Our offering

Our offering

This document outlines our proposal to support Volker Rail by delivering ‘value for money’ plant solutions to best support the delivery of projects throughout the SP&C Framework workbank.

It is intended to give a flavour of our capability and capacity alongside details of our proposed solution for Story to carry out a wide range of works to support the completion of signalling, power and telecomms schemes throughout Scotland.

Based from our strategic locations, our team are ideally located to support projects across the length and breadth of Scotland, from the Borders to the Highlands.

Our team in Salsburgh is supported by our team from our Carlisle Head Office, and with the upcoming addition of a base in Dingwall, our team is able to efficiently deliver for Volker on schemes across the country.

Through the early engaegement and the establishment of our upcoming Dingwall location, we will be able to establish a sustainable and efficient long-term plant solution for projects. This will enable the required machines to be housed at our new location, removing the requirement for costly transportation of machines back to the Central Belt.

Led by a single point of contact for Volker, we will provide a consistent core team who will drive targets and embed behaviours. Using our local resources, we will reduce lodge costs and reduce worker fatigue from excessive travel.

Our capabilities include:

• Installation of OLE piles and civils bases

• Installation of masts and small part steel

• Transportation and positioning of LOCS

• Cable run-out and transportation

• MEWP supply to support all OLE works

• Aroboriculture and vegetation management solutions

• Off-track lifting and civils

• Trackside signalling works

We pride ourselves on high quality delivery of our projects across the UK and strongly believe in transparency and collaborative working. We will work closely with the Volker team to utilise our extensive experience and knowledge of best practices to provide effective advice on best plant solutions and methodologies.

As a trusted plant solution partner, we are able to offer Volker much more than a spot hire service, instead providing added value by realising efficiencies throughout the Volker workbank. Through the adoption of a Pain & Gain model, we are committed to developing best-for-all solutions and ensuring the safe and efficient delivery of schemes.

In addition, through collaboration with the Story Contracting team, we are also able to explore the possibility of co-habitation of site facilities, providing further cost efficiencies through the reduction of costs such as access and welfare.

We operate a fleet of 30 RRV MEWPs consisting of 16 Manitou and 14 Promax EVOs, both giving 400kg basket capabilities and are set up for ALO working, we provide additional storage space for OLE works, with drop down trailers/towed trailer types which enables further materials to be transported on the machine, improving on-site efficiencies.

With the use of our MEWP and wider RRV fleet, we are able to support OLE works including maintenance, contact wire runs, OLE resilience and main part steel installations.

Our fleet of 130 machines includes state-of-the-art a range of heavy-lifting wheeled excavators capable of carrying out a variety of works, as well as tracked excavators which boast incredible flexibility and versatility on-site.

Our fleet also includes our Colmar T10000 RRV Crane enables a wide range of lifting activities to be carried out inlcluding signal masts and LOCS. In addition, our tracked Colmar T10000 provides unrivalled lifting capabilities, often enabling activities which previously required tandem lifting activities to be carried out utilising a single machine.

Story Plant have over 10 years experience in installing piled foundations on and off the rail infrastructure. Our inhouse ‘pile ready’ fleet of Colmar RRV, side grip hammers, impact hammers and telescopic auger drivers are engineered for OLE piling works.

• Augered foundations

• Helical pile foundations

• Ground stabilisation

• Signal foundations

• Gantry foundations

• OLE foundations

• King post installation

• Sheet piling

• Tubular piling

Our fleet of Colmar RRVs are capable of installing all types of OLE main steel with various attachments available.

Alternative OLE main steel installation solutions have been developed using ‘rhino horn’ boom extensions, pile pitching clamps and a ground release shackle. This method eliminates damage to fixing bolts and removes any work at height hazards.

Our plant fleet is supported by a team of in-house POS Reps, plant operators, MC/CC, OLEC 2-3 Linesmen, OLEC 4-5 supervision, engineering assurance and construction management.

Our fleet of machines and specialist attachments enable us to support a wide range of lineside civils activities on the rail network. We are also able to utilise our hi-ab wagon fleet to provide just in time deliveries to site, reducing security risks of storing materials on site.

