TEA SHACK NEWS

WORKFORCE ENGAGEMENT SUPPORT TEAM

REBOOTED WEST

WORKFORCE ENGAGEMENT SUPPORT TEAM

The winners of the Offshore Safety Awards 2024 were announced at the Beach Ballroom in Aberdeen in July.

The annual awards ceremony, jointly organised by Step Change in Safety and Offshore Energies UK and sponsored by Harbour Energy, celebrates the outstanding individuals and companies going above and beyond to improve safety across offshore energy operations.

have positively influenced or improved a major accident hazard system.

Also new for 2024 is the Wellbeing and Workforce Environment award, sponsored by SLB. This award aims to recognise those who have actively engaged in improving their worksite or made a difference to their company’s approach to employee wellbeing and the workforce environment.

• Award for Maritime Safety Sponsored by Marine Safety Forum Paul Davison, Anasuria Operating Company Limited

Included in this year’s awards were two new categories. The Major Hazard Awareness award, sponsored by CNOOC International, aims to recognise an individual or team who

A total of 18 finalists were considered for six categories of awards, and the audience had the unique opportunity to decide the winners through an interactive vote.

Craig Wiggins, CEO, Step Change in Safety, commented: “It is always a pleasure to co-host these awards which shine a spotlight on individuals and organisations who play their part in making the energy industry a safer, healthier and happier workplace.

“We can all be inspired and learn from the finalists and category winners’ stories which each reflect shining examples of best practice across industry sectors. I would like to thank all those involved in making this flagship event a success and to everyone who took the time to submit nominations. Once again, my congratulations to the finalists and winners.”

• Award for Safety Representative of the year - Sponsored by OPITO Kevin Clark, Serica Energy plc

• Award for Wellbeing and Workforce Environment - Sponsored by SLB David Leiper, Harbour Energy

• Award for Workforce Engagement Sponsored by Apache Broken Rules Campaign Team, TotalEnergies

• Award for Major Hazard Awareness Sponsored by CNOOC International Frank French, Blair Field Services Ltd

• Award for Sharing and Learning Sponsored by Spirit Energy Callum Chesshire, Anasuria Operating Company Limited

Gatsbyd Forsyth, Senior Vice President North Sea HSES at Harbour Energy said: “Being a safety leader is not just about adhering to protocols; it’s about inspiring others to take safety seriously. That is exactly what the Offshore Safety Awards are all about – recognising and showcasing the efforts of our most valuable asset, our people, to drive a culture of safety excellence across the sector.”

“Congratulations to this year’s winners and the many excellent finalists, who took the time to share their commitment to, and accountability for, transforming our industry.”

•

•

•

12 September Human Factors Quarterly Forum: Human Factors in Incident Investigation 09:00–11:30 4th floor, Annan House

15 September Sunday Safety Session - Q3: Lifting, Drops, Working at

15:00–15:45 Online Event

•

When we are fatigued, we have the cognitive impairment similar to that of being drunk! Our reaction times are delayed and our focus becomes blurred. This is why we are clumsy when we are tired.

• Improve communication and better understand your colleagues

When we are trying to switch off but have something on our mind, our sleep is the first thing that is affected. Quite often our brain runs away with thoughts and images that appear so real, the body reacts chemically and emotionally as if it were real. And these stressed or excited feelings induce the production of cortisol, the ‘wake up’ hormone, which is why we can’t sleep.

We will always be presented with something that bothers our sleep, so this is what to do to help.

1. Put the 5 point switch-off routine into practice, you will be more likely to fall asleep open and relaxed posture then closed up tight (see ‘How to Sleep Smarter’ in Q2 2024 Tea Shack News)

2. Change the narrative

Sometimes we get bogged down with thinking about how little time we’ll get to sleep, wondering

why we are not sleeping etc. Ask yourself why you aren’t sleeping and can anything be done about it. If the answer is ‘yes’, fix it! If ‘no’, move to point 3.

3. Give it up as a bad job instead of lying in bed annoyed about not sleeping. Rest in bed, watch TV, listen to music, read a book, go on your phone (in orange mode not blue light). You are more likely to fall asleep resting than when you’re just lying there annoyed.

4. If all of the above have failed, then tell someone at work about your lack of sleep. If you are seriously tired at work, you’re a risk to yourself and your coworkers. This isn’t a cop-out for working, its simply making you safer. Telling a supervisor or colleague means they can check your work or you can be mindful of it yourself. Once you’re at this point, the best advice I can give is sleep any time you get the chance – breaks, lunch or even 7pm after dinner. Just get what sleep you can!

