editor ’ s note

Caitlan Mitchell Editor-in-Chief caitlan@reviewmags.com

The Quiet Disruptor

It doesn’t always make headlines, but packaging is quietly reshaping how food and beverage brands operate, innovate, and grow. While ingredient trends and tech breakthroughs tend to steal the spotlight, packaging is where many of the most impactful changes are happening. Often behind

the scenes, but with very real implications for cost, compliance, and consumer loyalty.

In recent years, packaging has shifted from being purely functional to being deeply strategic. It's now central to how brands communicate values, meet sustainability targets, and manage supply chain pressures. The rapid rise of mono-material solutions, refill models, traceable QR codes, and even edible films is not just exciting. It’s becoming essential.

As regulations tighten and consumers become more discerning, packaging has to work harder than ever. It needs to protect the product, look good on shelf, meet environmental expectations, and increasingly, tell a story that builds trust. For many

businesses, it’s the first, and sometimes only, interaction a customer has before they taste what’s inside.

This issue of F+B Tech dives into packaging as both a challenge and an opportunity. We explore how businesses are rethinking their approach to materials, automation, and lifecycle planning. We also look at how design plays a crucial role in creating packaging that’s not only sustainable, but scalable.

Packaging might not always be the loudest part of the F&B conversation, but it’s undoubtedly one of the most important. Because if you get the outside right, the inside has a much better chance to succeed.

Caitlan Mitchell

ASSOCIATES Jenelle Sequeira, Sam Francks

SALES caroline@reviewmags.com, daniel@reviewmags.com

DESIGNER Raymund Sarmiento

DESIGNER Raymund Santos

Our team will help you do it right

The Ministry for Primary Industries’ Exporter Help team supports new and established New Zealand exporters with advice and ongoing support on regulation and certifications. We make it easier to understand exporting requirements so you can reach more markets overseas and grow your sales with confidence.

local news

Molecular Filtration Tech To Reclaim Wine

A new precision wine technology has changed how winemakers address quality challenges and recover value from faultaffected and heavily phenolic wines.

Amaea, a New Zealand developer of custom-

engineered molecularly imprinted polymers (MIPs), has gained industry validation for its novel molecular filtration technology, which enables precision wine remediation and palate fining.

Read more here

NZ Grass-Fed Certification Takes On Global Competitors

New Zealand is raising its game on the global stage with a new Grass-Fed certification scheme to help red meat and dairy producers compete with international competitors in premium markets.

Agriculture Minister Todd McClay announced at Fieldays that international consumers are increasingly willing to pay more for high-quality grass-fed food, and New Zealand intends to lead that space, not follow it. This new standard puts a clear, trusted stamp on what New Zealand farmers have always done best - producing high-quality, safe pasture-raised meat and dairy. Read more here

JAC Reveals New PHEV Ute

JAC signalled the brand’s bold future in top commercial vehicles at this year’s Fieldays.

As a major Fieldays sponsor, JAC has proudly backed New Zealand’s biggest agricultural event, unveiling the T9 PHEV front and centre.

On display as a pre-production prototype, the highperformance hybrid ute gives farmers, tradies, and fleet buyers a first look at what could be coming down the pipeline and what the brand’s truly capable of.

The T9 Hunter PHEV promises serious punch, pairing a next-gen 2.0-litre turbocharged petrol engine with dual electric motors to target a massive 1000Nm of torque, outmuscling the BYD Shark 6, one of the latest PHEV utes to arrive on the New Zealand market

Read more here

Walter & Wild Acquires Hansells Under New Entity

The manufacturing operations of Hansells will remain in Masterton under new ownership following an independent receivership process managed by BDO Auckland.

The assets have been acquired by Hansells Acquisition Limited (HAL), a newly formed entity owned by Walter & Wild, ensuring continuity for the historic facility, its Masterton employees and their families. This transaction followed the difficult but necessary decision earlier this year to place Hansells Masterton Limited into receivership to address unsustainable financial challenges. Read more here

Solar On Farms Unlocks Farm Cost Savings

The Government’s new Solar on Farms initiative will support farmers in taking the next step towards installing solar and battery systems. This will help them reduce energy costs, increase on-farm resilience, and gain greater control over their power use, leading to increased efficiency and productivity.

Read more here

Mauri Seeks Clearance To Acquire Farmers Mill

The Commerce Commission has received a clearance application from George Weston Foods (NZ) Limited, trading as Mauri New Zealand, to acquire the wheat milling and storage assets used by Farmers Mill Limited in the course of its business.

Both Farmers Mill and Mauri mill wheat into flour

and supply this flour to customers across New Zealand.

Mauri operates flour mills in Auckland, Wellington, and Christchurch. Mauri supplies flour in bulk to large users of flour, such as industrial food manufacturers, and bagged flour to wholesalers, bakeries, and supermarkets.

Read more here

global news

DHL Group x Shopify Accelerate Cross-Border Shipping

DHL Group has expanded its partnership with Shopify to make it easier for merchants to ship their products worldwide.

With DHL pre-integrated into the Shopify Shipping platform, sellers worldwide can access DHL’s global network and shipping solutions with just a few clicks. Sellers on Shopify will no longer need to onboard a logistics provider independently, allowing them to streamline operations and reduce administrative burdens. Read more here

Detmold Group Announce Plans For New HQs

Leading Australian-owned international packaging company, Detmold Group, is constructing new Adelaide headquarters. To foster collaboration, innovation, and support continued local and international growth, the group has built on a legacy of strong family values for a sustainable future.

FairPrice Group x Google Cloud Reimagine Retail

This week at NRF's Big Show Asia Pacific 2025, FairPrice Group (FPG) and Google Cloud showcased FPG’s Store of Tomorrow (SOT) programme.

This was a roadmap to embed the latest cloud and AI technologies into new and existing in-store and omnichannel retail touchpoints, redefining

customer experiences at FairPrice supermarkets. Currently being piloted at FairPrice Finest in Sengkang Grand Mall, FPG’s cloud-connected shopping carts, called “Smart Carts,” help guide consumers through instore navigation, spotlight promotions for nearby products as they browse aisles, and provide product recommendations tailored to their shopping needs.

Read more here

Treasury Wine Estates Unveils Low & No Winemaking Facility

Treasury Wine Estates unveils $15m state-of-theart ‘low and no’ winemaking facility

Treasury Wine Estates (TWE) has officially opened a new AUD 15 million in-house facility dedicated to ‘low and no’ alcohol wine production in the Barossa Valley.

The opening reaffirmed TWE’s leadership in the global wine category and its commitment to innovation. Read more here

Its new global headquarters will accommodate up to 240 employees, with staff from eight sites across the Adelaide metropolitan suburbs of Brompton, Hindmarsh, and Regency Park consolidating under one roof by the end of 2026.

Read more here

www.barkersprofessional.nz

From New Zealand To The World: MPI’S EXPORTER HELP SUPPORTS FOOD & FIBRE BUSINESSES TAKE OFF

Exporting food & fibre products overseas?

Our team will help you do it right

The Ministry for Primary Industries’ Exporter Help team supports new and established New Zealand exporters with advice and ongoing support on regulation and certifications. We make it easier to understand exporting requirements so you can reach more markets overseas and grow your sales with confidence.

New Zealand is home to a thriving food and fibre sector, with businesses sending their products to all corners of the world every day.

TGet free expert advice on exporting requirements

0800 00 83 33 mpi.govt.nz/exporterhelp

he sector makes up 80.9 percent of New Zealand’s total merchandise exports and reaches over 200 marketplaces around the world. From our gates to their plates, Exporter Help at the Ministry for Primary Industries is dedicated to supporting businesses get Kiwi products overseas.

Doubling the value of New Zealand’s exports by 2034

The Government’s goal is to double the value of New Zealand’s exports by 2034. The Ministry for Primary Industries have an important role to play in supporting the Government’s goals to drive growth.

Maintaining an effective and trusted food safety system is critical to

achieving this goal and enabling the sector to successfully access global markets. Food safety is a key part of the wider New Zealand food story, and one of our main selling points to overseas consumers is our robust and reliable food safety system.

MPI's Exporter Help

The free Exporter Help service delivers one-to-one advice, develops educational resources such as guides and webinars, and works collaboratively within the Ministry for Primary Industries to share insights and minimise exporter challenges. Exporter Help supports small and medium-sized businesses on their export journey. The team helps exporters and those working with

exporters at all stages of their journey, from those thinking about exporting to established exporters needing clarification on requirements. Much of the food and fibre export journey depends on what is being produced, and which country it is going to. Sometimes the rules can be complex and change regularly. Understanding export requirements can be confusing, and providing businesses with accurate information makes it easier for them to export efficiently and avoid costly errors.

Wai Mānuka’s export success

Wai Mānuka have been producing a premium non-alcoholic beverage using Mānuka Honey, lemon juice and sparkling water here in New Zealand

since 2020. When they were preparing to send their beverage to various overseas markets, including the USA, Japan, China and Australia, they had some questions about meeting the specific requirements for transfer documents.

