SEPTEMBER / OCTOBER 2023 R39.90 (incl VAT) International R44.50 (excl tax) SADC’s rare earths revival JA Engineering’s Team (from left): Mbulelo Nkasana, Business Development, Sales & Marketing Director Matimba Mahange, CEO Rachel Babie, Supply Chain, Procurement & Logistics Director 70%: phosphates imported into SA 20 000t p/a: Kinusi copper production JA ENGINEERING Meeting mining equipment demands MIN NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za INSIDE: Phosphate mining and sustainability

IN BRIEF

6 Unlocking the full potential of robotic applications with high-performance abrasives.

FEATURES

14 Should we legalise zama zamas?

It has been suggested that zama zamas should be viewed as artisanal miners, something that could result in a boost to SA’s economy.

19 Tracing value by minimising mining waste

Taking a look at how gold mining companies can scramble through waste to track hidden value in raw gold hiding in those rocks initially declared waste.

22 SADC’s rare earths revival

Looking into three key projects focusing on producing/ exporting commodities such as lithium, tantalum, graphite, cobalt, rare earths, copper and nickel.

25 Joburg Indaba

The Joburg Indaba is here, and will feature topics such as geopolitical and macro-economic developments, ESG considerations, energy security, and decarbonisation e orts.

28 Can phosphate mining be done sustainably?

Considering the e orts mines should make to minimise the ecological damage of phosphate mining, and ensure the industry remains sustainable.

22 20 000t p/a: Kinusi copper production

28 70%: phosphates imported into SA

REGULARS

4 Out of Africa

Business Spotlight – Enaex Africa’s plans to embrace artificial intelligence

Gary Alfonso speaks to CEO of Enaex Africa, Francisco Baudrand, about the company’s plans to embrace artificial intelligence, while also looking into incorporating sustainability within the organisation’s strategic objective.

https://youtu.be/2U0RMa_6bko

www.samining.co.za or www.businessmediamags.co.za

www.linkedin.com/company/samining/ businessmediamags.co.za/mining/sa-mining/subscribe/

www.facebook.com/businessmediaMAGS/company/samining/

CONTENTS SEPTEMBER / OCTOBER 2023 14

SEPTEMBER OCTOBER 2023 R39.90 (incl VAT) International R44.50 (excl tax) SADC’s rare earths revival JA Engineering’s Team (from left): Mbulelo Nkasana, Business Development, Sales & Marketing Director Matimba Mahange, CEO Rachel Babie, Supply Chain, Procurement & Logistics Director 70%: phosphates imported into SA 20 000t p/a: Kinusi copper production JA ENGINEERING Meeting mining equipment demands MIN NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za INSIDE: Phosphate mining and sustainability COVER STORY: PAGE 8 Local design and manufacture of OEM mining equipment and a er-market parts helps JA Engineering meet the demands of underground and opencast mines.

New approaches to the zama zama challenge.

NEWS IN NUMBERS

twitter.com/BMMagazines

19 22

rare earths

Optimising value by minimising mining waste. WATCH:

www.instagram.com/business_media_mags/

SADC’s

revival.

IN CASE YOU MISSED OUR INTERVIEW!

SCAN HERE

FROM ZAMA ZAMAS TO SUSTAINABILITY

Rodney Weidemann

Illegal artisanal miners – or zama zamas – have been in the news recently due to the impacts of their activities. Although their impacts are diverse and virtually all negative, the Artisanal and Small-Scale Mining Policy 2022 seeks to change this.

It has been suggested that zama zamas should be seen as artisanal miners, and that established mining companies should seek to work with the zama zamas by making them part of their operations, thereby bringing them into the formal economy. While there are many challenges with this proposal, it could conceivably result in a significant increase in the contribution of the junior mining sector to the South African economy.

Elsewhere, Marula Mining, a battery metals investment and exploration company, has three key projects under way in the Southern African Development Community region. All are focused on producing and exporting high-value commodities such as lithium, tantalum, graphite, cobalt, rare earths, copper and nickel – essential minerals of strategic importance to modern technologies and the global economy.

These projects – Blesberg Lithium and Tantalum Mine in South Africa, Nkombwa Hill Project in Zambia, and Kinusi Copper Mine in Tanzania – are expected to not only have a significant impact on the renewable energy sector, but a positive impact on the communities surrounding these projects.

We are aware that one of the inherent contributing factors in excessive mineral loss through waste is due to outdated mineral testing methods of the materials extracted during the mining process. In this issue, we take a look at how gold mining companies can scramble through waste to track hidden value in raw gold hiding in those rocks initially declared waste.

Although phosphate mining is considered essential for global agriculture and the role it plays

in food security, it is a mineral extraction process that can easily cause massive environmental damage. We take a look at the methods being used to make this more sustainable. From the responsible management of water resources to reducing chemical usage and developing cleaner extraction and processing technologies, we look at the various e orts being made to make phosphate mining safer and more environmentally friendly. Ensuring miners in remote areas have access to fresh water is critical, and we consider how this is achieved and why it is of such crucial importance. In addition, we look more deeply into the complex and at times risky challenges faced when undertaking sha sinking.

In a unique case study, we look at how Mammoet recently conducted the move of a several hundred tonne face shovel excavator between Kromdraai and Emalahleni – dealing with infrastructure challenges like fragile road surfaces and potholes.

EDITOR

Rodney Weidemann

Tel: 062 447 7803

Email: rodneyw@samining.co.za

ONLINE EDITOR

Stacey Visser

Email: vissers@businessmediamags.co.za

ART DIRECTOR

Shailendra Bhagwandin

Tel: 011 280 5946

Email: bhagwandinsh@arena.africa

ADVERTISING CONSULTANTS

Ilonka Moolman

Tel: 011 280 3120

Email: moolmani@samining.co.za

Tshepo Monyamane

Tel: 011 280 3110

Email: tshepom@samining.co.za

PRODUCTION CO-ORDINATOR

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

SUB-EDITOR

Andrea Bryce

BUSINESS MANAGER

Claire Morgan

Tel: 011 280 5783

Email: morganc@sahomeowner.co.za

GENERAL MANAGER MAGAZINES

Jocelyne Bayer

SWITCHBOARD

Tel: 011 280 3000

SUBSCRIPTIONS

Neesha Klaaste

Tel: 011 280 5063

Email: neeshak@sahomeowner.co.za

energy supply security, and

The Joburg Indaba is around the corner once again, and the upcoming event will feature topics such as geopolitical and macro-economic developments, collaboration between industry and government, the energy transition and its critical metals and minerals, and innovation and digital transformation. Highlights will also include a focus on environmental, social and corporate governance considerations, energy supply security, and decarbonisation e orts within mining operations.

Finally, in our cover story, we talk to JA Engineering – now in its fourth decade of operations – to find out how its local design and manufacture of OEM mining equipment and a er-market parts, as well as its strong refurbishment capabilities, meet the varied demands of underground and opencast mines.

Gary Alfonso speaks to CEO of Enaex Africa, Francisco Baudrand, about the company’s plans to embrace artificial intelligence, while also looking into incorporating sustainability within the organisation’s strategic objective. https://youtu.be/2U0RMa_6bko

PRINTING

CTP Printers, Cape Town

PUBLISHER

Arena Holdings (Pty) Ltd, PO Box 1746, Saxonwold, 2132

Copyright Arena Holdings (Pty) Ltd. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic or mechanical, without prior written permission. Arena Holdings (Pty) Ltd is not responsible for the views of its contributors.

www.samining.co.za 2 SA MINING SEPTEMBER / OCTOBER 2023 FROM THE EDITOR

NG READ WHAT REALLY GOES DOWN IN SADC SA www.samining.co.za

MIN

WATCH: Business Spotlight – Enaex Africa’s plans to embrace artificial intelligence IN CASE YOU MISSED OUR INTERVIEW!

Efficient mining. Fleet and Driver Services Workshop Services Finance and Services Haul 39 For more information contact us on: 087 286 6707 zaMarketing.Communications@scania.com Time for smarter solutions. With our extensive Lean Production experience, tailored mining solutions, we’ll give you everything you need to optimise your production flow and drive efficiencies across your chain. Together with the world’s most sustainable transport fleet and an industry-leading total cost of ownership, we can cut your emissions like no one else can. The future of safe, productive, and sustainable mining operations begins with Scania.

AfCFTA

A DRIVING FORCE FOR TRANSPORT AND LOGISTICS IN AFRICA

The African Continental Free Trade Area (AfCFTA) envisions a borderless Africa, removing barriers to trade and investment by eliminating tari s on most goods, harmonising customs procedures, encouraging entrepreneurship and foreign investment, and promoting the free movement of people and capital.

From e icient road networks and modern rail systems to well-performing port facilities and streamlined air transportation, transport and logistics are the catalyst for sustainable, cross-border exchange and economic development, and have a pivotal role to play in the success of the AfCFTA.

During a recent online panel discussion involving key players in the AfCFTA talks, various challenges and opportunities were placed high on the agenda and will be unpacked at various trade shows during this year.

Beatrice Chaytor, head of Division –Trade in Services of the AfCFTA Secretariat in Ghana, believes once the free trade agreement is fully implemented, tra ic routes across air, ports, rail and road travel will improve.

“There are significant opportunities for investors in vital infrastructure like airports, warehousing, cold storage and more, and with tourism on the continent back to 88% of pre-pandemic levels for the first quarter

of the year, ensuring a robust and reliable transport and logistics system across the continent makes good business sense.”

She says 46 out of 54 African countries have signed the AfCFTA, and governments now need to embrace this commitment and regulations must follow. Transport and logistics will be prioritised to be “liberalised” under the AfCFTA, with developments expected in the coming months.

improved transport and logistics will boost job creation and reduce poverty, among other benefits.

“Accessibility, connectivity, productivity, capacity and predictability matter. The faster people can move around, the more the African economy can progress,” he says. He suggests that breaking down silos in government and working together will drive greater progress. “This is because digitisation is also important to boost global access.”

Bowale Odumade, VP at Africa Finance Corporation, agrees, as nearly 30% of African countries are landlocked, so “we need to remove cross-border constraints. All stakeholders must come together for the common good.”

In particular, she highlights the challenges in successfully financing African infrastructure projects, due to the current costly and lengthy processes involved.

John Bosco Kalisa, an economist and East African Business Council (EABC) executive director, agrees that transport and logistics are enablers of the AfCFTA, and says intraAfrica trade is currently at 17%. “Intracontinental trade in Africa could reach 81% by 2035,” he says.

