element.ac

Premium lubricants for HVAC&R professionals

Contents Copyright © 2022 All rights reserved No part of this document shall be reproduced in whole or in part without the permission of SuperCool Group of Companies. This includes reproduction or copies in any form or by any means including photocopying, printing or electronic media. IMPORTANT DISCLAIMER This is a guideline document containing professional information using representative graphs, charts, diagrams and tables. Manufacturers’ specifications must be consulted for specific guidelines. SuperCool Group of Companies expressly disclaims all and any liability and responsibility to any person or business as a result of any actions taken on the basis of information in this publication. The lifeblood of any system..........................................2 Confidence in a can......................................................3 PAG (Polyalkylene glycol) Lubricants...........................5 Vacuum Pump Oil.........................................................7 Spray Lube....................................................................9 POE Electric Compressor Oil.....................................10 POE (Polyolester) Lubricants......................................11 PAO (Polyalphaolefin) Lubricants...............................13 Contents Copyright © 2022 All rights reserved No part of this document shall be reproduced in whole or in part without the permission of SuperCool Group of Companies. This includes reproduction or copies in any form or by any means including photocopying, printing or electronic media. IMPORTANT DISCLAIMER This is a guideline document containing professional information using representative graphs, charts, diagrams and tables. Manufacturers’ specifications must be consulted for specific guidelines. SuperCool Group of Companies expressly disclaims all and any liability and responsibility to any person or business as a result of any actions taken on the basis of information in this publication. The lifeblood of any system..........................................2 Confidence in a can......................................................3 PAG (Polyalkylene glycol) Lubricants...........................5 Vacuum Pump Oil.........................................................7 Spray Lube....................................................................9 POE Electric Compressor Oil.....................................10 POE (Polyolester) Lubricants......................................11 PAO (Polyalphaolefin) Lubricants...............................13 Scan the QR Code or visit our website at www.supercool.group/element.ac for more information

Lubricating oil is the lifeblood of any system.

This humble, yet fundamental fluid can make or break a system. element.ac provides reliable lubrication, hour after hour, year after year. With element.ac, you can be assured that we started from the ground up, developing an outstanding range of oils that you can use with confidence.

Drawing on decades of experience in HVAC&R, our team worked with the best in the industry to deliver this new range, offering a high-performance solution for every application.

A complete range of premium HVAC&R lubricants that guarantee precision chemistry, all under one brand.

2

Confidence in a can.

Confidence in a can.

