The Atlantic Heavy Equipment Show is marking its 40th anniversary edition.

Atlantic Canada’s largest heavy equipment showcase will make its return to the Moncton Coliseum this Spring. This all-inclusive showcase will feature the latest technology and innovations within the industry, March 26-27, 2026.

“This has been the key

gathering place for all facets of the industry for the last four decades” says National Show Manager, Mark Cusack. “This milestone edition already has tremendous momentum with the show floor being nearly sold out with only a few months to go.”

Registration is now open

online. Those interested in attending the event can preregister at no cost with promo code “AHESRETURNS.V”

Price at the door is $25.

The Atlantic Heavy Equipment Show biennially attracts thousands of eager buyers from across the region and beyond. With more than 200,000 square feet of indoor and outdoor exhibit space, the show deliv-

Nors Canada is pleased to announce the appointment of Sudhanshu Singh as Chief Executive Officer, Nors Construction Equipment Canada, effective March 1, 2026.

This appointment marks a key milestone in Nors’ transition to a unified national leadership structure in Canada, reinforcing the company’s commitment to operational excellence, governance alignment, and enhanced customer service across its Canadian businesses.

Singh was appointed CEO of Nors Construction Equipment Canada ST (serving primarily Eastern Canada) on January 5, 2026, and is currently completing a twomonth transition period to assume leadership of Nors Construction Equipment Canada GW, which operates in Western Canada. During this period, Singh is working closely with current CEO Colin Matejka, whose tenure will conclude on February 28, 2026, ensuring continuity across the organization.

“The creation of a uni-

fied national leadership and this appointment mark a new chapter for Nors Canada,” said Tomás Jervell, CEO of Nors. “Sudhanshu’s proven leadership and deep industry expertise position him well to strengthen our market presence and deliver exceptional value to our customers across Canada. We also extend our sincere appreciation to Colin Matejka for his role in building Great West into a company known for its quality and strong reputation, and for his exceptional leadership, professionalism and dedication to Nors Construction Equipment Canada GW over the past two years.”

Singh emphasized collaboration and alignment as central priorities as Nors continues to integrate its Canadian operations. “Nors has a long and respected history, and I’m excited to build on

that legacy as we strengthen our operations in Canada and continue delivering exceptional support to our customers across the country.”

Singh brings more than 30 years of global industry experience, including senior leadership roles with construction equipment manufacturers such as Terex and Caterpillar. He has over a decade of executive leadership experience, with a strong track record in customer-focused growth strategies and supporting market expansion across North America. In his role, Singh will focus on advancing integration across Nors’ Canadian businesses and strengthening governance and operational alignment nationwide.

Nors Canada is a distributor of construction and industrial equipment, providing sales, service and support through its Nors ST and Nors GW operations. The company operates across more than 80 per cent of the Canadian construction equipment market and is part of the global Nors Group. It has circa 750 employees spread around 40 branches in Canada.

Nors Construction Equipment Canada ST (formerly Strongco Corporation) is a leading heavy equipment dealer in Canada, serving sec-

ers an impressive lineup of big iron, breakthrough technology, and the newest products from the sector’s leading companies.

Follow the event on Facebook and Instagram for the latest updates. For complete details on the Atlantic Heavy Equipment Show, visit www. AHES.ca. SP

Source: MPE Shows

tors including construction, infrastructure, mining, oil & gas, utilities, municipalities, waste management, and forestry. It represents globally recognized brands such as Volvo Construction Equipment, Case Construction, Manitowoc Crane, National and Grove, Fassi, Sennebogen, and Konecranes.

Nors Construction Equipment Canada GW (formerly Great West Equipment) has been part of the Nors Group since March 2024 and operates within Nors’ Construction Equipment business segment. It specializes in construction and forestry equipment and represents leading global brands including Volvo Construction Equipment, Madill, Metso, Sennebogen, and Falcon.

Driven by progress and built on a legacy of more than 90 years, Nors continually adapts to market needs and transforms itself to elevate life and business through leadingedge services and equipment. Nors operates globally across five business areas - Trucks & Buses, Construction Equipment, Agro, Aftermarket, and Ventures - and offers a diversified portfolio and integrated services, while preserving close, trustworthy relationships with partners, customers, and the broader market. Present in seven countries, Nors represents top global manufacturers in each of its business areas, delivering services, solutions, and equipment designed to make everything work better, every day. SP

