South Africa, much like other nations, faces the challenge of navigating the shi away from coal towards cleaner sources of energy. The nation is well aware that such a transition has to be considered “just”. The term “just energy transition” describes the move to lower carbon technologies as taking place gradually in order to ensure this transition doesn’t negatively impact society. When it comes to the climate-related energy transition, the reality is that mining companies are energy-intensive enterprises that emit large volumes of greenhouse gases, says Otsile Matlou, chief operating o icer at law firm ENSafrica. It is for this reason, he says, that mining is a key industry that needs to e ect a just energy transition.

“The big challenge facing mines is around how they can e ectively reduce their carbon footprint by limiting emissions, while still retaining their production at current levels,” he says.

“In the context of SA, this is made even tougher by the instability of our electricity grid, which already hinders production. In addition, mining has for many decades been a mainstay of our economy. In fact, it was our best performer during the pandemic, so it is imperative we ensure we do not disrupt this economic impetus while undertaking the transition.”

Matlou suggests that there are two components to the just transition. The first is the need to shi to cleaner methods of

energy generation, but the second part is that this shi must be undertaken in a just manner. In the case of mining, this means the transition must have a positive, rather than a negative, impact on the individuals and communities a ected by the mine.

“A er all, having vast reserves of clean air doesn’t help if those breathing it remain stuck in poverty and unemployment. Thus, it is vital to balance the two components so you can be certain that as we transition from the old ways to the new, we don’t lose sight of the social, economic and health impacts the transition might bring.”

He notes that ENSafrica’s core business is to provide legal support and advice, and the firm aims to be viewed as a trusted adviser in respect of its clients’ legal needs.

“We see our role as being to assist mining in the just transition through the provision of specialist legal services in di erent practice areas where our people have specialist knowledge and deep skills,” he says.

“In other words, while we have experts across all three key areas encompassed by the transition – namely environmental, social and governance (ESG) – we also understand that our people need a deep understanding of the issues impacting ESG. A er all, many of the questions around the transition relate to social and political challenges, and require policies to control.”

To this end, he indicates that the firm assists clients to formulate programmes and policies to respond directly to the challenges created by the transition.

“We have played a role in the provision of legal services, and have engaged with government and other social partners through multiple initiatives. Furthermore, we perform advocacy work and focus on ensuring that the advice we dispense is not only about profit maximisation for our clients, but rather about addressing the social realities in which our clients operate.”

Matlou adds that when it comes to the critical, “just” part of the transition, which is about ensuring people aren’t negatively impacted by it, and that jobs aren’t lost, the country cannot prioritise energy transition over this.

“If one looks at SA’s contribution to emissions as a proportion of global impact, our footprint is minimal. In fact, I think the total contribution of Africa is less than that of the top five polluters from the developed world.

“Therefore, if we talk a just transition, it is something that must also be economically just. Considering the economy of the developed world was built

for 200 years on dirty energy, Africa cannot now be expected to shed jobs and increase poverty, simply to be more climate-friendly. That is not to say we shouldn’t be moving away from coal, but that we need to do it in a way, and at a pace, that doesn’t hurt our people and economy further.”

He notes that while he is in favour of a transition from coal, this is a journey that will take some time, if we place our main focus on our people and our economy. In other words, we need to continue to use coal to develop our energy system until we can get to a point where renewables are capable of providing our base load needs.

“Of course, when we have to install new generating capacity, we must obviously be looking to renewables. However, since our base load is still coal, the challenge lies around what we do when our coal stations reach their end of life.

“Do we spend a small fortune refurbishing them to continue burning coal, or do we repurpose these into renewable energy facilities? I certainly believe the latter is the better answer. So instead of mothballing these old power stations or keeping them burning coal, they should be refitted as renewable generation facilities, to help keep our grid functional until the transition is complete.”

What is worth mentioning, he continues, is that any transition like the one we are describing may have many challenges and issues, but it also presents numerous opportunities for the mining industry.

“For one thing, we are seeing an increasing number of mines automating vehicles, or enabling them for remote

operation. Many are also using electric or even hydrogen powered trucks. And, of course, mines’ ability to build their own power generation plants will not only enable them to generate power, but means they can also store and even sell this back into the grid.”

Matlou further points out that the growing drive towards electric vehicles (EVs) means that green metals and commodities will be increasingly prized. Therefore, mining houses are investing heavily in these minerals in their portfolios, because the demand has seen their value increase significantly.

“The opportunities presented by the just transition will also help mines to improve on their older methods of working. For example, automation and remote piloting of vehicles removes many workers from dangerous underground roles. Improvements in safety and health and a reduction in harm are among the key immediate benefits to be gained from the transition.

“ENSafrica has been involved in the renewable space from the first round of bidding, and we have participated in all of the rounds. Our involvement is such that our experts have provided capacity to government in bid evaluation and environmental regulation.

“Moreover, the bulk of the independent power producers that have renewable projects in SA have had dealings with our firm in some way, all of which provides clear evidence that ENSafrica has been, and remains, at the forefront of the just energy transition,” he says.

As we transition from the old ways to the new, we mustn’t lose sight of the social, economic and health impacts the transition might bring.

– Matlou

“

mine Existing practices extract New ideas deliver Solutions

While geopolitics, most notably the ongoing war in Ukraine, supply chain issues, and the increasing digitisation of the sector are all impacting the mining industry, a focus on climate and environmental, social and governance (ESG) commitments remains among the top trends for 2023.

This is unsurprising, as some of the key areas for ESG improvement are not new: improving diversity, equity and inclusion is still a major challenge, and mine closures and rehabilitation require a longerterm, more strategic view.

However, ESG is evolving, and is thus requiring miners to consider di erent issues and broaden their capabilities to manage them e ectively. Among the urgent priorities for 2023 are water stewardship and biodiversity, which are vital amid a changing climate.

Increasingly important for the development of sustainable technologies, including the production of numerous types of renewable energy batteries, cobalt is quickly becoming an in-demand mineral critical to the green energy supply chain.

However the Democratic Republic of the Congo (DRC) accounts for more than 70% of the world’s cobalt production, and there is a dark side to the mining of this mineral in the DRC. Child labour, fatal accidents and violent clashes between artisanal miners and security personnel of large mining firms are recurrent within the DRC’s cobalt mining landscape. Fortunately, e orts are now under way to establish a sustainable battery value chain.

Operator comfort may not be top of mind when making business decisions, but uncomfortable

operators become fatigued operators. Fatigue of any kind poses a workplace hazard and reduces productivity, so ensuring operator comfort – in the form of ergonomically designed equipment – is a crucial way to reduce the physical and mental toll on employees.

While mines have traditionally been considered slow adopters of technology, a combination of digital technologies and improved emulsions are helping mines to improve their blast planning, initiation and analysis – and making a significant contribution to improvements in e iciency and safety.

At the same time, the mining sector is leveraging the numerous digital technologies that are available today to help overcome several potential challenges – from environmental to social, financial and legal pressures – by using these solutions to improve project management processes.

We also take a look at what we can expect from the bigger, better and more focused Mining Indaba in 2023, which will discuss the very real geopolitical shi s and economic disruptions we are experiencing. These, a er all, are providing pressure points – as well as opportunities – within African mining as global economies.

Finally, in our cover story, boutique environmental law firm NSDV considers just how important ESG scorecards are for modern mines, in terms of helping these businesses to build resilience, create sustainable value, and enhance profitability and competitive advantage.

Here’s to 2023 being the year where SA’s mining industry adopts the technologies and scorecards that will help it rise to meet its many challenges.

