Stef Fernandes Industrial Designer

Stef Fernandes Industrial Designer

Kompact

Onida (MIRC) Electronics, India - Internship

A signicant number of Mumbai's lowincome residents live in compact living spaces called Chawls, where many lack essential amenities like direct water supply for cooking and washing.

How can we optimize space and elevate their cooking experiences?

User survey

Cooking and storage space of the households

Insufficient cutting space; floor is used for cutting.

Gas stove moved to the floor due to limited platform space.

Some homes lack an adequate washing area.

Most houses lack taps or water supply in washing areas, requiring the use of one hand to pour water while washing vessels.

Kerosene stoves used when gas cylinders are empty.

User survey - Space test of cooking preparations (a newspaper was used

House 1 - Cooking preparations

House 2 - Cooking preparations

House 1 - Cooking preparations

House 2 - Cooking preparations

used for the test)

Washing area

Washing area

User

survey - House layouts

House no. 5

Stove Kitchen area

House no. 6

All the houses are within 100-200

Washing area

House no. 1

House no. 2

100-200 square feet each House no.

Other storage

Steps to the entrance door

3

4

House no.

House no. 7 House no. 8

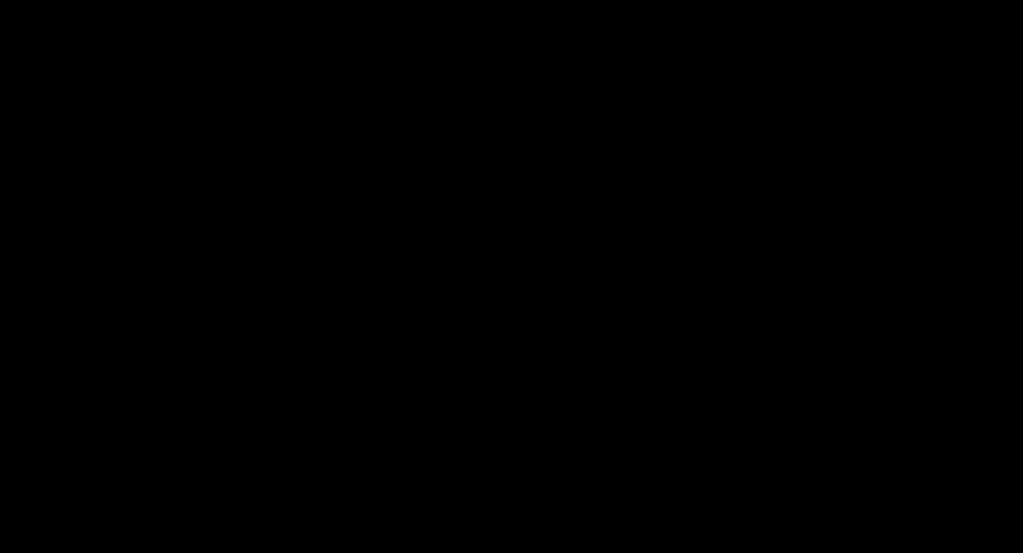

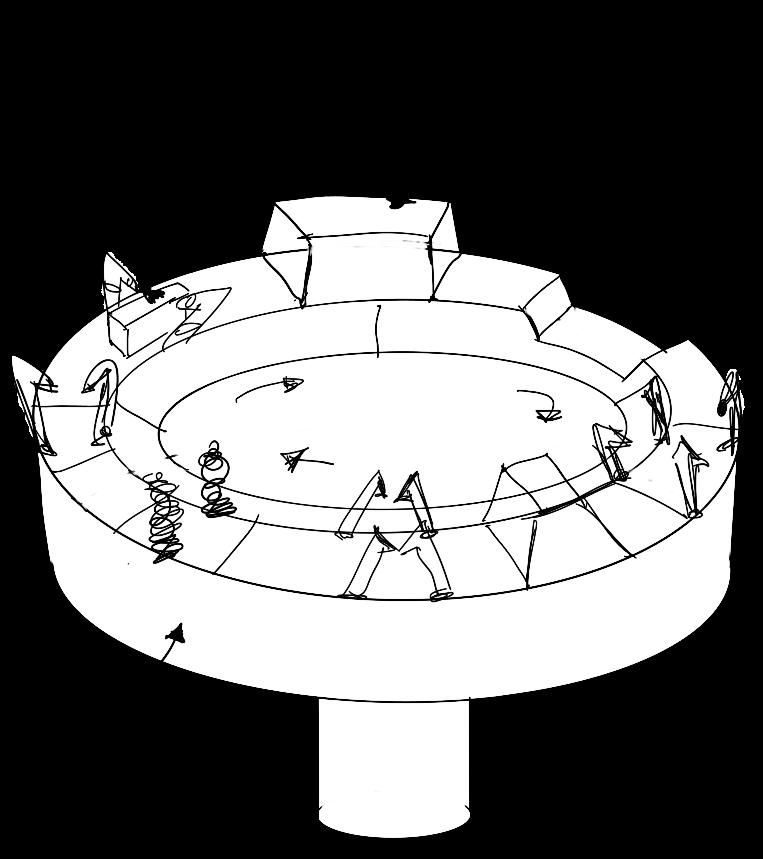

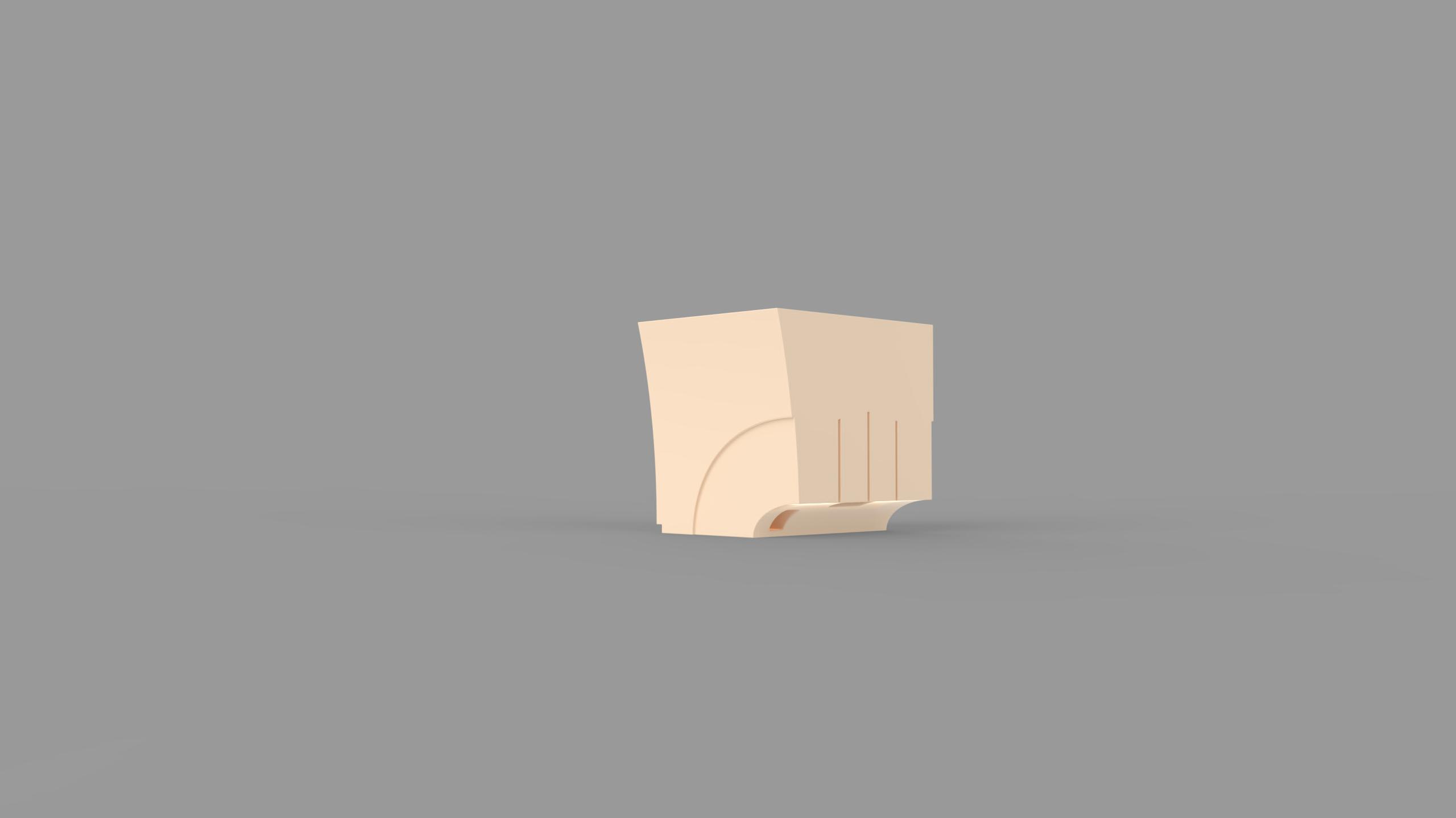

Ideation

Ideation

2

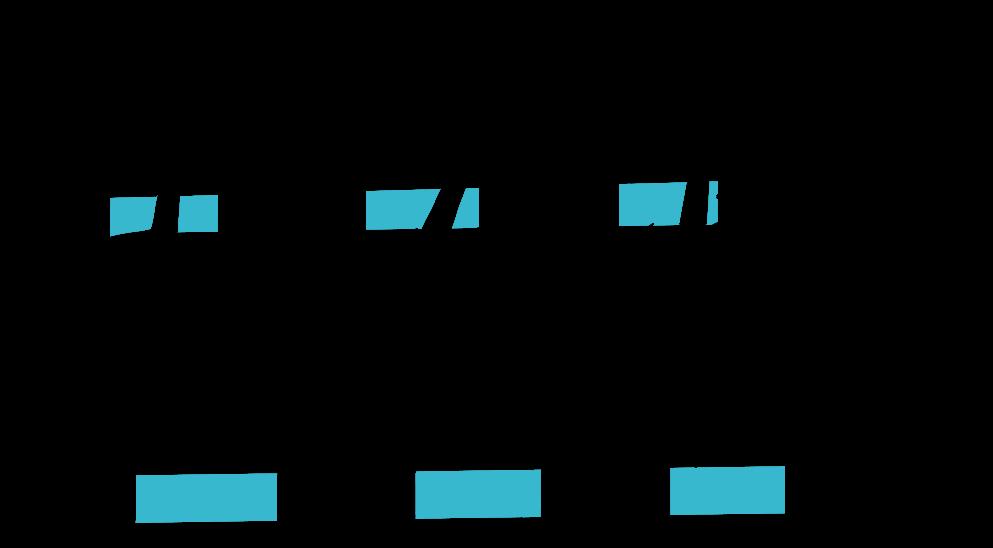

Layout 1 Layout 3 Layout

platform layouts

Layout 2 selected based on user feedback

Layout 1 Layout 3 Layout 2 Preparation Cooking Washing 5 4 4 5 4 5 3 1 5 Total 13 9 14

