the future — in our people, our customers, and the infrastructure needed to support them.”

The video released alongside this announcement captures insights from key members of the team, including leadership and staff from the Caledon facility. Together, they share how this expansion is helping Alamo Group Snow & Ice strengthen its commitment to service, innovation, and growth across North America.

Watch the video online at SupplyPost.com/news. SP

Source: Alamo Group

MAXAM Tire is proud to announce a comprehensive expansion of its AgriXtra product line, including new VF and CFO (Cyclic Field Operation) capable sizes designed to meet the evolving needs of next generation agricultural equipment.

These additions support MAXAM’s ongoing mission to provide durable, high-performance solutions engineered for the modern farmer and OEM platforms worldwide.

MAXAM’s AgriXtra series now includes new fitments specifically built for the most demanding equipment categories, including high horsepower tractors, sprayers, floaters and harvesters. With growing equipment sizes and higher load requirements becoming the norm across the agricultural industry, these tire solutions are engineered with advanced casing technology and steel belted construction to deliver exceptional strength, flotation, and endurance – while reducing ground impact and enhancing overall productivity.

New Additions by Product Family Include:

• AgriXtra 85: New VF and CFO rated tires designed for 180-430 HP MFWD tractors and harvesters, including sizes tailored for track rear and front axle drive fitments.

• AgriXtra 70/65: Expanded fitments for small tractors below 100 HP, as well as rear axle steer tires for class 7-8 harvesters and flotation tires for high-clearance sprayers.

• AgriXtra XL: VF super single options for both front and rear axle drive positions in high HP MFWD tractors, engineered for the North American and EU markets.

• AgriXtra H: CFO capable solutions for 3 and 4-wheel floaters, offering

superior load endurance and stability in high-capacity applications.

• AgriXtra N: Narrow row crop solutions for vegetable and vineyard applications, with VF CFO options designed for high-clearance sprayers operating at up to 50 MPH.

These additions mark a key milestone in MAXAM’s commitment to delivering one simple, highvalue tire solution across diverse agricultural platforms. All VF-rated tires in

the AgriXtra family are engineered with steel belts for enhanced contact patch, optimal traction and minimized soil compaction, ensuring top-tier performance in the field.

“The addition of these new sizes allows MAXAM to better serve the full range of agricultural applications, from narrow tractors and small platforms to high horsepower sprayers and harvesters,” said Greg Gilland, Vice President of Agriculture at MAXAM Tire. “Each tire is

engineered to meet the demands of today’s evolving equipment – delivering durability, traction and load capacity that farmers and OEMs can rely on season after season.”

Each MAXAM VF CFO tire combines advanced casing materials with cuttingedge compounding technology, allowing farmers to operate under fluctuating loads and speeds without compromising tire integrity—especially in applications where adjusting air pressure

isn’t feasible. The result: higher load capacity, reduced soil compaction, and improved operational uptime across all major ag platforms.

MAXAM’s continued investment in product development reflects its long-term commitment to providing innovative, field-proven solutions that empower dealers, OEMs, and farmers to get the job done more efficiently. SP