Rodney Weidemann

Tel: 062 447 7803

Email: rodneyw@samining.co.za

ONLINE EDITOR

Stacey Visser

Email: vissers@businessmediamags.co.za

ART DIRECTOR

Shailendra Bhagwandin

Tel: 011 280 5946 Email: bhagwandinsh@arena.africa

ADVERTISING CONSULTANTS

Tel: 011 280 3120 Email: moolmani@samining.co.za Tshepo Monyamane

Tel: 011 280 3110 Email: tshepom@samining.co.za

PRODUCTION CO-ORDINATOR

Neesha Klaaste

Tel: 011 280 5063 Email: neeshak@sahomeowner.co.za

SUB-EDITOR Andrea Bryce

BUSINESS MANAGER

Claire Morgan Tel: 011 280 5783 Email: morganc@sahomeowner.co.za

GENERAL MANAGER MAGAZINES

Jocelyne Bayer

SWITCHBOARD

Tel: 011 280 3000

SUBSCRIPTIONS

Neesha Klaaste

PRINTING Hirt & Carter

PUBLISHER Arena Holdings (Pty) Ltd, PO Box 1746,

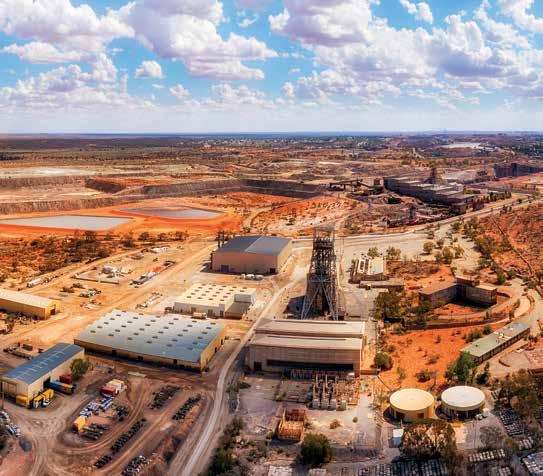

Barrick’s Loulo, Gounkoto and its recently disposed of Morila mine asset, have jointly contributed $8.7-billion to the Malian economy in the 25 years the company has been in the country, and over the past decade has accounted for between 5% and 10% of its GDP.

President and chief executive Mark Bristow notes that throughout Barrick’s long partnership with Mali, it has supported the country through some di icult times. Its relationship with successive governments continues to be mutually beneficial, with the Loulo-Gounkoto complex – one of the company’s elite Tier One1 assets – on track to meet its 2022 production guidance.

“In line with our long-term commitment to Mali, we continue to invest in exploration to extend the life of the complex, which regularly more than replaces the gold it mines each year.

“The Loulo district is still delivering high-quality targets and we’re upgrading the complex’s infrastructure to support both open-pit pushbacks and extensions at Yalea and Gara. In the meantime, the new Gounkoto underground mine is progressing its development towards scheduled commencement of stoping next year,” he says.

Bristow says Loulo-Gounkoto is an outstanding example of Barrick’s policy of recruiting and developing the people of its host countries. Malian nationals account for 95% of the complex’s workforce and they are led by an all-Malian management team.

Similarly, it has invested in the growth of local business partners, ranging from key contractors to fuel and lubricant suppliers. In the year to date, it has spent $395-million with these partners, representing 80% of its total purchases. Loulo-Gounkoto has also significantly improved the quality of life in its surrounding communities through its investment in projects designed to provide them with access to healthcare, education, food security and potable water. An ongoing programme to train local entrepreneurs in business development has been initiated, with the first cohort recently graduating.

Malaria remains one of Africa’s biggest health problems and Loulo-Gounkoto is taking aggressive action to reverse the recent rise in the infection rate a er a long period in which it steadily decreased. This includes a door-to-door awareness campaign in the local villages, a workshop held alongside the country’s national director of malaria control, close cooperation with regional healthcare authorities, and working with other mining companies to identify and leverage synergies in the various malaria response plans.

Bridgestone Southern Africa mining services and OTRACO Southern Africa will join forces to accelerate mining tyre management and mobility solutions in Southern Africa, under one banner. OTRACO Southern Africa is a leader in o -the-road tyre management solutions.

This acquisition will accelerate the growth of Bridgestone SA’s mining solutions business and expand the company’s service network. The acquisition was completed in December 2022 and André Bode will continue as managing director of OTRACO, reporting to Jacques Fourie, vice president of Bridgestone Middle East & Africa.

As part of Bridgestone’s initiative to improve mobility solutions and tyre-centric services across all market segments, the company identified a need in the mining market for specific mining services and enhancements.

“The acquisition of OTRACO, with its strength in tyre management systems, is an exciting milestone in our history and presents a new opportunity to extend our mobility solution o erings to the market. Together, Bridgestone and OTRACO have market-leading mining tyre management and mobility solutions,” says Fourie.

Going forward, Bridgestone SA will go to market under the OTRACO banner. “Bridgestone and OTRACO are proud to join forces, under the OTRACO banner, to o er industry-leading mobility solutions and mining tyre management services to our valued customers,” says Carl Martins, Bridgestone’s mining services executive manager.

Solving the challenge of scrap tyres in a way that’s ethical and sustainable could be around the corner for Southern Africa. After opening a thermal conversion OTR tyre recycling facility in Chile that converts scrap tyres into its base elements, Kal Tire hopes to bring this scalable solution to other regions.

The Mandela Mining Precinct, Minerals Council South Africa and champion mines SibanyeStillwater and Impala Platinum congratulate Reutech Mining for winning the Rock Hazard Identification and Safe Removal Innovation Challenge.

At the beginning of 2022, these organisations set out to identify novel solutions in rock hazard identification and safe rock removal – for further development, testing and piloting – with the aforementioned partners’ mines, with a focus on the reduction in falls of ground and improved worker safety.

A call for proposals in the Rock Hazard Identification category resulted in the submission of solutions featuring groundpenetrating radar technology, thermal and acoustic imaging, LiDAR-compatible drones and mmWave SAR imaging for realtime rock mass quality inspection, among others.

In November 2022, a panel of judges representing the Mandela Mining Precinct, Minerals Council South Africa, SibanyeStillwater and Impala Platinum shortlisted the top seven submissions by contestants. In December 2022, the shortlisted submissions underwent a final round of judging at a virtual “pitching den” event.

This culminated in the announcement of South African engineering trailblazer Reutech Mining as the challenge winner, with the Council for Scientific and Industrial Research’s Advanced Internet of Things Group, TCS Research and Flyability being named runners up. Other finalists in the challenge were Stratafy, Ramjack Technology Solutions and RockMass Technologies.

conjunction with the Mandela Mining Precinct’s Advanced Orebody Knowledge (AOK) programme.

The FOGAP’s objective is to eliminate fallof-ground fatalities, which have historically been cited as one of the leading causes of worker fatalities in the mining industry, while the AOK programme seeks to improve geological confidence at and beyond the rockface.

“We are incredibly encouraged by the significant reduction of fatalities due to falls of ground this year, and hope this is a great step towards reaching zero fatalities – but the work is not done,” says Lerato Tsele, senior policy analyst for safety and sustainability at the Minerals Council.

Johan le Roux, Mandela Mining Precinct director, says innovation has shown to directly enhance performance in the environmental, social and governance space – the clearest evidence of this being improvements in health and safety and the significant progress made to date towards zero harm for the workforce.

The Rock Hazard Identification and Safe Removal Innovation Challenge was undertaken as part of the Fall of Ground Action Plan (FOGAP), a programme developed and approved by the Minerals Council’s CEO Zero Harm Forum, in

Both Tsele and Le Roux express hope that the collective e ort between the Mandela Mining Precinct and the Minerals Council will uncover a fit-for-purpose solution that will provide tangible results of lives saved and a more e icient, productive workflow.