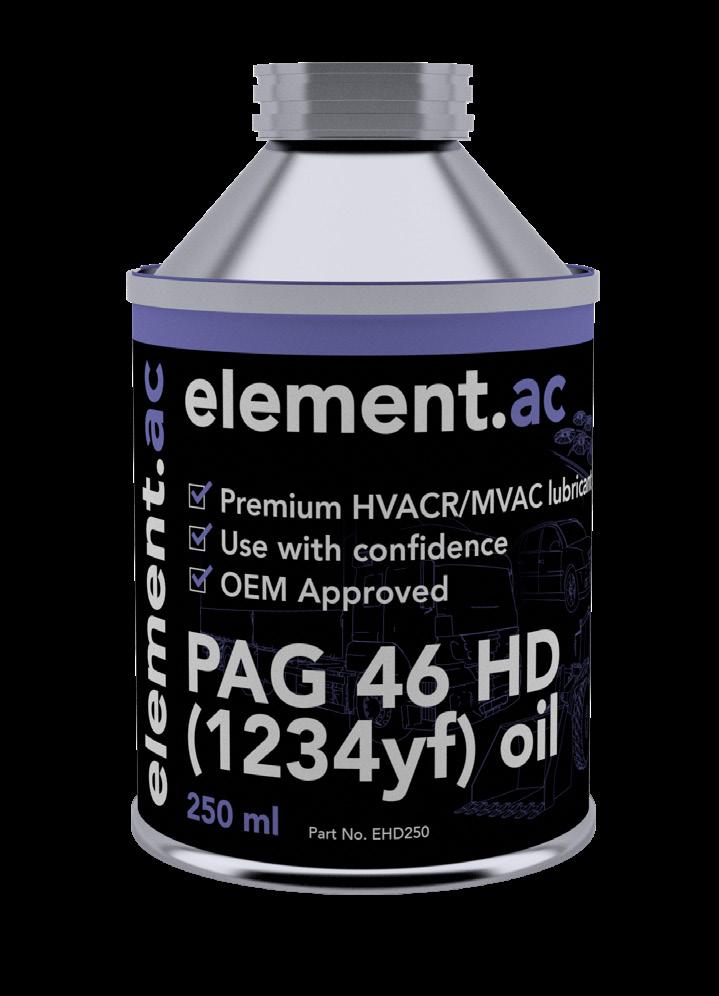

The element.ac range is your new best friend. The lubricant you need, in the correct viscosity, packaged in robust, environmentally friendly, moisture-rejecting steel cans. Our bespoke high-performance additive-pack chemistry guarantees you can use with confidence.

The element.ac range is your new best friend. The lubricant you need, in the correct viscosity, packaged in robust, environmentally friendly, moisture-rejecting steel cans. Our bespoke high-performance additive-pack chemistry guarantees you can use with confidence.

PAG 46 oil Polyalkylene glycol 250ml EPAG46 Part No. PAG HD 46 Double

capped R1234yf oil 250ml EHD250 Part No. PAG 100 oil Polyalkylene glycol 250ml PAG 150 oil Polyalkylene glycol 250ml Vacuum Pump oil 4 litre EPAG15 Part No. Vacuum Pump oil 1 litre EVP001 Part No. EVP004 Part No. EPAG10 Part No. 3

end

PAG 46 oil Polyalkylene glycol 250ml EPAG46 Part No. PAG HD 46 Double end capped R1234yf oil 250ml EHD250 Part No. PAG 100 oil Polyalkylene glycol 250ml PAG 150 oil Polyalkylene glycol 250ml Vacuum Pump oil 4 litre EPAG15 Part No. Vacuum Pump oil 1 litre EVP001 Part No. EVP004 Part No. EPAG10 Part No. 3

Spray Lubricant

Polyolester

Spray Lubricant

300g

Polyolester

1 litre

POE 32 oil

Polyolester 1 litre

POE 32 oil

POE 32 oil

Polyolester

4 litre

POE 68 oil

Polyolester litre

POE 68 oil

Part

POE 68 oil

POE 68 oil

Polyolester

Polyolester

1 litre

Polyolester

4 litre

EPE321 EPE68S Part No. EPE681 Part No.