Our lineside civils works typically include:

• Cable laying

• LOC deliveries

• REB installations

• Troughing and material distribution

We operate a fleet of technologically advanced fleet which provides the capability to complete a range of signalling works.

Alongside our MEWP fleet, we also utilise a fleet of RRVs with Rhino Horn attachments, and our in-house developed Colmar Crane. These machines are ideally suited to complete works such as:

• Signal post replacement

• Signal head replacement

• Signal base installations

• Haulage and lifting provision

We operate a fleet of MEWPs with large 400kg basket capacities, providing addition storage space for OLE works. In addition, we have also developed bespoke storage solutions, which enable further materials to be transported on the machine, improving on-site efficiencies.

In order to support the vegetation management requirements of our clients, we have invested in a number of specialist attachments. In addition, our in-house team have worked with our clients to develop bespoke solutions to help reduce waste and improve productivity during vegetation management works on-site, including:

With the use of our MEWPs and wider RRV fleet, we are able to support OLE works including:

• Contact wire runs

• OLE resilience

• Main part steel installation

• Flailing

• Chipping

• Hedge cutting

• Site clearance

Our Geotechnical Engineering team delivers practical, costeffective design and construction solutions that make ground conditions safe, stable and sustainable. We provide support from the earliest stages of design through to construction and long-term asset monitoring, ensuring full alignment between investigation data and engineering delivery. Our experience includes:

• Slope stabilisation and earthworks remediation

• Soil nailing, ground anchoring and mesh installation

• Mine grouting and void treatment

• Rock drilling, scaling and netting

• Foundation design and installation

• Structural coring, testing and inspection

Our Ground Investigation team delivers a full range of site investigation, inspection and monitoring services, tailored to meet the needs of each project. We combine traditional and modern techniques to assess soil, rock and groundwater conditions, providing the vital data needed to inform safe and sustainable design.Our capabilities include:

• Desk studies and feasibility assessments

• Trial pits, window sampling and rotary drilling

• Dynamic probing, CBR and plate bearing tests

• Soakaway and infiltration testing

• Core drilling for structural investigations

• In-situ and laboratory testing

• Instrumentation installation and monitoring, including inclinometers, piezometers and gas standpipes