We are incredibly encouraged by the significant reduction of fatalities due to falls of ground this year, and hope this is a great step towards reaching zero fatalities . – Tsele

“ “

SAFE

Mining, by its very nature, is a massive operation with quite arduous requirements for training, certification, safety and compliance. In any venture of this scale, it is important to focus on the core of the business. Using specialised suppliers for non-core business functions can make a huge di erence in the amount of core management time that needs to be invested into non-core functions.

“Most printers in the market today are general printers,” according to Edge Digital Print & Finish’s managing director Francois Liebenberg. “General printers pride themselves on being able to print almost anything for almost anyone.

“There are two types of specialised printers. First are those that focus on a niche product or service, like printing on ceramics, or gi branding. The second type specialises in servicing specific market segments, who understand the specific needs of those segments and then adjust their o erings accordingly.”

He notes that using a printing partner that understands your industry can make a huge di erence.

“They already have systems and processes in place, reducing the amount of time and e ort you will have to put into managing them as a supplier. They have a general insight into what you need, how you need it, and should be able to o er the most cost-e ective and practical solutions due to

their alignment with your industry,” he says. According to Liebenberg, understanding the industry goes a long way, but even in the same industry, every business is still unique, and this is where the correct printing partner really shines – by listening to and being able to adapt to your unique needs.

losses due to redundancy, and keeps your cash in the bank, instead of on the shelf. This also makes distribution of training and related materials the responsibility of the supplier, leaving you to focus on your core business functions.”

Training has its own set of unique variables. Student numbers vary greatly across courses, and even for di erent rounds of the same course. Venues can be on the job, on-site classrooms, or o -site, and sometimes geographically distributed. Some course materials are updated regularly to keep up with the fast-evolving industry.

“Digital print on demand has made it possible to get the correct materials where, when and in the quantities that you need. Large quantities of stock are no longer required for e ective pricing. This reduces

Edge Digital originated in the 1980s, he says, and has never been a general printer. The company started printing for the basic education market, giving it a strong foundation in educational and related needs, such as certificates and posters.

“This naturally evolved into the launch of our Digital Print Express brand eight years ago, which is focused on adult and commercial training. Being involved in training for manufacturing exposed us to compliance and safety needs, including custom safety signage (which is handled by our Sign Focus brand).

“O ering our specialised services to the mining industry was the natural next step, as our experience and capabilities aligned perfectly,” he says.

Training, compliance and safety are all of core importance to a mining enterprise. Printing is not – and using the right printing partner can make a huge difference

“ “

© ISTOCK –VanderWolf © ISTOCK –oatawa

The NSDV environmental, social and governance (ESG) scorecard facilitates an industry-specific scoring of a company’s ESG risk situation, as measured across all ESG dimensions.

According to Lili Nupen, a director and co-founder at law firm NSDV Inc, globally the mining industry is facing increased pressure to be more mindful about ESG compliance. Evaluating companies on their ESG score, or perhaps lack thereof, is rapidly gaining prominence within the global investment community, she notes.

“Some industry players may feel overwhelmed by the obligation to comply, but there are inherent benefits to ESG scorecard adoption. Using a reporting tool like ours allows these entities to build resilience and create sustainable value in their business, thereby enhancing profitability and their longterm competitive advantage,” she explains.

Nicolas Marsay, ESG and circular economy specialist at NSDV, adds that ESG is a focused lens that allows customers and investors to look deeper into a business, to understand how it is impacting society.

“A good way to explain this is that someone who invested early in something like cellphone technology would have made a significant profit. ESG scorecards, however, take into account issues such as the economic and social impact that occurs through the value chain as determining factors when reporting on these great returns,” he says.

“In such a scenario, there may be significant problems in the value chain, such as how cobalt plays such a big role in cellular technology. Much of this mineral comes from areas like the Democratic Republic of the Congo, where exploitation is rife and doing business is challenging. Once you start taking such things into consideration, you begin to see the negative impacts such an investment

has on broader society.”

Marsay notes that NSDV’s approach to ESG is to take a hands-on approach with each client, where the company delves deeply into the client’s data to truly understand their needs and requirements. Ultimately, an ESG scorecard o ers a company the opportunity to visualise the impact the business is having within the various ESG categories and to have a baseline from which to improve on.

“To be listed on the JSE, companies are required to have an ESG disclosure report, but this is not the same thing as a scorecard. In order to change the report into a scorecard, it is necessary to utilise metrics and weighting to determine the correct numbers for things like water quality, air pollution, community development, and job creation.

While not yet mandated into law, getting a head start on your ESG scorecard can help businesses build resilience, create sustainable value, and enhance profitability and competitive advantage

For mines to be ESG compliant, focus should be placed on meeting the regulatory requirements of environmental and social issues, and mines should go beyond these, to proactively implementing enhanced governance well beyond the basics of current best practice.

“The challenge is that because these scorecards are currently only for internal company use and nothing is o icially legislated, weighting for these various ESG categories remains subjective.”

He suggests that this is the big flaw in the ESG space currently, adding that to help resolve this, NSDV is able to develop custom weighting for specific industry sectors or individual businesses based on the team’s deep knowledge of the sector and combining law and business consultation to deliver a unique and tailored scorecard.

“The purpose of our o ering is to take clients beyond report-based compliance by helping them properly track, transform, and improve scores on the ESG scorecard. Obviously, you need to be able to track and measure your scores if you hope to improve.

“It is also worth recognising that scorecards will be increasingly important moving forward, because it o ers a reflection

of what has been measured for shareholders and all relevant stakeholders. The NSDV ESG scorecard works on the same principle as broad-based black economic empowerment (BBBEE) ones.

“As an example, if your business launched when you were BBBEE level 4, and you can now see you are at level 2, you can see exactly how well you have embraced transformation and made a positive impact on addressing legacy issues, and also how far you still have to go to reach your target.”

Marsay says with an ESG scorecard, you are essentially tracking from the start how you are improving in these significant areas. If a mine previously used 15KW of electricity per tonne mined, and now only uses 12KW per tonne, the company can demonstrate to the public that it has reduced its impact on the planet. In terms of investment, such positive disclosures also show potential foreign investors that the business is a less risky long-term investment.

“It is vital to remember though that everybody’s journey is completely di erent. Although the JSE has released disclosure standards, the process to get there, the understanding of which metrics should be tracked and much more, means there is a di erent process, method, and implementation depending on the individual client.

“You simply cannot adopt a cookiecutter approach, which is why NSDV makes an e ort to sit with each client to clearly understand what they do, how they work, where their pressure points are, and what they are currently doing in the ESG arena.”

He explains that the hard data is supplied in raw form by the client, and the scorecard is produced by NSDV experts using this data, which has to be verified against thirdparty audits.

NSDV recommends developing an ESG scorecard sooner rather than later … [to] a ord businesses significant experience in the preparation of their scorecards.

– Marsay

“© ISTOCK –Panksvatouny © ISTOCK –Barraud © ISTOCK –Bilanol

Nupen adds that as a boutique law firm, NSDV focuses on remaining a trusted adviser to its clients. To this end, the team will explain what the legal requirements are (if any) to clients while also helping them understand what to measure, how to measure it, how this can be improved, and how to ensure they remain compliant in future, particularly in the “E” and “G” space.

“We already have a few clients who are familiar with the requirements so that when a scorecard is finally mandated into legislation (which is inevitable in our view), they are ready. Legislation aside, this is the way in which the world is moving and we’re very proud to help our clients do better business with better insights.”