Source: Nors Canada

EXCAVATORS

2022 YANMAR SV08-1D 2'3"-2'9" WIDE, DIG BKT, 2 BKTS, Q/C, 106 HRS $26,900

2025 YANMAR SV08-1D RUBBER, 2'3"-2'9" WIDE CALL

2024 YANMAR VIO17-1E RUBBER, 2 BKTS, HYD THUMB, 308 HRS CALL

2023 YANMAR VIO25-6B, CANOPY, BLADE, 2 BKTS, HYD THUMB, 378 HRS CALL

2025 YANMAR VIO25-6B, CAB HEAT, BLADE, 2 BKTS, HYD THUMB, 245 HRS CALL

2017 DEERE 26G, CANOPY, 2 BKTS, Q/C, HYD THUMB, 2,455 HRS CALL

2014 YANMAR VIO35-6A, CAB, HYD Q/C, 2 BKTS, HYD THUMB, 7,240 HRS $25,900

2023 YANMAR VIO35-6A, CANOPY, BLADE, 2 BKTS, HYD THUMB, 319 HRS $48,900

2023 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 431 HRS CALL

2024 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 695 HRS CALL

2025 YANMAR VIO35-6A, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB CALL

YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 790 HRS CALL

2023

2023

YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB, 431 HRS CALL

2025 YANMAR SV40, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB CALL

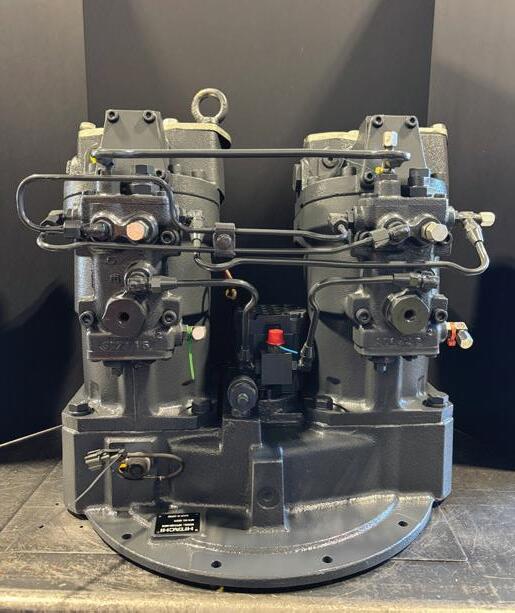

2021 HITACHI ZX50U-5N, CAB AIR, 2 BKTS, THUMB, +WRIST BKT, 1,851 HRS CALL

2024 YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX, 600 HRS $71,500

2024 YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX HYDS, 196 HRS CALL

NEW YANMAR VIO50-6A, CAB AIR, 2 BKTS, HYD THUMB, AUX CALL

4-YANMAR VIO55-6A CAB AIR, 2 BKTS, HYD THUMB, 553 - 1,330 HRS CALL

2025 YANMAR VIO55-6A, CAB AIR, RUBBER, 2 BKTS, HYD THUMB, AUX CALL

2016 KOMATSU PC78US-10, 18" PADS, BLADE, AUX PIPING, 3,698 HRS $54,900

2019 HITACHI ZX75US-5B, 18" PADS, BOR, BLADE, ONLY 1,131 HRS CALL

2020 HITACHI ZX75US-5B, 18" BOR, BLADE, 4,273 HRS CALL

2019 CAT 308E2 CR 18" BOR, BLADE, AIR, 520 HRS CALL

2019 CAT 308CR-07A, 18" PADS, BLADE, AUX PIPING, 2,054 HRS $78,900

5-YANMAR VIO80-1A CAB AIR, 2 BKTS, HYD THUMB, 250-1,033 HRS CALL

2024 YANMAR VIO80-7, CAB AIR, 2 BKTS, HYD THUMB, AUX, 188 HRS CALL

5-YANMAR SV100-2A CAB AIR, 2 BKTS, HYD THUMB, 762-1,330 HRS CALL

2025 YANMAR SV100-7, RUBBER, CAB AIR, 2 BKTS, HYD THUMB CALL

2025 YANMAR SV100-7, STEEL, CAB AIR, HYD THUMB, 2 BKTS, AUX CALL

2019 CAT 312F GC, 20" PADS, AIR, ONLY 2,168 HRS $74,900

2022 CAT 313 GC 20" BOR, AUX HYD PIPING, ONLY 875 HRS CALL

2019 HITACHI ZX120-6, 24" PADS, AIR, ONLY 1,887 HRS CALL

2008 HITACHI ZX135US-3, Q/C, DIG, HYD THUMB, 8,971 HRS, NEW U/C $69,900

2011 HITACHI ZX135US-3, 20" PADS, 2 BKTS, HYD THUMB, 8,136 HRS $59,900

2014 KOMATSU PC138US-10 20" PADS, AIR, BLADE, ONLY 3,779 HRS $61,900

2016 HITACHI ZX135USBL-5, 20" BOR, BLADE, 4,865 HRS CALL

2017 HITACHI ZX135US-6, 20" PADS, BOR, AIR, ONLY 2,768 HRS CALL

2017 HITACHI ZX135USBL-6, BLADE, 2 BKTS, HYD THUMB, 4,086 HRS $129,900

2017 HITACHI ZX135USBL-6, BLADE, 2 BKTS, Q/C, HYD THB, 2,611 HRS $124,900

2018 HITACHI ZX135USBL-6, 20" PADS, BLADE, 8,503 HRS CALL

2018 HITACHI ZX135US0S-6, BLADE, O/S BOOM, 1,551 HRS, Q/C, 2 BKTS $89,900

2020 HITACHI ZX135USBL-6 C/GUARD, BLADE, PL THB, 2 BKTS, 2,508 HRS $139,900

2020 HITACHI ZX135USBL-6 20" BOR, BLADE, AUX HYD PIPING, 2,795 HRS CALL

2020 HITACHI ZX135USBL-6 20" BOR, BLADE, ONLY 2,013 HRS CALL

2020 HITACHI ZX135USBL-6 20" PADS, BLADE, ONLY 1,862 HRS CALL

2020 HITACHI ZX135USBL-6 20" PADS, BLADE, AUX HYD PIPING, 1,451 HRS CALL

2020 HITACHI ZX135USBL-6 20" PADS, BLADE, AUX HYD PIPING, 1,565 HRS CALL

2020 HITACHI ZX135USBL-6 BLADE, 2 BKTS, Q/C, HYD THUMB, 1,226 HRS CALL

2022 HITACHI ZX135USBL-6 28" PADS, AIR, BLADE, AUX, ONLY 1,490 HRS CALL

2023 HITACHI ZX135USBL-6 20" BOR, AIR, BLADE, PIPING, ONLY 317 HRS SOON

2021 CAT 315 GC, BLADE, Q/C, 2 BKTS, HYD THUMB, 1,502 HRS $179,900

2022 CAT 315 GC, BLADE, 2 BKTS, HYD THUMB, ONLY 831 HRS CALL

2022 CAT 315 GC, 20" PADS, BOR, BLADE, 2 BKTS, Q/C, ONLY 319 HRS CALL

2024 CAT 315 GC, 20" BOR, BLADE, AUX PIPING, 1,105 HRS CALL

2024 CAT 315 GC, BLADE, AUX PIPING, UNUSED CALL

2018 HITACHI ZX200-6, Q/C DIG & CLEAN UP BKT, 5,182 HRS $82,900

2021 HITACHI ZX200-6, Q/C, HYD THUMB, DIG BKT, 1,296 HRS $149,900

2021 CAT 323 AIR, HYD THUMB 2 BKTS,HYD Q/C, 529 HRS CALL

2018 HITACHI ZX200LC-5, 2 BKTS, Q/C, HYD THUMB, ONLY 3,690 HRS, CABGUARD, SIDE GUARDING, NO DEF/NO REGEN $154,900

2019 HITACHI ZX200LC-5, 2 BKTS & Q/C, HYD THUMB, 2,786 HRS CALL

2021 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, 1,000 HRS $164,900

2020 HITACHI ZX200LC-6, 32" PADS, AIR, AUX PIPING, ONLY 80 HRS CALL

2011 HITACHI ZX225USR-3 24" PADS, AIR, Q/C, 2 BKTS, 9,640 HRS $52,500

2020 HITACHI ZX225USRK-6 24" AUX HYD PIPING, 8,253 HRS CALL

2020 HITACHI ZX245USLC-6N, 32", 2 BKTS, Q/C, THB, C/GUARD, 4,910 HRS CALL

2022 HITACHI ZX225USRLC-6 ,24" PADS, AIR, 3,354 HRS, SLIDE ARM $136,900

2015 HITACHI ZX245USLC-5N, Q/C, 2 BKTS, PL THUMB, 8,800 HRS $119,900

2021 HITACHI ZX245USLC-6, Q/C, 2 BKTS, HYD THUMB, 3,347 HRS CALL

2018 HITACHI ZX345USLC-6, HYD WEDGE Q/C, HYD THUMB, 2 BKTS, CABGUARD, 4,450 HRS CALL

2019 CAT 330 07A 24" PADS, AIR, 2 BKTS, HYD THUMB, ONLY 2,454 HRS $252,900

2023 YANMAR V4-7, CAB AIR, HYD BOBTACH Q/C, .91 CU YD BKT, 360 HRS CALL

2017 CAT 907M CAB AIR, HYD Q/C, AUX HYDS, BGP BKT, 3,808 HRS $59,900

2021 CAT 910 - 14A, CAB AIR, 3,981 HRS CALL

2023 CANYCOM SC75PDH PIVOT DUMP CARRIER 2,200 LB CAP, 379HRS CALL

2022 YANMAR C50R-5AR, CAB AIR, SWIVEL DUMP, 8,379 LB CAP, 795 HRS CALL 2021 MOROOKA MST1500VDR 360 SWING DUMPER, 17,637 LB CAP, 1,558 HRS $179,900 2021 MOROOKA MST2200VDR 360 SWING DUMPER, 24,000

2011 KOMATSU D51EX-22, CAB AIR, PAT BLADE, MS RIPPER, 3,814 HRS $129,900

SKID STEERS/COMPACTORS

2015 BOBCAT S590, HYD Q/C, A/C CAB, 2 SPEED, 1,826 HRS $49,900

2013 BOBCAT S650, CAB AIR, BKT & FORKS, HYD Q/A, 3,383 HRS CALL

2015 BOBCAT T590, CAB AIR, SJC CONTROLS, 2,351 HRS CALL

2019 BOBCAT T650, CAB AIR, STD CONTROLS, 74" BKT, 1,657 HRS CALL

2022 KUBOTA SVL65-2, HYD Q/C, 68" HD LO PRO BKT, 1,280 HRS CALL

2023 KUBOTA SVL75-3, TRACK SKID, AIR, HI FLOW, 74" HD BKT, 970 HRS CALL

2025 YANMAR TL65RS, 67" BKT, 67 HP, 2100 LB ROC, CAB AIR, HI FLO CALL

2025 YANMAR TL75VS, 67" BKT, 74 HP, 2555 LB ROC, CAB AIR, HI FLO, 377 HRS CALL

2025 YANMAR TL80VS 72" BKT, 74 HP, 2,900 LB ROC, CAB AIR, HI FLO, 532 HRS CALL

2014 VOLVO SD75, 66" DRUM DRIVE, CAB AIR, ONLY 1,744 HRS CALL

2016 VOLVO SD75B, 66" DRUM, CANOPY, ONLY 2078 HRS CALL

2021 SAKAI SV544DC, 84" SMOOTH DRUM, CAB AIR COND, 3,565 HRS $89,900

LIFTS & LIFT TRUCKS

2008 GENIE GTH-5519, CAB, AIR RIDE SEAT, 19' LIFT, 5,500 LB CAP, 48" FORKS, 3,285 HRS CALL

2014 GENIE Z34/22, 4X4, KUBOTA, 34' LIFT, 4' JIB, 6,288 HRS $26,900

2014 GENIE Z60/34, 4X4, ART BOOM LIFT, DEUTZ, ONLY 3,532 HRS CALL

2011 GENIE S65, 4X4,6 5' STRAIGHT BOOM, DIESEL, 3,375 HRS $42,900

TRUCKS/TRAILERS

2019 KOMATSU HM400-5 ARTICULATED WATER TRUCK, RETARDER, RVC, EMERG STEER, PAS, REAR SPRAY, 29.5R25 TIRES, 10,137 HRS $174,500

2009 INT 8600, CUMMINS 6 CYL, 10 SPEED, FRONT/REAR/DUAL SIDE SPRAY, 2,500 GALLON TANK,133,496 MILES $52,900

2005 FREIGHTLINER M2 106, CAT C7 ENG, ALLISON AUTOMATIC, 2,500 GAL

SUPREME TANK, PUMP, FRONT, REAR, SIDE SPRAY, 251K MILES $52,900

THUMB

2 HITACHI ZX345USLC-6, 2 BKTS, HYD THUMB, CABGUARD

6 HITACHI ZX330/ZX350LC-6, 2 BKTS, HYD THUMB

DOZERS

CAT D3K2 LGP, 6 WAY DOZER, CAB AIR, 80HO, 20K LBS

2 KOMATSU D39/RIPPER, 6 WAY, CAB AIR KOMATSU D71PXI PAT/RIPPER, 6 WAY DOZER, MS RIPPER, “I” MACHINE

LOADERS

2 YANMAR V4-7, CAB AIR, BOBTACH Q/C, .91 CU YD BKT

8 KOMATSU WA200/250/270/320, 2.5-3.75 YD KOMATSU WA380-8, FORKS, BKT

CAT 950K, FORKS, BKT GRADERS/COMPACTORS

2 CORNIVER CT40 40” SMOOTH DRUM, KUBOTA ENG

8 CORNIVER CT48 48” SMOOTH DRUM, KUBOTA ENG

8 SAKAI SV204/VOLVO SD45, 45” SMOOTH DRUM, CANOPY

8 SAKAI SV414/VOLVO SD75, 67”/66” DRUM, CAB AIR

6

4 SAKAI SV544, 84” SMOOTH DRUM, CAB AIR CAT 140M, 14 TIRES, SCARIFIER, CAB AIR DUMP TRUCKS 6 CANYCOM SC75 SWIVEL DUMP MOROOKA MST700 VDR

2 MOROOKA MST 110CR

JLG highlights strategic progress and continued commitment to access industry leadership.

JLG Industries, Inc. reveals key strategic milestones achieved in 2025 that strengthen its market position in North America and reinforce its long-standing commitment to advancing safe, reliable and innovative access solutions.

“For more than 55 years, JLG has remained focused on advancing the access industry,” says Tim Morris, chief commercial officer, JLG. “It is the business we started, it is the business we continue to

invest in and it is the business we are committed to leading. Our actions this year — from infrastructure expansion and product innovation to portfolio enhancement through integration — reflect our continued commitment to the customers and industries that rely on JLG® equipment to work safely and efficiently at height, as well as demonstrate our intent to continue to build on our strong foundation as we move into 2026.”

Earlier this year, JLG announced the addition of a new 113,000-sq.-ft. facility in Frederick, Maryland, to serve as a dedicated hub for product development, innovation, equipment testing and cross-functional collaboration. The facility is now open and operational, and the investment provides expanded capacity to support future product initiatives.

JLG also made significant investments in its Reconditioning and RESET Centers, restructuring its Hiram, Georgia, RESET location to add 22,000-sq ft of production space; building a new RESET facility in Fort Worth, Texas, that will have 15,000-sq ft of production space when it becomes fully operational in early 2026; and opening its new 120,000sq ft Reconditioning site in Houston, Texas. RESET Centers manage JLG’s Certified Pre-Owned Equipment Program, making sure certified used machines receive updates and repairs under a JLG Certified warranty that can extend their usable life by several years. At JLG’s

dedicated Reconditioning Centers, expert technicians restore boom lifts to like-new condition through a comprehensive, multi-step process. Each machine is restored to factory-approved, like-new condition, is backed by a JLG warranty and provides greater flexibility for fleet management.

