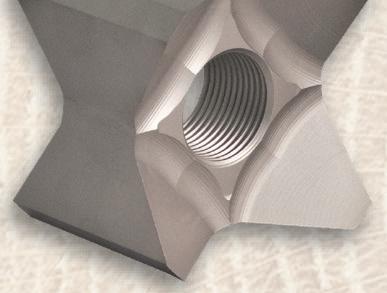

As the forestry industry advances with technological improvements, the partnership between Quadco and Log Max combines decades of experience to introduce the new cutting-edge 7000XTDS Harvester Head.

Both companies are renowned for their robust and efficient designs, and the 7000XTDS Harvester Head is a testament to their commitment to enhancing productivity and operator satisfaction in forest operations.

Key Features of the 7000XTDS Harvester Head

The 7000XTDS is not just an improvement but a revolution in harvesting technology. By integrating Quadco’s Intermittent Disc Saw into Log Max’s acclaimed 7000XT model, this harvester head reduces downtime and opera-

tional costs compared to traditional chain saw systems. Its standout feature, the swingout disc saw, boasts a cutting speed of 600-700 rpm, ensuring high-quality cuts and exceptional productivity.

Combined with the Logmax Logmate 510 Control system, this package will ensure high-quality cuts and exceptional productivity.

Advantages of Disc Saw Felling Over Traditional Methods

Traditional chain systems are prone to wear and damage, particularly in challeng-

ing conditions such as heavy underbrush or mixed wood stands. The 7000XTDS’s disc saw offers a low-maintenance, reliable alternative that enhances the durability and uptime of harvesting operations. Its design allows for quick and easy maintenance checks and minimal tooth damage, extending the life of the cutting components.

This harvester head features a solid center and a rotating ring that enables instant cutting speed, making it

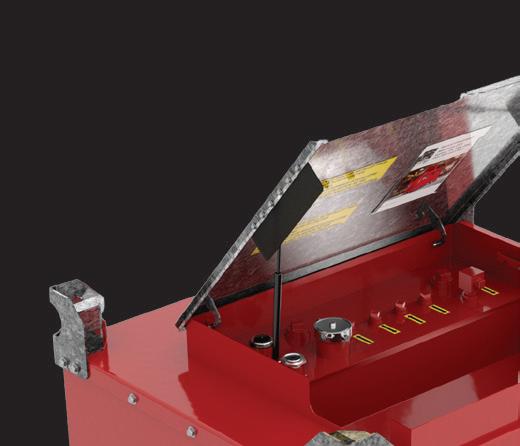

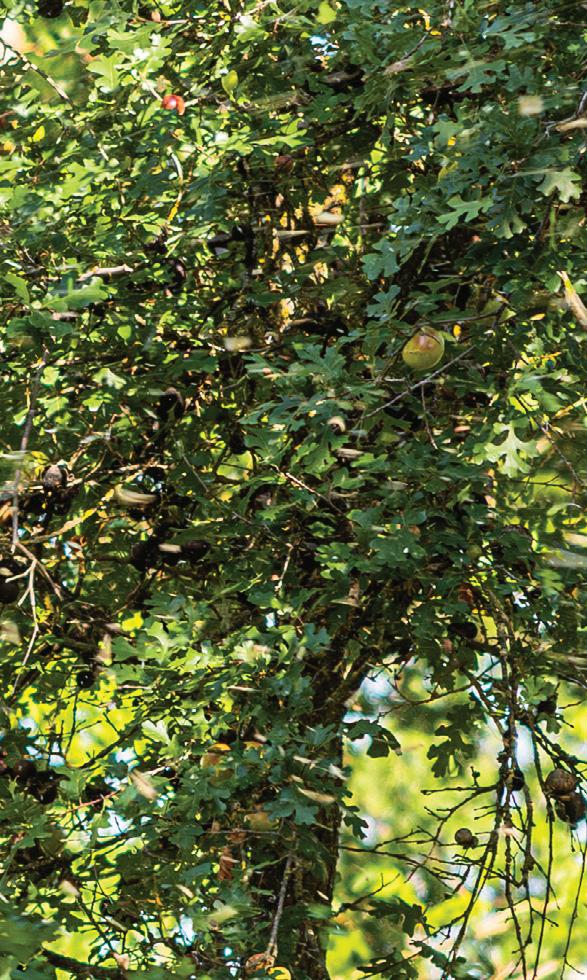

FAE is expanding its range of top-of-the-line forestry mulchers for excavators with the introduction of the new UMM/S/EX model for excavators up to 40 tons; particularly for feller bunchers.

The new UMM/S/EX can be used for mulching trees and vegetation with a diameter of up to 40 cm and is com-

patible with excavators from 25 to 40 tons. Its hydraulic capacity ranges from 250 to 450 L/min., and it can handle pressure of up to 400 bar. This mulcher model is recommended for use anywhere a large mulching capacity is required, including in wooded areas or green spaces.

The UMM/S/EX has been designed with a num-

ber of specific features to provide top performance. Its VT automatic variable displacement motor allows for increased torque, and its double Poly Chain belt transmission ensures optimum power transfer and reliability over time. Spike PRO bolted counter blades produce very fine mulch and make maintenance easy, while the

ideal for delimbing, topping challenging trees, and clearing underbrush. The fixedmount and Quadco-designed lateral tilt mechanism offer unmatched control and maneuverability, adding to its operational efficiency.

Designed with the operator in mind, the 7000XTDS is as user-friendly as it is powerful. The fixed head design with the patented Quadco 360 degree rotate, allows operators to easily extricate the machine from difficult spots and execute tight turns without impacting the surrounding area. Simple maintenance routines—such as a quick 1000-hour check for wear— make this harvester head a favorite among fleet owners for its ease of use and reduced training requirements.

The 7000XTDS Harvester Head is more than an equipment upgrade—it’s a significant leap forward in forestry technology. With its superior design, ease of maintenance, failsafe measuring system, and robust construction, it sets new standards in the industry, promising enhanced operational efficiency and reduced costs. For professional contractors and fleet owners, the 7000XTDS offers a compelling combination of performance, reliability, and ease of use, making it an essential tool for modern forestry operations. SP

Source: Quadco

mulching chamber features bolted protections made of an anti-wear material. The sturdy type-C rotor makes it possible to use different tooth models for different applications and comes with side teeth, which help keep the crushing chamber clean at all times. Finally, with a sturdy steel frame, the UMM/S/EX is built to last. This head is available in UMM/S/EX/VT150 size.

With the introduction of the UMM/S/EX, FAE forestry mulchers can now be used with even more powerful vehicles, which have only been used in a limited capacity for this application up to now. SP

Source: FAE

2022 YANMAR SV08-1D RUBBER, 2'3"-2'9" WIDE, 2 BKTS, HYD THB, 268 HRS CALL

2023 YANMAR VIO17-A RUBBER, CANOPY, 2 BKTS, THB, AUX HYDS SALE OR RENT

2024 YANMAR VIO17-1E RUBBER, CANOPY, 2 BKTS, HYD THUMB CALL

NEW YANMAR VIO17-1E, RUBBER, CANOPY, 2 BKTS, HYD THUMB, AUX HYD CALL

2023 YANMAR VIO25-6B, CANOPY, BLADE, 2 BKTS, HYD THUMB, 160 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, BLADE, 2 BKTS, HYD THUMB, 286 HRS CALL