PAO 68 oil

PAO 68 oil

Polyalphaolefin litre

Polyalphaolefin 1 litre

PAO 68 oil

PAO 68 oil

Polyalphaolefin with UV dye 1 litre

Polyalphaolefin with UV dye

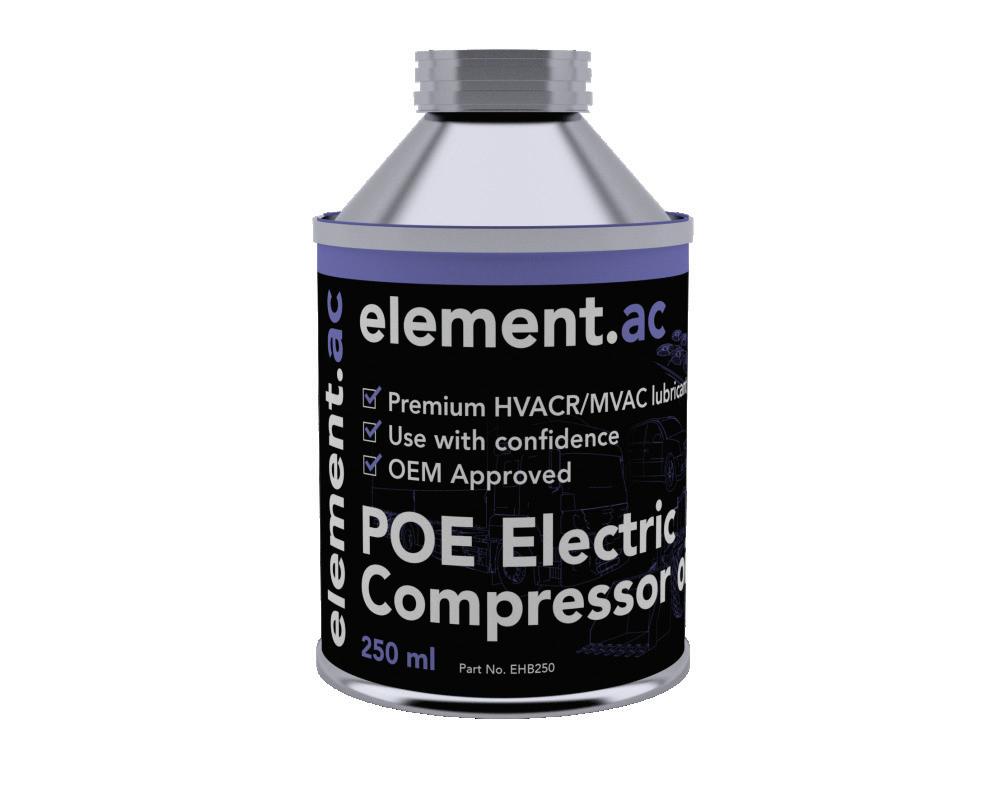

POE Electric Compressor oil

POE Electric Compressor oil

Polyolester Oil with dielectic additive for use in electric compressors 250ml

PAO 68 oil

PAO 68 oil

Polyalphaolefin

4 litre

Part No. EPE684 Part No. EPAO10 No. EPAO1U Part No. EPAO40 Part No. EPE68S No. EHB250 Part No. EPE324 Part No. EPE681 No.

Polyalphaolefin 4 litre

4

1 litre No. EPAO10 Part No. EPAO1U Part No. EPAO40 Part No.

Polyolester

POE 32 oil

EPE321

300g 4

PAG (Polyalkylene glycol) Lubricants

PAG (Polyalkylene glycol) Lubricants

element.ac PAG oil is a premium synthetic lubricant primarily designed for automotive air conditioning systems.

element.ac PAG oil is a premium synthetic lubricant primarily designed for automotive air conditioning systems.

• Provides excellent wear protection in the demanding environment of automotive compressors

• Provides excellent wear protection in the demanding environment of automotive compressors

• Available in 46, 100, and 150 viscosities to suit piston, scroll, swashplate, wobbleplate and vane type compressors

• Available in 46, 100, and 150 viscosities to suit piston, scroll, swashplate, wobbleplate vane type compressors

• Approved for use with Burgaflex flexible hose systems

• Approved for use with Burgaflex flexible hose systems

• Specific PAG 46HD chemistry for HFO1234yf refrigerant applications

• Specific PAG 46HD chemistry for HFO1234yf refrigerant applications

• Designed for automotive AC professionals

• Designed for automotive AC professionals

• Offers high efficiency in mobile AC systems

• Offers high efficiency in mobile AC systems

• Batch tested for consistency and quality

• Batch tested for consistency and quality

• OEM approved by Unicla

• OEM approved by Unicla

• 250ml steel cans with the viscosity printed on the cap for instant identification

• 250ml steel cans with the viscosity printed on the cap for instant identification

Viscosity

Viscosity

46

5

EPAG15 EHD250 EPAG46

PAG 100 PAG 150 PAG 46 HD PAG

Part No. EPAG10

5

PAG

PAG

PAG

PAG

No. EPAG10 EPAG15 EHD250 EPAG46 Size 250ml 250ml 250ml 250ml

100

150

46 HD

46 Part

Analysis Viscosity @ 100ºC (cSt) Viscosity Index Pour Point (°C) Density @ 20°C (g/ml) Flash Point COC (°C) Acid Value (mg KOH/G) Water Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 PAG10 20–24 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 90–110 PAG15 27–28 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 135–165 PAG 46 & PAG 46 HD 10–12 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 41.4–50.6 6 PAG Analysis Viscosity @ 100ºC (cSt) Viscosity Index Point (°C) @ 20°C (g/ml) Point COC (°C) Value (mg KOH/G) Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 PAG10 20–24 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 90–110 PAG15 27–28 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 135–165 PAG 46 & PAG 46 HD 10–12 120–140 -50 0.99–0.1 ≥200 ≤0.10 ≤0.05 41.4–50.6 6 PAG