“These expansions reinforce JLG’s commitment to investing in U.S.-based operations and providing enhanced support for our customers and team members,” says Morris, “These facilities strengthen our ability to deliver a wide range of highquality equipment solutions, including new, used and reconditioned options, to meet market needs.”

JLG made several significant product introductions in 2025, including new ClearSky Smart Fleet™ features, rotating telehandler line additions, micro-sized scissor lift lineup, low-level access lift line updates and new accessories like the Aviation Package. In addition, JLG also added several new platform solutions, which included:

• Narrow Boom Platform: Designed for contractors and service providers working in ultra-tight residential or urban areas, the new 31-in x 48-in Narrow Platform allows operators to navigate spaces as narrow as 36-in between structures. With a 500-lb capacity and integrated tool storage, lighting and charging ports, it helps boost productivity in confined applications.

form: Engineered to minimize machine downtime and keep fleets operational, the platform can be replaced in 15-20 minutes, compared to hours with traditional platform swaps. Available on select boom lifts and as a retrofit option, it maintains full rated capacity and compatibility with JLGapproved accessories, delivering a simple, servicefriendly solution for busy job sites.

“These options are designed to enhance productivity, safety and serviceability on job sites,” says Morris.

“With these new platform options, JLG continues to bring practical, everyday solutions to market that address real-world job site challenges while also setting new benchmarks for the customer-inspired innovations from an industry leader.”

When downtime means lost dollars, customers need prompt access to answers and information. This has led JLG to grow its customer support capabilities through an omnichannel approach that includes self-service, contact centers, field and operation service providers, advocates and product experts.

point of need, improving service efficiency and helping equipment stay productive on the job.”

This year marks the oneyear anniversary of AUSA’s integration into the JLG family. The collaboration has expanded JLG’s product portfolio within compact and material handling equipment categories with solutions.

“AUSA brings a reputation for durable equipment and trusted performance — values that are aligned with JLG’s legacy,” says Morris. “Together, we are offering a wider range of products to our customers in North America without compromising the standards for quality, engineering and customer support excellence that define both brands.”

• Mid-Rail Deck: To solve overhead reach limitations in steel erection, construction and maintenance projects, the JLG Mid-Rail Deck accessory is now available for both boom lifts and scissor lifts. Installed inside the platform’s mid-rail, it provides an additional 19.5-in of working height, enabling access between overhead obstacles without modifying the platform or compromising safety. For exceptional versatility, the lightweight accessory is removable, foldable and transportready.

• Rapid Replaceable Plat-

“Our customers can access our industry expertise and leadership through selfservice troubleshooting via our Knowledge Base article library on Online Express,” says Morris. Plus, we’re using technologies like artificial intelligence (AI) through virtual assistance and voice-totext to enrich our customer support capabilities even more.”

To further enhance service efficiency and operational uptime, JLG will begin implementing machine-specific QR codes across select models in early 2026. This technology will provide direct access to serial numberspecific documentation and support resources, including parts catalogs, service bulletins, interactive manuals and hydraulic schematics.

“Uptime is critical for our customers, and the ability to quickly access accurate service information can make all the difference,” says Morris. “With QR code-enabled machines, we’re delivering real-time support at the

Looking to 2026, JLG will remain focused on driving growth through continued innovation, investments and partnerships. The coming year will see JLG showcasing “Job Site of the Future” concepts at CES (West Hall #4418) and introducing new product solutions at World of Concrete (#O31525), GCSAA Conference & Trade Show (West Building #3013, GCBAA Pavilion), The ARA Show (#2249) and CONEXPO-CON/AGG (North Hall #N12308). These launches will highlight the company’s commitment to shaping the future of access — delivering customer-inspired innovations that advance productivity, safety, technology and lifecycle solutions to meet evolving job site needs.

“JLG has always been defined by its ability to anticipate change and lead with purpose,” says Morris. “As we look ahead, we’re continuing to build on the momentum of 2025 by investing in new technologies, expanding our product portfolio and exploring both organic and inorganic opportunities for growth. Our focus remains on advancing the access industry we created — providing customers with the innovative, high-quality solutions they expect from JLG.” SP

Source: JLG Industries

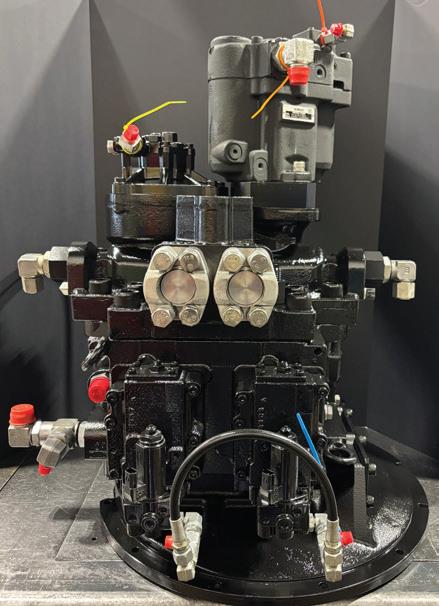

Perkins continues to invest in its product range with the addition of an 18-liter engine designed to meet the specific needs of the North American rental industry for mobile electric power generation.

Building on its already comprehensive U.S. EPA Tier 4 Final power offering, Perkins has continued to expand the range with the addition of the 2806F-E18TAG2 ElectropaK. With over 90 years of design experience and several million Perkinspowered generator sets operating around the world, Perkins understands the needs of the power generation industry. This knowledge and expertise have driven the design and development of the 2806FE18TAG2, a new engine that delivers a powerful package and ease of integration.

The 2806F-E18TAG2 is designed specifically for mobile generator set

applications and tailored to meet the needs of the North American rental industry. By achieving ISO 8528-5 G2 performance, the 2806F – which is now available to order – provides excellent load acceptance for a wide range of electric power applications that rely on mobile generator sets for jobsites, events, and many other locations where mobile generator sets deliver electric power.

Keeping the power on “Rental companies and their customers have unique requirements but still need reliable electric power to keep operations running,” says Jaz Gill, vice president of Global Sales, Marketing, Service

and Parts. “The new 2806F has been engineered and expertly crafted to provide capable, stable and sustainable power specifically for the North American rental mobile generator set industry. It is our latest offering in a long line of products that deliver reliable power with a low total cost of ownership and demonstrates Perkins commitment to meeting both our customers’ and their end users’ needs.”

Subject to using fuel that meets Perkins’ fuel specifications, the 2806F can run with biodiesel up to B20 based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil (HVO).

The ElectropaK 2806F produces up to 500 kWe prime power at 60 Hz and features the latest electronics with a single, on-engine electronic control module (ECM) that simplifies wiring harnesses, eases installation, supports future diagnostics and is capable of integration with customers’ telematics solutions.

The ECM also manages all aspects of aftertreatment operation and regeneration without operator input. Regeneration occurs automatically with no impact on performance, maximizing uptime. This allows rental customers to focus on the task at hand without worrying about their supply of electric power.

Together, we power ahead

The new 2806F-E18TAG2 joins the Perkins full line up of U.S. EPA Tier 4 Final certified engines for electric power generation: 400 Series, 904 Series, 1200 Series, 1700 Series, and the 2000 Series, with power ranging from 7 kWe @ 1800 rpm to 500 kWe @ 1800 rpm.

As with all Perkins en-

gines, the new 2806F is supported by Perkins’ global support network, ensuring stable and sustainable electric power when customers need it, where they need it and how they need it. Contact your local Perkins distributor today to find out more about how the 2806F-E18TAG2 can boost your bottom line. SP

Source: Perkins

Komatsu PC350LC-8, 3 bkts, thumb, cabguard, catwalks, exc. cond. 4,415 hrs.

Komatsu PC200LC-8, 3 bkts, Q/C, thumb, cabguard, catwalk, exc. cond., 1,772 hrs.

Komatsu PC170LC-10, 3 bkts, thumb, cabguard, exc. cond., 2,725 hrs.

Komatsu PC138USLC-II, 2 Bkts, Hyd. Q/C, Thumb, Exc. Cond., 2,300 Hrs. P.O.R.

Komatsu PC88MR-8, 2 bkts, hyd. Q/C & thumb, swing boom and blade, 2,400 hrs.

Komatsu D65EX-17, sigma blade, ripper & forestry guarding, 75% U/C, exc. cond., 6,050 hrs.

Komatsu D39 PX-24, 6-way blade, winch, forestry guarding, 3,100 hrs.

Hamm H13iX, 84” smoothdrum packer w/cab, A/C, low hrs, exc. cond.

Hamm 3307, 66” smoothdrum packer w/shell kit, cab, A/C, exc. cond. 3 cond.

Simex is exploring new frontiers for on-site material separation, promoting the advantages of cost savings, operational efficiency, and environmental sustainability.

Selective separation and on-site screening of materials is an increasingly relevant topic in the earthmoving sector, opening up new scenarios and market opportunities. Treating waste materials directly on-site, whenever possible, offers numerous benefits—especially in terms of time and cost savings, the two key drivers of every job site.

By analyzing its reference market, Simex has identified two main application areas that have seen significant growth in recent years:

• HEAVY DUTY - Screening of aggregate waste materials from demolition.

• LANDSCAPING & SOIL REGENERATION:Cleaning and reclaiming topsoil from debris for horticultural purposes and green spaces restoration. In both cases, the goal remains the same: to preserve all “valuable” materials that can be recovered and reused directly on-site or easily transported elsewhere. In the case of demolition debris, reprocessing the material on the

job site significantly reduces disposal costs and eliminates expenses related to purchasing and transporting new raw materials.

In the second case—recovering topsoil—it is worth noting that in many construction sites, proper screening operations can clean and reclaim the soil by removing stones, roots, and debris, resulting in the disposal of the inert fraction only. The soil cleaned and refined with Simex screening buckets is immediately reusable, aerated, and has the right particle size for subsequent planting operations.

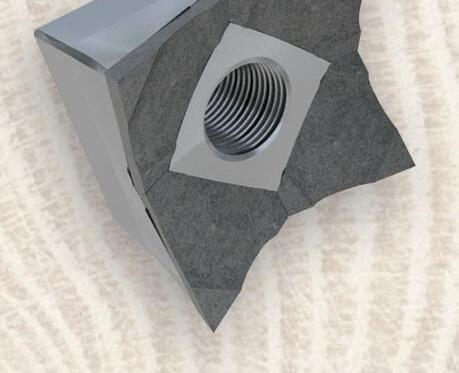

Simex expands the horizons of screening by launching a new line of screening

buckets for excavators designed for light-duty applications such as landscaping, green area maintenance, gardening, and small urban jobsites—where maneuvering space is limited and compact dimensions are essential.