2025 YANMAR VIO25-6B, CAB HEAT, BLADE, 2 BKTS, HYD THUMB CALL

2023 YANMAR VIO35-6A, CANOPY, BLADE, 2 BKTS, HYD THUMB, 139 HRS $55,500

2022 YANMAR VIO35-6A, CANOPY, RUBBER, 2 BKTS, HYD THB, AUX, 248 HRS CALL

2023 YANMAR VIO35-6A, HYD Q/C, 2 BKTS, HYD THUMB, 348 HRS CALL

2024 YANMAR VIO35-6A, HYD Q/C, 2 BKTS, HYD THUMB, 352 HRS CALL

NEW YANMAR VIO35-6A, HYD Q/C, 2 BKTS, HYD THUMB, 426 HRS CALL

NEW YANMAR VIO35-6A, HYD Q/C, 2 BKTS, HYD THUMB CALL

2023 YANMAR SV40, HYD Q/C, 2 BKTS, HYD THUMB, 496 HRS CALL

2023 YANMAR SV40, HYD Q/C, 2 BKTS, HYD THUMB CALL

2021 HITACHI ZX50U-5N, CAB AIR, 2 BKTS, THUMB, +WRIST BKT, 1,818 HRS CALL

NEW YANMAR VIO50-6A, CAB, 2 BKTS, HYD THUMB, AUX, 404 HRS $74,900

NEW YANMAR VIO50-6A, CAB, 2 BKTS, HYD THUMB, 2ND PTO, 203 HRS CALL

2024 YANMAR VIO50-6A, CAB, 2 BKTS, HYD THUMB, AUX HYDS CALL

NEW YANMAR VIO50-6A, CAB, 2 BKTS, HYD THUMB, AUX HYDS CALL

2020 YANMAR VIO55-6A, CAB, 2 BKTS, HYD THUMB, AUX HYDS, 2,895 HRS CALL

2023 YANMAR VIO55-6A, CAB, 2 BKTS, HYD THUMB, AUX, 784 HRS CALL

2023 YANMAR VIO55-6A, CAB, HYD THUMB, 2 BKTS, AUX, 890 HRS $80,500

2023 YANMAR VIO55-6A, CAB, 2 BKTS, HYD THUMB, AUX, 606 HRS CALL

2023 YANMAR VIO55-6A, CAB, 2 BKTS, HYD THUMB, AUX, 288 HRS CALL

2024 YANMAR VIO55-6A, CAB, 2 BKTS, HYD THUMB, AUX, 142 HRS CALL

NEW YANMAR VIO55-6A, CAB, AIR, RUBBER, 2 BKTS, HYD THUMB, AUX HYDS CALL

2020 HITACHI ZX75US-5B, 18" PADS, BOR, BLADE, PIPING, ONLY 2,191 HRS CALL

2021 HITACHI ZX75US-5B, 18" PADS, BOR, BLADE, PIPING, ONLY 1,212 HRS CALL

2019 CAT 308CR-07A, 18" PADS, BLADE, AUX PIPING, ONLY 2,054 HRS $78,900

2023 YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB, 1,068 HRS CALL

2023 YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB, 832 HRS CALL

2023 YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB, 577 HRS CALL

2023 YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB, 432 HRS CALL

2023 YANMAR VIO80-1A, STEEL, 2 BKTS, HYD THUMB, AUX, 267 HRS CALL

2023 YANMAR VIO80-1A, CAB AIR, 2 BKTS, HYD THUMB AUX, 73 HRS CALL

2024 YANMAR VIO80-7, RUBBER, CAB AIR, 2 BKTS, HYD THUMB, AUX CALL

2023 YANMAR SV100-2A, RUBBER, CAB, 2 BKTS, HYD THB, AUX, 1,051 HRS CALL

2023 YANMAR SV100-2A, STEEL, CAB, HYD THUMB, 2 BKTS, 882 HRS CALL

2023 YANMAR SV100-2A, RUBBER, CAB, 2 BKTS, HYD THB, AUX, 1,015 HRS CALL

YANMAR SV100-2A, RUBBER, CAB, 2 BKTS, HYD THUMB, AUX, 867 HRS CALL

2023

2023

YANMAR SV100-2A, RUBBER, CAB, 2 BKTS, HYD THUMB, AUX, 555 HRS CALL

YANMAR SV100-2A, RUBBER, CAB, 2 BKTS, HYD THUMB, AUX, 438 HRS CALL

2023

2025 YANMAR SV100-7, STEEL, CAB AIR, PTO2, HYD Q/C CALL

2019 CAT 311FL RR 20" PADS, BLADE, PIPING, 4,392 HRS CALL

2019 CAT 312F GC, 20" PADS, AIR, ONLY 2,168 HRS $79,900

2008 CAT 313D CR 20" PADS, AIR, BLADE, PIPED, 6,555 HRS CALL

2008 HITACHI ZX135US-3, 20" PADS, AIR, ONLY 5,108 HRS $58,900

2011 HITACHI ZX135US-3, 20" PADS, 2 BKTS, HYD THUMB, 8,136 HRS CALL

2014 KOMATSU PC138US-10 20" PADS, AIR, BLADE, ONLY 3,779 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, HYD THUMB, 2,451 HRS CALL

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, HYD THB, AUX, 3,596 HRS $135,900

2017 HITACHI ZX135USBL-6 BLADE, 2 BKTS, Q/C, HYD THUMB, 2,073 HRS CALL

2018 HITACHI ZX135US0S-6, BLADE, O/S BOOM, 1,551 HRS, Q/C, 2 BKTS $99,900

2018 HITACHI ZX135USBL-6 20" PADS, BLADE, ONLY 2,541 HRS CALL

2020 HITACHI ZX135USBL-6 CABGUARD, BLADE, PRO LINK THUMB, 2 BKTS, 2,487 HRS $159,900

2020 HITACHI ZX135USBL-6 BLADE, CABGUARDS, ONLY 2,040 HRS $169,900

2020 HITACHI ZX135USBL-6 20" PADS, BOR, BLADE, 2,260 HRS SOON

2020 HITACHI ZX135USBL-6 BLADE, AUX HYD PIPING, 1,451 HRS CALL

2020 HITACHI ZX135USBL-6 BLADE, AUX HYD PIPING, 1,565 HRS CALL

2020 HITACHI ZX135USBL-6 BLADE, 2 BKTS, Q/C, HYD THUMB, 1,226 HRS OUT 4 MTHS

2020 HITACHI ZX135USBL-6 BLADE, 2 BKTS, Q/C, HYD THUMB, 1,430 HRS CALL

2022 HITACHI ZX135USBL-6 28" PADS, AIR, BLADE, AUX HYDS, 1,490 HRS CALL

2021 CAT 315 GC, 28" PADS, BLADE, Q/C, 2 BKTS, HYD THB, 1,244 HRS $192,500

2022 CAT 315 GC, BLADE, 2 BKTS, HYD THUMB, ONLY 249 HRS CALL

2022 CAT 315 GC, 20" PADS, BOR, BLADE, ONLY 227 HRS CALL

2023 CAT 315, 20" PADS, BLADE, PIPING, 1,024 HRS CALL

2018 HITACHI ZX200-6, Q/C DIG & CLEAN UP BKT, 5,182 HRS

2021 HITACHI ZX200-6, AIR, AUX HYDS, ONLY 1,296 HRS CALL

2022 CAT 320 07, 24" PADS, AIR, AUX HYDS, 2D, ONLY 999.3 HRS CALL

2012 HITACHI ZX200LC LR, 32" PADS, AIR, 18M SUPER LONG REACH, ONLY 3,551 HRS, Q/C DIG BUCKET $124,900

2018 HITACHI ZX200LC-5, 2 BKTS, Q/C, HYD THUMB, ONLY 3,690 HRS, CABGUARD, SIDE GUARDING, NO DEF/NO REGEN $164,900

2020 HITACHI ZX225USR-6 32" PADS, AIR, ONLY 1,114 HRS CALL

2021 HITACHI ZX225USR-6 24" PADS, AIR, ONLY 1,807 HRS CALL

2022 HITACHI ZX225USRLC-6, 24" PADS, AIR, ONLY 3,354 HRS SLIDE ARM SOON

2015 HITACHI ZX245USLC-5N, Q/C, 2 BKTS, PRO LINK HYD THUMB, CABGUARD CATWALKS, 8,808 HRS

$119,900

2021 HITACHI ZX245USLC-6, Q/C, 2 BKTS, HYD THUMB, 3,347 HRS CALL

2018 HITACHI ZX250LCK-6, 24" PADS, AIR, 2 BKTS, HYD THB, 3,296 HRS $189,900

2018 HITACHI ZX345USLC-6N, HYD WEDGE Q/C, HYD THUMB, 2 BKTS, CABGUARD, 4,250 HRS CALL

2021 HITACHI ZX330-6, 24" PADS, AIR, 2 BKTS, HYD THUMB, 938 HOURS CALL

2021 CAT 336 07C, ONLY 778 HRS, 2 BKTS, HYD THUMB, CATWALKS, CABGUARD, 2D EQUIPPED CALL

LOADERS/DUMPERS/DOZERS

2012 YANMAR V3-6, CAB HEAT, GP BKT, ONLY 2,924 HRS $26,900 2023 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT, 360 HRS CALL