As mining, construction and environmental specialists, NSDV works with investors who clearly understand the value of a business in relation to its contributions to the greater climate good.

“We are facing a future where there will be increasing penalties levied on those who fail to demonstrate environmentally friendly approaches. In fact, I have no doubt that we are reaching a point where the penalties for not going ‘green’ become so substantive that they begin to negatively affect a company’s share price directly.

the preparation of their scorecards, which can be finessed and sharpened over time and with increasing data,” says Nupen.

The global shift towards doing business more conscientiously is set to continue. Now that’s all well and good for communities and the environment… but it’s positively brilliant for our clients who want to do good and well. By monitoring, and optimising, all things ESG on their behalf, NSDV’s experts have been able to turn their client’s great intentions into even greater profits – and we’d love to do the same for you.

If your ESG initiatives could use some governance, visit us at nsdv.co.za

“This is why NSDV recommends developing an ESG scorecard sooner rather than later. This will afford businesses significant experience in

We are facing a future where there will be increasing penalties levied on those who fail to demonstrate environmentally friendly approaches.

– Nupen

Environmental, social and governance (ESG) is essentially a key driver in measuring a company’s progress and maturity. Government incentives and taxations are rapidly moving to incorporate ESG scores, and JSElisted companies are required to disclose their ESG impact, obliging companies to incorporate ESG into their business models.

According to Minnette le Roux, principal environmental specialist at law firm NSDV, mining companies adopt an integrated and holistic approach to operating in an ESG-targeted manner. Within each of the ESG pillars, there are metrics which overlap legislation that mines are required to comply with.

“From an environmental perspective, mines have started to adopt the circular economy approach and begun moving towards renewable sources of energy to improve their ESG performance and set targets. Responsible energy and water usage, considering climate change and resource optimisation are all key disclosure areas in ESG.

“Mines have started to power their operations with renewable energy, operate

electric or hydrogen-powered truck fleets, and integrate recycling in their value chains. These mines will be best placed to sell lowcarbon premium minerals,” she says.

“From a social perspective, mines have identified the lack of adequate education, employment opportunities, poor health facilities, and infrastructure as areas to focus on, when acting on the issues raised by local communities. Mines have started to adopt a holistic approach to managing health and wellness programmes, not only for their employees, but also for the host community members.”

Le Roux says the interrelationship between the ESG pillars has resulted in mine closure planning moving from a regulatory compliance tick box to a tool for sustainable end land use. And where there is an increase in collaboration with regulators, stakeholders, employees, and local communities involved and consulted on during all phases of the planning for closure of the mines.

The legislation on closure planning in South Africa is also catching up to the trend of involving stakeholders and communities, with a dra Mine Closure Strategy that was

published for comment in 2021, she says.

“Investors, regulators and local communities are pressuring mines to disclose their ESG performance and set targets. Therefore mines are being forced to improve their ESG data gathering in order to collect accurate and reliable ESG data to assist with disclosure in their integrated reports.

“Adequate information will further enable stakeholders to quantify the ESG impact of their investment and evaluate the company accordingly, giving the business a competitive advantage over its rivals.”

Law firm Norton Rose Fulbright notes that ESG scores highlight whether the company is promoting natural resources and sustainable use by minimising environmental impacts, or perhaps transitioning to a low-carbon future.

By way of example, relevant metrics could include reducing electricity consumption, water consumption and waste to landfill, considering alternative energy sources, reducing greenhouse gases and improving biodiversity management and air and water quality.

The need for mines to measure ESG performance – and demonstrate improvement – is key to their approach to sustainability, as well as to their being added to strong investment portfolios© ISTOCK –photomaru

As to the social pillar of ESG, social considerations include communities, stakeholder engagement and safety and health. Furthermore, questions that can be asked include: Is the company supporting local communities through economic empowerment? Has the mine delivered on programmes and improved living conditions? Is there proactive and meaningful engagement with stakeholders based on inclusion and transparency?

In addition, have all work-related injuries and diseases been reduced? And lastly, has the health of employees and the surrounding communities been improved?

By way of example, relevant metrics could include undertaking social assessments and monitoring deliverables in terms of a mine’s social and labour plan; providing appropriate grievance mechanisms; considering land-use rights; implementing measures to reduce risks in terms of safety; and monitoring and measuring occupational hygiene and health of employees and the community.

In terms of governance, these questions

should be considered: whether e ective processes have been identified to evaluate compliance with all applicable legal requirements; whether there are adequate controls in place to minimise any environmental, health, safety and social risks; and whether the mine’s performance is being adequately disclosed.

NSDV’s Le Roux says: “We believe that as sustainability disclosure matures, the measure of a mine’s good standing will be measured, weighted and indexed according to the di erence between the inputs it receives and the outputs it gives.

“Sustainable disclosure that could be measured would provide for continuous improvements and alignment with the global sustainability frameworks. It will further disclose a company’s ability to achieve sustainable growth and prosperity by identifying the risks and opportunities, and providing for a consistent, complete, comparable, and verifiable disclosure to regulators, communities, investors and stakeholders.”

When it comes to the matter of investment, the jury remains out on the issue of ESG. But according to Campbell Parry, resources analyst at Investec, the real di erentiator will ultimately not be between those who are either good or bad at this, but rather investment will be driven based on who is improving their ESG scores, and who isn’t.

“For example, a mine whose previous carbon footprint is 60 million tonnes of CO2, but which reports say is 55 million tonnes, can be said to have made a huge improvement. At Investec, we feel that if we can see that a business is making a material di erence to the world from an ESG perspective, then they may well be worth investing in,” he says.

“One might query whether it is worthwhile having a mining company in an investment portfolio, but we consider it from the point of view that electric vehicles, wind farms, photovoltaic panels and other renewable technologies cannot function without key rare earth elements being mined.

“Thus one cannot separate the old economy from the new – wind and solar cannot exist without mining, so mining must be an enabler of the renewable transition.”

It is also worth noting, he says, that a business added to an investment portfolio needs to score well from an ESG perspective – and the mining sector has been at the leading edge of ESG for a long time, simply because these are areas where this industry has had to be responsible to some degree for many years.

“At Investec, we take a pragmatic view of things – our world won’t be able to reach net zero unless everything works in lockstep together. This process begins with mining, and we recommend owning mining stocks as this industry is a key enabler of the green energy transition.

“But only of those mines that demonstrate significant improvement in their ESG scores and demonstrate they are leaders in tackling the change the world requires,” he says.

Investors, regulators and local communities are pressuring mines to disclose their ESG performance and set targets.

– Le Roux

The just energy transition is both a business issue and a governance one, meaning it is critical to talk to a specialist in this rapidly developing area of law and business

The need to mitigate climate change clearly requires much of industries, and none more so than the mining sector, whose transition to a low-carbon economy is vital.

According to Adam Gunn, legal director at multinational law firm Pinsent Masons, less than a decade ago environmental issues were still peripheral ones, and certainly not considered core to a mining business. However, he suggests that this is now a focus that is taking centre stage, as these entities recognise the need to go green.

“Mining clearly understands the need for the Just Economic Transition (JET), and many mining organisations are making progress and setting ambitious goals. For example, Anglo American launched their hydrogen-powered mine trucks a er realising that the fuel they burn impacts around 15% of the company’s emissions. This is basically the low-hanging fruit in terms of emission reduction,” he says.

“Naturally, the next step is to consider renewable, self-generated power. A er all, this is not only the right thing to do to reduce one’s carbon footprint, but also minimises the impact of load shedding on the business, by ensuring cleaner, cheaper and more reliable energy.”