Exporter Help provided Wai Mānuka with the support they needed to make sense of the regulatory environment for beverages, providing clear explanations of requirements for each country. Thanks to the

team at Exporter Help, Wai Mānuka were confident that they were doing the right thing and are successfully exporting their products from New Zealand.

Get in touch

For support navigating your exporting requirements, contact the Exporter Help team on exporterhelp@mpi.govt. nz, call 0800 674 490, or visit www. mpi.govt.nz/export/get-help-withexporting/

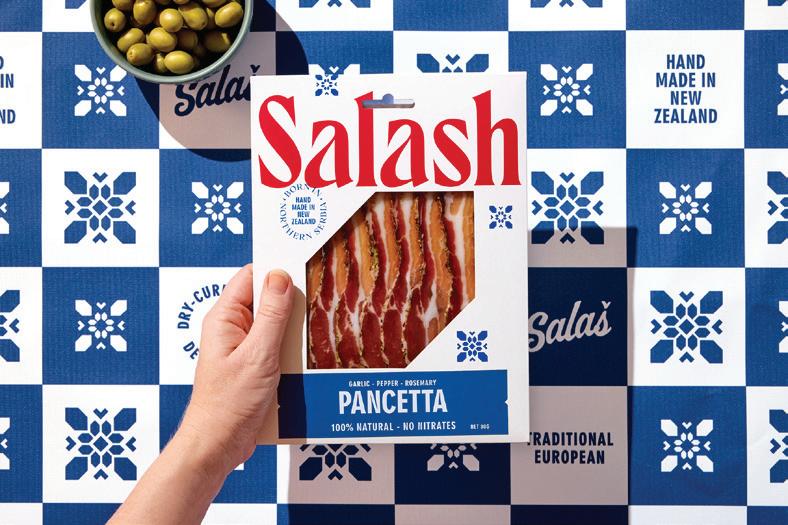

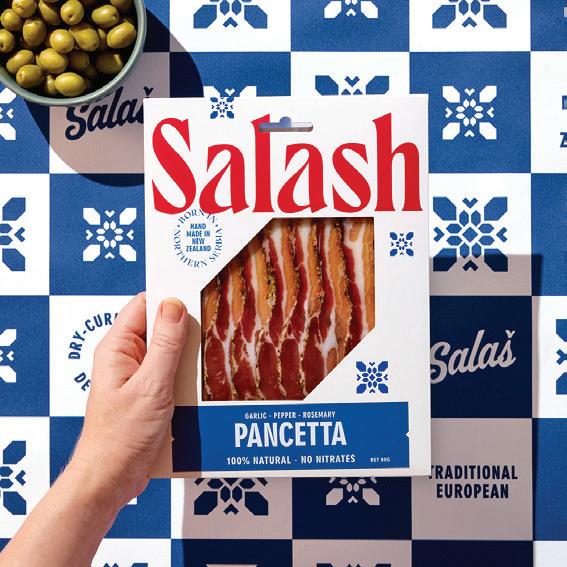

NZ Agency Wins Top Prize AT INTERNATIONAL AWARD SHOW

To ring in 2025, which also happens to be Onfire Design’s 20th Anniversary, the company has picked up several prestigious international awards.

Three Gold, a Silver, and two Bronze from the World Brand Design Society – recently judged in the UK.

To top it off, Onfire was also awarded Best Agency Work of the Year for its brand refresh of Salash Delicatessen.

What a way to celebrate 20 years in business!

The Best Agency Work of the Year was reflected in three Gold for Salash Packaging, Typography and Brand Redesign.

A small, family-run smallgoods business based in Kumeu, Salash’s point of difference is its family history and geographic origins in Northern Serbia.

The design process explored Eastern European region’s visual styles, patterns, and culture, taking historical cues, and reinterpreting them for today’s foodie consumer.

The bespoke wordmark draws inspiration from the Cyrillic alphabet, while Serbia’s national flag directly inspires the colour palette. The simple blue, white, and red also contrast starkly with the earthy tones used by competitor brands.

Early success has seen the brand achieve its goal of being listed in Farro food market stores and positioning in nationwide retailers. Proving good design can lead to awards – and real ‘gold’ rewards!

A silver award from the World Brand Design Society went to Onfire client Veesey for Brandmark and Type Design.

Having established itself in the growing dairy-free cheese category, Veesey needed to refresh its packaging and positioning to help differentiate from competitors using similar freeform language and assets.

‘Intolerant to boring’ became the new position, opening a design language based on happiness, epic food, and enthusiasm. This is reflected in the new Veesey wordmark as well as bright and punchy pack formats.

Veesey is difficult to miss in chillers and challenges consumers to rethink their perceptions of what dairy-free cheese should look like. Something that the Award judges also noticed!

Not to be out done, Rolling Meadow cleaned up with two Bronze Awards for Packaging Design. One for Illustration and another for Product Redesign.

As an existing cheese brand in New Zealand supermarkets, Rolling Meadow lacked any ownable brand or visual assets which led to the range losing its impact instore and lacking a compelling proposition for the consumer.

The brand’s visual language underwent a significant transformation to align with its new positioning “We keep you rolling.”

Driving ideas of big energy, healthy fuel, and versatility, the new visual assets are anchored by bold, vibrant, and award-winning food illustrations.

The new brand logo and messaging system also caught the eyes of the judges who rewarded it with Bronze for Product Redesign.

Onfire Design Founder, Sam Allan, is extremely proud of his team’s efforts and acknowledges his clients’ vision for his company’s success. “It was a tough year for all business in NZ but thanks to our hard-working team, and our clients’ spirit of adventure, we were able to finish 2024 positively –on an international stage. It’s an exciting start to our 20th Anniversary year!”

Igniting New Zealand’s most famous FMCG brands for 20 years.

Where did those 20 years go? It seems like only yesterday that we set up shop.

To all our clients, industry colleagues, and team members down the years, thank you for helping us reach this landmark occasion. Now here’s to the next 20 years.

Ignite your brand now. Call Sam Allan, Managing Director, on 021 608 204 or sam@weareonfire.co.nz.

Only Good receives the sole WORLDSTAR PACKAGING AWARD FOR NEW ZEALAND

As a leading manufacturer and distributor of New Zealand-made personal care products Apex Brands has been recognised for their new refillable packaging in the 2025 round of the prestigious global WorldStar Packaging Awards. Apex Brands are the only New Zealand company to receive a WorldStar Packaging award this year.

NERIDA KELTON

Executive Director Australian Institute of Packaging

This global recognition follows winning the gold in the Australasian Packaging Innovation & Design (PIDA) Awards; which are the exclusive entry point for Australia and New Zealand packaging innovations.

When Only Good Hand & Body Wash (Apex Brands) went through a significant re-brand and packaging overhaul to reclaim the position as the go-to ‘only good’ personal wash range in the New Zealand grocery market, their customers were top of mind throughout the process.

Only Good knew that ‘another brown bottle’ wasn’t what their

customers wanted, so they created a clean, luxurious product at an accessible price point, that also had great sustainable design appeal.

The Only Good mission is to be good - inside and out- so that meant the bottle itself needed to offer a low environmental impact and to be able to meet the Sustainable Packaging Design principles.

The simplistic bottle and artwork design combined with the desire to remove single use plastic wherever possible, led to the artwork being screen printed directly on to the bottle, removing the need for a plastic label.

The recyclable, refillable and reusable bottles are also made with a blend of sugar cane and recyclable plastic that has been domestically sourced in New Zealand. The Only Good team worked closely with partners at Forward Plastics to create a sustainable and responsible alternative to virgin plastic packaging.

Bottle design, material and finish have been carefully considered utilising a range of different HDPE options, such as Sugar Cane HDPE and Recycled HDPE across all products.

In addition, all hand washes are available in an economical 600ml refill format. The Pump lid and mechanism has also been designed for multiple repeat uses.

Developing reusable packaging also enables brands to become more circular by design through:

Designing durable packaging that can withstands multiple uses.

The ability to design refillable packs that incorporate recycled content.

Packaging that is designed at the start to be truly recyclable in the country it is sold.

The ability to incorporate intuitive recycling labels such as the Australasian Recycling Label (ARL) on-pack to effectively communicate to consumers the correct disposal of the packaging at end of life.

Refillable packaging also enables customers to become loyal to a Brand’s journey towards more circular and sustainable business practices.

Reusable and Refillable Packaging like the Only Good Hand & Body Wash (Apex Brands) from New Zealand is a perfect example of one way to meet packaging design targets with an ultimate aim of designing out waste at the start, reducing single use plastics, reducing the amount of packaging used, incorporating recycled content and renewable materials and adding the benefit of refillable and reusable. The end result of the re-brand was a new design which showcases a combination of contemporary design aesthetics and clean credentials.

The AIP congratulates Hand & Body Wash (Apex Brands) for the WorldStar Packaging Award and this global recognition helps shine the light on New Zealand as an innovative country for Sustainable Packaging Design.

packaging

A Fresh Look FOR STRAWBERRIES

Perfection Fresh has partnered with global packaging leader Detpak to launch a new eye-catching strawberry punnet that is set to raise the bar in the berry aisle, combining standout shelf appeal with smart, functional design.

