APPLICATIONS OF 3D LASER SCANNING

IN AEC PROJECTS

Laser scanning is applicable in many industries due to its precision, efficiency, and versatility.

Laser scanning is applicable in many industries due to its precision, efficiency, and versatility.

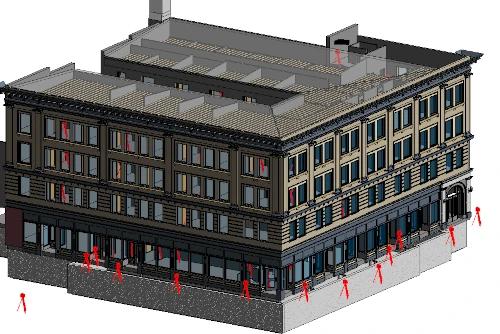

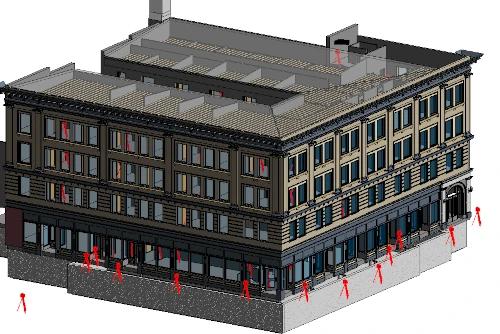

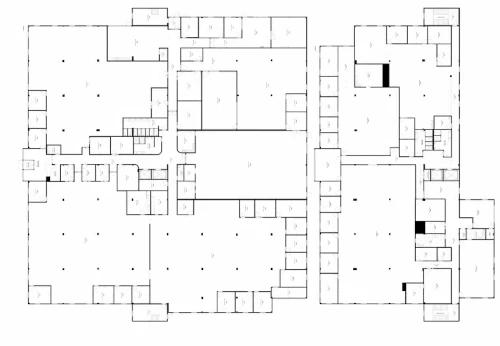

3D laser scanning documents the as-built details of a building, capturing the exact layout, dimensions, and locations of architectural, structural, MEP features, walls, windows, doors, stairs, roof, railings, exposed columns, beams, equipment, piping, ducts, and more.

By overlaying proposed renovation plans onto the 3D scan data, potential conflicts or clashes can be identified and addressed early in the planning phase. Whether you’re renovating a stadium, theatre, historic building, church, school, etc., 3D laser scanning provides comprehensive as-built data for any site, adding value to the planning, design, and execution phases of any renovation project.