2024 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT 56 HRS CALL

2023 CANYCOM SC75PDH PIVOT DUMP CARRIER 2,200 LB PAYLOAD, 35"W CALL

2004 YANMAR C12R, RUBBER, DUMPER, TAILGATE, 1,046 HRS $8,900

2022 YANMAR C50R-5AR, AIR, SW. DUMP, 8,379LB PAYLOAD, 610 HRS $109,900

2021 MOROOKA MST1500VDR 360 SWING DUMPER, 17,637 LB & 6.5 CU YD CAP, 1,392 HRS SOON

2021 MOROOKA MST2200VDR 360 SWING DUMPER, 24,000 LB & 8 CU YD CAP, 877 HRS CALL

2002 CAT 725, AIR RIDE SEAT, TAILGATE, 23.5X25 TIRES, 11,800 HRS CALL

2014 CAT 730, 750/65R25 TIRES, RV CAMERA, AIR RIDE SEAT, PAS, HEATED BODY, TAILGATE, 9,756 HRS CALL

SKID STEERS/COMPACTORS

2016 BOBCAT S70 HLA, 36" GP BKT, AUX HYDS, ONLY 748 HRS $15,900

2015 BOBCAT S590, HYD Q/C, A/C CAB, 2 SPEED, 1,826 HRS $49,900

2015 BOBCAT T590, CAB AIR, SJC CONTROLS, 2,351 HRS CALL

2021 BOBCAT T76 R SERIES, CAB AIR, HYD Q/C, 74" BKT 2 SP, 1,878 HRS $66,000

2025 YANMAR TL65RS, 67" BKT, 67 HP, 2100LB ROC, CAB AIR, HI FLOW, RVC CALL

2025 YANMAR TL75VS, 67" BKT, 74 HP, 2555LB ROC, CAB AIR, HI FLOW, RVC CALL

2025 YANMAR TL80VS, 72" BKT, 74HP, 2,900LB ROC, CAB AIR, HI FLOW, RVC CALL

2024 YANMAR TL100VS, 84" BKT, 104HP, ROC 3,600LBS, 102HRS CALL

2011 VOLVO SD25D, 41" DRUM DRIVE, PADFOOT SHELL KIT, 1,135 HRS $32,500

2012 VOLVO SD45D, 54" DRUM, CANOPY, ONLY 1,365 HRS CALL

2018 SAKAI SV204TF, 54" BOLT-ON SHELL KIT, CANOPY, 616 HRS CALL

2006 ING RAND SD70D TF, 66" SMOOTH DRUM, SHELL KIT, CANOPY $39,900

2013 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1713 HRS CALL

2014 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1,744 HRS CALL

2016 VOLVO SD75B, 66" DRUM, CANOPY, ONLY 2078 HRS CALL

2014 SAKAI SV513D, 84" SMOOTH DRUM, CAB AIR COND, 1,771 HRS $104,900

2021 SAKAI SV544DC, 84" SMOOTH DRUM, CAB AIR COND, 3,201 HRS CALL

ATTACHMENTS AND MISC

2019 MULTIQUIP WT5CSG 7K GVWR, NEW HONDA ENGINE & NEW 2" PUMP, PUMP,

525 GAL POLY TANK, 7,000 LB GVWR $9,900

2024 ALLMAND LIGHT PLANT

2025 SUP 200 16M LONG REACH BOOM/STICK, TO FIT ZX200/210LC

2025 SUP 290 18M LONG REACH BOOM/STICK, TO FIT ZX250/290/300

2025 SUP 350 21M LONG REACH BOOM/STICK, TO FIT ZX350

2025 SUP 35 40" TILT BUCKET, TO FIT VIO35

2025 SUP 55 48" TILT BUCKET, TO FIT VIO55

2025 SUP 80 60" TILT BUCKET, TO FIT VIO80/SV100

NEW HLA 48"

20

2 HITACHI ZX345USLC-6, 2 BKTS, HYD THUMB, CABGUARD

6 HITACHI ZX330/ZX350LC-6, 2 BKTS, HYD THUMB

DOZERS

CAT D3K2 LGP, 6 WAY DOZER, CAB AIR, 80HO, 20K LBS

2 KOMATSU D39/RIPPER, 6 WAY, CAB AIR KOMATSU D71PXI PAT/RIPPER, 6 WAY DOZER, MS RIPPER, “I” MACHINE

LOADERS

2 YANMAR V4-7, CAB AIR, BOBTACH Q/C, .91 CU YD BKT

8 KOMATSU WA200/250/270/320, 2.5-3.75 YD KOMATSU WA380-8, FORKS, BKT

CAT 950K, FORKS, BKT GRADERS/COMPACTORS

2 CORNIVER CT40 40” SMOOTH DRUM, KUBOTA ENG

8 CORNIVER CT48 48” SMOOTH DRUM, KUBOTA ENG

8 SAKAI SV204/VOLVO SD45, 45” SMOOTH DRUM, CANOPY

8 SAKAI SV414/VOLVO SD75, 67”/66” DRUM, CAB AIR

4 SAKAI SV544, 84” SMOOTH DRUM, CAB AIR CAT 140M, 14 TIRES, SCARIFIER, CAB AIR

Equipment Sales & Service Limited was recognized for its industry-leading performance, its global business practices, and its sustained growth by receiving the prestigious 2025 Canadas Best Managed Companies award.

Celebrating over 30 years, Canada’s Best Managed Companies program awards excellence in private Canadian-owned companies with revenues of $50 million or

greater. To attain the designation, companies are evaluated on their leadership in the

areas of strategy, culture and commitment, capabilities, and innovation, governance and financial performance.

OR SALE

• 2020 Komatsu PC138USLC-II, 2 Bkts, Hyd. Q/C, Thumb, Exc. Cond., 2,300 Hrs. P.O.R.

• 2018 Komatsu PC200LC-8, 3 bkts, Q/C, thumb, cabguard, catwalk, exc. cond., 1,772 hrs.

• 2017 Komatsu PC350LC-8, 3 bkts, thumb, cabguard, catwalks, exc. cond. 4,415 hrs.

• 2015 Komatsu PC170LC-10, 3 bkts, thumb, cabguard, exc. cond., 2,725 hrs.

• 2014 Komatsu PC88MR-8, 2 bkts, hyd. Q/C & thumb, swing boom and blade, 2,400 hrs.

• 2012 Komatsu D65EX-17, sigma blade, ripper & forestry guard., 75% U/C, exc. cond., 6,050 hrs.

• 2014 Hamm H13iX, 84” smoothdrum packer w/cab, A/C, low hrs, exc. cond.

• 2014 Hamm 3307, 66” smoothdrum packer w/shell kit, cab, A/C, exc. cond. FOR RENT

“We are very proud of our highly trained and skilled employees and support staff and view them as key drivers in attracting industry-leading companies to partner with us. Their deep expertise, professionalism, and commitment to excellence ensures that we consistently deliver superior results and innovative solutions tailored to our clients’ needs. By fostering a culture of continuous improvement and top-tier service, our team builds trust and confidence with major industry players, making us a preferred partner for organizations seeking reliability, quality, and longterm success. These factors are also key components of our continued success in being designated a member of the Platinum Club within the Best Managed Company program,” said Peter M Willis, Executive Co- Chairman, Equipment Sales & Service Limited.

Canada’s Best Managed Companies is one of the country’s leading business awards programs recognizing innovative and world-class busi-

nesses. Every year, hundreds of entrepreneurial companies compete for this designation in a rigorous and independent evaluation process.

Applicants are evaluated by an independent panel of judges with representation from program sponsors and special guests.

“We are delighted to be again chosen as part of the Platinum Group of the Best Managed Company program. In addition to having a highly skilled and motivated work force I would like to recognize the investments made by the ownership of Equipment Sales & Service in the business. The construction of a state-of-theart service facility will allow us to take care of our customers and foster growth into the future. Thanks again to all at Equipment Sales & Service for helping to achieve this honour,” said J. Morgan Cronin, President & CEO, Equipment Sales & Service Limited.

The 2025 cohort of Best Managed Companies shares common themes, including

fostering a people-centric culture, implementing a strategic company framework, investing in innovation and technological advancement, and maintaining financial resilience and strong corporate governance. Together, these practices strengthen the Canadian economy by promoting sustainable growth, enhancing competitiveness, and cultivating a thriving business ecosystem.

“To become a Best Managed Platinum Club winner is nothing short of remarkable. Their continued adaptability in an era of uncertainty sets the standard for how to overcome new barriers and demonstrate resiliency at the highest levels,” said Derrick Dempster, Partner, Deloitte Private and Co-Leader, Canada’s Best Managed Companies program. “These companies truly impact how Canada is viewed on the world stage when it comes to the success of private business.” SP

Source: ESS Limited

Bobcat has expanded its North American product lineup with the introduction of its 9-Series high-capacity diesel pneumatic tire forklifts.

Engineered for demanding applications, this series boosts business productivity with high-output diesel engines, increased control and enhanced reliability.

The 9-Series features five new models, D100S-9, D120S-9, D140S-9, D160S-9 and DV160S-9, which offer industry-leading features, including a redesigned drivetrain and hydraulic system that provides improved performance while reducing fuel costs. From maximizing productivity to supporting all-day comfort to putting safety at the forefront, this new product series is designed to give businesses the lift they need.

“Bobcat’s new D(V)160 family of diesel pneumatic tire forklifts were designed for a diverse range of mate-

rial handling applications ranging from moving fragile aircraft jet engines to logging or mining,” said Forrest Crawley, senior product specialist, Bobcat Company.

“Our industry-leading products are designed with durability, efficiency and safety in mind. Equipped with a highvisibility ergonomic cabin, operators are kept comfortable, improving their overall productivity. Operators will experience the difference and business owners will reap the benefits of the series’ impressive load capabilities, efficiency and overall lower cost of ownership.”

The 9-Series helps operators achieve optimal productivity with its highperformance engine, class-

leading travel speeds and lift speeds, and one of the tightest turning radiuses in the industry.

With the latest engine technology and optimal power transfer through the drivetrain and hydraulic system, the 9-Series offers more strength to power through slopes and heavy loads. The series’ fuel-efficient engine provides the choice of standard or eco-mode for the operator to customize for increased power and lifting performance or to maximize fuel economy.

The Bobcat 9-Series forklifts are designed to reduce fatigue and elevate productivity. Their redesigned floating cab supports greater operator visibility and features a fully adjustable suspension seat and tilting and telescoping steering column. The wellinsulated cab supports lower noise levels, while the automatic heat and air conditioning system keeps operators comfortable in various work environments.

A multi-function, 7-inch display comes standard to put more control at operators’ fingertips. The display

is mounted to the A pillar for easy accessibility with heads-up operation. The display can be fully integrated with an optional rearview camera.

The 9-Series forklifts are engineered to withstand tough job sites, including several features that simplify maintenance to maximize uptime. Durability starts with its robust frame which is built to withstand heavy use in harsh conditions, and its shaft-type carriage provides superior strength when handling wider and longer loads. The loadsensing hydraulic system reduces fuel consumption and ensures the coolest possible operating temperature for longer component life.