Furthermore, notes Andrew Othieno from Uganda’s Prime Minister’s Delivery Unit,

The panellists further agreed that without partnerships and the private sector’s support, it would be di icult to take infrastructure projects forward. Dr Christian Kingombe, a consultant trade, transit and transport expert from Geneva, says 75% of the product cost in Africa goes into logistics, whereas this cost only accounts for 7% of products in the United States.

“If we reduce trade barriers and costs, and stamp out corruption, we will see significant results,” he says.

www.samining.co.za 4 SA MINING SEPTEMBER / OCTOBER 2023 OUT OF AFRICA

Improved transport and logistics in Africa have immense potential to realise the vision of the African Continental Free Trade Area

“ “

Accessibility, connectivity, productivity, capacity and predictability matter. The faster people can move around, the more the African economy can progress.

–

Othieno

© ISTOCK –thitivong

UNLOCKING THE FULL POTENTIAL OF ROBOTIC APPLICATIONS

WITH HIGH-PERFORMANCE ABRASIVES

The use of robotics in manufacturing continues to grow at a rapid rate as businesses invest in automation to remain competitive. A shortage of skilled labour and a shi towards low-margin, highvolume models are fuelling this need to automate.

However, while more and more manufacturers are investing in robotic applications, many are not realising the full benefits of the technology, including increased productivity, improved quality, better e iciencies, and cost savings, because they are failing to pair the technology with equally high-performing consumables.

According to the latest World Robotics Report, the top five industries for robotic adoption include electronics, automotive, metal and machinery, plastic and chemicals, as well as the food industry.

Technological advancements and the proliferation of robot technologies mean that robots are more cost-e ective and easier to use than ever before. Given their ability to work alongside humans and perform complementary tasks, collaborative robots (cobots) have ensured that robotic technology is within reach even for smaller businesses.

The advantage of robotic applications is that they improve the overall e iciency and e ectiveness of the manufacturing process by reducing manual work and delivering consistent results in shorter cycles. When choosing a robot, the most suitable is the one that can achieve productivity gains and meet the technical requirements of the application. Other considerations are safety, space utilisation, upfront investment and a er-sales support.

The types of processes that are suitable for automation in the industrial sector are repetitive tasks that require precise movements, consistent accuracy, and tasks that are too dangerous or strenuous for humans to complete. Selecting the most appropriate robot for an industrial application requires weighing up di erent attributes and criteria.

implementing robotic applications, it’s crucial to pair this high-performance equipment with equally high-performing consumables if the aim is to optimise processes, reduce costs and improve overall operational e iciency.

“One of the biggest mistakes businesses make is that they combine a high-performing robot asset with sub-standard consumables, making it harder for the asset to reach its full potential and deliver repeatable e iciencies.”

A key benefit of robotic and automated processes is consistency. Surface finishes, for example, are reproducible by programming the robot with the same parameters repeatedly. Phillips explains that when a sub-standard abrasive is incorporated, the robot will be incapable of producing this consistency.

“This is because sub-standard or low-cost consumables don’t go through the stringent manufacturing processes and quality controls as, for instance, PFERD’s abrasives do,” he says. These are used in a variety of robotic applications, including milling, cutting, grinding, brushing and polishing processes, he says.

Typically, the selection criteria will be based on application, reach, payload capacity, number of axes, precision, repeatability and mounting position, among others, all of which need to be weighed up against production demands, manufacturing systems design and economic impact.

Dennis Phillips, national sales manager at PFERD-South Africa, reveals that when

Every production manager’s worst nightmare is unscheduled downtime, which is why robots must be relatively easy to operate, repair and maintain. One of the consequences of incorporating sub-standard or incorrect consumables is decreased productivity.

“If the robot is paired with the incorrect consumables, downtime will increase due to the low or reduced service life of standard products resulting in regular stoppages to change out the used consumables. This can massively impact the equipment’s output,” says Phillips.

www.samining.co.za 6 SA MINING SEPTEMBER / OCTOBER 2023 IN BRIEF

It’s crucial to pair this high-performance equipment with equally highperforming consumables if the aim is to optimise processes, reduce costs and improve overall operational e iciency.

– Phillips

“ “

WE CAN HANDLE THE PRESSURE. GUARANTEED.

