pg 22

pg 14 Good Forklift Safety

ALL THE TIME pg 34

pg 22

pg 14 Good Forklift Safety

ALL THE TIME pg 34

Caitlan Mitchell Editor-in-Chief caitlan@reviewmags.com

As we close out another month of innovation and insight across the food and beverage industry, this issue of FB Tech Magazine brings together a mix of forwardlooking features and global perspectives. We begin at the ground level with Soil Health & Fertilisers, exploring how sustainable farming practices and smarter inputs are shaping the future of food production. From there, we shift focus to the factory floor with Material Handling and Forklifts, highlighting improved efficiency, safety, and productivity.

On the global stage, we take a look back at Drinktec, the world’s leading beverage and liquid food technology trade fair, uncovering the key trends and breakthroughs on display. Looking ahead, we also prepare for one of the industry’s biggest gatherings with our Anuga preview coverage, offering a first look at what to expect when the global food and beverage community converges in Cologne. As always, our goal is to bring you practical insights, thought leadership, and the international context you need to stay ahead.

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES caroline@reviewmags.com, daniel@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC

Raymund Santos

The new Te Waihekeora Reservoir has been officially opened in Northland, supporting local horticulture and job opportunities.

Horticulture and job opportunities in Northland will get a major boost with the completion of Te Waihekeora Reservoir, a large water storage project south of Dargaville. Prime Minister Christopher Luxon and Regional Development Minister Shane Jones officially opened the 3.3 million cubic metre reservoir’s opening at Te Kōpuru.

“Northland is often at the mercy of drought but also flooding. It also has tremendous economic possibilities through its fertile soil but without the means to store the generous rainfall these possibilities are limited,” Jones said.

The water infrastructure will unlock more than 1000ha of land for horticulture. This could be quadrupled with the recently announced 22km Kaipara pipeline which will eventually connect the reservoir to Dargaville.

Read more here

As a global leader in fresh produce labelling solutions, Sinclair has launched the first platform of its kind for the industry.

Created to provide educational content that helps understand regulations, compostable products, composting, product certification, and more. The platform's goal is to provide packaging stakeholders, and even consumers, with the resources needed to make informed decisions. Over time, it will develop into a comprehensive and everexpanding resource hub.

“Since launching our certified compostable label, Sinclair - T55, last year, we've identified a significant gap in clear and accessible information regarding packaging waste and compostable products”, said Duncan Jones, Senior Marketing Manager at Sinclair.

Read more here

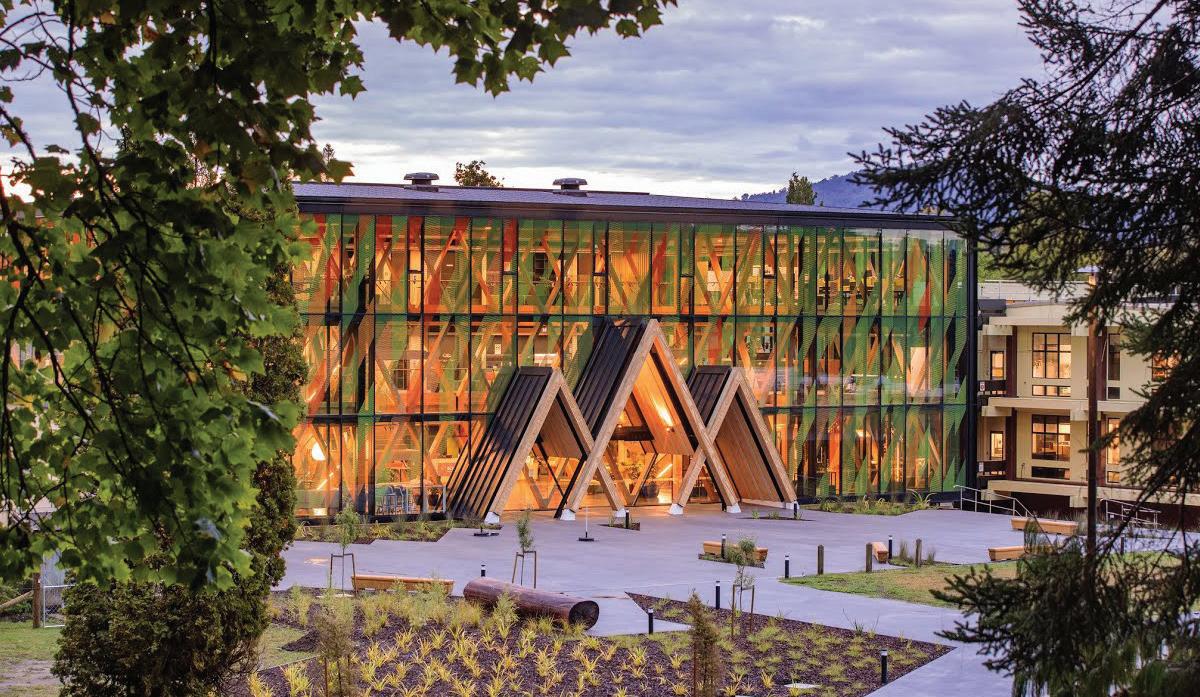

Australia’s oldest family-owned chocolate maker, Haigh’s Chocolates, has officially opened its new AUD 120 million production, warehouse and online fulfilment facility in South Australia as it prepares to increase chocolate production.

The 18,000m2 state-of-the-art facility located in Salisbury South has been built to support the business's ongoing expansion and plans for wider distribution.

Currently producing 1,100 tonnes of chocolate to fulfil the needs of its 22 retail and online stores, the new facility will allow for future growth, including increasing production to 2,000 tonnes of chocolate per year.

Representing the biggest investment in its 110-year history, CEO Peter Millard recognised the significance of this milestone for Haigh’s.

Read more here

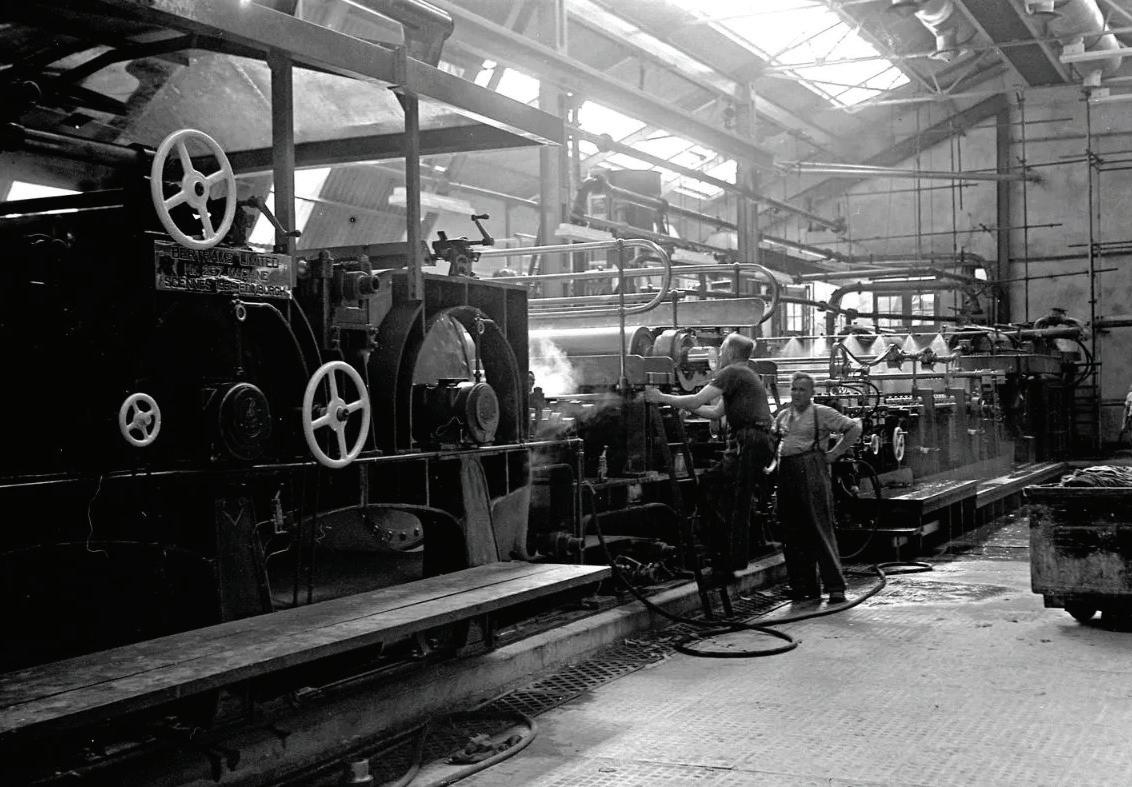

From the foothills of the English Lakes District to the forefront of global innovation, James Cropper has spent 180 years pushing boundaries, shaping industries and making a material difference.

This year, the sixthgeneration family business celebrates nearly two centuries of papermaking excellence and advanced materials, with festivities at its Burneside mill, where employees and their families came together to honour a legacy built across generations.

Founded in 1845, James Cropper has grown from its Cumbrian roots in Burneside to a global group, with sites

in Cornwall, Crewe, and Schenectady, USA.

Across generations, its people have earned an international reputation for colour mastery, craftsmanship, technical excellence and sustainable innovation, a culture that

continues to define the business today.