Other key features promoting uptime include the forklifts’ dual-element air cleaner to increase engine service life; oil-cooled disc brakes with a life span of up to 20,000 hours; and a standard hydraulically driven variable speed fan with optional reverse function adjusts to coolant and break oil temperatures to maximize cooling performance while its reverse function helps to keep the radiator cleaner.

When maintenance is needed, the components are easier to access via the rear hood’s wide-open angle and the tiltable cab.

Bobcat forklifts are designed to put safety first. Several features support allaround visibility, stability and greater worksite awareness.

Included in the 9-Series lineup is the DV160S-9. This

forklift offers a max load capacity of 36,000 pounds at 48-inch load center, plus travel speeds of 21.1 mph and a lift speed of 76.8 fpm when loaded. These machines are trusted workhorses for a variety of job sites including lumberyards,

utility work, steel foundries, shipyards, ports, and more. The new 9-Series is available now at select Bobcat North American material handling dealers and distributors. SP

Source: Bobcat Company

Holcim has acquired the operations of Langley Concrete Group Inc., a leading provider of precast solutions based in British Columbia.

This strategic move marks the company’s entry into the precast concrete market in the province, expanding its national capabilities and strengthening its footprint in the rapidly growing infrastructure sector.

“We are pleased to welcome 180 talented Langley Concrete Group Inc. employees to our team,” said Jaime Hill, Region Head, North America, Holcim. “This acquisition is a natural extension of our growth strategy. By combining Langley Concrete Group Inc.’s technical capabilities with our operations, we are better positioned than ever to deliver enhanced value to our customers through expanded reach, service, and a strong portfolio of advanced and high-quality products.”

The acquisition includes two state-of-the-art production facilities in Chilliwack and Duncan, British Colum-

bia. These facilities will serve the local region and manufacture a wide range of drycast and wet-cast concrete products for both above- and below-ground infrastructure applications. The portfolio includes various products such as manholes, concrete pipe, box culverts, and other custom components essential to municipal, commercial, and industrial products.

Mark Omelaniec, president of Langley Concrete Group Inc., added, “We’re proud of the 75-year family-based business legacy we’ve built, and confident that Holcim is the right partner to carry it forward as the growth opportunities continue in B.C. This transition brings long-term opportunity for our team and customers, all while building on the quality and service standards that define who we are.” SP

Source: Holcim

The CX380E is rumbling onto jobsites with more power, functionality and operator-first features for comfort and control

CASE Construction Equipment continues to focus on developing swift, smooth, smart machines that help operators get more done with the launch of the new CX380E large excavator. The 268-horsepower, 83,114 lb (37,700 kg) unit is the newest addition to CASE’s robust excavator lineup.

Whether it’s clearing land, trenching, craning pipes on construction and road sites, or even breaking rock, the CX380E gives crews brute power and intelligent hydraulics for more productivity. Rental companies can also count on the CX380E to expand customer options for a dependable jobsite workhorse.

Power, Performance and Control

The CX380E is built for heavy-duty tasks, with 56,000 lbs. of breakout force and fast cycle times. Operators can adjust the power to the task with four fuel-efficient

work modes in a range up to 10 throttle settings: Super Power for the maximum possible power; Power for a hardworking mode suitable for daily operation; Eco for more fuel efficiency; and Lifting for maximum control during lifting and craning tasks. Eco mode lowers fuel consumption by up to 18 percent compared to previous CASE excavators. In addition, CASE telematics and software provide precise data to measure fuel usage and other metrics to further improve efficiency.

“Big jobs demand big machines and the CASE CX380E large excavator is exactly that. Built like a beast, it delivers more power and more torque with faster response times,” says Terry Dolan, head of CNH Construction Brands, North America. “But it also delivers big on the total operator control that our customers expect from CASE.”

Like all CASE E Series large excavators, the CX380E offers advanced controls and

customizable sensitivity settings so that users can dial in responses exactly to their preferences for easier operation. The 10-inch touchscreen lets operators store settings for up to 10 attachments (one-way and two-way) on one screen, making it simple to change attachments in seconds at the touch of a button — instead of hours — while reducing the risk of downtime or damage from overloading the attachment. The intelligent Hydraulic Flow Control Balance also makes the excavator even more responsive and efficient by customizing the priority of hydraulic flow used for movements like arm in and boom up as well as arm in and swinging.

For added control, the CX380E features selectable free swing functionality, giving operators more stability and improved safety with less fatigue when lifting and placing swinging loads, working on uneven terrain or loading trucks. Along with advanced

controls, operators can also work more confidently using the 270-degree camera which provides a bird’s-eye view via the display screen for improved visibility and safer operation, as well as setting up arm and swing preferences.

Just as visibility and control support safer operation, the cab is designed to support the operator through long hours on the jobsite.

“Operators work hard, so creating an operator-first experience to help fight fatigue and increase efficiency is a priority in every new CASE machine,” says Dolan.

“We designed the CX380E cab with automotive-like features, with heated, airsuspension seating and lots of legroom. A suspended

operator station locks the seat and console together so no matter the operator’s size, they have the same experience and ergonomic access to the controls. Together, these features boost comfort and help workers get more done on the job.”

For maintenance and serviceability, the CX380E has advanced telematics, allowing dealers to run diagnostics and update software

remotely without the need for an on-site service technician—saving time and money while promoting more uptime. In addition, the comprehensive CASE ProCare heavy machine support program comes standard, with a 3-year/3,000-hour full machine factory warranty, plus 3-year/2,000-hour planned maintenance support and a 5-year advanced telematics subscription. SP

Source:

CASE CE

With

Finance

Brandt

Hundreds of municipal, First Nations and BC Wildfire Service (BCWS) firefighters from across the province are coming together at the Wildfire Resiliency and Training Summit in Penticton, British Columbia to train, collaborate and learn about new technology and practices ahead of the 2025 wildfire season.

“We don’t know exactly what this wildfire season will bring, but I want British Columbians to know that we are working hard every day to be ready,” said Ravi Parmar, Minister of Forests. “With year-round operations, cutting-edge technology and strong partnerships with First Nations and local fire departments, we’re putting in the work to protect our communities.”

The Wildfire Resiliency and Training Summit brings together First Nations and local government representatives, emergency managers, wildfire mitigation specialists, and firefighters to collaborate and train with the BCWS and discuss the latest developments in wildfire technology, mitigation and prevention.

fessionals and includes two days of collaborative training between structural fire departments from throughout the province and the BCWS. The training focuses on fireline operations, deployment of fire engines, large water supply operations and overall approach to structure protection in the wildland-urban interface to better protect communities from the threat of wildfires.

Following the training session, a three-day conference for more than 700 municipal and First Nations leaders will focus on wildfire resiliency and community action through FireSmart.

“Learning and training are vital to thriving in high-risk environments,” said Brian Hutchinson, superintendent

sionals attending the training summit portion of the conference, we continue to collaboratively build capacity, capabilities and resilience to the impacts of wildfires.”

Representatives from the California Department of Forestry and Fire Protection (CALFIRE) will be in attendance this year, further developing the partnership with B.C. In January 2025, BCWS staff were deployed to California to support CALFIRE with expertise and personnel during the devastating wildfires in Los Angeles. Working alongside Californian crews, BCWS gained valuable experience managing large fires in the wildland-urban interface. Building on this interagency experience, BCWS and CAL

Ahead of the upcoming wildfire season, the Province is working to keep communities safe by focusing on all four pillars of emergency management: prevention, preparedness, response and recovery. This work includes:

• securing equipment and aircraft contracts;

• continuing to implement new technologies and innovation;

• focusing on prevention work; and

• engaging with local partners, including communities and local equipment operators.

mitted to date.

• There has been $90 million allocated in 2025 for wildfire prevention initiatives through BCWS, FireSmart initiatives, and the Forest Enhancement Society of BC (FESBC). Technology and innovation improvements for the 2025 wildfire season include:

• implementing new wildfire predictive technology across the province;

with the best data available to inform operational decision-making.

• There are 88 cultural and prescribed-burn projects planned for 2025. There were 48 completed in 2024.

• BCWS is planning to treat 9,600 hectares in 2025-26 with more than an additional 2,100 hectares planned under FESBC.

Since 2018, the Province has partnered with the Union of BC Municipalities and First Nations Emergency Services Society to reduce wildfire risk through the FireSmart Community Funding and Support (FCFS) program, with $185 million com-

• working with UBC Okanagan to pilot a camera network that communities can tie into for wildfire detection;

• respiratory protection now available to all operational staff, with plans to study fire camp air quality;

• continuing to utilize and further develop night-time firefighting operations, including NVIS technology piloted in 2024; and

• improved provincial weather stations that expand weather prediction windows to provide staff

Working together to prevent wildfire and keep communities safe

To increase wildfire prevention and help keep people safe, the Province has taken action over the past six years to strengthen provincial and community capacity for wildfire mitigation and preparedness. In recent years, the BC Wildfire Service’s (BCWS) wildfire prevention and mitigation efforts have expanded rapidly, supported by the BCWS growing into a year-

round organization focused on proactively reducing wildfire risks as well as responding to fires. Prevention efforts have included hundreds of wildfire risk-reduction and fuel-management projects with partner agencies, with 88 cultural and prescribed fire projects planned for 2025, of which eight have already been implemented this spring.