Rolling out in Coles from July, the new 240g punnet features ventilation holes to maximise freshness, showcasing premium strawberries in a format that’s both practical and visually striking, featuring three large viewing windows that let shoppers inspect the fruit from the top and bottom.

Detpak Business Manager Christian Bell said the new strawberry packaging would be a leader in the transition from plastics to fibre-based packaging in Australia’s fresh produce industry.

“As our LaunchPad capabilities grow, we’ve also been able to create and further develop fibrebased solutions which outperform the plastic alternative when it comes

to shelf life performance,” said Bell.

“Keeping that in mind, we worked with Perfection Fresh to highlight what was important – their fresh strawberries – and we know consumers instinctively check the bottom of the punnet to see how the fruit looks. So we designed a punnet that shows off the fruit from every angle. It’s an elegant solution that looks great, packs efficiently, and supports the quality of the strawberries from packhouse to shelf.”

Designed by Detpak’s Research & Development team at its LaunchPad facility, the Perfection Fresh Signature Premium Strawberry Punnets are primarily made from sturdy, recyclable board and enable easier hand-packing, storage and transportation.

The Signature Premium Strawberry Punnets blend form with function by reducing plastic by 87 percent, while also featuring a unique locking mechanism to keep fruit secure.

Perfection Fresh is one of Australia’s leading suppliers of fresh produce to the retail sector and has collaborated with Detpak and its LaunchPad team on other packaging initiatives, such as its grape bag, which has helped reduce unnecessary plastic use.

Luke Gibson, Chief Marketing and Innovation Officer at Perfection Fresh, said the design was led by consumer behaviour and a clear ambition to hero the fruit itself.

“With our new Signature Premium Strawberry Punnets, we can highlight the premium quality of produce inside the packaging, while creating a new standard of messaging through graphics and design that simply cannot be achieved with plastic containers,” said Gibson.

“Our strawberries really are the heroes on the shop shelves, and we can show that we have a premium product that has a new and modern look and feel to it.”

The Signature Premium Strawberry Punnet was launched at Australia and New Zealand’s largest horticulture conference and trade show at Hort Connections, with the first in-store trials kicking off soon after.

U.S. Flexible Packaging Industry GROWTH AND SUSTAINABILITY

In 2025 and beyond, the U.S. flexible packaging industry remains well-positioned to continue to dominate food packaging.

DAN FELTON President & CEO Flexible Packaging Association

According to our “2024 State of the U.S. Flexible Packaging Industry Report (SOI),” released earlier this year, the U.S. flexible packaging industry was estimated to reach USD42.9 billion in annual sales in 2023, marking a 3.3 percent growth from USD41.5 billion in 2022. We forecast that our industry will grow to USD43.8 billion in 2024 and to USD47.3 billion in 2028, representing a compound annual growth rate (CAGR) of 2.0 percent from 2023 to 2028. Flexible packaging continues to hold a significant portion of the U.S. packaging market, representing 20 percent of the total USD210.8 billion U.S. packaging market. The only category currently surpassing flexible packaging is

corrugated materials, which account for 22 percent of the U.S. packaging market.

Food packaging for retail, institutional, and non-retail environments remains the largest enduse market for flexible packaging in the U.S., contributing USD22.2 billion in annual sales, or close to 52 percent of the market. The medical and pharmaceutical sectors follow closely with USD6.1 billion in sales, holding a 14 percent market share. Other markets, including beverages, nonretail food, and personal care, make up smaller portions of the market, with each contributing less than 6 percent.

Converter and supplier respondents to the survey for our 2024 SOI report both included sustainability within

their top three challenge areas for 2024. Converters were asked about a range of sustainable packaging materials/options they are using or producing. “Recycle Ready” came out on top, with 85 percent of respondents currently providing that. This was followed by 80 percent offering an “All PP” or mixed polyolefin structure consisting of polypropylene (PP) and polyethylene (PE), and then 77 percent utilising “Post-consumer Recycled (PCR)” resin. “Paper” was offered by 58 percent of converters, and “Compostable” was offered by 56 percent – both not surprisingly increasing over percentages included in our 2023 state of the industry report.

Looking forward, survey respondents indicated a very strong prevalence for focusing even more on mono-material flexible packaging structures. This in addition to continued focus on recycleready and the use of post-consumer recycled (PCR) content. All these packaging materials and options align with the general sustainability trends

About the Flexible Packaging Association

that many brand owners are seeking as they strive to meet their long-term sustainability goals, and will likely remain a key trend for all packaging formats in the foreseeable future.

In March, we announced our 2025 Flexible Packaging Achievement Award winners. Competition submissions clearly placed a strong emphasis on sustainability trends as a key driver for flexible packaging, where nearly 70 percent of submissions entered the sustainability category or demonstrated clear advantages of flexible packaging over alternative structures. One Gold Award for Sustainability went to PPC Flex for their manufacture of a fully compostable package for HiPPiE ORGANiCS® organic asparagus. Another One Gold Award for Sustainability went to Novolex for their TerreGloss™ and Terrecote™ compostable butter wraps. Look no further than these two award-winning examples to confirm that sustainable flexible packaging for food products is advancing and here to stay.

The Flexible Packaging Association is the voice of the U.S. manufacturers of flexible packaging and their suppliers. The association’s mission is connecting, advancing, and leading the flexible packaging industry. Flexible packaging represents over USD42 billion in annual sales in the U.S. and is the second largest and one of the fastest growing segments of the packaging industry. Flexible packaging is produced from paper, plastic, film, aluminum foil, or any combination of those materials, and includes bags, pouches, labels, liners, wraps, rollstock, and other flexible products. Learn more at flexpack.org.

Brand Packaging Remains

CRUCIAL FOR STORYTELLING

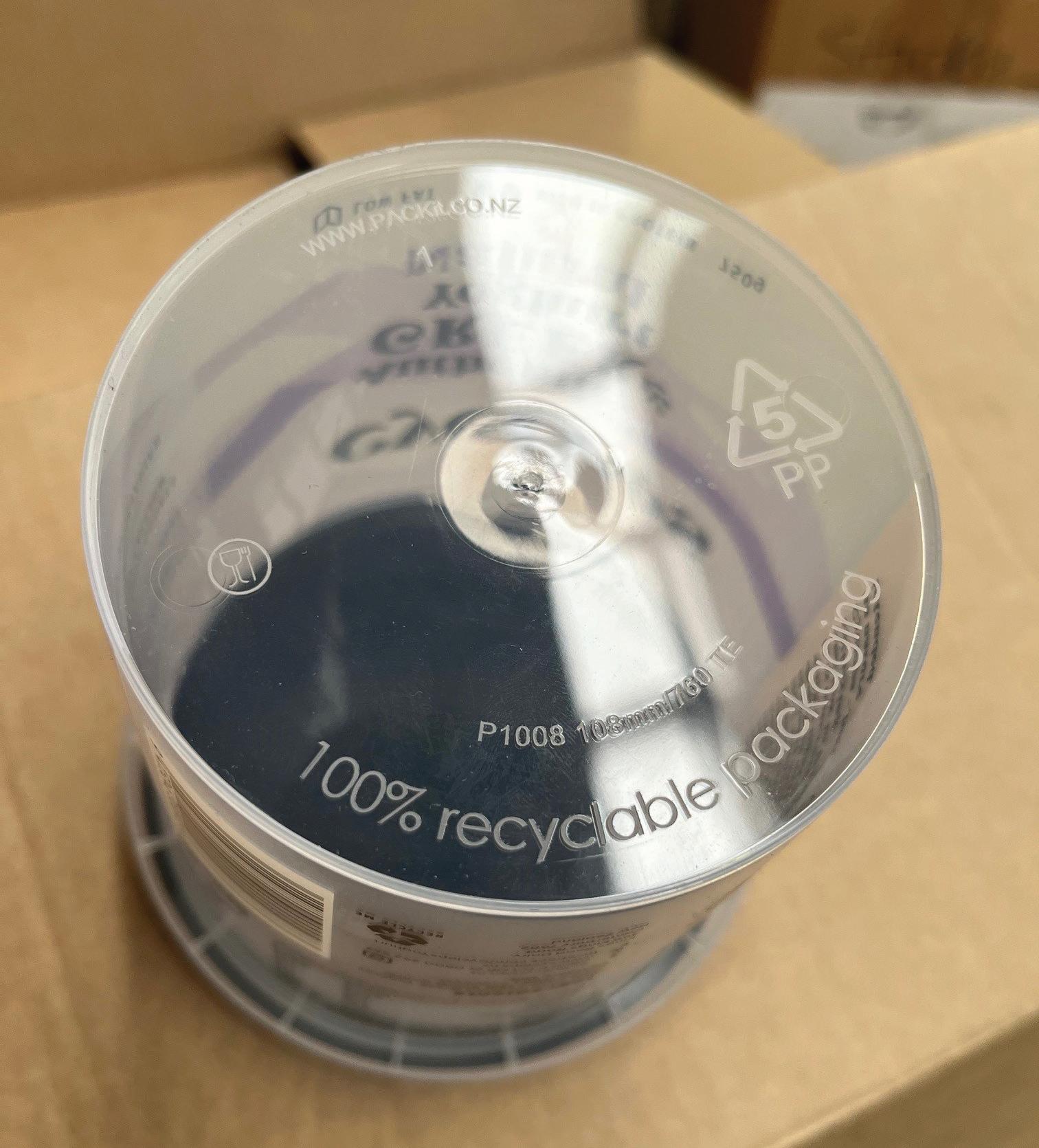

Packit Packaging has observed a shift toward smaller, volume-sized packaging with minimalist, clean designs, transparent materials, and environmental messaging.