• Geo-environmental sampling and contamination testing

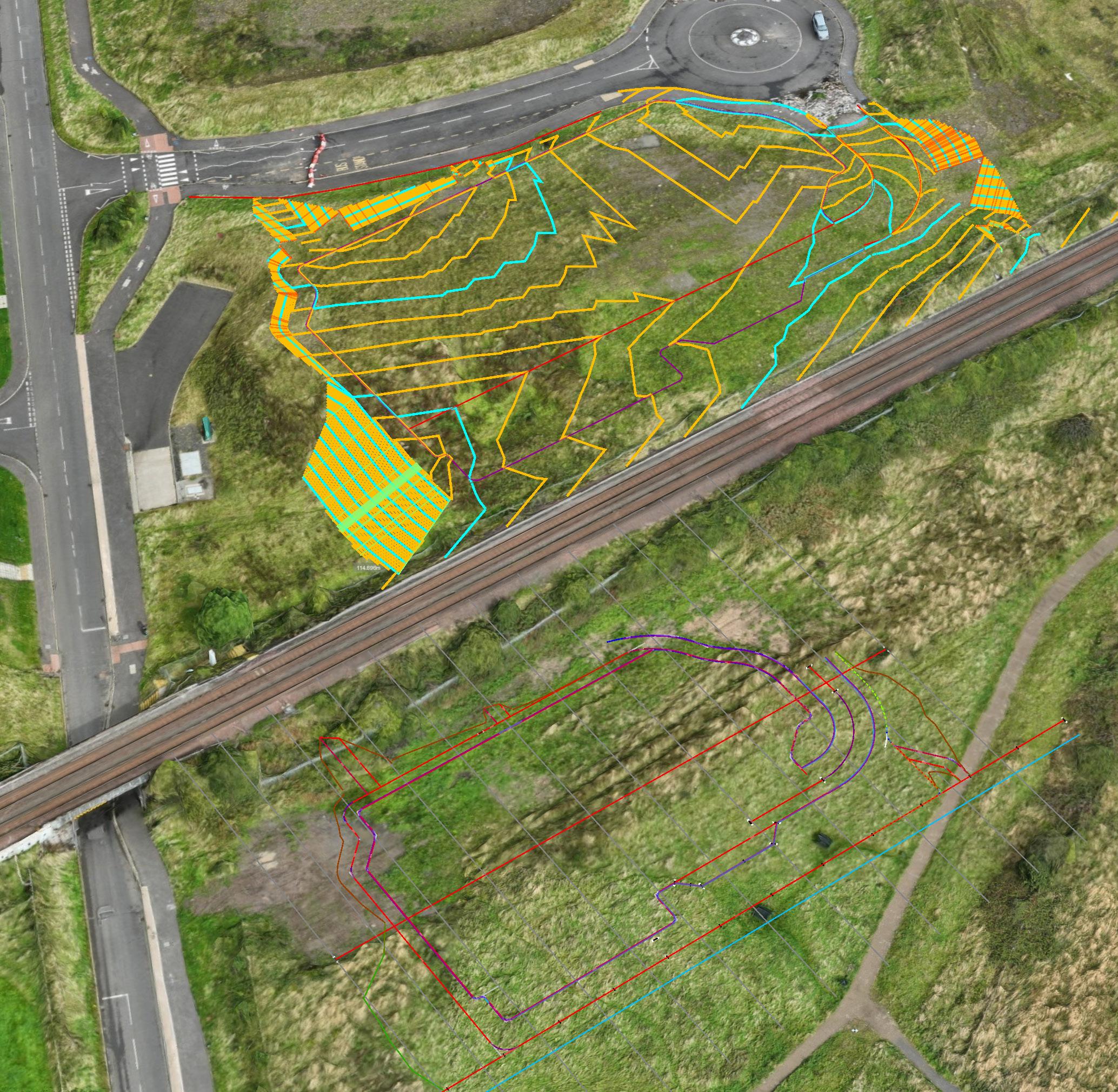

Our in-house Drone Survey team hold Civil Aviation Authority accreditation and use directly employed licensed pilots.

Using the latest survey technology, the team deliver photogrammetry, survey inspection, 3D point cloud and media data to deliver:

• Improved Safety: surveys completed with fewer ‘boots on ballast’

• Reduced Cost: surveying large areas quickly and without track access

• Fully integrated: with direct data transfer to design software and BIM

• Supporting TRU, Story Drones can:

• Provide topographical survey of compound locations to identify cut and fill volumes

• Enhance planning, delivery mapping and pre works briefings

• Reinforce As-Built data recording of completed installations

Operating our own fleet of haulage vehicles enables us to transport our machines to projects as and when required, even at late notice. By using our own in-house planning and delivery teams, we provide our clients with confidence that machines will be delivered to site safely and ontime, reducing the risk of programme disruption.

Our hi-ab wagons also enable us to provide just-in-time delivery for clients, reducing the security risk of storing machines and materials on site.

Our highly experienced team has a deep understanding of ALO, with expertise in delivering projects in compliance with Network Rail ATP 04 standards. From the planning to final delivery, we work collaboratively with all relevant stakeholders and construction teams to develop a safe, efficient, and fully compliant ALO working methodology. Our structured approach ensures that all ALO activities are carefully planned and executed to the highest standards. We operate a modern, versatile fleet of machinery, all equipped with certified ALO working systems. This enables us to deploy the right specialist equipment for each project and maximise productivity.

Our POS planning team are experienced rail staff who are implanted into our clients’ teams and work alongside their staff to ensure successful project planning and delivery.

Our POS provision provides efficiencies by de-risking works and freeing up members of your team, but also generates cost savings. This is achieved through machine selection, innovative pricing packages and working collaboratively to achieve efficiencies in project methodologies. We can track the savings generated on a monthly basis, with our existing clients seeing savings of up to 29%.