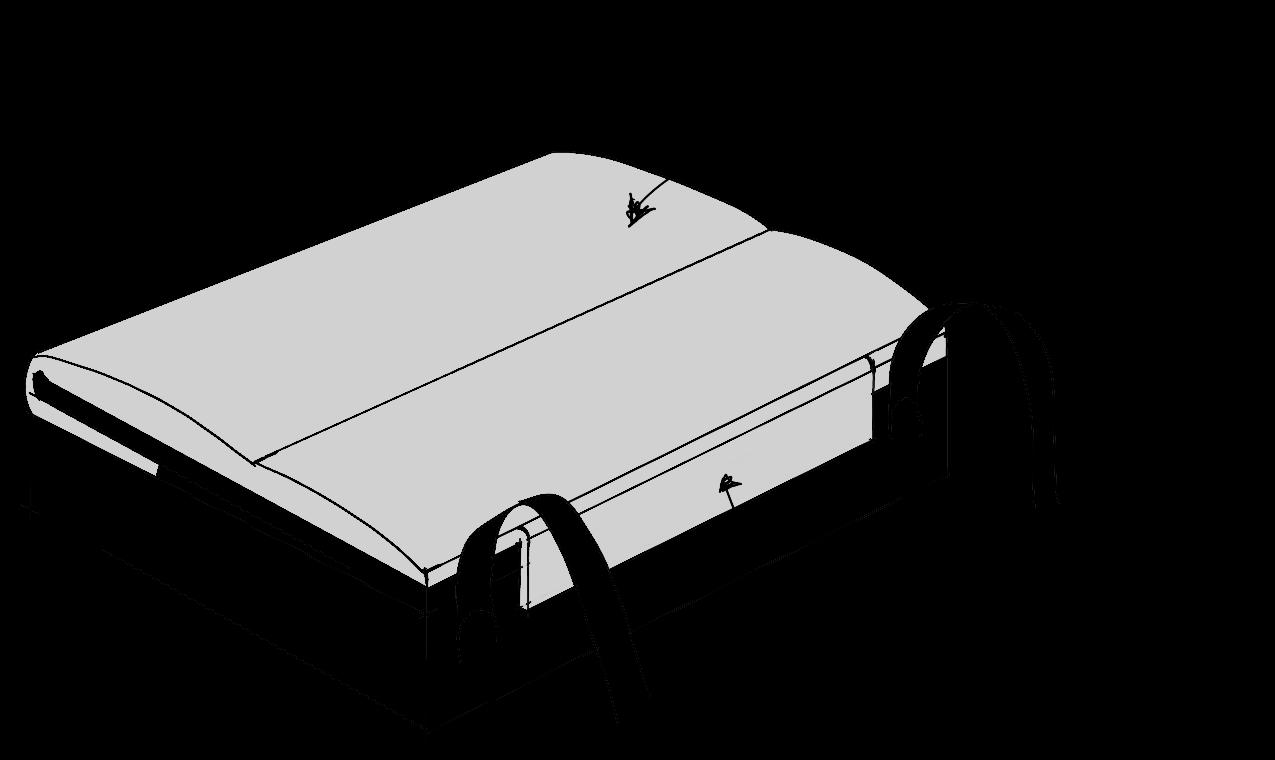

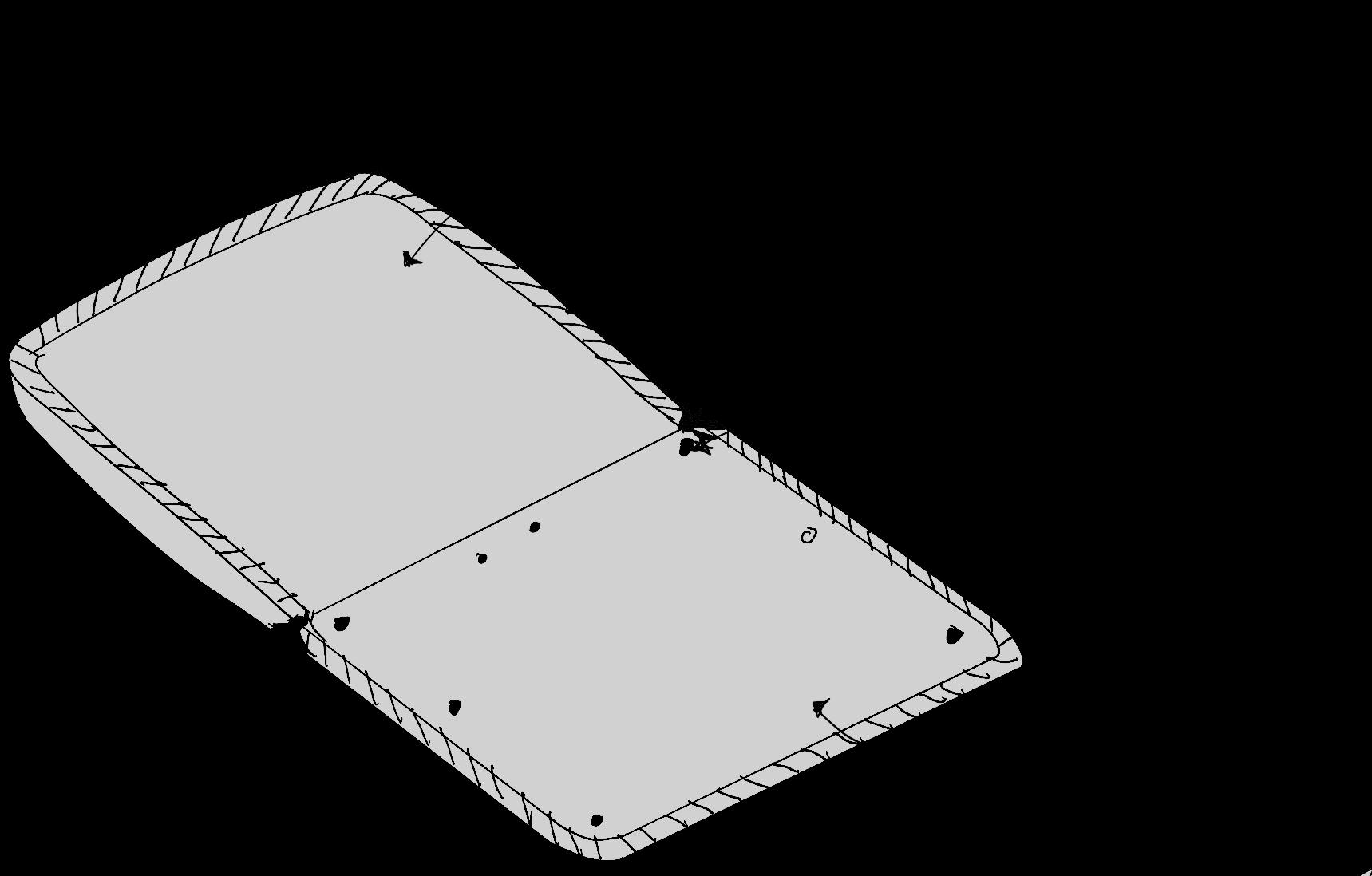

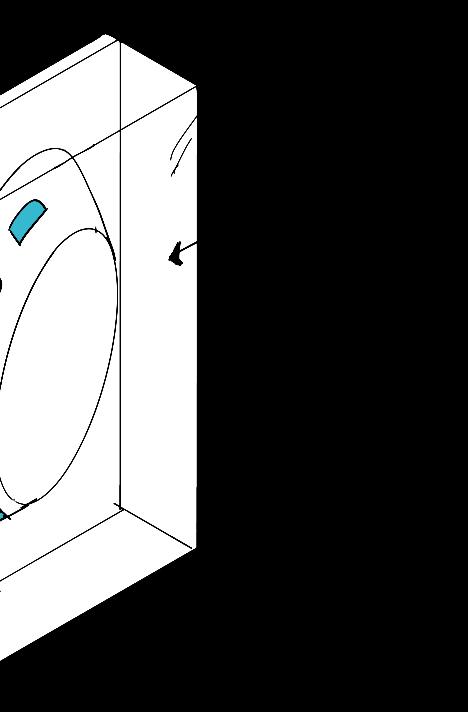

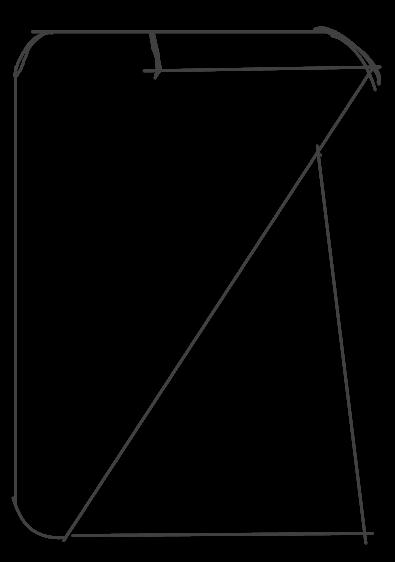

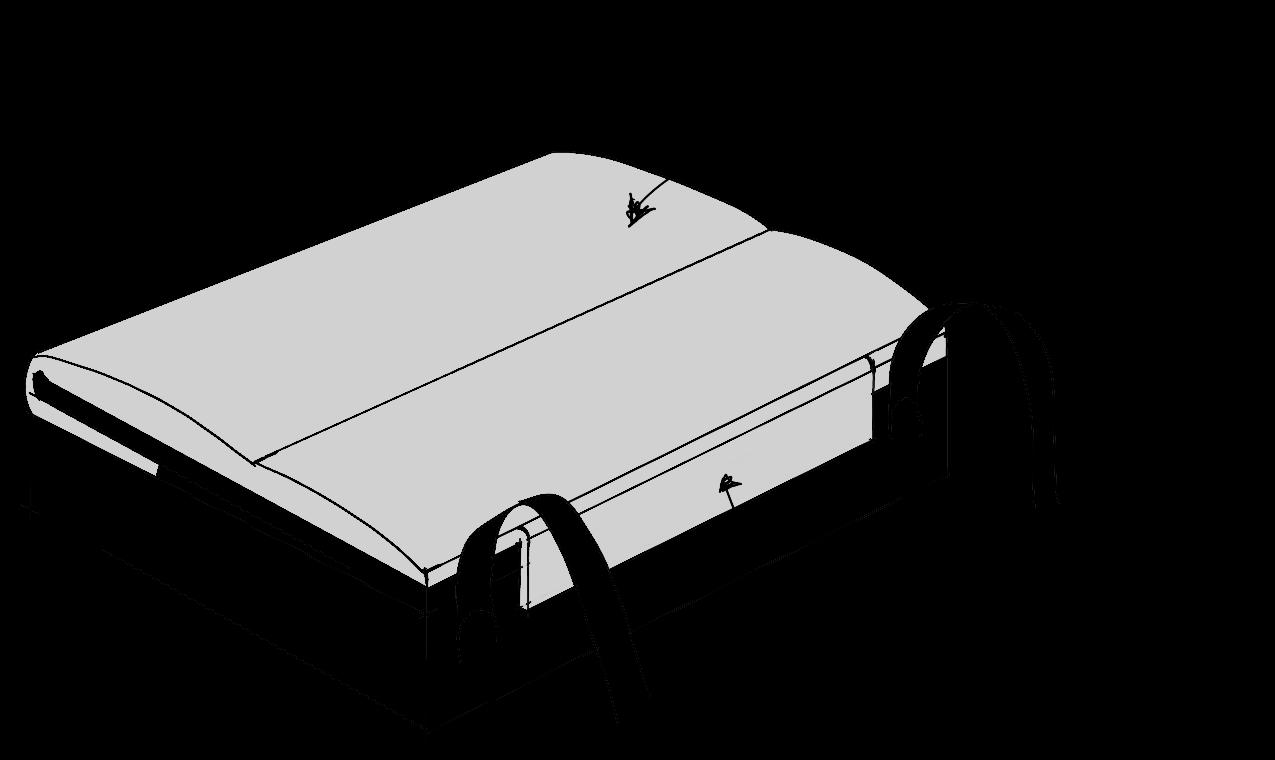

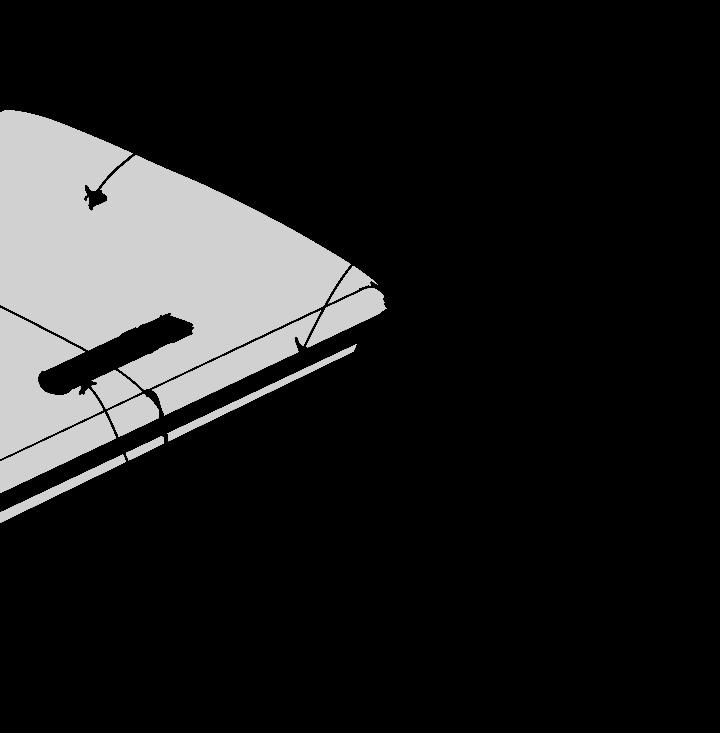

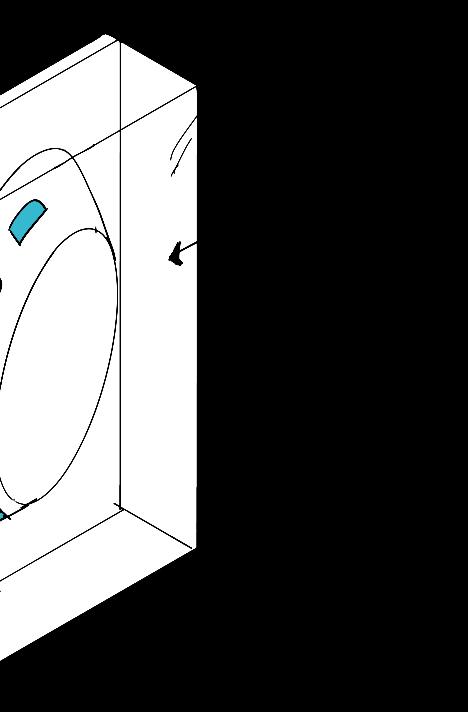

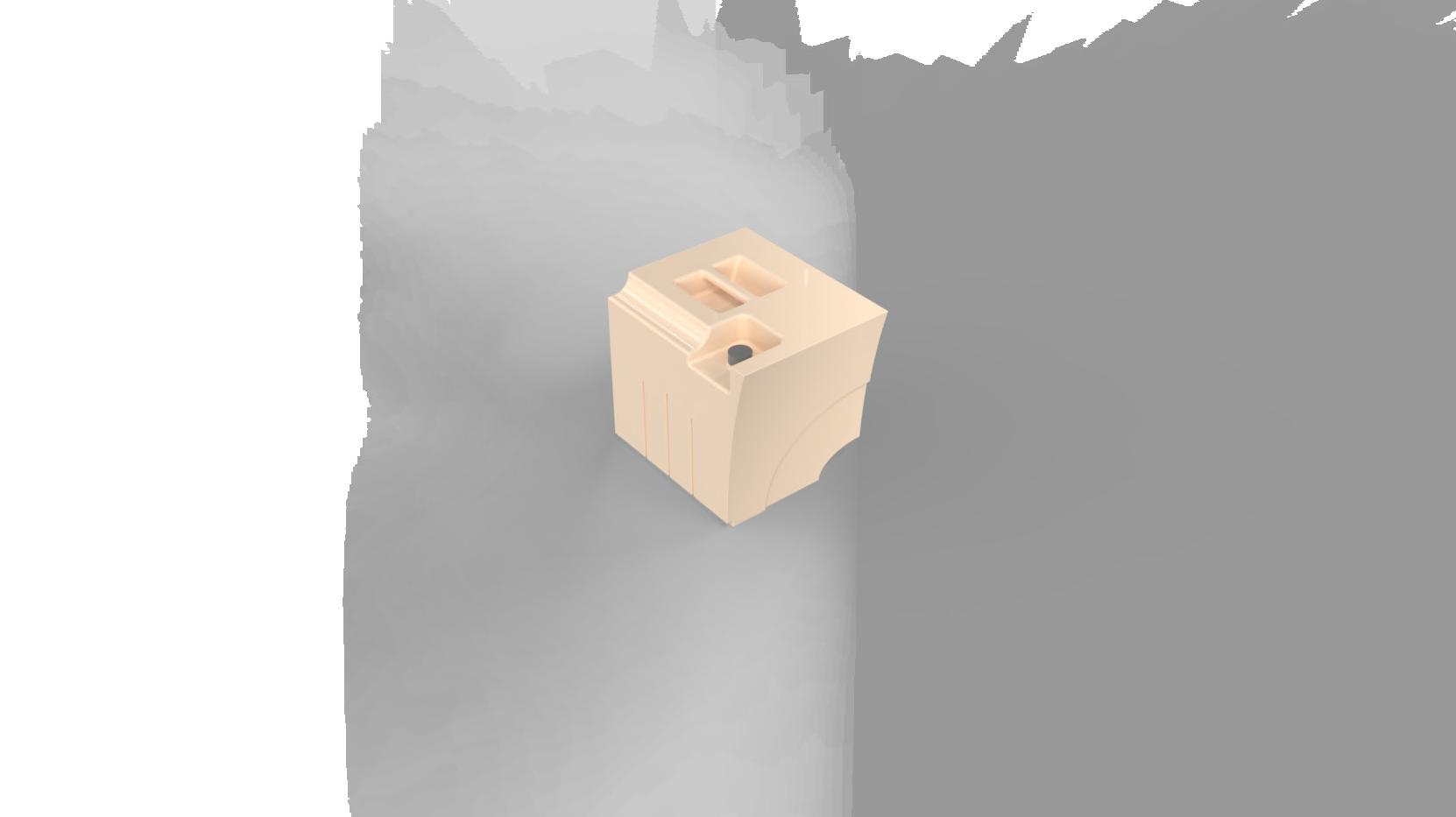

1:1 Working mock up

1:1

Working mock up to test the

Food preparation space

Induction cooktop Sink

Working mock up to test the

Food preparation space

Induction cooktop Sink

the space, height and water ow

Storage space

(can be used to keep essential cooking ingredients like oil and salt bottles)