Join us in the next issue to read about issues such as noisy cabin mates, snoring and sleep apnoea.

This year’s service of remembrance was once again kindly organised by the Pound for Piper Memorial Trust (PFP) and held in the North Sea Memorial Rose Gardens at the Piper Alpha Memorial, located in Aberdeen, Hazelhead Park on Saturday 6th July 2024.

The service was conducted by Reverend Michael Mair (Oil & Gas Chaplain), featuring Calum McIlroy, an accomplished musician who provided music composed especially for the service alongside a traditional piper.

Email: editor@teashack.news

The service included:

• Prayer & Act of Remembrance

• Reading of the names of 167 Souls

• One Minute Silence

• Laying of Wreaths/Flowers

• Commemoration

Refreshments were also provided courtesy of the Pound for Piper Memorial Trust (PFP) and were served to family and friends at the Park Café.

This year the oil chaplaincy kindly agreed to display the Piper Alpha Book of Remembrance, which has recently been rebound, so those attending the private reception could view it.

The Trustees of Pound for Piper and industry representatives, including Step Change in Safety, were also in attendance to support those who remain deeply impacted by the events of July 6th 1988.

You can view the recording of this year’s service, produced by Roy Stewart of RS Films, here: https:// www.stepchangeinsafety.net/ workgroups/major-accident-hazard/ remembering-piper-alpha/

www.stepchangeinsafety.net/teashack-news

Within our industry, it is recognised that we have a strong focus and commitment on ensuring competent personnel undertake our lifting operations. Key to ensuring sustainability of this focus is the need to train and develop the competency of personnel.

The typical well-established training and competency route for lifting trades is:

1. the initial onshore training, followed by 2. a period of monitored development to achieve the necessary experience to develop. This is often controlled by a logbook, and is then formally assessed against the competency standard for the trade.

This requires a commitment from duty holders and employing companies to manage the development of trainees. However, do we provide suitable guidance to supervisory personnel on the decision-making involved to help trainees develop, whilst ensuring everyone stays safe?

The following guidance has been developed and implemented by one duty holder and, whilst focussed on lifting operations, it can be adapted for any trade with a similar training and competency route.

If you have identified an opportunity for a trainee to potentially participate within a lifting operation then consider the following points:

• Have the minimum competency requirements for the lifting operation (as defined within the lifting plan) been met without the inclusion of additional trainees? Trainees should never be used to “make up the numbers” if you have insufficient suitable competent personnel for the lifting operation.

• Can the lifting activity support the inclusion of trainees in the activity without introducing additional hazards? For example, there may be sufficient space for the designated lifting team to work safety within an area, but adding additional personnel may hinder safe escape routes etc.

• Is there sufficient supervisory experience within the lifting team to safely monitor and supervise the trainee? This point opens up the considerations such as:

- Who is supervising the operation and do you know them? E.g. is it your experienced core crew or an ad-hoc vendor lifting team?

- How complex is the lifting operation with regards to the experience of the individual trainee? Are you comfortable that the activities you are assigning the trainee are within their current experience level? Do you really want a green hat guiding the load through that tight space during a blind lift?

- How much direct supervision is required? Different levels of direct supervision are required for a newly qualified green hat on their first trip offshore compared to an individual approaching readiness for their competency assessment. Gauge the requirements based upon the individual and activity.

Ultimately, whilst there is a desire to continually develop trainees, not every lifting operation is suited as a training and development opportunity.

Hopefully, considering these simple guidelines will help you reach a practical and safe decision on an individual basis.

Have you ever wondered how offshore wind turbines are installed?

The next generation of modern offshore wind turbines (WTG) – 15 to 20 MW – are getting bigger and bigger, with a nacelle weight exceeding 500 tons, as well as exceeding 100m in height for the tower.

The nacelle component is the housing at the top of the tower that enables the transfer of the wind power harvested through the blades and converts it into electric power through the critical components (permanent magnet generator or gearbox, drive train and generator)

The offshore installation of such a heavy load at 120m above sea level requires detailed planning and a heavy lift vessel capable of executing the lifting operations safely. One complete turbine set consists of one tower, one nacelle and 3 blades.

To install a complete offshore wind turbine (excluding the foundation), a sequence consisting of 5 lifts is carried out with loads ranging from 60 tons for a single blade, to more than 900 tons for the full tower. Moreover, it’s not done only once but, during construction phase, it’s repeated more than 60 times on average and up to 100+ times for larger wind farms.