Jamie Hodgins, General Manager at Packit Packaging Ltd, said that consumers want packaging that communicates freshness, sustainability, and convenience, which is environmentally friendly and recyclable within the current systems.

“Our use of high-resolution IML allows brands to showcase vibrant, durable graphics that truly stand out on shelves,” said Hodgins.

IML provides a premium look and feel to the packaging, with photographicquality graphics that are resistant to moisture, scratching, and fading.

Unlike stickers or sleeves, IML is integrated directly into the packaging during the moulding process, meaning there is zero chance of peeling or wrinkling, even in harsh retail or refrigerated environments.

The label material is manufactured from PP film, and, when integrated into the injection-moulded packaging, it becomes a mono-material that enhances recyclability.

“IML gives our clients a consistent, high-end brand presence and allows for more complex, eye-catching designs without compromising durability, recyclability or food safety.”

As packaging is often the first point of brand interaction, Hodgins said it can significantly influence purchase decisions and must communicate value instantly. Packit has focused on creating designs that deliver brand recognition while still aligning with product functionality and recyclability.

More brands are beginning to treat packaging as a crucial part of their storytelling and user experience. Packaging now reflects brand values and consumer lifestyle. This shift is pushing packaging design to be more tactile, interactive, and aligned with digital marketing strategies.

“I think we will see more lightweighting of products, and a shift to using RPP as a percentage of the mass of the packaging as it becomes more readily available and cost-effective. I think there is a growing demand for smart packaging and labelling that offers QR codes for product engagement with consumers,” added Hodgins.

“This will be a great opportunity to

get our customers’ brand and their story out there. We need to see more mono materials used in packaging, and a move away from plastic-coated board, polystyrene and other nonrecyclable materials.”

Sustainability is a key driver of Packit’s business model. It is deeply committed to creating packaging that aligns with a circular economy and reduces environmental impact. Internal recycling is a core part of its operations.

“We recycle all our internal plastic waste and actively incorporate post-consumer and laboratory Polypropylene waste into our processes. We can guarantee that none of the plastic we handle goes to landfill.”

To make packaging more recyclable and identifiable to consumers, Packit also began re-engraving its tooling two years ago with a more prominent #5 PP recycling logo and message; a step that improves consumer recycling clarity and

encourages correct disposal.

In 2019, it also launched a pilot postconsumer #5 Polypropylene take-back scheme, before local councils even introduced kerbside recycling for these materials. This proactive move helped educate consumers and build momentum toward better recycling systems.

Some significant challenges that Hodgins highlighted included balancing sustainability with food safety and shelf life, regulatory pressures on single-use plastics, cost management amid rising raw material prices and compliance costs, and consumer confusion about recycling.

He added that the industry has come a long way over the last few years and has responded with innovations like barrier coatings that replace multilayer plastics, better consumer labelling for recycling. Looking ahead, Packit remained focused on leading the way in sustainable, high-performance packaging solutions. It will continue to invest in automation and R&D, with a strong focus on utilising recycled materials.

“We’re excited about the potential for smart labelling to play a greater role. We see packaging not just as a necessity, but as a real opportunity to deliver value. Our goal is to provide solutions that meet the demands of today while helping our customers stay well ahead of the challenges of tomorrow.”

Cloud-Connected LABELLING FOR RETAIL OPERATIONS

Today’s retail operations are no longer centralised, and neither should their labelling be.This insight was the driving force behind a new cloudconnected labelling solution from Loftware and SATO, designed specifically to support retail’s complex, distributed ecosystems.

Traditional desktop-based label printing doesn’t scale in a retail world that spans stores, warehouses, 3PLs, and suppliers. With Loftware Cloud and SATO cloud-connected printers, retailers can now access a truly cloudfirst solution, one that eliminates the need for local drivers altogether.

In conventional labelling systems across sectors, businesses are often constrained by driver dependencies. Specific printer drivers require complex installation and maintenance. Managing label templates across multiple locations is also timeconsuming, complicates compliance, and increases the risk of errors due to outdated templates.

With Loftware Cloud, label templates can be centrally stored and managed, ensuring consistency and compliance across all printing

locations. This means no more IT troubleshooting, driver updates, or ERP/WMS workarounds.

Users benefit from secure, browserbased access to the latest approved label templates from anywhere, with full control over permissions and print history.

“The system is not decentralised; it’s actually about centralising IT management,” said Kevin Leidheiser, Public Relations Assistant Manager at SATO Corporation.

“Labelling becomes a plug-and-play operation with back-end control by HQ, rather than being handled by local offices as it has traditionally been. This reduces the burden on local staff and allows organisations to flexibly add new locations without local IT support.”

A cloud-based approach to labelling allows growing enterprises to

Labelling becomes a plug-and-play operation with back-end control by HQ, rather than being handled by local offices as it has traditionally been.

scale quickly in response to market demands. It supports remote printing and integrates seamlessly with existing on-premise or cloudbased ERP, WMS, and PLM systems, facilitating agile operations. It also extends labelling capabilities across departments and external partners, including suppliers and 3PL providers. ERP or WMS systems connect to Loftware Cloud via Loftware Cloud Print APIs. A SATO printer application called Loftware Connector serves as a bridge between the ERP system and the physical printer.

Using an HTTP request, the ERP system triggers the print event and sends the data through the Loftware Cloud Print API to the SATO printer. To the end user, it appears as if the label is printing directly from the ERP system, but in reality, it is processed in the background by Loftware Cloud.

This setup eliminates the need for IT departments to install, troubleshoot, and update printer drivers, a significant advantage.

“In the past few years, we’ve also seen issues with Windows updates causing conflicts with printer drivers. So, if you don’t have printer drivers, you won’t have that issue,” Leidheiser added.

Users can print from any PC with internet access, and setup is straightforward. Once the printer is preconfigured and shipped, customers only need to plug in a LAN cable to start printing. This ease of setup offers a significant benefit, especially for medium to large enterprises.

Looking ahead, Leidheiser said that cloud-connected labelling is set to fundamentally reshape packaging and supply chain strategies by enabling companies to centralise and standardise label management across global operations, driving greater agility, scalability, and compliance. With real-time updates, improved data accuracy, and seamless collaboration across sites and partners, organisations can respond swiftly to market changes, regulatory shifts, and evolving customer needs. Cloud solutions will also reduce the IT burden while providing enhanced visibility and analytics. This empowers businesses to optimise supply chain performance, reduce errors, and accelerate time-to-market, ultimately transforming labelling from an operational task into a strategic advantage.

packaging

Leading with Purpose TO REVOLUTIONISE SUSTAINABLE PACKAGING

From hot cups and coffee bags to food packaging and more, decent packaging has made sustainability simple for the specialty coffee market.

CRAIG IRWIN Managing Director BioPak New Zealand

The essential concept at the heart of decent packaging is “everything we make, we can unmake”, referring to the use of raw materials designed to be composted or recycled, minimising the environmental impact at end-of-life.

While under the BioPak Group umbrella, decent operates with a distinct voice, creatively driven, community-focused, and hyper-local. It complements BioPak’s corporate and international reach by speaking more directly to independent businesses and changemakers.

decent is currently piloting projects focused on sourcing materials locally to significantly reduce transport emissions, aligning with their sustainability goals. Additionally, it has been experimenting with innovative home compostable fibre blends and designs crafted specifically for boutique foodservice brands to offer unique sustainable solutions tailored to their needs.

It is also building community connections through collaborations with local artists, infusing creativity and regional culture into its packaging. For instance, the new limited edition compostable canvas hot cups, designed by New Zealand-born artist Zac Fay, showcase imaginative and bold illustrations inspired by seeing the ordinary and complex from a fresh perspective.

BioPak and decent packaging share a strong commitment to driving

meaningful change in sustainable foodservice packaging. Their core objective is to eliminate fossilbased plastics from the industry while accelerating the transition to certified compostable and reusable alternatives.

By driving innovation, education, and increasing access to sustainable

solutions, the companies empower both businesses and consumers to significantly reduce their environmental impact.

“Sharing our knowledge is central to our approach, with programs like Compost Connect playing a vital role in increasing awareness of composting and the benefits of compostable packaging. We also actively advocate for stronger regulations that enforce certification standards and combat greenwashing,” said Craig Irwin, managing director, BioPak New Zealand.

