2022

MSRP: $55,400 Starting at $44,900

•

4 FINAL 225 hp (168kW); 4.2cu yd GP QC Bucket; Operating weight 44,423lbs; Deluxe cab

(230mm) WIDE; 2-Speed travel system auto shift w/travel alarm; Manual Wedge Coupler; 12” Dig bucket; 24” Clean up bucket; Hydraulic Thumb; Dozer Blade; *Financing is NOT available* MSRP: $34,250 Starting at $17,999

2020 CAT 320GC, Stk #93665, Cab, A/C & Heater, Dig Bucket, FMS Quick Attach & FMS Hyd. Thumb, BU Camera, Radio, 2-Spd. Travel Motor, Block Heater, Good U/C w/ New 600mm Triple Grouser Pads, Good Paint & Cosmetics – For Rent or For

2018 CAT 336FL, Stk #93654, A/C & Heat, Straight Travel Pedal, A/R Seat, R/V Cam, 10’ 6” Stick, Q/C, 72” Bkt. w/ Serrated Edge, Aux. Hyd. Plumbed to the end of Stick, 33.5” Triple Grouse Pads, Good Paint & Cosmetics $250,000

2019 CAT 305.5e2, Stk #93652, Enclosed Cab, A/C & Heater, Radio, 77” Piling Blade, 28” Cat Dig Bucket w/ Side Cutters, Aux. Hydraulics Plumbed to End of the Stick, 16” Triple Grouser Pads, 2.75” Rail Height - For Rent or For Sale $85,000

2011 CAT D6T XW, Stk #93615, A/C & Heat, Powershift Trans. w/ Diff. Steering, 160” Pat Dozer Blade, Standard U/C w/ 31” Single Grouser Pads w/ Ice Lugs, New Idlers, Bottom Rollers, Sprockets & Track Group, Winch $275,000

2020 CATERPILLAR 307, Stk #93650, Enclosed Cab, A/C & Heater, Radio, 92” Blade, Hyd. Thumb, Dig Bucket, Aux. Hydraulics Plumbed to End of the Stick, 17.5” Triple Grouser Pads, 3” Rail Height, Good Paint & Cosmetics - For Rent or For Sale $110,000

New Allu Dh3-17, w/ Axe Blades 25/50mm Drums, Stk #AL7559, Adj. Blades Between 25mm & 50mm Screens, Crusher Screener Bucket, Dual Motors, Three Drum Bucket, 1.7m Wide, New w/ Warranty, Couple w/ a Variety of Machines – For Rent or For Sale CALL

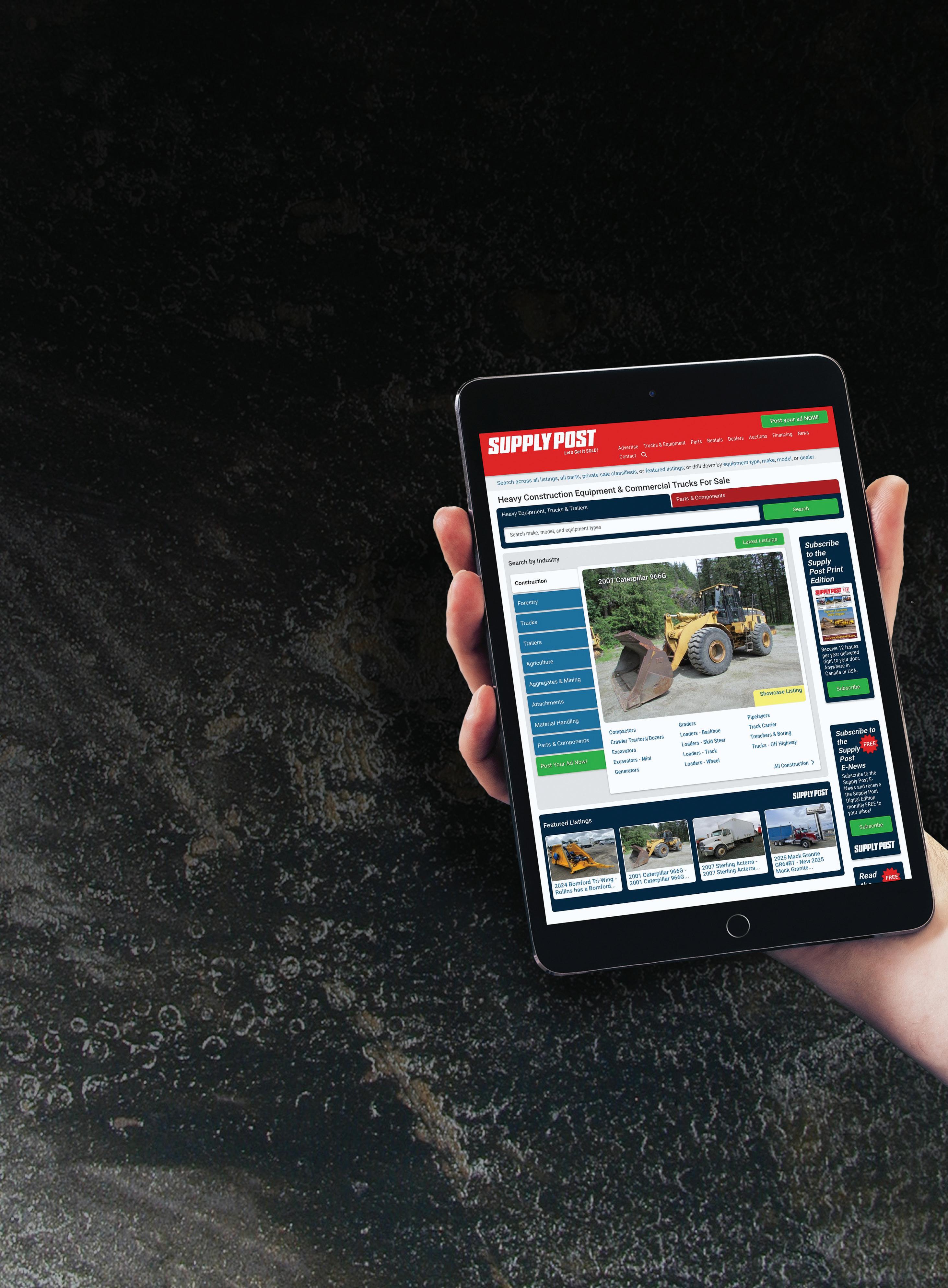

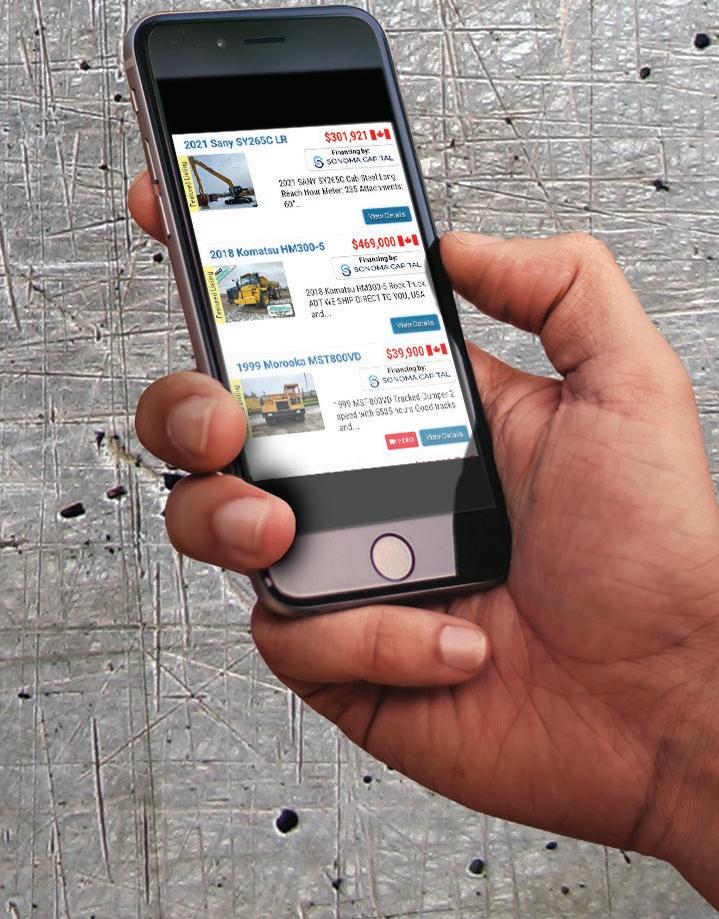

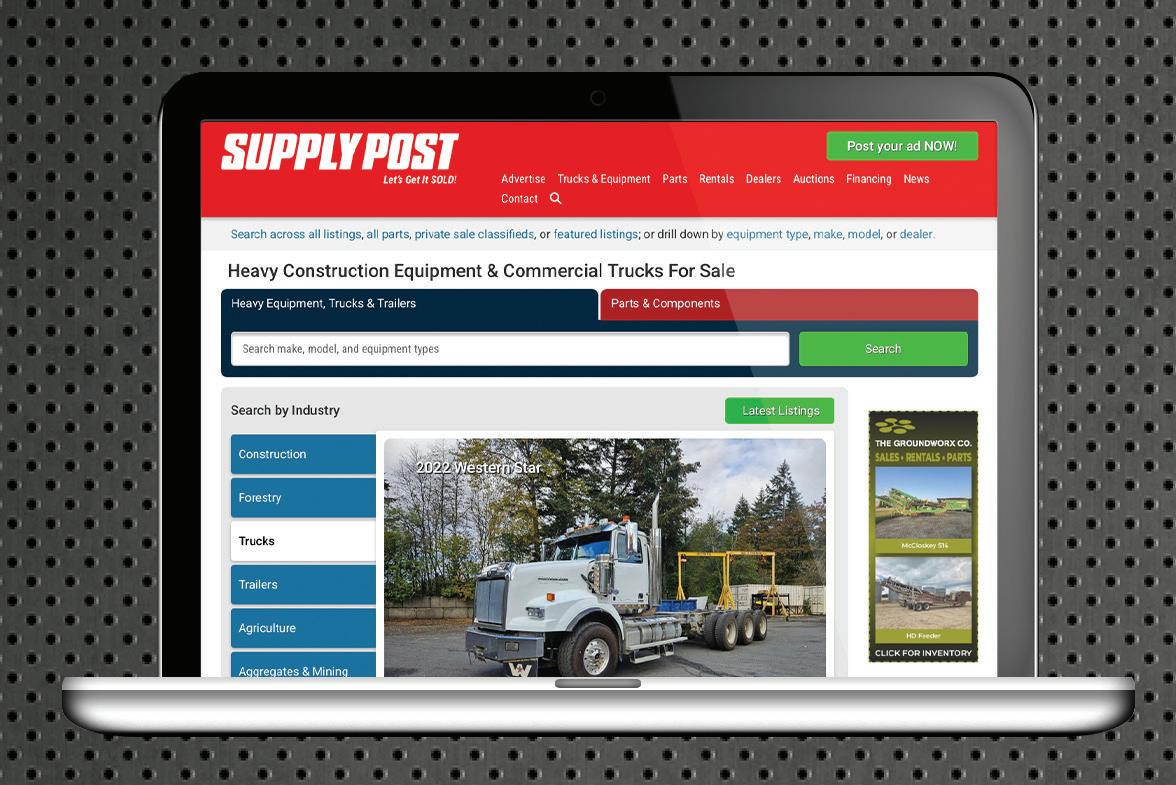

For over 53 years, our family-owned newspaper has connected hardworking Canadians in the heavy equipment and trucking industries.