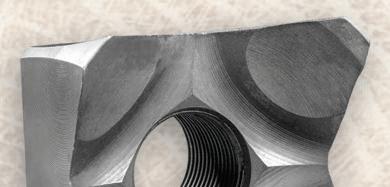

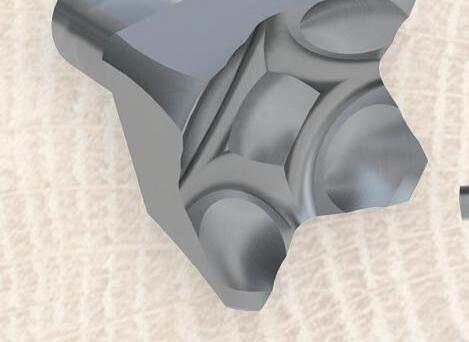

The VSE TORNADO screening buckets are engineered to separate materials of different sizes directly onsite, even with the presence of moisture. The new threeshaft configuration with starshaped elements enhances material swirling, optimizing processing efficiency and improving overall productivity.

The VSE TORNADO buckets feature an innovative quick-change system for replacing the entire shaft or individual screening elements. This solution allows for quick and easy maintenance directly on-site, minimizing downtime and ensuring continuous operation and higher efficiency.

triple bar pads and shows 11,089.0 hrs on the meter $48,900 Road Building Package. John Henry Drill (new Cat 3054 compressor engine) on Cat315 Excavator, Cat 330L Hoe drill (1238 Atlas Copco hammer and valve resealed), (2) M40 Tank Drills, Hitachi EX270LC Excavator, Kobelco 350-9 Excavator (new undercarriage), Hitachi EX300-3 parts machines, Terex TA27 Rock Truck, 2001 Terex TA30 Rock Truck, 2004 TerexTA30 Rock Truck (low hr transmission), 2008 Ford F350 Dually Powder Truck, Powder Mags, 1996 Western Star 4964S Tractor with Tandem step deck and Tridem lowbed, (2) Tandem axle water trucks, LW Kenworth with 13,500L Diesel tank and pump mounted on it, 5000L Diesel Tank, 1200L gas tank, (3) shop trailers loaded with parts, Genset trailer with 45Kw & 13 Kw single phase gensets with a dry room, GMC cab over flat deck, GMC welding truck with Hiab, Dodge 3500 dually shop truck, Tandem axle off-highway lowbed $399,500

the Comp. Snorkel & a Rebuilt Esco Grapple, Unit has Not Worked Since the Repairs POR

Designed for mini and midi excavators from 1.5 to 10 tons, the TORNADO range is ideal for cleaning soil from debris, stones, and gravel, as well as for compost aeration. It is also perfectly suiteìable for preparing bedding layers and covering underground utilities and pipelines.

This makes it possible to screen, reduce, clean, and aerate organic waste and soil in a single bucket load—accelerating the composting process and producing screened material with an ideal particle size for green area restoration and subsequent planting. The minimized waste volume also helps reduce disposal and transport costs to specialized facilities.

The standard output particle size is 0–20 mm, however, by adjusting the spacers, it can be reduced to 0–10 mm or increased to 0–30 mm, depending on application needs and site requirements.

Depending on the material type, the bucket can be equipped with polyurethane tools, ideal for wet or sandy soils and for preserving the integrity of the screened material, or with steel tools, recommended for heavier-duty applications and abrasive materials.

“Simex has been invest-

ing in screening buckets for years, though the focus has traditionally been on recovering heavy aggregate materials from demolition and crushing,” said Nicola Sisti, R&D Project Engineer at Simex and head of the company’s screening bucket division.

“In recent years, however, the market has increasingly expressed the need for on-site soil cleaning and recovery. I’m referring to urban green maintenance, compost aeration, gardening, and small private worksites. The goal is to clean the soil from stones and debris, avoiding total disposal in landfills and reusing directly on-site a valuable soil suitable for planting.”

“This approach aims at reducing disposal costs and help private users save on the purchase of new soil,” concluded Sisti. SP

Source: Simex

Hamm expands the portfolio with Smart Compact for earthworks.

Roller manufacturer Hamm is expanding its HC series with the 13 t HC 130i C VA compactor which, in conjunction with Smart Compact, enables automatic compaction to a target value. The new model joins the 20 and 25 t HC 200i C VA and HC 250i C VA models that have already been unveiled, this sets new standards for compaction in earthworks.

The HC 130i C VA compactor is equipped with the new variable amplitude (VA) drum which enables automatic compaction depending on the ground conditions and machine capacity. This technology not only ensures homogeneous compaction but also increases cost-effectiveness by reducing the number of double passes and lowering diesel consumption. The machine meets exhaust emission

standard EU Stage V and EPA Tier 4f.

Automatic compaction, precise measurement

In day-to-day work, drivers can choose between automatic and manual mode. In automatic mode, the amplitude is regulated by the machine control system; in manual mode, five fixed amplitudes are available. Before compaction, the target compaction value in MN/ m² can be specified based on typical load-bearing capacity values. The basis for the automatic regulation of the compaction forces is the Smart Compaction Value (SCV), which is now determined by Hamm and is continuously and precisely recorded independently of influencing factors such as driving speed, frequency, or direction of travel.

The new VA compactors offer numerous advantages for operators and construction companies alike. Automatic adjustment of amplitudes not only ensures homogeneous compaction but also effectively prevents over-compaction and particle crushing at the same time. These features make the new VA compactors an attractive choice, even for less experienced operators. In addition, the cost-effectiveness of construction projects is improved by the reduced number of double passes, which leads to lower diesel consumption and less mechanical stress on the machines. Making fewer double passes also means a reduction in CO2 emissions. In addition, the machine control system reliably prevents jump operation, contributing to a longer service life of the machines. The direct adjustment of the amplitude makes the VA technology an energy-efficient system overall. SP

Source: Hamm

LOG LOADERS

2018 Tigercat 890 Heel Boom, c/w: T-Mar 72” grapple, forestry cab highwalker U/C w/ 28” SBP. 7,128 hours $514,500

2017 Deere 3756G, c/w: T-Mar 60” grapple, Tier 3 eng., 5,XXX hrs $424,500

Caterpillar 988K “Millyard

2010 Caterpillar 330DFMLL Heel Boom, c/w: T-Mar 60” log grapple $62,500

YARDERS

2001 Madill 124 Swing Yarder, Recent major work orders, can be viewed working $1,395,000

1989 Madill 123 Swing Yarder, Recent $250K in work orders $839,500

1988 Cypress 7280C Swing Yarder $649,500 Madill 044 Grapple Yarder, c/w: Cummins power CALL

HYDRAULIC EXCAVATORS

2013 Hitachi ZX290LC-5N, w/Cat 42” dig bkt., CWS Q/C, CWS hyd. thumb, hoe front, cab guard, catwalks, std U/C w/32” TBP, 13,056 hrs. $59,500

2013 John Deere 3754D “Road Builder”, c/w: 44” Accurate dig bkt., spare dig bkt., hyd. Q/C, hyd. thumb, hoe front, Forestry cab on 8” risers, highwalker U/C w/ 28” DBP. $184,500

2006 Caterpillar 315CL w/2 bkts, hyd Q/C, hyd thumb. 9,687 hours $44,500

2005 John Deere 3554 “Road Builder”, w/ 2 bkts, 10,330 hours $37,500 Komatsu PC300HD-5 “Backspar”, w/ single shive backspar attachment. $24,500

PROCESSORS

2015 Hitachi ZX290F-3 Log Loader, c/w: 2014

Southstar QS605 processing 10,904 hours $219,500

2011 Hitachi ZX290F-3 Log Loader, c/w: 2010

Waratah HTH623C proc. head, 13,858 hrs.. $164,500

2003 Caterpillar 330C Processor, c/w: 2004 Waratah HTH626 processing head. CALL

• 17’ Brutus steel &

• Graco grease, antifreeze, oil, and waste oil systems

• VMAC H40 hydraulic rotary screw compressor

• Truck and body heating system with 4 Espar heaters

FREIGHTLINER M2 4X4 EXTENDED CAB (UNIT 6134)

• 12’ Brutus aluminum service body

• Cobra 12000X.2 RMTH hydraulic wireless crane

• Enpak A60GBH diesel multifunction

• Maxistab stabilizers

FREIGHTLINER M2 4X4 EXTENDED CAB (UNIT 6146)

• 14’ Brutus aluminum service body

• Cobra 12000X.2 RMTH wireless crane

• VMAC H60 compressor

• Maxistab stabilizers

FREIGHTLINER M2 4X2 EXTENDED CAB (UNIT 6179)

• 12’ Brutus aluminum service body

• Cobra 12000X.2 RMTH wireless crane

• VMAC H60 compressor

• Maxistab stabilizers

CONSTRUCTION

Brokk, the world leader in remote-controlled demolition machines, proudly marks its 50-year anniversary in 2026.

Since 1976, Brokk has consistently pushed the boundaries of what is possible in the demolition industry, transforming hazardous work environments and redefining productivity, precision, and safety on jobsites worldwide.

Brokk’s journey began in northern Sweden, in-

side a smelter furnace at Rönnskärsverken. Faced with dangerous manual demolition tasks, brothers Lars and Per-Martin Holmgren envisioned a new solution: a remotely operated machine capable of doing the job with greater safety and efficiency. Their first prototype did far more than solve a local chal-

lenge, it laid the foundation for an entirely new industry.

From that first machine to today’s advanced fleet operating around the globe, Brokk has remained true to the same core mission to protect workers, increase efficiency, and engineer equipment built for the most demanding environments.

“Brokk was born from necessity, to protect workers and improve productivity in some of the toughest industrial settings,” says Martin Krupicka, CEO Brokk Group. “Fifty years later, that driving purpose remains unchanged. While our technology has evolved dramatically, our commitment to solving real-world challenges for our customers is as strong as ever.”