Since 2018, the Province, through BCWS, has invested approximately $466 million in wildfire resiliency and riskreduction projects. The Province’s approach to wildfire risk reduction is through strategic partnerships with communities, First Nations, and external partners, in addition to the BCWS’ direct wildfire mitigation. In advance of this year’s wildfire season, the Province continues to work on fuel mitigation and community preparedness activities to reduce the threat of wildfire, in partnership with local governments and First Nations, and the following organizations:

FireSmart actions are tested and proven, and they increase your home’s chance of

survival in the event of a wildfire. FireSmart is the Canadian standard recognized by all provinces and territories based on National Fire Protection Association (NFPA) standards. This year, there are 250 FireSmart recognized neighbourhoods throughout B.C., and approximately 140 FireSmart co-ordinators within local governments and First Nations. More than 113 local governments and First Nations participate in the Wildfire Mitigation Program, formerly the Home Partners Program, including 20 of the 28 regional districts

As a leader in wildfire mitigation and preparedness, work by FireSmart BC includes:

• funding 309 local governments and First Nations to undertake FireSmart activities;

• 231 FireSmart positions proposed for funding or partially subsidized in communities across the province; and

• 57 garden centre locations across B.C. now participate in the FireSmart Plant Program.

• Union of BC Municipalities and First Nations’ Emergency Services Society.

Since 2019, the Province has taken action in partnership with the Union of BC Municipalities and First Nations’ Emergency Services Society to reduce wildfire risk through FireSmart grants and supports, with $185 million committed to date. The Union of BC Municipalities, in partnership with First Nations Emergency Services Society (FNESS), administers the FireSmart Community Funding and Supports (FCFS) program to communities on behalf of the Province. More than 936 applications have been received since 2019, leading to more than $126 million in approved completed projects.

The Province partners with FESBC to reduce wildfire risks, enhance wildlife habitats, improve damaged or low-value forests, and manage greenhouse gases. Since 2016, $79.6 million has been invested in 201 community wildfire risk-reduction projects through FESBC. As part of Budget 2024, an additional $60 million was announced

Continued on page 16

2015 Link-Belt 350X2RBW “Road Builder,” c/w: CWS power clam grapple, 10,7XX hrs $174,500

2013 Hitachi ZX210LC-5N, c/w: 36” CWS dig bkt. & CWS Q/C, hyd. thumb, 9,454 hrs $69,750 LOG LOADERS

2017 John Deere 3756G, c/w: T-Mar “Extreme Duty” grapple, Tier 3 eng., 5,070 hours $424,500

2010 Caterpillar 330DFMLL Heel Boom, c/w: T-Mar 60” log grapple $64,500

Madill 4800 Heel Boom, T-Mar log grapple $274,500

2001 Madill 124 Swing Yarder, Recent major work orders,

for FESBC, with $20 million to be allocated each year for the next three years. This funding supports wildfire risk reduction and/or enhanced wood fibre utilization.

The Fire Chiefs’ Association of British Columbia is a non-profit organization that serves as an essential source of information, education, and community for its members. It proactively engages with the government and standards organizations on issues relating to fire services, resulting in effective and supported fire departments across the province. Through an agreement with the Fire Chiefs Association of BC (FCABC), BC Wildfire Service has worked closely with local fire departments to coordinate equipment and personnel, with more than 100 fire departments that have pre-registered their personal and equipment for provincial deployments this season.

Farmland Advantage helps farmers identify and enhance the natural values on a

farm that can be protected, restored, and enhanced and develops recommendations and plans to preserve them. Since 2021, the BCWS has worked with Farmland Advantage on $1.4 million in wildfire riskreduction and community resiliency projects, focusing on strategic areas in the wildland-urban interface.

After the 2023 fire season, the Premier’s Expert Task Force on Emergencies recommended defining clear pathways for organized and trained local people to play a role in wildfire preparedness and response, based on consistent safety, pre-season training and readiness standards and plans, and integration into the BCWS or local emergency management structure with appropriate co-ordination, accountability and oversight. The BCWS partnered with the Fraser Basin Council in fall 2023 to engage rural communities as part of the Wildfire Roundtables they facilitate.

Through this engagement, the Fraser Basin Council received responses from 37 out of 89 electoral area directors. Of the 37 responses, 35 identi-

fied existing groups that were outside of structural protection areas. Twenty-four of these groups were organized, and 11 were not organized at the time.

The feedback received was instrumental in guiding the steps BCWS took leading into the 2024 fire season to invest in the preparedness for these groups by training more than 430 community members across 21 groups and engaging them in co-operative response efforts in the 2024 fire season. The groups that were hired in the 2024 fire season were engaged in lowcomplexity tasks aligned with their basic training such as mopping up, cooling ash pits and patrolling areas to prevent potential flare-ups.

In recognition of the need to grow this program beyond the initial training intake in 2023, the Regional District Cooperative Community Wildfire Response Organizations program was established to assist in funding training and equipment purchasing of rural response groups.

Columbia Basin Trust

Initially launched as part of the BC Economic Recovery

Manitou is pleased to expand its line of aerial work platforms with the launch of two new electric scissor lift models for the North American market: The SE 1932 and SE 2632.

Purpose-built by Manitou to meet the demands of construction, manufacturing, facilities maintenance, and equipment rental, these lifts deliver the same high standards of performance, durability, safety, and low total cost of ownership (TCO) that define an entire lineup of lift and access solutions.

The SE 1932, with a 19foot platform height, and the SE 2632, with a 26-foot platform height, are batterypowered and equipped with efficient, reliable AC drive motor controls for precise positioning. These hydraulicpowered scissor lifts ensure smooth elevation, enabling users to reach new heights with confidence. Designed for both indoor and outdoor applications, these models feature a 507-pound basket capacity, offering the versatility required for a wide range of jobsite tasks.

Plan in 2021 to support wildfire risk-reduction projects in the Columbia Basin, this program became the Columbia Basin Wildfire Resiliency Initiative in 2022-23. With an ongoing investment of $4 million to support expanded wildfire risk reduction in the Columbia Basin, the program is supported by the BCWS, the Ministry of Forests Regional Operations, and the Columbia Basin Trust.

To date, there have been 20 projects supported in 18 communities.

Cattlemen’s Association

The Province partners with the British Columbia Cattlemen’s Association

The SE 1932 (19-foot plat-

to support beef cattle producers in B.C. Since 2021, $300,000 has been provided in grant funding to build and expand on an existing initiative that develops, pilots and tests new models of targeted livestock grazing as a supplemental tool for managing fine fuels in B.C.’s forested rangelands.

B.C. Community Forest Association

BCWS works alongside the B.C. Community Forest Association (BCCFA) to reduce wildfire risk in community forests. BCCFA is a non-profit society serving as the voice and advocate of community forests in BC. Currently BCCFA represents more than 100 rural and In-

form height) and the SE 2632 (26-foot platform height) are battery-powered with efficient, reliable AC drive motor controls for positioning and a hydraulic powered scissor lift to take you to new heights. They are capable of both indoor and outdoor work, and both feature a basket capacity of 507 pounds for jobsite versatility. The compact design, zero turn footprint and standard extendable threeposition working platform (up to 8’, 4” x 2’, 5.5”) make it extremely versatile in providing stable access in all applications.

Each Manitou scissor lift features 100 percent electric power with durable AC motors direct drive, proportional intuitive controls & joystick, and hydraulic lift technology that provides fast, smooth and precise operation

digenous communities across the province. Under the BC Economic Recovery Plan, $5 million was allocated to the BCCFA to reduce wildfire risk and stimulate employment opportunities in 15 community forest tenure areas located around rural communities between 2020 and 2023.

Additionally, community forests have invested $8 million of their own funds and managed more than $17 million in grants from outside sources such as FESBC to build wildfire resiliency and reduce risk through mechanical treatments and use of prescribed fire. SP

Source: Province of British Columbia

“We are excited to introduce the SE 1932 and SE 2632 scissor lifts for North America,” announced Brian Rabe, Product Marketing Manager - MEWPs & Forklifts. “These new scissor lifts expand our strategic MEWP offering, built by Manitou on decades of experience in manufacturing high quality and high performance equipment for working at height.”

The work platform itself is built for optimal operator flexibility. A full-height swing gate ensures easy operator access to the work platform. The control interface within the basket can be moved/placed to allow the operator to position the controls where they make the most sense – either based on operator preference or the type of work being done. The ground-level control panel is also extremely intuitive to use and is aligned very well for visibility to the work platform. It features an integrated screen that is easy to read and puts machine diagnostics at the operator’s fingertips. The electric operation of the scissor lifts also eliminates emissions in the work area and keeps sound levels at

an absolute minimum.

The platform can be locked into three different positions to meet the needs of each application, and the rails can be lowered in a way that allows the lift to pass through doors less than 6.5 feet. Antirollover bars ensure stability regardless of ground conditions.

Each model also features side and rear fork pockets for lifting and placing the lift with a forklift or other machine, making it easy to load onto trucks for the rental industry, or to simplify movement of the lift around a jobsite.