Gunn notes that as a law firm, Pinsent Masons views climate change as a key focus going forward, which is why the company took a strategic decision to focus on this

area, both internally and externally.

In fact, he notes, the firm runs courses on this for all employees, covering issues like sustainability and climate change. He says this is because they recognise that environmental issues are everyone’s business, rather than just that of certain specialists in the organisation.

“We continue to educate our people because this is a rapidly developing area of law and business. Not only do we study our clients’ business carefully, in order to o er the correct advice, but we have added to our competitive advantage with the recent acquisition of international sustainable finance specialists, Morgan Green Advisory. In this way, we can help businesses to reach their sustainability goals by accessing market opportunities, adding value and mitigating risk.

“However, our o erings are still broader than this, as we are more than a climate change advisory – we are also recognised as an infrastructure and energy specialist firm. Therefore, with the drive towards renewable energy and independent power producers, we are also fully involved in all aspects of the environmental, governance and regulatory issues relating to this.”

He suggests that it is a field that o ers multiple opportunities, adding that the company has assisted clients with measuring their carbon footprints and helping them

understand where the low-hanging fruit is. Self-generation, he adds, is a wonderful opportunity for these organisations, as it reduces both emissions and costs, while a ording the possibility of selling excess power back to the grid.

“Ultimately, the environmental, social and governance (ESG) aspects are challenging and it is a broad framework that, depending on the definition, can cover the entire operations of a company. Moreover, it is both a business issue and a governance one – meaning organisations have governance obligations to meet, not forgetting the social challenges around gender equality, job security and community upli ment.

“We are a purpose-led and -driven firm, with values around equality, fair opportunities and continuous education around ESG and sustainability. Ultimately, in terms of what we are trying to achieve as a business, we view ourselves as more than just lawyers, but rather as a firm that can make a positive and beneficial impact on our clients’ businesses,” says Gunn.

Jannie de Villiers, a partner at Pinsent Masons, points out that a key part of “going green” lies in the transition away from coal power, something that is already under way. South Africa is still heavily reliant on coal power – and will be for the foreseeable future – but net-zero targets, compounded with

Pinsent Masons have extensive experience in the mining sector that will enable our expert team to provide end to end transactional support in a number of key regions, including Africa, Asia and Oceania. Our mining team includes dual-qualified lawyers fluent in English, French, Spanish, Chinese and Arabic. We provide support to investors from our o ices in Beijing and Shanghai and are actively involved in Francophone Africa from our Paris o ice.

In the year ahead, we can expect to see more large private renewable energy projects announced.

South Africa’s electricity supply troubles, have fast-tracked South Africa’s energy transition.

In the year ahead, we can expect to see more large private renewable energy projects announced, especially a er the cap on private energy generation has been wholly removed.

“The two solar plants currently being developed for Tronox Mineral Sands, by SOLA Group, have set the scene for future private renewable energy projects, while demonstrating the scale at which these projects can be operated in South Africa,” he says.

“Following the removal of the cap on private generation, we’re seeing more large projects announced. Rio Tinto’s Richards Bay Minerals has announced a 148MW project with Voltalia – estimated to be the largest renewable power plant dedicated to a single corporate customer. And similarly Sibanye Stillwater, Gold Fields, Harmony Gold and Exxaro have all announced, or are in the process of developing, renewable energy projects.”

De Villiers also notes that as a law firm,

Pinsent Masons is at the forefront of leading renewable energy companies through large-scale private generation projects, having recently advised SOLA Group on the o take transaction with Tronox Mineral Sands, and currently advising a number of other clients, including Voltalia, on similar projects.

The benefits of these projects and transactions are numerous, says De Villiers, with the most obvious being the removal of large electricity consumers from the Eskom grid. Another benefit of the mining companies getting involved in these large projects is the possibility of reskilling their employees, thereby securing employment not only at the mines, but also in local communities that surround the renewable projects.

“In fact, preserving and creating employment is likely one of the biggest challenges to South Africa’s JET, because some of the most polluting industries are some of the most significant players in South Africa’s economy – and some of the largest employers.

“While job losses are a key concern for the just transition, it’s worth noting that there are also a number of jobs and empowerment opportunities within the Just Transition Framework – particularly in cleaner energy industries.”

De Villiers intimates that one of the most exciting developments for him lies in working with clients who recognise the opportunities around repurposing old coal mines and their surrounds into farming operations. This is because o en, coal mines have large water deposits that can be treated and used for farming.

“The opportunity with these old mines is to make use of investment available for green energy and just transition initiatives, to create a sustainable business that employs the local community – and the local community must have a share in the business.

“An additional layer here would be to then introduce some form of green energy, as this will help to ensure security of electricity supply for both the farming operation and the local community, and may in future allow for the selling-on of carbon credits,” he says.

We can help businesses to reach their sustainability goals by accessing market opportunities, adding value and mitigating risk. – Gunn

“

In 2023 the trend that remains top of the agenda for mining and metals companies is that of environmental, social and governance (ESG) commitments.

However, costs and productivity continue to raise concerns as inflation bites, and mines explore new ways to manage variability and unlock value. In addition, geopolitical uncertainty – most notably the war in Ukraine – and supply chain challenges will continue to demand leaders’ focus.

The latest ranking of the top 10 mining and metals risks and opportunities reflects the competing priorities for miners in a fastchanging, volatile world. It is no surprise to learn that ESG remains the number one challenge – one that is broadening in scope and complexity, as pressure is increasing to improve reporting transparency.

According to Paul Mitchell, EY Global Mining & Metals leader, some of the greatest areas for ESG improvement are not new: improving diversity, equity and inclusion is still a major challenge, and mine closures and rehabilitation require a longer-term, more strategic view.

“However, ESG is evolving, and is thus requiring miners to consider di erent issues and broaden their capabilities to manage them e ectively. For example,

water stewardship and biodiversity are fast becoming urgent priorities amid a changing climate,” he says.

“It is clear that more rigorous reporting will become critical if companies are to meet growing stakeholder expectations, not to mention avoiding accusations of ‘greenwashing’. Miners that achieve this can get an edge on competitors in many ways –from accessing capital to securing a licence to operate and even attracting talent.”

PwC, in its SA Mine 2022 report, agrees that a global low-carbon energy agenda remains a key focus, adding that this is anticipated to result in increased demand for a number of commodities in the medium to long term. Global constraints in supply of these commodities will mean increased prices and a need for investment in supply.

When looking at a “just transition” away from fossil fuels, PwC says, the pace of this is likely to be limited by the availability of resources needed for the transition. Here, understanding the supply constraints will be key to mapping a realistic transition for the future.

Another trend that is higher up the rankings in 2023 is that of geopolitics, which is being driven by global conflict and resource

nationalism. This rising trend requires miners to develop a deeper understanding of the impact of geopolitics on strategy.

The South African Mining Industry Trends Report 2022 notes that the invasion of the Ukraine by Russia at the end of February 2022 led to unprecedented impacts on energy and industrial commodities markets.

According to the report, the price of energy commodities and precious metals, which started to so en towards the end of 2021, increased to near-historic highs by March 2022. Volatility in commodity prices hold risk for the economy and the mining sector, while higher petroleum prices fuel inflation.

EY, in turn, suggests that with many geopolitical factors beyond the control of mining and metals companies, this is a particularly di icult risk to mitigate. The greatest opportunities probably lie in forging closer ties with government, increasing collaboration with stakeholders, including trade and sector groups, and exploring the potential of government incentives and coinvestments.