Since 1971, Supply Post has been committed to supporting this vital sector by providing a trusted marketplace for buying and selling quality equipment and trucks.

Today, more than ever, it’s crucial that we continue to invest in our own economy by buying Canadianmade products, purchasing from Canadian businesses, and supporting local sellers.

Every time we choose a Canadian-made machine or

truck, or buy from a Canadian dealer or private or local seller, we are keeping skilled tradespeople employed, strengthen our manufacturing sector, and ensure that our money stays within our own communities. The same applies when we purchase parts, tools, and services from Canadian suppliers. These decisions sustain jobs and drive innovation right here at home.

In light of recent political events, we have decided to

highlight articles that have a Canadian origin. We know this is complicated, with our intertwined supply chains and manufacturing. Look for the following symbol in an article; it will have some kind of Canadian origin:

Whether it is partially manufactured in Canada, assembled, or contains Ca-

nadian parts, or the owners are based in Canada, we hope that it will spotlight Canadian products.

The challenges of recent years have reminded us of the importance of economic resilience. When we prioritize local businesses, we ensure that Canada’s heavy equipment and trucking industries remain strong for future generations. Next time you’re making a purchase, consider where your money is going. Let’s keep it local, keep it Canadian, and keep our industry thriving.

Since 1971, the Supply Post has proudly served as a resource for buyers and sellers throughout BC and across the country. We are 100% Canadian family owned and operated and we will continue to champion Canadian businesses. SP

Jeff Watson is owner and president of Supply Post Newspaper. He can be reached at jeff.watson@sup plypost.com or give him a call at 1-800-663-4802.

EXCAVATORS

2022 YANMAR SV08-1D RUBBER, 2 BKTS, HYD THUMB, 268 HRS CALL

2023 YANMAR VIO17-A CANOPY, 2 BKTS, HYD THUMB, 423 HRS CALL

2023 YANMAR VIO17-A CANOPY, 2 BKTS, HYD THUMB, 372 HRS CALL

2023 YANMAR VIO17-A CANOPY, 2 BKTS, THUMB, AUX HYDS, 324 HRS CALL

NEW YANMAR VIO17-1E, RUBBER, CANOPY, DIG BKT CALL

2022 YANMAR VIO25-6A, CAB HEAT, RUBBER, HYD THUMB, 2 BKTS, 725 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, 2 BKTS, HYD THUMB, 160 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, 2 BKTS, HYD THUMB, 286 HRS CALL

2022 HITACHI ZX35U-5 RUBBER, CAB AIR, L ARM, 2 BKTS, THUMB, 499 HRS CALL

2023

YANMAR VIO35-6A, CANOPY, BLADE, 2 BKTS, HYD THUMB, 139 HRS $55,500

2022 YANMAR VIO35-6A, CANOPY, RUBBER, 2 BKTS, THUMB, AUX, 248 HRS CALL

2023

YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 390 HRS CALL

YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 348 HRS CALL

2023

2024 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 352 HRS CALL

2024 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 426 HRS CALL

NEW YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB CALL

2010 HITACHI ZX40U-3 STEEL BOR, CANOPY, PIPING, 2,894 HRS CALL

2017 KUBOTA KX40-4, CAB AIR, 6 WAY DZR, 4,287 HRS, DIG BKT CALL

2018 KUBOTA KX40-4, CAB AIR, ANGLE BLADE, THUMB, DIG BKT, 3,560 HRS CALL

2023 YANMAR SV40, CAB AIR, 2 BKTS, HYD THUMB, 563 HRS CALL

2023 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 496 HRS CALL

2023 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 389 HRS CALL

NEW YANMAR SV40, PAT DOZER BLADE, 2 BKTS, HYD THUMB CALL

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 209 HRS CALL

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, 2ND PTO, 203 HRS CALL

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX HYDS CALL

NEW YANMAR VIO50-6A, CAB AIR, RUBBER, 2ND PTO CALL

2020 YANMAR VIO55-6A, AIR, 2 BKTS, THUMB, AUX HYDS, 2,893 HRS $59,900

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 784 HRS FOR RENT

2023 YANMAR VIO55-6A, CAB AIR, HYD THUMB, 2 BKTS, AUX, 890 HRS $80,500

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 657 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 677 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 606 HRS CALL

2023 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 288 HRS CALL

2024 YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 142 HRS CALL

NEW YANMAR VIO55-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX HYDS CALL

2020 HITACHI ZX75US-5B, BLADE, PIPING, ONLY 2,103 HRS CALL

2021 HITACHI ZX75US-5B, BLADE, PIPING, ONLY 1,212 HRS CALL

2019 CAT 308CR-07A, BLADE, AUX PIPING, ONLY 2,048 HRS CALL

2023 YANMAR VIO80-1A, RUBBER, CAB AIR, 2 BKTS, HYD THUMB, 1,068 HRS CALL

2023 YANMAR VIO80-1A, RUBBER, CAB AIR, 2 BKTS, HYD THUMB, 832 HRS CALL

2023 YANMAR VIO80-1A, RUBBER, CAB AIR, 2 BKTS, HYD THUMB, 577 HRS CALL

2023 YANMAR VIO80-1A, RUBBER, CAB AIR, 2 BKTS, HYD THUMB, 432 HRS CALL

2023 YANMAR VIO80-1A, STEEL, CAB AIR, 2 BKTS, HYD THB, AUX, 267 HRS CALL

2023 YANMAR VIO80-1A, RUBBER, CAB AIR, 2 BKTS, HYD THB, AUX, 73 HRS CALL

NEW YANMAR VIO80-7 RUBBER, CAB AIR, PTO 2 CALL

2023 YANMAR SV100-2A, RUBBER, AIR, 2 BKTS, HYD THB, AUX, 1,051 HRS CALL

2023 YANMAR SV100-2A, STEEL, CAB AIR, HYD THUMB, 2 BKTS, 882 HRS CALL

2023 YANMAR SV100-2A, RUBBER, AIR, 2 BKTS, HYD THB, AUX, 1,015 HRS CALL

2023 YANMAR SV100-2A, RUBBER, AIR, 2 BKTS, HYD THUMB, AUX, 867 HRS CALL

2023 YANMAR SV100-2A, RUBBER, AIR, 2 BKTS, HYD THUMB, AUX, 555 HRS CALL

2023 YANMAR SV100-2A, RUBBER, AIR, 2 BKTS, HYD THUMB, AUX, 438 HRS CALL

NEW YANMAR SV100-7 RUBBER, CAB AIR, 2 BKTS, HYD THUMB, AUX CALL

NEW YANMAR SV100-7 RUBBER, CAB AIR, PTO 2, HYD Q/C CALL

2025 YANMAR SV100-7, STEEL, CAB AIR, PTO 2, HYD Q/C CALL

2017 CAT 312F GC, 20" PADS, AIR, ONLY 2,868 HRS CALL

2019 CAT 312F GC, 20" PADS, AIR, ONLY 2,168 HRS CALL

2008 HITACHI ZX135USK, 20" PADS, 2 BKTS, HYD THUMB, 14,900 HRS $39,900

2008 HITACHI ZX135US-3, 20" PADS, AIR, ONLY 5,108 HRS $58,900

2011 HITACHI ZX135USBL-3 20" PADS, BLADE, 8,736 HRS CALL

2017 HITACHI ZX135US-6, REAR & SIDE CAMERAS, ONLY 2,560 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, HYD THUMB, 2,182 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, HYD THB, AUX, 3,407 HRS $137,900

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, Q/C, HYD THUMB, 2,073 HRS CALL