Today, Brokk robots operate in industries including construction, cement and metal processing, nuclear decommissioning, tunneling, mining, and more. Brokk continues to develop specialized machines and attachments designed to meet the evolving needs of complex and high-risk workplaces. SP

Source: Brokk

Mass excavation is about volume, not finesse. When you are moving thousands of yards of material for site prep or infrastructure development, your machine has to deliver nonstop performance, high capacity and the kind of breakout force that gets the job done fast. Every pass matters.

SANY’s SY385, SY500, and SY750 are designed with production in mind. These machines bring the strength, scale and flexibility to move more material with fewer passes, saving both time and operating costs.

Mass excavation stick configurations are available across the lineup, supporting larger buckets up to 6.5 cubic yards. This setup shortens the stick to boost breakout force and cycle speed while reducing load times. When paired with high-horsepower Cummins engines and advanced hydraulic systems, SANY machines deliver consistent digging power in even the most compacted material.

The SY385 is ideal for contractors balancing mobility and strength. It is well-suited for mid-sized

earthmoving, foundation prep and subgrade work. The SY500 adds more lifting power and counterweight capacity, making it a proven choice for commercial sites and infrastructure projects. The SY750 is the top performer, with extreme breakout force and cycle efficiency designed for bulk earthmoving, and deep cuts.

Hydraulics are engineered for control. Dual auxiliary circuits, a case drain and quick coupler plumbing come standard. Operators can adjust pressure and flow from the cab, tailoring performance to buckets, rippers or hammers without delay. These excavators are also compatible with major grade control systems, helping crews dig to design faster with less rework.

Operator comfort and safety come standard. Each model features climate control, suspension seating, multifunction monitors and wide entry steps. Rearview and blindside cameras are standard on new-generation machines.

Durability is non-negotiable. Full steel construction, reinforced frames and Cummins engines ensure these machines withstand high-pressure production cycles. And with a 5-year 5,000-hour warranty, SANY provides both peace of mind and long-term value.

For contractors who need machines that dig deeper, swing faster and move more with every pass, SANY mass excavation models deliver. SP

Source: SANY

A compact, high-torque offering for construction and forestry industries.

JCB, a global leader in construction and agricultural machinery, launches the 109 hp 4TS-8T Teleskid and 400T compact track loader (CTL).

As the largest models in JCB’s compact track loader lineup, these machines are a step up from the popular 3TS, delivering more horsepower and higher torque for operators tackling tougher jobs. Engineered for power, precision, versatility and safety the 4TS and 400T redefine what compact track loaders can achieve, offering unmatched performance for those who demand more from their equipment.

“These machines reflect our commitment to equipping operators with the tools

they need to work smarter, not harder,” said Lee Tice, Product Manager, JCB. “The 4TS and 400T were developed with extensive customer feedback, incorporating updates that deliver more power, greater reach and improved productivity,” continued Tice. “Whether you’re managing construction projects, tackling forestry challenges or handling versatile applications, these machines are built to exceed expectations.”

The 4TS Teleskid is a game-changer for construction contractors looking to streamline jobsites and maximize equipment usage.

The 3TS revolutionized the industry, taking the versatile compact track loader to the next level. Now the 4TS raises the bar even higher –nearly 2 full feet higher. Featuring a 15-foot lift height and nearly 4,000 pounds rated operating capacity, the 4TS eliminates the need for a separate telehandler in many situations, providing a single machine that handles everything from grading and trenching to material handling and loading. As a true start-to-finish tool, the 4TS empowers contractors to consolidate equipment fleets and increase jobsite efficiency.

The 4TS is built to tackle demanding tasks on large construction sites, delivering

pin height, the 4TS is perfectly suited for stacking, loading and accessing hard-to-reach areas. Addressing feedback from 3TS owners, the 4TS is designed to run high-flow attachments even when the boom is fully extended, overcoming a key challenge and expanding its capabilities for complex jobsite operations.

The 4TS features a newly designed low-leak valve body that prevents boom drift, ensuring materials stay exactly where you need them – even when the boom is fully ex-

tended. This design delivers unmatched precision and enhanced safety on the jobsite.

land clearing, the 400T delivers power and durability.

“The 4TS Teleskid bridges the gap between compact and capability,” said Tice.

“It’s the ultimate all-in-one machine for contractors who need to get more done with less equipment.”

400T CTL: built for the toughest tasks

For operators facing demanding applications like forestry, snow removal and

Source: JCB unmatched versatility and performance. Its compact profile – 13,000 pounds SAE operating weight and 6 feet 10 inches in overall height – enables it to navigate tight spaces with ease while excelling in heavy-duty applications. With a 15-foot

With an operating weight of 12,544 pounds, the 400T is built to handle heavy-duty tasks with unmatched power while maintaining the agility expected from a compact loader. Its redesigned chassis and expanded cooling pack eliminate the need for auxiliary coolers, ensuring optimal performance during extended high-flow operations. Delivering over 40 gallons per minute of hydraulic flow at 4,000 psi, the 400T powers demanding attachments like drum mulchers with ease, making it a reliable workhorse for the toughest applications, day in and day out.

“When you need equipment that works as hard as you do, the 400T is the answer,” said Tice. “With its increased engine and hydraulic performance, it’s a true workhorse built for operators tackling the most challenging applications.”

Developed at JCB’s North American headquarters in Savannah, Georgia, the 4TS and 400T reflect years of customer feedback and industry expertise. From enhanced operator comfort to increased safety and performance, these machines are designed to deliver what compact equipment owners need to succeed in today’s demanding environments. Both models are now available at JCB dealerships across North America, offering operators powerful new options to expand their capabilities and streamline their equipment fleets. SP

The Fecon FTX150-2 mulching tractor with fire package wows firefighters and land management pros with its power and precision in creating firebreaks.

In the rugged hills of Tonner Canyon, Fecon brought the heat to showcase how our FTX150-2 mulching tractor with the fire package is a game-changer for battling California’s wildfires. Led by West Coast Regional Sales Manager Marc Rivas, the hands-on event drew pros from LA County Fire Department, Moreno Fire Department, Cal Fire, USDA, and Wildlife Fish and Game, all eager to get dirty and see this beast in action.

We kicked things off with a solid safety huddle, covering gear, controls, and safe spacing around the machine. Then, it was up the canyon to chew through vegetation, carving out firebreak lines and clearing rights-of-way.

Attendees jumped in the seat, feeling the raw power of the 155HP Cummins engine and the Fecon Power Management system that delivers lightning-fast recovery times

even in rocky terrain where our durable carbides held strong without skipping a beat.

The FTX150-2’s fire package shines with features like the TriMax Fire Suppression System, severe-duty air pre-cleaners for engine and HVAC, and a positive air shut-off to keep things safe in high-risk zones. Add in the 60 GPM hydraulics at 5,000 PSI, 20-inch steel tracks with 21inch ground clearance, and loader arms for precise control, and you’ve got a mulcher built to create defensible spaces, remove underbrush, and slash wildfire fuel loads without the mess of traditional methods.

“You can check out videos and specs online, but nothing beats grinding through the

brush yourself,” Rivas shared. “Everyone raved about the power and how it tackles tough jobs head-on.”

After the morning grind, we fueled up with lunch, walked around more units,

and chatted options like leasing, rental-purchase, and buying straight up. It was all about real talk for fire departments and land agencies looking to gear up against the next blaze.

Want to grab the controls like these frontline heroes? Head to fecon.com and request a demo. Get hands-on with the FTX150-2 and join the fight against wildfires. SP

Soucre: Fecon

CANADIAN CONCRETE EXPO 2026

February 11 - 12, 2026 Booth #1-6104

MB Crusher demolition pulverizer and crusher bucket. Demolish. Crush. Recycle.

Scan for the full range of attachments MBCRUSHER.COM

The PT300 D:MINE is the

vehicle from FAE designed to withstand the most extreme forces. Used all over the world for mine clearing, it is effective against both anti-personnel and anti-tank mines under even the toughest working conditions.

The field of application for the PT300 D:MINE consists, first and foremost, of humanitarian demining. A variety of operations are carried out in the field in order to make the land safe and restore it for civilian use. True demining, which is the clearing of minefields containing anti-personnel or anti-tank landmines. Battle Area Clearance (BAC) and Explosive Ordnance Disposal (EOD), which consist of removing and neutralizing unexploded

ordnance, like bombs, mortar and other munitions. Improvised Explosive Device Disposal (IEDD), or the identification and neutralization of unexploded improvised ordnance, often used in asymmetrical warfare.

The PT300 D:MINE stands out for its versatility. It can be equipped with a demining head or another type of FAE machine, like a forestry mulcher or tiller, a stump cutter or a dozer blade. It also offers a multipurpose front

arm, which can be fitted with a manipulator grapple or with a bucket for excavations.

Two types of equipment are used for pure demining: a demining tiller, which has a fixed-tooth rotor, or a demining flail with a rotor of mobile chains. Both strike the ground at a specific depth in order to neutralize mines mechanically, either by destroying the entire mine or detonating it.

For the disposal of “improvised” ordnance, known

as IEDD, FAE’s solution is the PT300 D:MINE with the front arm equipped with the manipulator grapple. This configuration allows objects which may contain ordnance, or the ordnance itself, to be moved in complete safety. If equipped with a bucket, the arm can dig to reach deeply buried unexploded ordnance. It also provides a way to create a trench in which the explosives can be inserted for controlled detonation. The multipurpose arm boasts some impressive technical features. Thanks to the rotation system, the arm can not only move in classic excavator style to the front and sides, but can also rotate the excavating bucket or manipulator grapple on its axis. This allows them to be positioned swiftly and accurately in relation to the area being worked on or the object to be handled. The camera system, which consists of fixed

or motorized units with a zoom function, gives remote operators an overview of the environment they are working in as well as a clear view of the equipment’s activities. Two independent hydraulic stabilizing feet provide excellent stability during different applications.

For overgrown battle areas, the PT300 D:MINE can be equipped with an FAE forestry mulcher for vegetation clearance. This allows operators using metal detectors, for example, to better pinpoint the location of ordnance, as they can hold the detectors close to the ground. Finally, the PT300 D:MINE can be equipped with a dozer blade to cover the trenches created with the bucket back in again.