EY’s Mitchell points out that while more miners are setting net-zero ambitions, pathways to achieve these are sometimes unclear. This is because an accelerated

While geopolitics, supply chain issues and digital transformation are all impacting the mining sector, a focus on climate and ESG remain among the top trends for 2023© ISTOCK –karatas

decarbonisation agenda, and sharper focus on reporting emissions, is creating a new urgency around better mitigating climate change risk.

“For example, more action needs to be taken to minimise the physical risks of climate change, such as wildfires and flooding, which may threaten operations. Companies that explore a mix of options – including carbon offsets, partnering up and down the value chain and collaborating with suppliers and vendors to monitor Scope 3 emissions – can build a proactive strategy to address a risk that is likely to become even more complex.”

The mining sector is a major contributor to greenhouse gas emissions, says Andries Rossouw, PwC’s Africa Energy, Utilities and Resources leader.

“In 2021, up to 81.4% of South Africa’s electricity was generated from coal, and considering that up to 60% of the energy used in the mining sector comes from electricity, issues of decarbonising as well as sustainable and reliable power supply are directly connected,” he says.

“Addressing these dual challenges will require the mining sector to make major investments in alternative and renewable energy sources and energy planning.”

The global energy transition won’t be smooth, he adds, as was reflected in the

record coal prices experienced for the year. As a coal export producer, it is essential for South Africa to maximise the value obtained from its coal, through supporting global energy supply stability in these times of energy volatility.

EY further suggests that soaring inflation and talent costs are significantly increasing mining expenses, squeezing productivity and delaying expansion plans.

With costs likely to remain high, Mitchell points out that more innovative approaches to managing variability, including improved modelling and digital twins, should unlock genuine productivity gains.

“Managing costs needs to be done with an eye on long-term value, as well as shortterm gains. Sustainable cost reduction measures include, for example, switching to renewable energy, encouraging innovation to reduce costs in the longer term, and creating strategic joint ventures to optimise economies of scale.”

Additionally, the Mining Industry Trends Report indicates several reasons for the recent decline. These include the gold industry experiencing one of its most protracted strikes into May 2022; platinum mines rebuilding furnaces and having

operational difficulties; and coal mines being affected by higher-than-expected rainfall and electricity cuts.

Industry players are hopeful that the situation can be turned around, says the report, depending on commodity demand and prices holding up, as well as the creation of a conducive policy environment and the elimination of physical infrastructure constraints.

Meanwhile, PwC indicates that the industry’s financial performance exceeded expectations on most fronts, as global supply chains jostled to find their way back to prepandemic levels. This resulted in a growing demand for commodities in the sector, which saw record rand prices for the platinum group metals basket, iron ore, and coal. Most other South African commodity prices remained at relatively high rand levels.

On the subject of the supply chain, EY notes that the recent disruptions have created new urgency to accelerate supply chain transformation.

“Supply chain disruption is new to the ranking, amid recent pressures, but it’s an issue mining and metals companies have long grappled with. Now organisations are intensifying efforts to transform supply chains, to better weather current volatility

It is clear that more rigorous ESG reporting is critical, to meet growing stakeholder expectations and avoid accusations of ‘greenwashing’. – Mitchell

and find new opportunities to boost e iciency, resiliency and transparency,” says Mitchell.

“Miners are considering more innovative, sophisticated approaches to mitigating supply chain risk, including through stronger relationships with suppliers and collaborative contracting. With the pandemic exposing weaknesses in the ‘just-in-time’ model, we expect to see a mix of ‘just-incase’ and ‘just-in-time’ supply strategies as miners find a way to balance supply chain resilience with costs.”

Changing demand and investor expectations are also shi ing capital allocation strategies, suggests EY.

Miners are maintaining their focus on capital discipline, but are also exploring how to invest in growth and transformation. The energy transition is shi ing demand, and companies are responding through more investment in “future-facing” commodities, such as copper and lithium, while also divesting coal assets.

Such decisions are not only motivated by a desire to adapt to an evolving market, but also to meet investors’ expectations around ESG performance. Organisations’ access to capital is increasingly linked to their ability to show how they create value beyond the bottom line.

From the perspective of the workforce, the company notes that building a purposeful brand and placing a greater focus on reskilling can help overcome talent shortages.

“Mining and metals companies face their greatest ever talent shortage following a massive wave of retirements and

resignations. Replacing these workers and finding talent with critical skills will require a radical rethink of the sector’s approach to attracting, retaining and nurturing talent. With younger workers deterred by mining’s image, companies must double down on e orts to build a purposeful brand that aligns with today’s values,” says Mitchell.

The EY survey found that mining leaders recognised the need to reskill and upskill workers, but few are embracing this opportunity. A greater focus on training existing workers and sector newcomers in di erent skills can fill talent gaps and build a more flexible, agile workforce.

Mitchell says that with demand for certain commodities set to increase and sustainability becoming a bigger focus, now is the time for organisations to rethink business models.

“We see miners analysing where optimal value can be found, then designing their business models to capture this. Whether companies decide to reshape models to rationalise, grow or transform – or consider a strategic blend of all three – those that act now to future-proof their business will best withstand disruption, navigate changing commercial relationships and ultimately win competitive advantage.”

Marc Poualion, Global Industry Marketing head, Metals and Mining at Aspen Technology, explains that mining has traditionally been known as a laggard in terms of technological adoption.

“Boston Consulting Group estimates that the mining industry is between 30% to 40% less technologically mature than comparable industries. Therefore, 2023 presents a

substantial opportunity to generate value, by adopting technology that has been proven in other industrial sectors,” he says.

“Battery metals and rare earths are in boom markets, as developed nations are removing hydrocarbon-powered vehicles from production and sale, with many governments worldwide targeting zero sales of new hydrocarbon-powered vehicles by 2035. Mines need to tap into technology that allows more e icient mining with lesser impact on the environment.”

The need for electric vehicles grows in tandem with decarbonisation, population growth, and the inevitable replacement of gasoline and diesel-fuelled vehicles. These trends are reflected in the price booms created for lithium, copper, nickel, manganese and cobalt, among others, notes Poualion. This unabated demand will pressure the mining industry to pursue digitalisation and extract existing deposits as e iciently as possible.

“Major drivers to catalyse the adoption of technology includes the need to manage complexity in mining, to be more productive, and to stay ahead of the competition. A er all, not being at the cutting edge of the technology available can position mining companies at existential risk. Therefore technology is mandatory, as it underwrites the future for mines, especially the ones mining lower-grade resources.”

Many organisations seek holistic technology strategies. But given the vast number of processes, stakeholders and commodities within the sector, it’s di icult for organisations to not only know where to start, but what will present the most immediate, impactful and measurable e ects on productivity, profitability and sustainability.

The price of energy commodities and precious metals increased to nearhistoric highs by March 2022, following Russia’s invasion of Ukraine. – SA Mining Industry Trends Report 2022

“© ISTOCK –Niteenrk Addressing climate change will require mines to make major investments in alternative and renewable energy sources and energy planning.

It is for this reason, he continues, that a bite-sized, targeted deployment strategy is the most pragmatic and effective approach. Budgets, time and expertise to support any solutions are limited, so priorities need to be made clear.

“Risk also presents a very real factor that must be considered by leadership teams attempting to implement technological solutions. Adoption of a given technology must be successful – or the time, money and potentially the careers linked to those endeavours could be placed at risk if things don’t work out.

“No one wants to be responsible for the failed implementation of a given technological solution, as this can have far-reaching ramifications for the individual, as well as the operation and the company at large,” says Poualion.

A key technological innovation in mining and resources right now is machine learning, which is transforming the industry. Solutions empowered by algorithms that can learn from past behaviour and adapt to changing conditions can positively impact many operations.