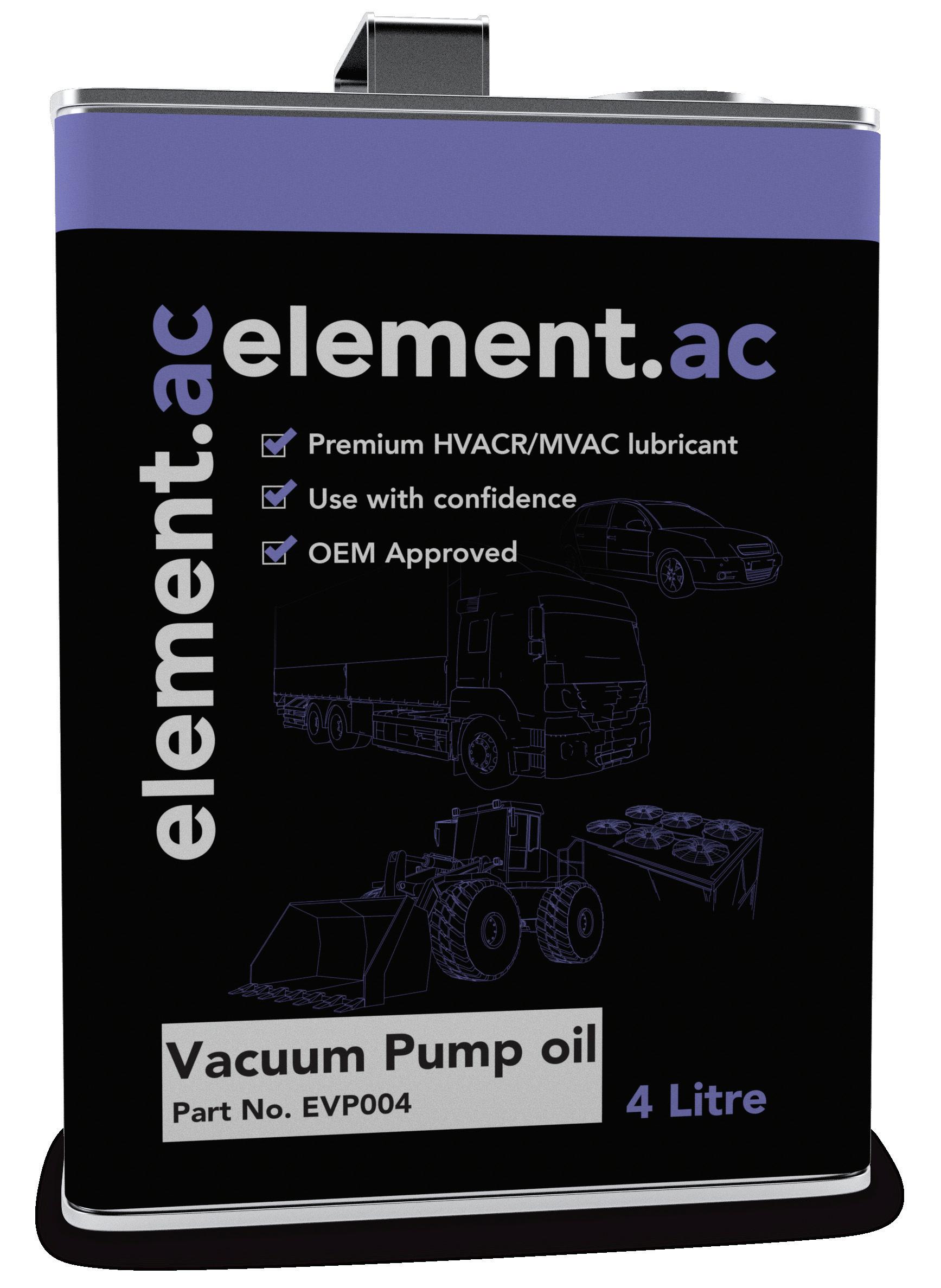

Vacuum Pump Oil

Vacuum Pump Oil

Premium mineral oil lubricant for all vacuum pump applications.