That spirit of restless curiosity has shaped defining moments in the company’s history: producing paper for the British government during WWI, supplying the iconic

red paper for Remembrance Day poppies and welcoming Her Majesty The Queen in 2013 to open the revolutionary CupCycling plant, the world’s first facility dedicated to recycling coffee cups at scale.

Read more here

Anuga has expanded its international portfolio, specifically addressing growth markets, highlighting regional specialities, and identifying innovations in the food and beverage industry at an early stage.

Within the scope of Anuga Select Ibérica, which will celebrate its premiere from February 16 to 18, 2027, the brand family has expanded its European presence to

include a third trade fair, alongside Cologne and Milan. At the same time, ISM will reinforce the raw materials section from 2026 onwards with the new format ISM Ingredients, thereby creating its own platform for pioneering solutions in the sweets and snacks industry. A portfolio with geographical and thematic diversity has thus evolved. Read more here

Microlise APAC has obtained type approval from Transport Certification Australia (TCA) for its flagship telematics device, SmartGateway 14, joining an exclusive group of only 15 approved telematics suppliers across

Swisslog has announced the expansion of its Partnership with Rexel following the successful deployment of a next-generation AutoStore system at Rexel France’s logistics centre in Miribel, Ain, located in the AuvergneRhône-Alpes region.

Spanning 36,000 m² and certified Breeam Very Good for environmental performance, this strategic site was designed to meet Rexel’s increasing supply chain demands for performance, responsiveness, and sustainability. The goal is to ensure delivery to regional branches and customers within 24 hours.

At the heart of the system is an AutoStore solution

integrated by Swisslog. It houses up to 50,000 bins, operated by over 70 robots, and features 13 picking ports and six receiving (replenishment) ports,

managing more than 68,500 products.

This modular and ultracompact system, powered by Swisslog’s SynQ WMS/WCS software, enhances storage

efficiency and accelerates order processing. It also improves working conditions by automating repetitive tasks.

Read more here

Phosta began as a humble guano-importing business, driven by a simple yet bold mantra: “Bird shit? Bat shit? But not bullshit.”

While tongue-in-cheek, this early slogan reflected our genuine commitment to transparency, quality, and integrity, values that continue to guide our work today.

At Phosta, our mission is to provide sustainable, environmentally responsible fertilisers without compromising on performance. From the beginning, we’ve invested heavily in research and development to ensure that every product we offer delivers real value to farmers. Quality is not just a goal; it’s our standard. One of the key ways we maintain this standard is by employing staff in the countries of origin. While unusual in the industry, we consider this approach essential. Our on-

the-ground teams are responsible for monitoring and verifying that our rigorous production and quality standards are consistently met. This hands-on approach ensures traceability, reliability, and accountability at every stage of the supply chain.

To support this commitment, we maintain our own fully equipped laboratory. Its primary function is to perform quality control testing, ensuring every batch of fertiliser meets our specifications. In addition, our lab drives innovation, developing new products and analytical techniques to stay ahead of industry needs. We provide full quality control data for each container we import, giving our clients confidence in both performance and safety.

Guano remains a cornerstone of our product line. Our mineralised guano is relatively young, between one to three million years old, compared to conventional phosphate rock (RPR), which ranges from 30 to 60 million years. This younger deposit contains significantly lower levels of contaminants. For example, fluoride content is about one-seventh that of RPR, and cadmium levels average around 40 mg/kg P, compared to the industry standard of 280 mg/kg P. For those interested in the science, the alpha angle of our guano is also higher than that of standard RPR, indicating more favourable structural properties for solubility and uptake. Phosta K starts life as sugarcane and is transformed into a sustainable potassium fertiliser, enriched with a full spectrum of minerals naturally found in plants. Our internal estimates suggest the product contains approximately NZD 250 worth of additional trace minerals per tonne, adding both agronomic and economic value.

In response to market demand and environmental necessity, we also developed an organic nitrogen product two years ago, available in both solid and liquid forms. Made from starch derived from renewable sources such as corn and sugarcane, it offers a more sustainable and biologically friendly alternative to conventional nitrogen products.

Knowledge is the most powerful tool a farmer has when it comes to making better fertiliser decisions. There was a time when widespread superphosphate application was the best option for New Zealand soils, and Continued on page 10.

the country led the world in fertiliser research. However, that was more than 50 years ago. The challenges we face today, such as cadmium accumulation, fluoride toxicity, and soil degradation, require new thinking and modern approaches.

One example is nitrogen use. While applying nitrogen can produce visible growth responses, the deeper story lies beneath the surface. Soil chemistry is highly complex, and overuse of nitrogen can disturb microbial balance, reduce longterm productivity, and harm the environment. It’s time to focus on soil biology; microorganisms are the true engine of productivity.

Modern soil testing provides a snapshot of what’s happening in the soil, and more advanced analytical

techniques can paint a clearer picture. The information exists, and the trials have been done. For example, humates have been shown to reduce nitrogen requirements while enhancing soil health, an environmental win. Similarly, many farmers are now adopting cationbalancing strategies, often reporting reduced nitrogen use with no loss in productivity. While further research is needed, the early results are promising.

At Phosta, we’ve conducted our own trials, and the data speaks for itself. Our guano products consistently outperform RPR and DAP on soils

with high phosphate retention. We’ve also demonstrated that guano leaches less than TSP, making it a better environmental option, especially in sensitive catchment areas.

The future of farming lies in using fertilisers more intelligently, not just more intensively. We believe that smarter application methods, such as foliar sprays, bio stimulant integration, humate enrichment, and using nutrients in more bioavailable forms, will play a critical role in the transition to more sustainable agriculture.

It’s time to put soil health at the centre of farming decisions. Building soil carbon, improving nutrient cycling, and reducing pollution will ensure we leave our land in better condition for future generations.

At Phosta, we’re proud to be part of that journey.

Lime (calcium carbonate) is a powerful tool for improving nutrient availability, productivity and help reduce emissions of a long-lived greenhouse gas.

Nitrous oxide is a long-lived gas and is produced from fertiliser and animal urine along with industrial processes.

In Agriculture, these losses occur regardless of whether N Fertiliser is applied or not, they are a function of a fertile soil. However, inappropriate use of N fertiliser can exacerbate these losses.

Denitrification is a process of reduction and one of these losses is through nitrous oxide (N₂O) escaping to the atmosphere through incomplete denitrification occurring under anaerobic conditions. The enzyme responsible for the final step of denitrification, nitrous oxide reductase, is inhibited

in acidic soils. Thus, low pH combined with waterlogged conditions creates a “perfect storm” for N₂O emissions.

Lime raises soil pH, enabling complete denitrification and reducing N₂O emissions. Studies from New Zealand, Ireland, and Denmark show that liming improves soil conditions, enhances microbial activity, and increases plant biomass—factors that collectively reduce the availability of nitrogen for denitrification and limit anaerobic conditions.

For example, under research conditions, Irish research found that soils limed to pH 6.9 emitted 36% less N₂O per tonne of dry matter than non-limed soils. A meta-analysis of

over 1,100 measurements revealed that reducing nitrogen application from 200kg N/ha to 140kg N/ha could cut N₂O emissions by up to 42% at pH 5 and 38% at pH 6.5.

Lime also improves soil structure through flocculation. Calcium ions (Ca²+) released from lime bind negatively charged clay and organic matter, forming stable aggregates that enhance porosity and drainage—critical for balancing aerobic and anaerobic conditions.

Soil pH also plays a pivotal role in nutrient availability. Most major nutrients (Ca, Mg, N, P, S, K, Na) and trace elements like molybdenum and boron are most accessible in near-neutral

soils (pH 6.3–6.5). Acidic soils, often worsened by rainfall, legumes, and fertiliser use, hinder nutrient uptake and microbial activity.

Lime corrects soil acidity, unlocking nutrients already present or added over time. For instance, phosphorus

becomes unavailable in acidic soils due to binding with iron and aluminium. Liming reduces these compounds, enhancing phosphorus availability—a phenomenon known as the “P-sparing effect.” A Northland study on Kaipara

Clay Soils showed that applying 5t/ha of lime to pH 5.8 soils resulted in a phosphorus-sparing effect equivalent to 500–670kg/ ha of superphosphate over three years.

Sulphur, essential for plant growth, is also more available in limed soils due to increased microbial mineralisation. Magnesium, vital for both plants and livestock, becomes optimally available at pH 6 and above. Deficiencies can lead to serious health issues in animals, such as hypomagnesaemia in lactating cows.

Micronutrients, though required in smaller amounts, are crucial for processes like nitrogen fixation, seed formation, and chlorophyll synthesis. Liming ensures their balanced availability, supporting both plant and animal health.

Beyond pH correction, lime provides calcium (Ca), which supports water and nutrient uptake, carbohydrate storage, and legume nodulation. It also encourages earthworm activity, further enhancing

soil structure and fertility. It is important to note that Ca as a nutrient has for a long time not been a concern when soil testing due to the regular applications of Superphosphate. However, in recent times, there has been a shift away from Superphosphate towards imported fertilisers that supply lesser amounts of Ca.

In short, lime is a multifunctional soil enhancer— improving nutrient availability, and boosting productivity. For farmers looking to get more bang for their buck while caring for the environment, lime is a smart investment.