2018 HITACHI ZX135US0S-6, BLADE, O/S BOOM, 1,551 HRS, Q/C, 2 BKTS $99,900

2018 HITACHI ZX135USBL-6 20" PADS, BLADE, ONLY 2,541 HRS CALL

2019 HITACHI ZX135USBL-6 20" PADS, BLADE, AUX PIPING, 4,213 HRS CALL

2020 HITACHI ZX135USBL-6 BLADE, CABGUARDS, ONLY 2,040 HRS, 2 BKTS, Q/C, PRO LINK HYD THUMB $169,900

2020 HITACHI ZX135USBL-6, 20" PADS, BOR, BLADE, 2,260 HRS SOON

2020 HITACHI ZX135USBL-6, BLADE, AUX HYD PIPING, 1,451 HRS CALL

2020 HITACHI ZX135USBL-6, BLADE, AUX HYD PIPING, 1,565 HRS CALL

2020 HITACHI ZX135USBL-6, 20" PADS, BLADE, 1,212 HRS CALL

2020 HITACHI ZX135USBL-6 20" PADS, BLADE, AUX HYDS, 1,430 HRS SOON

2021 HITACHI ZX135US-6, 20" PADS, AIR, ONLY 71 HRS CALL

2022 HITACHI ZX135USBL-6, 28" PADS, AIR, BLADE, AUX HYDS, 1,490 HRS CALL

2021 CAT 315 GC 07, 28" PADS, BLADE, Q/C, 2 BKTS, HYD THB, 1,161 HRS $192,500

2022 CAT 315 07, 2D, BLADE, 2 BKTS, HYD THUMB, AUX HYDS 1,014 HRS CALL

2022 CAT 315 07 2D, BLADE, 2 BKTS, HYD THUMB, 999 HRS CALL

2022 CAT 315 GC BLADE, 2 BKTS, HYD THUMB, ONLY 249 HRS CALL

2022 CAT 315 GC, 20" PADS, BOR, BLADE, ONLY 227 HRS SOON

2023 CAT 315 GC, BLADE, Q/C, DIG, WRIST BKT, AUX HYD, 475 HRS $224,900

NEW CAT 315 GC 07, 20" PADS, BOR, BLADE, AUX PIPING, DIG, NEW CALL

2022 CAT 320 07, 24" PADS, AIR, AUX HYDS, 2D, ONLY 999.3 HRS CALL

2023 HITACHI ZX160LC-6, BOR PADS, ONLY 79 HRS, DIG BKT

$174,900

2018 HITACHI ZX200-6, Q/C, DIG & CLEAN UP BKT, 5,182 HRS $103,500

2021 HITACHI ZX200-6, 24" PADS, AIR, AUX HYDS, ONLY 1,296 HRS CALL

2019 HITACHI ZX200LC-6, 32" PADS, AUX HYD PIPING, ONLY 1,362 HRS CALL

2020 HITACHI ZX225USR-6, 24" PADS, AIR, AUX PIPING, ONLY 2,712 HRS CALL

2020 HITACHI ZX225US-6, 24" PADS, AIR, AUX PIPING, ONLY 1,950 HRS CALL

2015 HITACHI ZX245USLC-5N, Q/C, 2 BKTS, PRO LINK HYD THUMB, CABGUARD, CATWALKS, 8,808 HRS $119,900

2019 DEERE 245G LC-6, Q/C, PRO LINK HYD THUMB, 2 BKTS, 2,320 HRS $209,900

2021 HITACHI ZX245USLC-6, Q/C, 2 BKTS, HYD THUMB, 3,347 HRS CALL

2021 HITACHI ZX245USLC-6, Q/C, 2 BKTS, THB, WINDOW GUARD, 3,174 HRS CALL

2018 HITACHI ZX250LCK-6 AIR 2 BKTS, HYD THUMB, ONLY 3,296 HRS $189,900

2021 HITACHI ZX330-6 AIR, 2 BKTS, HYD THUMB, 938 HOURS CALL

2021 CAT 336 07C, 28" PADS, AIR, ONLY 778 HRS, 2 BKTS, HYD THUMB, CATWALKS, CABGUARD, 2D EQUIPPED CALL

LOADERS/DUMPERS/DOZERS

2012 YANMAR V3-6, CAB HEAT, GP BKT, ONLY 2,924 HRS CALL

2018 YANMAR V4-7, CAB AIR, HYD Q/C, AUX HYDS, ONLY 1,137 HRS CALL

2024 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT, 56 HRS

YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT CALL

2023 CANYCOM SC75PDH PIVOT DUMP CARRIER 2,200

YANMAR C12R, RUBBER, DUMPER,

YANMAR C30R-3, SWIVEL DUMP,

YANMAR C30R-3, STANDARD DUMPER,

2021 YANMAR C30R-3R SWIVEL DUMP, 5,513 LB PAYLOAD, 619 HRS

2022 YANMAR C50R-5AR, AIR, SWIVEL DUMP, 8,379 LB, 610 HRS $109,900 2023 MOROOKA MST110 CR 360 SWING DUMPER, 24,000

& 8 CU YD

2022 TERRAMAC RT14R 360 SWING DUMPER, 28K LB, ONLY 460 HRS $224,900

2014 CAT 730, 750/65R25 TIRES, RV CAMERA, AIR RIDE SEAT, PAS, HEATED BODY, TAILGATE, 9,756 HRS CALL

2021 CAT D6LGP, 6 WAY FOLDING BLADE, MS RIPPER, ONLY 522 HRS CALL

SKID STEERS/COMPACTORS

2021 BOBCAT T76 R SERIES, CAB AIR, JOYSTICK, HYD Q/C, 74" BKT, 2 SPEED, 1,871 HRS, BRAND NEW ENGINE JUST INSTALLED (WARRANTY) $66,000

2025 YANMAR TL75VS, 67" BKT, 74 HP, CAB AIR, HI FLOW, RVC SALE OR RENT

2024 YANMAR TL100VS, 84" BKT, 104 HP, ROC 3,600 LBS, NEW, 102 HRS CALL

2024 YANMAR TL100VS, 84" BKT, 104 HP, ROC 3,600 LBS, NEW MODEL CALL

2011 VOLVO SD25D, 41" DRUM DRIVE, PADFOOT SHELL KIT, 1,135 HRS $39,900

2012 VOLVO SD45D, 54" DRUM, CANOPY, ONLY 1,365 HRS CALL

2018 SAKAI SV204TF, 54" BOLT ON SHELL KIT, CANOPY, 616 HRS CALL

2006 ING RAND SD70D TF 66" SMOOTH DRUM, SHELL KIT, EXC COND $44,900

2014 SAKAI SV513D, 84" SMOOTH DRUM, CAB AIR, 1,771 HRS $104,900

2021 SAKAI SV544DC, 84" SMOOTH DRUM, CAB AIR, 3,201 HRS CALL TRUCKS/TRAILERS

2013 FORD F750XL CUMMINS 6.7L, 6 SPEED, KLEIN 2,000 GAL TANK, PTO PUMP, FRT, REAR & SIDE SPRAY CALL

2005 FREIGHTLINER M2 106, CAT C7 ENG, ALLISON AUTOMATIC, 2,500 GAL SUPREME TANK, PUMP, FRONT, REAR, SIDE SPRAY, 251K MILES CALL 1990 WESTERN STAR KG105 60 SERIES DETROIT, 18 SPEED, NAHANNI HIGH LIFT BOX $26,000

20

2 HITACHI ZX345USLC-6, 2 BKTS, HYD THUMB, CABGUARD

6 HITACHI ZX330/ZX350LC-6, 2 BKTS, HYD THUMB

DOZERS

CAT D3K2 LGP, 6 WAY DOZER, CAB AIR, 80HO, 20K LBS

2 KOMATSU D39/RIPPER, 6 WAY, CAB AIR KOMATSU D71PXI PAT/RIPPER, 6 WAY DOZER, MS RIPPER, “I” MACHINE

LOADERS

2 YANMAR V4-7, CAB AIR, BOBTACH Q/C, .91 CU YD BKT

8 KOMATSU WA200/250/270/320, 2.5-3.75 YD KOMATSU WA380-8, FORKS, BKT

CAT 950K, FORKS, BKT GRADERS/COMPACTORS

2 CORNIVER CT40 40” SMOOTH DRUM, KUBOTA ENG

8 CORNIVER CT48 48” SMOOTH DRUM, KUBOTA ENG

8 SAKAI SV204/VOLVO SD45, 45” SMOOTH DRUM, CANOPY

8 SAKAI SV414/VOLVO SD75, 67”/66” DRUM, CAB AIR

4 SAKAI SV544, 84” SMOOTH DRUM, CAB AIR CAT 140M, 14 TIRES, SCARIFIER, CAB AIR

TRUCKS

CANYCOM SC75 SWIVEL DUMP

MST700 VDR

MOROOKA MST 110CR 6 YANMAR

Ballard Power Systems has announced the signing of a new Long Term Supply Agreement with Canadian Pacific Kansas City, including the initial supply of 98 fuel cell engines for use in the North American freight rail market.

Each engine has a nameplate of 200 kW, totaling approximately 20 megawatts (MW) of fuel cell power. Deliveries of all 98 engines are expected in 2025.

The LTSA builds on an existing partnership between Ballard and CPKC, which started in 2021, and has included delivery of approximately 10 MW of fuel cell

engines to date and the successful integration of Ballard fuel cell engines into hydrogen-powered locomotives for regular switching and freight service applications in Alberta, Canada. The fuel cell engines purchased from Ballard will support the expansion of CPKC’s hydrogen locomotive program.

“We are thrilled with the

opportunity to further develop our strategic relationship with CPKC to decarbonize not only their locomotive fleet but also participate in the electrification of freight rail across North America,” said Randy MacEwen, President and CEO of Ballard Power.

“This order represents a step forward in CPKC’s decarbonization vision and confidence in hydrogen fuel cells as a potential long-term replacement of diesel engines, providing the environmental benefits along with long range, fast refueling, heavy payloads, and cold weather operation.”

Prototype diesel freight locomotives retrofitted with hydrogen fuel cells, hydrogen storage and battery packs have undergone various testing at CPKC since 2022. CPKC currently has three hydrogen locomotives in operation. SP

Source: Ballard

In order to reinforce the strategy of a single brand and to boost its differentiated offer globally, Nors has started a plan of roadshows in the various countries in which it is present, including Canada, with stops in British Columbia, Alberta, Manitoba, Ontario, and Atlantic provinces.

Highlighting the importance of this market for the organization’s legacy, this roadshow is taking place as part of Nors’ rebranding process and transformation journey, which has taken on a unique, transversal and global dimension, and is now designated as a single brand in all the geographies where it is present.

This new strategy and brand architecture will globally boost Nors’ differentiated offer, which in 2024 recorded an estimated turnover of $596.5 million Canadian dollars, and delivered 875 units of construction equipment, positioning itself as a benchmark player in the construction sector.

Positioning itself as a strategic market for Nors since 2020, with the acquisition of Strongco and then, in 2024, with Great West Equipment, the activity in Canada has been driven by the ability to provide innovative, high-quality solutions, adapted to the specific needs of this market and which add value for its customers.

Employing more than 760 collaborators and with a total of 36 branches in 8 provinces of the country,

the global roadshow in the Canadian regions reaffirms Nors’ commitment to the sustainable and innovative development of this market.

For Francisco Ramos, COO of the Nors Group, “The Canadian market is of great strategic relevance to Nors, both in the present and for our future, given its growth potential. Since 2020 we have been gradually bringing our 90+ years of experience and expertise to Canada, by building a value proposition based on high-quality products and partnerships, anchored in an excellent after-sales service, in close proximity to our clients. With this in mind, we are undertaking an ongoing investment process in excellent products and services, technology and infrastructures that will enable us to better serve our current and potential clients in the future.”

“The We Are One” roadshow will tour the different countries in which Nors is present, reinforcing the purpose of “Improving life and business through a service and equipment of reference, creating continuous value for all” and based on the values of

Legacy, Humanism, Ambition, Agility and Integrity.

Driven by progress and building on a legacy of more than 90 years, Nors adapts to market needs and transforms itself to elevate life and business through reference services and equipment. Now with a single brand, Nors operates globally in five business areas: Trucks and Buses, Construction Equipment, Agro, Aftermarket and Ventures. Thanks to the strategic change, it offers a diversified portfolio and integrated services, maintaining close and trusting relationships between partners, customers and the market.

Nors’ brand is present in seven countries and represents the main manufacturer brands in the business areas in which it operates, offering services, solutions and equipment to make everything work better, every day.

Nors has operated in Canada since 2020, in the construction equipment segment. In this market Nors employs more than 760 collaborators within 36 branches

and 8 provinces. It’s comprised of the former Strongco Corporation, a major heavy equipment dealer in Canada, which sells, rents and provides after-sales service for equipment used in various sectors, such as construction, infrastructure, mining, oil & gas, utilities, municipalities, waste management and forestry. It represents the main

equipment manufacturers with globally recognized brands, including Volvo Construction Equipment, Case Construction, Manitowoc Crane, National and Grove, Terex Cedarapids, Terex Trucks, Fassi, Sennebogen, Konecranes and SDLG.