CRAFTING A REPUTATION

FOR EXCELLENCE

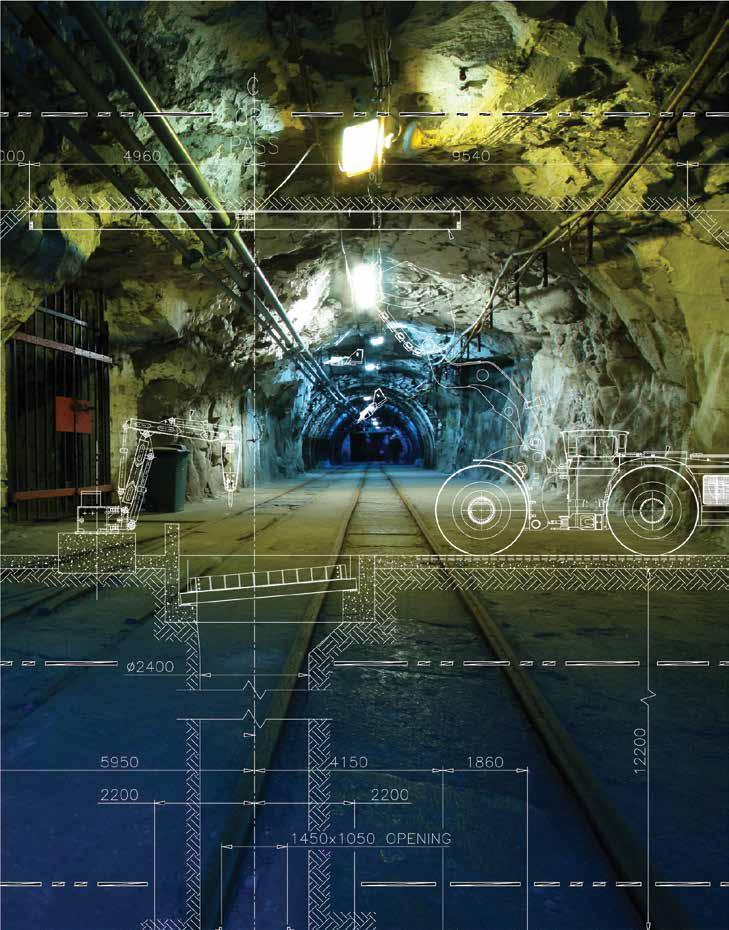

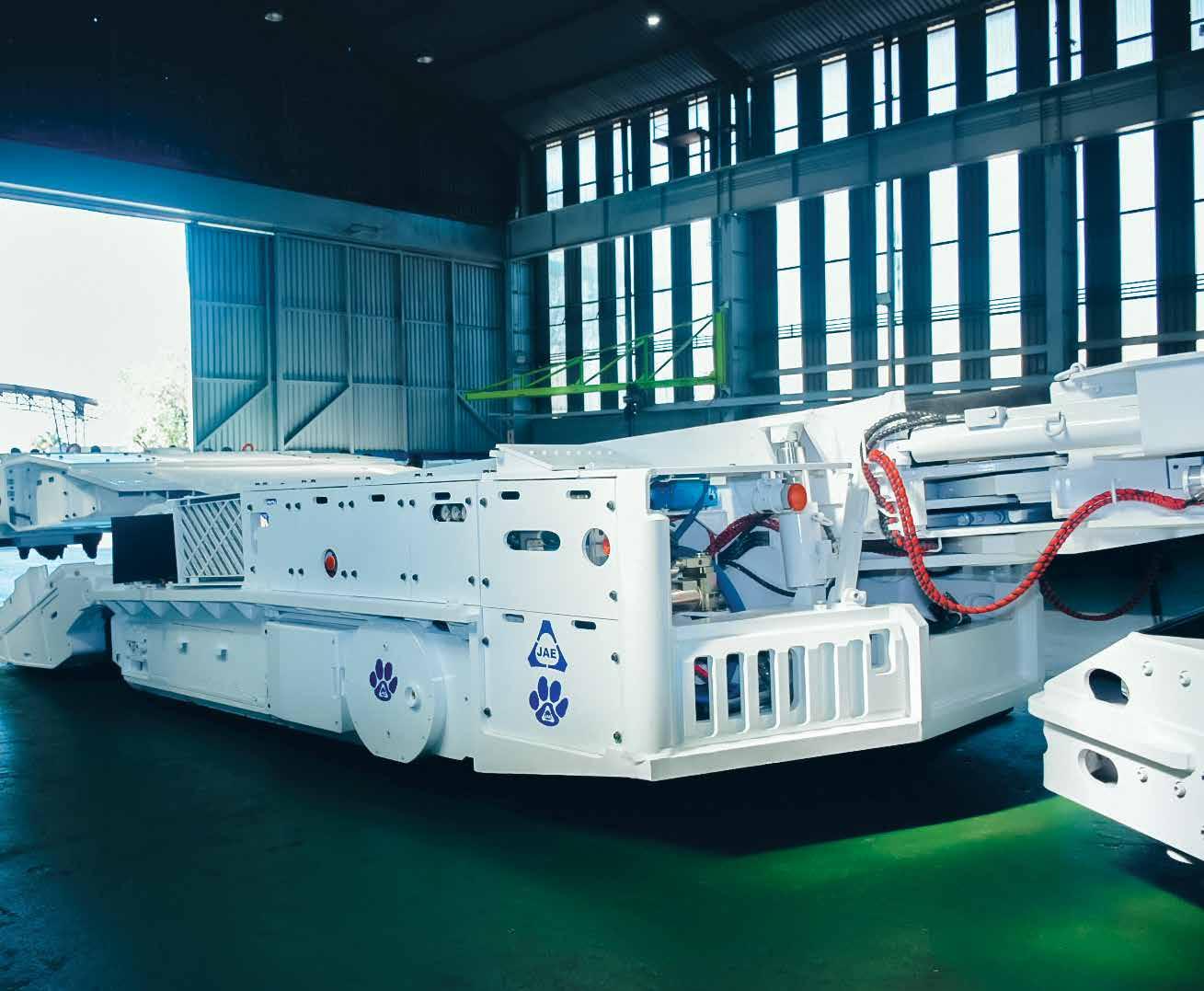

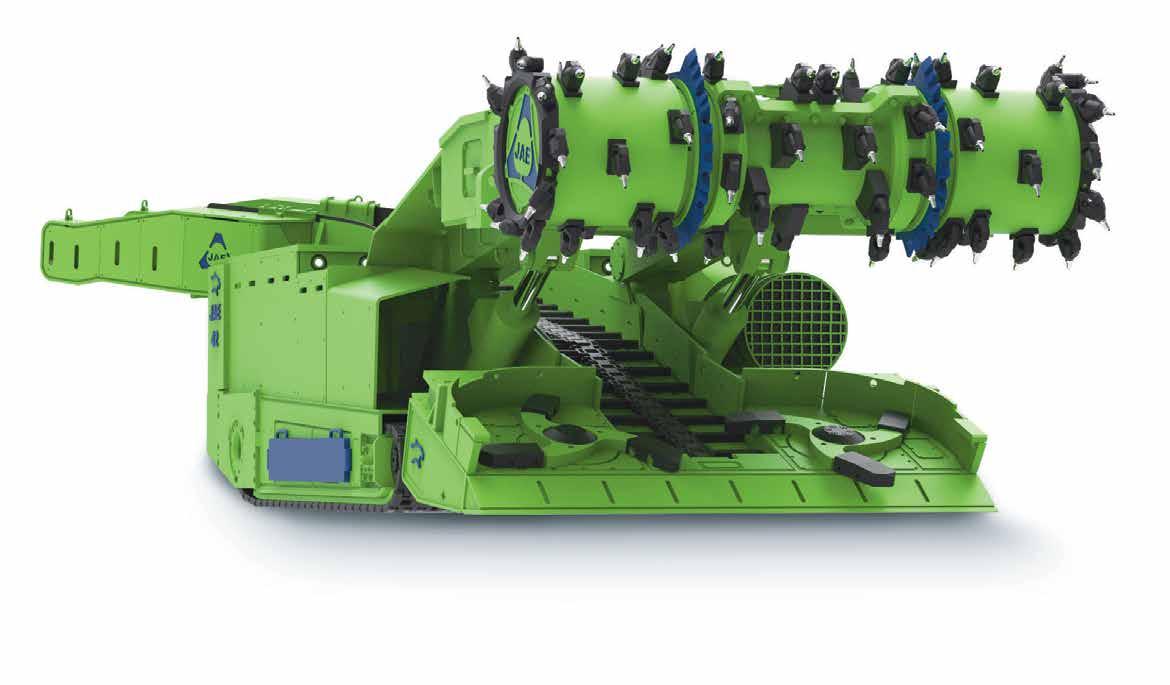

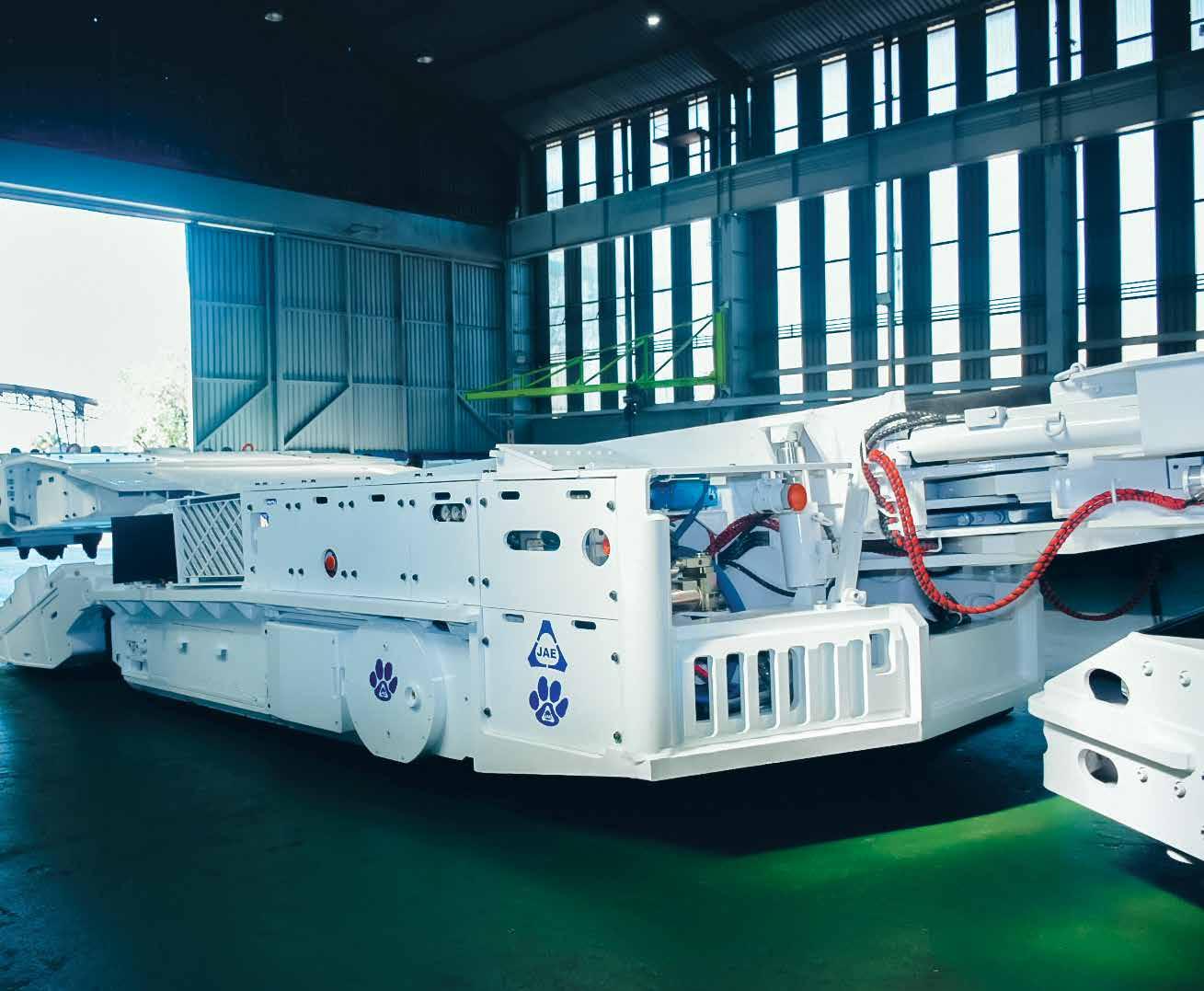

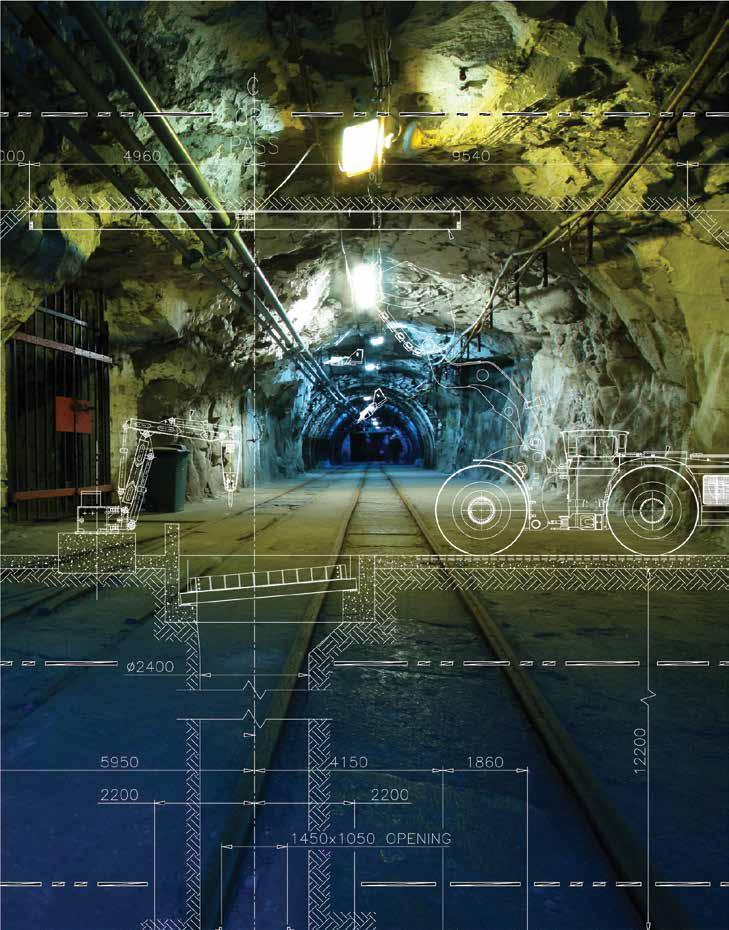

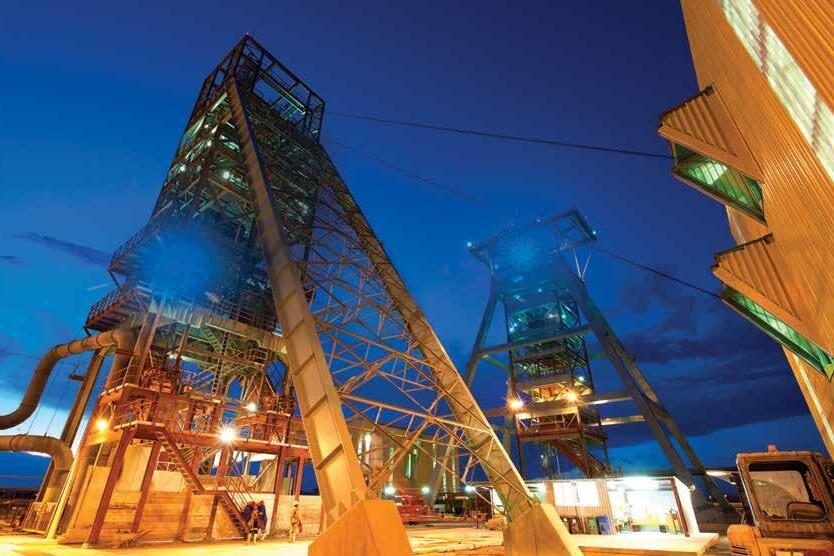

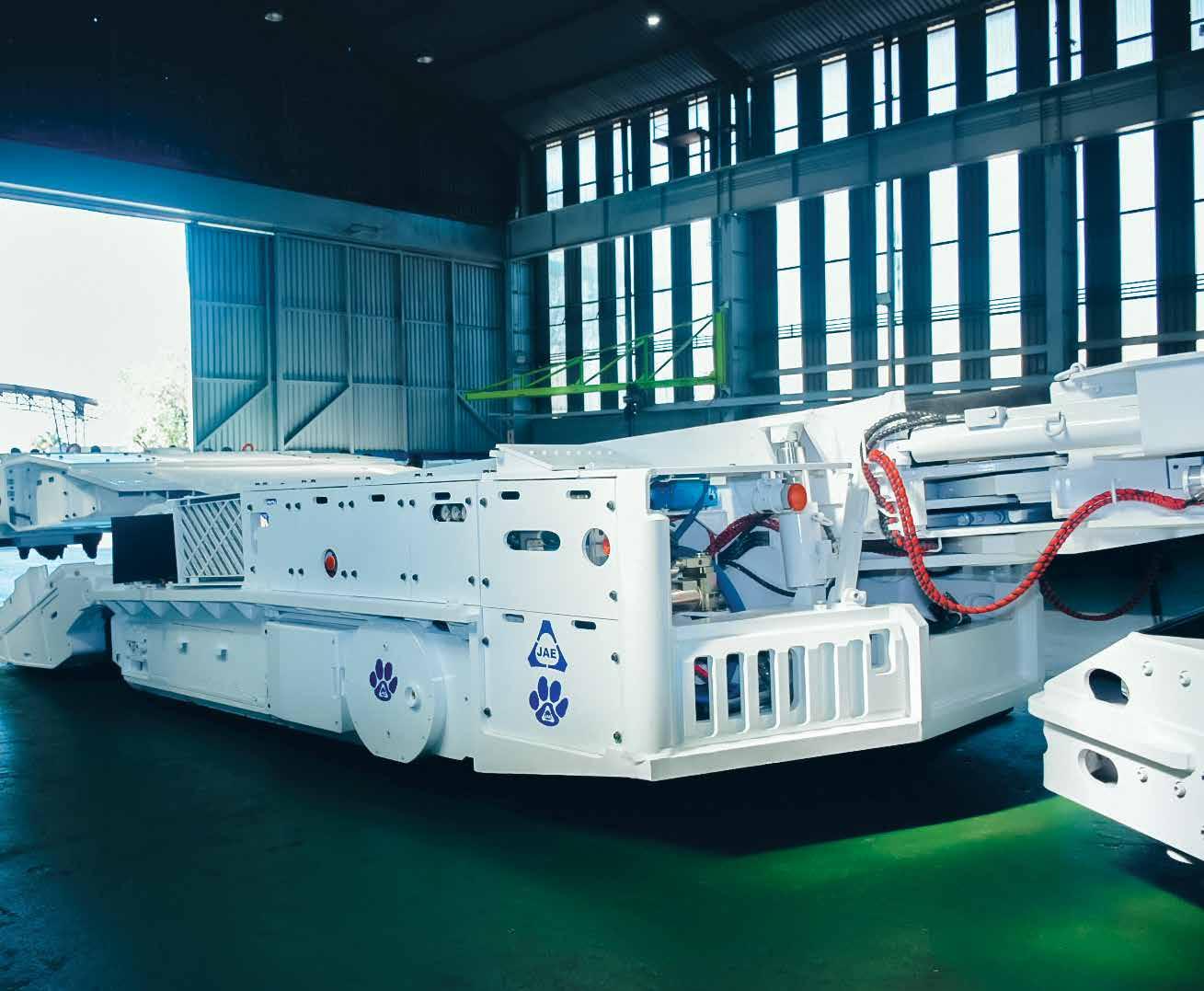

Established in 1987 by the Alexander family, as a way to provide the South African mining industry with alternative a er-market support through exceptional reverse engineering solutions, JA Engineering continues to design and manufacture hitech, sophisticated machines for the mining industry.

JA Engineering CEO Matimba Mahange says the company’s original equipment manufacturer (OEM) products, as well as its refurbishment capabilities, cover both underground and opencast mining.

Looking firstly at underground mining, Mahange says that in this space, the company designs and manufactures OEM mining equipment predominantly for the coal mining sector.

“The products we market and supply include continuous miners, roof bolters, shuttle cars, battery scoops and feeder breakers. This equipment is used by our customers for the mechanised mining of coal underground. We also have the capability to refurbish equipment and components for both coal and hard rock mining equipment,

even if this comes from other OEMs,” he says.

“Moreover, we are able to do this at a competitive price point, while meeting our inherent high-quality standards.”

From an opencast mining perspective, Mahange notes that JA Engineering has invested in capabilities to repair equipment and components from a variety of other OEMs. Successful refurbishments include everything from drills to surface truck major components, dozer components, dragline shutdown repair work and shovel repair work.

NEW FACILITY

“As a company, we have grown organically over the years, to the point where the business now employs more than 260 people and designs and manufactures equipment for both local and international customers.

“Today the business prides itself on being recognised as a multinational engineering solutions provider. To this end, we can reference customers in India, Australia and across Southern Africa.”

JA Engineering designs, manufactures and distributes both its equipment and a er-

market parts at its new plant in Boksburg, Gauteng. He says the facility, which measures approximately 20 000m2 under its roof, stands on a property some three times that size (60 000m2).

“It is worth mentioning that our extensive repair and rebuild capability includes electrical and mechanical repairs to surface mining blasthole drills, rope shovels, walking draglines and underground mining equipment that encompasses everything from continuous miners and battery scoops to haulage systems, feeder breakers and roof bolters.

“The business has always concentrated on building its reputation on quality, with a deep focus on manufacturing excellence and being the go-to engineering solutions provider. This is the core of the business, and JA Engineering has invested significantly in relevant technologies. We remain extremely proud of the fact that we are a mining supplier that designs and manufactures all its products within South Africa,” says Mahange.

He says the main reason for the shi to the big new property is that the business

www.samining.co.za 8 SA MINING SEPTEMBER / OCTOBER 2023 ENGINEERING COVER STORY

JA Engineering meets the varied demands of underground and opencast mines through the local design and manufacture of OEM mining equipment and after-market parts

JAE 38 Wildcub manufactured and shipped o to India.

The JAE Experience Our Product. Our Service. Safety. Quality. Performance. JA Engineering Works (Pty) Ltd Increased Capacity | Surface Mining Support | Underground Mining | Design Support + 27 11 397 3237 | www.jae.co.za JAE Advanced Technology Fleet Visit us at our new premises: 60 Atlas Road, Boksburg Innovative Engineering Solutions

has managed to double in size, almost every four years.

“Our previous facility was situated in Jet Park, Boksburg, and had grown to a point where it could no longer accommodate the additional demand. We also had a limited number of cranes, which impacted on the size of repair work we could undertake. Furthermore, our product line has expanded, as more customers gain confidence in the productivity and quality of our products,” he says.

To complement the new facility, JA Engineering has invested in a new boring mill, as well as a five-axis computer numerical control machine to increase its machining capabilities.

“We have also invested in new jigs and fixtures to improve our productivity and quality, and even our electrical panels department is able to wire more panels per month than we were able to in Jet Park. Finally, our electrical technology lab is also being upgraded with the move.”

Core to the company’s growth strategy, he says, is the ability to attract the best talent in the industry. This has been possible due