Avoca has a team of experienced advisers throughout Northland, Waikato and BOP and offer custom lime and fertiliser blending. Whether you’re looking to optimise yields, address nutrient deficiencies, or simply want to discuss the best options for your farm. We’re here to help you make informed decisions that support the health and productivity of your land. Visit www.avocagroup.co.nz or phone 09 433 5720

Regenerative practices, such as compost and cover crops, led to measurable gains in soil health and crop yields within two years, particularly on heavy clay soils.

Atwo-year research project into regenerative growing methods has found that regenerative management interventions, cover cropping and compost application can deliver short-term improvements in soil health and crop performance in commercial vegetable systems.

The project, led by Woolworths New Zealand in partnership with Gisborne

grower LeaderBrand and scientists from Bioeconomy Science Institute, tested cover cropping and composting application across two soil types under intensive vegetable production.

Supported by the Ministry for Primary Industries’ Sustainable Food and Fibre Futures Fund, the project aimed to understand how regenerative practices could fit within intensive, high-

one season, cover cropping with vetch enabled a 34 percent reduction in nitrogen fertiliser inputs to a subsequent sweetcorn crop with no impact on commercial yield.

“We want to support our growers, and by investing in innovative trials - such as regenerative agriculture - we’re doing our part to help prepare for the future,” said Catherine Langabeer, Head of Sustainability at Woolworths New Zealand.

“What this project has shown is that cover cropping, when used in the right way, can reduce fertiliser needs, support healthier soils and help build resilience over time.”

The project also reinforced the importance of input quality, with lower-grade compost contributing to weed pressure and reduced yields in year one.

choice, can have measurable impacts in a relatively short timeframe.”

While results varied across conditions, the project has created a credible starting point for growers who want to strengthen their growing systems and future-proof their land through more regenerative methods.

“This project helped move regenerative agriculture out of the theory and into practice,” said Gordon McPhail, General Manager at LeaderBrand.

“We’ve come away with a much clearer understanding of what works where, and we’re already starting to adapt our own systems based on the insights the two-year research project provided.”

turnover production systems.

While not all methods delivered the same results across both sites, the study found that the combined use of compost and cover crops led to measurable gains in soil health and crop yields within two years, especially on heavy clay soils.

Cover cropping was shown to be an especially useful tool for improving soil structure and nutrient cycling on heavy clay soils. For example, in

“Compost is best viewed as a soil conditioner in intensive vegetable production systems, rather than a replacement for synthetic fertiliser sources”, said Matt Norris, Scientist at Plant & Food Research.

“This is because nutrient release from applied compost is slow and generally insufficient to meet nutrient demand in a commercial production setting. Overall, it’s encouraging to see that even modest changes to soil management, especially through the right cover crop

Woolworths is now focused on sharing the project findings with its network of more than 100 direct fruit and vegetable suppliers, while also exploring how best to support them in building a resilient and sustainable food system in New Zealand.

The Regenerative Agriculture project was supported by the Ministry for Primary Industries’ Sustainable Food and Fibre Futures Fund, which supported problemsolving and innovation in New Zealand’s food and fibre sector by co-investing in initiatives that made a positive and lasting difference.

Uptake Fertiliser believes that farming should be enjoyable, profitable, and sustainable.

With over 40 years of experience, the company has pioneered a more innovative, cleaner approach to fertiliser, developing highpurity suspension blends. Its soil and herbage testing, on-farm trials, and ongoing product innovation ensure everything offered is backed by science and results.

“In a time of rising costs and unpredictable weather, farmers need fertiliser solutions that are targeted, flexible, and proven to work,” said Daniel Moffitt, managing director of Uptake.

“Treat in combination, not isolation - at Uptake Fertiliser, we’ve spent the last 40 years pioneering the Uptake technology, which has always been learning to blend, supply and apply minerals in combinations that soil plants and animals can utilise.”

By drastically reducing input volumes, Uptake not only improve nutrient uptake efficiency and pasture yield but also helps address key sustainability

goals, specifically reducing the risk of nutrient leaching and waterway pollution.

Uptake’s suspension blend also supports long-term soil health by restoring nutrient balance and stimulating biological activity. Elements like calcium, magnesium, and sulphur improve soil structure and nutrient retention, while nitrogen, phosphate, and potassium promote vigorous plant growth, increasing organic matter through root mass and residue.

Other trace elements enhance microbial activity, feeding beneficial soil organisms essential for nutrient cycling. By delivering nutrients efficiently through fine-particle foliar application, Uptake reduces leaching and waste. This balanced, biologically friendly approach builds healthier soils over time, supporting sustainable pasture productivity and animal health.

With advancements in Tow and Fert machines, drones, and helicopter applications, Moffit added that

applying high-purity suspension fertilisers has now become more efficient and accessible than ever.

“We’ve trialled Fast 4 Folia (one of our off-the-shelf products) for thistle spraying with excellent results. Tow and Fert branded machines are a breakthrough for the dairy farmers, their technology keeps the product constantly agitated even while spraying.”

Moffitt also highlighted the key challenges New Zealand growers faced, centred around weather extremes, cost pressures, and efficiency of nutrient use. He said that many have been dealing with seasons that are either too wet or too dry, making fertiliser applications tricky.

At the same time, the rising cost of imported products is driven by global market instability and freight challenges. Farmers are increasingly seeking cost-effective, efficient solutions that provide a return on investment, products that operate in a single pass, reduce waste, and adapt to changing conditions.

Moffit emphasised that soil testing is the foundation of effective and sustainable pasture production, encouraging farmers to ensure their soil tests cover all key trace elements essential for animal health, including selenium, copper, cobalt, boron, zinc, and iodine, among others, not just the Olsen Ps.

Charles Hyland, Chair of the Soil & Health Association of New Zealand

Rising fertiliser costs, new freshwater and nutrient rules, and growing export-market demands mean soil health has evolved from a technical concern into both a risk and a competitive edge.

Growers who invest in soil resilience gain cost savings, better yields, and stronger credibility with buyers.

Horticulture and viticulture have faced immense pressure due to compaction from repeated machinery passes, uneven organic matter, and poorly timed irrigation. In terms of arable land, the decline in structure from intensive tillage has increased erosion risk, while pugging, nutrient hotspots near infrastructure, and uneven dung distribution have continued to affect the pastoral sector. Effective solutions must be tailored to each farm; no universal fix works everywhere. Cover crops and crop rotations improve soil structure, cycle nitrogen, and reduce pest and weed pressure. Compost and organic mulches release nutrients steadily, retain moisture, and foster microbial activity.

Effluent (used wisely) recovers nutrients, boosts soil carbon, and cuts runoff when applied at the correct rate and time. Biological inoculants can help in specific cases (e.g., legumes needing rhizobia), but only when soil conditions and carbon inputs are addressed first. Avoid chasing silver bullets; topsoil biology thrives only where structure,

pH, and drainage are already managed.

A tidy soil health checklist could include baseline indicators such as soil organic matter or total carbon, pH, bulk density, aggregate stability, and pH-appropriate nutrient tests.

Additionally, it could include biology indicators, such as quick respiration or mineralisable nitrogen tests, earthworm counts, or simple infiltration checks.

Focus on trends and changes over time, rather than chasing perfect numbers. Freshwater rules, climate reporting, and retailer programs are tightening. Organic certification frameworks, backed by law, give growers a ready-made path to differentiate and assure. Consistent, verifiable soil health gains become a story, not just compliance.

Remote sensing, variable-rate technologies, and sensor-driven irrigation models all offer value. But the key is using them to validate realworld gains, not to replace hands-on observation and discipline.

What might the next decade bring?

• Compost, effluent, and biological inputs treated as system levers

• Practical metrics driving both

compliance and marketing stories

• Organic exports and certified land continue strong growth

• Soil health seen as central to productivity and resilience

The future of farming belongs to those who see soil as more than a medium for inputs; it is the foundation of resilience, productivity, and trust. By pairing proven practices like composting and cover crops with smarter measurement and credible certification, New Zealand can meet regulatory demands and consumer expectations. These methods are not new; organic producers here have relied on them for decades. What is changing is recognition that the soil biology principles behind organic systems are practical, scientifically grounded, and relevant to all growers.

As demand for food and fibre free from synthetic pesticides rises, and as conventional farmers increasingly adopt these insights, the organic sector will continue to expand. This model of farming is commercially viable, ecologically resilient, and globally competitive.

Soil health is not abstract but a direct pathway to profitability, sustainability, and long-term security for both growers and the land.

The Bioeconomy Science Institute’s research aims to enhance soil health to help ensure long-term sustainability for New Zealand. This means growers across horticulture, viticulture, arable and pastoral farming industries can better address the challenges they each face, such as climate change mitigation.

Generally, New Zealand’s soils are naturally acidic, with low levels of nitrogen, phosphorus and sulphur.

Radiata pine forests are usually established on less fertile, steeper land with poor-quality soil that makes it unsuitable for agricultural and horticultural use. The impacts of this planting on New Zealand soil have been studied, with positive results. Evidence suggests well-managed planted forests can maintain or improve soil health while supporting a diverse range of soil microorganisms and other flora and fauna, as well as filtering groundwater and regulating flooding.

Bioeconomy Science Institute researchers have studied the nutrient

uptake and demand on these sites for over 30 years.

“We’ve found that, depending on how those trees are harvested, we can control the quantity of nutrients removed,” said Christchurch-based Bioeconomy Science Institute principal researcher Peter Clinton.