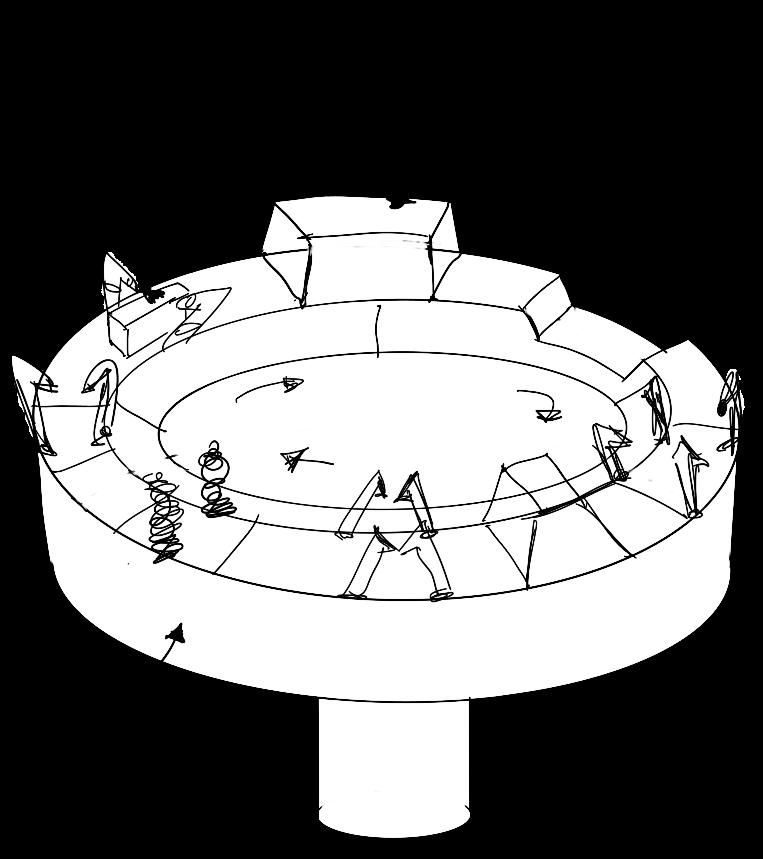

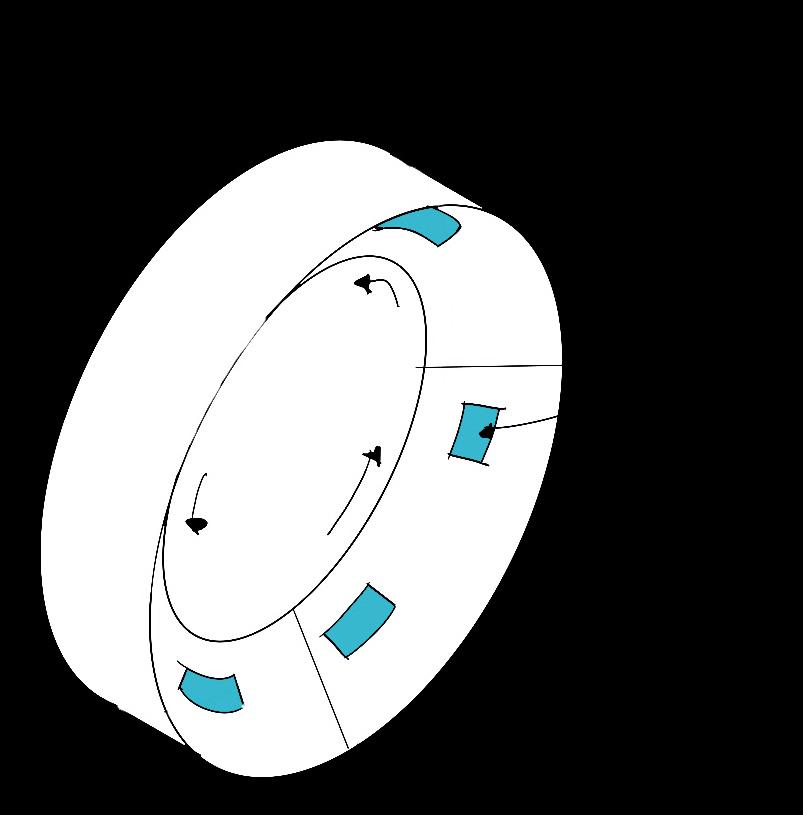

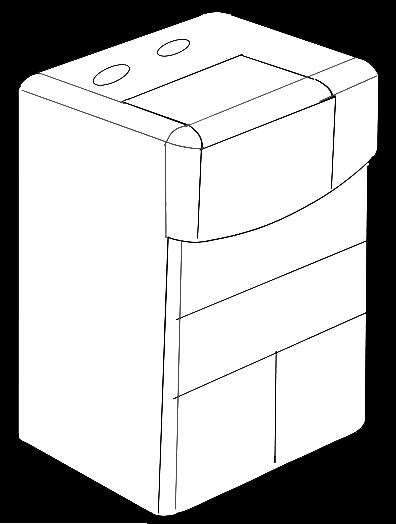

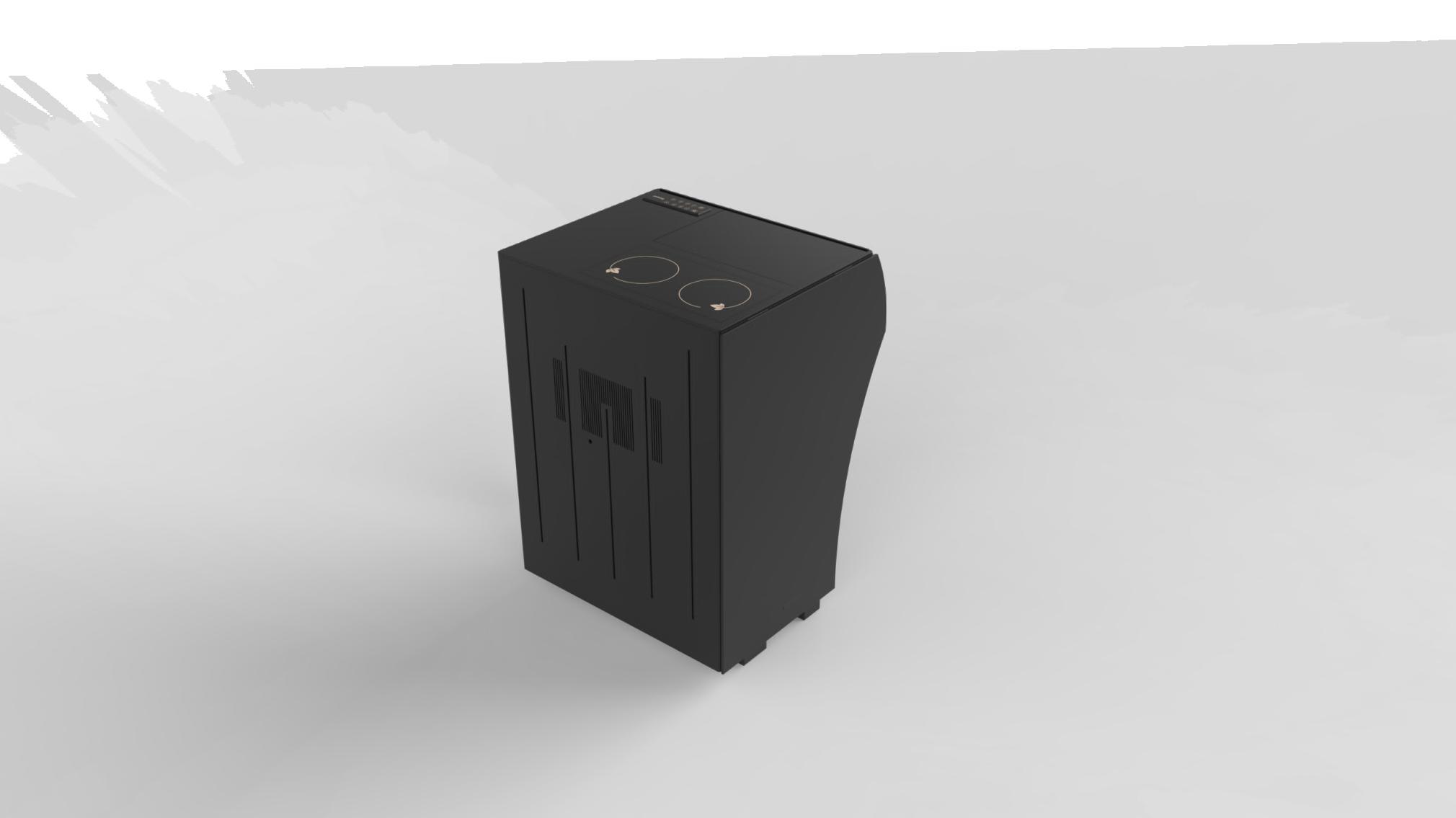