“With the Fourth Industrial Revolution in full swing, the mining industry will see greater access to information that is handled by machine-learning algorithms to produce insights that have never been possible before. Insights derived from realtime access to all forms of information as each of the processes and solutions within the mining value chain become more and more integrated, allowing for immediately actionable information and the introduction of a truly proactive approach to adapting to changing conditions on the ground.”

EY’s

“Companies are reaping significant cost, productivity and safety gains from the implementation of new technologies, including drones, remote operating centres and autonomous trucks.

“However, despite encouraging progress across the sector, we still see a largely siloed approach to digital and innovation. A more integrated strategy across the value chain in 2023 will increase return on investment and help miners better tackle their most complex challenges, including ESG and productivity,” he says.

By

By

Renewable energy from solar and wind sources is essential for the decarbonised domestic and global economy. Rechargeable batteries containing the mineral cobalt are used to store electricity produced by these and other renewable energy sources. These batteries are critical for the continued electricity supply when the wind is not blowing, the sun is not shining, and the tides are not flowing.

Cobalt is quickly becoming an in-demand mineral critical to the green energy supply chain and is a part of the base metal group that is becoming the heart of the renewable energy transition. It is a critical component of battery materials that power electric

vehicles (EVs) and renewable energy sources and is facing a sustained surge in demand as decarbonisation e orts progress.

Due to the push for global decarbonisation, countries have begun to renew minerals exploration, with African countries such as South Africa relying on secondary exploration to maintain existing operations. South Africa is one of many African countries with a cobalt supply, with the Kruisrivier mine currently being worked commercially, with operations focused solely on cobalt.

Speaking to Tebogo Kale, director of Gravitas Minerals, about the increased occurrence of secondary mining opportunities in South Africa concerning

cobalt and other battery materials, he says: “We are currently seeing strong demand for base metals such as cobalt, manganese, and zinc within South Africa. The main province of interest is the Northern Cape, which will become the new renewable minerals mining Mecca.”

Although cobalt is vital for the production of numerous types of renewable energy batteries, the regions in which it is produced are prone to child labour, human rights violations and other types of exploitation

Benjamin van der Veen© ISTOCK –Manciagli © ISTOCK –m_a_n

The uses of cobalt are as diverse as they are enduring. First isolated as a metal in 1739, cobalt has formed the cornerstone of many essential applications in operation today, from alloys used in jet turbines, hard metals and orthopaedic implants, to clean fuels, and the inks and pigments applied to pottery, enamel and glass.

It is also the active constituent of vitamin B12 and is essential for human and animal health and vitality. But the most significant use of cobalt, as the world develops more sustainable energy solutions, is as a raw material in rechargeable batteries.

“More than 50% of the cobalt produced globally today is found in rechargeable batteries, namely those used in portable devices, stationary applications, and e-mobility,” says Shane Bradshaw from Energy Management SA.

“As electric modes of transportation continue to evolve, the demand for battery commodities like lithium-ion and cobalt is set to increase, amid concerns over whether there are su icient amounts available,” he says.

The Cobalt Institute (CI) is a non-profit trade organisation that promotes the responsible and sustainable production and use of cobalt in all forms. CI past president David Weight explains about the growing importance of cobalt in the renewable energy market and why this metal – and others – will play an essential role in the green energy transition.

“It is important to realise that over 90% of cobalt is produced as a by-product of largescale copper and nickel mining. The only small exception to this is Managem’s BouAzzer mine in Morocco, which mines cobalt as a principal metal from a polymetallic sulphide ore,” says Weight.

“The majority of cobalt (70%) comes from the Democratic Republic of the Congo (DRC) as a by-product of large-scale copper mining and there is a proportion produced through artisanal and small-scale mining operations too. This activity is perfectly legal and o en at subsistence level, but is very poorly regulated.”

All in all, he says, the large-scale

mines, particularly those in the western jurisdictions, “operate to standards of international best practice and have very well-established Entreprise Générale du Cobalt (ECG) programmes”.

“As such, these mines will have environmental stewardship, occupational health and safety etc., and will be highly regulated. Over the past 30 or 40 years, there has been a much bigger push for sustainable mining practices, and you will see from the larger mining companies that within their ECG obligations, there are sustainable performance requirements that must be adhered to.”

More than 50% of the cobalt produced globally today is found in

International metrics will also measure the sustainable performance of the more significant copper and nickel producers, and they are expected to validate their performance independently and transparently, too. The most critical concern for cobalt and all metals and minerals is that they are responsibly and sustainably sourced and used.

Responsible sourcing means that when you source your raw material, you know who has provided it and that it is being produced in an ethically acceptable way. Issues around sustainability are constantly addressed and improved because globally, the environmental footprint of any product must be measured to assess its environmental impact through its life cycle.

“At the moment, it is bordering on the essential,” says Weight. “We must look at this in a broad context because, in the first instance, a paradigm shi occurs from the internal combustion engine to electric mobility, driven by the global desire to decarbonise global economies.”

For example, he notes that the massive change from the horse-drawn carriage to an internal combustion engine is similar to the shi from the internal combustion engine to the rechargeable batteries used for electric mobility. It will be a substantial disruptive transition.

“The world will wean itself o fossil fuels and look more towards renewable energy. This is only possible with a specific suite of energy metals and rare earth elements.

“The lithium-ion battery has changed the game enormously, permitting electric mobility, and most lithium-ion batteries contain cobalt, including lithium-nickelmanganese-cobalt-oxide (NMC) and lithium-nickel-cobalt-aluminium-oxide (NCA) batteries.

“The batteries with the highest specific power density and specific power capacity

mining in the DRC is estimated to produce some 15% of the global cobalt supply.

contain cobalt. Without access to this whole suite of metals, there will be no energy transition.”

In 2020, South Africa produced 1 800 metric tonnes of cobalt, which is only a fraction of the total annual global cobalt mine production of roughly 140 000 metric tonnes. Staying in Africa, cobalt is currently being mined in the DRC, Madagascar, Morocco, Zambia and Zimbabwe.

Zimbabwe has one of the world’s largest copper and cobalt reserves. The world’s largest cobalt supplier is, however, the DRC, where it is currently estimated that up to a fi h of cobalt production in the country is produced through artisanal miners.

The DRC accounted for more than 70% of the world’s cobalt production in 2019, producing 100 000 metric tonnes. As a result, many of the world’s largest mining companies have established operations within the DRC.

The Katanga Province is a productive region within the DRC, home to some of the world’s biggest cobalt mines, including Mutanda, Kamoto, Etoile and Ruashi.

However, a significant artisanal mining sector has also bloomed in recent years, buoyed by growing demand for cobalt. A

report from the World Economic Forum (WEC) estimates small-scale mining accounts for 15%-30% of all cobalt production in the DRC.

For years, human rights groups have documented severe human rights issues in the DRC’s artisanal and small-scale mining. The DRC is a country where violent ethnic conflict and high levels of corruption have weakened oversight. Child labour, fatal accidents and violent clashes between artisanal miners and security personnel of large mining firms are recurrent within the DRC’s cobalt mining landscape.

E orts to meet the demand exerted by EVs have been focused on increasing the cobalt supply. In 2021, the DRC was estimated to be producing between 60% and 70% of the world’s cobalt supply.

Most of the extracted cobalt is a byproduct of existing copper mines. However they cannot increase their output to meet existing demands and have little financial incentive until copper prices also rise to complement mining activity. The other primary source of cobalt outside existing copper mines in the DRC is produced via artisanal mining, which is estimated to produce up to 15% of the global cobalt supply.

Given that artisanal miners within the DRC are producing more than Russia – the world’s second-largest producer – their role

It is crucial that the rapidly rising demand for batteries does not come at the expense of adults’ or children’s basic human rights.