“We’ve also done experiments on how harvesting intensity can impact long-term productivity and have seen many of these plantation sites go through a second rotation without any loss of productivity.”

Throughout their full lifecycle, plantation forests and natural forests can withstand a similar level of soil disturbance.

“Natural forests undergo quite catastrophic disturbances at times, through weather events that might see trees topple and root plates come out of the ground,” he added.

“But they recover. The same is true of the soil disruption caused by harvesting in planted forests. Soil is quite robust – if you don’t burn it, you won’t typically see a big shift in nutrients.”

Over the past 40 years, the practice of establishing planted forests on pasture has increased. In doing so, farmers have seen significant improvements in nearby water quality indicators, including better sediment and nutrient concentrations and reduced microbial contamination.

On balance, planted forests are ecologically closer to native forests than any other productive systems we

have in New Zealand, including food production and dairy farming.

Foresters determine the quantity of nutrients removed during harvest, controlling the impact on the long-term productivity of the site.

Disrupting soil in the harvesting process can be beneficial, bringing unweathered material and subsoil to the surface.

That process happens naturally as part of forest management. The other thing that happens is nutrient cycling, where you will see nutrients entering a forest with rain or dust. There are lots of natural processes going on that help maintain the fertility of a forest site.

Planted pine forests can provide many long-term ecosystem services, such as soil stabilisation. They can also help recharge nearby aquifers and maintain groundwater flow in dry seasons, contributing to the security of water resources downstream. The deep roots of planted forests can also bind soil and slow slip movement, reducing erosion and decreasing runoff.

The Bioeconomy Science Institute’s research into forest soil carbon and sequestration is also contributing to New Zealand’s climate change goals and long-term sustainability.

At Biorich, innovation is about looking back to what Mother Nature has been doing for millions of years.

Instead of relying on synthetic inputs, Biorich recycle nature’s own age-old materials, green waste, organics and natural by-products and returns them to the soil in the form of high-quality compost. This process harnesses the soil food web and the natural cycles of decomposition to build fertility in a way that is both productive and sustainable.

By working with nature’s own technology, Biorich can improve soil structure, nutrient availability and water-holding capacity, which supports stronger yields for growers. At the same time, its approach reduces waste, cuts the need for chemical fertilisers, and builds longterm soil health, so farmers and

gardeners can achieve results today while caring for the land for future generations.

Biorich organic compost is full of beneficial microbes, fungi, and other tiny organisms that break down organic matter into nutrients that plants can use. This not only improves soil structure but also helps the soil retain water and nutrients.

Adding organic matter back into the soil also supports the hidden network of life, aka the soil food web, which keeps the ecosystem balanced and productive. Over time, this means soils become stronger, more resilient, and capable of supporting abundant growth year after year, while also contributing to a healthier environment.

Compost solutions can also be tailored by focusing on how they can be applied most effectively for different crops and conditions. For example, certain crops or practices can be tough on soil structure, so Biorich guides the right quantities and application methods to protect and rebuild the soil. By making compost practical and cost-effective to use, growers can get the best results while maintaining healthy, resilient soils.

Looking ahead, the most significant opportunities in fertilisers lie in working with nature’s proven “recipe”, recycling organic matter, building healthy soils, and supporting the soil food web. This is a promising future for sustainable agriculture.

Humates are carbon-rich compounds derived from prehistoric organic matter. When applied to soils, they increase cation exchange capacity, improving nutrient retention and reducing leaching. They also feed soil microbes, acting as a “superfood” for beneficial fungi and bacteria that drive nutrient cycling.

Over time, humates build stable organic matter, improve soil structure, and enhance water-holding capacity, all critical for long-term soil resilience.

“Many growers talk to us about the need to improve nutrient efficiency, getting more from what they already apply and how to build soil health for longterm productivity rather than relying on short-term fixes,” said Julia Uffindell from New Zealand Humates Ltd.

“In our view, the most effective solutions are those that balance productivity with sustainability. There is no one-size-fits-all answer, but combining conventional fertilisers with humate-based products offers a practical, scalable way to get better results with fewer losses across a wide range of soil types.”

New Zealand Humates has focused

on ensuring growers understand how to achieve the best results from its products by providing practical advice and making it easy to integrate products into existing fertiliser programs.

“The more people know how humates work, the more value they’ll see in their soils and crops.”

Uffindell added that the company was aware that a kiwifruit orchard in the Bay of Plenty has very different needs from a dairy farm in Taranaki or a vineyard in Marlborough, which was why the product range includes both solid products and liquid formulations that can be tank-mixed with trace elements, foliar feeds, or fertigation systems.

“We work directly with growers and distributors to recommend the correct rates and timings for crop types and soil conditions.”

A key innovation for New Zealand Humates has been Nitrogen Express

Liquid, which combines liquid nitrogen with fulvic acid. Traditional nitrogen applications can be inefficient, with a significant portion lost through leaching or volatilisation.

By adding fulvic acid, Nitrogen Express improves plant uptake and nitrogen-use efficiency, allowing growers to achieve better yields with lower inputs, boosting productivity while reducing environmental impact.

At the end of the day, Uffindell said everything the company did came back to supporting farmers and growers. Its goal is to make fertiliser programs work harder, helping reduce nutrient losses, build healthier soils, and ultimately get more value from every dollar spent.

“We keep things practical and easy to use, so growers can focus on what matters most: running productive and resilient farms.”

20 minutes with...

Louis Parent and Charles Durand had always been passionate about food and driven to create something distinctive in the culinary space. After an underwhelming experience involving snails at a restaurant in Dunedin, they started to question the availability and quality of escargot in New Zealand.

Their research revealed that all escargots in the country were imported, usually canned and shipped from Europe. They saw a gap in the market for something fresher, more flavourful, and environmentally conscious and something grown locally. This was the foundation for Otago Escargots, New Zealand’s first commercial snail farm.

The pair chose to farm petit gris, the same variety used in parts of southern and western France. Already present in New Zealand, the petit gris adapted well to local conditions and offered a finer, more delicate texture than the larger Burgundy snails.

“It suits high-end cuisine beautifully,” they said, pointing out that it was ideal for chefs looking for premium, local ingredients.

Parent and Durand’s day-to-day varied with the seasons. In winter, the snails hibernate, giving them time to focus on infrastructure and prepare for breeding. During the breeding season, they care for the snails indoors under controlled humidity and temperature, ensuring everything, from feeding to hygiene, is just right.

Spring marks the move outdoors, with daily feeding, watering, and predator checks, while autumn is all about harvesting and processing, the crucial final step before delivery.

One of their biggest hurdles came early: navigating the compliance and licensing needed to introduce a nonconventional protein source to New Zealand’s food system.

Farming snails turned out to be a lot more technical than simply

letting them roam in a garden. They studied snail biology, adapted traditional European methods to the local climate, and developed bespoke systems from scratch.

Because escargots are not a standard protein, there was little regulatory framework to follow. The food control plan process has been complex, and they have been working closely with MPI to obtain approval for everything, along with their food consultant.

“It’s a new thing for us, but also for MPI. We’re figuring it out step by step.”

Despite the behind-the-scenes challenges, the response from the food industry has been incredibly positive. Local chefs have been enthusiastic, particularly because the snails are grown in New Zealand.

“We’ve brought samples to a few

We’ve brought samples to a few chefs, and the feedback has been fantastic. They’re impressed by the flavour and freshness. Some are already calling us to see when we’ll be ready.

chefs, and the feedback has been fantastic. They’re impressed by the flavour and freshness. Some are already calling us to see when we’ll be ready.”

Looking ahead, Parent and Durand see escargots fitting into broader conversations around alternative proteins and sustainable gourmet meats. Nutritionally, escargots are high in protein, low in fat, and highly versatile.

From a sustainability perspective, they are a dream as they require minimal space, very little feed, and almost no water compared to traditional livestock.

“New Zealanders are conscientious about sustainability, and we think they’ll see the value.”

The duo also mentioned the potential ‘ick factor’ for unfamiliar consumers, but remain optimistic.

“You’d be surprised how many people have already tried them, especially while travelling in France and loved them. Most can’t wait to eat more,” they said.

With food trends increasingly focused on local and responsible sourcing, they believed Kiwis would be

open-minded. They also drew parallels with now-mainstream foods, such as oysters, sushi, and even insects.

While snails might not yet have the same everyday appeal, they have a long culinary tradition and are far more approachable than many emerging protein alternatives.

Looking beyond restaurants, Parent and Durand hinted at long-term plans to host on-farm tastings and explore cosmetic products made from snail mucin, an ingredient prized for its skinrepairing properties.

The vision was to create a complete experience in the Gibbston Valley, one that celebrated food, sustainability, and innovation.

“Imagine tasting escargots paired with local wine, surrounded by vineyards,” they said. “It’s a beautiful setting and a special product, and we want to share that with people.”

For now, their focus remained on getting it right, building relationships with local chefs, refining their systems, and gradually introducing New Zealand to a delicacy that’s anything but ordinary.

New Zealand’s food and beverage industry is not only a cornerstone of the nation’s economy but it’s also a key player in a global market.