to the organisation’s investment in creating the right culture and environment – one where talent can truly flourish.

INTERNATIONAL PROJECTS, TOP TALENT

“The heart of our business lies in engineering design skills, coupled with high-quality local manufacturing capability. In order to achieve this, we focus strongly on attracting topcalibre design engineers, artisans and other support technology capabilities, and we also invest in continuous training, so that our talent remains globally competitive.”

Having recently hosted an open day –where the business showcased a continuous miner, roof bolter, feeder-breaker and shuttle cars, all of which were destined for a customer in India – JA Engineering took over 100 visitors through the new facility.

“This enabled us to display and demonstrate our capabilities, including the high-quality standards we adhere to. Clearly it was a success, since we are now in the process of finalising another contract, for similar equipment, for a new customer in India.”

Other key international projects that have occurred in the past two years include the export of parts, components and equipment to Australia, to the value of R80-million.

“Looking at the interest we are receiving from abroad, it is clear that there is a growing demand for our products and services, on a global scale. JA Engineering plans to invite more stakeholders to its facility, as and when it is about to deliver significant equipment.”

He says the business currently has four shuttle cars in final assembly, which are destined for Australia. He says the company welcomes customers to come and see the massive new facility, particularly as more than 80% of the content used in manufacturing at the site is local.

“Ultimately JA Engineering is an entity that is 100% black-owned, and describes itself as being proudly South African. We are proud to be able to o er the kind of capabilities that attract the export market, while at the same time, we have a unique South African capability that we believe will be pivotal to the industrialisation of Africa,” says Mahange.

www.samining.co.za 10 SA MINING SEPTEMBER / OCTOBER 2023

“ “ KEY PRODUCTS SUPPLIED ■ Continuous miners ■ Roof bolters ■ Shuttle cars ■ Battery scoops ■ Feeder breakers

Our extensive repair and rebuild capability includes electrical and mechanical repairs to everything from rope shovels to underground mining equipment. – Mahange

JAE 42 Wildcat manufactured by JAE and launched in 2016.

JAE Battery Scoop delivered in 2023.

Shuttle car fleet.

Training unlocks performance

In our business, the machines do the heavy work. But it’s the people operating and maintaining them where real performance and safety lie. Invest in your most valuable asset with Komatsu training programs: online, at your OE partner, at your site.

© 2023 Komatsu Ltd. or one of its subsidiaries. All rights reserved.

12 Commercial Road, Wadeville, Germiston | Tel. +27 11 872 4000

THE CASE FOR NEMLA SECTION 24G

Of the many changes made to the National Environmental Management Act, 1998 (NEMA) by the National Environmental Management Laws Amendment Act, 2022 (NEMLAA4), the amendment of section 24G is notable.

This particular section provides for the retrospective authorisation for the commencement of a listed or specified activity without an environmental authorisation, or the commencement, undertaking or conducting of a waste management activity without a waste management licence – collectively referred to as “unauthorised activity”.

According to Luca Maraschin, an associate in the mining and environmental team at NSDV, there are numerous specific listed activities under these environmental regulations that require authorisation that must be preceded by an environmental impact assessment (EIA) process. He says section 24G was introduced for those cases where one of these activities was undertaken without having the requisite environmental authorisation or waste management licence.

Luca Maraschin Associate NSDV

the unauthorised activity to cease this until the application is finalised.

“Both the increased fine and the fact of making it mandatory for the activity to cease are great deterrents, because the situation has now changed for a company undertaking any unauthorised activity – not only has the fine doubled, but they will also be obliged to immediately stop the process.

“Think about this in the context of, for example, an organisation building a solar plant for a mine, but doing so without authorisation. Not only will the fine itself hurt, but having to stop in the middle of such a project will impact everything from labour to timelines to project budgets.”

Of course, he adds, the first change is also beneficial, in that it allows the property owner or a new mining right holder, who is conducting activities on property where an unauthorised activity took place, to apply for a section 24G, even if the original party that began the unauthorised activity is no longer involved in the mine, or has refused to undertake the process themselves.