Premium mineral oil lubricant for all vacuum pump applications.

• element.ac vacuum pump oil meets the highest industry specifications

• element.ac vacuum pump oil meets the highest industry specifications

• Behaves as a blotter by absorbing moisture and non-condensable substances during evacuation

• Behaves as a blotter by absorbing moisture and non-condensable substances during evacuation

• Specifically designed for vacuum pumps, oil separators and reservoirs

• Specifically designed for vacuum pumps, oil separators and reservoirs

• Suitable for lubricating pump bearings and sealing glands

• Suitable for lubricating pump bearings and sealing glands

• Low volatility and excellent wear protection properties

• Low volatility and excellent wear protection properties

• Improves vacuum pump performance with a regular oil change schedule

• Improves vacuum pump performance with a regular oil change schedule

7 Part No. EVP004 EVP001 Size 4 Litres 1 Litre

7 Part No. EVP004 EVP001 Size 4 Litres 1 Litre

@ 40ºC (cSt)

Viscosity @ 40ºC (cSt)

@ 100ºC (cSt)

Viscosity @ 100ºC (cSt)

Viscosity Index

(°C) @ 20°C (g/ml)

Pour Point (°C)

Density @ 20°C (g/ml)

COC (°C)

Flash Point COC (°C)

(mg KOH/G)

Acid Value (mg KOH/G)

Water Content

VACUUM PUMP

VACUUM PUMP

Analysis

Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 Mineral (VAC) 7.5–9 120–140 -10 0.9 ≥160 ≤0.05 ≤0.05 90–110 8

Analysis

Viscosity

Point

Point

Content Viscosity

Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 Mineral (VAC) 7.5–9 120–140 -10 0.9 ≥160 ≤0.05 ≤0.05 90–110 8

Viscosity

Index

Value

Spray Lube element.ac assembly lube provides premium lubrication in a convenient spray can. Ideal for A/C system components such as flares, flanges, o-rings, seals and composite assemblies.

Spray Lube element.ac assembly lube provides premium lubrication in a convenient spray can. Ideal for A/C system components such as flares, flanges, o-rings, seals and composite assemblies.

EPE68S LUBE

Part No.

Part No. EPE68S Size 300g LUBE

Analysis Viscosity @ 100ºC (cSt) Viscosity Index Pour Point (°C) Density @ 20°C (g/ml) Flash Point COC (°C) Acid Value (mg KOH/G) Water Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 POE 68 9.3 90–120 -39 0.98 ≥200 ≤0.02 ≤0.05 68.5

9

Analysis Viscosity @ 100ºC (cSt) Viscosity Index Pour Point (°C) Density @ 20°C (g/ml) Flash Point COC (°C) Acid Value (mg KOH/G) Water Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 POE 68 9.3 90–120 -39 0.98 ≥200 ≤0.02 ≤0.05 68.5