Perfect execution of each offshore lifting operation is critical for the safety of the technicians, the safety of the installation jack up vessel sitting on the

seabed with her legs adjacent to the WTG foundations, and for the success of the project.

To assist with the lifting operation, special lifting and guiding tools are used to control the load, particularly for

lifting the blades; by nature, blades are designed to catch wind power. Despite the progress made over the past years on safe-by-design and engineering out some risk (e.g. by removing technicians from under suspended load), lifting operations are still an area of focus for the offshore wind industry developers and contractors; G+ (offshore wind health and safety organisation) has again this year highlighted this issue, with lifting operations remaining the most common incident-prone process.

A new interesting area within lifting operations in the offshore wind industry is now emerging as floating wind projects are developed; new ways of working for lifting offshore will need to be investigated, particularly for the operation and maintenance phases.

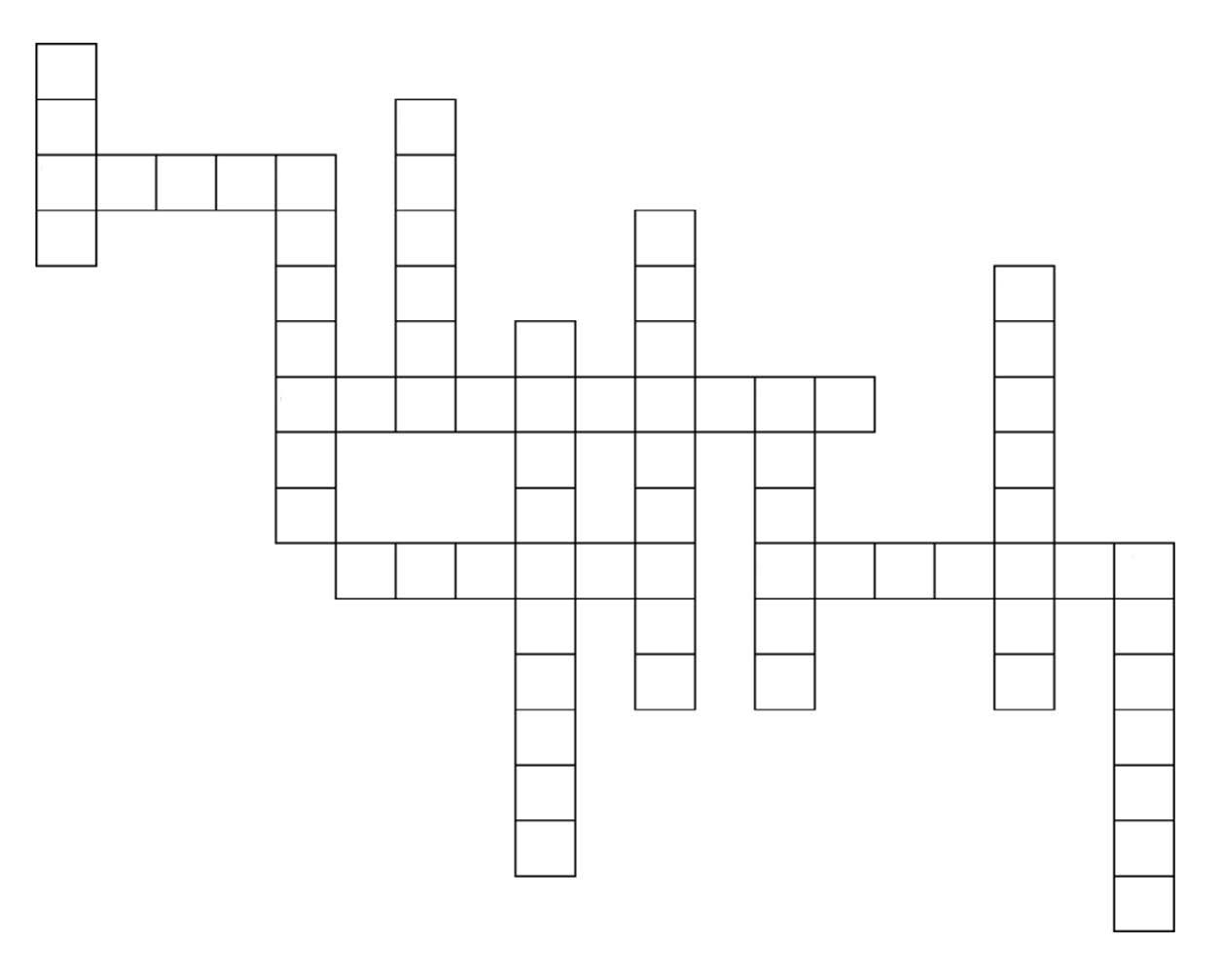

You should _____ Working at Height where reasonably practicable to do so

Safe _______ Lifting - one of the 9 IOGP Lifesaving Rules 10. I ______ tools and work materials to prevent dropped objects (When W@H)