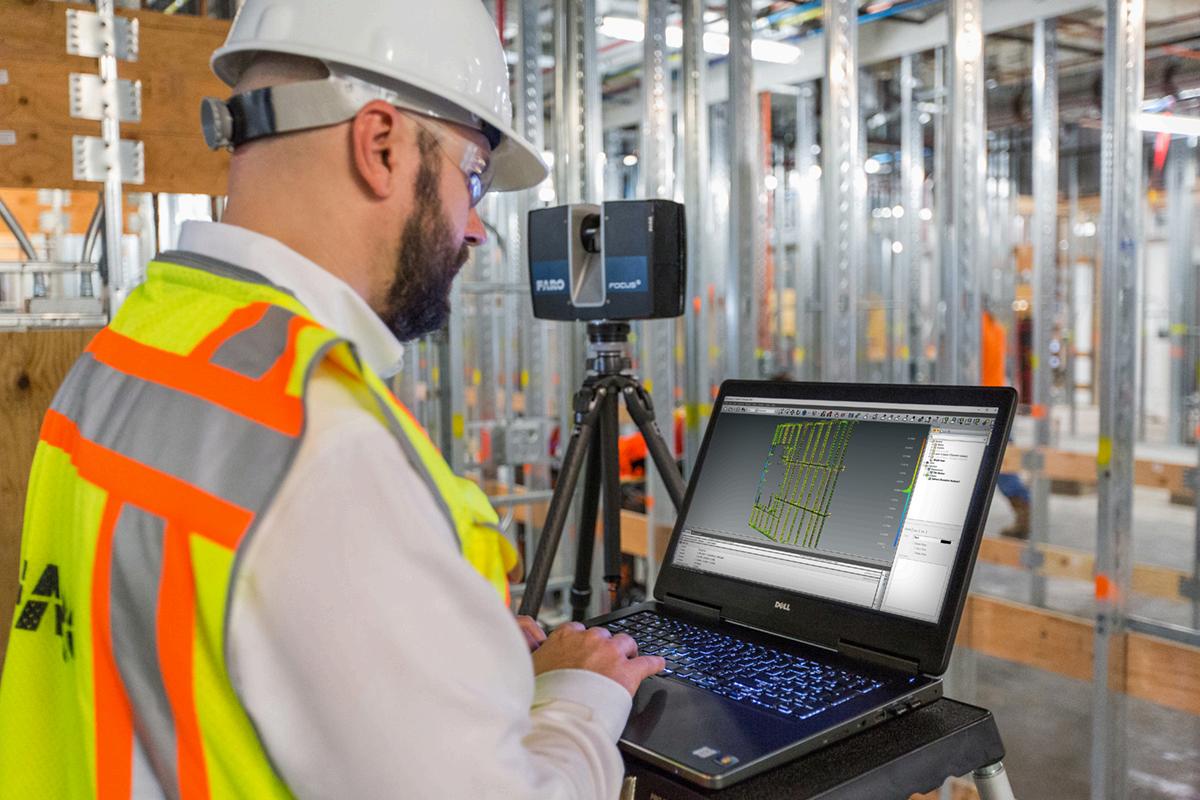

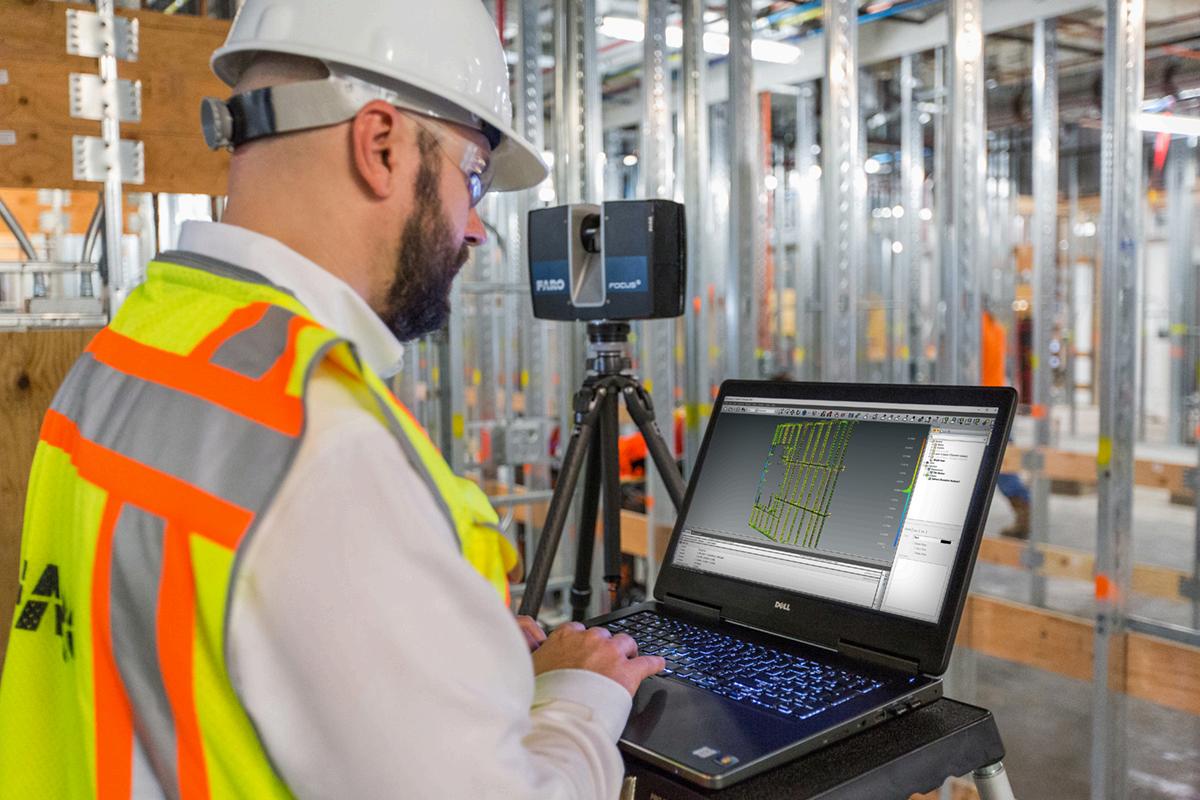

3D laser scanning aids in the architectural design process by delivering accurate existing conditions to create design models, monitor construction progress, and verify as-built accuracy. 3D laser scanning quickly and accurately provides comprehensive as-built documentation of a building or site unmatched by other technologies.

From walls and windows to HVAC, mechanical, electrical, and plumbing features, 3D laser scanning can accurately identify and document all visible elements of a structure.

3D laser scanning lets your architectural team focus on design rather than capturing and modeling existing conditions.