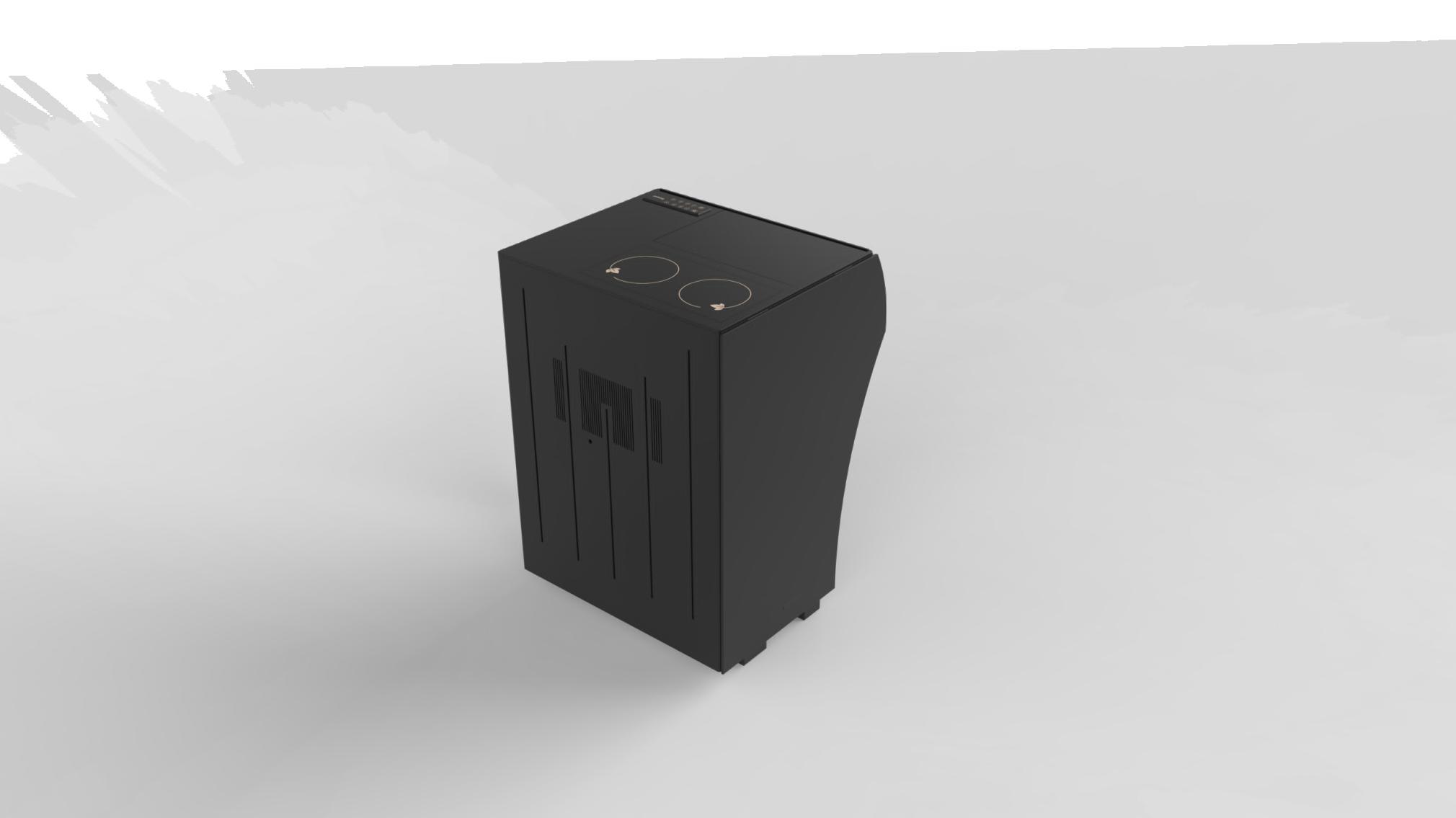

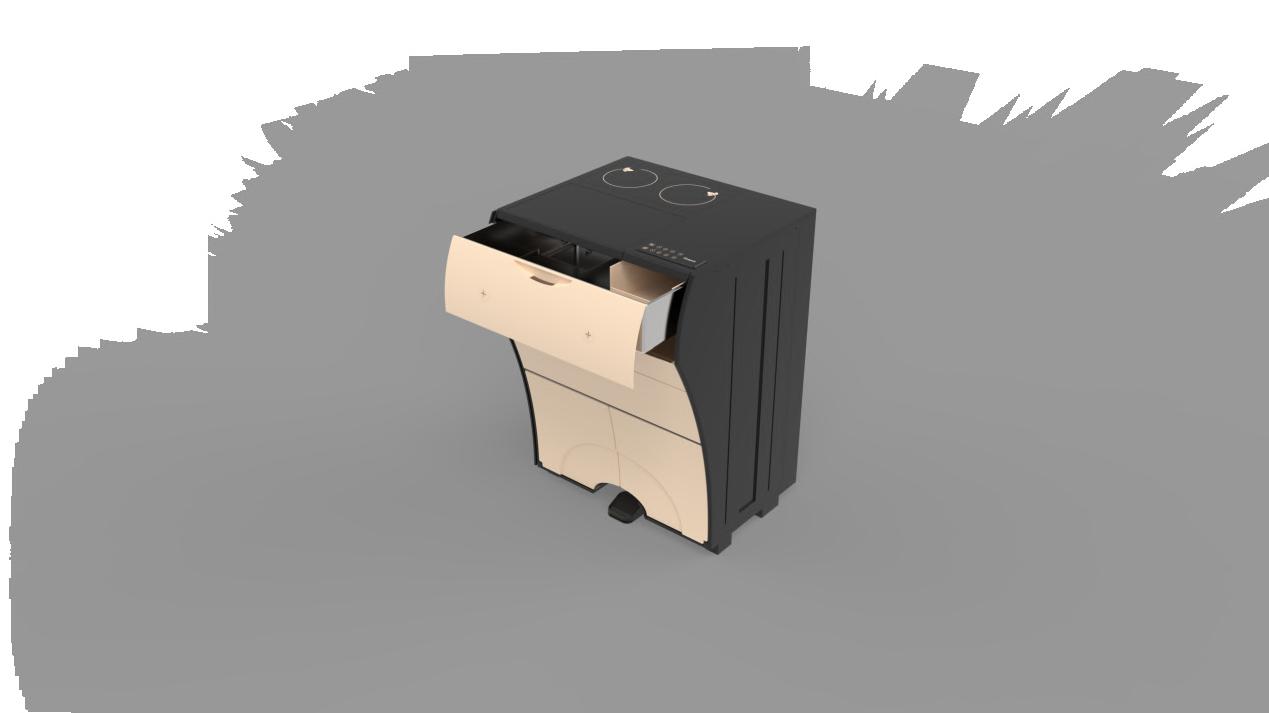

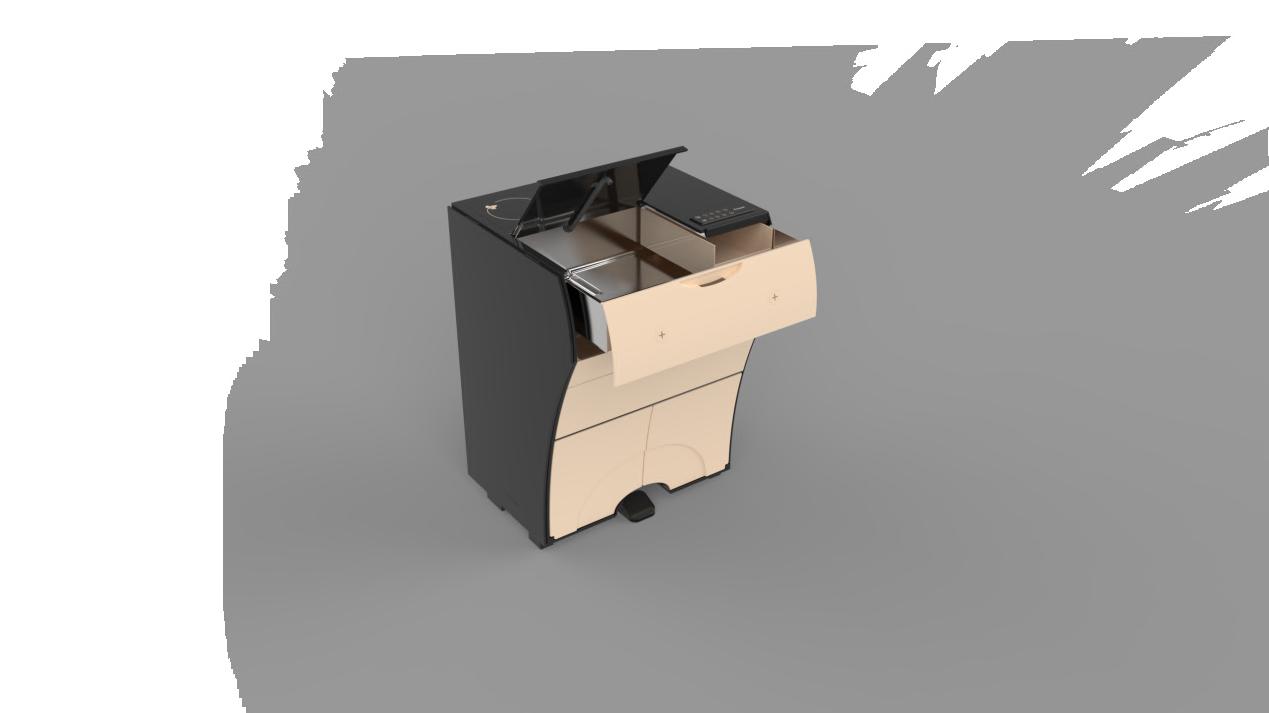

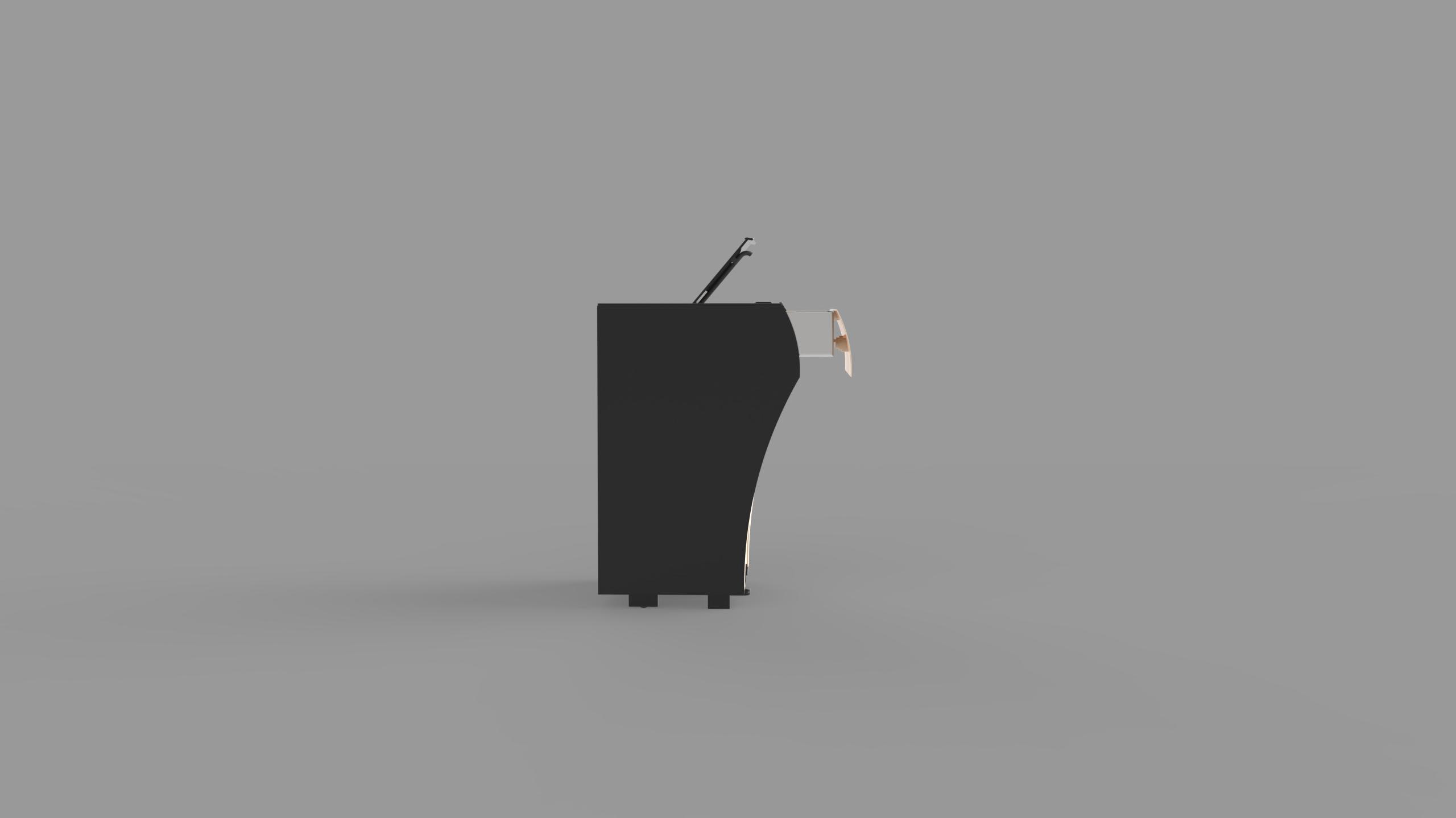

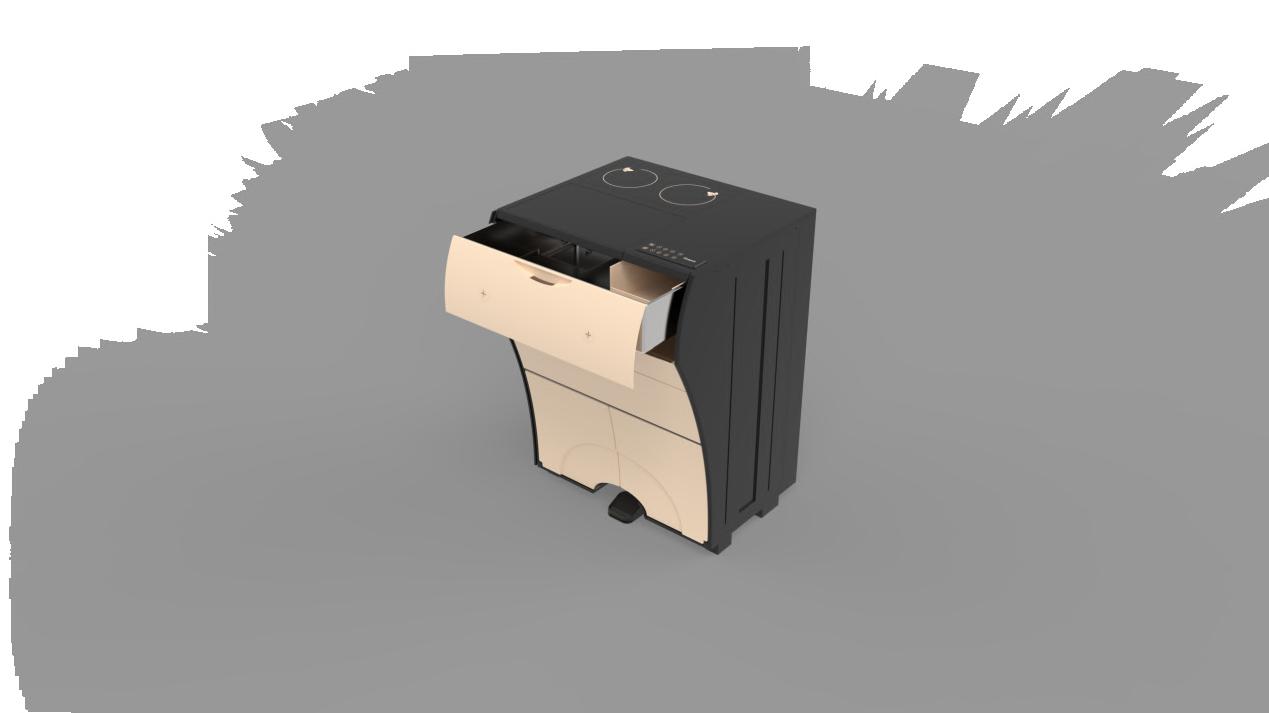