GAJ PASUPATHY SVP of Delivery Services APJ at Syniti, Capgemini

With billions in exports and thousands of jobs dependent on its success, the industry faces both opportunities and challenges in an increasingly digital world. From dairy and meat to wine and seafood, data has become the critical ingredient driving efficiency, quality, and innovation. Embracing a data-driven approach is no longer optional. It is essential for sustaining New Zealand’s competitive edge and delivering on consumer expectations.

It’s an unfortunate reality that many Kiwi food and beverage companies still rely on outdated enterprise resource planning (ERP) systems and fragmented databases for their operations. These legacy systems may hinder agility, making it difficult to adapt to changing market demands, manage inventory efficiently, and streamline procurement.

For example, a seafood exporter may rely on manual spreadsheets for inventory tracking which may lead to struggles with stock forecasting. This in turn results in times of excess supply where seafood is wasted, or

in ‘stockouts’ where the customer is disappointed.

Implementing an integrated data platform, potentially powered by artificial intelligence, can significantly enhance demand forecasting, optimise inventory levels, and reduce waste. Additionally, cloud-based data solutions enable real-time collaboration, allowing businesses to respond swiftly to disruptions such as supply chain bottlenecks or regulatory changes. This might all sound complicated, but once up and running, it dramatically simplifies the running of a food and beverage business.

Referring to the seafood example again, New Zealand’s seafood industry is one sector that has started to embrace digital transformation. Some of the larger seafood companies have now adopted IoT (internet of things)-enabled tracking systems to monitor the location and condition of seafood throughout the supply chain. The investment made by these market leaders into datadriven operations has demonstrably reduced losses, improved inventory management, and strengthened relationships with international buyers who demand traceability and quality assurance.

New Zealand’s food and beverage industry operates within intricate supply chains that reach around the globe. Producers, importers, suppliers, and retailers are required to synchronise their operations to ensure a seamless flow of goods from New Zealand’s farms to international tables. However, data fragmentation remains a significant obstacle. Critical data-focused information within companies, such as production schedules, supplier details, and logistics data is often stored across a variety of separated platforms, and digital locations, meaning the data can’t be cross-correlated or used wholly and in real-time to make better supply chain decisions.

For example, if a Kiwi lamb exporter was shipping its coveted, premium New Zealand lamb to European consumers, it would have to rely on multiple data points. These would

include the farm origin, processing dates, temperature tracking, and shipping logistics. If these datasets are not integrated, inefficiencies often arise, leading to potential delays, stock shortages, or even compliance issues. By leveraging a unified data strategy, players in the lamb export sector can ensure endto-end visibility, optimise logistics, and enhance coordination between stakeholders, delivering tangible operational improvements.

Strict regulatory requirements govern New Zealand’s food and beverage industry, necessitating precise data management for quality control and safety compliance. Whether it is ensuring dairy products meet stringent export standards or verifying seafood sustainability certifications, the accuracy of data is paramount.

Manual data entry or disconnected systems increase the risk of errors, which can result in costly product recalls, non-compliance fines, and reputational damage. For example, if a winemaker was exporting to the United States, they must comply with various labelling and traceability regulations. A single misstep in tracking sulphur levels or alcohol content could lead to shipment rejections. Implementing an advanced data management system mitigates these risks by automating compliance checks, reducing human error, and maintaining transparent audit trails – critical for successful market entry and sustained reputation.

Modern consumers both in New Zealand and overseas demand more than just high-quality food and beverages, they also seek transparency. From verifying organic certifications to understanding a product’s carbon footprint, consumer expectations are, for better or worse, at an all-time high. New Zealand’s food and beverage sector must adapt by providing detailed, accessible product information.

For example, if you are manufacturing chocolate in New Zealand, the source of the cocoa beans might be very important. By integrating data-driven traceability solutions, a chocolate company in New Zealand can foster consumer trust, command premium pricing, and differentiate themselves in competitive markets by providing sustainably sourced their ingredients – a key differentiator for premium products.

To secure the future of New Zealand’s food and beverage industry, companies must consider their data as a strategic asset that can be leveraged for growth and company efficiency. The foundational data is often present but the challenge lies in implementing a modern data management solution to unlock its full benefits.

These benefits include real-time decision-making, where AI and predictive analytics can enhance production planning and supply chain coordination and give food and beverage businesses actionable insights to enhance their operations and decision-making.

Data management capabilities can also allow companies to consolidate disparate data sources and create a single and cohesive view of the supply chain that helps reduce inefficiencies, enhance traceability, and mitigate risks related to out-of-date or incomplete information.

Thirdly, operational efficiency is increased as areas where cost savings and performance improvements can be made are identified and flagged to decision-makers with empirical evidence to back it up.

New Zealand’s reputation for premium, high-quality food and beverages is built on trust, safety, and sustainability. By embracing a datadriven future, the industry can not only overcome current challenges but also unlock new growth opportunities in global markets. In a rapidly evolving landscape, those who effectively harness the power of data will lead the way in shaping the next chapter of New Zealand’s food and beverage success story.

A recent Coeliac New Zealand member survey confirmed that 68 percent of respondents actively choose products that are Crossed Grain Logo accredited when they shop for gluten-free products.

The Crossed Grain symbol is nationally and internationally recognised by those who follow a gluten-free diet. The logo gives consumers confidence and is a quick reference point when shopping and faced with uncertainty about the genuine gluten-free status of a product.

Products displaying the logo are subject to accredited laboratory testing and random audit testing and meet the Food Standards of Australia and New Zealand (FSANZ) gluten-free standard of ‘no detectable gluten’.

The Crossed Grain Logo (CGL) symbol is a certified trademark

owned by Coeliac New Zealand for the certification of products produced and licensed in New Zealand and sold in the territories of New Zealand and Australia.

Manufacturers who use the logo programme have been licensed to use the logo on certified product packaging and marketing material. The use of the CGL is operated via a licence agreement, renewable every year. The licence fee varies according to the total gluten-free gross annual sales turnover of the certified products you wish to license.

Dana Alexander, Sales

and Marketing

Manager, Coeliac New Zealand, mentioned that startups face several hurdles when navigating gluten-free labelling compliance in New Zealand.

“There is still a knowledge gap among startups and small food producers when it comes to compliance with allergen declaration requirements, but it is getting better.”

The FSANZ code has one of the strictest definitions globally, prohibiting even trace amounts of gluten and banning ingredients like oats or processed gluten-containing cereals –but there are exclusions.

Every ingredient, including additives

and processing aids, must be verified as gluten-free, but supplier documentation is not always adequate, and there’s a constant risk of crosscontamination. “May contain” statements aren’t permitted on glutenfree products, and misleading claims can lead to complaints or recalls.

While independent lab testing isn’t mandatory for gluten-free products, accreditation like the CGL offers a recognised standard that elevates your product but adds cost. With a highly informed coeliac community, one compliance breach can cause lasting brand damage.

Alexander said common packaging errors included misusing the “glutenfree” claim, contradictory allergen statements, missing or incorrect allergen declarations under PEAL rules, vague ingredient naming that hides gluten sources, unsubstantiated claims of suitability or certification, and combining gluten-free claims with unauthorised health benefits.

FSANZ approved a new Plain English Allergen Labelling (PEAL) standard in 2021 with a three-year transition. Packaging produced from 25 February 2024 must comply to the new rules, while pre-existing labels may be sold until 25 February 2026.

The gluten-free market is growingand so is consumer awareness. Coeliac NZ’s Crossed Grain Logo isn’t just a mark of compliance; it’s a symbol of trust and transparency. Licensing with the CGL shows your brand is committed to safety and integrityqualities that resonate with consumers and retailers alike.

• Download MPI’s plain-English allergen labelling guidebook and checklist to help you navigate ingredient declarations, as the deadline for compliance has now passed.

• Learn about the Crossed Grain Logo accreditation programme from Coeliac New Zealand at coeliac. org.nz. This globally recognised certification mark assures people with coeliac disease and those on a strict gluten-free diet that a product is safe and meets strict gluten-free standards. The logo is only granted after a thorough review of the product, including ingredient integrity and checking that product testing meets FSANZ standards of ‘nil detected.’

• Coeliac New Zealand also provides gluten-free food safety training, covering best practices for risk reduction, compliance requirements, and building staff confidence in gluten-free handling and communication.

• For routine gluten testing, use AsureQuality or other accredited laboratories. CGL licensees receive an added discount on lab testing.

Failing to comply with the requirements of the Australia and New Zealand Food Standards Code (Code) and the Fair Trading Act 1986 (FTA) can attract the attention of regulatory bodies, like the Ministry for Primary Industries and the Commerce Commission.

KATHRYN WALLACE Practice Leader, Legal Vision

These bodies have wide-ranging powers, from requiring product recalls and sending warning letters to carrying out prosecutions. This is a situation any business wants to avoid, not only for the stress and potential loss of income involved, but also for the possible reputational damage.

Key legal requirements that food and beverage businesses in New Zealand must consider when creating a product labelling panel are set out in the Code.

Labels must also be part of, or attached to, the package, easy to read and in English. It is also important that food and beverage businesses comply with the FTA regarding labels on their products.

This means that all labels and claims must not contain information that is misleading regarding the food or beverage product, and any claims made about the product must be substantiated, which means the claims must be supported by evidence, such as a scientific study. Note that the Code also contains special rules relating to health claims made about food.

The Weights and Measures Act 1987 is also relevant for stating the correct weight, quantity, or volume of food or beverage using the metric system’s weights and measures. This relates to the label only; there is other legislation, such as the Food Act 2014, which helps ensure that food sold in New Zealand is safe and suitable to eat.