In 2021, BioPak launched Compost Connect to boost commercial composting and support the circular economy. The initiative has supported hundreds of foodservice businesses across Australia, New Zealand, and the UK in diverting organic waste from landfill by linking them with commercial composting services.

“Innovation at BioPak is fueled by our vision to create truly circular, sustainable packaging solutions. We’re constantly investing in research and development because we understand that the packaging of today won’t meet the needs of tomorrow.”

BioPak has also worked closely with partners to improve their entire packaging ecosystem. A great example has been its collaboration with BurgerFuel, where it reimagined their supply chain.

“We partnered with our manufacturers, conducted extensive R&D to redesign their custom packaging in more sustainable formats, sourced alternative raw materials, and invested in new machinery. The outcome was simplified logistics, reduced costs, and a lower environmental impact.”

This project highlighted BioPak’s holistic approach to innovation, where strategy, design, and sustainability converge to deliver scalable, sustainable solutions.

Another example was BioPak’s partnership with Toast Martinborough, New Zealand’s premier wine and food festival. In 2025, the event achieved an impressive 99.05 percent waste recovery rate, coming remarkably close to becoming a zero-waste event.

“This milestone was made possible through a combination of strategic planning, vendor education, and an exclusive partnership with BioPak and Compost Connect.”

However, Irwin mentioned that significant challenges remain. Regulations are inconsistent across regions, with some Australian EPA

jurisdictions restricting compostable packaging in FOGO and organics bins, limiting access to composting infrastructure.

In New Zealand, recent policy backtracking has further stalled progress, with key kerbside composting and recycling reforms quietly shelved at the end of 2024.

He said there’s also a lack of mandatory compost certification, which enables greenwashing and confuses businesses and consumers.

“Composting capacity itself is a barrier. Without more infrastructure and regulatory alignment, we can’t fully close the loop. Compost Connect is a critical step in the right direction, but achieving a circular system will require collaboration across government, industry, foodservice and the wider community.”

Globally, BioPak has seen growing demand for fibre-based formats like trays, clamshells, and containers as businesses move away from traditional plastic. Certified compostable packaging has also gained traction, particularly in regions implementing single-use plastic bans.

Another noticeable shift has been toward reusable systems in controlled, closed-loop environments such as stadiums, events and universities. In parallel, mono-material packaging is being favoured for its ease of recycling and lower contamination risk.

“Increasingly, brands and consumers are seeking products backed by verified carbon data and traceable sustainability claims. Transparency is no longer optional, it’s expected.”

Looking ahead, BioPak is building on its Emissions Reduction Plan in line with its 2050 net-zero commitment, focusing particularly on cutting product-related emissions, which currently represent 89 percent of BioPak’s total footprint.

packaging

Thermal Label PRINTING SYSTEMS

In the world of logistics and supply chain management, labels do more than just stick to boxes; they carry critical information that keeps everything moving smoothly.

TSC thermal label printers are built to last and designed to meet the needs of various applications. These label printers are available in either direct thermal-only or thermal transfer/ direct thermal configurations.

Direct thermal and thermal transfer are two distinct printing technologies used to create a range of printed materials, including labels, receipts, and barcodes.

Direct thermal printing utilises heat to create images on specially coated paper or film. The printer has a thermal printhead that contains

hundreds of tiny resistors.

When an electrical current is passed through a resistor, it heats and causes a small dot to appear on the paper. The pattern of dots is what creates the ability to produce black-and-white images and text.

Thermal transfer printing utilises heat to transfer ink from a ribbon to a label or other materials, such as paper, plastic, and metal, depending on the ribbon’s grade. The printer features a thermal printhead that heats a small area on the ribbon, which is composed of wax or resinbased ink.

The ink on the ribbon melts and is transferred to the material. Thermal transfer printing is more durable than direct thermal printing and can produce high-quality images that are resistant to fading and abrasion.

Across New Zealand, Techspan Industrial Printing Systems (TIPS) has been helping businesses to label smarter, faster, and more reliably. It distributes a comprehensive range of TSC thermal transfer and thermal direct label barcode printers. Techspan also offers a range of printer spares, print heads and associated accessories.

Diverse Innovations IN JAPANESE FOOD TECHNOLOGY

Innovations are revolutionising Japan’s food sector, providing new solutions to old problems and promoting healthy eating habits.

Japan’s numerous food technology breakthroughs, ranging from microbial fermentation to molecular farming, are paving the way for a more sustainable and healthy future.

Microbial Fermentation and Upcycling: Japanese scientists and sake brewers are utilising waste materials, such as rice husks and wastewater, to produce valuable products like food, compost, and non-chemical detergents. Researchers are uncovering novel microbes that can produce beneficial compounds to help build a circular bioeconomy.

Ministry of Agriculture Grants for Food Tech: The Japanese Ministry of Agriculture has awarded grants to nine food tech businesses for projects such as mycoprotein, cooking robots, alternative meat, and food waste upcycling. These awards support large-scale technology demonstration projects aimed at accelerating the adoption of new technologies.

UNESCO Recognition of SakeMaking with Koji Mould: UNESCO has designated Japanese sake-making with koji mould as an intangible cultural asset, emphasising the traditional knowledge and techniques. Koji mould converts starches into

sugars for fermentation, which is utilised in a variety of Japanese beverages.

Molecular Farming for Dairy Proteins: Kinish, a Tokyo-based company, utilises molecular farming to produce animal-free dairy proteins within rice grains. Kinish utilises vertical farming to produce casein that mimics the functionality of milk without relying on traditional dairy farming methods.

Innovative food innovations developed in Japan are setting the stage for a more sustainable and healthful future. Customers can now choose healthier options due to advancements in food safety and quality, including lab-grown meats and enhanced food preservation techniques.

At the same time, a wide variety of traditional meals that highlight premium, fresh ingredients and meticulous preparation techniques are available, thanks to Japan’s rich culinary heritage. Modern and traditional Japanese cuisine both support a healthier lifestyle because of this well-balanced fusion of tradition and innovation.

Innovative food innovations developed in Japan are setting the stage for a more sustainable and healthful future.

Traditional Japanese Cuisine MEETS MODERN TECHNOLOGY

Japan’s food scene combines innovative ideas with long-standing customs in a harmonious way.

Both the traditional foods that have been consumed for millennia and modern technological advances that are influencing the direction of food are examples of this convergence. Here are the traditional Japanese dishes and the innovative technologies enhancing them:

SUSHI: Tradition Meets Innovation

A staple of Japanese cuisine, sushi is created using vinegared rice and a variety of ingredients, such as fish, vegetables, and even tropical fruits. While traditional sushi places a strong emphasis on using only the best, freshest ingredients, contemporary culinary technology is making sushi more sustainable. To lessen the negative effects of fishing on the ecosystem, for instance, lab-grown seafood is being created.

TEMPURA: Preserving Quality with Smart Packaging

A popular cuisine in Japan is tempura, which includes seafood and vegetables that have been lightly battered and deep-fried. Smart packaging innovations help maintain the integrity and freshness of tempura components. Temperature-sensitive sensors and active packaging methods guarantee the freshness and safety of the seafood and vegetables used in tempura.

SUKIYAKI: Enhancing Flavour with Lab-Grown Meat

A great illustration of how contemporary

technologies can enhance traditional cuisine is sushi, a hot pot dish consisting of thinly sliced beef, vegetables, tofu, and noodles cooked in a sweet soy sauce broth. Without sacrificing taste or quality, lab-grown Wagyu steak, created using bioprinting technology, offers a sustainable and ethical alternative to conventional cattle.

RAMEN: Sustainable Ingredients for a Classic Dish

A mainstay of Japanese cuisine is ramen, a noodle soup dish made with Chinese-style wheat noodles in a broth flavoured with pork or fish. To create a more ethical and sustainable version of this traditional dish, animal-free dairy proteins are being produced using molecular farming techniques and used in ramen broths.

YAKITORI: Tradition and Technology on a Skewer The grilled and skewered chicken known as yakitori is a common meal at Japanese pubs, or izakayas. Technological advancements in lab-grown chicken meat are enabling the production of ethical and sustainable chicken meat for yakitori, ensuring that this traditional dish can be enjoyed without the negative environmental impacts associated with traditional poultry rearing.

Experience the essence of Japan’s F&B excellence at “JAPAN’S FOOD” EXPORT FAIR SUMMER, held from the 9th to the 11th of July 2025, at Tokyo Big Sight.

New Zealand’s Unique AMARASATE GOES GLOBAL

The Nelson region in the South Island is a hop-growing paradise. Its long hours of sunshine, pure air, rich soils, and ideal climate create the perfect conditions for thriving hop crops.

While the area has been well-known for producing flavourful hops for brewing, it’s also uniquely suited to growing a specific variety to extract the bitter compound Amarasate, Calocurb’s active ingredient.

Amarasate stands apart from other hop extracts because it resulted from 15 years of research and over NZD 30 million in investment by Plant & Food Research, New Zealand’s largest Crown Research Institute.