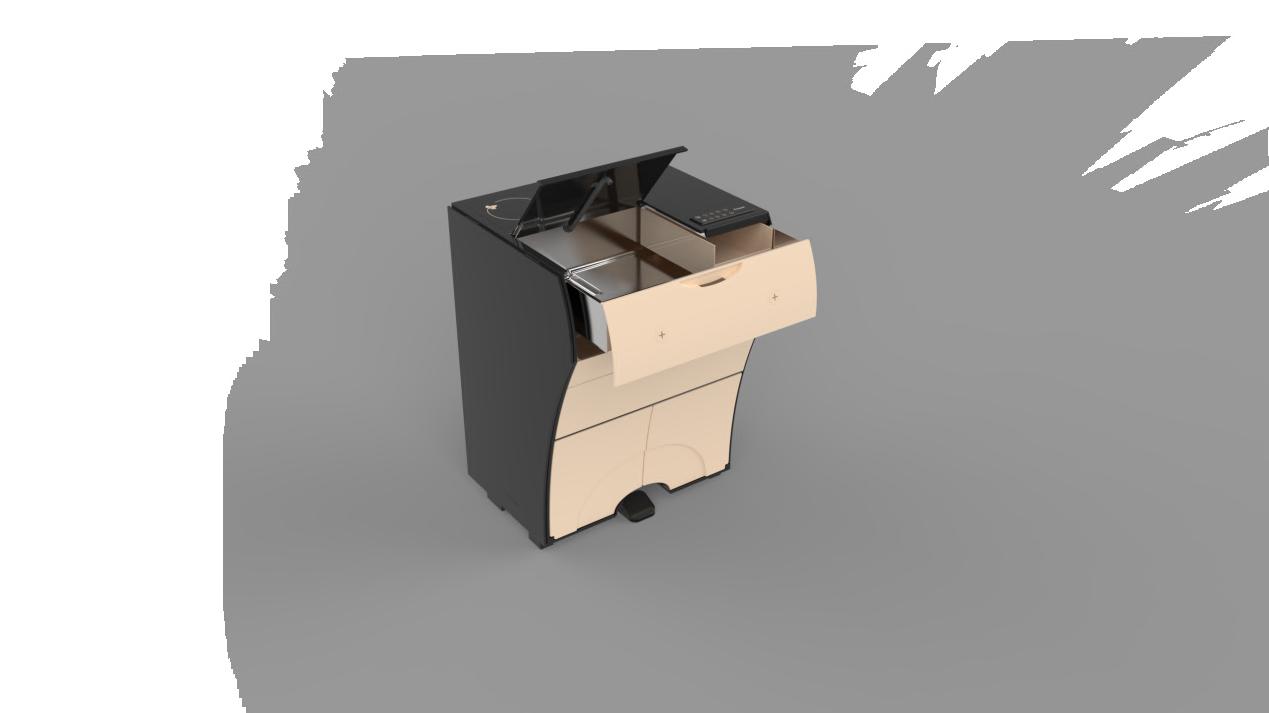

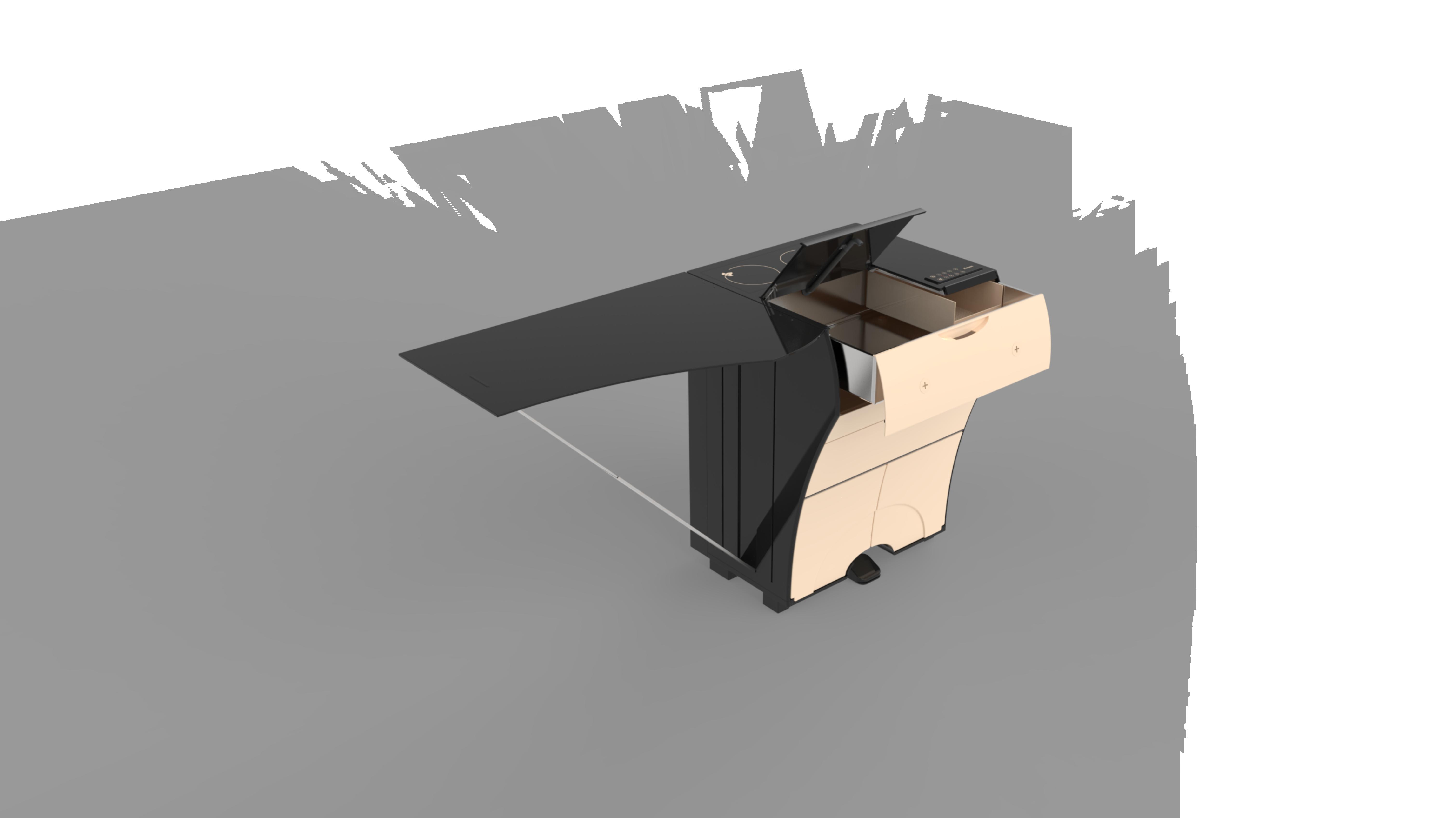

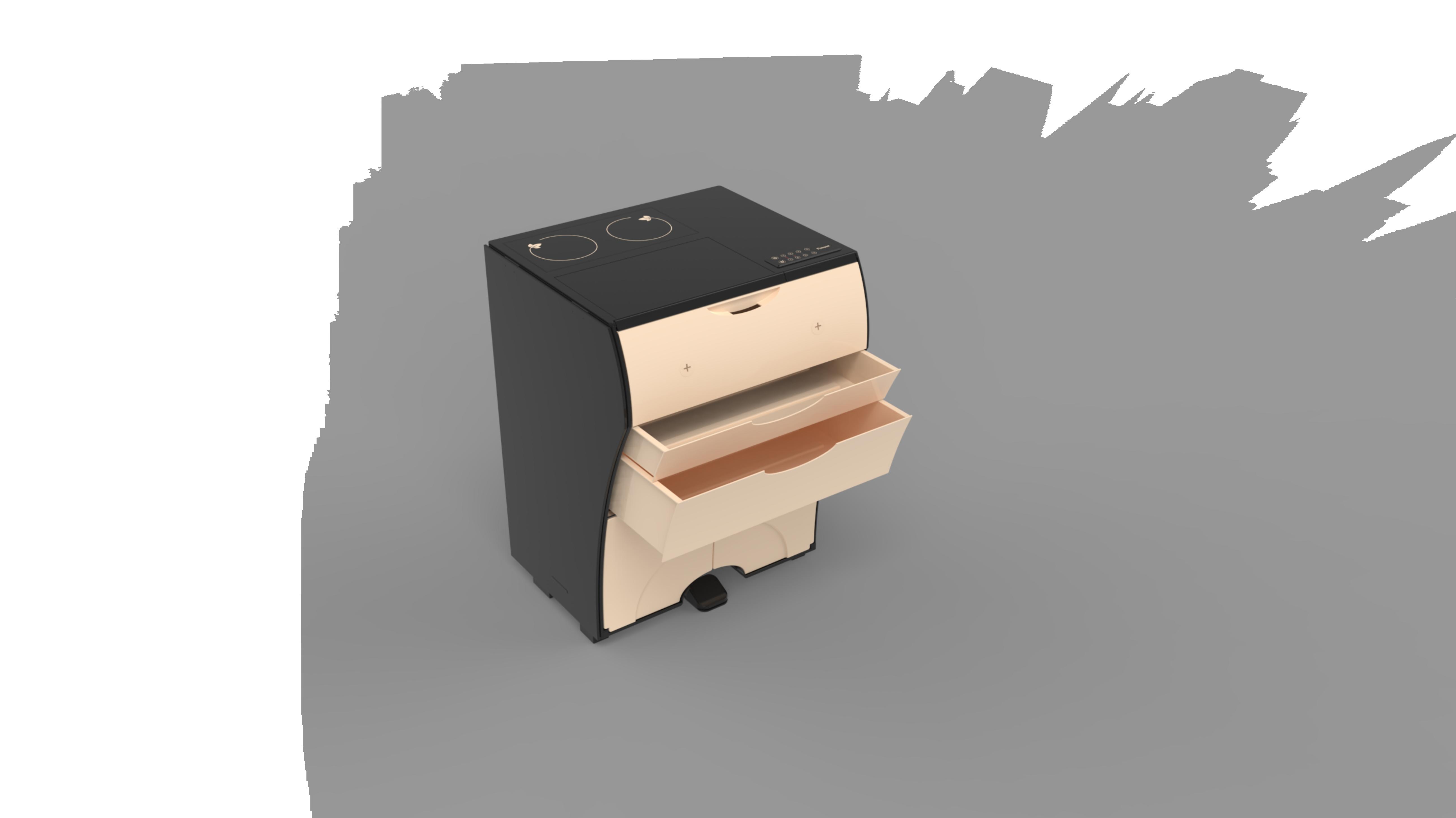

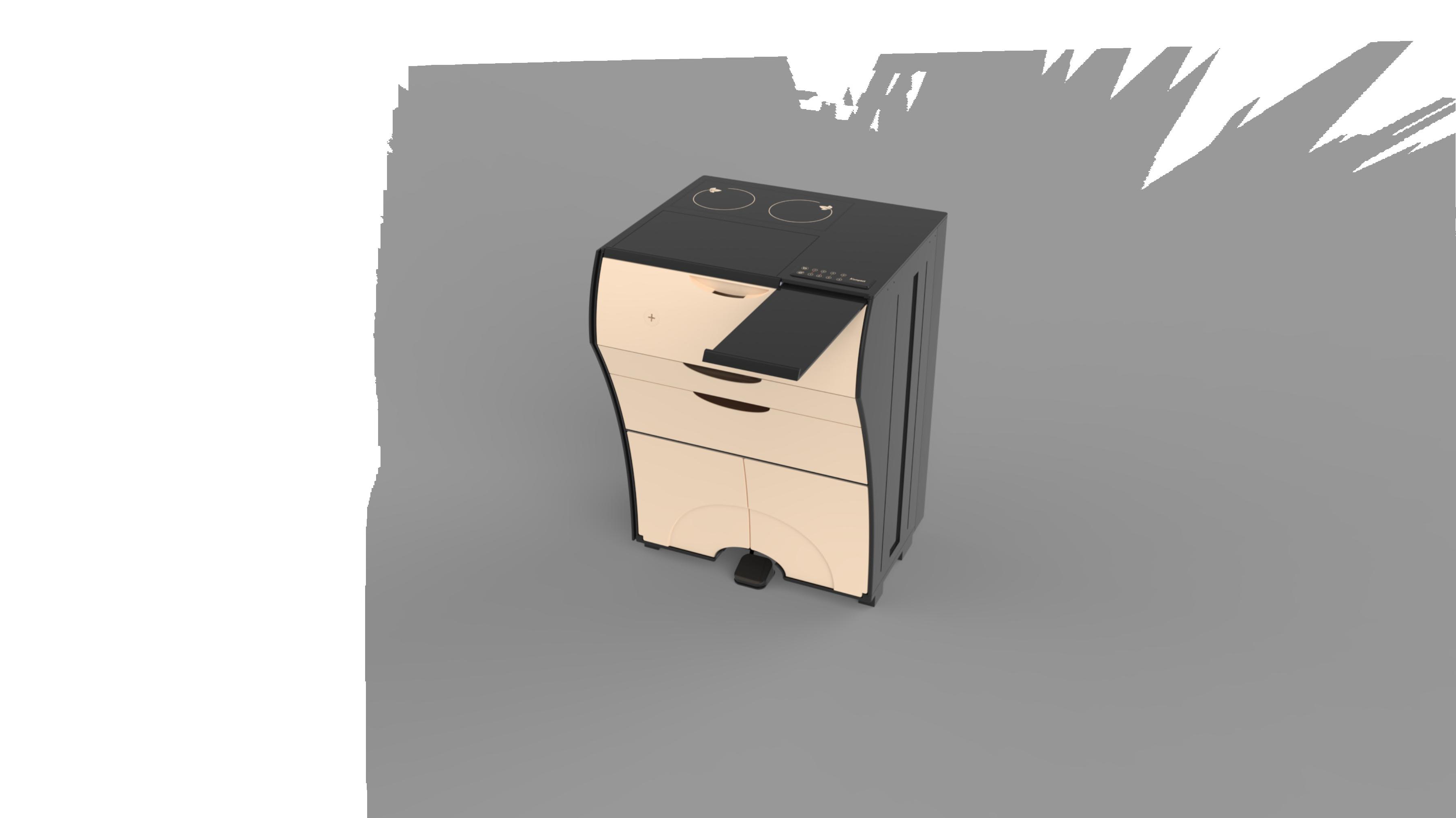