9

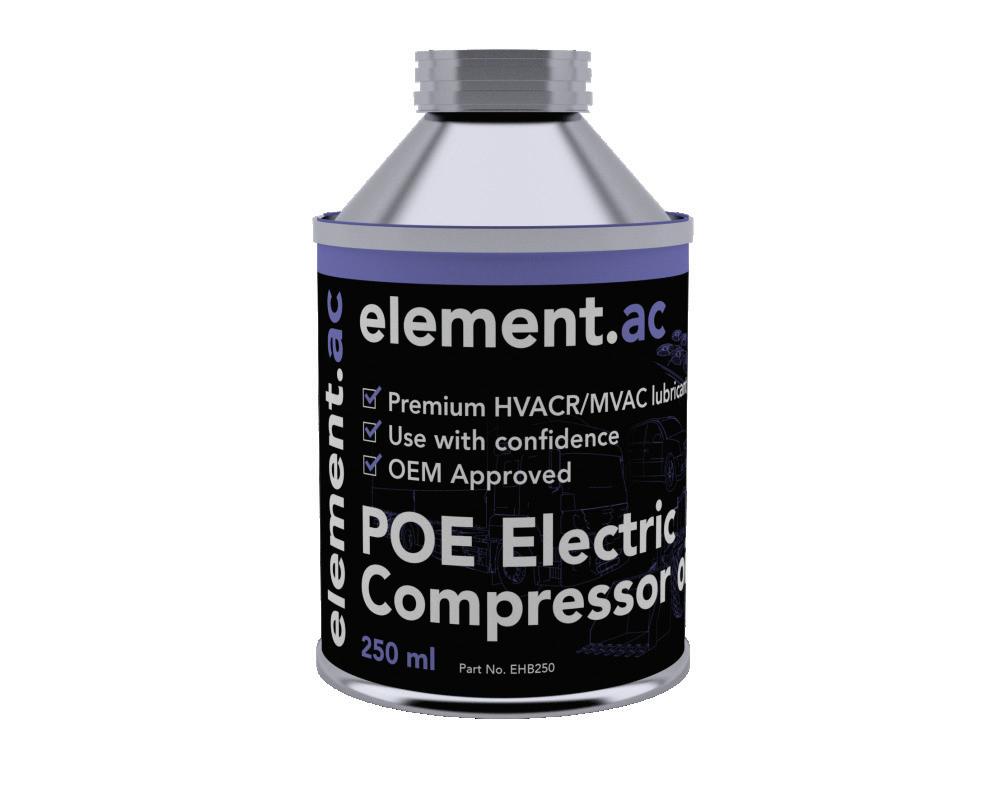

POE Electric Compressor Oil

POE Electric Compressor Oil

EHB250 is an advanced POE lubricant with special additives semi-hermetic and hermetic electric compressors used in electric and hybrid vehicles. EHB250 offers a high level of electrical resistance and corrosion protection.

EHB250 is an advanced POE lubricant with special additives for semi-hermetic and hermetic electric compressors used in electric and hybrid vehicles. EHB250 offers a high level of electrical resistance and corrosion protection.

10

No. EHB250 Size 250ml POE

Part

10 Part No. EHB250 Size 250ml POE

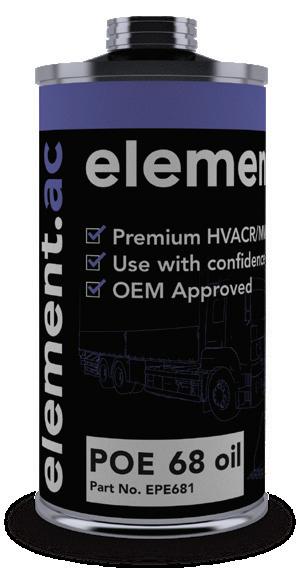

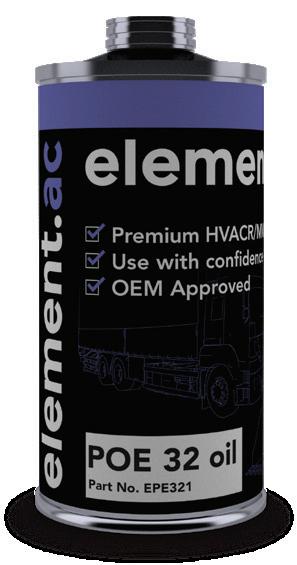

POE (Polyolester) Lubricants

POE (Polyolester) Lubricants

element.ac POE (Polyolester) oil is a premium synthetic lubricant for HFC, CFC and HCFC refrigerant applications.

element.ac POE (Polyolester) oil is a premium synthetic lubricant for HFC, CFC and HCFC refrigerant applications.