After screening more than 900 plants, scientists identified a specific New Zealandgrown bitter hop flower as the most effective natural ingredient for appetite regulation.

Three human trials,

and a fourth nearly complete, have shown that Amarasate can reduce hunger by 30 percent, cravings by 40 percent and calorie intake by 18 percent, all within an hour of taking a capsule.

Most hop products on the market are developed for flavour or relaxation. In contrast, Amarasate was a purposebuilt, standardised extract explicitly developed to support appetite control in a natural, measurable way. It supports the body’s biological hunger cues with plant-based ingredients and clinically backed science.

Calocurb can be used alone as a natural weight management tool, but it has also proved valuable for those transitioning off GLP-1 medications and looking to maintain their results.

For others, it can serve as a supportive complement, helping to enhance appetite control and potentially reduce reliance on higher doses of medication.

“Hops are a fascinating botanical

with a range of bioactive compounds that continue attracting scientific attention, so exploring their broader potential is natural. That said, our focus with Calocurb has always been on what we know works, and that’s the unique combination of our Amarasate extract and its patented delivery system,” said Brittany Birch, affiliate and partnerships manager for Calocurb.

“While other wellness applications may emerge through future research, we’re careful not to generalise the effects of hops. Without our precise formulation and delivery method, you don’t get the same proven, measurable outcomes.”

She added that consumer response has been incredibly encouraging, and health professionals have also appreciated the research behind Amarasate.

At the same time, Calocurb has had growing interest from other industries that are curious about the role of natural bitter compounds in health and wellness.

“Simply adding a bitter extract to a food or drink won’t trigger the same

response because it won’t reach the right part of the digestive tract at the right time or in the correct form. That’s why the appetite-regulating effects seen with Calocurb can’t be replicated in other formats. It’s not just about the ingredients; it’s about the delivery.”

Birch said that nature always brings some variety, but Calocurb has designed its extraction process to deliver consistent results. It uses supercritical CO₂ extraction, which isolates only the key bitter compounds needed in the purified hops extract, leaving minimal waste.

Each batch is rigorously tested to meet strict quality standards so consumers can count on the same reliable benefits of Calocurb every time.

“We work hand-in-hand with NZ Hops and their community of passionate local growers. These farmers care about quality and sustainability, which matches our ethos. We track everything from planting to harvesting to extraction; every batch is completely traceable,” she added.

“Our hop and extraction partners in New Zealand are set up to meet

While other wellness applications may emerge through future research, we’re careful not to generalise the effects of hops. Without our precise formulation and delivery method, you don’t get the same proven, measurable outcomes.

growing demand, and we’ve built flexibility into our supply chain so we can scale quickly. Our strong relationships allow us to grow without compromising quality or sustainability.”

Looking ahead, Calocurb has focused on scaling, with strong partnerships and science leading the way. Its expansion in the US, Australia, and Asia across retail and practitioner channels is underway, bringing Calocurb’s natural, clinically proven approach to appetite control to a broader audience.

“This is just the beginning, and we’re building a foundation for longterm growth in markets that value innovation and patient success.”

Tasman Hops

GO GLOBAL AT drinktec

Located in the Tasman countryside, Kiwi-owned and operated business, Clayton Hops, is the proud operator of New Zealand’s premier hop processing, packaging and cool store facility, nestled on a picturesque 16-hectare block of land.

Each of its farms (Battery Hill Hop Farm, Blue Rock Hop Farm, Korere Hop Farm and Mt Arthur Hop Farm) has its own modern, high-capacity and centralised harvesting facilities, comprising hop picking, sorting and drying equipment. These provide a real edge at harvest time, allowing the team to pick hops in their prime and at scale.

“Hop variety harvest windows can change yearly, both in timing and length, and often overlap. Crucially, we have substantial and reliable capacity to ensure all hops are picked at the right time. Our flat-bed drying kilns are exhaust and fume free,” said Belinda Brosnan, head of marketing at Clayton Hops.

Being fully integrated has allowed

the business to maximise product quality, speed to market and most importantly, customer satisfaction.

The cutting-edge plant, equipment, controls and process design has the capacity of 2,500 to 3,000 kgs of T90 hop pellets per hour, far exceeding anything else in New Zealand.

In addition to processing hop pellets, the facility has been expanded to process the unique Amplifire concentrated lupulin pellets and Amplifire fresh hop oil. The business has also installed a brewery to enable the team to test new products and hop varieties.

Amplifire hop oils and concentrated hop pellets were developed based on customer insights. Brosnan said that brewers have sought more efficient, sustainable and flavourful products to

meet the needs of their businesses and craft beer consumers.

“The response and uptake from the global brewing community has been incredible - we have installed further infrastructure at the processing facility this year to keep up with demand.”

The team at Clayton Hops are also very passionate about sustainability. Developing the Amplifire hop oils as a product with a very low carbon footprint has been a testament to this. The business also partnered with BX to measure its environmental performance across four key areas –soil health, water, waste & energy, and biodiversity.

Looking ahead, Clayton Hops has several new hop varieties in its innovation pipeline that they are very excited about and have had very promising responses from international brewers.

Brosnan mentioned that Clayton

Hops’ first exclusive variety has sweet peach, juicy orange, ripe passion fruit, and sticky mango characteristics, which make it a very appealing and unique combination of aromas for craft brewers.

Clayton Hops NZ is ready to showcase its innovation at the upcoming drinktec fair from the 15th to the 19th of September 2025.

“For us, drinktec is a great opportunity to not only showcase our products to a global audience, but also understand the broader beverage market and key innovations shaping the category at an international level,” added Brosnan.

“It is an excellent platform for a New Zealand company to not only fly the Kiwi flag in the beverage ingredients space but also understand how the category is evolving and how we can keep pushing ahead with creative solutions to keep up with that.”

From Paddock TO PINT DOWN SOUTH

Based in Southland, Garston Hops is the southernmost commercial hop farm in the world.

Being located in this region has meant the business has taken an experimental approach right from the start. The latitude is similar to some of the great hop-growing regions in the Northern Hemisphere, allowing hops not only to tolerate but to thrive in the local climate.

“Because no one had done this before in our area, we spent the first few years trialling a variety of cultivars to see what would suit our unique conditions,” said Lizette McNamee, Business Manager of Garston Hops.

“We’ve landed on a mix of wellknown New Zealand hop varieties that not only perform well here, but also give us a nicely staggered harvest window.”

McNamee noted that by selecting both early and late varieties, the harvest can be spread across roughly three weeks, which has helped manage labour, logistics, and quality control.

At the same time, they have continued to learn and adapt every season, refining trellising systems, irrigation schedules, and fertigation strategies.

“It’s exciting to be pioneering hops in a region with so much potential.”

Sustainability is embedded in the DNA of the farm, which integrates a fifth-generation sheep operation with a newer hop enterprise. McNamee said that this synergy has created natural opportunities for regenerative practices.

One such example is grazing

integration, where sheep graze among the hop rows in the offseason, helping with weed control and naturally fertilising the soil. The farm also uses biodegradable coir twine to train hops; this breaks down naturally, avoiding plastic waste.

Smart irrigation and precision fertigation have been employed through drip irrigation systems combined with soil moisture sensors, enabling efficient water use and the direct delivery of nutrients to plant roots. This has also reduced both runoff and waste.

Additionally, cover crops and clover have been planted to enhance soil structure, fix nitrogen naturally, and support microbial life.

Solar power is another key feature. The pump shed is already solar-

It’s exciting to be pioneering hops in a region with so much potential.

powered, with plans underway to extend this to the harvest shed. Postharvest plant material is composted and spread back on the paddocks, helping to create a closed nutrient loop.

The farm has also prioritised working with local engineers and services, reducing travel and contributing to the resilience of the rural community.

Many of these sustainability initiatives, particularly smart irrigation, precision fertigation, and the use of biodegradable materials, have not only reduced the farm’s environmental footprint but also improved crop performance.

On the tech front, the farm has been exploring data-driven tools for yield tracking and plant health monitoring. These technologies support the development of highquality cones and help mitigate disease risk.

McNamee has observed a growing demand for traceability and transparency. Brewers, both local and international, are increasingly drawn to the idea of “paddock to pint” or “garden to glass.” They want to know the story behind the hops: where and how they were grown, who grew them, and what makes them unique.

This relationship-based model has worked well for Garston Hops, thanks

to its hands-on approach and passion for working with brewers who value provenance, innovation, and flavour.

She believed New Zealand has an incredible opportunity to grow truly world-class hops, particularly due to its clean environment, strict biosecurity, and unique growing conditions.

“Our latitude gives us a point of difference; there’s no other country producing hops quite like ours along the same latitude.”

However, McNamee acknowledged that challenges remain. Labour costs in New Zealand are high, and the distance from major export markets has led to increased shipping expenses.

As global competition intensifies, it has become essential for the industry to focus on quality, innovation, and sustainability rather than trying to compete on volume or price.