The former Great West Equipment has been part of the Nors Group since March

2024, and is also part of Nors’ Construction Equipment segment. It is a dealer in construction and forestry equipment and also represents leading equipment manufacturers with globally recognized brands, including Volvo Construction Equipment, Madill, Metso, Sennebogen and Falcon. SP

Source: Nors

• 2020 Komatsu PC138USLC-II, 2 Bkts, Hyd. Q/C, Thumb, Exc. Cond., 2,300 Hrs. P.O.R.

• 2018 Hitachi ZX290LC-5N, 2 bkts, thumb, cabguard, catwalks, exc. cond., 3,800 hrs.

• 2018 Komatsu PC200LC-8, 3 bkts, Q/C, thumb, cabguard, catwalk, exc. cond., 1,772 hrs.

• 2017 Komatsu PC350LC-8, 3 bkts, thumb, cabguard, catwalks, exc. cond. 4,415 hrs.

• 2015 Komatsu PC170LC-10, 3 bkts, thumb, cabguard, exc. cond., 2,725 hrs.

• 2014 Komatsu PC88MR-8, 2 bkts, hyd. Q/C & thumb, swing boom and blade, 2,400 hrs.

• 2012 Komatsu D65EX-17, sigma blade, ripper & forestry guard., 75% U/C, exc. cond., 6,050 hrs.

• 2014 Hamm H13iX, 84” smoothdrum packer w/cab, A/C, low hrs, exc. cond.

• 2012 Hamm 3412, 84” smoothdrum packer w/shell kit, cab, A/C, exc. cond.

• 2014 Hamm 3307, 66” smoothdrum packer w/shell kit, cab, A/C, exc. cond.

customers. The dealership is located at 9300 192nd Street in Surrey, British Columbia, Canada.

Bobcat of Vancouver, a subsidiary of Surrey-based Cullen Diesel Power, has been named a newly authorized, full-line Bobcat Company dealership.

Featuring sales, parts, services and rentals, Bobcat of Vancouver offers a full line of machines, attachments and portable power units to customers throughout the Greater Vancouver Regional District.

“With our connection to Cullen Diesel Power, the history of our company goes back 100 years, so we have been servicing customers in the marine, mining, power generation, construction, industrial and highway markets

across North America for a long time,” said Paul Zhang, Chief Operating Officer at Bobcat of Vancouver. “Joining the Bobcat dealer network and offering a full line of Bobcat products and services is a good fit with what we do and the customers we already serve.”

Bobcat of Vancouver provides expert service and support to area landscaping firms, civil contractors, municipalities, farm operations, rental fleets and individual

“We believe Bobcat equipment, when paired with local support and rental options, provides the best value for our customers and helps make them and their businesses more successful,” continued Zhang.

As a full-line Bobcat equipment dealer, Bobcat of Vancouver offers compact track loaders, skid-steer loaders, mini excavators, mini track loaders, compact tractors, zero-turn mowers, telehandlers, backhoe loaders, portable power equipment, attachments and more.

“We are excited to partner with Bobcat of Vancouver and welcome them to our network of dealers,” said Ian Drugmand, director of channel development at Bobcat Company. “With their trusted reputation and longstanding history of service to many industries throughout Canada and beyond, we are excited about our new partnership and the value they bring to customers.” SP

Source: Bobcat

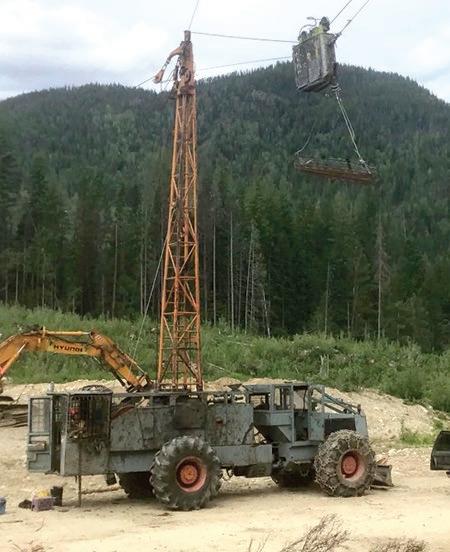

Tigercat launches remote control 120 Winch Assist, offering end-to-end Tigercat steep slope harvesting solution.

The new Tigercat 120 Cable Assist is Tigercat’s second model in the cable systems product line. Tigercat has long been recognized as the leader in conventional ground based steep slope harvesting. With the release of the 180 Swing Yarder and now, the 120 Winch Assist, Tigercat is leveraging its deep experience in steep slope harvesting systems to create cable systems that complement the ground-based machines. It is now possible to as-

semble a fully mechanized Tigercat steep slope harvesting system with the option for cable assisted feller bunchers, shovel loggers, track and wheel harvesters, skidders and forwarders, as well as the very capable 180 swing yarder.

The 120 Winch Assist is fully integrated with all the latest generation Tigercat steep slope capable carriers, providing seamless communications and optimal hydraulic efficiency. The 120 is

also designed to work without travel signal integration. The basic installation, requiring only the in-cab control unit and antennas, allows the 120 to be mated to any carrier.

The 120 sits on a full forest duty F8 undercarriage for excellent durability and mobility. The upper assembly has a sloped tail for added maneuverability on narrow

mountain roads. Access to daily service points and major components is convenient with large swing outdoors for

The largest heavy equipment trade event in Eastern Canada will soon return to Quebec for its 2025 edition.

Expo Grands Travaux moves into Espace SaintHyacinthe this Spring, March 26th and 27th, and will round together some of the industry’s biggest players.

“The planning process is coming along quite smoothly for the return of this key event.” said Mark Cusack, National Show Manager.

“After talking with exhibitors its clear everyone is ea-

the engine and pump enclosures and prop-up roof sections to access winch system components.

All machine functions are actuated with an ergonomic and intuitive remote-control system. The powerful, heavy duty boom system with choice of a bucket or other attachments firmly anchors the machine and can take on basic roadbuilding duties. With ample below grade capability, the boom can extend over the road bank to firmly anchor the machine.

High-capacity cooling combined with a secondary hydraulic braking circuit provides highly effective braking assistance and heat dissipation for higher-speed rubber tire machines such as skidders, forwarders and harvesters.

The relatively long distance between the boommounted sheave and the winch, and the powered cable tension system combine to provide neat and reliable rope spooling. With the boom anchor system planted firmly in the ground, the cable can be operated off to the side of the machine, thanks to the pivoting sheave. SP

Source: Tigercat

ger to be back on the show floor.”

Registration is now open online. Visitors are encouraged to pre-register in advance to save money and fast-track their entrance by using promo code “EGT2002.” Visitor registration can be found online.

With over 144,000 square feet of space, this event displays major OEM’s, big iron and offers an unparalleled opportunity to network with other professionals from across the country.

Companies interested in exhibit opportunities are encouraged to contact a member of the show team as space is limited, and likely to sell out.

For full details and updates, stay tuned to the show’s website or find the show on Facebook.

For more details, visit: www.egt.mpltd.ca. SP

With

Finance

Brandt

With the threats of a proposed 25 per cent tariff on all imports from Canada and Mexico by U.S. President Donald Trump, many businesses are starting to assess how these changes might impact them.

While these tariffs have not been finalized and will require negotiations between the two sides, it’s always wise to be prepared.

The Canadian Construction Association (CCA) offers the following tips to help construction professionals navigate potential changes in tariffs and protect their businesses.

For existing contracts: What you should know

Review your contract:

Check if your contract includes provisions for price adjustments due to changes in taxes and customs duties, such as paragraph 10.1 in CCDC 2—Stipulated Price Contract or CCA 1—Stipu-

lated Price Subcontract. Remember to review the supplementary conditions even with standard CCDC and CCA contract forms.

Contracts without duty provisions: If no duty provisions are included, contractors may be liable for covering the increased costs.

CCA encourages owners to fairly consider requests for price adjustments if contractors are facing unforeseen cost increases due to tariffs.

For new contracts: How to address tariff uncertainty

Raise the issue early: If the contract for a potential project lacks duty provisions, especially if you’re aware of upcoming changes to taxes or customs duties, formally bring this to the owner’s attention.

Include duty provisions: Encourage the owner to include duty provisions or address this uncertainty in the bid documents. Look to GC

10.1 of CCDC 2 for standard, industry-accepted wording.

Other considerations: Key points to remember Argue for cost recovery: If you’re facing unforeseen costs due to increases in taxes and customs duties, you may have a case for recovering additional costs. However, without clear duty provisions in the contract, this may be challenging.

Cost recovery due to delays: If a project experiences changes, delays, or suspensions that postpone material purchases and result in escalated costs, contractors might be able to recover these additional expenses, depending on the contract and situation.

Final tip: Always read your contract

The most important piece of advice is to carefully read and understand your contracts.

Staying informed and prepared will help your business navigate potential tariff changes with confidence. Learn more at SupplyPost. com/news. SP

Source: Canadian Construction Association

DC Equipment, a manufacturer of logging and forestry equipment, is expanding its presence at the Oregon Logging Conference in Eugene, Oregon.

The company showcased Madill logging equipment for the first time in the United States along with its Falcon Forestry Equipment brand.

“Last year, we relaunched production of the Madill brand, renowned for its reliability in the logging industry, and are excited to be bringing a Madill 3000B log loader to this important

event along with our Falcon equipment series,” said Dale Ewers, Managing Director of DC Equipment. “We now have the capacity to support North American logging contractors and customers first hand.”

A new generation of forestry equipment

Mr. Ewers noted that DC Equipment has actively listened to customer feedback over the past year, gathering insights from owners, operators, technicians, forestry managers, industry partners and distributors on its current models and future product developments. “Their input guided our design team

to incorporate technological enhancements into our equipment as part of our commitment to continuous improvement,” he said.

The return of Madill log loaders comes with machine improvements. For example, a comprehensive review of the boom and stick has translated into increased durability and strength in key stress areas. “We have also redesigned the cooling package to reduce vibration, generate extra capacity for warmer temperatures and provide access improvements for serviceability,” said Mr. Ewers.

The DC Equipment team looked forward to attending the 2025 Oregon Logging Conference and taking advantage of this unique opportunity to discuss the future of Madill Equipment with customers.

should have the opportunity to be involved.”

“We [invited] contractors, forest managers and operators to our stand to discuss what they would like to see from Madill in North America,” said Mr. Ewers. “Madill is coming back to America and we believe that the people who support the brand

DC Equipment’s expansion into North America is part of a broader strategic initiative to enable local manufacturing while meeting global demand. DC Equipment now has facilities in South America, North America and Oceania, ensuring that the company can meet demand for the Falcon and Madill products worldwide while maintaining strong manufacturing capabilities at home.