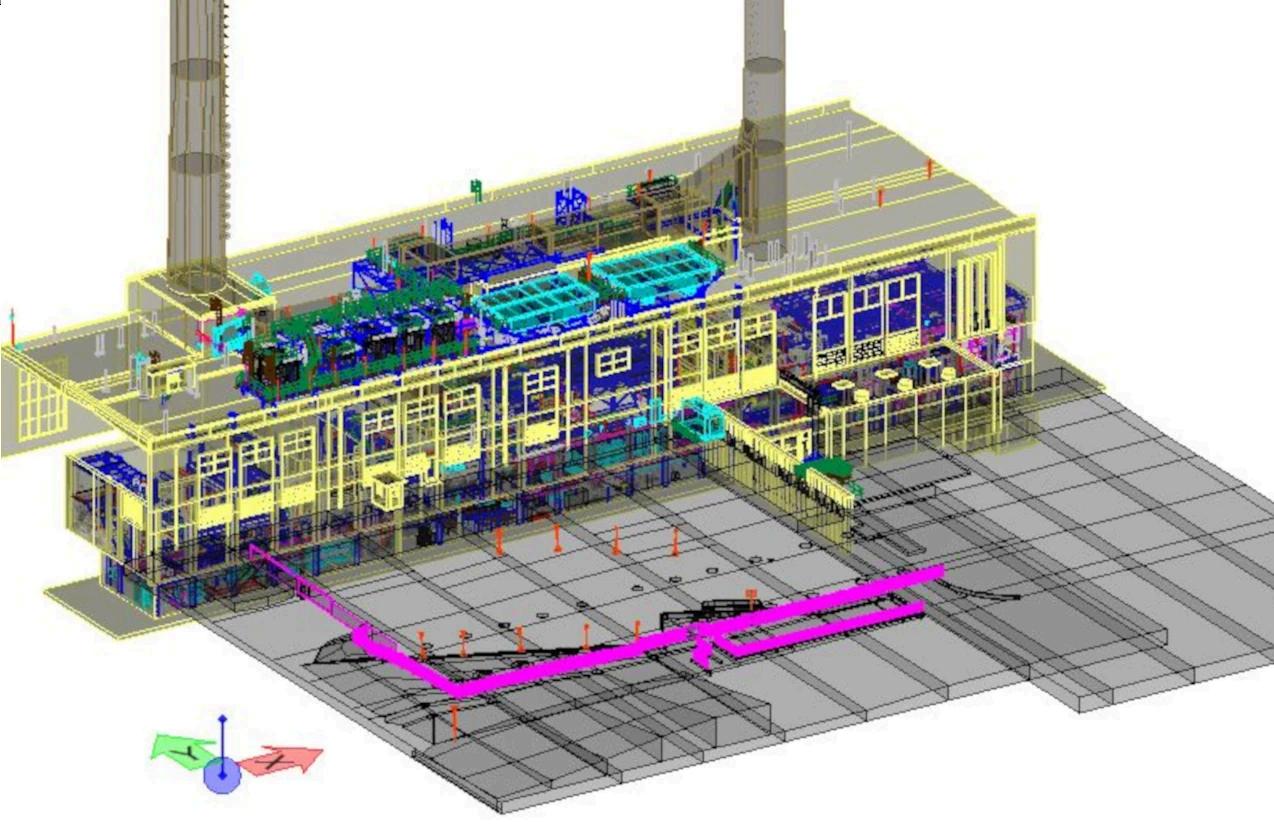

As power plants evolve to meet changing regulatory requirements or adopt new technologies, retrofitting existing infrastructure is often necessary. 3D laser scanning provides highly detailed and accurate representations of the plant's as-built conditions, including structural components, equipment, piping, boilers, generators, turbines, pumps, condensers, heat exchangers, and more.

This comprehensive documentation serves as a reliable reference for maintenance, retrofitting, and future expansion projects.