“In the past, if an entity did this, it could, ex post facto, apply for authorisation and list the activities that were undertaken without authorisation, then by paying a fine – up to a maximum of R5-million – be brought back into compliance.

“Concerns were raised about companies using this regulation cynically, adopting the principle of ‘it’s better to ask forgiveness than permission’, and also that the size of the maximum fine was not large enough.”

Maraschin adds that the amendment by NEMLAA4 is interesting, as firstly it e ectively allows the owner, or person in control of the property – as opposed to just the entity with the mining right and conducting the unauthorised activity – to apply for a section 24G to obtain the relevant authorisation. He notes too that the administrative fine has also been increased to R10m, while the competent authority must further direct the applicant undertaking

“So for example, if mining house X is mining on the property, and someone else purchases either the right or the property, the purchaser can undertake a 24G to fix an unauthorised activity undertaken by the previous owner.”

He notes that there is an additional implication for entities considering purchasing property, or allowing further activities to happen on their properties.

“If mining house X wants to sell their mine to me, the first thing I must ensure is that I won’t have to undertake a section 24G in the future. Perhaps the key takeaway here is that this highlights the need for really thorough due diligence to be undertaken, before making such a purchase.

“Ultimately, this demonstrates the importance of planning ahead, of checking all the fine print, and recognising the importance of engaging a legal specialist to help determine whether any previous – or future – projects will trigger any of the NEMAlisted activities,” says Maraschin.

www.samining.co.za 12 SA MINING SEPTEMBER / OCTOBER 2023 COLUMN FINANCE & LEGAL

© ISTOCK –Bilanol

The views expressed are the author’s own and do not necessarily reflect SA Mining’s editorial policy.

The amendments to NEMLA section 24G offer both better deterrents to unlawful operations than before, and an improved manner to achieve such compliance

Concerns were raised about companies using this regulation cynically, adopting the principle of ‘it’s better to ask forgiveness than permission’. – Maraschin

“ “

NEW APPROACHES

TO THE ZAMA ZAMA CHALLENGE

By the Junior Mining Council’s Dr Andries van der Linde PhD (UH, UK)

By the Junior Mining Council’s Dr Andries van der Linde PhD (UH, UK)

Although the term “junior mining” is not unique to South Africa, the country is unique in several ways. The Minerals Council South Africa defines junior miners as producers having an annual turnover below R500-million per annum, which di ers from the Department of Mineral Resources and Energy’s measurement of R150m per annum.

Grouped with junior mining but recognised as a grouping with unique challenges are the “emerging miners”. This is a term indigenous to South Africa, and typically refers to small mining companies or micro-enterprises. It encompasses a diverse group of mining and mining-related entities, including prospecting and smaller producer companies and contractors.

An additional grouping that has been in the limelight for all the wrong reasons are known as “artisanal miners”, known colloquially as zama zamas. This refers to illegal mining in the informal sector, usually by individuals, groups, families, or cooperatives, with minimal or no mechanisation.

Although the Minerals Development Act recognises large- and small-scale mining,

it criminalises all mining outside these categories. However, on 30 March 2022, South Africa’s Minister of Mineral Resources and Energy, Gwede Mantashe, published the Artisanal and Small-Scale Mining (ASM) Policy 2022 for implementation. Legislation is yet to be promulgated to translate the policy into a regulatory framework for implementation.

ASM POLICY

While the ASM Policy states that the ASM industry received o icial recognition following the 1994 democratic elections, no mention was made of artisanal mining. Notably, however, the ASM Policy sets out thresholds to distinguish between artisanal and small-scale miners. These are set at maximums of R1m and R10m per annum, respectively.

It’s also interesting to note the policy’s definitions for the two. Artisanal mining is defined as traditional and customary mining operators using traditional or customary means, basic methods and manual and rudimentary tools to access ore, usually on or close to the surface. Small-scale mining is defined as prospecting activities or

operations that do not employ specialised prospecting, mechanised mining techniques, chemicals, or explosives, or prospecting or mining operations that do not exceed the maximum financial limit.

To put the junior mining sector into perspective: the mining sector contributes approximately 8% of GDP, which amounted to R1.2 trillion in 2022, and provides direct employment to roughly 500 000 people. Compared to the rest of the mining industry, the junior mining sector’s contribution of R88-billion cannot be seen as insignificant.

However, approximately 1 490 mining licences have been issued to junior mining companies, making up 80% of the mining licences issued. It is estimated that they employ up to 40 300 people directly, and considering the multiplier e ect, the job creation potential of the junior mining industry can be as high as 800 000.

It is against this backdrop that we should recognise that illegal mining activities cannot be ignored – whether you call them zama zamas or artisanal miners – because their impact is diverse and all of it negative. It is estimated that the direct loss to the economy is approximately R4bn, which was estimated

www.samining.co.za 14 SA MINING SEPTEMBER / OCTOBER 2023 FINANCE & LEGAL

The challenges posed by artisanal miners – or zama zamas – are vast. However, the Artisanal and SmallScale Mining Policy 2022 seeks to change this

©

–

ISTOCK

tifonimages

by the Minerals Council to be a total of R20bn loss to the fiscus, in lost sales, royalties, and taxes in 2016. Indirect costs to the economy can be attributed to the the of copper, steel, diesel, and other materials, resulting in an expenditure on security services.

SERIOUS CONSEQUENCES

Other than that, the negative social impact of illegal mining activities can be devastating to communities. For organised crime syndicates, illegal mining is a lucrative enterprise. In South Africa, it is o en linked to rape, murder, violence, intimidation, prostitution, child abuse, collusion in criminal activities, human tra icking, and extortion.

Unintentional consequences can be even worse, such as the deaths of at least 17 people, including the deaths of three children, when toxic gas leaked from a cylinder near Johannesburg, which emergency services attributed to illegal mining activities. Other than that, there is also a serious risk to the illegal miners themselves because of unsafe working conditions and environments, resulting in unacceptable numbers of fatalities.

Although the large-scale devastation witnessed in South America, Ghana, and the Democratic Republic of the Congo is not evident in South Africa, the negative impact on the environment in South Africa resulting from illegal mining activities is still a challenge. These include damaged pipelines leaking contaminants, sinkholes resulting from water pipe spiking, underground fires and explosions, chemical and mercury contamination, and the reopening of sealed, rehabilitated mines.

There is no doubt that the junior mining industry is a significant contributor to the South African economy. It is also true that the junior mining industry is multifaceted and that, especially with the small to medium mines, there are challenges when it comes to finance, regulatory issues, and logistics, and the smaller the operation, the bigger the challenges.

It would appear that with the ASM Policy, the minister is setting out to solve the emerging and illegal mining problem. In 2019, he expressed the intention to legalise illegal mining through the issuance of licences, and the policy seems to be the first step towards that, because an illegal miner

It is estimated that the direct loss to the economy from zama zamas is approximately R4bn, while total loss to the fiscus - in lost sales, royalties, and taxes - was estimated by the Minerals Council to be a total of R20bn.

is in fact an artisanal miner. If he can achieve this, it will result in a significant increase in the contribution of the junior mining sector to the South African economy.

Established mining companies could also play a role by working with the zama zamas and making them part of their operations, while representative bodies such as the recently established Junior Mining Council could get involved as well.

This idea may look far-fetched, but the zama zamas are here to stay, and it is the mining companies who are the ones who lose the most. On the other hand, the criminal syndicates will not easily relinquish their hold on this sector – so the question is, where to next?

www.samining.co.za SA MINING SEPTEMBER / OCTOBER 2023 15

JUNIOR MINING COUNCIL

“ “ ©

Illegal mining activities cannot be ignored, because the impact of zama zamas is diverse, and all of it negative.

ISTOCK –Paralaxis

WILL TAX INCENTIVES ENCOURAGE GREENFIELD EXPLORATION?

In April 2022, the Survey of Mining Companies 2021 was published by the Fraser Institute. In it, investors explained exactly what mineral endowments and public policy factors – such as regulatory uncertainty and taxation – impacted their decision to invest in exploration in a region. Interestingly, for most organisations of this nature, around 40% of the decision is based solely on the policy factors within their chosen country, with 60% based on the region’s mineral potential.

This is concerning for South Africa, as the country has abundant mineral resources and extensive mining experience, but this didn’t stop the nation from being ranked in the bottom 10 jurisdictions on the investment attractiveness index, says Andries Myburgh, tax executive at law firm ENS.

Even the Department of Mineral Resources and Energy (DMRE) recognises the country’s challenges here, he says. The department’s own Exploration Strategy for the Mining Industry of South Africa report outlines the strengths, weaknesses, opportunities and threats relating to mining exploration, and the strategic initiatives to encourage such exploration to take place.

“It goes without saying that one of the South African mining industry’s key strengths, as noted by the DMRE, is our numerous mineral endowments, along

with the range of such minerals. Just as obviously, the country’s weaknesses have been identified as encompassing energy instability, road and rail infrastructure challenges, and unsatisfactory policy implementation,” he says.

ENCOURAGING EXPLORATION

Myburgh points out that the DMRE wants to capitalise on the country’s mineral wealth, which is why it has described a number of strategic initiatives and actions it plans to undertake, in order to encourage mining exploration.

He explains that the vision outlined in the DMRE strategy document is to secure a minimum of a 5% share in global exploration investment within a five-year period.

“This is an admirable goal and would be an impressive and notable achievement. A er all, the country needs to massively improve its attractiveness – or at least the perceptions of its attractiveness – as a mining destination, if it hopes to achieve the desired 4% increase in its share of global exploration investment.

“Unfortunately, these weaknesses have also not gone unnoticed by investors, with exploration investment decreasing significantly over time. In fact, the exploration budget was around $400-million in 2007, but had sunk to under $100m by 2018. This means that South Africa’s share of global exploration budgets has decreased to just 1%.”

“It is fair to say that the government has recognised many of the key issues impacting the economy, and is working to fix these. Among the key issues to be focused on are rail and shipping challenges, the need for more transparency, and the cutting of red tape to make it easier to do business.”

Exploration simply must be encouraged, he adds, as it’s important to continue finding viable mineral prospects. Not only does the opening of a new mine impact the economy positively, but it also helps to create jobs in remote areas and

www.samining.co.za 16 SA MINING SEPTEMBER / OCTOBER 2023 FINANCE & LEGAL CORPORATE PROFILE

There is little doubt SA needs far more minerals exploration, but how does it achieve this?

One option is to offer better tax incentives to encourage equity finance by investors in junior exploration mining companies

One way to encourage more greenfield exploration is through the implementation of tax incentives for equity investors that fund exploration companies. © ISTOCK –cla ra

“ “

improve the overall development of the communities in the region.