“By manufacturing locally, we can ensure faster delivery times and maintain the highest standards of quality and innovation that our customers have come to expect from Madill and DC Equipment,” said Mr. Ewers.

DC Equipment was established to enhance safety and productivity in steep-slope logging operations through mechanization and mitigating the harm of people in high-risk logging environments through its Falcon Forestry Equipment brand.

DC Equipment manufac-

tures and exports equipment to North and South America while supplying the New Zealand and Australian markets. With the recent acquisition of the Madill brand, DC Equipment has opened a Prince George facility to build on the Madill legacy and recognize its heritage in British Columbia.

Through Madill and Falcon, DC Equipment is poised to deliver integrated, innovative solutions to logging contractors worldwide, advancing towards automation, data integration, and lower- emission technologies. SP

Source: DC Equipment

Genie expands its family of telescopic handlers with the addition of two shorter boom, high-capacity models.

The GTH-1244 and GTH1044 are designed with the best load chart in their respective category classes and new features, making them highly efficient for pick-and-carry applications.

“These short-stick telehandlers are ideal for rental fleets, looking to diversify their product offering, or for specialty rental companies serving customers in industrial maintenance, energy, and steel erection. This improves costs while delivering capacity and productivity to maximize ROI,” said Amalija Kopac, Senior Global Product Manager.

The booms in Genie’s telehandler portfolio are robust, with proven durability over thousands of hours of real-world testing. That same boom design with strong load chart capacities is incorporated into the new GTH-1244 and GTH-1044, but with one less section.

Eliminating the weight of

long lasting, significantly reducing tire replacement costs.

• 80% commonality of parts through the full telehandler portfolio reduces parts inventory and simplifies maintenance.

that boom section allows for other design changes that reduce maintenance costs.

• A single master and lift cylinder extends and retracts the boom, compared with two cylinders found on competing models. In addition, hydraulic hoses are routed away from sharp edges. The flexible hoses are encased in a protective wrap to prevent wear.

• Both models come standard with a 74 hp DEFfree engine that eliminates service costs associated with DEF filters or regeneration.

• Electronics can be sensitive and expensive to repair. A redesigned gauge cluster comes with an IP67 seal and thicker housing, preventing exposure to dust and moisture, reducing maintenance and repair.

• Standard foam-filled Enduro A/T tires with improved tread design are

Both the GTH-1244 and GTH-1044 offer the most efficient way of handling loads without the need for stabilizers. “These pick-and-carry machines have high capacities for quickly moving loads lower to the ground because the absence of stabilizers reduces cycle time,” said Kopac.

Several intentional features are designed for supporting high-cycle load handling. The 74 hp engine delivers a high power –toweight ratio, ensuring fast drive speeds, and the drivetrain has front and rear limited slip differentials as standard, improving traction through rough terrain. Genie’s limited slip differentials increase machine power and speed by utilizing engine power more efficiently, and reduce stress on tires and axle shafts, improving their durability.

Operators have 360-degree visibility of all four tires, while a single, multi-functional joystick results in half as many hand movements required to position loads. In addition, operators can make load adjustments at full height without locking the rear axle.

A heavy-duty lifting shackle comes standard for added convenience when lifting unpalletized materials; in addition, a variety of optional accessories—rotating and swing fork carriages, side shift and fork positioner carriages, and truss and bucket—can be used across many of the other models in Genie’s GTH product line.

The GTH-1244 and GTH1044 complement existing telehandler fleets by providing rental companies with the ability to differentiate equipment by application, increasing utilization and maximizing return on invested capital.

“If your customers are working in energy, oil and gas, industrial maintenance or certain construction applications like jobsite staging or clean up or steel erection, then these high-capacity short boom telehandlers can get you top rental rates and satisfy customer challenges,” said Kopac. SP

Cat 68” clean up bkt, Cat manual Q/C, Cat hyd. thumb. aux. hyd., hoe front, WBM cab guard, rear view camera, catwalks, Proheat, rig saver, under guarding, std U/C w/ 34” TBP. 10,775 hours $142,500

2013 Hitachi ZX210LC-5N, c/w: 36” CWS dig bkt, CWS quick coupler, hyd thumb, Viking West cab guard, PAS, catwalks, under guarding, std U/C w/ 32” TBP. 9,451 hours. $89,500

LOG LOADERS

2013 John Deere 3754D, c/w: WBM grapple, heel rack, LL front, WC elev. rear entry cab on 60” riser, tandem swing drives, Forestry guarding pkg. w/ aux. fuel, HW U/C with 30” triple bar pads. 18,350 hours, service records available from new. Ready to work! CALL

2013 Hitachi ZX290F-3, c/w: Pierce M55 grapple, heel rack, LL front, elev. rear entry cab on riser, Isuzu eng., Forestry guarding pkg w/ aux. fuel tank, HW U/C w/36” TBP. 24,434 hrs, service records available from new. Call for pricing! CALL

2012 Tigercat LS855C Steep Slope Shovel Logger, c/w: T-Mar grapple, heel rack, plumbed & wired for FL85 felling head, harvester front, ER boom system, ROPS cab, fire suppression, self-leveling undercarriage with 28” SBP. 18,1XX hours $89,500

2010 Caterpillar 330DFMLL, c/w: T-Mar 60” log grapple, T-Mar heel rack, log loader front, west coast elevated rear entry cab on 70” riser, forestry guarding package w/aux counter weight & aux fuel tank, tandem swing drives, high walker undercarriage with 36” triple bar pads. $64,500

1998 Madill 4800, T-Mar log grapple, heel rack, log loader front, west coast elevated rear entry cab on 60” riser, tandem swing drives, Detroit Diesel Series 60 engine, forestry guarding pkg. highwalker U/C w/ 32” DBP $274,500

2001 Madill 124 Swing Yarder, c/w: Grapple, lines, 60’ boom w/ fairleads, hyd. tilt rear entry cab, 40’ gantry, Series 60 eng., Allison trans., 2 guy lines, mounted on Madill D7 crawler carrier with 28” DBP $1,395,000

1989 Madill 123 Swing Yarder, c/w: Grapple, lines, 60’ boom w/ fairleads, hydraulic tilt cab, T-Mar “Log Champ” control system, 40’ gantry, Cummins eng., two guy lines, mounted on Madill hydraulic drive crawler carrier w 28” triple bar pads. Recent $250K in

ident and CEO, BC Council of Forest Industries

The Province has formed a new council to advance the interests of British Columbia in the longstanding softwood lumber dispute with the United States.

The council brings together leaders from the forestry sector and labour, alongside experts on U.S. relations and officials from the B.C. government.

The B.C. Softwood Lumber Advisory Council convened its first meeting on Jan. 30, 2025, and will meet regularly. It advises the Minister of Forests on the dispute, including the sixth administrative review, providing recommendations on steps B.C. can take to eliminate the 14.4% softwood lumber du-

ties. The council will also help the Province advocate to the federal government as these duties continue to take their toll on B.C.’s forestry sector.

“The U.S. has imposed unjustified softwood lumber duties on Canada for years, and we anticipate that they will likely double before the end of this year,” said Ravi Parmar, Minister of Forests.

“Bringing this team together, I am ready to throw the full weight of B.C. in the ring to fight these duties. We are going to defend the hard-work-

ing forestry workers of B.C. from these unfair duties.”

Parmar will chair the council with a focus on diplomatic and trade strategy and measures to fight for B.C.’s interests in the softwood lumber dispute with the U.S. Council members are:

• Harry Bains, former minister of labour, Government of B.C.

• Dan Battistella, former president, Interior Lumber Manufacturers’ Association

• Linda Coady, former pres-

• Geoff Dawe, national president, Public and Private Workers of Canada

• Rick Doman, chairman, Boreal Carbon Corporation and former forestry executive

• Scott Lunny, western director, United Steelworkers

• Gavin McGarrigle, western regional director, Unifor

• Ric Slaco, former vicepresident and chief forester, Interfor

• Dallas Smith, president and CEO, Nanwakolas Council

• B.C. softwood lumber accounts for nearly 10% of lumber used to build American homes.

“The U.S. forest industry alleges that Canadian softwood lumber is subsidized, and companies sell in the U.S. at below-market prices,” Parmar said. “This is wrong; these allegations couldn’t be further from the truth. We’ve been very clear that we’re happy to come to the table, but that can’t happen if the U.S. industry isn’t willing to negotiate.”

Although this dispute with the U.S. goes back decades, this most recent iteration of the dispute follows the expiry of the Softwood

Lumber Agreement in 2015. At the request of the U.S. lumber industry, the U.S. imposed duties on Canadian softwood lumber, starting in 2017. The B.C. government has worked with the Government of Canada to pursue claims through all available avenues, including under the North American Free Trade Agreement, the CanadaU.S.-Mexico Agreement, the World Trade Organization and the U.S. Court of International Trade.

Past dispute settlement panels have consistently ruled in Canada’s favour in the ongoing softwood lumber dispute, determining that B.C.’s forest policies are compliant with international agreements.

• Canada is the U.S.’s largest source of forest product imports, making up 44% in 2023.

• U.S. consumers will pay for these tariffs and duties, leading to higher prices for the goods and materials people need to build homes, or repair and remodel them.

• In 2023, B.C. exported more than $3.3 billion worth of softwood lumber to the U.S. SP

Source: Province of British Columbia

Kubota Canada Ltd. is proudly celebrating its 50th year in Canada.

The substantial local demand for Kubota products and the associated company growth also led to an investment exceeding $80 million in a new, state-of-the-art 65,000 sq. ft corporate office and 500,000 sq. ft warehouse in Pickering, Ontario, in 2022. Today, the company directly and by extension, employs over 1,500 Canadians, reflecting its sustained growth since 1975 by meeting the equipment needs of Canadians.

This significant milestone reflects the company’s engineering excellence, focus on quality and the dedication of Kubota’s employees along with its locally owned and operated dealer network –all of whom are dedicated to serving Kubota’s customers in communities across the country.

“We are exceptionally proud of our half century of continued growth in Canada,” said Yannick Montagano, President of Kubota Canada. “When we launched

in Canada 50 years ago, our goal was to sell compact agricultural tractors to Canadians. Since then, we have significantly expanded our award-winning product line-up to meet the evolving needs of a broad range of markets and individuals. We launched the first-ever heavy equipment cold weather testing facility in Timmins, Ontario, in 2013, which is now the global gold standard for Kubota, ensuring our machinery consistently lives up to real-life conditions.”