Each scissor lift was designed and built by Manitou, produced in Manitou’s factory which keeps the machine

simple with extremely reliable technology — minimizing downtime and lifetime total cost of ownership. Scissor arm pivot points are maintenancefree, and key operational points and joints have all been designed to prevent water infiltration to reduce opportunity for corrosion. AC/DC motors are all controlled by a single drive for greater simplicity, and the structure of the machine itself is designed of high-quality steel and components for optimal reliability. Each lift comes standard with Manitou telematics including six years of connectivity to the EasyMANAGER fleet management system for optimal tracking of service intervals, machine location and health. SP

Source: Manitou

The 2025 season of the FIA World Rallycross Championship has been officially announced to begin this June, with Volvo Construction Equipment resuming its central role as Official Track Building Partner.

As Official Track Building Partner, Volvo CE is tasked with building new features on existing racetracks or sometimes building courses entirely from scratch – in the most sustainable and efficient way possible, and always under tight timeframes. The company is also tasked with maintaining the tracks and recovering crashed cars during the races themselves with its innovative safety solution.

These challenges require power, precision, and adaptability. Volvo CE’s advanced electric machines are engineered to handle the unique challenges of shaping and maintaining these high-intensity circuits while reducing reliance on fossil fuels. With their near silent operation, electric machines increase

efficiency by making it possible to build tracks during the night or during unsocial hours.

By integrating electromobility into track construction, the company is demonstrating the strength of its sustainable solutions in demanding, real-world applications like motorsport. This year, the solutions are bigger and better with the inclusion of new mid-size machines like the L120 Electric and L90 Electric wheel loaders and the updated EC230 Electric excavator, now boasting a full day of operation.

This pioneering approach to drive efficiency and sustainability both on and off the track, allows the partnership to maintain the fast-paced thrills of motorsport with a

lighter carbon footprint. Volvo CE’s commitment to sustainability extends beyond construction. The electricpowered CE Dealer Team by Volvo Construction Equipment, the only genderbalanced team in World RX, returns to competition this season. It is a clear demonstration of how to combine high-performance motorsport with a bold, forwardthinking approach and brings the company’s performancedriven, purpose-led mindset to the track.

Bill Law, Head of Brand Marketing & Communications for Volvo CE, said: “The FIA World RX Championship continues to be a fantastic format to raise awareness of the transition to a more sustainable future for construction and motorsport alike. Through an unbeatable mix of state-of-the-art sustainable power and digital innovation, we are proud to be leading the way for a new era of high-performing electromobility. Thanks to our continued partnership with the FIA, the 2025 season is set to be more dynamic than ever before.” SP

Source: Volvo CE

Euro Auctions Group is excited to announce that North Toronto Auction has officially joined its global network of auction houses.

The move sees NTA align with fellow Canadian auction leaders, Michener Allen Auctioneering and Jardine Auctions Inc, further expanding Euro Auctions’ presence across Canada — effective immediately.

North Toronto Auction, a Canadian auction company specializing in industrial equipment, automotive, and RV sales, becomes part of the Euro Auctions Group, headquartered in Northern Ireland, in a strategic move to strengthen the Group’s position in the Canadian marketplace.

Euro Auctions will retain all 64 employees and maintain the North Toronto Auction brand, both of which are highly valued by the group. The business will continue to be led by Matt Rispin and will operate from its state-of-the-art 17-acre auction facility in Innisfil, Ontario, just 50 minutes north of Toronto Pearson International Airport.

With the addition of North Toronto Auction, the Euro Auctions Group now operates from 15 global locations including sites in Canada, the USA, Europe, the Middle East, and Australia — with 5 sites now in Canada alone this provides

Founded in 2002 by Matt Rispin, Frank Panza, and Stuart Ralph, North Toronto Auction has become a leading auction house in Toronto and commands significant market share.

significant national coverage.

North Toronto Auction began life as a dealer-only automotive auction in Innisfil. Due to growing customer demand, the company quickly expanded into public auctions for cars, commercial trucks, heavy equipment, and recreational vehicles. Heavy equipment auctions are now held monthly which have complemented the strong automotive base.

Matt Rispin, Managing Director of North Toronto Auction, comments:

“The acquisition by the Euro Auctions Group, and aligning with our close Canadian allies Michener Allen and Jardine Auctions Inc, marks the next exciting chapter in our journey. This is a perfect fit for North Toronto Auction, and we’re excited for what lies ahead. In May 2025, we celebrate 22 years in business, now joining forces with Euro Auctions a rapidly expanding first rate auction house with significant national coverage across Canada can only be good news for our customers and employees.”

Derek Keys, Founder and Managing Director of Euro Auctions Group, added:

“North Toronto Auc-

tion enhances our offerings alongside Michener Allen and Jardine Auctioneers, expanding our regional reach to better serve customers across Canada. This

acquisition is strategically important in providing Canadian clients with both national and global support.

Our focus is now working with Matt and his team to

build upon what they have already achieved. Their experience in the market is unmatched.” SP

DEVELON is helping logging professionals take on tough forestry and timber processing jobs with its new, next-generation -7 Series log loaders and road builders.

The initial -7 Series launch includes the DEVELON DX225LL-7 log loader and DX225RB-7 road builder, with more log loaders and road builders to be announced in the upcoming months. The new lineup features enhanced safety features, heavy-duty

components and easy serviceability to help logging companies move more timber and build access roads to the harvesting and log loading areas.

“We took learnings and incorporated features from our previous products to directly shape the design and function

of the new -7 Series log loaders and road builders,” says Morgan Stallings, senior director, product management and marketing. “Equipped with reliable performance, and comfort and visibility enhancements, they are designed to help those working in challenging conditions. Feedback from a longtime log loader customer operating a DX225LL-7 prototype in the Pacific Northwest confirms that our design and enhancements are paying off.”

The -7 Series log loaders and road builders are ready to take on high-demand tasks. They have increased horsepower, faster cycle times and more lifting capacity to complete timber harvesting and log loading faster.

An increased swing torque helps the machines swing heavy loads more efficiently, even when moving the load uphill. The fine swing function reduces the amount of shaking when lifting heavy objects, resulting in greater control, more accuracy and safer operation.

When higher lifting capacity is needed, operators can use a convenient one-touch power boost button on the right-hand joystick to provide a momentary hydraulic boost. Operators can also choose from four selectable power modes to best match the application they’re working in to increase efficiency and minimize fuel consumption.

Matt Smith of Skookumchuck Logging in Chehalis, Washington, is a forestry professional and has previously owned older generations of DEVELON log loaders. He’s seen considerable evolution in the machines since he first started using them for timber harvesting. Matt’s company has been operating a DX225LL-7 log loader prototype for several months in partnership with local dealer Cascade Trader.

“The new DX225LL-7 log loader has been bulletproof for us,” says Smith. “We’re using it for shovel logging and loading trucks, and it’s smooth to operate. It’s got

more power for faster cycle times and increased productivity, especially when we’re swinging logs.”

Improved

DEVELON -7 Series log loaders and road builders are built with heavy-duty construction for harsh forestry conditions. The machines feature heavy-duty side doors, with guards over the hydraulic pump and cooling system door, along with quarter-inch side panels. A robust front guard protects components against debris and obstacles. A fully guarded, heavy-duty, high and wide undercarriage

2004 Hitachi ZX230LC Excavator. Machine comes with quick change Rotobec hydraulic grapple and heel, cleanup bucket. This machine is fully guarded with 32” triple bar pads and shows 11,089.0 hrs on the meter $48,900

Road Building Package. John Henry Drill (new Cat 3054 compressor engine) on Cat315 Excavator, Cat 330L Hoe drill (1238 Atlas Copco hammer and valve resealed), (2) M40 Tank Drills, Hitachi EX270LC Excavator, Kobelco 350-9 Excavator (new undercarriage), Hitachi EX300-3 parts machines, Terex TA27 Rock Truck, 2001 Terex TA30 Rock Truck, 2004 TerexTA30 Rock Truck (low hr transmission), 2008 Ford F350 Dually Powder Truck, Powder Mags, 1996 Western Star 4964S Tractor with Tandem step deck and Tridem lowbed, (2) Tandem axle water trucks, LW Kenworth with 13,500L Diesel tank and pump mounted on it, 5000L Diesel Tank, 1200L gas tank, (3) shop trailers loaded with parts, Genset trailer with 45Kw & 13 Kw single phase gensets with a dry room, GMC cab over flat deck, GMC welding truck with Hiab, Dodge 3500 dually shop truck, Tandem axle off-highway lowbed $480,000 1986 Kenworth W900 Water Truck with 2000 Gal Tank. Monarch TSP-3HRF pump driven by Honda GX270 gas engine. The truck has a Cat 3406 engine, 15 spd Transmission and SSHD Rockwell drive axles $14,750

helps improve ground clearance over stumps and other debris on logging sites.

The DEVELON DX225LL-7 log loader cab is designed with a 4-foot riser and robust front and top guards, providing protection without sacrificing operator visibility. The log loader cab also features hydraulic 90-degree tilting for ease of transport on a trailer.

All DEVELON -7 Series log loaders and road builders feature a large, allweather steel cab that has superior comfort, excellent operator visibility, low noise levels and more room to work. The heated airsuspension seat adjusts to operators’ height and weight and features adjustable headrests and armrests and

an optional 4-point seat belt. Joystick controls move up and down with the seat for more ergonomic operation to reduce operator fatigue. Front and rear LED lights enhance operator visibility, especially during low-light situations in early morning and at night.