An arrangement of straps buckled or looped together

1. Hannibal loved it when a (lifting) ____ came together

2. ______ Drop, Refers to an object that falls under it’s own weight

4. _______ Drop, Refers to an object that falls due to an applied force

5. LOLER = Lifting Operations and Lifting _______ Regulations

6. Signs and _______ - erected to create an safe working area or exclusion zone

7. Drops _______ - a chart that allows the user to determine the impact potential of a dropped object

9. Always tie-off to approved ______ points when working at height

12. Banksman ______ - person who directs lifting operations

Step Change in Safety met John Turnbull, Technical Sales Manager at Caledonian Access who shares his 40+ years of energy industry knowledge and experience on how we can all take a safer approach to low level working at height.

John has spent 20+ years managing and co-ordinating access onshore and offshore, which has driven his passion for change through innovation, introducing multiple safer practices worldwide.

This quarter, he is calling for low level working at height practices to be placed under the microscope, believing there is always an opportunity to reduce risk and improve efficiency.

John advises, “Step ladders contribute to a high number of working at height injuries every year. So, if they are one of the most dangerous tools in the access toolbox, why are step ladders still considered ‘first choice’ low level access in the energy industry?

By comparison, if you walk onto a new build construction site at fit stage, you will be hard pushed to find any step ladders because the sector is ‘choosing steps and ladders last’. This work environment is largely smooth level flooring with no wind, but offshore, we use step ladders hundreds of feet up in the air, on gratings and warped plate decks that can be wet.

The HSE step ladder guidance advises limiting work to lightweight, noncomplex activities, of up to 30 minutes duration. Three points of contact are recommended but you are allowed to have both hands free for a brief period, provided that the body is supported by the stepladder. There will always be a need for ladders and steps and they are not banned by the HSE.

But when using step ladders, are we considering our accumulated working at height risk?

If a scope of work involves multiple step ladder deployments, e.g. a scope of detailed explosive protected (Ex) equipment inspection which involves 30 minutes of step ladder use multiple times over, this adds up to hours of exposure to the risk of a fall. Should we not look for safer equipment that reduces the risk of this fall?

Email:

Non-powered Push Around Vertical (PAV) access platforms

Non-powered Push Around Vertical (PAV) access platforms have been used in the construction market for several years. These small mobile access platforms are recognised as the safest, most cost-effective alternative to step ladders and small scaffolds in the construction sector.

This technology has been adapted for and approved by the oil and gas industry and is being used at onshore and offshore installations. The elevating mechanism is manual and they are Ex approved.”

3 Safety: alternative to steps, scaffolds, and low-level rope access, reduces work at height risk.

3 Efficiency: one-person can complete tasks previously requiring 2-3 operatives.

3 Mobility: unlike scaffolding, does not block walkways and escape routes.

3 Ergonomics: comfortable to use, always at the perfect height resulting in reduced fatigue. Reduces manual handling.

3 Reduced Risk: tools can be tethered and all equipment is to hand, minimising dropped objects

3 Usability: E-Learning training available.

Find additional support at the link below and access resources on this quarter’s theme of “Safe Lifting, Working at Height, and Preventing Dropped Objects”: https://www.stepchangeinsafety.net/ annual-themes-2024-q3-safe-liftingworking-at-height-and-preventingdropped-objects-2/

The survey was originally launched at Step Change in Safety’s bi-annual Safety Rep Forum on 18th April, in partnership with specialist data-driven process safety company, Empirisys.

The survey examined the eight Principles of Process Safety Leadership and followed on from the organisation’s 2023 Process Safety Leadership Survey, which received responses from more than...

450 senior leaders

73 companies

1,949 respondents from 90 organisations

...participated in the Process Safety Workforce Survey, the biggest process safety survey carried out to date.

The majority of respondents have worked in the industry for 10 – 20 years with high-hazard workers in Operations well represented.