The Food Standards Authority for Australia and New Zealand (FSANZ) has recently proposed a new definition of what constitutes genetically modified food. This new definition, if adopted, stipulates that food is considered genetically modified if it contains foreign DNA in the final product.

This means that if a food has been gene-edited, but contains no “novel DNA,” then it will no longer need to be labelled as genetically modified. The final decision on whether to adopt this definition is expected within the next few weeks.

“The most common mistakes we see are that labels lack the required level of detail and that claims made or implied on the packaging aren’t substantiated with reputable evidence. It usually comes down to finding a balance between meeting legal obligations regarding labelling and the aesthetic of the packaging, so that

the food or beverage is appealing to consumers,” said Kathryn Wallace, Practice Leader, at Legal Vision.

Although each aspect of food labelling is relatively detailed and complex, the key points Wallace highlighted were:

• Two types of health claims can be made - general-level and high-level.

• Food must meet specific nutrition requirements to carry a health claim.

• General health claims can be made based on a pre-approved foodhealth relationship as outlined in the Code, or self-substantiated with scientific evidence per the Code’s requirements.

• High-level health claims can only be made using a pre-approved foodhealth claim in the Code.

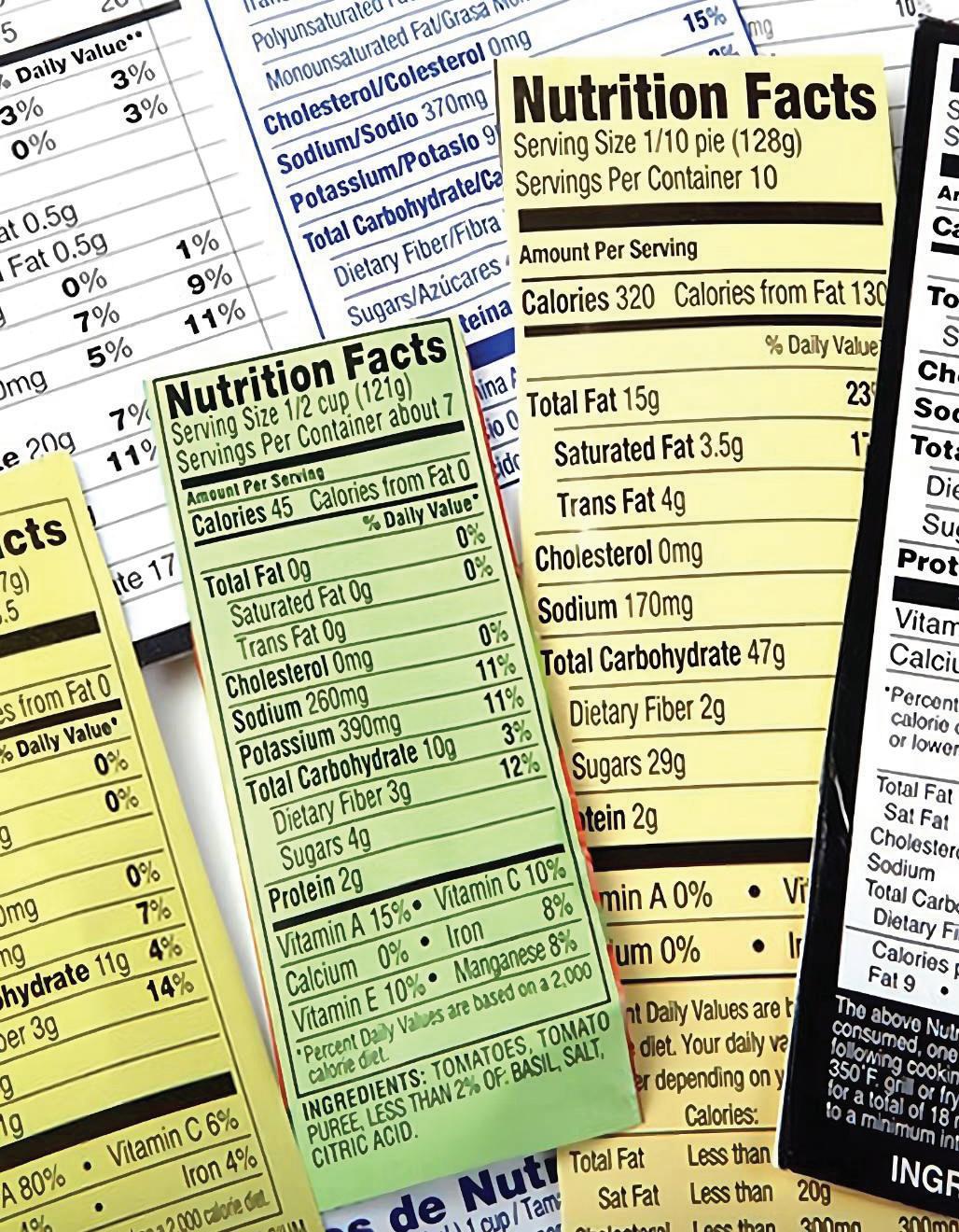

The nutrition information panel must contain the following information:

• Serving size for the food/beverage.

• Quantity per 100g/100ml of each nutrient

• Energy/kjs of the food/beverage

• The amount of each of the proteins, fats, carbohydrates, sugars, fibre, and salt in the product.

• Required allergen names must be used on a label. For example, if the product contains nuts, the type of nut must be specified.

• Allergens must be in bold font in the ingredients list, and there must also be a “contains” statement listing the allergens in bold.

Wallace’s advice to emerging businesses was to do everything by the book and ensure compliance with all requirements.

“This means you won’t be subject to recalls based on labelling (which is seen often in the Ministry for Primary Industries food recalls list, where allergens have not been declared on the label as required by the rules) and therefore damage to reputation,” added Wallace.

“This means you start from day one as a brand that shows it knows what it is doing and is across the requirements. This establishes you as a trusted label/ brand. Whilst taste and nutrition are important, people often buy products from brands they trust.”

Labelling requirements in the Australia New Zealand Food Standards Code (the Code) are designed to protect public health and safety, help consumers make informed choices, and prevent misleading and deceptive conduct.

Chapter 1 of the Code includes general labelling standards that apply to all foods, with specific requirements depending on the context, such as food for retail sale or catering. Chapter 2 includes additional labelling and information requirements that are specific to certain foods. More information is available here - Labelling | Food Standards Australia New Zealand.

“While we set the standards in the Code, we do not enforce them. This is the responsibility of the New Zealand Ministry for Primary Industries (MPI), Australian state and territory food regulatory agencies, and the Department of Agriculture, Fisheries and Forestry at the Australian border, under the Imported Food Inspection Scheme,” said a FSANZ spokesperson.

Cathy McArdle B.Tech (Food Tech), NZCS (Chem), Food Labelling Consultant and Managing Director of McFoodies Ltd, said that startups and small businesses often do not realise there are strict rules in Australia and New Zealand about what ingredients can be added to food and drinks, and that these are often different to other countries.

There are also particular and detailed rules about the format for compliance content, such as nutrition information panels, ingredient listings, allergen statements, net quantity statements or country of origin declarations.

“We have some complicated rules to navigate when determining which standard applies if wanting to include a specific ingredient, or if making a

claim, or even if using a particular product name. It’s easy to get it wrong and have the expense of fixing it later,” said McArdle.

“When preparing ingredient listings, make sure you look for all hidden ingredients that need to be declared. Saying that, you can ignore processing aids (like oil used on raisins to prevent sticking in production) as long as they are not allergens and include the percentage after any ingredients highlighted in graphics or words on the pack.”

She added that mislabelling allergens can be life-threatening; therefore, it was essential to include them all. With recent changes to legislation in this area, they also need to be declared in multiple places, including with the slightly confusing rule that the (allergen) summary statements must be ‘directly next to’, but also ‘distinctly separated from’ the statement of ingredients.

For small businesses trying to balance creative branding with meeting strict compliance requirements, McArdle’s advice was to be creative with the brand and product images, colours, and font types, but when a technical member asks for bolding or a space or a particular font size, listen to them.

“They are trying to save a whole lot of drama if the packaging is printed and a competitor, auditor, retailer, or regulatory enforcement agency (including at the border) picks up an issue, a few months after you started selling thousands of units of the product.”

When preparing ingredient listings, make sure you look for all hidden ingredients that need to be declared.

IGD announced the launch of its new allergen risk assessment template and accompanying guidance. This significant initiative is set to bring greater consistency in allergen procedures and support improved food safety for allergy sufferers in the UK.

With food allergies and intolerances rising across all UK demographics, the need for a consistent and effective approach to allergen management has never been greater. The new template will help to eliminate confusion caused by inconsistent labelling and ultimately support a safer shopping experience for consumers.

The new allergen risk assessment template is the result of extensive collaboration through IGD’s Technical Leaders Forum and Network, which has brought together senior

stakeholders throughout the food and consumer goods industry to discuss common technical issues and strategic opportunities.

IGD was able to facilitate open dialogue in its role as an impartial industry convenor to coordinate the development of this industry-wide solution.

Kate Reynolds, Senior Manager, Resilience Programme at IGD, said the launch of this allergen risk assessment template demonstrated how industry collaboration can deliver positive change.