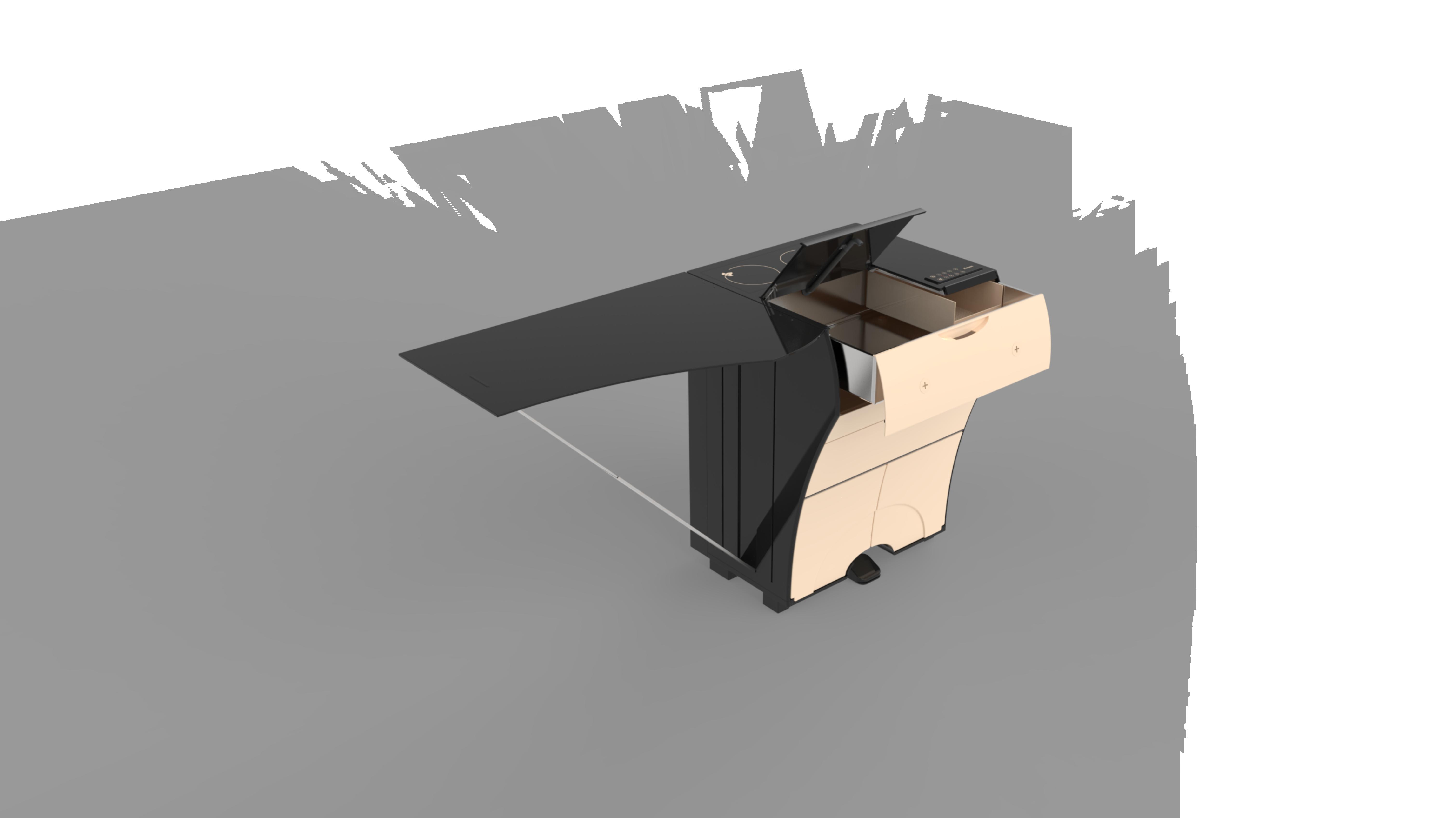

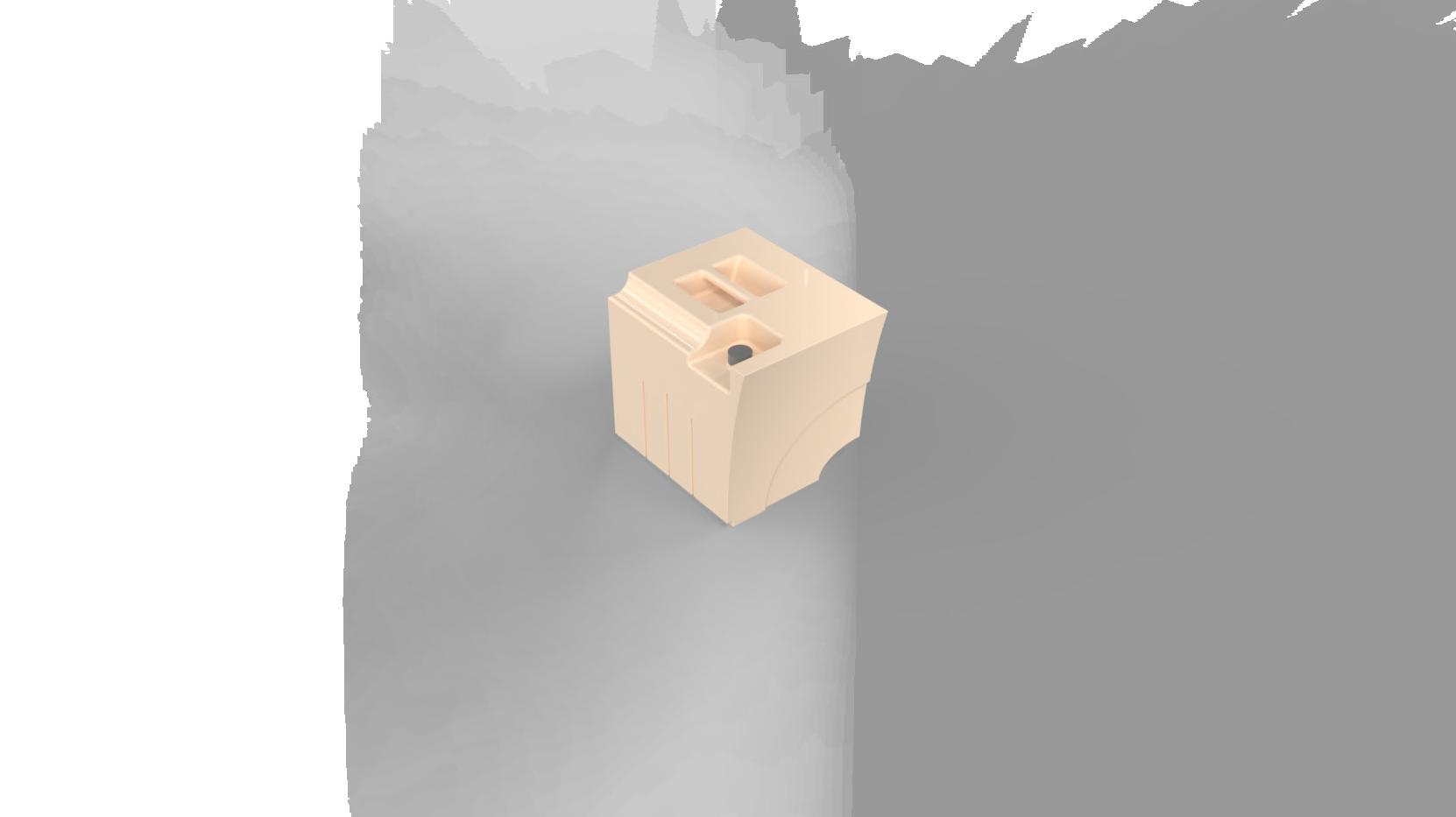

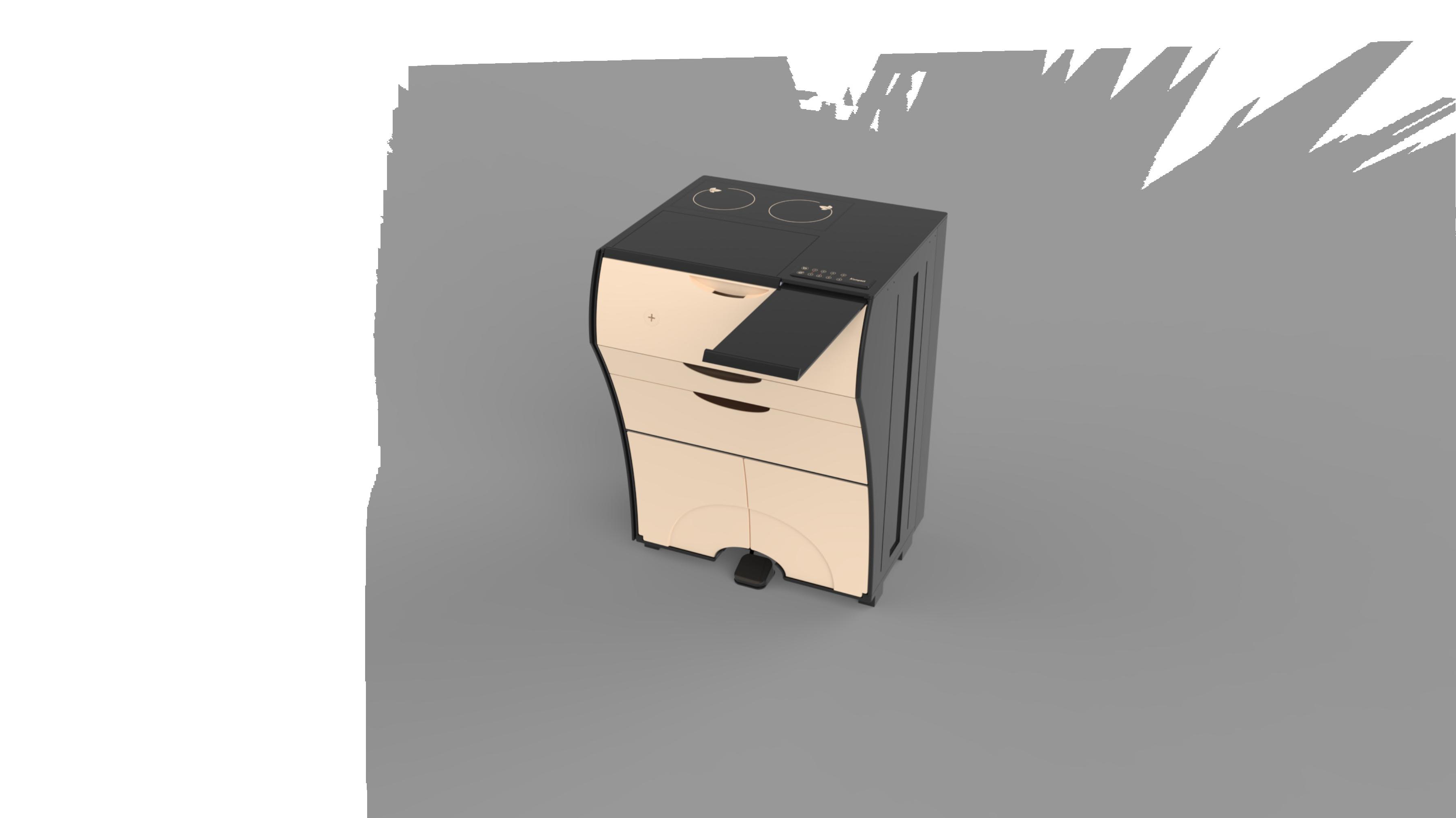

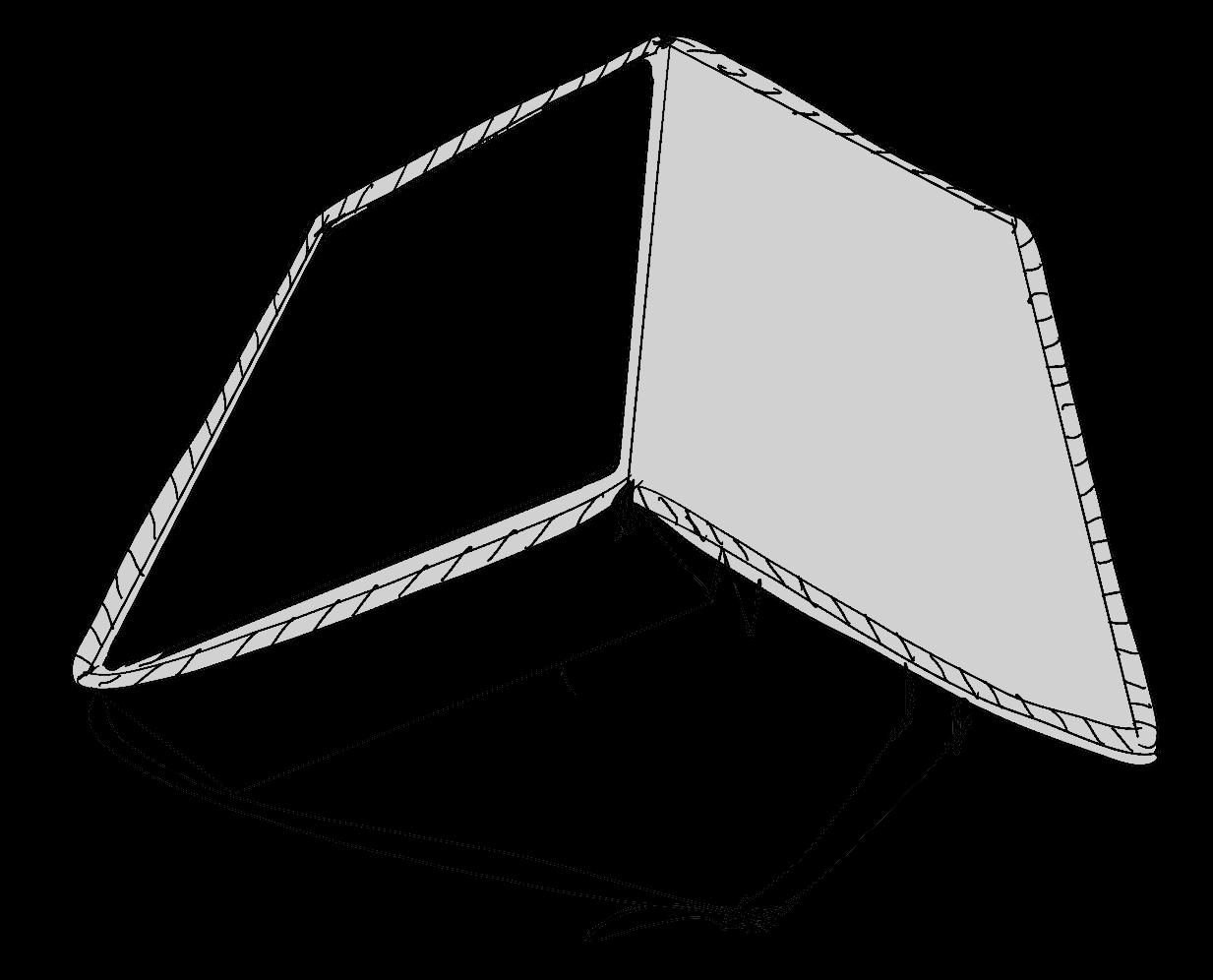

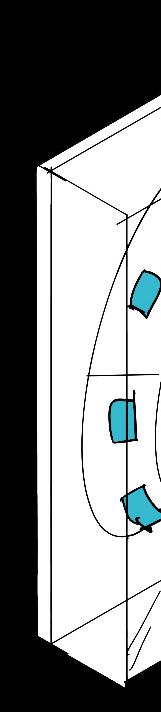