• Designed for HVAC/R professionals

• Designed for HVAC/R professionals

• Provides high efficiency in mobile and stationary HVAC/R systems

• Provides high efficiency in mobile and stationary HVAC/R systems

• Provides excellent wear protection in the demanding environment of HVAC/R compressors

• Provides excellent wear protection in the demanding environment of HVAC/R compressors

• Steel cans have the viscosity printed on the cap for instant identification

• Steel cans have the viscosity printed on the cap for instant identification

• Approved for use with Burgaflex flexible hose systems

• Approved for use with Burgaflex flexible hose systems

• Compatible with R134a, R404A, R452a, R513a, for use in high-performance HVAC/R compressors and equipment

• Compatible with R134a, R404A, R452a, R513a, for use in high-performance HVAC/R compressors and equipment

• Batch tested for consistency and quality

• Batch tested for consistency and quality

• Available in 32 and 68 viscosities

• Available in 32 and 68 viscosities

• OEM approved by Unicla

• OEM approved by Unicla

Analysis Viscosity @ 100ºC (cSt) Viscosity Index Pour Point (°C) Density @ 20°C (g/ml) Flash Point COC (°C) Acid Value (mg KOH/G) Water Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 POE 32 5.8 90–122 -46 0.977 ≥200 ≤0.02 ≤0.05 32.5 POE 68 & POE 68 Electric 9.3 90–120 -39 0.98 ≥200 ≤0.02 ≤0.05 68.5 Viscosity POE 32 POE 68 POE 68 POE 32 Part No. EPE324 EPE681 EPE684 EPE321 Size 4 Litres 1 Litre 4 Litres 1 Litre POE 12 Analysis Viscosity @ 100ºC (cSt) Viscosity Index Point (°C) @ 20°C (g/ml) Point COC (°C) Value (mg KOH/G) Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 POE 32 5.8 90–122 -46 0.977 ≥200 ≤0.02 ≤0.05 32.5 POE 68 & POE 68 Electric 9.3 90–120 -39 0.98 ≥200 ≤0.02 ≤0.05 68.5 Viscosity POE 32 POE 68 POE 68 POE 32 Part No. EPE324 EPE681 EPE684 EPE321 Size 4 Litres 1 Litre 4 Litres 1 Litre POE 12