Leveraging customer and dealer feedback to drive research and development, prioritizing customer needs above all else has driven success for Kubota. According to the North American Equipment Dealers Association’s 2024 Dealer-Manufacturer Relations survey, Kubota Canada is ranked as the number one full line OEM with dealers when it comes to overall satisfaction, product and parts quality, parts availability, product support, warranty, communication with management and manufacturer responses to needs and concerns. Additionally, continued innovation has been a sigContinued on page 21

nificant driver of Kubota’s success. Earlier this month, Kubota Canada introduced three new additions to its robust compact construction lineup, with a strong pipeline of new products set to be announced throughout the coming year. Given the significance of the Canadian market, Kubota Canada plays a crucial role in the company’s global product development cycle, ensuring rele-

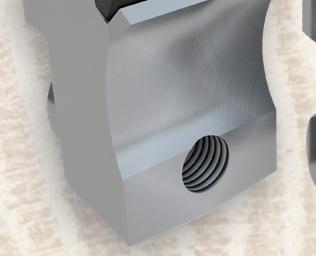

Engcon has launched a new and improved tiltrotator for excavators in the 2-4 ton weight class, EC204.

This model has the same functions and features as engcon’s larger models.

More and more people are discovering the benefits

of tiltrotators. One of the main advantages is that it makes digging more efficient and broadens the excavator’s range of applications. The til-

vant products are designed to meet the unique needs of both Canadian and worldwide customers.

Montagano further remarked, “We became industry leaders by listening to our customers, addressing their needs, and continuously looking towards the future. Fifty years of equipment manufacturing progress with an unwavering commitment to our dealers and the customers they serve, is what makes Kubota Canada

trotator transforms the excavator into a flexible tool carrier, reducing both the need for other machines and labor around the excavator. The result is increased profitability for the end customer.

engcon is constantly working to improve its products. As a further step forward in improving for the end customer, engcon is now launching an improved version of the popular EC204 with the same functions and features as engcon’s larger models.

The updated model of the EC204, which is suitable for excavators in the 2-4 ton size class, features engcon’s EC-Oil quick coupler system both above and below the tiltrotator, which is unique on smaller machines. This makes it easier to change attachments or to disconnect the tiltrotator if necessary. It offers a 45-degree tilt angle,

infinite rotation and the ability to easily mount different attachments, contributing to versatility and flexibility in excavation work. The model is also prepared for EPS, engcon’s innovative positioning system.

“I’m very proud that we can deliver our EC-Oil automatic quick coupler system both above and below the tiltrotator for the 2 to 4 ton class, this really makes the excavator the ultimate tool car-

one of the most respected equipment companies globally today. We prioritize quality and excellence every day so that our customers can focus on feeding and building our world. I am immensely proud of the work

rier,” says Martin Engström, Product Manager at engcon.

“Our customers can rely on engcon to always deliver state-of-the-art technology that improves their profitability,” he continues.

The updated model of EC204 is available on the market from January 2025.

About EC-Oil:

EC-Oil is an attachment consisting of hydraulic blocks with hydraulic, electrical

that we do here in Canada, and Kubota looks forward to working with a new generation of Canadian customers and businesses for the next 50 years and beyond.” SP

Source: Kubota

and central lubrication connections. When EC-Oil is mounted on the Q-Safe quick coupler, the combination provides fully automatic connection of hydraulic attachments such as tiltrotators, grapples, sweepers, ground vibrators, etc. The operator does not have to leave the driver’s seat to connect the attachments, which increases the safety of the excavator operator. SP

Source: engcon

New Holland is elevating its trusted telehandler range with the North American launch of its new TH6.26 Compact Telehandler.

Designed to meet the diverse needs of farmers, contractors and landscapers, it brings together a powerful combination of maneuverability, strength and advanced technology.

“The TH6.26 represents our commitment to delivering a full line of telehandlers from New Holland,” said Lena Patton, North America product marketing manager for small tractors, telehandlers

and loaders, New Holland. “With its compact design, superior lifting capabilities and advanced comfort features, this telehandler offers unmatched versatility and reliability for today’s demanding work environments.”

This latest addition to the TH Series is built to excel in a wide variety of environments. Its compact size and robust performance make it an indis-

pensable tool for dairy and livestock farms, landscaping businesses and material handling operations to conduct tasks like stacking bales, loading feed, manure handling and more.

The TH6.26 is also built to enhance operational efficiency in tight spaces while delivering impressive lifting capabilities.

Boasting a narrow frame and low cab height of just 75 inches, the TH6.26 is ideal for navigating tight working environments like poultry houses. Despite its compact profile, the TH6.26 is made to handle heavy-duty tasks with ease, offering a

maximum lift height of 19.7 feet (6 meters) and a lifting capacity of 5,732 pounds (2,600 kilograms).

Equipped with a fuel-efficient, Stage V/Tier 4 Final compliant 74 hp, 4-cylinder engine, the TH6.26 provides reliable power for a wide range of agricultural and landscaping applications. Its hydrostatic transmission offers operators smooth, precise control with speeds that reach over 18 mph, while a variety of operator modes allow operators to customize performance for specific tasks to optimize both productivity and fuel economy.

At over 37 inches wide, the TH6.26’s cab is a comfortable operating space for any day’s tasks. It features a modern, ergonomic layout that further ensures maximum operator comfort during long working hours.

Key comfort and control enhancements include:

• All-round visibility with a large, wrap-around windshield and slim pillars.

• Easy-to-use joystick control, integrating key func-

tions for smooth operation.

• Air conditioning, heat and an adjustable seat to keep operators comfortable in all climates.

One of the cornerstones of the TH6.26 is the innovative features integrated into the telehandler to simplify operation and reduce downtime.

The telematics functionality on the TH6.26 can be specified to help owners track equipment location, performance and other critical operating parameters. It can do this alongside other connected New Holland machines in owners’ fleets via the New Holland FieldOps™ management app.

Contributing to the simplification of operation and reduction of downtime are features and design tangibles like:

• Auto Boom Suspension System that minimizes vibrations and enhances stability during transport.

• Quick-Attach Coupler that allows fast, tool-free attachment changes. This makes it simple to switch between buckets, forks and

other implements common to the full range of TH Series telehandlers.

• Maintenance-friendly design, with easy access to service points for efficient routine checks and reduced overall service time. Further standard features on the TH6.26 are constantflow hydraulics and in-cab components that include push-button engine start and customizable controls with a touchscreen display for an instant view of operating data (engine, transmission and boom), operation of the Bluetooth radio and control of work lights. Automotive-style controls are incorporated on the TH6.26 and comprise a multifunction steering column stalk for road light and wiper control. A rear-view camera is incorporated to further enhance safety and aid reversing and trailer-hitching. Externally, front, rear and boom-mounted LED work lights provide strong illumination at night and in un-lit buildings.

The new TH6.26 compact telehandler will be available beginning summer 2025 at New Holland dealers. SP

Source:

New Holland Ag.

BUILDINGS COMPACTORS COMPACTORS-LANDFILL COMPACTORS-SOIL COMPRESSORS CONCRETE CONTAINERS CRAWLER TRACTORS/DOZERS CURB MACHINES DOZERSWHEEL DRILLS DRILLS-DIRECTIONAL DRILLS-ROCK DUMPERS DUST SYSTEMS EQUIPMENT-SHOP EQUIPMENT-SURPLUS EXCAVATORS EXCAVATORS-MINI EXCAVATORS-WHEELED GENERATORS GOLF CARTS GRADERS HEATERS ICE RESURFACER INTEGRATED TOOL CARRIERS LIGHTING LOADERS-BACKHOE LOADERS-SKID STEER LOADERS-TRACK LOADERSWHEEL MISCELLANEOUS OTHER PAVERS PIPELAYERS PRESSURE WASHERS RIG MATS SCRAPERS SWEEPERS TANKS-FUEL TANKS-VACUUM TRACK CARRIER TRENCHERS & BORING TRUCKS-OFF HIGHWAY WELDERS WELDING SKIDS AGGREGATES & MINING ASPHALT PLANTS BATCH PLANT CHUTES COLD PLANERS COMPOST MACHINES CONVEYOR BELTING CONVEYORS CRUSHERS-CONE CRUSHERS-IMPACT CRUSHERS-JAW CRUSHERS-PORTABLE FEEDERS GOLD CLAIMS HOPPERS MINING OILFIELD EQUIPMENT OTHER POWER VANS QUARRY SCREENING EQUIPMENT SURGE BINS TANKS-DRILLS TROMMELS WASH PLANT EQUIPMENT FORESTRY ATV / RTV / UTILITY VEHICLE BOATS CAMPS CHIPPERS DEBARKERS DELIMBERS DREDGE PUMPS EMERGENCY EXCAVATORS-ROADBUILDER FELLER BUNCHERS FIREWOOD PROCESSORS FORWARDERS GRINDERS HARVESTERS LOADERS-LOG LOADERSSKIP LUBE SKIDS MULCHERS OTHER PROCESSORS SHREDDERS SKIDDERS STUMP GRINDERS YARDERS ATTACHMENTS ASPHALT LAYER ATTACHMENTS AUGERS BACKHOE BALERS BLADES BOOMS BROOMS BRUSH CUTTER BUCKETS BUCKETS-CLEANUP BUCKETS-CRUSHER BUCKETS-FROST BUCKETS-GP BUCKETS-LIGHT MATERIAL BUCKETS-OTHER BUCKETSROCK BUCKETS-SCREENING BUCKETS-SKELETON BUCKETS-SPADE NOSE BUCKETS-TRENCHING BUCKETS- WRIST COMPACTORS COUPLERS DELIMBER DITCHING DOZER DRAWBARS FORESTRY HEADS FORKS GRAPPLES HAMMERS & BREAKERS HITCH JIBS MULCHERS PAVING PLATFORM PULVERIZERS PUSH BLOCK RAKES RIPPERS ROCK GUARDS SAWS SCARIFIER SCREEN/SWEEPS SHANKS SHEARS SHELL KIT SKID STEER SNOW PLOW SNOW REMOVAL SNOW WING SWEEPS THUMBS TRACTOR TRENCHERS WINCHES TRUCKS SEWER CAMERA BUCKET BUS CAB & CHASSIS CARS CONCRETE CRANE DAY CAB TRACTOR DECK DECKING DECKS/BOXES DIGGER DUMP/GRAVEL FIRE FUEL & LUBE GARBAGE/RECYCLING GATE GRAIN HIGHWAY/ SLEEPER HOOKLIFT LOGGING MIXER MOTORCYCLES MOTORHOMES MULTI PURPOSE OILFIELD OTHER PARTS & ACCESSORIES PICKUP PLOW PRESSURE WASH REEFER VAN ROLLOFF SUVS SELF LOADERS SERVICE SPREADER TOW UTILITY VAC/COMBO VAC VAN WATER/ TANKER WINCH MATERIAL HANDLING CRANES CRANES-CRAWLER CRANES-GANTRY CRANES-KNUCKLE BOOM CRANES-WHEELED FORKLIFTS FORKLIFTS-TELEHANDLERS HANDLING LIFTS LIFTS-BOOM LIFTS-MAN LIFTS-SCISSOR RAIL CAR MOVERS RIGGING-CRANE AGRICULTURE & FARMING EQUIPMENT COMBINES COMMERCIAL ELECTRIC REMOTE CONTROL MOWERS CONVEYORS CULTIVATORS DISCS DRILLS GRAIN HANDLERS GRINDERS / MIXERS LANDSCAPE COMPOST MANURE SPREADERS MOWERS MOWERS-COMMERCIAL MOWERS-RIDE ON OTHER PLOWS / SUBSOILERS RAKES / TEDDERS SEEDERS / PLANTERS SNOW BLOWER SNOWMOBILES SPRAYERS / APPLICATORS SWATHERS/

or

Using an EDGE VS420 low-speed shredder in combination with a high-speed grinder results in major benefits.

average fuel consumption of just 25 litres/hr (6.6USG/ HR).