The three highest-scoring themes were Clarity, Culture and Engagement, with Competency and Auditing also performing well. The findings have highlighted key areas of focus including Sharing, Proactivity and Informing

Following the high-level sharing, a process safety panel was chaired by awards host Andrea Brymer for further

Email:

We shared preliminary findings from our Process Safety Workforce Survey with the energy industry during the Offshore Safety Awards in Aberdeen’s Beach Ballroom (Tuesday 2nd July) in partnership with

discussion with the audience. The panel included:

• Peter Sueref, CTO and Co-founder of Empirisys

• Samantha Peace, Director of Energy Division, HSE

• Bruce Webb, Associate Director, Scapa Energy

• Steve Rae, Director, Fortitude –Action Beyond Compliance

• Gatsbyd Forsyth de Barrera, North Sea HSES SVP, Harbour Energy

• Colin Boud, OIM, Anasuria Operating Company

• Ian Phillips, Production Technician/ ESR, Beryl Alpha, Apache

Craig Wiggins, CEO of Step Change in Safety says, “The Process Safety Workforce Survey was designed to allow our member companies to seek the views of the workforce and provide a comparison to the 2023 Process Safety Leadership Survey. The key takeaways from the 2024 workforce survey are that there were many positives around culture – which was a consistent strong point in the theme questions and the comments, and also a high point for leadership. Clarity and Competence also performed well, particularly related to training and incident reporting which is encouraging.”

Craig continues, “The results also show that there is more work to be done around Sharing across the industry, which was once again a low score and

a persistent theme in the comments. Although Engagement scored more positively than amongst leaders, there is still work to do around involving frontline employees. Each member company which took part will soon receive their own report so that they can review their survey data, but individual member data will remain anonymous within the industry-wide report.”

Craig concludes, “The results of these individual surveys will give organisations a better indication of how their workforce understands and values process safety, a strong leading indicator of Major Accident prevention. Additionally, the combined industry data will allow Step Change in Safety to direct its future work.”

The next steps, following the release of the preliminary survey findings, will be a white paper released in August with full results and breakdowns, alongside organisation-specific results and benchmarking provided to the individual organisations who participated.

Slides of the preliminary findings can be accessed here: https://www. stepchangeinsafety.net/resources/ process-safety-workforce-engagementsurvey-presentation-preliminary-results/ Contents include:

• Who filled out the survey?

• What are the main takeaways?

• How does this compare with 2023?

Tell us by taking part in the industry-wide...

Tell us where your head is at, by taking part in a new vital wellbeing survey aimed at the energy sector workforce.

Step Change in Safety, proudly working with IADC North Sea Chapter’s Mental Health Task Force and the Marine Safety Forum, has designed this vital survey to cover all aspects of physical and mental wellbeing

By understanding the unique challenges faced by our industry’s workforce, we

can help shape future initiatives and support systems that will promote a stronger culture of safety and care.

Data from a PWC study on the UK workplace showed that a third of UK workers are currently experiencing a physical health, wellbeing or mental health issue and 39% of the workforce have taken time off work or reduced their responsibilities due to a wellbeing issue.

Our goal is to create a safer, healthier and more supportive working environment for everyone. The survey

aims to understand the workforce’s current state of wellbeing and identify key areas where additional support and resources can be provided.

We encourage everyone to take just 10 minutes to share their experiences. Responses are completely anonymous; names and employing organisation details are not requested.

By sharing our experiences, we can support each other and help make a difference now and for future workforce generations.

1. Which bird can fly backwards?

2. Alberta is a province of which country?

3. What does IPA stand for?

4. What is the longest running soap opera in the UK?

5. What is Lady Gaga’s real name?

6. Who was the only British Prime Minister to be assassinated?

7. Who is the only musician ever to have been awarded the Nobel prize for literature?

8. In what Netflix series does actress Gillian Anderson play a sex therapist?

9. In ‘The Jungle Book’, what kind of animal is Baloo?

10. What is the name of James Corden’s character in Gavin & Stacey?

11. Who famously said “You must be the change you wish to see in the world.”

12. What year did Rihanna achieve global success with the mega-hit ‘Umbrella’?

13. What is the name of the fictional town where the series Stranger Things is set?

14. How many Michelin stars does Restaurant Gordon Ramsay in London currently hold?

15. Sofia is the capital of which country?

16. Who won the FIFA Women’s World Cup in 2019?

17. Who was Henry VIIIs last wife?

18. Who was Donald Trump’s vice president?

19. How many world titles has Phil Talyor won in darts?

20. One Direction is known for being the runners-up in The X Factor in 2010, but who came first?

Answers to the general knowledge quiz can be found by clicking this link or view at the bottom of this page, no cheating!

Got any interesting ideas or stories you’d like to share with the rest of industry? Anyone you’d like to recognise for being a safety champion?

Please get in touch with editor@teashack.news and we will consider it for future issues. We would also love to hear what you think about Tea Shack News Rebooted; all constructive feedback is welcome!