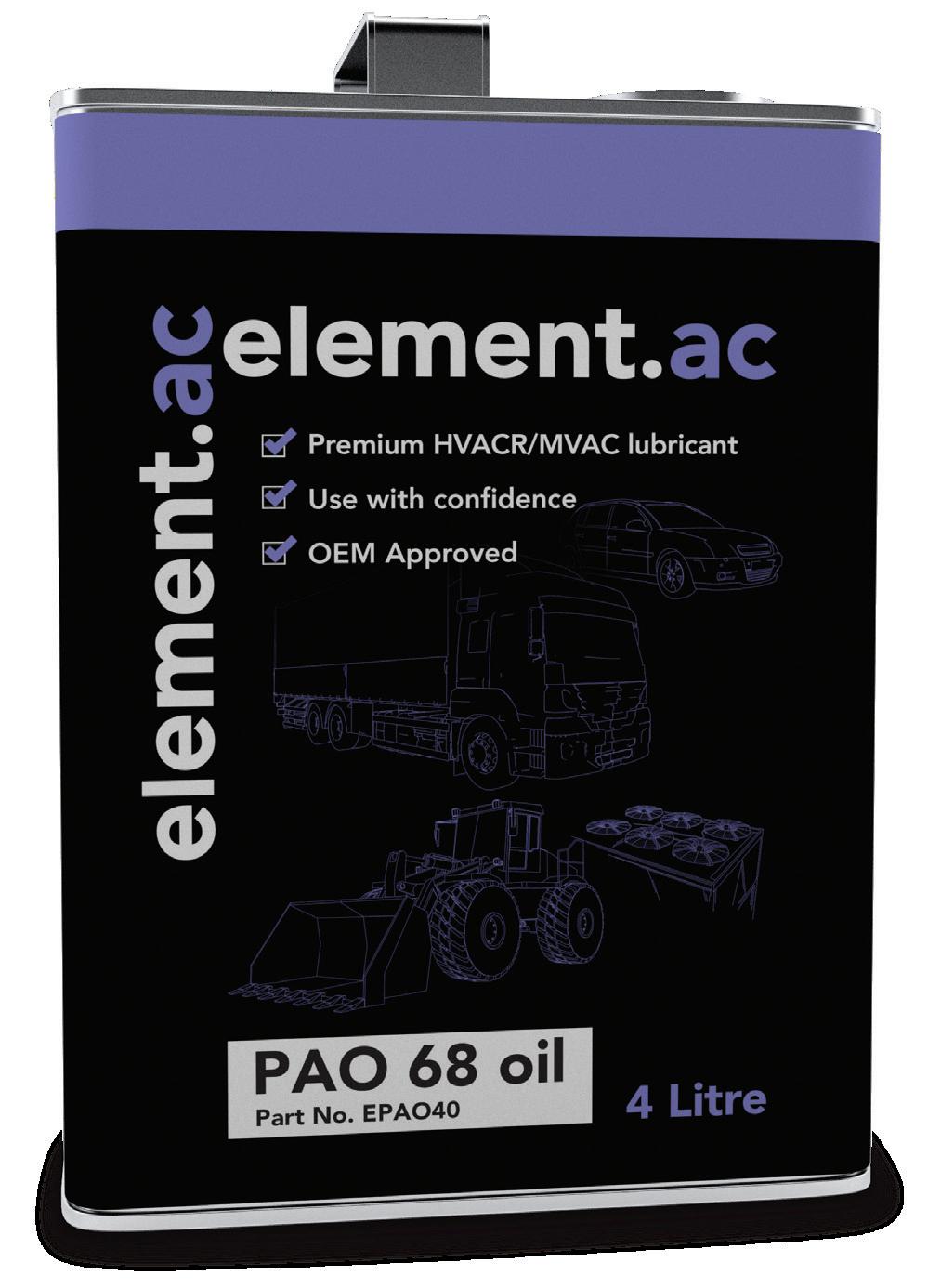

PAO (Polyalphaolefin) Lubricants

PAO (Polyalphaolefin) Lubricants

This fully synthetic lubricant is commonly used in a range of automotive and industrial applications.

This fully synthetic lubricant is commonly used in a range of automotive and industrial applications.

• Designed for mobile A/C and industrial users, to be used as a premium universal compressor oil in aftermarket applications

• Designed for mobile A/C and industrial users, to be used as a premium universal compressor oil in aftermarket applications

• Compatible with mineral oils and offers high performance at low temperatures

• Compatible with mineral oils and offers high performance at low temperatures

• Steel cans with the viscosity printed on the cap for instant identification

• Steel cans with the viscosity printed on the cap for instant identification

• Approved by Burgaflex flexible hose systems

• Approved by Burgaflex flexible hose systems

• Low volatility and oxidative stability

• Low volatility and oxidative stability

• Available with or without UV dye

• Available with or without UV dye

13

Analysis Viscosity @ 100ºC (cSt) Viscosity Index Pour Point (°C) Density @ 20°C (g/ml) Flash Point COC (°C) Acid Value (mg KOH/G) Water Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 PAO68 & PAO68UV 7–8 130–140 ≤-50 0.83–0.86 ≥200 ≤0.05 ≤0.03 61–74

PAO 68 PAO 68 (with UV dye) PAO 68 Part No. EPAO40 EPAO1U EPAO10 Size 4 Litres 1 Litre 1 Litre PAO 14 Analysis Viscosity @ 100ºC (cSt) Viscosity Index Point (°C) @ 20°C (g/ml) Point COC (°C) Value (mg KOH/G) Content Viscosity @ 40ºC (cSt) Method ASTM D445 ASTM D2270 ASTM 97 ASTM D1298 ASTM D92 ASTM D664 wt% ASTM D445 PAO68 & PAO68UV 7–8 130–140 ≤-50 0.83–0.86 ≥200 ≤0.05 ≤0.03 61–74 Viscosity PAO 68 PAO 68 (with UV dye) PAO 68 Part No. EPAO40 EPAO1U EPAO10 Size 4 Litres 1 Litre 1 Litre PAO 14

Viscosity

element.ac Your new best friend. Distributed by: SuperCool Group of Companies Phone: +61 5549 4000 Technical Support: 1800 628 133 Website: www.supercool.group Cat No. U-ELE-BKT-2201v1

by:

Approved