“We’re incredibly proud of what we’re building in Southland. It’s a combination of heritage and innovation, drawing on generations of farming experience while pushing into new territory with hops.”

Although still in the early stages, Garston Hops is eager to continue learning, improving, and sharing its hops with brewers who are just as passionate about flavour and sustainability.

bird pests

Falcon Conservation AT LAKE CHALICE WINES

Marlborough’s vineyards have observed a unique partnership between nature and viticulture.

The New Zealand falcon, or kārearea, has been utilised to protect vineyards from bird pests, providing a natural and highly effective solution to an agricultural challenge.

Proudly featured on every bottle of Lake Chalice wine, the kārearea is New Zealand’s only remaining endemic bird of prey. Once found in large numbers across the Marlborough region, its numbers have reduced due to habitat loss, introduced predators, and electrocution.

Today, with a threatened population of just 5,000 to 8,000, these birds play a significant role in conservation efforts linked to the wine industry.

Lake Chalice Wines has partnered with the Kārearea Falcon Trust, releasing rescued New Zealand falcons onto their Eyrie Vineyard due to its ideal landscape and minimal human interference, providing the perfect conditions for the kārearea to transition into the wild while remaining protected and supported.

These falcons not only represent a conservation success story but also act as guardians of the grapes, scaring off pest birds like finches, starlings, blackbirds, and robins, which are known to damage fruit by pecking holes or consuming entire berries, particularly at the critical stage of veraison when grapes begin to colour.

“At Lake Chalice, our goal is to encourage the kārearea to remain in and around our vineyards for as long as possible. After their release into the wild, these native birds of prey often stay nearby while they sharpen their

hunting skills,” said Nick Williamson, brand manager of Lake Chalice.

“In our Eyrie Vineyard, where specially built hack boxes support their development, our winemaker Chloe has even noticed a kārearea watching over her during harvest. She jokes that it’s nice to know she’s not the only one quality-checking the grapes.”

Birds have traditionally posed a significant challenge in vineyards, as they feed on the fruit and can cause damage that leaves grapes vulnerable to rot and disease, especially during the warmer summer months.

The presence of the kārearea, however, has proven to be an effective natural deterrent. Their territorial behaviour discourages smaller birds from nesting in the area, and their carnivorous diet also helps control other pests, such as rabbits, contributing to the overall health of the vineyards.

Williamson added that, as wild birds, kārearea are free to come and go, and the team does not actively manage their movements or implement measures to keep them within the vineyards in the long term. However, they do play an essential role in their early development with hack boxes.

The hack box provides a safe, elevated environment where

young falcons can adapt to their surroundings, strengthen their flight skills, and gradually learn to hunt on their own, while avoiding the concern of predators on the ground.

To support their safety, Lake Chalice has also worked to insulate electrical transformers near the vineyard, thereby reducing the risk of injury to birds. The team hoped that by offering them a secure environment during this transitional phase, they would choose to remain in the wider Marlborough region as they learn to hunt and establish their independence.

Williamson said that in theory, any vineyard could install hack boxes, but their effectiveness depends entirely on them being part of a structured breeding or rehabilitation program. Without that context, the boxes may simply become nesting spots for other bird species or go unused altogether.

“The success of this approach relies on careful coordination with organisations like the Kārearea Falcon Trust. The kārearea Falcon Trust does an incredible job rehabilitating and releasing these native birds of prey. If you come across an injured falcon along the roads in Marlborough, please transport it safely to your nearest DOC (Department of Conservation) office as soon as possible.”

Bird Control NEW ZEALAND

Located in Napier, New Zealand, Simon Horsfall, Operations Manager at Ngai Tukairangi Trust, faced a distinctive challenge on the farm.

The overhead nets, intended to protect approximately 60 kiwi fruit trees from hail and wind, unintentionally became a magnet for a substantial seagull population.

A staggering number of over 600 birds would roost on the nets overnight, resulting in a messy situation and considerable hygiene concerns.

By installing three lasers over 60 hectares, the farm has experienced a remarkable transformation. The lasers, operational for about three years now, effectively deterred seagulls from landing on the nets, providing a respite from the damage caused during the seagull roosting season, which typically spanned from December until June.

The impact of implementing this solution was remarkable. Once the lasers covered the entire net area, the absence of birds brought immediate financial gains. Horsfall estimated that the farm incurred damage costs ranging from NZD 25,000 to NZD 30,000 before adopting the laser solution. With the lasers in place, the reduction in bird-related damage translated into significant cost savings and a sound return on investment.

To address this persistent issue, the farm has turned to an innovative solution: the AVIX Autonomic Laser Bird Deterrent. This state-of-the-art bird control technology employed green laser frequencies to discourage birds from crucial areas, boasting significant success with over 1000 customers worldwide.

Impressed by his positive experience, Horsfall recommended the laser deterrent to other farmers, citing that blueberry farmers faced similar challenges. Laser technology protects crops and enhances the efficiency and hygiene of farming operations.

bird pests

Managing Birds IN F&B SPACES

Bird control in cafés, restaurants, and supermarkets isn’t just an aesthetic concern; it’s a complex and often challenging task. These spaces naturally attract birds, offering food, shelter, and easy access. These are ideal conditions for them, but not so ideal for businesses.

Michael Krause, Director of Bird Control New Zealand, explained that the most effective approach is a mix of exclusion, behaviour modification, deterrents and education.

“It starts with simple steps: clear tables quickly, keep doors and windows shut, and educate customers not to feed the birds,” he said.

“Food leftovers left out are an open invitation.”

A clear strategy and understanding of bird behaviour are needed to implement the right solution.

Understanding bird behaviour is key.

“For example, a café near the coast

MICHAEL KRAUSE Director, Bird Control New Zealand

will likely attract gulls, while urban cafés might deal more with pigeons or sparrows. We assess the area first, including what species are present, why they’re there, and how they’re getting in. Are there nests nearby? Open spaces? Roller doors?”

For hospitality venues, any system must balance effectiveness with aesthetics.

“No one wants their place to look like a fortress. That’s why exclusion and education work best; they’re low-impact visually but high-impact behaviourally.”

Legal and ethical concerns also apply. Not all bird control methods are safe for public or food-handling

environments. Krause said there are health and safety considerations, and the wrong technique can risk customer well-being and compliance.

Bird Control NZ primarily works in commercial, agricultural, and industrial sectors, with installation times varying from a few hours to several days and disruptions ranging from minimal to moderate, depending on the site and solution. However, Krause added that one thing is constant: ongoing maintenance and monitoring.

“Bird control isn’t one-and-done. It needs strategy, monitoring, and flexibility.”

We assess the area first, including what species are present, why they’re there, and how they’re getting in. Are there nests nearby? Open spaces? Roller doors?

waste to taste

Food Waste: THE NEXT SUPER INGREDIENT?

The global food & beverage industry is experiencing a major revolution with the food upcycling market taking centre stage.

DEVENDRA YADAV

Group Manager, Food, Automotive, Chemical, & Energy Operations

Ingenious e-Brain

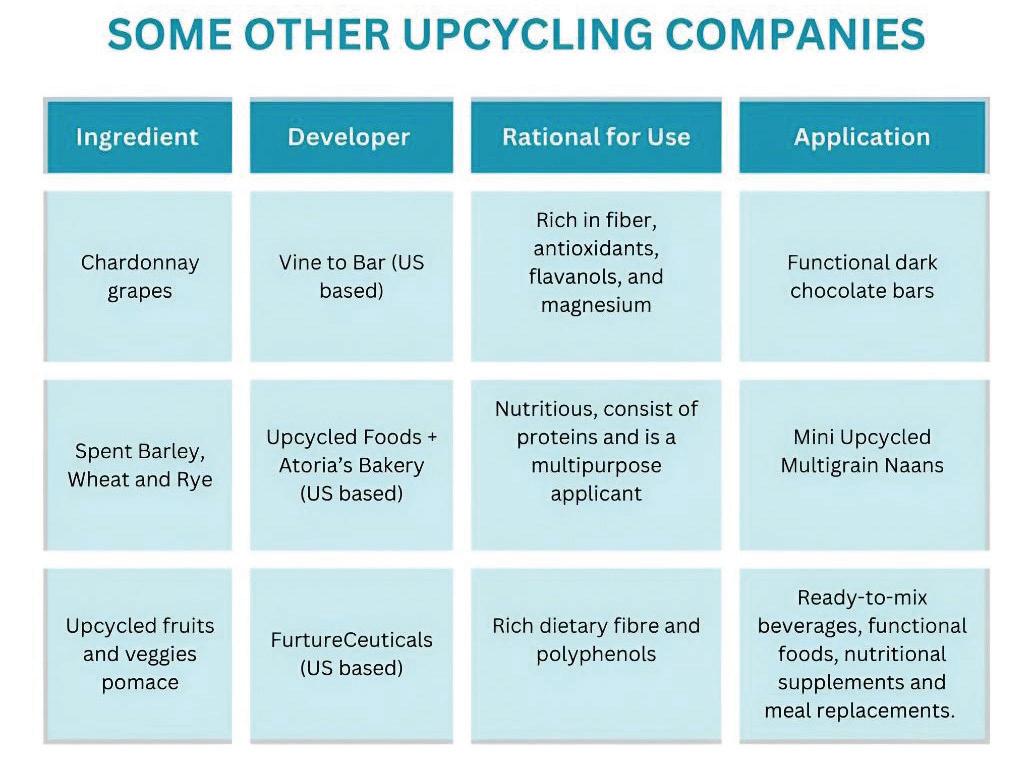

Upcycling is the process in which food waste is converted into high-value, nutritious, and eco-friendly ingredients. This process strategically helps tackle global food waste, which poses a significant environmental challenge. The increase in consumer conscience, the need for green practices, government encouragement, and improvements in food processing technologies have favoured the upcycle food product market in driving forward. What was previously thought to be unsuitable for the plate is now surfacing as an ingredient with vast culinary, environmental, and business potential.

