DIGITAL TWINS FOR EFFECTIVE FACILITY MANAGEMENT

By bringing real-time data into decisionmaking, digital twins help facility managers better manage facilities

WHAT IS A DIGITAL TWIN?

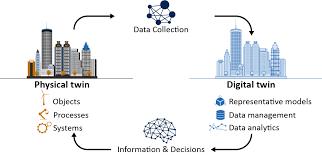

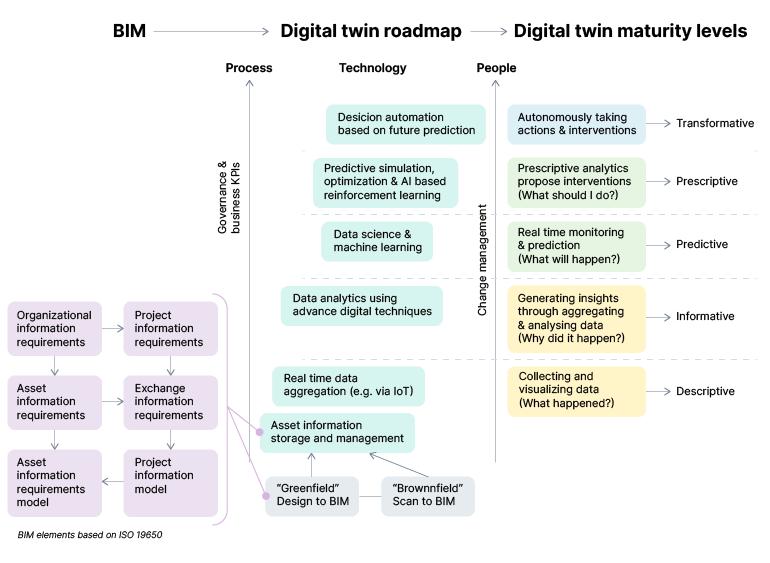

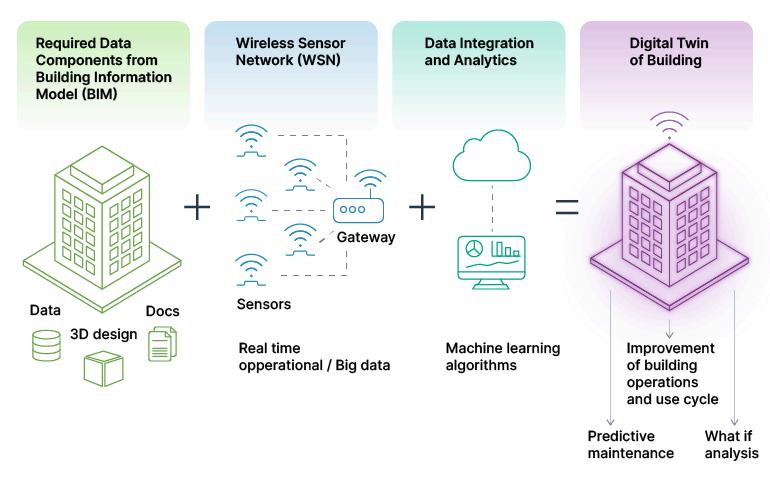

A digital twin is a virtual replica of a physical asset (such as a building) powered in real time from on-site sensors, cameras, and various business systems. Digital twin technology helps bring together compartmentalized data sets and systems to perform real-time facility monitoring, analysis, and optimizations. While most construction costs are rather predictable, ongoing operations and maintenance costs are anything but. These costs fluctuate a lot based on occupancy rates, seasonality, and operating practices.

Yet, pulling all relevant data points to get the big picture hasn’t always been easy.

On the analytics side, a digital twin facility enables managers to conduct more precise evaluations, simulate future use, and implement predictive maintenance scenarios.

6 FACILITY MANAGEMENT CHALLENGES TO BE SOLVED WITH DIGITAL TWINS

FRAGMENTED

DATA

POOR SYSTEM

INTEROPERABILITY

SOARING OPERATING COSTS

SUSTAINABILITY

CONCERNS

SUPPLY CHAIN ISSUES LABOR SHORTAGES

1. FRAGMENTED DATA

A digital twin in facility management helps e a virtual connection between different physic digital assets, bringing together compartmen data streams into one unified platform for re monitoring and analysis. For example, a digital twin can include data f

Asset management software

Computerized maintenance managemen systems (CMMS)

Building automation systems (BAS)

On-site cameras

Any number of installed IoT devices

Explained

2. POOR INTEROPERABILITY

Digital twin for facility management emerged opportunity for transformation. The technolo act as an extra connectivity tissue, aggregatin standardizing data from different sources in a shared virtual repository. By design, digital twins are built with more operability in mind, taking advantage of nativ cloud architecture and application programm interfaces (APIs). The aggregated data can be used for a variet data analytics scenarios. AI and ML models, in can be used to enable predictive and prescrip use cases.

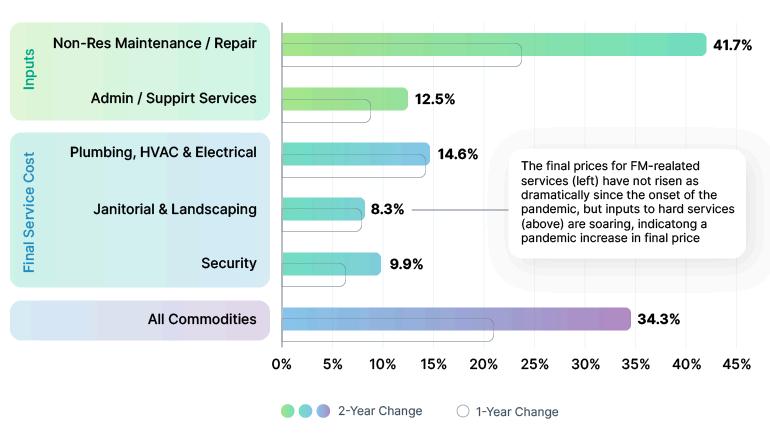

3. SOARING OPERATING COSTS

Digital twins can consolidate all utility data an understand energy consumption rates under different occupancy scenarios.

For example, you can automatically switch m systems to power-saving mode after the last leaves the workplace or automatically adjust temperature in unoccupied rooms.

A digital twin solution helped companies sav average of 40% on energy costs, 15% on facilit management costs, and 30% on operating co

Source: CBRE — Facilities Management Cost Trends in 2022

4. SUSTAINABILITY CONCERNS

Digital twin platforms can help cap data around carbon output, emiss company-owned assets, orcontrol emissions such as electricity, gas, f to document the starting point.

Digital twin sustainability in facility can help locate opportunities for o resource use, be it reducing energ through optimized light managem reducing waste through the purch supplies.

5. SUPPLY CHAIN ISSUES

Digital twins can help facility managers switc reactive to predictive maintenance. By having better visibility into the age of managed asse service history, spare parts counts, and locatio managers can implement just-in-time procu to avoid costly delays and timely servicing.

This way you can not only extend asset life bu optimize maintenance schedules.

6. LABOR SHORTAGES

Digital twins can help determine the optimal schedule for dispatching janitorial, repair, and maintenance teams to ensure timely and effe services. They can streamline planning and e dispatch tasks by automatically notifying onemployees about urgent new tasks. And, in outsourcing scenarios, they can automatically transmit instructions, equipme information, and operating guides to hired te via a connected mobile app.