However, if we wish to continue to explore, it is vital that we encourage the equity investments from businesses that are necessary to fund ongoing exploration.

“There is a theory that we can achieve this by o ering increased tax deductions for exploration – though this should be o ered to both the company doing the exploration, and the equity investor company investing in them, to enable the prospecting to be appropriately financed.

“Remember, this kind of equity investment is high risk – if they find nothing, the equity partner receives no returns, so the possibility of o ering tax breaks has instead been mooted,” says Myburgh.

TAX INCENTIVES

He says one way to encourage more greenfield exploration is through the implementation of tax incentives for equity investors that fund exploration companies. One concept that is being considered is the system of “flow-through shares” investment by equity investors.

“Basically, the way a flow-through share model works is that it allows for the

provision of equity funding by investors into those companies that carry out exploration activities, and thus incur expenditure which qualifies for a tax deduction.

“While the exploration company carries out its prospecting, it would not be deriving any income, and yet it would be accumulating deductible expenditure. With the flow-through model, these deductions are renounced by the prospector in favour of the equity investor shareholder, which can then enjoy the benefit of decreasing its tax liability as a direct result of investing in the exploration company.

“The idea is to implement a similar approach to what Canada has done, but with a definite South African flavour, which should encourage organisations to invest in and fund exploration and prospecting in the country by way of equity funding as opposed to debt funding.

“A lot of work has already been done here, including by ENS, which has been assisting on a pro bono basis, giving input from a tax perspective as to how this could work.”

He says experts suggest that o ering such tax breaks may cause some erosion to the fiscus in the short term, but this will be more than made up for by the job creation and

IMPACTING THE ECONOMY

In terms of economic improvement, economists suggest that SA’s current 1% share of exploration spend will potentially add:

■ R2.8-billion to GDP on average per year.

■ Create and/or sustain an estimated 7 700 direct and indirect jobs on average annually.

■ R740-million to total government revenue, through the collection of direct and indirect taxes.

If this share is increased to 5%, as the DMRE hopes, this will potentially generate the following economic activity:

■ Potentially add R14.2bn to GDP on average per year.

■ Create and/or sustain an estimated 38 400 direct and indirect jobs on average a year.

■ Add a potential R3.7bn to total government revenue, through the collection of direct and indirect taxes.

additional taxes that a fully implemented project will bring to the table.

“We are starting to witness a shi , with plans to implement the DMRE’s new cadastral system, and the department bringing together a working group including the JSE, Minerals Council SA, and the Council for Geoscience, to develop a fully-fledged and workable plan to increase investment in exploration.

“It is clear that there are positive signs that the right things are starting to happen. Once the cadastral system is up and running, and should these tax incentives be implemented, we will at the very least have laid the groundwork to enable SA to make the e ort to increase its share of exploration spend from 1% to 5%.”

www.samining.co.za 18 SA MINING SEPTEMBER / OCTOBER 2023 FINANCE & LEGAL CORPORATE PROFILE

“

It is fair to say that the government has recognised many of the key issues impacting the economy, and is working to fix these.

“

© ISTOCK –Nneirda

© ISTOCK –tifonimages

OPTIMISING VALUE BY

MINIMISING MINING WASTE

By Levi Letsoko

By Levi Letsoko

The gold mining sector in SA has faced numerous challenges recently, ranging from compromised investment policies and frameworks, to the scourge of illegal mining. National news feeds share a common view when describing the sector as embattled, and the sector has been put under a microscope in search of practical solutions to mitigate the lingering impact of a recovering business environment that is still trying to find its place in the post-Covid marketplace.

Based on a report published by the South African Reserve Bank, the terms of trade (including gold as the key commodity for the economy) “improved in the first quarter of 2023 as the rand price of exported goods and services increased while that of imports decreased.” These green shoots, however, can only be fully beneficial if the mining industry operates under an investor-friendly climate.

Mining companies have transparently expressed their drive to find innovations that limit indirect or method induced mineral loss from the neglected phases of the mining process. One of the inherent contributing factors in excessive mineral loss through waste is the outdated extraction methods coupled with unwavering mineral testing, processing and smelting techniques

performed on the extracted compounded material that is unearthed during the mining process.

INNOVATIVE EXTRACTION TECHNIQUES

The mining process is much more complex than merely extracting ore from the earth. It requires a lot of pre-planning and process management before setting out the actual extraction plan. In order to preserve the mined ore, it is imperative for mining operations to integrate methods that are

It makes sense for these companies to invest heavily in laboratory solutions and services in order to gain, collect and utilise the data around the cycle of damage caused by waste – in order to optimise value while minimising waste.

conscious of the need to stage practical and accurate waste reduction methods. Methods that guarantee high output in terms of extraction of ore, while minimising the damage to the immediate environment.

A proper mining process plan or design naturally prioritises accurate ore extraction from the earth, but that process is not always a seamless encounter for the operations manager. The integration of blasting agents in soliciting ore from the core of the earth makes a measured and properly managed outcome more elusive.

As a result, the process will then produce raw ore, compounded with surrounding materials, plus hydrocarbon waste, waste rock, chemical waste and tailings. Underground mining methods on their own don’t o er much in guaranteed separation of ore from surrounding material. This pushes mining processes to prioritise ore preservation by deploying means that don’t destroy the commodity.

IMPROVED ORE TESTING METHODS

As observed through industry trends and developments, innovation has blasted across the mining process design perimeters, by introducing new insights, resources and tools to help improve mineral testing processes. Usually, this step in the mining design plan is an in-house duty, as this approach allows

www.samining.co.za SA MINING SEPTEMBER / OCTOBER 2023 19 GOLD

Outdated extraction methods, mineral testing, processing and smelting techniques all contribute to excessive mineral loss through waste. Here’s how mines are starting to minimise such losses

©

© ISTOCK –

Nordroden

ISTOCK –Kakmyc

GOLD

mines to secure the commodity without external or outsourced interactions.

Major laboratories and laboratory equipment manufacturing companies have received a significant boost from the mining sector by aligning with a constant reassurance from the rising demand for innovative utility stacks.

These stacks that illustrate an understanding of what is required for appropriate testing facilities and equipment to be effective in their role in their production process. Advanced testing processes that improve the eradication of surrounding material from mined ore, while securing maximum value from the mined ore, remain an industry benchmark.

While most water and electro-chemistry inventions have broken the mould in this regard, it is imperative for mining companies to keep up with leading solutions in this regard, not only locally but internationally. PerkinElmer South Africa is a renowned geology and mining specialist, operating in numerous countries. The company has made incredible explorations in its specialised field, through research and studies conducted in observing the various mining landscapes’ physical structures, its layout and on-thesurface rocks.

In its seasonal report in the Analytical Reporter, Issue 3 of 2023, the organisation reaffirmed its commitment to advancing the insights gained through its initiatives to its client engagements when delivering the service offering.

According to PerkinElmer: “These generative and targeted explorations are deployed by the company to ascertain mining sites, accurately predicting the quantities of available ore and the concentration levels of the available commodity.”

ALTERNATIVE MEANS OF OPTIMISING VALUE

Microsep Pty (Ltd) is a South African organisation that has deployed the Fire Assay method as the accepted method for determining the amount of precious metals in metal ore. In an article published by the Analytical Reporter, Issue 3 of 2023, Microsep indicated that assay laboratories and mines, weighing regulus, lead buttons and ore samples require accurate and reliable instruments necessary to assess the amount of precious metals such as gold, silver and platinum in metal ore”.

As a result, the company has manufactured inventions that promise low repeatability (of monotonous processes) and stabilisation time, so that the weighing of precious metal samples for fire assay applications is reliable and fast. This avails specially designed funnel stacks that enable accurate weighing and testing of metal ore,

including in the smallest of samples.

In fact, for decades, the government gazette on the mineral and energy sector has highlighted the importance of having an economy that relies on mining to understand its obligation to be consistently cautious around issues of mining waste and its impact on the environment. The current legal frameworks and policies, designed to hold these companies liable for any damages occurring as a result of these mining activities, are viewed as handling mining companies with kid-gloves.

As a proposed norm, it makes sense for these companies to invest heavily in laboratory solutions and services in order to gain, collect and utilise the data around the cycle of damage caused by waste – in order to optimise value while minimising waste. More importantly, identifying the resources that can help minimise losing ore that is naturally absolved as waste.

www.samining.co.za 20 SA MINING SEPTEMBER / OCTOBER 2023 GOLD

“

“

Advanced testing processes that improve the eradication of surrounding material from mined ore, while securing maximum value from the mined ore, remains an industry benchmark.

© ISTOCK –jasonbennee

© ISTOCK –JONGHO SHIN

SADC’S RARE EARTHS REVIVAL

Marula Mining, an Africa-based battery metals investment and exploration company, has three SADC-based mines that will be key to a renewable future

By Rodney Weidemann

As the world shi s from the fossilfuel economy to a renewable future, there is a desperate need for the metals and minerals that will facilitate such a transition. This is the space Marula Mining plays in, as an Africa-based battery metals investment and exploration company.

The company’s focus is on producing and exporting high-value commodities such as lithium, tantalum, graphite, cobalt, rare earths, copper and nickel – all of which are of increasingly strategic importance to modern technologies and the global economy.

In this feature, we will take a closer look at Marula’s three key Southern African Development Community (SADC)-based projects, and their impact on both the renewable future and the mines’ surrounding communities.

NKOMBWA HILL, ZAMBIA

Unlike most of its other projects, the company currently doesn’t have a majority interest in this one, due to certain regulatory issues – although it plans just such a stake in the near future. According to CEO Jason Brewer, the project involves a major mineralised carbonate complex.

He says previous exploration has defined

a JORC 2012 Compliant Total Indicated and Inferred Mineral Resource of 21.8 million tonnes, at a grade of 7.06% P2O5 and 1.17% Total Rare Earth Oxides.

“What’s exciting is that the reported Total Mineral Resource was defined on an area of less than 5% of the Nkombwa Hill deposit. This highlights the significant resource upside potential that exists for both phosphate and rare earth elements, as well as tantalum and niobium mineralisation,” he says.

“This mine is important, because the focus on rare earths is key to the green energy transition and makes this a very attractive project, due to the fact that the minerals produced here are so in demand for the new industries of the 21st century.”

He notes that while Marula is keen to get things started, certain regulatory issues need to be resolved before the company commits significant additional capital to the project. He says Marula hopes to increase its shareholding from 23.75% to more than 50% in the near future.