Source: MAXAM

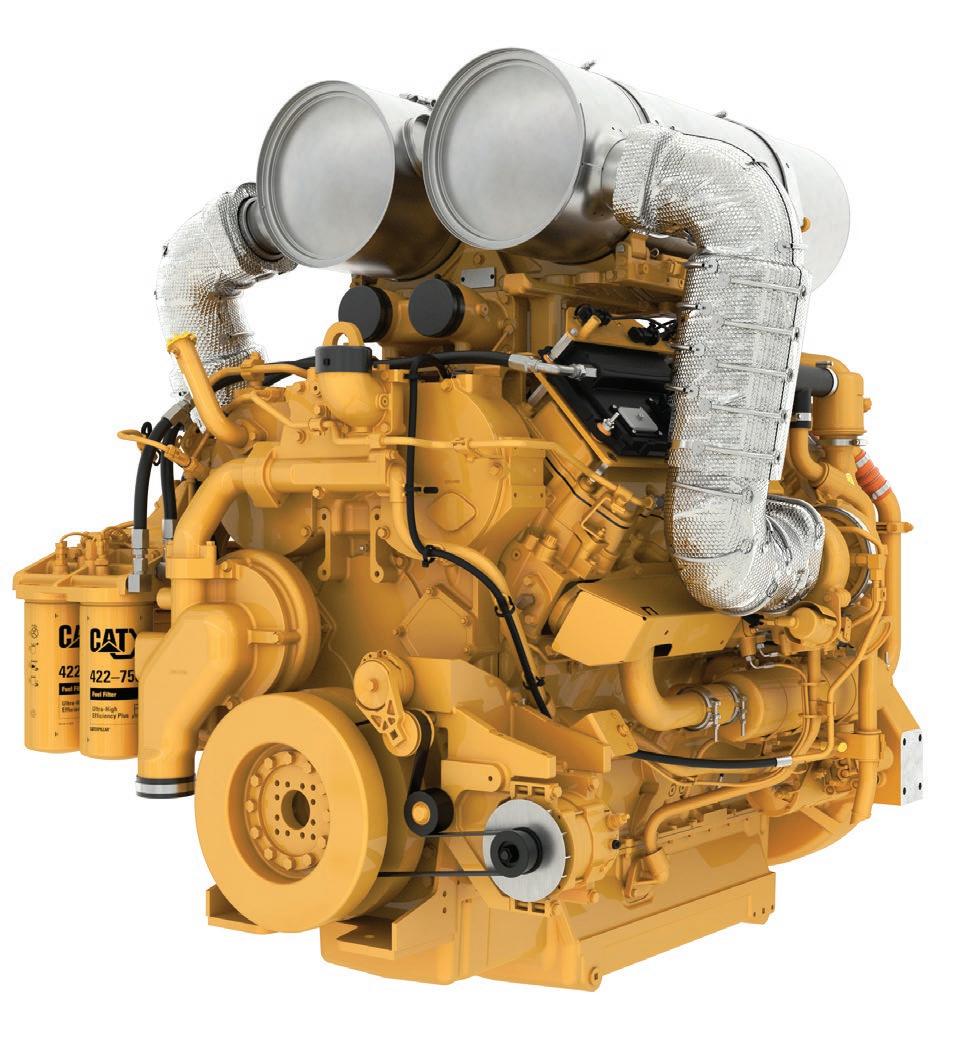

The new C32B builds on the success of the C32, offering improvements to boost reliability and increase durability.

Caterpillar has introduced the Cat C32B diesel engine, a new power platform featuring best-in-class power density and enhanced durability for large off-highway machines and equipment.

Available now at Cat dealers worldwide, the new 32.1-liter, 12-cylinder engine has been re-engineered with numerous design improvements to boost power density and reliability while extending the time between rebuilds when compared with the previous generation engine

on newly developed engine ratings.

Power without compromise

The C32B reliably delivers power up to 895 kW (1200 hp) and 5,861 Nm (4,323 lbft) for U.S. EPA Tier 4 Final and 839 kW (1,125 hp) and 5,499 Nm (4,056 lb-ft) for EU Stage V. A version for less regulated territories offers a peak rating of 1,007 kW (1,350 hp) and 6,166 Nm (4,548 lb-ft).

The engine is ideal for large loaders, cranes, dredgers, hydraulic power units, paving,

surface hauling equipment, trenchers, pumps, forestry equipment, compressors and bore/drill rigs, among other applications.

“For nearly 20 years, the Cat C32 engine platform has set the standard for premium power and endurance in construction, mining and other industrial applications,” said Steve Ferguson, senior vice president of Caterpillar Industrial Power Systems. “The new Cat C32B builds on this field-proven reputation with a series of upgrades and new

technologies that will drive the superior performance of off-highway equipment for years to come.”

The new C32B engine has been redesigned from the bottom up with power density and durability in mind. The new engine block is made from a strong cast-iron alloy known for its durability with internal changes made to increase structural capability.

The induction hardened crankshaft includes larger journal diameters and increased bearing area to handle higher loads. The connecting rods also include larger journals to increase durability by optimizing bearing performance.

an optimized water jacket geometry to improve heat transfer.

An improved lube system offers a higher capacity oil pump, an oil cooler with improved performance and higher flow piston cooling jets ensuring optimal wear performance and improved durability.

To improve reliability, the C32B has a thicker shim gasket than its predecessor to increase head-to-block sealing. The piston for the new C32B features increased compression height enabling increased power density for select applications. The cylinder head has been upgraded to include design features that integrate external fuel lines along with

Additionally, the cylinder head components feature updated valve geometry and oil metering stem seals to reduce wear and extend cylinder head life. Its new dual sensor coolant protection feature detects potential cooling system leaks sooner to avoid costly downtime.