A multi-function color LCD monitor shows a variety of machine diagnostic information. It also displays video from the standard rearview or side-mounted camera. Operators can use the hybrid screen mode to see machine information and the camera at the same time. The optional around view monitor (AVM) camera system is equipped with its own dedicated display monitor, which shows a full view of the machine’s surroundings. The AVM system is available for new -7 Series road builders. It gives operators greater confidence when

DICA, a leading provider of high-performance outrigger pads, cribbing and blocking and ground protection and site access products, announces EcoMax, a new crane pad.

Using a combination of steel and composite materials, crane operators can now take advantage of the benefits provided by both. EcoMax delivers the same performance, durability, and longevity customers expect from DICA’s engineered products at a lower overall cost.

“EcoMax expands our

crane pad line and fills a gap in the market,” said Kris Koberg, CEO of DICA. “It’s more durable and will last significantly longer than wood timber mats, and is a costeffective alternative to steel crane mats and pads without sacrificing performance,” said Koberg.

EcoMax pads leverage the

operating or positioning the machine in tight areas.

Optional on -7 Series log loaders and road builders is a side-entry forestry cab certified for Oregon OSHA and British Columbia WCB standards. The forestry cab is built with guarded polycarbonate front, side and rear windows, as well as a rear secondary exit. For added protection, optional 32-mm polycarbonate glass is available.

Additional options for the new road builders include a boom and arm lock valve. A straight travel pedal feature, which allows the operator to travel in a straight line more easily, is standard on all log loader models and optional for road builders. Both log loaders and road builders have the option for an air compressor and fuel filler pump.

Other notable features on DEVELON -7 Series log load-

stiffness and strength of steel with the durability, longevity and lower cost recycled composite material resulting in maximized load distribution. The flanges of the I-beams engage the specially designed and molded composite timbers to create a single, rigid body that moves uniformly. This is different from traditional wood mats, where the timbers are held together with a through-bolt.

A center plate built into the pad creates a designated operating area to assist crane operators with outrigger float placement. This physical guide makes it easier to place the float for optimal load distribution, reducing setup time and improving safety on the job site.

ers and road builders include:

• Radio and Bluetooth audio

• Travel alarm

• PA system: standard for log loaders, optional for road builders

“The DX225LL-7 has been very operator-friendly and makes it easy for our operators to run,” says Smith. “Operator comfort is huge in today’s forestry environment.”

Daily maintenance is simple with easy component access and centralized grease banks on the base of the boom. This allows operators to grease multiple points from one location.

Engine filters, hydraulic filters and the hydraulic tank are centrally located in a protected area — simplifying service and filter changes. The radiator with reverse fan

Additional practical features include built-in lifting lugs, which allow crews to safely lift individual pads or full stacks using standard synthetic wire rope or chain slings. To further enhance safety and functionality, the steel components are finished

automatically helps prevent debris buildup and keeps the cooling system clean.

An optional air compressor located in the cab makes it easy for operators to keep the interior clean of dirt and debris, creating a more comfortable working environment.

MY DEVELON fleet management telematics system is a standard feature on all log loader and road builder models so owners can remotely monitor and maintain their machines. This tool monitors the health, location and productivity of DEVELON equipment, and machine owners can access the data from a user-friendly mobile app and website.

Experienced and highly skilled professional service technicians from local DEVELON dealerships are avail-

with a non-slip coating that improves the friction of the steel components. The current EcoMax model is 24 sq. ft. and is rated for a maximum capacity of 160,000 lbs. (80 tons), making it ideal for cranes up to the 150-ton lifting class.

able to help keep equipment running at its peak. With two DEVELON-exclusive parts distribution centers in Georgia and Washington state, local dealers can offer more parts inventory and faster delivery on a majority of genuine DEVELON parts.

Log loader and road builder operators can take advantage of the superior standard warranty, with full coverage for 36 months or 5,000 hours and service support from their local authorized DEVELON dealer.

DEVELON also offers Protection Plus extended warranty coverage, with more than 70 different plan options so operators can customize their coverage. This coverage protects from deficiencies in materials or workmanship for up to 60 months or 7,500 hours, whichever comes first. SP

Source: DEVELON

“EcoMax is about giving crane users more options. It offers the reliability and performance of an engineered product with a price point that makes sense for more customers,” said Koberg. SP

Source: DICA

EcoMax also features two distinct rating scenarios. The first is the standard rated capacity, which applies to conditions when the pad is fully supported. The second rating–referred to as the “Bridge Rating,” applies to situations where the ends of the pad are supported by the ground and a gap exists beneath the center.

“Materials should be in full contact with the supporting surface. However, we understand this is not always possible. EcoMax pads have the strength and stiffness properties to support loads without full contact with supporting materials, which enables EcoMax pads to be used in this de-rated scenario,” said Koberg.

Supply Post got the chance to test drive the latest Liebherr equipment at the Liebherr Demo Day. By Kristen Washburn

In early June, I had the chance to attend the Liebherr Demo Day in Maple Ridge, BC! They brought their R 945 crawler excavator, A 918 Compact wheeled excavator, TA 230 articulated rock truck, PR 726 dozer, and L 556 Z XPower wheel loader. Located at the IUOE Training Facility, their impressive lineup of equipment was ready for hands-on testing.

I’ve never had the chance to operate heavy equipment before, so it was more than a little intimidating crawling into the cab. I was able

to test out the R 945 crawler excavator, as well as the L 556 Z XPower wheel loader. Both machines look incredibly complex with multiple joysticks and controls to operate the various moving parts. It was daunting trying to figure out how to move everything in coordination with each other, but with the help of the Liebherr team I was successfully able to fill buckets, raise and lower attachments, and drive laps around the gravel yard.

The Liebherr team was fantastic, talking through the controls, explaining

fundamentals, and staying in the cab to guide me through the various tasks that equipment operators tackle every day. The thoughtful engineering behind Liebherr’s userfriendly interfaces really

shows. The controls responded smoothly, the visibility from the cab was excellent, and even a total beginner was able to complete tasks without mishap.

It’s amazing how advanced technology, thought-

ful design, and good teachers can make such powerful equipment accessible to newcomers. This experience left me with a new appreciation for both the machinery and the skilled operators who make it look effortless every

By

A leading producer of recycled wood products wanted to increase its efficiency and productivity to meet an ever-growing demand for its compost and mulch ranges.

It turned to its trusted partner Greenrock Equipment, the exclusive distributors for EDGE Innovate products in California, Arizona and Hawaii.

They came up with the perfect solution: the EDGE TRM831 wheeled mounted trommel, the largest mobile mounted trommel screen on the market. Encompassing a 31ft (9.3m) long screening barrel powered by a Cat C4.4 Stage V engine, the TRM831 trommel is capable of screening material at 400 meters per hour, ensuring customers achieve better value for their business.

it to keep up with the demand for its product ranges has been the EDGE Innovate TRM831 with its unrivalled production rates, intelligent load management and extensive stockpiling capacities, incorporating a host of impressive design features such as a remote 180°radial fines conveyor as standard, and an eco-power saving functionality which reduces unnecessary running costs.

Like all well designed products, the EDGE trommels supplied by GreenRock are smartly designed to make operating them simple. They are loaded with several smart features such as an intelligent load management system that ensures the unit is running at optimum capacity at all times whilst minimizing the risk of blockages occurring, all the operator needs to do, is to keep loading in the feed stock. Full remote functionality over all major functions such a feeder speed and screening angle comes as standard, allowing the loader operator to stay in complete control from a safe distance, whilst a 180-degree remote controlled radial fines conveyor reduces the need to constantly move screened material.

“The TRM831 is the largest wheel mounted trommel on the market. Its sheer scale provides operators with unrivalled production rates, ideal for operators seeking to boost their production capabilities. High-capacity processing equipment, such as the TRM831 will play an important role in helping Recycled Wood Products meet its production demands.” says GreenRock’s John Connolly.

“To further reduce the chances of bridging or drum overload, EDGE Innovate has complimented its intelligent load management system with a larger designed hopper opening and supplied industry leading belt widths to allow a smooth flow of material through the trommel” John says.

The Californian producer of recycled wood has been serving landscape contractors, growers, businesses and homeowners throughout Los Angeles, Orange County and the Inland Empire in southern California for more than four decades. Since it first opened its doors in the mid 1980’s, its green recycling operation has grown to cover almost 180 acres. It manufactures compost and mulch products from landscape trimmings and salvaged wood at one of its six green recycling facilities located throughout the Inland Empire, sourcing and transporting the wood from furniture factories, cabinet shops, lumber yards, landscaping and tree trimming operations using a large fleet of trucks.

Instrumental in helping

The EDGE TRM831 portable trommel not only guarantees huge production rates but offers ultra reliability with minimum upkeep, according to John. “Trommel screens from EDGE Innovate are simple to operate and are designed to require minimal maintenance. Customers know they will start up and consistently process large volumes of material day after day without any of the major upkeep you would associate with other products such as star screens. That’s the biggest selling feature of a machine like this.”

“In the project with Recycled Wood Products, GreenRock’s engineers thoroughly analyzed their feedstocks, making precise adjustments to parameters like drum speed, screening angle, feed rate, and the aggressiveness of the drum lifters. They also selected the appropriate screen media to ensure the finished product met stringent quality standards—all before the final handover was completed,” John explains.