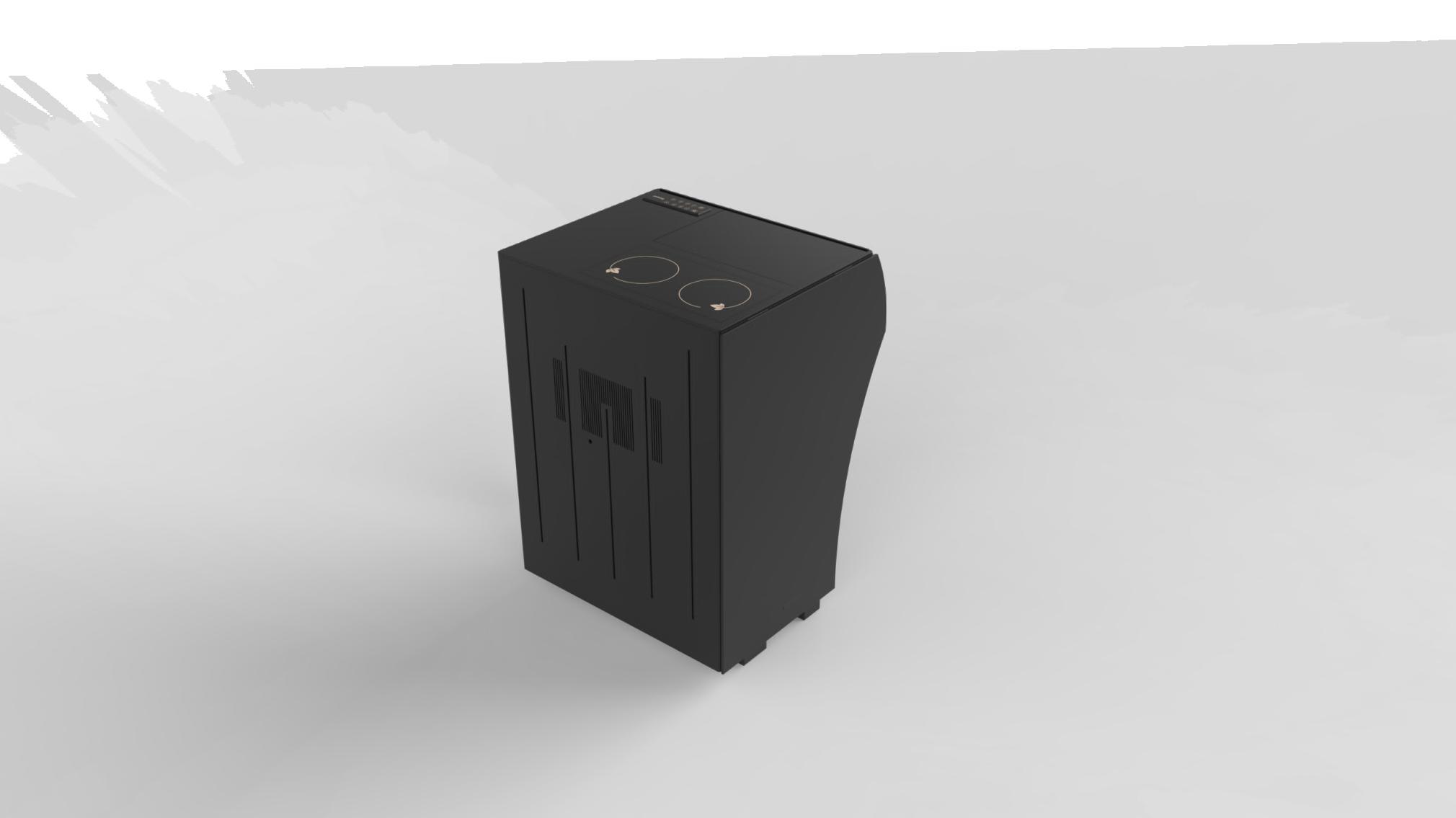

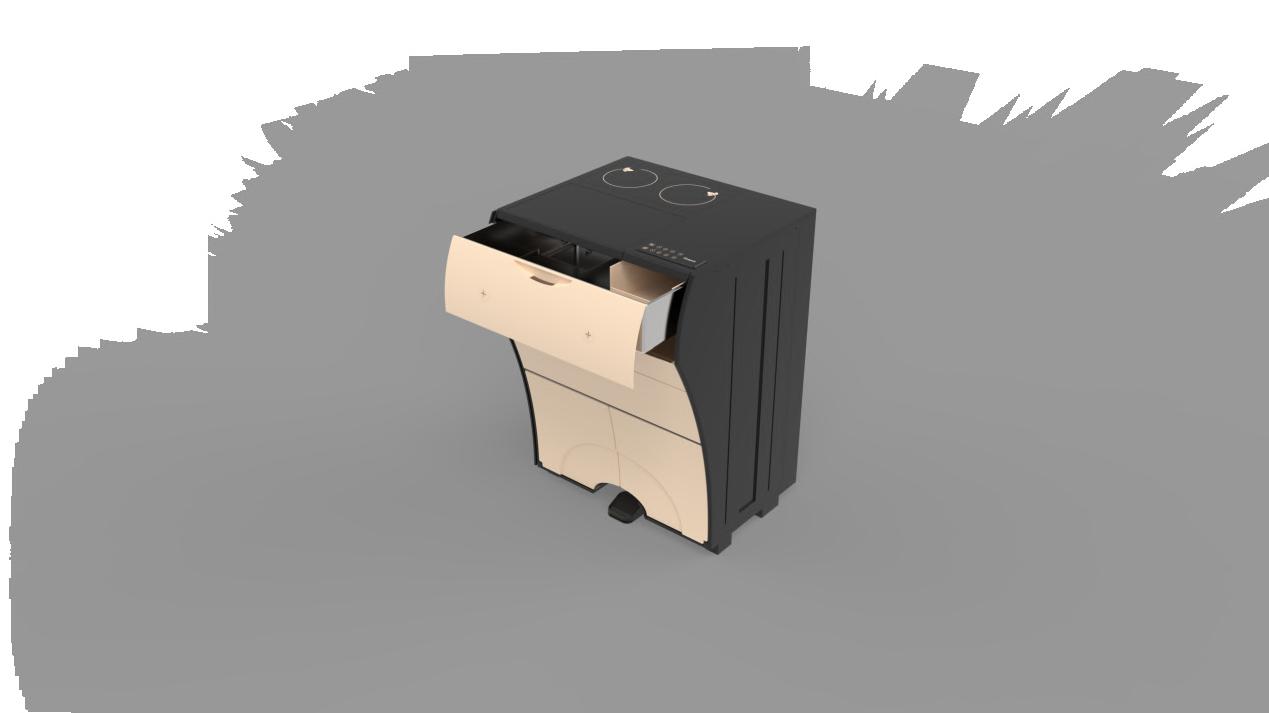

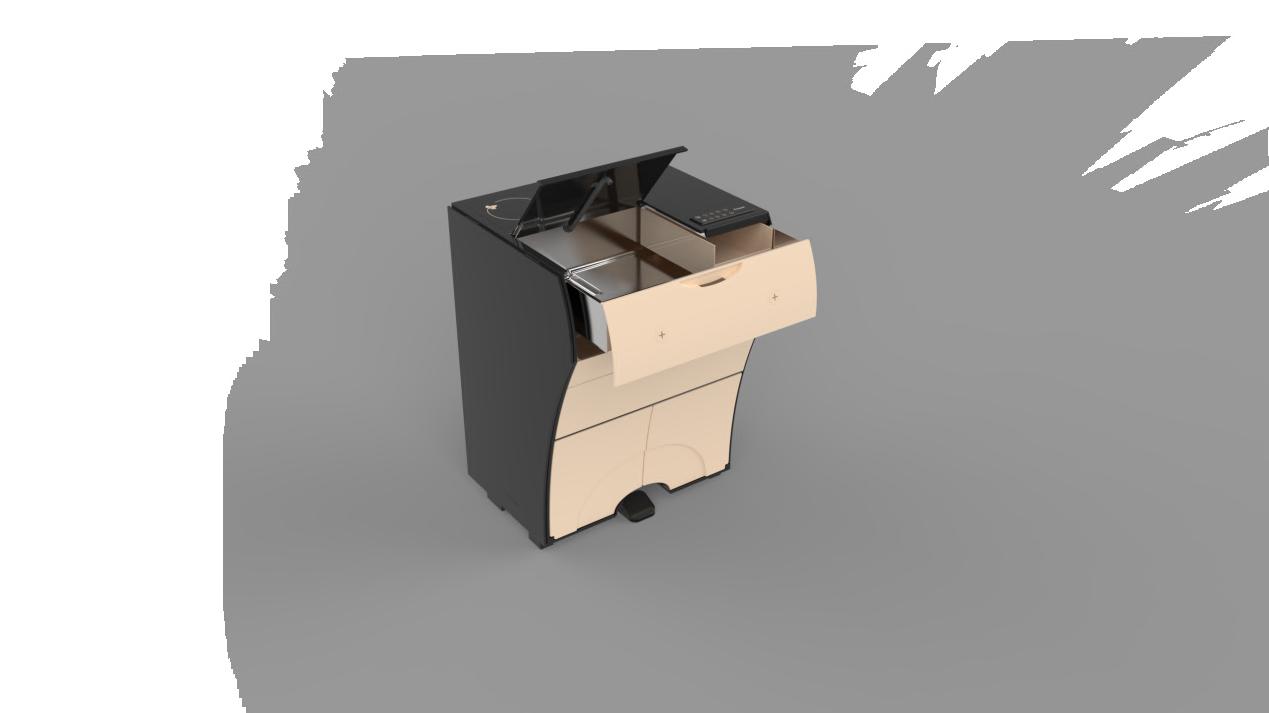

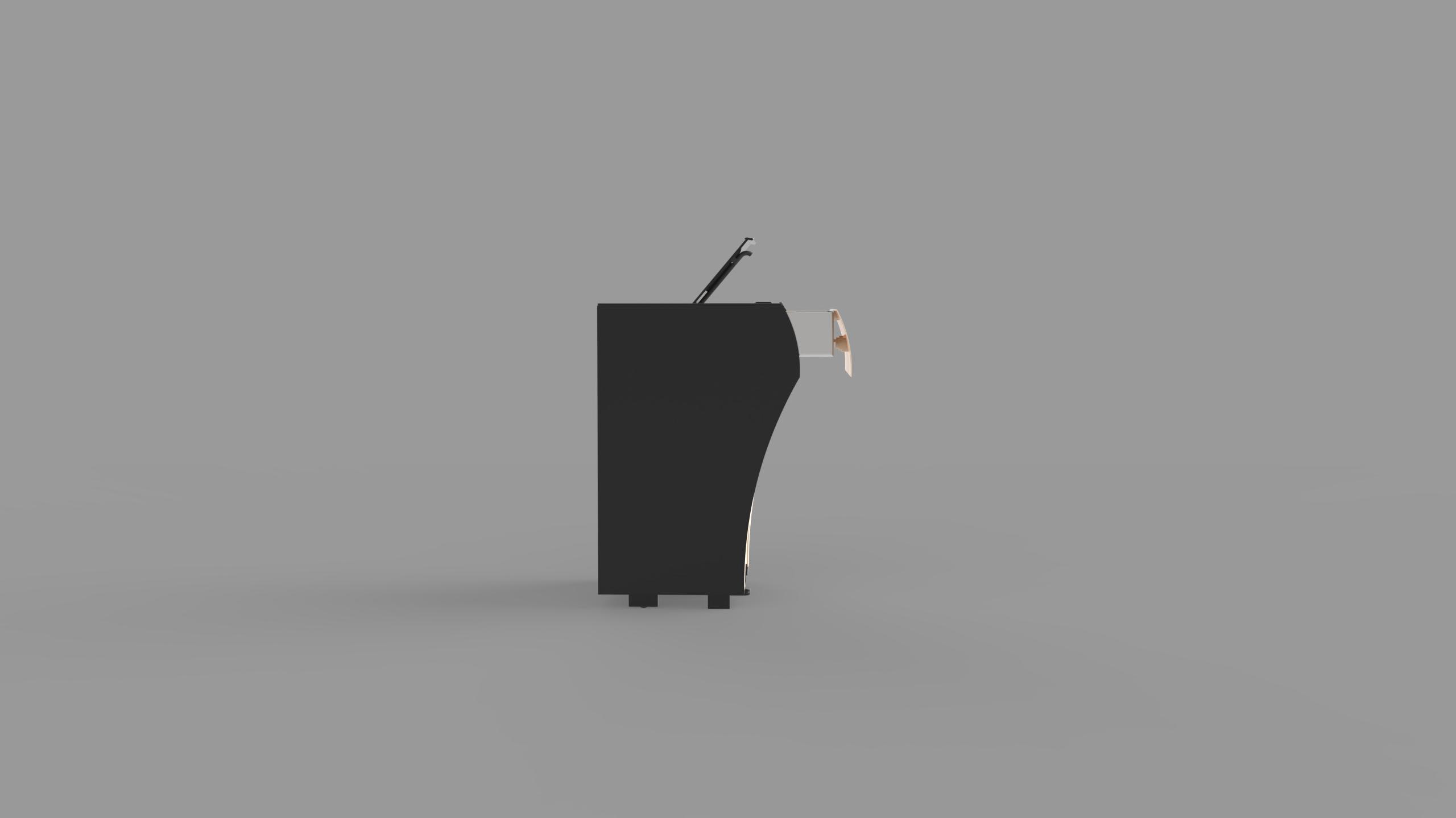