“Marula is dedicated to assisting the communities surrounding its projects, but the company does not come into a region with pre-defined projects. Instead, we work with the communities to find what their

most pressing needs are, and then we attend to these.

“We understand that we cannot adopt a one-size-fits-all approach. Instead, we sit down and listen to what the community’s requirements are – be these improvements to education, infrastructure or something else – and we then assist with these specific projects.”

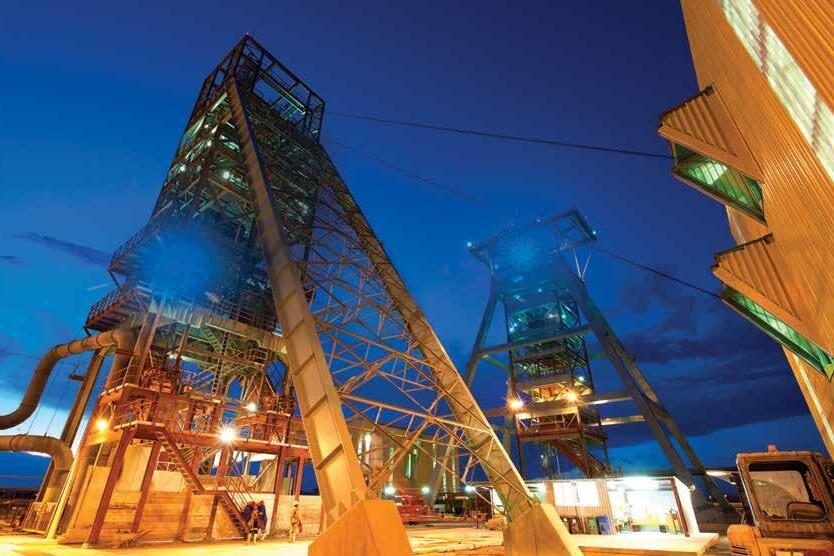

KINUSI COPPER MINE, TANZANIA

A far more developed project than the previous one, Marula has a 75% commercial interest in 10 primary mining licences at Kinusi, and considers the investment to be firmly in line with the company’s battery metals focus, and its identification of highgrade, near-term production and cashflow generating projects.

“This is probably the most exciting project we have,” says Brewer, adding that Marula has seen some special copper projects in its time, but believes that this one looks especially exciting. We are thrilled to be in a partnership with locally based Takela Mining, as we believe copper mining is about to take o in Tanzania.

“In fact, we consider this mine to be a game changer for the region, chiefly because Tanzania is mostly not known for copper, but

www.samining.co.za 22 SA MINING SEPTEMBER / OCTOBER 2023 PROJECTS IN SADC

© ISTOCK –J-Picture

Engineering solutions for the Global Mining Industry

Mining Geotechnical Ventilation Mechanical Electrical Metallurgical

SOUTH AFRICA OFFICE: +27 11 476-7091

Etienne de Villiers: +27 83 327 6517 / etiennedv@baraconsulting.co.za

Jim Pooley: +27 82 373 0796 / jim@baraconsulting.co.za

Clive Brown: +27 82 557 5373 / clive@baraconsulting.co.za

www.baraconsulting.co.za

UNITED KINGDOM OFFICE

Andrew Bamber: +44 744 486 4046 / bamber@baraconsulting.co.uk

www.baraconsulting.co.uk

rather for other minerals, and this massive deposit will put the nation on the world map as a huge mining region.”

Brewer says at this mine, Marula can extract up to 20 000 tonnes of copper per year, which at current rates would be worth almost $60-million per annum. More crucially, he adds, the company has a projection of genuinely high-grade (up to 40%) copper from the mine.

“At the end of the day, copper is exported to the same o taker as our lithium, so we will be strongly targeting the same renewables market. There is tremendous demand for these minerals from the electric vehicle and battery metals markets. With the market for copper only increasing in scope, the fact that we have access to such a high-quality copper deposit can only help our business, moving forward.

“At Kinusi, our social investment programmes are slightly di erent. In this region, there is little by way of employment, outside of farming or government work. Thus, we will be providing full-time employment to people in the area who may never have held a job before. This will have a huge impact in terms of job creation, skills development and quality of life on the entire community.”

BLESBERG MINE, NORTHERN CAPE, SA Blesberg Mine, according to Marula, is one of the largest known economically mineralised pegmatite deposits, and has been the largest single source of tantalum in the country.

Historic production from the Blesberg Mine has included spodumene concentrate (containing lithium) and tantalite, as well as feldspar, bismuth, beryl, and mica.

“Lithium grades of the samples assayed demonstrate a high-grade and high-value lithium product that can potentially be recovered from the existing stockpiles, without incurring high upfront capital costs and high mining and processing costs,” he says.

“In addition, previous drilling and trenching in 2017 at the Blesberg mine confirmed areas of spodumene lithium mineralisation present in the highly zoned pegmatites. Due diligence work has led us to believe that there is potential to increase the spodumene (lithium) resources in the pegmatites, with the view to accelerate new mine development – given the robust market conditions and market pricing of lithium concentrates.”

When to comes to supporting the surrounding communities, all employees at the mine are sourced from surrounding

Marula Mining focuses on producing and exporting highvalue commodities such as lithium, tantalum, graphite, cobalt, rare earths, copper and nickel.

areas, boosting job creation in a part of the country were unemployment is rife, he says.

Marula aims to draw on a workforce of around 50 to 75 people initially, and as the business moves forward, to expand its sourcing from these local communities.

“We are also involved in providing local services, supplies and consumables, and we are investing in education and training as well. Similar to our other projects, we work closely with local charities too, as we focus on improving three key areas, namely education, health and sport, in the region.

“Although Marula Mining is listed in London, unlike other companies listed there, our headquarters remain on the continent in Nairobi, Kenya, and we continue to view ourselves as an African company.

“Because we recognise this as our home, we work in an environment where we are not merely seeking to build a business, but rather a long-term project that encompasses the communities and people around our mines, and boosts the local economy,” says Brewer.

www.samining.co.za 24 SA MINING SEPTEMBER / OCTOBER 2023

© ISTOCK –Fotonio-Bcn

Nkombwa Hill is important, because the focus on rare earths is key to the green energy transition and makes this a very attractive project.

“

– Brewer

“

© ISTOCK –Michael Grund © ISTOCK –Media

PROJECTS IN SADC

WE PROVIDE GIW ® SLURRY PUMP SOLUTIONS

Wear Resistant, High Performance –Global Quality Mining Pumps.

Through GIW® Slurry Pumps, KSB is an innovative partner that provides you with the best and longest wearing slurry solutions. We are your partner over the entire lifecycle of your GIW® slurry pump.

KSB Pumps South Africa is a globally recognized pump solutions provider that manufactures globally recognized products locally to the highest quality standards both internationally and locally.

We not only manufacture and service your slurry pumps, we offer total slurry solutions to your industry.

One team - one goal.

KSB Pumps and Valves (Pty) Ltd

Tel: +27-11-876-5600

www.ksb.com/en-za

Level 1 B-BBEE Supplier

LCC MDX LSA LCV

THE IMPORTANCE OF COMPLIANCE MONITORING

In an era of heightened environmental awareness and regulatory scrutiny, the importance of e ective water and air compliance monitoring cannot be overstated. Ensuring that industrial and commercial activities do not harm our natural resources, or compromise the air we breathe, is a shared responsibility that demands continuous vigilance.

WATER COMPLIANCE MONITORING

Water is an invaluable resource essential for sustaining life and supporting ecosystems. However, various human activities, ranging from industrial processes to agricultural run-o , can introduce pollutants into water bodies, posing significant risks to aquatic life and human health. Water compliance monitoring involves systematic assessments of water quality, to ensure that pollutant levels remain within permissible limits.

KEY ASPECTS OF WATER COMPLIANCE MONITORING:

Regular sampling and analysis: Regulatory agencies and organisations employ a combination of automated sensors and manual sampling techniques to monitor a wide array of parameters such as pH, dissolved oxygen, temperature, turbidity, and the presence of contaminants like heavy metals, pesticides, and pathogens.

Data integration and analysis: Advanced data analytics and modelling are used to detect trends, potential hotspots, and anomalies in water quality data. This proactive approach helps identify emerging issues before they escalate into severe problems.

Real-time monitoring: Technological advancements enable real-time monitoring systems that provide instant alerts in the event of sudden changes in water quality, enabling prompt responses to mitigate risks.

AIR COMPLIANCE MONITORING

Air quality directly impacts human health and the environment. Emissions from vehicles, industrial processes, and energy production can release pollutants like particulate matter, volatile organic compounds, nitrogen oxides, and sulphur dioxide into the air. Air compliance monitoring plays a crucial role in tracking these pollutants and ensuring that they remain within acceptable limits.

KEY ASPECTS OF AIR COMPLIANCE MONITORING:

Emission source monitoring: Industries and facilities are required to monitor emissions from stacks, vents, and other sources. Continuous emission monitoring systems track pollutants in real time, providing a comprehensive picture of air quality and compliance.

Ambient air quality monitoring: Networks of air quality monitoring stations are strategically placed to measure pollutant

concentrations in the atmosphere. These stations provide a comprehensive understanding of air quality across di erent regions.

Remote sensing technologies: Satellitebased and remote sensing technologies o er insights into air quality on a larger scale, aiding in the identification of pollution sources and their dispersion patterns.

CONCLUSION

Water and air compliance monitoring serve as the front lines in our e orts to preserve the environment and ensure public wellbeing. As technology continues to advance, monitoring methods become more sophisticated and data-driven, enabling us to make informed decisions to safeguard our natural resources and mitigate the detrimental e ects of pollution. By maintaining a watchful eye on our water and air quality, we can pave the way for a cleaner, healthier, and more sustainable future.

www.samining.co.za 26 SA MINING SEPTEMBER / OCTOBER 2023 SAFETY, HEALTH & ENVIRONMENT CORPORATE PROFILE

Envass water and air compliance monitoring serves as the front lines in our efforts to preserve the environment and ensure public wellbeing

Envass conducting a baseline air quality assessment (Particulate Matter) by using a MET One Mass monitor.

Gravimetric dust fallout monitoring and sampling.

Water quality monitoring field measurements. (pH, EC, temperature)

Envass conducting a baseline air quality Assessment (Particulate Matter) by using a MET One Mass monitor.

Your Partner in Calculating Environmental Solutions

The ENVASS Group is a distinguished provider of accurate environmental solutions within the South African mining and beneficiation sector. ENVASS stands renowned for its unwavering commitment to delivering independent and exceptionally effective environmental services across diverse industries in South Africa. Leveraging our extensive environmental expertise, we facilitate value-added services by seamlessly integrating costeffective environmental compliance and performance solutions.