The C32B features dualcan diesel oxidation catalyst (DOC) aftertreatment, a maintenance-free, passive aftertreatment solution that eliminates the need for thermal management or regeneration. With flexible mounting options, this technology simplifies the aftertreatment solution, helps overall package size and reduces opera-

Loftness Specialized Equipment introduces the first auxiliary hydraulic cooler to be specialized for the new Kubota SVL97-3 compact track loader.

Offering an industry-leading cooling performance of up to 150,000 BTUs per hour, the Cool Flow is available with a custom roof mount specifically developed for the SVL97-3 to help increase ma-

chine performance and minimize heat-related downtime.

The Cool Flow features two 14-inch-diameter fans, which are automatically controlled by a thermostat. It is engineered to allow full hy-

tional costs by minimizing total fluid consumption and eliminating infrastructure requirements associated with diesel exhaust fluid (DEF).

The new Cat C32B engine platform enables the use of renewable liquid fuels such as 100% HV. Fuels must meet the specifications and characteristics described on cat. com in order to be used in Cat engines and reduce the risk of downtime.

Industrial power units (IPU) configured with engine-mounted aftertreatment and cooling packs will also be available from the factory, helping to reduce installation and validation costs for original equipment manufacturers (OEMs). SP

Source: Caterpillar

draulic flow to attachments from either direction, providing flexibility to use with multiple attachment styles.

A heavy-duty steel frame gives the Cool Flow outstanding durability, while its lowprofile design minimizes the risk of contact from overhead obstructions. Additionally, it includes easy-access screens for simplified maintenance and debris removal.

“Dealers are finally starting to receive the highly anticipated SVL97-3, and we’re prepared with the industry’s first auxiliary hydraulic cooler to be compatible with it,” said Shannon McComas, Vice President, Sales & Marketing of Loftness Specialized Equipment. “The Cool Flow is an excellent accessory to protect your track loader investment against heat-related damage and help maximize performance in the toughest operating conditions.” SP

Source: Loftness

Before imitators even knew what to copy, CBI had already spent decades perfecting it.

With over years of grinding innovation behind us, the patented offset helix rotor remains at the core of the industry’s most productive machines; not just holding up in the field but dominating it.

CBI didn’t just build grinders - we engineered a better way to grind. The offset helix rotor, a product of years of innovation and field refinement, set a new standard for what industrial horizontal grinders could do. With years of proven success in forestry, land clearing, and biomass applications, CBI’s rotor design isn’t just an upgrade - it’s a benchmark.

At the center of every CBI grinder is our patented offset helix rotor - a design that’s earned its reputation through relentless performance and efficiency. Unlike traditional

straight or staggered rotor setups, the offset helix delivers a continual diagonal striking sequence, maximizing the power of every impact while minimizing energy loss.

This unique configuration requires less power to rotate, increasing fuel efficiency without sacrificing throughput. As material is washed diagonally across the rotor, wear is distributed evenlyextending the life of internal components and keeping machines running stronger, longer.

Rotor Performance

Advantages

• Continual diagonal striking sequence for aggressive, efficient grinding

• Lower power demand, higher productivity

• Material flow washes

FAE is upgrading its range of MTL multitask heads for the Construction sector, making them compatible with tractors up to 300 hp and available in the new MTL-250 width.

The MTL enables soil stabilization, asphalt and rock slab shredding, and stone crushing, down to a maximum operating depth of 28 cm. The FAE MTL multitask head has been designed for the maintenance and upgrading of dirt, gravel, and asphalt roads. The variable-geometry grinding chamber, adjust -

across rotor to reduce concentrated wear

• Delivers cleaner, more consistent sizing

• Offset helix design delivers full power with every strike, maximizing impact efficiency.

The Original Advantage

• Some grinders may attempt to imitate the look of a CBI, but they can’t replicate the performance, durability, or innovation that’s been built into every machine we’ve ever made.

• Competitors often mimic the design - but without the engineering backbone and field-tested evolution behind our rotor, they simply fall short when it matters most.

• Performance isn’t a matter of marketing - it’s measured in uptime, output, and results. And that’s where CBI stands alone.