The EDGE TRM831 is purpose-built to maxi-

Continued on page 27

Following a strong showing at the 2025 Oregon Logging Conference, Madill has officially returned to the U.S. forestry market, marking its relaunch with the first American sale of the upgraded Madill 4000 Log Loader.

Now manufactured and backed by DC Equipment, which acquired the iconic Madill brand in 2023, the Madill 4000 Log Loader is back— with significant improvements over its predecessor.

The updated model features enhanced structural reinforcements, an upgraded boom and stick, improved cooling systems, and streamlined serviceability. These improvements reflect extensive feedback from industry professionals across North America, collected through DC Equipment’s direct outreach.

“This is more than a machine delivery—it’s the revival of a well-known brand in American logging,” said Dale Ewers, Managing Director of DC Equipment.

At the Oregon Logging Conference in February, DC

Equipment also showcased the Madill 3000B, underscoring its direct-to-market approach. DC Equipment has proactively begun establishing a support network for the West Coast, partnering with reputable service provider Cascade Traders. With a presence in Chehalis, Washington and Hayden, Idaho the partnership provides a foundation for the growing U.S.based team and ensure timely and dependable support.

In a move that strengthens Madill’s connection to its legacy, industry recognised Russ Smith has joined the DC Equipment team as Madill Product Specialist for the U.S. market. With over 44 years in the forestry equipment industry—and a long history with the Madill brand—Smith brings unmatched field experience and customer insight

to the role.

“Madill is more than just a brand to me—I’ve spent much of my life around these machines and to be able to continue honouring the past while building the future is something I’m excited to be part of,” said Smith.

Based in the Pacific Northwest, Smith is providing support to contractors, including machine demonstration opportunities and in-field consultations.

DC Equipment’s expansion into the U.S. marks more than just a geographic move—it’s a commitment to the future of logging in the Pacific Northwest and beyond. As part of a broader global strategy, the company is investing locally to ensure contractors have dependable access to industry-leading

machinery, responsive service, and continuous innovation.

With deep roots in forestry and a reputation built on reliability, DC Equipment is focused on being where it matters most: on the ground, alongside the people who keep the industry moving.

“Madill belongs in the Pacific Northwest,” said Ewers. “And we’re here to stay.”

By partnering with local service providers, expanding its U.S.-based support team, and continuing to evolve its product offering, DC Equipment is bringing Madill back to the region where it earned its name—restoring its legacy while showing commitment to the region and industry. SP

Source: Madill

mize operator convenience, simplify maintenance, and boost overall uptime. Key features such as a large canopy and upward-opening drum bin doors offer unobstructed access to the power unit and trommel drum, significantly streamlining routine servicing. Additionally, the hydraulic sliding feeder and hydraulically raising drum cleaning brushes enable quick and effortless drum changes; minimizing downtime and keeping production moving.

Equally important is having properly trained staff. Operators who understand how to safely and efficiently run and maintain the machine contribute significantly to both productivity and workplace safety. GreenRock Equipment recognizes this, which is why, during the installation of the EDGE TRM831, they worked closely with the Recycled Wood Products service team and plant operators throughout the commissioning process. This collaboration ensured that the entire team received thorough training, empow-

ering them to operate the TRM831 confidently and effectively from day one. Service and support from GreenRock Equipment, the exclusive supplier of EDGE Innovate’s entire product line of shredders, screeners, sorters, and stackers, is a cornerstone of their customer offering. With engineering expertise at the helm, founders John Connolly and Shea McKiver maintain a direct line to EDGE Innovate’s manufacturing base in Ireland, ensuring a responsive, hands-on approach to customer care.

With a deep understanding of their customers’ needs and a commitment to delivering tailored solutions, GreenRock Equipment has become a trusted partner to some of the most demanding operations on the West Coast. Their hands-on approach, technical expertise, and unwavering dedication to service and support ensure that customers not only get the right equipment for the job but also the training, maintenance guidance, and ongoing assistance required to maximize performance. SP

Source: EDGE Innovate

Caterpillar announces multiple updates for its Cat Hydraulic Excavator line as part of its annual product update (APU) program.

Helping to improve machine efficiency and get operators quickly to work, the enhancements include Cat Grade technologies, a new User Interface (UI) for quick navigation and an Advanced Payload option for Cat track excavators. These updates apply to Cat small, medium, and large excavators, plus material handlers, wheeled excavators, and forestry and specialty machines.

Cat Grade enhancements

With 2025 model builds, Cat Grade with Advanced 2D features and functions are now integrated into standard Cat Grade with 2D. Compared to traditional grading methods, Cat 2D technology empowers operators to work more efficiently in a range of applications by delivering real-time guidance for accurate vertical and horizontal control. It helps to ensure that cuts and fills are made to

exact specifications, without undercutting or overcutting, and can eliminate the need for ground stakes in most applications.

“Our 2D grading technology provides easy adjustments to target depth and slope using joystick commands, the touchscreen interface, or a jog dial. It displays target grade with visual guidance plus height and depth,” says Jason Ho, senior global product consultant – excavation for Caterpillar. “To help ensure long life, the integrated components are protected from damage, and 2D works with multiple bucket types, including digging, cleaning, grading and tilting.”

For customers grading complex designs, Grade with 3D technology is now a factory-installed option that can be

ordered for track and wheeled excavators. This new option includes all the hardware required for the 3D system, installed and tested from the factory. It provides an easier upgrade path for customers who want to add Cat Grade with 3D after initial purchase.

New user interface

Cat Payload for excavators and material handlers delivers precise bucket load information with on-the-go weighing to help prevent overloading or underloading. From reordering work tool lists to creating new work tool combinations, the display’s new UI starts quickly and enables operators to easily set up machines and access information so they get to work without delay. Operators keep track of the amount of material moved and can split tasks between truck loading in Weigh Mode and moving material around the site in Stockpile Mode. The ability to input couplers and attachments into the sys-

tem makes setting up work tool combinations highly efficient by significantly reducing calibration time.

“While Cat Payload helps operators to accurately hit load targets and avoid underloading, overloading or misloading materials,” adds Ho, “customers with track excavators can upgrade the system to Advanced Payload for expanded capabilities such as custom tags, daily totals and electronic ticketing. When combined with VisionLink®, Advanced Payload enables customers to analyze job sites and individual assets for remote management of production targets and key metrics.”

Cat Advanced Payload helps customers to:

• Lower costs – by saving time, labor and fuel consumption.

• Improve accuracy – with precise payload targets that help eliminate over and underloading.

• Monitor safety – by helping to prevent truck overloading, which results in heavier and more unstable loads.

All the latest APU 2025 features in action can be viewed on Cat Operator Training at www.catoperatortraining.com. Caterpillar’s Equipment Training Solutions (ETS) team develops and executes training programs for Cat equipment operators and jobsite supervisors and certifies operators in the Cat dealer network. The comprehensive training solutions help operators maximize production and improve safety through a variety of training solutions, including eLearning, instructor-led, simulators, and custom training programs. SP

• Increase efficiency – helping new operators to get up to speed faster and experienced operators work more accurately.

Source: Caterpillar

CASE Construction Equipment has introduced two new compact, feature-packed midi excavators designed to bolster productivity and flexibility on the job: the powerful CX85E and CX90E midi excavators.

These midi excavators offer heavy-duty performance without sacrificing maneuverability. The CX85E and CX90E are ideal for construction crews working in residential or commercial construction sites, landscapers who are trenching, lifting, grading and digging, or rental companies seeking to offer a wider range of excavator options for their customers.

“Meeting modern worksite challenges takes innovative equipment that can help crews achieve more with less,” said Terry Dolan, head of CNH Construction Brands, North America.

“Listening to what contractors need is what drives our ingenuity-obsessed mindset, and it’s why we built our newest CASE midi excavators to deliver big-machine performance in a smart, space-efficient design. It’s all about empowering crews

to be more productive than ever in the most challenging environments.”

Combining space-saving dimensions with heavyweight performance, the CASE CX85E and CX90E midi excavators boast a robust 72-horsepower engine that provides ample power for aggressive digging, land clearing, craning, loading or using high-performance attachments. Operating weight on the CX85E is 19,467 lb (8,830 kg) while the CX90E operating weight is 20,305 lb (9,210 kg).

Both machines come with a comprehensive hydraulic package with standard auxiliary, drain-to-tank functionality and quick coupler circuits to drive a wide array of advanced attachments. These features eliminate the

The highest viewing tower in the Harz Mountains, described as “the world’s largest witches’ broom,” has been erected in picturesque Rothesütte, not far from the Lower Saxony border.

A Liebherr 340 EC-B 16 tower crane, with an impressive hook height of 57.5 metres and a 40-metre radius, was used for the challenging lifting work on site.

The construction site in Rothesütte, Germany, presented the Liebherr crane from company Hüffermann with significant challenges. Access to the site was difficult, which meant that work had to be planned and car-

ried out with a great deal of precision. The Liebherr crane lifted 12.5 tonne steel sections into position on the tower’s concrete base for the planned lift installation.

Around 2560 steel parts were needed in total and over 22,300 bolts were used to create the 452 tonne steel structure.

The Liebherr crane was instrumental in the project’s progress. Its high lifting ca-