When it comes to the technical solutions adopted, the PT300 D:MINE represents the gold standard in its category, and has been tested and certified to meet CWA

15044:2009, the international demining standard. The innovations introduced this year include the possibility of equipping the vehicle and the multipurpose arm with cameras featuring a zoom function which allow operators to get a really close look at the ground, plus the addition of panels built into the front, sides and bottom of the vehicle to protect it against “bounding” mines. Thanks in part to the new equipment introduced, the FAE PT300 D:MINE is confirmed as a reliable and complete solution offering government agencies, the military, NGOs and organizations operating in active war zones around the world an increasingly effective and efficient product for reclaiming and restoring otherwise dangerous and unusable land and areas to public use. SP

Source: FAE

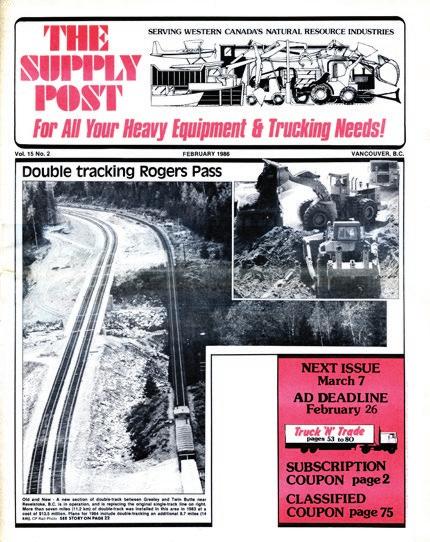

This article was originally published 50 years ago in the February 1976 issue of The Supply Post.

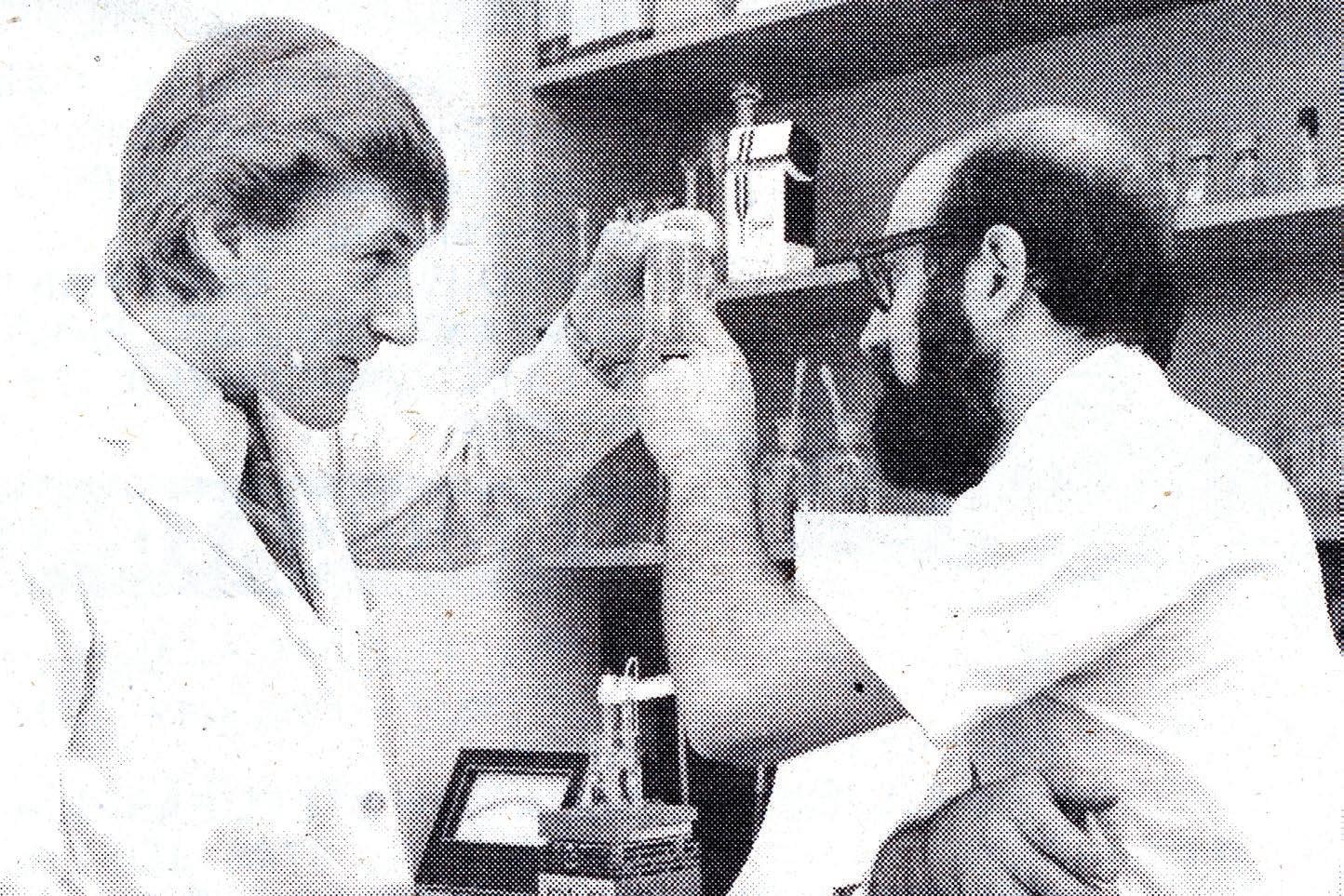

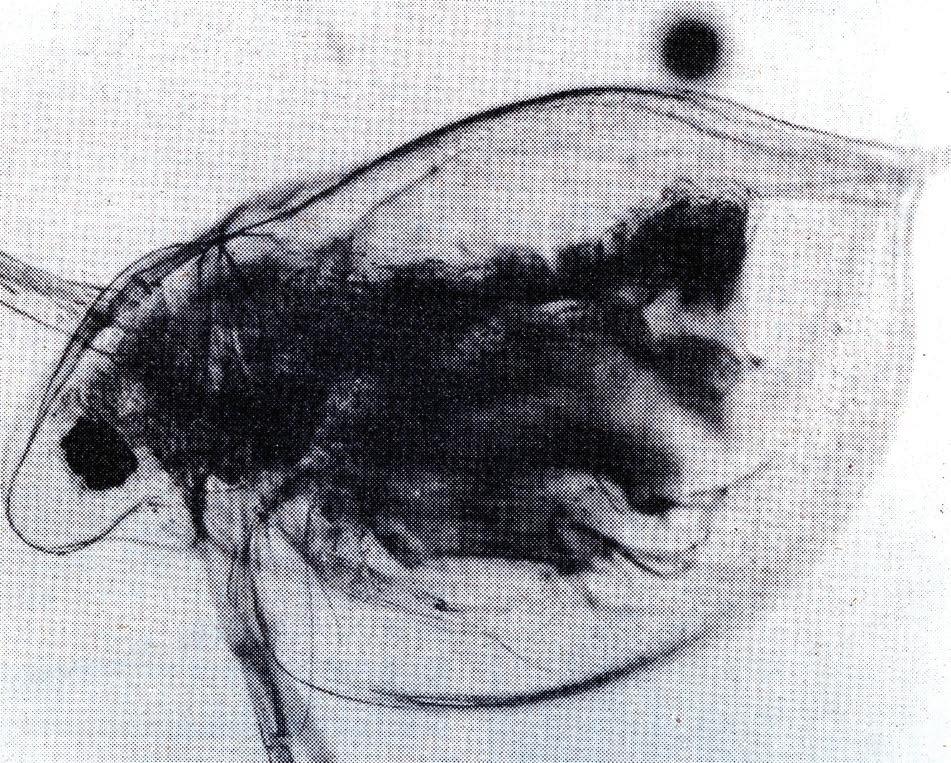

Chemist Marco Solinas and technician Ted Tunstall are the ringmasters for an aquatic circus of 1,000 trained fleas now performing at MacMillan Bloedel Research for scientific rather than entertainment purposes.

The water fleas are a key ingredient in efforts by MacMillan Bloedel’s research subsidiary to develop faster, cheaper and more efficient methods of testing pulp mill effluent for toxic elements.

The researchers hope that if their experiments — known informally as “Project Daphne The Waterbug” — are successful, the water fleas could replace fish fry in standard toxicity tests at MB mills.

“We got involved in this work as part of our continuing research efforts which support pollution abatement programs at MB mills,” said Solinas.

“Although our results so far are at a very preliminary stage, there are good indications that we’ll be able to work out a program of effluent tests using the water fleas instead of fish fry.”

Other MB Research teams, he said, are already investigating several methods of eliminating toxic elements from various types of mill effluent. But the first step is to determine whether toxicity is present, and if so, in what quantity.

That’s where Daphne comes in. Her formal Latin title is daphnia pulex, but she’s more commonly known

as the simple water flea, an aquatic organism about a millimeter in length that lives in most North American freshwater systems.

Solinas and Tunstall are using Daphne as a stand-in for the rainbow trout and coho salmon now used in government-approved biological water toxicity tests. Water fleas and freshwater fish are susceptible to similar toxic elements.

“Every time we try a new method of treating mill effluent we have to ensure that it is working,” said Solinas.

“To date the only practical way to do this has been by using fish fry. These tests are called fish bio-assay tests and they measure the effect on fish fry over a given period. The results are then compared with government toxicity standards.”

Emphasizing that the “Daphne” experiments have produced only preliminary results, Solinas said that bioassays using water fleas are a lot quicker and easier to perform.

The researcher said he’s been using young water fleas, 12 to 24 hours old — to ensure they don’t die of old age or natural causes — as substitutes for the fish.

A female water flea has a two-month lifespan and produces young at the phenomenal rate of 20 to 30 every couple of days, which means there’s never any supply shortage at MB Research.

“The test itself is very simple. We just take a standard

number of fleas, normally seven to ten, and put them in a test tube that contains the effluent we are studying, and after 24 hours we record how many fleas survive.”

At the same time, Solinas and Tunstall have been continuing the fish tests. By correlating the data they get from both sets of tests, they hope to work out an exact chart relating the effects of the effluent on fish and fleas.

“We’re still at an early stage, but there seems to be quite a definite trend — the more toxic the effluent to fish, the more toxic to daphnia. If we can perfect this test, we will use it in routine bioassays for research purposes and possibly at our mills,” said the chemist.