Proven in the Field

Trusted by the most demanding operations across North America, Europe, and beyond - CBI grinders are built to perform where others can’t. From high-volume biomass processors to land clearing crews working under pressure, professionals choose CBI because our equipment delivers. SP

Source: Terex CBI

able grille on the hood, and adjustable Hardox counter blade consistently enable optimal crushing results. Internal protection plates on the frame, bolted both centrally and laterally, ensure the head is robust and reliable while also guaranteeing excellent resistance to wear. The handy depth indicator allows you to check the operating level directly from the cab, and the central gearbox with universal-joint alignment system is designed to be compatible with a wide range of tractors on the market.

The new MTL is available in the following widths: MTL-150, MTL-175, MTL200, MTL-225 and MTL250. The head comes standard with G/3 teeth, with the option of G/3/HD teeth and R/65 or R/65/HD picks on a dedicated rotor. SP

Source: FAE

TW

Automated stockpile patterns Massive Capacity: Stockpile heights over 48’ 10” (14.9m) for 102,696 yd³ (78,517m³) Tool-Free Deployment/ Quick Setup Road Towable for easy transport User-Friendly Design

The ProStack range includes Telescopic Conveyors, Tracked Conveyors, Tracked Feeders, Bulk Reception Feeders, and Port Hoppers. Give us a call at 1-800-960-9939 to discuss your project.