– Sobotka

“ “Artisanal

and the conditions under which they operate are essential to understand. Artisanal miners hand-dig higher grade ores than those extracted through industrial or mechanised production. But there are well-reported problems with artisanal mining regarding social and environmental costs.

The small mines in which artisanal miners operate are o en dangerous and polluting. The mining and refining processes are o en labour-intensive and associated with various health problems due to accidents, overexertion, exposure to toxic chemicals and gases, and violence. And these miners, known locally as creseurs, are so economically reliant on this informal economy that these dangerous conditions cannot a ord full consideration.

The environmental costs of cobalt mining activities are also substantial. Southern regions of the DRC are home to cobalt and copper and large amounts of uranium. In mining regions, scientists have made a note of high radioactivity levels. In addition, mineral mining, like other industrial mining e orts, o en produces pollution that leaches into neighbouring rivers and water sources. Dust from pulverised rock is also known to cause breathing problems in local communities.

International firms that trade, refine and supply cobalt have been trying to understand how cobalt from artisanal mining

has entered their supply chains. While in theory there are legal di erences between industrial and artisanal mining supplies, the boundary between the two remains quite blurry. Although there have been pledges from companies to increase transparency regarding their cobalt sources and refineries, or promises to buy exclusively from other countries, very little in the conditions in the DRC has changed.

One reason there’s been so little change in the region in a decade is the strong economic incentives from artisanal mines. It is currently estimated that between 140 000 and 200 000 people work as artisanal miners in the DRC and most earn less than R170 per day.

Considering the vast economic incentives, both domestically and internationally, to keep artisanal cobalt mines open, what does the green energy transition look like next?

Given that cobalt-based batteries are a crucial and inevitable part of the green energy transition, large-scale industrial and artisanal mining are here to stay. A WEF white paper in 2020 outlined the current state of artisanal cobalt mining in the DRC and o ered recommendations to make the industry fair and safer.

Among them is the formalisation of a traditionally informal economy, which

would include adopting common standards and metrics, establishing a monitoring and assessment process, and knowledge-sharing to ensure that a formalisation process is a multi-stakeholder one.

The Global Battery Alliance (GBA), a multi-stakeholder organisation to establish a sustainable battery value chain, recently launched its Human Rights Index and Child Labour Index for the Battery Passport, ahead of Human Rights Day on 10 December 2022.

The indices are the world’s first frameworks to measure and score the e orts of any company or product specific to the battery value chain, towards supporting the elimination of child labour and respecting human rights.

Benedikt Sobotka, co-chair of the GBA and CEO of Eurasian Resources Group, says: “It is crucial that the rapidly rising demand for batteries does not come at the expense of adults’ or children’s basic human rights.

“The GBA is proud to have launched these human rights and child labour Indices, which aim to immediately and urgently eliminate child and forced labour, strengthen communities and respect the human rights of those employed by the battery value chain. The rollout of these indices has been possible thanks to the GBA’s global, collaborative approach, and we look forward to developing them further with valuable input from our members.”

Over 90% of cobalt is produced as a by-product of large-scale copper and nickel mining.

– Weight

“ “

By Arjen de Bruin, MD at OIM Consulting

By Arjen de Bruin, MD at OIM Consulting

For years, both government and the corporate sector have invested serious e ort and resources into skills development in the mining industry.

As a key employer of vulnerable groups and a significant revenue generator for the country, this comes as no surprise. According to the Minerals Council South Africa, an accumulative R6-billion was allocated to mining skills development and training in 2017 and 2018. This is not small change.

However, I would argue that while there has been a focus on technical training, there has not been su icient emphasis on coaching mining supervisors in critical behavioural skills in order to optimise job performance.

Why is this? Mining is indisputably the Clint Eastwood of all the “hard-man” industries. Historically a male-dominated sector, we’ve kept our focus fixed on the technical stu . How to drill and blast. We’ve got user manuals for days, long lists of standard operating procedures, and safety training which is integral to a high-risk work environment.

These technical skills o en mean the di erence between life and death and are rightfully prioritised, but they’re not the only areas of importance.

Instilling behavioural and problemsolving skills is far more complex. As a supervisor, how do you have di icult conversations with your team? How do you employ a more carrot than stick approach to coax the best out of your team? How do you drive culture in a way that motivates and energises? How do you solve daily operational challenges? These questions

Both technical and behavioural skills are vital in mining.

are o en ignored, as we default to the hardman’s first port of call: we yell to be heard.

If you’ve promoted someone to a supervisor role, you’ve done so because they’ve proven their proficiency in technical aspects of the job. Now it’s your duty to ensure they’re equipped to lead. This is the only way we’ll e ectively bolster output, consistently reach targets and improve productivity across the industry – and where we now need to focus our skills development programmes.

The digitisation of the global mining industry remains a global imperative, and automation will become increasingly prominent in South Africa. Change is coming and it will drive a recalibration of daily mining functions and roles. And this is where behavioural coaching and problemsolving skills will play a critical role.

Training in new technologies will be

important, but mechanisation alone will not boost output. Machines cannot replicate the empathy and judgement of a person, motivate and inspire a team, or solve operational obstacles. It will become critical for supervisors to step up to and into their new roles.

Behavioural skills coaching boosts output and empowers people. Our workers become more competent, which in turn boosts their confidence, streamlines the execution of daily activities, and leads to increased output.

Teaching the workforce how to plan, communicate and problem-solve gives them transferable skills that can be used at work, home and in the community. Overall, the development of behavioural skills is just as important as technical ones. It’s time to equip our supervisors with the right skills for tomorrow.

Investing in the right behavioural skills is just as important as inculcating technical ones in modern industry, and is something that is critical for mining’s sustainability

Bouncing back from two years of self-enforced isolation during the pandemic, the SA Mining Indaba returned with a vengeance in 2022, and is expected to be even bigger in 2023. The o icial theme of this year’s event is “Unlocking African Mining Investment: Stability, Security, and Supply”.

Attendees will hear from global leaders in the Mining Indaba network, including Anglo American chief executive Duncan Wanblad, Rio Tinto’s chief executive: minerals Sinead Kaufman, the relatively new CEO at Exxaro Resources Dr Nombasa Tsengwa, Minerals Council South Africa CEO Roger Baxter, and other top executives involved in Africa’s mining industry.

With commodity prices remaining strong, demand for critical minerals, battery metals and rare earth metals continues to accelerate, and we can expect this to translate to another bumper turnout, as the Indaba returns to its traditional date in February.

“The resounding success of the 2022 show lay in its ability to bring people back together safely, securely and in large numbers, a er such a long time apart. There were many unknowns in the lead-up to the show, so delivering an Indaba with record numbers in the way that was achieved proved a huge success,” notes Tom Quinn, head of content, Mining Indaba.

Looking more closely at the industry, the number of government leaders and heads of government increased significantly from the last live show in 2020, with three heads of state, one prime minister, 48 ministers

and 19 High Commissions and ambassadors. This really rea irmed the importance of the Indaba – highlighting the attention and support given by state o icials, and its ability to drive positive policy change across the continent.

“One particularly exciting new programme is the Explorers Showcase, where we want to highlight early-stage explorers through presentations and core samples to help stimulate those muchneeded conversations with investors. This ensures the Indaba can now claim to be driving investment into every stage of the mining production cycle – through explorers to juniors and on to mid-tiers and major mining companies,” he adds.

With Mining Indaba’s integration of 121 Group, the event is in an even stronger position to serve the thousands of delegates with bespoke meetings between investors and junior miners as part of their Mining Indaba experience.