The Emergence of Upcycled Food

The international food upcycling market is expected to expand from USD 56.4 billion in 2023 to around USD 93.6 billion by 2033 at a compound annual growth rate of 5.2 percent. As per the report, this growth is driven by rising awareness around climate change, sustainability and resource optimisation.

Additionally, several government and institutional initiatives are addressing

food waste. For instance, under the Singapore Green Plan 2030, the government aims to reduce landfill waste by 30 percent, by 2030. This initiative includes mandates from industrial food and large commercial waste to bifurcate their waste for treatment; requiring a significant infrastructure investment such as Tuas Nexus in Singapore, which integrates water and solid waste treatment facilities to enhance biogas production and carbon saving. On the private front, ReGrained, a startup in California converts spent malt from breweries into nutrient-rich flour utilising patented technology. Similarly, Mycorena in Sweden expands its operations of converting food waste into mycelium protein, highlighting the potential for large-scale application of upcycling technologies.

Fermentation and Fungi

Chefs and scientists are making different applications of fungi, such

as Neurospora intermedia to ferment food scraps by disintegrating complex carbohydrates and other nutrients into gourmet meals. This is done to convert fruit pulp, soy pulp, and plant milk byproducts into flavorful, nutritious, and sweet foods. Some popular restaurants such as Blue Hill at Stone Barns in New York and Alchemist in Copenhagen already have this process embedded within their kitchen.

For instance, engineers at UC Davis are growing “myco-foods”, which are small balls of edible fungi that can be processed into products like boba and lab-grown caviar with a wide range of textures, colours and flavours. These myco-foods are produced from the nutrients of agricultural byproducts like coffee grounds and almond hulls, which are a new source of protein.

Agricultural-Driven Solutions

Planetarians, San Francisco-based food tech company raised USD 6 million in a Seed II funding round to commercialise its vegan meat products curated from two upcycled components oil cakes and brewer’s yeast. These ingredients are byproducts of the vegetable oil and beer industries. Analysts at IAMECON have calculated that Planetarians’ vegan meat has a carbon footprint which is 50X lower than traditional animal meat and 9X lower than other plant-based meats.

Tech-Driven Solutions

Divert processed more than 630 million pounds of unsold and non-donatable food in 2024 by utilising advanced technology, a 52 percent increase y-o-y.

Companies like these convert waste into renewable energy.

Global Government Initiatives and Policies

Governments around the world are employing policies and initiatives to support upcycling and minimise food wast. New South Wales (NSW), has initiated a state-wide program for recycling Food Organics and Graden Organics (FOGO) with an objective to alleviating landfill pressure and lean towards a circular economy by recycling organic waste into composite for use in parks and agriculture. Businesses and institutions must comply with FOGO bins by July 2026, while households are required to comply by July 2030. Additionally, the initiative includes the introduction of FOGO bins across various establishments, parallelly supermarkets are urged to report surplus food for donations.

While the growth shows much promise, four of its major challenges are supply chain complexity, consumer

mistrust, expensive production, and scaling limitations. To overcome these, businesses are spending on R&D to enhance flavour and texture, working in cross-sector collaborations, and using storytelling to gain trust among consumers, rendering upcycled food not only feasible, but acceptable.

Emerging Trends to Watch Out

Certified Upcycled Food Aisles in Mainstream Retailers: With more than 560 Upcycled Certified products created by over 100 businesses, retailers are now more likely to devote shelf space to upcycled products.

Celebrity Chefs Promoting “GuiltFree Gourmet”: Famous chefs and restaurants are going for upcycled ingredients, converting food waste into culinary masterpieces. For example, Salt & Straw, an ice cream firm based in Portland, has redirected more than 40,000 pounds of food waste into distinctive flavours.

Cross-Border Partnerships for Zero-Waste Ingredient Systems:

International collaborations are emerging to address food waste collaboratively. Businesses such as Renewal Mill have redirected more than 700,000 pounds of food waste since 2018 by converting plant-based milk pulp into gluten-free flour.

Upcycled food is emerging as a cornerstone of future food innovation, not just as a sustainability measure, but as a scalable business opportunity. For B2B ingredient makers, it transforms underutilised by-products into high-value functional ingredients. B2C brands, meanwhile, are leveraging these to align with consumer demand for health and sustainability.

From brewers converting spent grains into protein-rich flours to juice companies turning pulp into fibredense powders, upcycling is unlocking new potential. As global regulations increasingly target food waste and carbon emissions, adopting circular production models will be critical for long-term competitiveness and future readiness.

Foodstuffs CO-OPS

At Foodstuffs North Island and Foodstuffs South Island, the safety and quality of the food we supply to New Zealanders is our top priority.

As 100 percent New Zealandowned co-operatives, we take pest control and food safety seriously and have key controls in place across our stores and supply chain.

Below is some information on how Foodstuffs North Island and Foodstuffs South Island co-ops manage bird pest control.

Retail and inward goods areas

• Food prep areas have sealed, dustproof ceilings to prevent bird roosting.

• Strip curtains and sensor doors reduce bird entry.

• Any nesting is removed immediately, and birds are managed by netting to prevent roosting or, if required, humane removal by licensed professionals.

• Waste is bagged and skip lids kept closed.

Each of our stores operate under a Food Control Plan (FCP), which is a legal requirement. These plans include a dedicated Pest Control Programme, which is strictly managed and can only be carried out by registered pest control professionals.

If pests are sighted, this is noted in a sighting register and the pest control contractor is informed. All potential pests, including birds, are required by law to be included within the scope of these programmes.

Foodstuffs works closely with registered pest control contractors across our stores and supply chain to ensure all methods are safe, humane, and in line with New Zealand legislation and best practice.

We aim to maintain a clean, hygienic, and compliant environment for all our customers and team members.

MORE FLUID THINKING

The world of water is evolving faster than ever, and every challenge is unique.

We are a fluid-thinking team of engineers, scientists, project designers, and sustainability specialists, committed to protecting our most valuable resources. We deliver tailored flexibility with innovative agility across the ANZ-Pacific water sector.

Whether you’re a local municipality or a global manufacturer, think of us as your performance partner. Here to help you maximise project lifecycle value and drive sustainable change.

Our in-depth hydro expertise, world-leading technology, and carbon-neutral services enable us to achieve exactly this—together.

Discover what more fluid thinking can do for you | hydroflux.nz

WATER WASTEWATER RENEWABLE ENERGY HYDROGEN TRANSITION ENVIRONMENTAL PROTECTION

FORUM

MADELINE NEWMAN Executive Director, AI Forum New Zealand

I joined the AI Forum as Executive Director about 6 months before ChatGPT entered our world with a BANG! – AI (and my world) has been running at top speed ever since.

It is relentless – and it’s enabling some great ideas to be realised –here are some of them:

Fighting back: At our recent AI in Creative Industries Summit we met Daisy, a state-of-the-art Conversational AI bot programmed to speak with scammers on the phoneline for as long as possible. That wastes their time and keeps them away from real people. That’s what dAIsy, the scam-fighting AI bot, is here to do.

SciFi coming to life: Linguistic earbuds that could be the first versions of the Bablefish in Douglas Adams in ‘The Hitch Hikers Guide to

the Galaxy’ are available on a couple of international marketplaces. It’s an earbud that uses AI to translate 45+ languages in real time, pitched at a relatively affordable price (USD100). These earbuds let people speak their own languages freely across international borders (though not yet interplanetary), reducing barriers to understanding and accessibility.

It’s too late to ignore this AI thing! The ability for businesses and other organisations to safely ignore AI has disappeared. People are naturally finding these tools and beginning to use them, whether they are ‘allowed’ to or not. All organisations need to address the very real current risks

they face around federated AI. Take a look at our free resources here: https://aigovernance.nz/ - these useful resources are curated by experts from across the AI Forum. More information is being added in the coming months, so its worth checking in again in August.

Safe places to play: If you haven’t tried Generative AI yet, have a go with one of the free versions – there are plenty to choose from. If you are concerned about your information being used, I usually say don’t share anything that you wouldn’t post on social media – you don’t need to give away your personal data to get a

scone recipe or some ideas for your