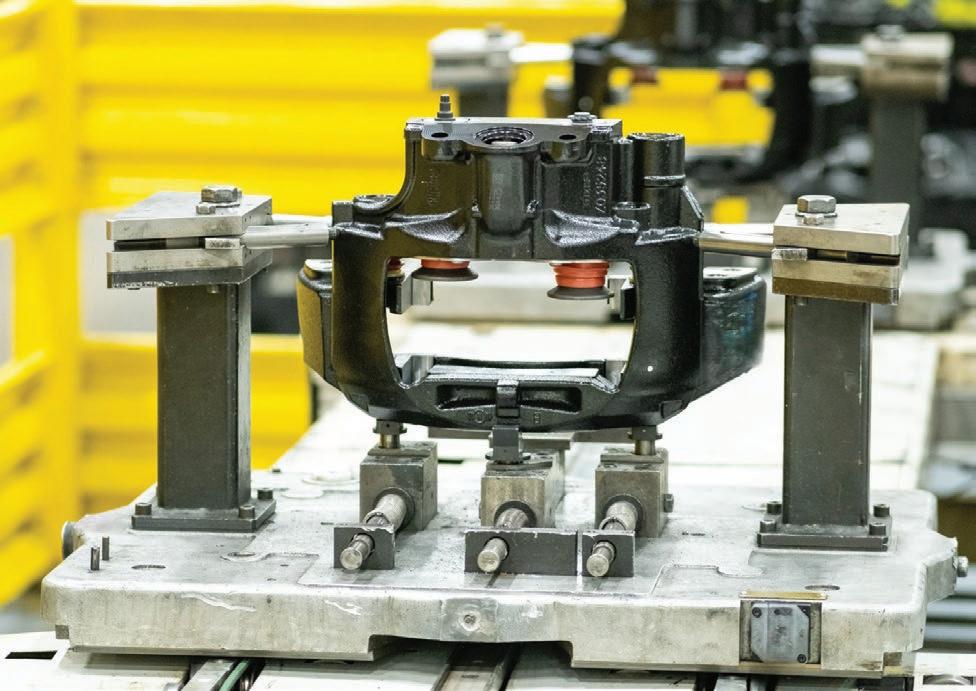

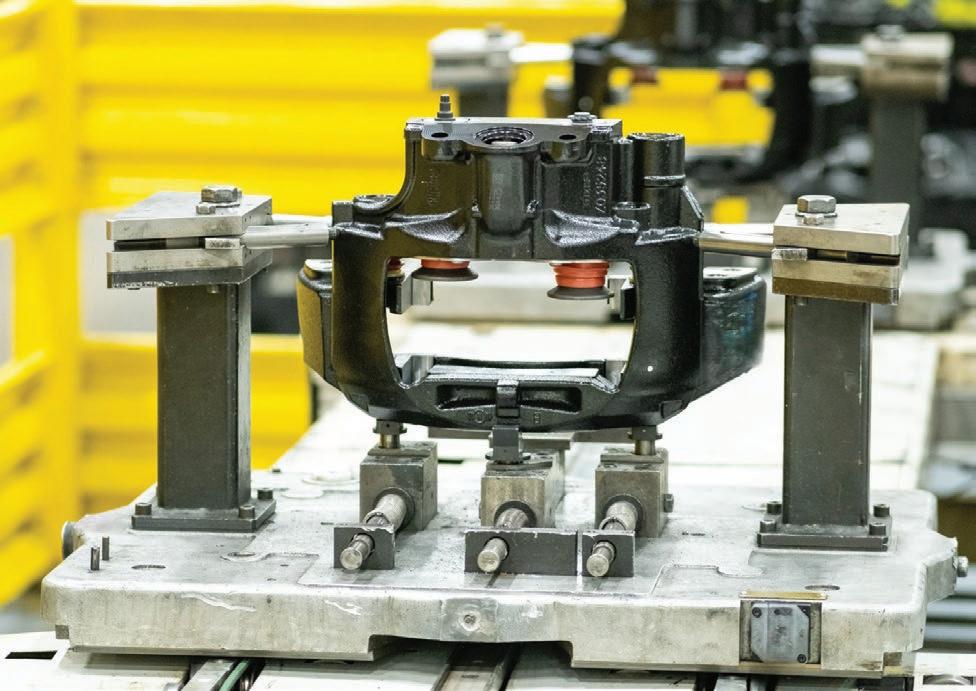

The most widely-adopted air disc brake across North America continues to set the standard for fleet value and reliability.

Bendix is celebrating 20 years of the Bendix ADB22X air disc brake (ADB) – a technology that has helped redefine commercial vehicle braking across North America. Since its 2005 debut, the ADB22X brake has delivered measurable gains in safety, performance, and maintenance efficiency, becoming the most widely equipped air disc brake in its class on the continent. With more than 7 million units produced for North America, the ADB22X continues to set the standard for fleet value and reliability.

Bendix, the North American leader in the development and manufacture of active safety, air management, and braking system technologies for commercial vehicles, is a part of Munich, Germanybased Knorr-Bremse, the global leader in air disc brake

production at more than 60 million and counting.

“The ADB22X air disc brake changed the way fleets and drivers thought about braking,” said Keith McComsey, technical sales lead for NA Wheel-End at Bendix. “With clear advantages in stopping power, reliability, and serviceability, it quickly became the go-to ADB for a wide range of vehicles. Two decades later, it continues to deliver daily value – and its legacy is still unfolding.”

Used on everything from line-haul tractors and refuse vehicles to school buses and construction trucks, the ADB22X has become a foundation of the Bendix wheel-end portfolio and a core enabler of the company’s broader mission to improve transportation safety and system efficiency.

As safety and life-cycle value rose to the forefront of fleet priorities, the Bendix ADB22X played a key role in accelerating the shift toward air disc brake spec’ing across North America – moving the technology from early adoption into widespread industry standard.

When the Bendix ADB22X air disc brake was first introduced, many fleets were still relying on drum brake systems characterized by shorter maintenance intervals and greater performance variability – especially in hightemperature or high-demand conditions. The ADB22X answered those challenges with a design focused on consistency, responsiveness, and durability.

Its shorter stopping distances and reduced brake fade made it an immediate safety upgrade for vehicles of all types, while its lightweight construction contributed to fuel economy and helped increase available payload. The brake also brought smoother, straighter, and more stable stops, as well as a car-like feel, additional performance advantages that increase driver satisfaction and retention. Safety was only part of the equation; for maintenance professionals and fleet operators, the ADB22X meant faster pad replacements –often taking one-quarter of the time compared to drum systems – and longer intervals between service, thanks to extended friction life and reduced component wear. Over time, the brake’s long-term impact on uptime, service, and total cost of ownership became just as central to its appeal as its

performance on the road –offering a compelling value proposition year after year.

“We built the ADB22X to solve problems that fleets were facing day in and day out,” McComsey said. “Its success is rooted in that philosophy: deliver measurable improvements, keep trucks moving, and never compromise on safety.”

Another key differentiator is Bendix’s ability to provide a complete ADB system – including the caliper, chamber, actuator, rotor, friction, and wear-sensing electronics – all engineered to work together for maximum performance and reliability. This vertically integrated approach eliminates piecemealing and ensures a fully optimized brake package.

The brake system has also evolved over time, incorporating new friction formulations and design adjustments to serve a broader array of vehicle types – from

on-highway tractors to vocational and medium-duty applications. Bendix ADB22X air disc brakes are available through all the major truck manufacturers, where they are offered standard on a range of models.

As advanced driver assistance systems (ADAS) have become more common in commercial vehicles, the Bendix ADB22X air disc brake has emerged as a key enabling technology behind them. Systems like collision mitigation and lane-keeping assistance depend on precise, consistent braking output at the wheelend in order to respond effectively in dynamic driving conditions. And for that, fleets and OEMs have increasingly turned to air disc brakes.