We recognize the complexity of environmental compliance and respond by staying abreast with legislative changes and interpretations. We engage in benchmarking and collaborative discussions with our clients, alongside our network of legal experts, to offer an exclusive array of compliance and technical environmental audit solutions.

Boasting a quarter-century of environmental auditing experience, our services include:

Water Use Licence Compliance and Technical Audits

Waste Management Licence Compliance and Technical Audits

Environmental Management Programme Performance Assessment

National Norms and Standards Compliance Audits and Review

Atmospheric Emission Licence Compliance and Technical Audits

Biodiversity Management Plan Implementation Audits and Reviews

Environmental Control Officer Audits

ISO 14001 Internal Audits

Our Audit reports link to clear interpretable documented evidence, strong visualization and an alignment with existing document controls on site. Feel free to reach out to our proficient team of auditors to inquire about recommendations or obtain a quotation for any of the services mentioned above.

Contact us today to learn more about how our consulting services can help your mining company achieve its environmental goals in a sustainable and responsible way.

012

460 9768 | info@envass.co.za | www.envass.co.za

| Gauteng | North West | KwaZulu-Natal | Western Cape

Office locations:

CAN PHOSPHATE MINING BE DONE SUSTAINABLY?

Sustainability is key to mining, and phosphate production

By Rodney Weidemann

By Rodney Weidemann

Phosphate mining is considered essential for global agriculture and the role it plays in food security. Like many mineral extraction processes, responsible production and manufacturing processes are vital to mitigate potential environmental damage and ensure a safe working environment.

These activities are governed by strict legislation, and a range of regulations designed to protect human health and safety, biodiversity, and to limit the extent of any polluting contaminants.

Mark Maynard, COO at Kropz, notes that at the company’s Elandsfontein mine, environmental and safety mitigation measures are engineered into its design and were implemented at the inception phase.

“At Elandsfontein, our focus has been on minimising habitat destruction; maximising land reclamation; responsible management of water resources and intensifying wastewater treatment; reducing chemical usage; and – through a focus on R&D – developing cleaner extraction and processing technologies,” he says.

To this end, Elandsfontein employs a full-time rehabilitation team, whose activities are closely aligned with the mine’s environmental management programme (EMPR).

Adelaide Ruiters, founder and CEO at Adelaide Ruiters Mining and Exploration, which is developing the Zandheuvel Phosphate Mine and Beneficiation Plant in Saldanha Bay, points out that many phosphates contain high levels of cadmium, which is illegal in SA.

Cadmium levels of more than 20 ppm may not be imported or used for agriculture production in SA, since cadmium is a toxic heavy metal that causes kidney and cardiovascular diseases, as well as cancer.

“The phosphates we produce are among those that have very low cadmium content, making them much healthier. However, the biggest problem in SA is that around 70% of our phosphates are actually imported. Are there any assurances that imports like these, and their cadmium levels, are being properly policed at the ports?

“Ultimately, we must remember that price is o en key in this market, so the imports coming from elsewhere may be cheap, but there is every likelihood they are also high in cadmium.”

It is for this reason, among others, that she indicates she is trying to form a Phosphate Producers Association to lobby other producers to advocate for both healthier phosphates and phosphate mining approaches. It would also be to ensure that South African phosphates are used in the South African agriculture value chain.

WATER ISSUES

In a water-stressed country like South Africa, explains Ruiters, a strict focus on water management and e iciency measures is clearly appropriate.

She notes that tailings dams are broadly at odds with the principles of sustainability, which is why her company uses filter presses to remove the water, so that it can be circulated back into the process.

“It’s worth mentioning that beneficiating phosphate rock

www.samining.co.za 28 SA MINING SEPTEMBER / OCTOBER 2023 SAFETY, HEALTH & ENVIRONMENT

comes with its fair share of challenges. We look at the efforts such producers are making to remain sustainable

©

ISTOCK –BrianBrownImages

HOW TO UNDERTAKE SUSTAINABLE PHOSPHATE MINING AND PRODUCTION

Grant Dreyer, MD for Future Metals and Materials at Afrimat, suggests that there are several areas of focus required to achieve sustainability in the mining process:

■ Exploration techniques: Identifying economically viable deposits early reduces exploratory digging and associated environmental disturbance.

■ E icient resource management: Minimising waste generation and resource depletion, through e icient practices such as mine planning and processing technologies.

■ Rehabilitation: A commitment to restoring mined areas and reducing environmental impact.

■ Community engagement: Continuous engagement with local communities fosters cooperation and awareness, while the actual mining and production leads to job creation and improved living standards for communities.

■ Continuous monitoring: the monitoring and analysis of production processes, with the aim of reducing potentially harmful contaminates, by-products and waste.

■ Regulatory compliance: It is vital to stay on the right side of the law, and authorities play an important role in enforcing regulations and compliance.

concentrate allows you to produce phosphoric acid, which is a key element in producing fertiliser and other agents, like dishwashing liquid. It can even be further beneficiated as a food chain preservative, and can be used in items like soap and toothpaste,” she says.

“However, when such beneficiation is undertaken – through Direct Froth Flotation Technology – diesel is usually used as the frothing agent. Because of the carbon footprint this creates, we have replaced diesel with a canola oil derivative, which is

far more sustainable and assists significantly in producing low carbon footprint phosphates.”

Ruiters adds that SA’s water scarcity issues mean that it is not really sustainable to use potable water in the beneficiation process. Therefore, her company has forged an arrangement with the local municipality, which allows them to utilise treated municipal wastewater instead.

“In the end, our beneficiation process has been made more sustainable in three ways. Firstly, we replaced the frother diesel with canola; then the fatty acid traditionally used in the process is now also derived as a byproduct of canola production; and finally, we replaced caustic soda with potassium hydroxide, which allows us to produce a greener, more sustainable low carbon phosphate fertiliser product, targeting more sustainable organic agriculture practices.

“We also designed a pipeline to pump our final product to the logistics facility at the Saldanha Bay deep sea port. In this way, we eliminated the need to have trucks transporting the product to the harbour, mitigating the dust and air pollution a mining operations causes.”

ARME is on track developing its new Zandheuvel Phosphate Mine and Beneficiation Plant in Saldanha Western Cape South Africa, to become one of the few phosphate producers in the world set up to produce low carbon, sustainable and environmentally friendlier beneficiated sedimentary phosphate rock. Certainly in South Africa, we are the only phosphate producer known to have successfully replaced all beneficiation chemical reagents with organic environmentally friendly reagents so as to produce a low carbon environmentally friendlier phosphate rock for sustainable agriculture practices. We are Proudly SA Black Woman Owned. Supported by the Industrial Development Corporation, Anglo Sefa Mining Fund and VBKOM.

Contact Adelaide Ruiters CEO and Founder adelaide@arme.co.za 0027 847234555

www.arme.co.za

The phosphates we produce are among those that have very low cadmium content, making them much healthier. However, the biggest problem in SA is that around 70% of our phosphates are actually imported – Ruiters

“

“

TECHNOLOGY TO THE RESCUE

According to Grant Dreyer, MD for Future Metals and Materials at Afrimat, technology can also be embraced throughout the value chain.

“From the identification of economically accessible resources, through to mine scheduling, monitoring and processing, and on to data analytics to help ensure compliance, technology offers plenty to the sector. Included in this is its ability to assist in the overall reduction of environmental and safety risks.

“These tools, together with a firm commitment to regulations, enable planning that helps to optimise mining and production processes, while reducing emissions, safety risks and other environmental impacts,” he explains.

Kropz’s Maynard points out that by integrating these modern, digital technologies into the overall mining planning and operation, organisations can significantly improve many aspects of the mining process.

M84 GEOTECH

“However, there are a few caveats. Improving your business using technology relies on observing practices and disciplines such as sound investment in research and development (R&D), collaborating closely with technology providers, as well as collaboration between mining companies and regulatory bodies. It is also imperative to ensure that the workforce is trained to use the digital tools.”

Digital technology plays a key role in managing sustainable mining initiatives and reducing a mine’s environmental risk profile, he continues. Elandsfontein, for example, has bespoke training programmes in place to keep employees skilled in the latest developments in this area, in order to benefit from these new innovations.

“Sustainable phosphate mining relies on an integrated collaborative approach, involving all the industry stakeholders –government at local, provincial and national level, NGOs, communities and others. Ultimately, it is important to balance the need for phosphates, which is critical for food security, with responsible environmental stewardship, to minimise any potential ecological damage,” says Maynard.

Rockfall Protection and Slope Stabilization Solutions for Open Pit Mines

As a company we pride ourselves in having 100% completion rate on every project we have done and also keeping a 100% safety record on-site. This is a big deal for us because we do high risk and high priority projects and that’s why we say, “Safety is Our Priority.” The systems we use to keep open pit operations safe from rockfall hazards and slope failure are one of the best in the market and with us as a contractor you are guaranteed a professional service and safest installation methods. The use of rope access techniques makes it possible for us to install the systems with minimum interruption to production. We can access high areas using the safest methods while keeping your miners and equipment safe from possible rockfall hazards.

We have successfully completed complicated projects such as installing a 200m x 200m drape mesh system on a rocky highwall and moved tricky positioned boulders on high walls.

Most if not all of our mining clients, safety is very important to them and as a company that’s what we bring on-site, safety. Rockfalls are a very serious risk in open pit mines and if such risk is not managed or controlled, lives could be lost and equipment damaged. The solutions can come in the form of preventative measures such as installing slope monitoring prisms or through protection systems such as drape mesh, slope stabilization or catchfences.

SAFETY, HEALTH & ENVIRONMENT

Tel: 015 023 1400 Cell: 072 203 8405 Email: info@m84geotech.co.za, admin@m84geotech.co.za Address: 11 Sussex Street, Mokopane 0601 26 Rhodesdrift Street, Building 4, Suite 3 Rhodesdrift Office Park, Bendor Polokwane 0699 Socials: Instagram: m84_geotech Linkedin: M84 Geotech Web: www.m84geotech.co.za

© ISTOCK –Brian Brown

“

At our Elandsfontein mine, environmental and safety mitigation measures are engineered into its design and were implemented at the inception phase. – Maynard

“

MINING CAN BE A THIRSTY BUSINESS

By David Noble, CCO at Swedish drinking water and beverage company Bluewater

As one of the country’s most significant industries, mining is crucial to South Africa’s economy and provides valuable resources that power various sectors. However, amid the grit and determination lies an o en-overlooked challenge – ensuring clean drinking water for those who toil above or beneath the earth’s surface.