“We understand that adapting to

new procedures will involve some policy updates and staff retraining, but we see the template as a positive development, designed to streamline risk assessment, empowering teams to deliver safer food for all.”

Nadim Ednan-Laperouse OBE, founder of The Natasha Allergy Research Foundation, was also pleased that the food industry was coming together to improve allergen management and hoped this would give greater reassurance to the millions of people living with food allergies in the UK and their families.

ShopCare Data & Innovation Manager, Wes van Deventer explains how forklift safety reflects leadership, and shares practical steps to make forklifts both safe and productive.

As the workhorses of Aotearoa’s supply chains, forklifts shift the goods that keep the country moving, but they also carry real risk. Every year, on average 1,195 kaimahi/workers are injured in forklift incidents and some ACC claims (ave. 1,157) can take months or years to resolve, with the worst cases ending in tragedy. These aren’t abstract numbers, they’re people, whānau, and workplaces dealing with harm that’s often preventable. Fortunately, with the right systems, training and everyday habits, forklift safety becomes second nature, supporting productivity and wellbeing rather than becoming a barrier.

A typical two-tonne forklift can

weigh more than double that with a full load. That’s a lot of mass moving through tight spaces, often close to pedestrians, racking, vehicles and blind corners. Although forklifts are compact and nimble, which suits cramped aisles, stability can often be compromised, especially when turning, travelling with the mast raised, or handling uneven or poorly stacked loads. Collisions, tip-overs, falling loads and exhaust exposure (for fuel-powered units operating indoors) are well-known risks across the country.

In our experience, forklift safety is often a mirror of business culture. When businesses invest in maintenance, insist on checks, resource training and listen to kaimahi, people

respond with care, attention and accountability. It’s important not to avoid hard conversations, but focus on having them with respect and clarity: “This matters because you matter.” Make the safe thing the easy thing by recognising and removing the friction that nudges people into risk in the first place, including unrealistic pick-rates, congested aisles, poor lighting, or paperwork that takes longer than the check itself.

What good practice could look like

• Training and competency. A licence or NZQA unit standard is a good starting point, but site-specific induction, regular refreshers and practical assessments keep skills current and relevant. If your operation includes attachments, ramps, rough terrain or confined areas, training needs to reflect those realities. Make it plain-language, culturally inclusive and anchored to the actual tasks people perform.

• Pre-operational checks. A short, thorough inspection at the start of every shift could prevent long, painful incidents. Tyres, brakes, hydraulics, forks, chains, alarms, seatbelts, lights and any attachments should be checked before the key turns for work. If something fails the check, tag it out and report it, no exceptions.

• Safe operating habits. Care should beat urgency every time. Travel with loads low and slightly tilted back, and keep speeds sensible, especially near people or at intersections. Your team should always use the seatbelt and stay fully within the cab. Never ride the forks, lift passengers, or improvise with pallets as platforms. Face the direction of travel, use the horn at blind spots, and adjust for conditions, wet floors, gradients, tight aisles, glare or noise.

• machine to the task, load type and weight, aisle width, racking height, indoor versus outdoor use, gradients, and environmental factors like dust, noise and fumes. If you’re handling awkward or unstable loads, use rated attachments, clamps, rotators, jibs and make sure they’re installed and certified correctly. Your training should cover those attachments specifically, as they can be different for each machine.

• Traffic management. The single most effective control is separation. Where possible, physically segregate forklift routes from pedestrian walkways

using clear line-marking, solid barriers, mirrors and lighting. You should also establish “no-go” zones around docking areas and high-risk movements like reversing or turning with elevated loads. Treat your traffic plan as a living system, updating it when layouts change, volumes spike or new risks appear, and making sure everyone from visitors to managers knows how to move through the site safely.

• Human factors. Fatigue, stress, hydration, temperature, noise and visibility all affect safe performance so make sure to provide adequate rest breaks and water. Keep cabins clean, seats supportive and adjusted, and filters maintained to reduce dust and fumes. Adequate lighting reduces mistakes, but good supervision reduces corners being cut. Operators should feel safe to speak up about discomfort, near misses and design flaws as this is how you learn before harm occurs.

Getting started or getting better If you’re unsure where to start, walk the floor and watch how people and machines actually move, not how the site plan says they should. Talk to operators about pinch points, blind spots and process pressure and fix a few small, visible issues as you go to set the tone. It can be as simple as replacing a torn seatbelt, adding a mirror at a blind corner or repainting worn lines, and then you can build from there. Tighten your pre-start process, refresh training, review attachments, update the traffic plan and repeat regularly.

Both WorkSafe NZ and the New Zealand Forklift Industry Association publish practical guidance around forklift safety. At ShopCare, we know health and safety isn’t about chasing perfection - it’s about making steady, practical improvements that reflect the realities of your workplace. As a charitable trust tasked with transforming health, safety and wellbeing outcomes for retail and its supply chain workers, you’ll find resources, tools and case studies on our website - all freely available thanks to our funding from ACC. www.shopcare. org.nz

With the right systems in place and a culture of care, forklifts can be both highly productive and safe. The key is to consistently weave safety into everyday practice.

Every year, harm continues to occur to people in and around forklifts. For 30 years, our statistics have remained consistent, and it seems there is a level of complacency, as no new approaches have been attempted to effect change.

Except now. The industry has mobilised, following the publication of the Forklift Good Practice Guidelines, which have provided updated guidance and support. This has led to a rethink of the shape and style of training. Furthermore, changes to the vocational education sector have created an opportunity to redefine competent operator training.

Over the past year, a team of engaged and motivated people, committed to improving forklift operator training, have developed a new nationally recognised and structured training framework. They have updated the old unit standard for forklifts to ensure learners receive better, more appropriate training, with in-depth competency assessment.

A PCBU can now be assured that their worker has received the

appropriate level of training to be work-ready.

This alone does not guarantee operating competency. Training and supporting the worker to consider all risks and how to control them is one of the improved performance outcomes of the new skills standards. Furthermore, barriers to NZQA-based training and assessment have been reduced, making this higher level of competency training easier to access.

The time has come to make a step change, to stop accepting lower-quality delivery and the continued harm to people in the workforce around forklifts.

There is much more work to do to lift forklift training out of the gutter (poor quality, short duration, and low value).

WorkSafe NZ must accept and support the new guidance and move away from outdated thinking tied to their aged Approved Code of Practice. The entire

training industry needs to accept, shift, and embrace the new skills standards, striving to improve the quality of instruction and ensure workers are competent in and around forklifts. Doing nothing, or doing the same, is no longer acceptable. As an employer or PCBU with forklifts, continuing to use these outdated training regimes exposes you, your team, and your business to increased risk.

Make the change: get your people trained to the new NZQA skills standards so they are capable and competent in baseline safe forklift operations, and can further hone their knowledge, skills, and behaviours in your workplace.

If you would like to know more about this or other initiatives from the Forklift Sector of the Hire Industry Association of NZ, please visit www. hianz.net.nz for contact details.

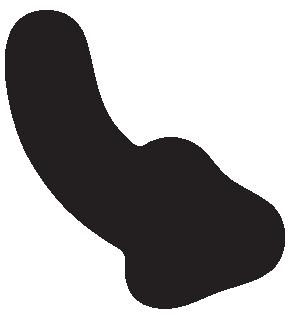

The Silvercard™ MEWP and Forklift Training Program continues to grow and strengthen its reputation and be seen as a strong brand in Competent Operator Training.

There’s a lot of grey matter around the subject of who is actually competent. So much so, no one knows whether the use of the word is for self-gain and glory or to tick a box. Furthermore, who makes the decision? Even greyer (is that word?).

APerson Conducting a Business or Undertaking (PCBU) holds all the authority, risk and accountability on who is competent.

The Health and Safety at Work Act 2015, section 36, 2 says: “A PCBU must ensure, so far as is reasonably practicable, that the health and safety of other persons is not put at risk from work carried out as part of the conduct of the business or undertaking.”

The PCBU has to make the call so that they meet their obligations on this above mentioned section of the Act. The act itself does not detail a competent person or who determines it as they leave it to the PCBU, who must determine competency.

How can a PCBU determine competence when they might not know enough on the matter themselves? That’s where guidance comes in. It provides the support for a PCBU on how to gather the evidence so they can determine a competent person.

The PCBU has a duty to record this information so that it can be referred to at a later date.

That’s where training comes in – it provides the support and evidence that a person is competent and the achievement of the performance

Currently offering ten courses including practical assessments, the programme is designed to educate, train, and verify the competency of MEWP and Forklift operators. Silvercard is owned and managed by the Hire Industry Association of New Zealand Inc (HIANZ) and delivered nationwide through independent Trainer/ Assessors and their respective training businesses, who assess to nationally recognised NZQA vocational education unit and skills standards.

Our goal is clear: to provide the market with the most recognised and

criteria of the course is the record.

The NZ Forklift Sector, part of the Hire Industry Association of NZ (HIANZ) released guidance on exactly this subject when referring to forklifts.

A competent person is a person who has acquired, through education, training, qualification or experience or a combination of these, enabling that person to perform the task required. When selecting personnel to operate, supervise, maintain, inspect, perform rescues, and transport forklifts,

it is essential to ensure they are appropriately trained, qualified, and experienced for their specific roles to maintain safety, compliance, and operational efficiency.