In today’s waste processing industry, companies are constantly looking for ways to maximize efficiency, protect equipment, and reduce operational costs. One effective approach to achieve these goals is by integrating a low-speed, high-torque shredder like the ever-popular EDGE VS420 as a processing step before feeding material into a high-speed grinder.

excel at breaking down or removing those hurtful contaminants and metals before reaching the grinder. This added layer of protection has transformed the operation making their grinding process much more reliable and repeatable with a significate reduction in forced downtime.

All of EDGE Innovate’s range of shredders can handle a wide variety of materials that might have been turned away in the past –from highly contaminated organic feedstocks, industrial waste and construction debris to tires and mixed municipal waste.

We saw this combination in operation when we recently travelled to California to meet the bosses of one of the largest family-owned companies on the West coast who operate a number of EDGE Innovate machines, including an EDGE VS420 shredder and multiple EDGE TRT622 trommels, all supplied by Greenrock Equipment, exclusive distributors for EDGE Innovate products in California and Hawaii.

For any company investing in an EDGE shredder like the VS420 (now available in Electric Hybrid), it will prove to be money well spent, as the shredder provides substantial long-term operational savings.

The major benefit witnessed at this operation was the ability of the VS420 to process feedstocks that contain tough contaminants, such as metal, rocks, or other hard objects. These high torque, low speed shredders

Another major advantage of the low-speed shredder is its ability to break down large, bulky items into smaller, more manageable pieces. This preliminary size reduction creates a consistent material flow that high-speed grinders can handle with greater ease and efficiency. By avoiding clogs and jams, this setup not only increases throughput but also maximizes the quality of the grinder’s output, and it significantly reduces wear and tear on the grinder, extending its lifespan and reducing the need for costly repairs, replacements, and downtime.

By reducing the load on the high-speed grinder, the shredder enables it to operate at a steady pace, increasing the volume of material processed per hour while consuming less energy. This energy-efficient workflow is essential in today’s industry, where minimizing costs and maximizing throughput are top priorities. For example, the EDGE VS420 has an

The EDGE waste shredder here brings operational flexibility to the forefront making it possible for the business to confidently say “Yes” to a wider range of materials, diversify their offerings and allow them to enter new market segments, such as composting, recycling, and biomass fuel production. With the added flexibility to take on new applications and serve a wider client base, companies can tap into new revenue streams and improve their competitive standing. An additional key benefit of EDGE Innovate’s low-speed shredders is their ability to reduce dust. The shredders’ lower operating speeds and controlled shredding action significantly minimize the formation of fine particles, which has multiple advantages. Reduced dust production enhances health and safety by improving air quality, lowering the need for costly dust control. Additionally, less dust accumulation on equipment and workspaces means lower maintenance and clean-up costs but the major benefit from this is a much cleaner, in spec final product, which

is especially beneficial for applications like biomass fuel and mulch.

As a trusted manufacturer in the field, EDGE Innovate is committed to helping waste processing companies enhance efficiency, protect their equipment, and broaden their service capabilities with their advanced lowspeed shredders. All EDGE Innovate shredders encompass a highly robust and durable design and being engineered to run at a lower rotor RPM but with high torque enables the shredders to process the most difficult of materials. In addition, all the waste shredders utilize EDGE’s Intelligent SelfProtecting control system with tramp metal cycles to prevent against asset damage and downtime, while multiple chamber configurations, screen options and cutting tools allow operators to customize their EDGE shredders to provide the right tonnage at the desired piece size.

“Integrating one of our shredders allows businesses to confidently accept a wider array of materials and appli-

cations, equipping them to enter new markets and meet evolving customer demands. While every operation has unique requirements, we believe that companies processing varied, bulky, or potentially contaminated waste streams will see clear benefits from our low-speed shredders, including increased throughput, operational flexibility, and superior product quality,” commented Greenrock Equipment’s John Connolly.

Although slow-speed shredders represent an initial large investment, EDGE Innovate’s shredders provide substantial long-term operational savings. Reduced wear on grinders, lower energy consumption, minimized dust control needs, and decreased maintenance costs all contribute to significant cost efficiencies. In addition to expanding the range of materials a company can process, a low-speed shredder offers a pathway to greater revenue, helping to offset equipment costs. Ultimately, a low-speed shredder transforms a waste processing company into a

more versatile and resilient operation that is prepared to meet the demands of modern waste management. With an EDGE Innovate slow-speed shredder paired with a highspeed grinder, your waste processing system becomes a powerful, efficient, and robust solution, primed for growth and adaptability in a dynamic market.

The new VS420E Hybrid from EDGE Innovate is a breakthrough in eco-friendly shredding technology, delivering top-tier performance with a significantly reduced environmental impact. By dramatically lowering CO2 emissions, this hybrid model not only cuts your carbon footprint but also reduces operating costs and maintenance requirements. It combines the mobility of a diesel-driven unit with the environmental and operational advantages of a stationary electric shredder—all in one innovative, self-contained package. Experience minimal environmental impact without compromising on power. SP

Source: EDGE Innovate

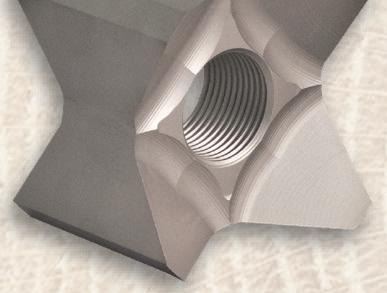

Metso introduces the 5th Generation MP Hydraulic power unit for Nordberg MP cone crushers.

This new unit marks a significant advancement in standardization with a modular base design, allowing for easy customization to meet specific applications.

The 5th Generation MP HPU is commercially available immediately.

“Metso has built a strong reputation among customers for delivering reliable power units for MP cone crushers, supported by a robust installed base. As even very reliable customers’ existing units age and components in the older units become obsolete, obtaining replacement quotes can be challenging for customers. The new power unit simplifies this process, enabling us to quickly provide quotes for replacement units with readily available components. With increased standardization, we can maintain stock or place orders for long lead-time assemblies, ensuring faster delivery times and supporting reliable opera-

tions,” says Andrew Lingenfelter, Vice President, Mining Crusher Products, Metso.

The 5th Generation MP HPU represents a significant leap forward in standardization for mining crusher operations. This generation introduces a modular base design, allowing for easy customization to meet specific operational needs. By transitioning to the 5th Generation MP HPU now, customers can proactively address the risks of unexpected failures and costly downtime, ensuring a seamless and efficient up-

grade process. Not only does this standardized approach improve safety and maintenance, but also simplifies the integration process for customers upgrading to the latest technology.

“Additionally, we have sought opportunities to enhance the existing offering, making it easier to maintain while retaining the same basic design and operation, so customer’s personnel do not need to learn a new piece of equipment,” Lingenfelter explains.

These safety and maintenance enhancements, developed in collaboration with customers, ensure efficient, safe and continuous operation in challenging mining conditions. SP

Source: Metso

Keestrack will focus on profitable and sustainable crushing and screening equipment at Bauma this April.

World’s biggest construction tradeshow, Bauma, is about to open its doors from April 7th until April 13th, in Munich, Germany. Bauma’s and Keestrack’s focus is on sustainability, alternative drive systems and providing solutions for the aggregates, recycling and mining industry.

Keestrack will be at booth FN 1016/9 and will launch 2 completely new machines at Bauma.

The R2, high performing and very compact track mobile impact crusher, has been designed to complete Keestrack’s product range of impactors. The R2 is easy to operate within city centres where high flexibility and mobility are essential. In a lot of European cities there is a need

for pure electric plug-in construction equipment. With the ZERO-drive, a full electric plug-in drive version, without any combustion engine onboard, Keestrack provides the ideal solution. The new impactor has a capacity up to 150 t/h.

The crusher design features are often similar to the award winning bigger R3 impactor. The hopper (3m³) with integrated vibrating feeder (3300 x 810mm) and pre-screen (1250 x 810mm) also has a asymmetric design to feed the material easy into the inlet (860 x 730mm) which is equipped with a replaceable entry beam.

The newly designed rotor, with a width of 840 mm and a diameter of 920 mm, is made of Hardox steel. The rotor has the same design concept as the bigger R3, R5 and R6, de-

signed to minimize wear. Rotor speed can be adjusted by a hydrostatic drive to finetune the desired grain size. The impact aprons can be serviced from the top which facilitates service maintenance.

The R2 impactor, fully equipped in closed circuit with a 1200 x 3040mm single deck after screen, magnet separator and windsifter has a total weight under 27t and a transport length of 13.05m, making it a very agile impactor. The return conveyor of the closed circuit can also swivel outside to be used as a stockpile conveyor for oversize.

As on all Keestrack equipment, maintenance has been reduced by design, using drive and return drums which are greased for life, is just one of the examples.

The diesel/hydraulic R2

version is driven by the new DEUTZ TCD 5.2 L4 engine, which is very efficient, powerful and clean. It applies to all EU Stage V and US EPA Tier 4 and is able to run on ecological biodiesel. The R2 is also available in ZERO drive version, which is full electric plug-in and has no combustion engine.

Keestrack will also introduce the brand-new high-capacity 3-deck classifier to complete the product range for high capacity precision screening. The C7,

with a capacity up to 600 t/h, is equipped with a triple deck screen box of 5450 x 1800mm with interchangeable screen meshes, which can be changed quickly. The C7 is specifically designed for accurate and high-capacity precision screening for sand and aggregates. The walkways on each side of the screen box give perfect service and maintenance access. The C7 has no support legs, resulting in quick set up times.

The C7 3-deck classifier is available in conventional diesel/hydraulic drive, but Keestrack’s R&D department already mention their plans

to make it available in ZERO, full electric plug-in drive, in near future. Also, the 2-deck version is foreseen to come to market soon.