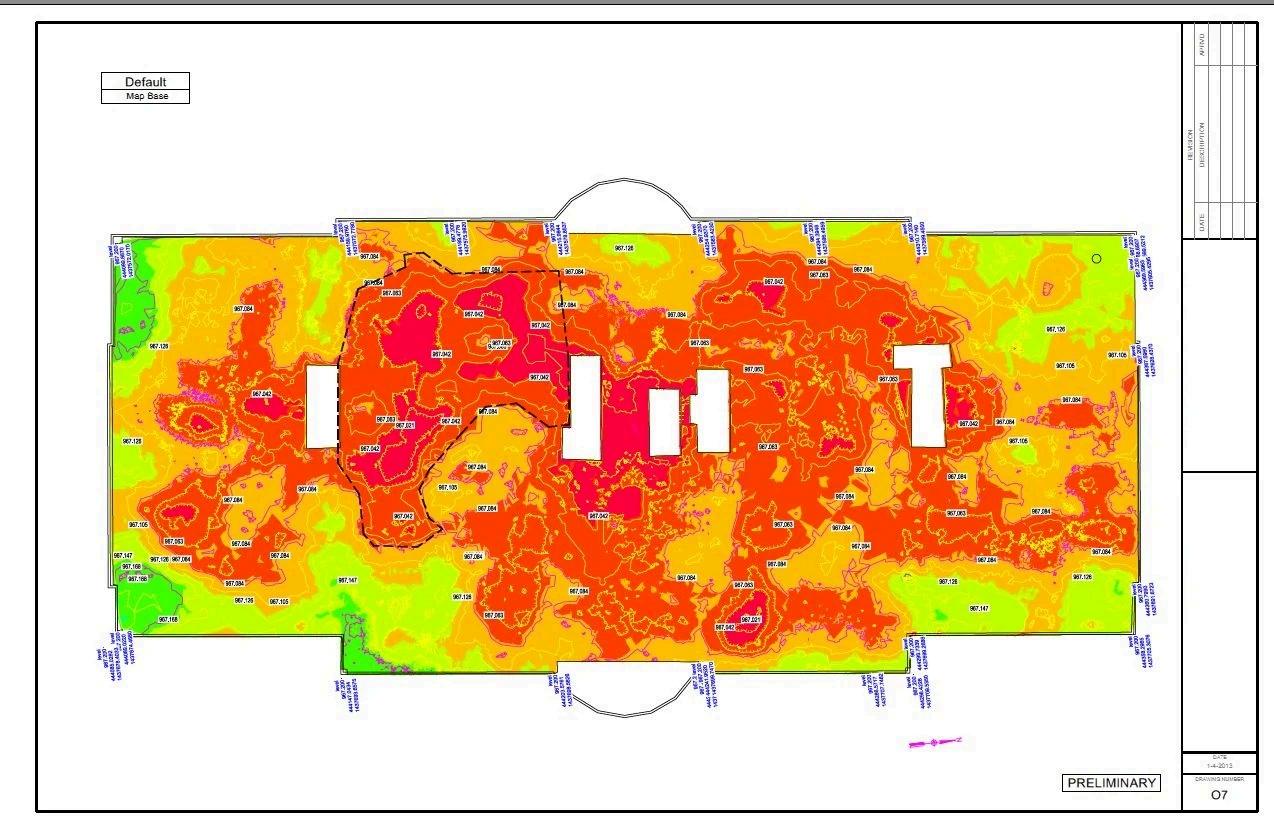

3D laser scanning is the best way to measure floor flatness (FF) and floor levelness (FL) with precision, efficiency, and accuracy. Highly detailed point cloud data from 3D laser scanning can be used to determine FF and FL values on concrete floor and flatwork.

Color elevation maps can be quickly produced from the point cloud data to visualize floor flatness and identify the high and low points in concrete and calculate the boundaries of any areas that need to be adjusted.

The data points collected maintain their coordinates and can be easily communicated to the project team. Fast and accurate cut and fill calculations can be computed.

As-built data of existing structures, equipment, piping, or manufacturing processes can be precisely captured with 3D laser scanning for facility modifications, expansions, and maintenance. Intelligent 3D models can be created from the point cloud data for planning, fabrication, and clash-detection.

Verified accurate measurements will aid in production, machinery, or process changes to optimize plant layouts. Virtual fit-outs guarantee installations will integrate seamlessly with existing conditions, comply with safety regulations, and reduce risk.

A digital twin is a 3D model that accurately represents a building or site’s existing physical space, assets, and processes. It is a real-time, accurate digital representation of the existing conditions of every component and system, including architectural, structural, and MEP features, walls, windows, doors, stairs, roof, railings, exposed columns, beams, equipment, piping, ducts, utility and concrete locate markings, and more. Clients can virtually walk-through a project site to plan for building improvements, increase efficiencies, and optimize workflows.

When plants retrofit new piping, equipment, vessels, valves, and flanges, etc., into an existing facility, it’s important they have accurate existing conditions data to complete virtual interference checks and ensure there are no clashes. The infrastructure of agricultural facilities, water and wastewater treatment plants, healthcare and pharmaceutical facilities, energy and utility companies, oil and gas facilities, government and defense facilities, telecom companies, etc., can be captured with 2–4-millimeter accuracy.

With careful planning and the as-built data, 2D CAD drawings and 3D models created from 3D laser scan data, new designs can be precisely engineered, minimizing installation delays, rework, change orders, and costs.

To get a building permit, you will need to submit a set of construction documents that show the details and specifications of your design. 3D laser scanning captures 24mm accurate layout, dimensions, and locations of your project requirements in the form of a point cloud.

Point clouds can be transformed into custom deliverables such as 2D CAD drawings, site plans, plan views, floor plans, elevations, sections, details, isometric drawings, and reflected ceiling plans to obtain a building permit.

Traditional data collection methods often involve manual measurements, which are prone to human error. 3D Laser Scanning provides highly accurate and detailed information, reducing the chances of mistakes during project execution.

The as-built data collected through 3D scanning accelerates the design and planning phases of projects, ensuring that concepts are practical and achievable.