“No matter how advanced the control algorithms or how many sensors you add

Freightliner has announced that, beginning with 2026 builds, all Freightliner M2 106 Plus, eM2, and M2 112 Plus models will feature advanced LED headlights as standard equipment.

This upgrade underscores Freightliner’s commitment to delivering safety, comfort, and operational value to medium-duty truck customers.

The new LED headlights feature a daylight-like white light with 6,000K color temperature, similar to natural sunlight. This lighting quality enhances visibility and supports driver awareness of road hazards, signage, and pedestrians. An optional automatic deicing feature keeps headlights clear in snow, ice, or freezing rain, ensuring reliable performance in all conditions without the need for manual driver intervention. Build to withstand harsh environmental conditions, the LED headlamp system is engineered for longevity, with a lifespan of up to 30,000

hours. This extended service life translates directly into reduced maintenance needs, fewer service interruptions, and lower replacement costs over the vehicle’s lifetime. They are also fully compatible with previous M2 Plus series and legacy models, allowing for easy upgrades across existing fleets.

“Whether navigating city streets before dawn or traveling rural roads after dark, by making advanced LED headlights standard across the entire M2 Plus line-up, we’re ensuring the driver is equipped with technology that supports safety, uptime and confidence on the road, no matter the route or conditions,” said Joanna Buttler as general manager, product strategy and market development at Daimler Truck North America.

Freightliner continues to lead the industry by implementing technologies that enhance safety, efficiency, and uptime for customers. With this enhancement, the entire Freightliner Cascadia and M2 Plus portfolio will feature allLED lighting starting January 2026. SP

Source: Freightliner

We’re excited to announce that we’re now your official Flail-Tec dealer for British Columbia! If you’re in the forestry, land clearing, or Agri industries, Flail-Tec has a mulcher to suit your application.

Whether you’re running a compact excavator, a 36-tonner, or a tractor, Flail-Tec has an extensive range including:

Hydraulic Mulchers (E1, E2, E3, E4 & E5):

Robust double-skinned chassis, with flail, 360 swinging hammer or fixed tooth rotors, PowerPulse torque boost, and sizes to suit 1.5-36T machines.

PTO Mulchers for Tractors:

Perfect for orchards, pasture, heavier brush or Forest clearing. Available with Flails, 360 hammers or fixed teeth.

Designed, manufactured and tested in Co. Tyrone, Ireland, made to withstand demanding conditions and now available right here in British Columbia. Give us a call or stop by - we’ll get you set up with the right machine for your work.

to a system, everything comes down to whether the brakes can perform in the critical moment,” said Rick Conklin, director of engineering, Wheel-End, at Bendix. “That’s why the ADB22X is such a vital part of ADASequipped vehicles. It offers a level of responsiveness and thermal stability that drum brakes can’t match.”

Conklin also emphasized the role the ADB22X plays in supporting quiet, lowemission vehicle environments. The brake’s consistent engagement and lower NVH (noise, vibration, and harshness) profile help reduce noise pollution and contribute to a smoother, more comfortable driving experience – goals that align with both regulatory pressures and fleet expectations.

As commercial vehicle adoption of air disc brakes has grown across North America – with rates on Class 6-8 vehicles topping 50%, up from approximately 25% in 2018 – Bendix has responded with continued investments in its manufacturing footprint. The company’s Bowling Green, Kentucky, facility, which has supported ADB production since the system’s earliest days and now houses the largest installed capacity for air disc brake production on the continent, has seen multiple expansions in support of increasing demand.

“Our ability to scale ADB production while maintaining quality and performance has been a critical part of our success,” McComsey said.

“The Bowling Green plant represents not just manufacturing capacity, but our longterm commitment to making these technologies available and accessible to customers across the industry.”

Bendix also draws on Knorr-Bremse’s global research and development capabilities – including engineering centers in Germany – to support product innovation tailored to North American needs. Testing labs feature advanced dynamometers, NVH evaluation tools, and lifecycle simulation environments that replicate the extreme conditions common on North American roads.

Alongside production scaling, Bendix has enhanced its testing and R&D capabilities. From advanced simula-

tion and dynamometer testing to corrosion resistance and thermal cycling evaluation, the company continues to develop the brake with both present-day performance and future-readiness in mind.