P3 Twin Shaft Shredder Keestrack, recently added the first tracked shredder, the P3, to its product range. This compact twin-shaft shredder is equipped with 2 heavy duty axles that can easily be changed within the hour. In different setups, the shredder can be used for various applications such as construction waste, mineral waste, biomass, green waste, logs and

roots, waste wood, industrial & household waste, plastics, light metal waste, tires etc.

The 14.5t Keestrack P3 tracked mobile shredder features a tillable loading platform to feed the shredder. The shredder has a feed opening of 1589 x 1200 mm and a shaft diameter of 700 mm. The torque of 90,000 Nm per shaft provides a massive power of 180,000 Nm. The shaft speeds are 45 and 25 rpm, and the rotation varies according to the program selected. The shredder features an automatic release system by reversing the direction of rotation.

The P3 is available with options such as a magnetic separator, to separate precious metals, remote control, after screen, working lights and a fuel pump. As expected, the P3 provides easy access for service, maintenance and repairs. The engine compartment is very accessible, with the new very efficient, powerful and clean DEUTZ TCD 5.2 L4 engine. It applies to all EU Stage V and US EPA Tier 4 and is able to run on ecological biodiesel.

Keestrack’s B5, available in 3-drive versions: conventional diesel/hydraulic, hybrid plug-in and ZERO full electric-drive, is a compact heavy duty jaw crusher used for primary crushing in quarrying and mining applications. The hopper (5m³) with heavy duty folding hopper walls with hydraulic locking system, is easy to load by excavator and wheel loader. The vibrating feeder (2300 x 1000mm) automatically adjusts the feeding material to the crusher to ensure the load capacity of the jaw crusher is optimal (80%).

The long independent 2-deck pre-screen (2300 x 1000mm) ensures a high crushing capacity while reducing wear of the crusher. The pre-screened fraction(s) can go through the crusher bypass or can be separately stockpiled by the optional side conveyor.

The jaw crusher has a feed opening of 1110 x 750mm and a feed size up to 600mm. The stroke of the swing jaw can be adjusted for hard stone or recycling applications. To remove blockages the jaw movement is reversed.

The Closed Side Setting

(C.S.S.) is from 45 to 180mm, even on worn jaws. The hydraulic gap settings can be changed via a wedge system.

During operation the automatic wear recovery is active every 50 working hours, which guarantees a consistent quality of your end-product.

The wear recovery can also be set manually, if needed.

Maintenance and repairs are facilitated by the design of the B5 through accessible walkways and doors and panels on all sides of the machine. Also, the hydraulic sliding frame ensures good service access under the feeder and

scalping unit. The jaw crusher has 3-piece cheek plates which make replacements easier. Replacement of the jaws is fairly simple due to the easy accessible jaw plate top locking system. The B5 is equipped with a Drop off engine/gen-set compartment like many other Keestrack crushers. The engine can be placed besides the machine in less dusty and vibrant conditions. Maintenance is much easier when having the compartment placed at ground level. SP

Source: Keestrack

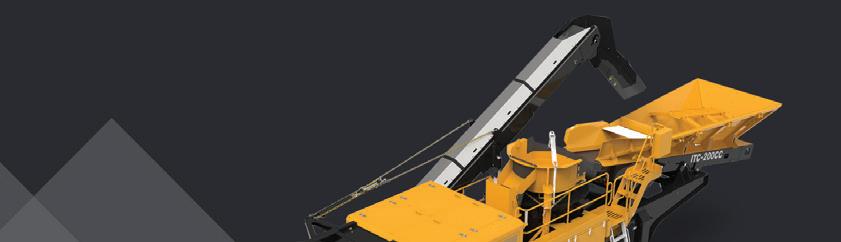

Finlay is setting a new standard for high-capacity production in the surface ore mining and aggregate industries with the C-1550+ tracked cone crusher.

Building on the strengths of its predecessor (the C-1550), the C-1550+ offers increased performance, enhanced efficiency, and improved serviceability.

At the core of the C-1550+ is the upgraded Terex 1300X cone crusher, which features a 1300mm (52”) head diameter. Engineered for durability and intelligent design, this crusher delivers a 15% increase in tonnage and

production compared to the C-1550. This improvement is achieved through higher clamp forces and a longer throw, resulting in greater profitability for owners, operators, and contractors. Additionally, the C-1550+ offers improved transportability, thanks to its lighter weight.

Performance is enhanced further with ultrasonic level sensors that regulate the material flow from the hopper to the crushing chamber. This ensures consistent and efficient crushing, while the machine’s ability to accept an all-in feed eliminates the need for additional screening equipment.

Other features that enhance the high-capacity production capabilities of the C-1550+ include full hydraulic closed side setting (CSS) adjustment with electronic monitoring for

AGGREGATE EQUIPMENT

precise control, as well as a fuel-efficient direct drive transmission through a wet

feeder is equipped with an automatic reset hydraulic tramp relief system that protects the chamber and minimizes downtime if uncrushable material enters the chamber. This system minimizes downtime by automatically removing contaminants via the purge chute, enabling smoother operations.

clutch to maximize fuel efficiency and reduce operating costs. The large hopper/

Cedarapids has announced the availability of the TI4250 Horizontal Shaft Impactor (HSI).

Engineered to deliver exceptional performance, the TI4250 is built to excel in tough applications such as construction, recycling, aggregates, and mineral processing.

The Cedarapids TI4250 crusher has a modern hydraulic assist apron adjustment enabling quick and precise setting changes to optimize operations. The crusher is equipped with four rear inspection doors and a hinged side door, providing comprehensive access to the rotor, blowbars, and aprons for inspection and servicing. The chamber hydraulically opens for general maintenance and for turning or replacing blowbars.

Constructed with durabil-

ity in mind, the heavy-duty crusher body is fabricated from high-strength structural steel. Its robust 4-bar rotor is outfitted with reversible

The C-1550+ is also designed with safety and maintenance efficiency in mind. Its mechanically designed liner retention and common upper frame make it compat-

blowbars secured by a wedge lock system, enhancing reliability and operational efficiency. The TI4250’s powerful 42-inch diameter rotor fractures material by propelling it against high wear resistant manganese alloy aprons, ensuring consistent and efficient crushing in a wide range of applications, from demolition to quarry operations.

In addition to its standalone capabilities, the TI4250 is a key feature of the Cedarapids CRH1113R Portable Closed Circuit Impactor &

ible with all liner configurations, including coarse, medium, and fine. This feature simplifies liner changes and maintenance, maximizing operational uptime. Generously sized catwalks provide easy access to the power pack from both sides, while a tagout engine isolator improves safety during maintenance. The hydraulically folding hopper, which can be locked from ground level, facilitates quick and efficient setup and teardown. SP

Source: Finlay

Screen Plant, delivering unmatched performance in a fully integrated solution. The CRH1113R combines the TI4250 HSI with a 6’ screen and feeder, providing a comprehensive crushing and screening solution that is ready to tackle even the most demanding projects. The TI4250 HSI delivers the performance and dependability that operators have come to expect from Cedarapids. SP

Source: Terex MPS

With funding from the Forest Enhancement Society of BC, uneconomic residual fibre is being delivered from locations farther from town to BioNorth Energy, a joint venture partnership between Arrow Group of Companies, the Nak’azdli Development Corporation, the economic development arm of the Nak’azdli First Nation, and low-carbon infrastructure developer, Nexus PMG.

The project, which began in the fall of 2023 after an intense wildfire season, will finalize this winter, helping reduce harmful greenhouse gas emissions from entering the atmosphere while also generating economic and social benefits for the community of Fort St. James.

“I want to commend the work of Arrow, NDC and Nexus PMG,” said Ravi Parmar, Minister of Forests. “By getting residual fibre out of our forests and into the hands of those who need it and can use it, they are creating jobs and revenue from what would have once been waste. During times of uncertainty, they show that by working

together, the forest sector and communities can have a major impact in ensuring forestry workers continue to have stable and steady jobs.”

The project focuses on grinding residual logging debris into feedstock for BioNorth Energy, a 40-mega-watt biomass power generation plant in Fort St. James.

“We have completed grinding projects within a 3-hour drive of BioNorth Energy. We grind approximately 200,000 cubic metres worth of slash piles every year that are used to produce clean energy,” explained Greg Kilba, Division Manager, Portable Wood Processing and Log Buyer at

Arrow. “Historically, many of these waste piles would have been outside of our economic zone and would have traditionally been burnt by industry and government.”

According to Chris McGourlick, RPF, Operations Manager with FESBC, the estimated fibre utilization from this project is equivalent to 4,635 truckloads. By grinding these slash piles that would otherwise be burnt, collaborators are taking action on climate change.

“The total greenhouse gas emissions avoided as a result of this work is 36,191 tonnes of avoided emissions, which is the equivalent of 7,817 ve-

hicles off the road,” added McGourlick.

The slash piles are now being utilized to create green energy in Fort St. James, adding value to the community by creating jobs for local community members and supporting primary services like the BioNorth facility, as well as secondary services such as tire shops and gas stations.

“Fibre utilization is more important than ever in our goal to reduce carbon emissions,” explained Tyler Dixon, Division Manager with Arrow in Fort St. James. “The grinding group directly has close to 30 high-paying fulltime positions, and BioNorth has around the same. This is money that stays in the communities we operate in and plays a large role in local economies. We also strive to support as many local busi-

nesses as possible for our service/parts needs, which is another way we are able to support our communities.”

As the Nak’azdli First Nation owns around 40% of BioNorth, they have invested a significant amount of money and effort to position its members and community to enjoy a more prosperous and sustainable future.

“We grind approximately 200,000 cubic metres worth of slash piles every year that are used to produce clean energy.”

“The opportunity to invest in a clean energy project within the traditional territory

of Nak’azdli Whut’en aligns with stewardship values while providing a long-term equity source that will benefit the community today and for future generations,” expressed John-Paul Wenger, Chief Executive Officer of NDC.

FESBC has played a crucial role in bridging the gap of being able to utilize more fibre with an incremental amount of money. The total project funding amounted to $1,867,000, which helped cover the cost of delivering the fibre to the facility.

As Kilba noted, each load delivered to the plant that has required additional funding represents 1.6 person-days of work that would have otherwise gone up in smoke.

“With less active logging in the area, we are seeing less fibre available. FESBC fund-

Continued on page 33

ing gives us the opportunity to expand our basket to areas that otherwise would not be economically viable,” added Dixon. “FESBC should be credited for playing a massive role in keeping BioNorth Energy’s yard full of fibre during some uncertain times in the industry.”

To traverse difficult access and improve delivery efficiency, the project utilized job specific trucks that are heavier and more robust to withstand gravel roads.

“This has resulted in fewer breakdowns and required less assistance to get to the challenging terrain that can be found on timber harvesting sites in the area,” explained Kilba.

Additionally, Arrow’s collaboration with local tenure holders has been key to the grinding and utilization of residual fibre.