The French government, he said, already uses water fleas as a method of checking water toxicity for several types of industrial effluent, although as far as he knows, MB is the first Canadian company to experiment with the organisms in relation to pulp mill effluent.

Solinas and Tunstall launched the project last year by reading all the available literature on water fleas, then ordered 1,000 fleas from a biological supply company. Care and feeding was the next order of business.

The fleas at MB Research now dine on what to them is a gourmet mixture of brewer’s yeast and horse manure. Solinas had to resort to some novel methods to keep his

fleas fat and happy.

“Ted brings in the yeast from home,” said Solinas. “We get the manure from one of our maintenance people who has an acreage and a couple of horses.”

Solinas added that Daphne the Waterbug is “quite an unusual organism” from a biological standpoint. She

reproduces without benefit of male participation if conditions are good and the food supply is plentiful.

However, if things get

crowded in the aquarium, she starts producing male offspring and reproduction takes place in a more conventional fashion. SP

A minute marine organism, daphnia pulex by name, but known more informally as the simple water flea, is being used experimentally to test water toxicity in various types of pulp mill effluent. “Project Daphne the Waterbug” was launched by MacMillan Bloedel’s research subsidiary, which shows the water flea many times larger than her normal size.

Kubota introduces three innovative products designed to boost jobsite versatility, productivity, and operator comfort.

Kubota Canada Ltd. has unveiled three powerful additions to its construction equipment portfolio – the new Kubota Tiltrotator, the SVL65-2s compact track loader, and the SVL110-3 compact track loader. These machines mark the first of Kubota’s 2026 product rollouts, showcasing Kubota’s commitment to delivering innovative solutions that address the evolving needs of Canadian contractors and landscapers.

“These three products represent Kubota’s dedication to enhancing jobsite efficiency and operator experience,” said Jonathan Gardner, Construction Equipment Product Manager at Kubota Canada.

“The Tiltrotator, SVL65-2s, and SVL110-3 each bring unique capabilities and features that empower contractors to work smarter, faster, and more comfortably. Whether you’re tackling precision work in tight spaces or handling heavyduty applications, the new products deliver the reliability and performance Kubota is known for.”

Kubota Tiltrotator: MultiTool Versatility for Every Application

Addressing the rising demand for greater versatility on the job site, the new Kubota Tiltrotator is engineered to handle a wide range of attachments, making it a true multitool for any jobsite. Whether grading large surfaces, digging at challenging angles, sweeping debris, or handling materials, the Tiltrotator provides seamless control and precision with 360-degree rotation and a 50-degree tilt angle.

“The tilt rotator turns one operator into a full crew— more efficiency, more production, and fewer people needed on the jobsite,” said Lorraine Wu, Product Specialist Excavators at Kubota Canada.

Compatible with buckets, grading beams, pallet forks,

grapples, broom, asphalt cutter and more, it allows operators to switch between tasks effortlessly – boosting productivity and reducing downtime. The compact, cylinderless design reduces wear and tear while delivering consistent torque and clamping force. With easy, plug-andplay installation, setup is fast and intuitive.

The Kubota Tiltrotator is compatible with popular excavator models including the U48-5, U55-5, KX057-5, and KX080-5.

With its lighter operating weight and smaller footprint, the SVL65-2s delivers exceptional versatility to tackle jobs of all sizes and locations – providing contractors with greater flexibility on diverse projects.

The machine features a premium 7” LCD monitor with touch and jog dial controls for quick operation selection, seamless Bluetooth compatibility for streaming and hands-free calling, and auto downshift technology to maximize traction when turning.

Operator comfort is a key priority, with a high back air ride heated seat designed for all-day productivity, rear view camera standard for enhanced safety and visibility, and an available Kubota shockless ride option to minimize material loss over rough terrain. LED work lights with delayed auto turn-off (1-20 minutes) ensure safe operator egress, while vertical lift arms reaching 118.5” hinge pin height expand the machine’s reach and capability.

The SVL65-2s offers track response settings in mild, normal, and quick modes for customized control, giving operators the flexibility to match machine performance to their specific application.

For demanding jobs, the SVL65-2s features high-flow hydraulic options delivering

27.0 gpm with a 14-pin connector, giving contractors the muscle they need for operating attachments in the toughest applications. All models include Work Smart Telematics for real-time equipment monitoring and maintenance alerts, keeping machines running at peak performance.

The SVL110-3 represents a significant leap forward in compact track loader technology, combining increased performance with operatorfocused features. The machine delivers high-flow auxiliary capabilities up to 45 gpm with a 14-pin connector, programmable into twenty preset flow modes, while the auxiliary performance system (APS) intelligently manages power for maximum productivity. A first for Kubota compact track loaders, creep mode allows precise speed adjustment from crawl to full low-range speed.

Operator comfort is enhanced with a sealed cab delivering a sound level of 79 dBa, a premium 7” LCD monitor with touch and jog dial controls, and a high back air ride heated seat. A rear-view camera standard, seamless Bluetooth radio integration, and an auto-idle function that reduces noise and fuel consumption round out the operator experience. Maintenance accessibility is simplified with easy-access radiator swing-out design and a tilting cab (72°) for quick hydraulic and filter access. All models include Work Smart Telematics for connected equipment management.

The Kubota Tiltrotator, SVL65-2s, and SVL110-3 will be available at select authorized Kubota dealers throughout the course of 2026. Visit Kubota.ca to learn more and to find a dealer near you. SP

Source: Kubota Canada

Komatsu’s new PC365LC-11 excavator is built to excel in multifunction applications by enhancing productivity, fuel efficiency and operator comfort.

Komatsu introduces the new PC365LC-11 multifunction plus excavator to the North American market. It features a refreshed exterior design, an enhanced operator cab, and several new standard and optional features built and optimized for the North American construction market.

The PC365LC-11 is the only excavator in its class featuring an innovative electric swing system with “boom-up” power assist. The dedicated electric swing motor improves swing speeds and operational efficiency, reducing cycle times in multifunction applications delivering up to a 15% increase in productivity. The ultracapacitor stores an additional 70 electric horsepower for acceleration when the engine is in ultra-low idle for instantaneous power to the work equipment on demand.

The ultra-low idle state reduces fuel consumption by up to 20%, extending runtimes and lowering total cost of ownership. All electrical energy used in this system is generated during normal operation and stored in the ultracapacitor — no external charging needed. Without the need for hydraulic power for swing operations, this power is fully available for the boom, arm and bucket cylinders. Optimizing hydraulic flow further reduces digging cycle times and reduces work equipment lag, enabling smoother operation in multifunction applications. These features also make the PC365LC-11 significantly quieter. Compared to the previous model, this workhorse brings new features and enhancements across three

key areas: operator experience, technology and attachment flexibility.

A new premium heated air-suspension operator seat features a high leather back, improved cushioning and multiple adjustments. New proportional joysticks offer an intuitive, ergonomic feel that’s easy to use, helping reduce operator fatigue and wrist stress.

The KomVision camera system comes as standard and provides a real-time bird’s-eye view of the machine and its surroundings to help improve situational awareness that drives Komatsu’s mission of zero harm. An optional Smart Construction 3D Machine

A range of excavators can deliver reliable hydraulic power, versatility, and operator comfort across compact, mid-size, and heavy-duty models, enabling contractors to efficiently handle utility and infrastructure projects of any scale.

Guidance kit can be factoryinstalled. This system provides operators in the field and managers in the office access to 3D design and topography data that help drive work accuracy, control load volumes and promote optimized operations.

Efficient, Fast and Versatile Attachment Operation

The tool control system is standard for machine configurations with an additional hydraulic piping line, which allows operators to configure and store flow rates/target pressures

for multiple attachments. Attachment information is displayed on the in-cab monitor interface. This system improves efficiency, precision and performance by enabling quick switching between attachments with accurate, preconfigured hydraulic settings tailored to each tool. Optional hydraulic quick coupler piping can be factory-installed for quick, easy attachment of tools, such as the Lehnhoff quick coupler system.

For added peace of mind, this machine’s electric powertrain components are

covered by a 7-year/15,000hour transferable warranty.

“The PC365LC-11 was engineered for excellence in multifunction applications by leveraging its innovative electric powertrain system to boost jobsite productivity while reducing fuel consumption,” says Matthew Moen, Product Manager. “To highlight these performance enhancements, we’re emphasizing the concept of ‘multifunction plus’ as the defining feature of this machine.” SP

Source: Komatsu

lifting capacity and breakout force. These models are often found on DOT projects, energy installations and other long-duration civil projects where uptime and performance cannot be compromised.

fine-tune their setup for accurate trenching or highvolume work.

Utility and infrastructure contractors know what they need out of a machine. It is not about gimmicks or oversized claims. It is about digging clean trenches, handling big lifts, running attachments without delay and keeping crews productive under aggressive timelines and tight site conditions.

day operator comfort and equipment that is ready to move when the job shifts.

That is exactly where SANY excavators fit in.

ideal for water line replacements, gas installations, and fiber trenching in tight residential or urban spaces. These compact machines are easy to trailer with standard trucks, deliver excellent visibility and provide the reach and breakout force required for shallow utility work without adding unnecessary weight.

You need hydraulic power, long-term reliability, all-

Smaller models like the SY26, SY35, and SY50 are

Mid-sized machines such as the SY60, SY75, SY80, SY95, SY135, and SY155 strike the right balance between power and portability. They are proven for municipal projects, stormwater installations, gas line installations and other high-demand tasks. With standard quick coupler plumbing, responsive hydraulics and long stick options, crews can switch between digging, lifting and placing without losing time.

For large infrastructure jobs like pipeline work, deep sewer and site development, full-size machines like the SY135, SY155, SY215, SY225 and SY265 bring exceptional reach,

And when the job calls for maximum production—whether you are dropping precast vaults, loading trucks or trenching across miles of rightof-way—the heavyweights step in. Machines like the SY335, SY365, SY385 and SY500 are engineered for nonstop material handling, deep trenching and heavy lifting. They bring serious horsepower, long stick options and cooling systems designed for continuous attachment work.