The Forklift GPG covers the operator, trainer/assessor, technician for maintenance, inspection, modifications and attachments, transporter and supervisor.

If you as a site foreman/ site entry authoriser want guidance on how to determine the competency of anyone relating to forklifts, use this guidance found on the HIANZ websitehttps://www.hianz.net.nz/forklift/ Whilst there, look at the other guidance available and stationary available to purchase for forklifts. Reach out through the website if you need more assistance or clarification.

Rodney Grant – CEO NZ Forklift Sector 021 997 184

trusted brand of competent operator training, delivered to the highest standard and consistent across the country.

Why is this important? It’s because HIANZ is committed to helping our members meet their duty of care obligations, by ensuring operators receive training and assessment they can trust. If you are employing MEWP or Forklift operators, you can look at their Competent Operator card or verify their competency on the Silvercard App or website (silvercard.co.nz) and be confident in the knowledge that they have been trained and were assessed

as being competent. No longer having to wonder what the quality of training was when they hand over a certificate or operator card created on a bubblejet printer and laminated.

Silvercard gives you peace of mind and supports you in identifying competent operators.

Silvercard is growing. You are about to see changes and increased training opportunities to ensure everyone operating if a safe, competent operator. The courses offered solidifies the duty of care the PCBU has to ensure workers are safe when using their plant and equipment.

Reloc8 NZ LTD has been a trusted name in the logistics industry for over two decades. With the recent launch of its aluminium pallet cages this month, the company’s focus on innovation and efficiency has set it apart.

Grant Rollo, who began his career in the logistics industry in 1977, said that the aluminium pallet cages were designed to semi-automate the supply chain, reducing injuries and damages associated with manual handling. They also maximise vehicle and warehouse space through clever design, improve productivity, and offer a safer, more sustainable alternative to traditional methods.

Compared with traditional options, Reloc8 Aluminium Pallet cages deliver twice the size of traditional pallets

(2.2m W x 1.1m D x 2.2m H). They are fully recyclable, made with recycled aluminium to support a circular economy, with no shrink wrap required, reducing waste.

Barcodes and unique identification numbers allow for traceability, and these cages are also compatible with all standard transport modes, including containers. The aluminium cages provide superior protection compared with shrink wrap.

Goods arrive at their destination in the same condition they were loaded, ensuring safer working conditions throughout the logistics process.

As a family-owned and managed business, Reloc8 has also fostered strong customer relationships and enabled agile decision-making. Over the past twenty years, the logistics sector has transformed significantly.

Automated systems have streamlined operations, boosting efficiency and accuracy across supply chains. Realtime tracking has improved visibility, ensuring suppliers and customers are always informed about shipment status, fostering transparency.

At the same time, as consumer expectations have evolved, the demand for speed, service quality, reliability, and durable operating practices has continued to rise.

“We pride ourselves on delivering flexible, customer-focused solutions. For example, we successfully innovated a system to invert cages at the destination, securing a contract to divert 115,000 end-of-life bumpers annually from landfill. This highlights how our solutions combine practicality with environmental responsibility,” said Rollo.

Looking ahead, Rollo said that the logistics sector will continue to evolve through broader adoption of ecofriendly practices, including electric vehicles, energy-efficient warehouses, and recyclable packaging, along with an increasing focus on traceability and transparency to enhance food safety and quality.

“At Reloc8 NZ LTD, our goal is to stay ahead of these trends, providing innovative, sustainable, and customerdriven solutions that strengthen the future of logistics.”

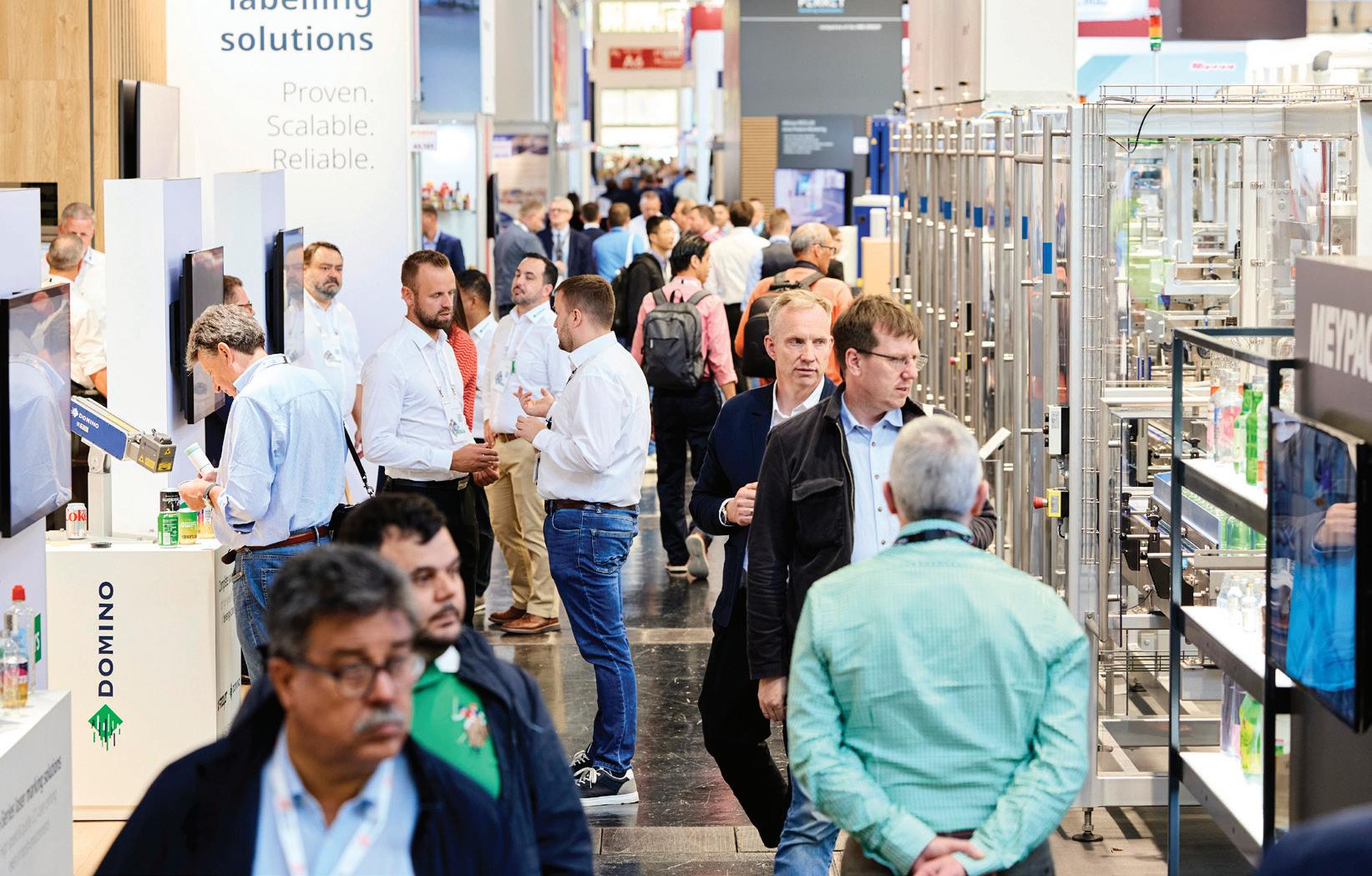

With around 8,000 exhibitors from 110 countries and a large exhibition space spanning around 290,000 m², Anuga 2025 is the biggest edition in the event’s history.

From the 4th to the 8th of October, Cologne will once again become the global capital of the food industry and the meeting point for over 140,000 trade visitors from almost 200 countries. With a 94 percent share of foreign visitors, Anuga is setting new benchmarks in terms of its internationality and industry relevance. The country with the highest number of exhibitors is Italy, followed by Spain, China, Germany, France, Greece, the Netherlands, Poland, Turkey, and the USA. In total, 174 groups from 78 countries will present their portfolios - along with the five biggest pavilions from Istanbul, China, Italy, Spain, and the USA, spanning up to 6,000 square meters of space.

“Anuga is far more than just a trade fair – it is a marketplace, a source of inspiration and a pacesetter for the global food industry. The leading minds of the industry meet up to present innovations and discuss tomorrow’s trends in Cologne. As such, the future of food becomes visible here – and at the same time negotiable,” said Gerald Böse, President and Chief Executive Officer of Koelnmesse GmbH.

Furthermore, with its revised hall structure, Anuga 2025 is creating a better overview and greater proximity between related segments. Segments that are closely related in terms of content are being bundled together more closely.

In this way, the newly created

Anuga Alternatives will be located in Hall 1 in future, with direct access to the biggest section of the trade fair, Anuga Fine Food, which traditionally extends over several halls. At the same time, the sections of Anuga Meat are now spatially consolidated in Halls 6, 7 and 9.

Innovations from all over the globe are under focus again. The focus of the new trade Fair Anuga Alternatives lies on plant-based and cell-cultivated products. Beyond this, the Anuga Trend Zone stage conveys current market data, the Anuga Taste Innovation Show showcases the top innovations of Anuga 2025, and a surface features over 100 start-ups, making up the Boulevard of Innovations as a hotspot for food trends and investments.

The event and congress program comprises of many highlights:

• The Halal Forum, in cooperation with the Islamic Chamber for Halal Services, under the title “Halal Food: A Global Gateway to Growth”.