SANY understands that reach matters. Long-stick configurations are available across nearly every size class, from compact models to production excavators, allowing deeper digging depths and greater flexibility in the field. With multiple bucket sizes available, operators can

Hydraulics are a core strength. SANY machines come standard with dual auxiliary circuits, a case drain and full plumbing for quick couplers. Combined flow functionality supports high-demand tools like hammers and compactors. Adjustable flow and pressure from the cab give operators the control they need to fine-tune performance for every attachment.

Operator comfort and safety are built in. All enclosed cab models include ROPS certification (FOPS-certified with cab guarding), automatic climate control, suspension seating and multifunction monitors that put diagnostics and hydraulic settings within reach. Rearview and blindside cameras are standard on new-generation machines for greater awareness in tight or congested environments. SP

Source: SANY

Genie is building on its extensive portfolio of quality aerial lifts with the introduction of Genie Recon, a new reconditioning business that will provide equipment owners the ability to add quality, like-new Genie lifts to their fleet at a lower price point than buying new.

Genie Recon is reconditioning units at a dedicated facility in Springfield, Missouri, where factory-trained specialists follow a structured process designed to replicate the standards of the original manufacturing. Using Genie Genuine Parts and quality assurance processes, each machine undergoes detailed inspection, functional testing, and targeted upgrades to ensure like-new consistent performance, safety, and reliability. The process mirrors the same quality benchmarks

applied to new equipment, delivering dependable outcomes every time. Every reconditioned unit is backed by a three-year warranty, offering customers peace of mind and a smart path to long-term value.

“By adding high-quality, like-new equipment to their fleets at a lower acquisition price, customers can boost the return on their investment,” said Amalija Kopac, Genie Product Director, Reconditioned Products.

“We’re excited to offer a so-

lution that blends affordability with the dependability of Genie engineering.”

Genie S-65 and S-85 telescopic boom lifts are now available as reconditioned units for customers in North America.

“This is just the start. We’re excited to build a world-class operation, and plan to expand our portfolio to add additional models and reconditioning services in the future,” Kopac said. SP

Source: Genie

Fixed telehandler or wheel loader: why choose just one? Discover all the advantages of the Agri Pivot for your farm.

The key features demanded by today’s agricultural machinery market are agility, speed and multi-functionality. Farms require solutions that, in addition to delivering high performance, are also optimized to handle a wide range of daily tasks, including material handling, working in tight spaces like barns and storage areas, and repetitive operations.

high-performance machines capable of reaching great heights and handling large quantities of materials such as hay, soil, grains, and more. At the same time, it’s essential to rely on compact, agile and maneuverable solutions that are able to work efficiently even in enclosed, restricted or complex spaces.

To meet the needs of those seeking a vehicle that can reach significant heights, offer versatility, and still maneuver easily in confined spaces, DIECI has developed the Agri Pivot range, combining the benefits of a wheel loader with the performance of a telehandler.

In this article, we explore all the features of the telescopic wheel loader, its applications, and the contexts in which this vehicle has become indispensable!

Why choose a telescopic wheel loader

To operate effectively on farms, it’s crucial to have

In the past, meeting these demands required the purchase of two separate vehicles — a telehandler and a wheel loader — but now there’s no longer a need to compromise between agility and lifting capability.

The Agri Pivot is the telescopic wheel loader that makes no compromises, combining the agility of a wheel loader with the lifting power of a fixed telehandler.

This versatile and multifunctional agricultural machine offers numerous advantages and technical functions, including:

• 2-speed hydrostatic transmission for the T60 model.

• Shift on Fly transmission for the T70 and T80 models.

• Lifting height ranging from 4.7 to 5.2 metres.

• Maximum load capacity between 2250 kg and 3500 kg.

• Maximum power from 54.6 to 114 kW.

• High-flow hydraulic system.

• Single-lever joystick for intuitive and comfortable control.

• Top speed of up to 40 km/h.

• Exceptional driving comfort thanks to double-sided accessibility, 180° opening doors, a raised driver’s seat and intuitive controls.

The Agri Pivot not only brings together the best features of telehandlers and wheel loaders, it also enhances them, making it the ideal vehicle for streamlining, accelerating and optimizing every work cycle.

The Agri Pivot telescopic wheel loader features a double-jointed central articulation for excellent agility and maneuverability, while its telescopic boom boasts a long reach, making it capable of performing tasks typically carried out by fixed telehandlers.

The Agri Pivot is an articulated telehandler with a dual-pivot central joint linking the front and rear frames, delivering strength, stability and maneuverability.

The centrally positioned boom and rear-mounted engine provide 360° visibility, ensuring complete control Continued on page 23

Continued from page 22

and an unobstructed view, even when lifting loads. The vehicle’s turning radius is always determined by the front or rear wheels, ensuring the rear does not obstruct maneuvers.

Thanks to these extraordinary features, the Agri Pivot is the ideal choice for farms requiring the agility of a wheel loader and the reach of a fixed telehandler.

Better than a wheel loader

The Agri Pivot articulated telehandler incorporates all the strengths of a wheel loader, such as agility, comfort and maneuverability, with improved and more efficient functionalities thanks to the DIECI Research & Development team.

Here are some of the most distinctive features of the Agri Pivot telescopic wheel loader:

• Excellent terrain adaptability thanks to its oscillating rear axle. This feature ensures four-point contact with the ground at all times, maintaining maximum lateral stability as if operating on level terrain;

• Superior maneuverability, reliability and safety, aided

by a large exit angle (>30°) and load limiter;

• Smooth, controllable forward movement, even with the boom at maximum power, thanks to the electronic accelerator and inching pedal.

• Load Sensing-Flow Sharing hydraulic distributors.

• Expedited operations with advanced boom functions: Shake, Wall, Memory, and Floating.

• Lifting height from 4.7 to 5.2 metres.

With this machine, farms can rely on a complete solution tailored to real operational needs, simplifying and improving every work cycle with an extensive range of technical features.

What are the telescopic wheel loader’s areas of application?

The telescopic wheel loader is a highly versatile machine, capable of delivering excellent performance in various operating contexts, such as material handling, green area maintenance, snow removal and more, offering both versatility and multifunctionality.

Like all DIECI telehan-

dlers, the Agri Pivot can be equipped with a wide range of attachments, including forks, buckets, lifting hooks, snow ploughs, sweepers and shredders.

The Agri Pivot supports both classic telehandler and wheel loader accessories.

Key areas of application include:

• Livestock farms, for stall cleaning and feeding tasks. The articulated telehandler moves effortlessly within stalls and offers excellent flexibility for multiple uses.

• Storage and handling of cereals, reaching high storage points even in narrow warehouses or aisles.

• Recycling facilities, where it allows for quick material loading/unloading, even in tight or congested areas, with frequent maneuvers.

For any operating context that requires a solution that delivers maneuverability, versatility, multi-functionality and lifting height, the Agri Pivot telescopic wheel loader offers an ideal way to streamline operations and maximize return on investment. SP

Source: Dieci

Cereals Canada and James Richardson & Sons, Limited have signed a Memorandum of Understanding pursuant to which Richardson Centre, a subsidiary of JRSL, will make an inkind contribution of land for the development of the Global Agriculture Technology Exchange (Gate) facility in downtown Winnipeg.

The MOU establishes a framework for the contribution of a parcel of land located at the corner of Lombard Avenue and Westbrook Street, steps away from Winnipeg’s historic Portage & Main intersection. The land to be provided will be a foundational asset to support the development of the Gate facility, contingent upon the success of the project’s capital campaign.

“Securing what we previously identified as the most desirable site for Gate is a significant step forward, and we are deeply appreciative of James Richardson & Sons for their generosity,” said Dean Dias, CEO of Cereals Canada. “Together, we are building the foundation for a project that will support Canada’s grain competitiveness well into the future.”

The signing of the MOU is a major milestone for the Cereals Canada-led project. It reflects the commitment of JRSL in supporting Gate and its vision of creating a world-

class hub for collaboration, innovation, and market development to ensure Canada remains at the forefront of the global cereals sector.

“Our family has been in the grain industry since 1857, and we appreciate the importance of the work that Cereals Canada performs to help expand and diversify export markets for the grain that Canadian farmers produce. We also believe that the heart of downtown Winnipeg, which is home to many of Canada’s leading agriculture companies and institutions, is the natural location for the Gate. We’re proud to contribute to a vision that advances the industry, as well as the revitalization of downtown Winnipeg,” said Thor Richardson, President of James Richardson & Sons, Limited. “The global trade environment upon which our grain industry depends is more challenging than ever, and we believe that by supporting Gate, we are helping ensure that Canadian agriculture and farm-

ing communities continue to thrive for generations to come.”

The $102-million state-ofthe-art facility will serve as a hub for research, training, and international collaboration. To date, the Gate Capital Campaign, led by former Manitoba Senator JoAnne Buth, has raised $32,150,000 towards its goal.

“On behalf of the cabinet, I would like to extend gratitude to JRSL and the Richardson family for their support and leadership,” said Buth, Gate Capital Campaign Chair. “The signing of the MOU demonstrates tremendous commitment to the community, grain sector and the future of Canadian agriculture.”

The Gate Capital Campaign is targeting contributions from industry groups, agribusinesses and individuals, and support from the three levels of government. SP

Source: Cereals Canada

Sandvik has announced plans to develop a new, purpose-built mechanical cutting and parts and services facility in Saskatoon, Saskatchewan, further strengthening its commitment to supporting mining customers across Central and Western Canada.

The new facility will be developed on a portion of the 155-acre development east of Highway 11 and north of Marquis Drive in the North Marquis Industrial Area. Representing an investment of approximately $51 million CAD, the 51,000-square-foot facility will bring mechanical cutting, parts and services, and aftermarket support competencies together under one roof to drive efficiency and collaboration. Groundbreaking is planned for February 2026, with operations expected to begin in Q4 2026, supporting long-term growth across Saskatchewan’s potash and uranium sectors as well as hard-rock mining in gold and copper.

“Building on the momentum of our recent Sudbury announcement, this facility is about expanding capability and readiness,” said Peter Corcoran, Vice President,

Sales Area Canada, Sandvik Mining. “The Saskatoon facility will strengthen our local presence in a key mining region and ensure we have the capacity, infrastructure and expertise to support our customers well into the future.”

The facility will include workflow-optimized workshop bays equipped with dedicated space for equipment maintenance and component repairs, wash bay and staging areas, and robust cranage and clearance to support next-generation me-