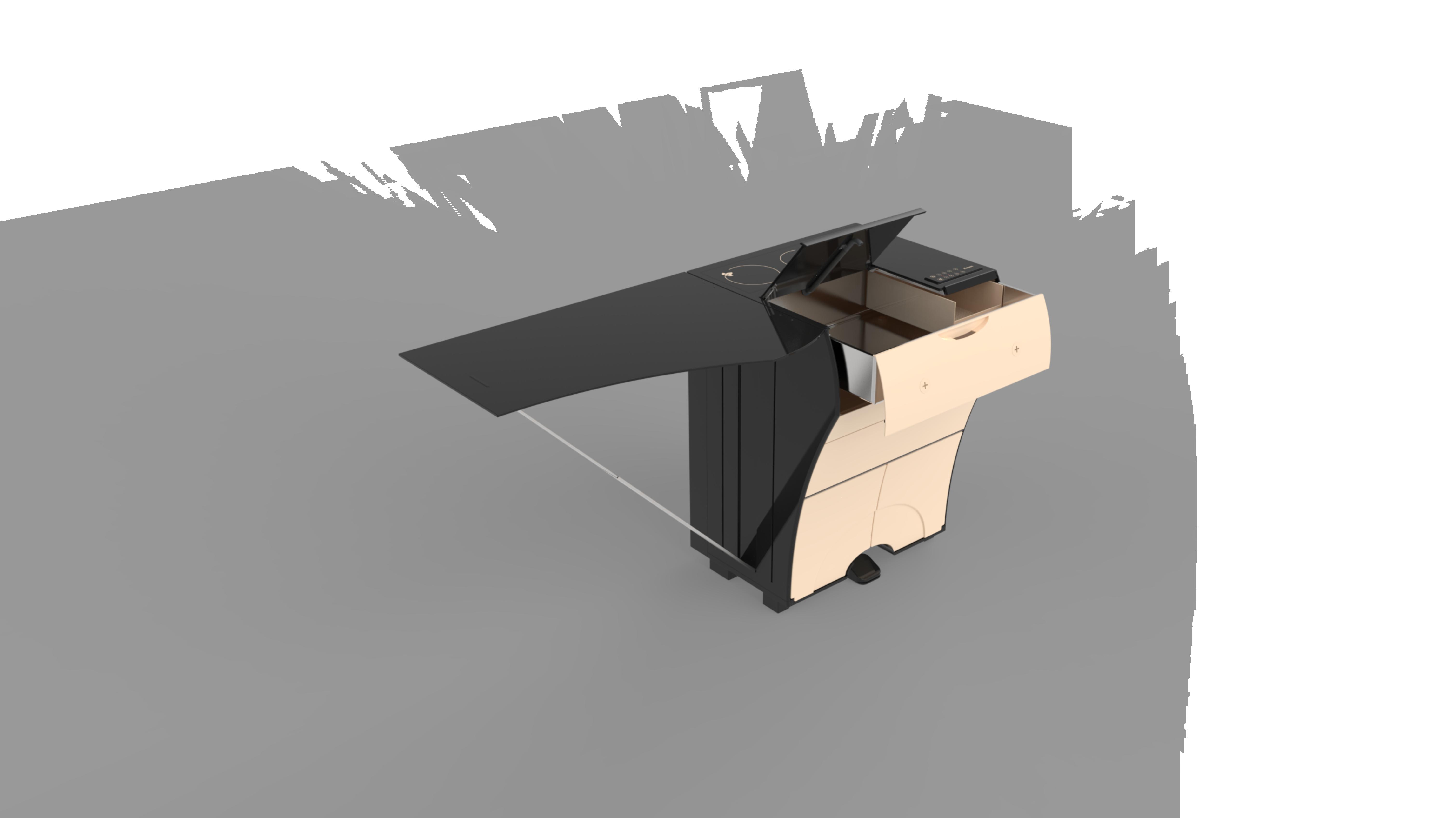

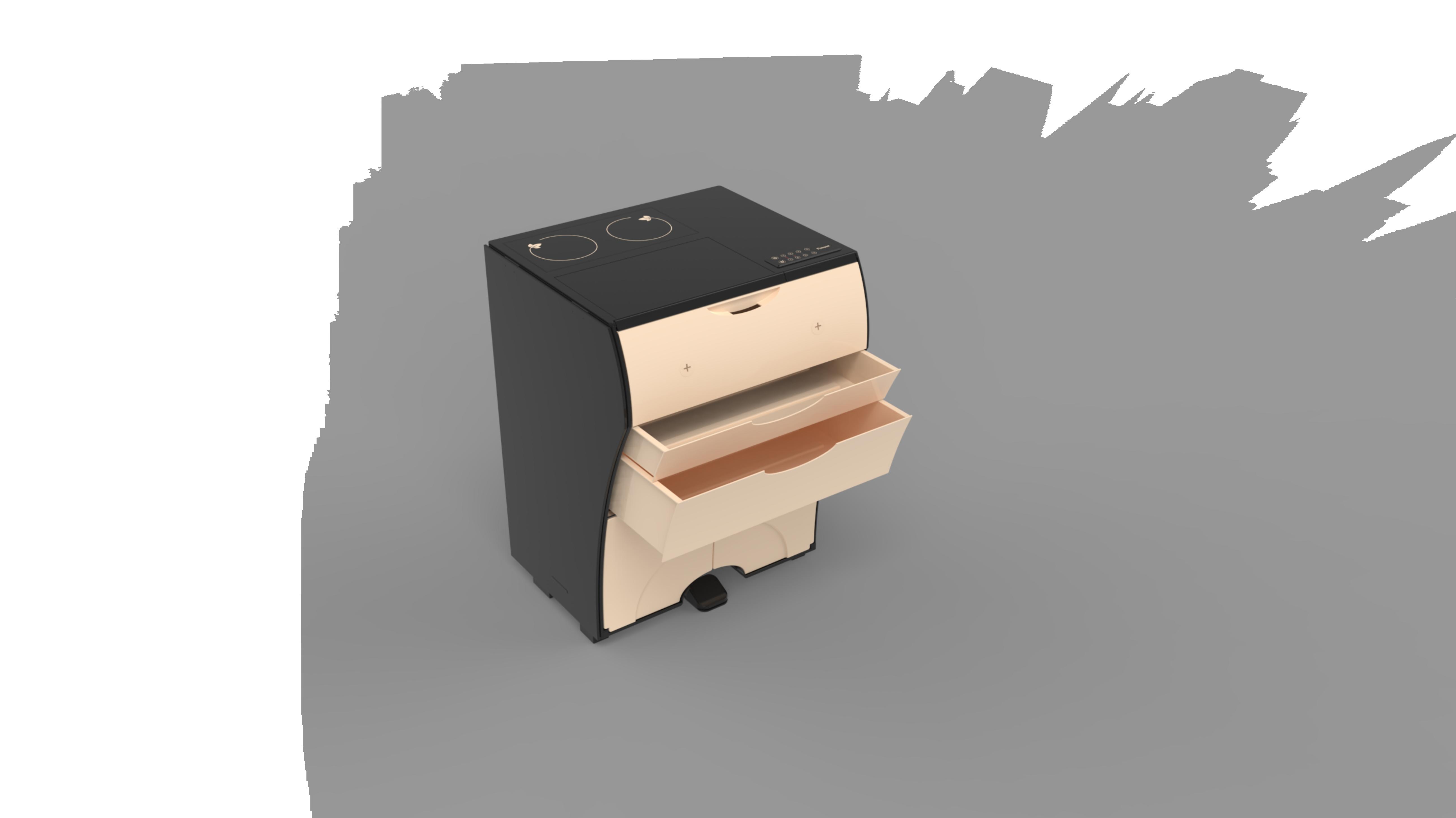

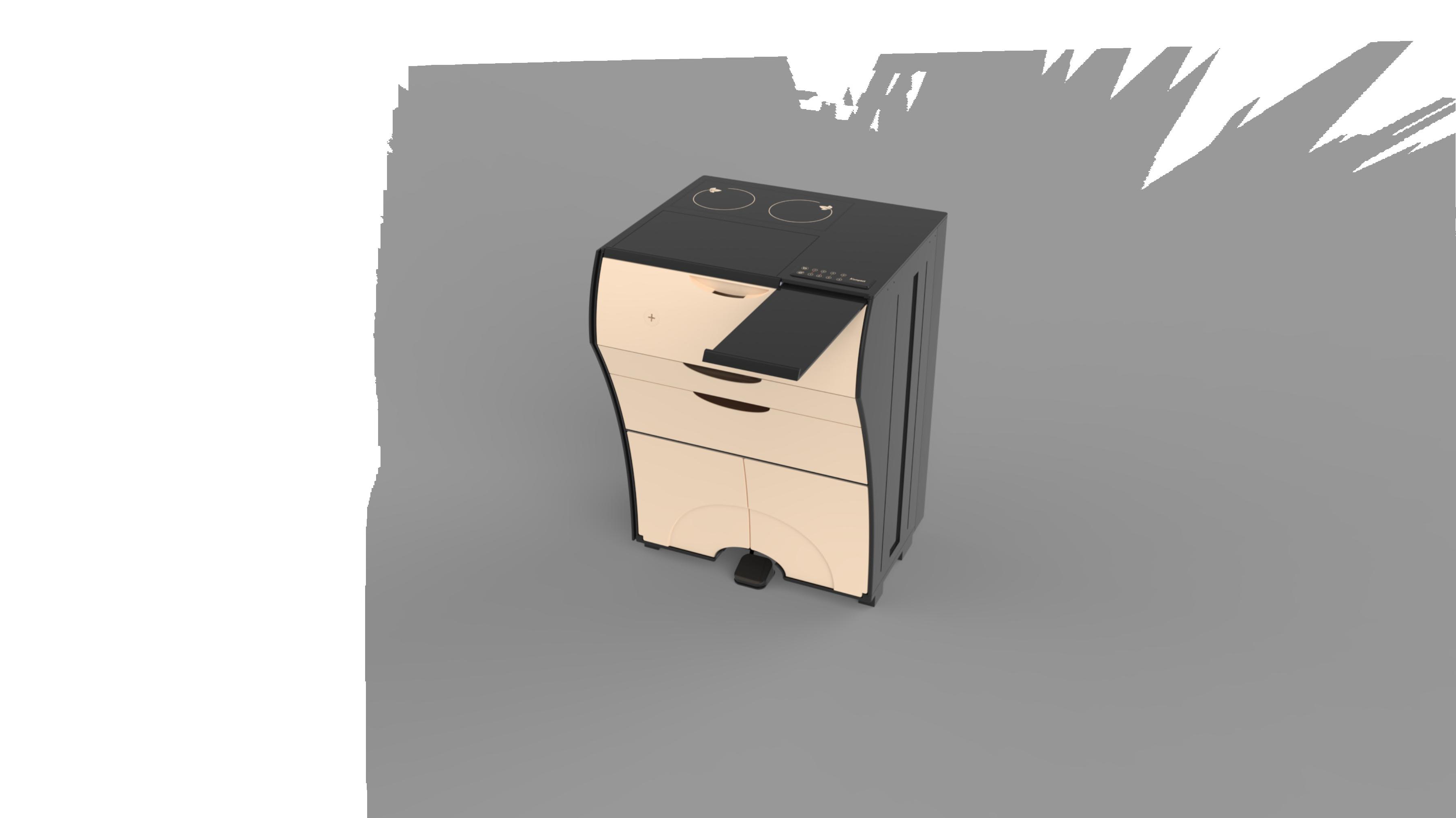

Final Design

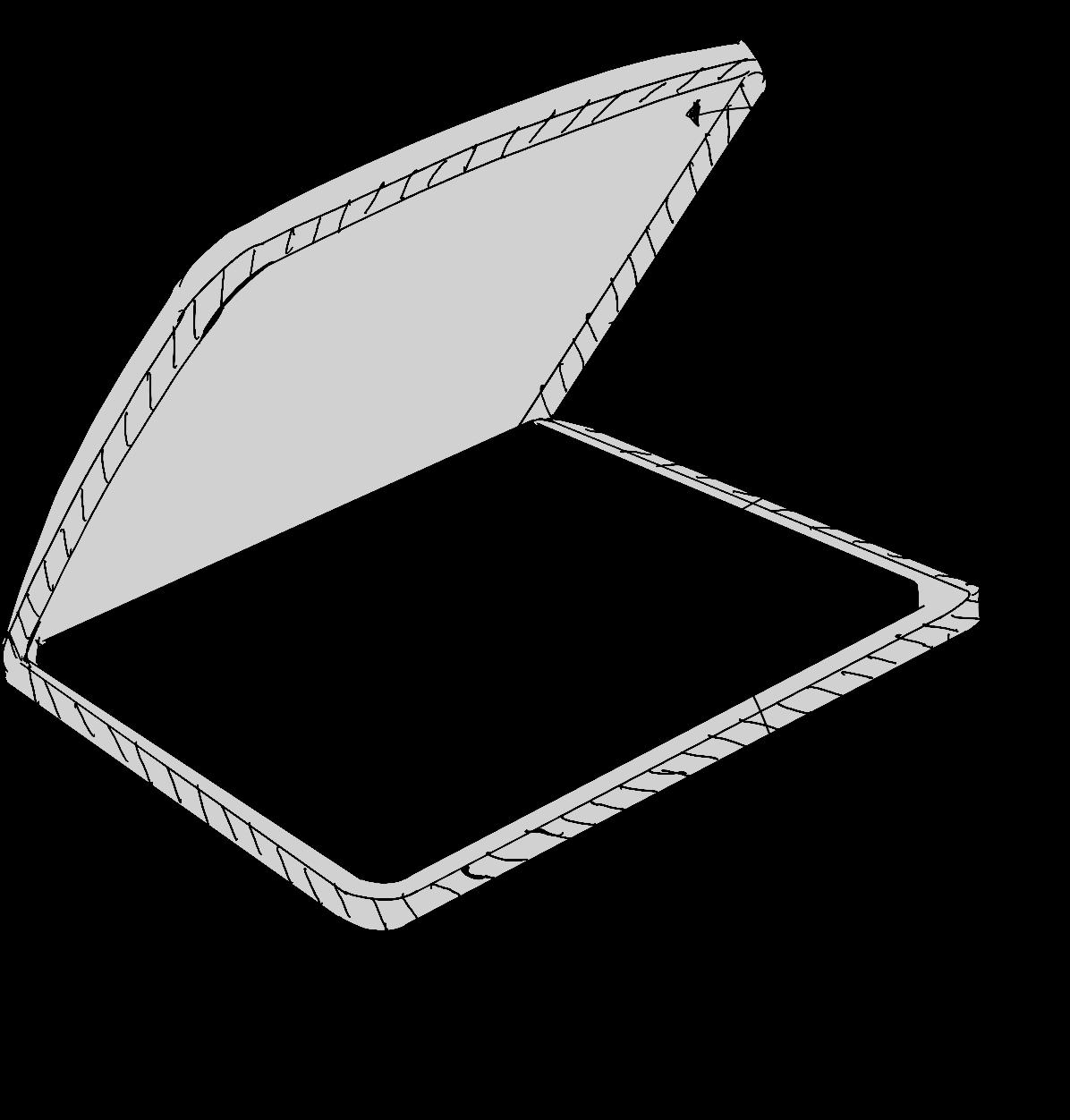

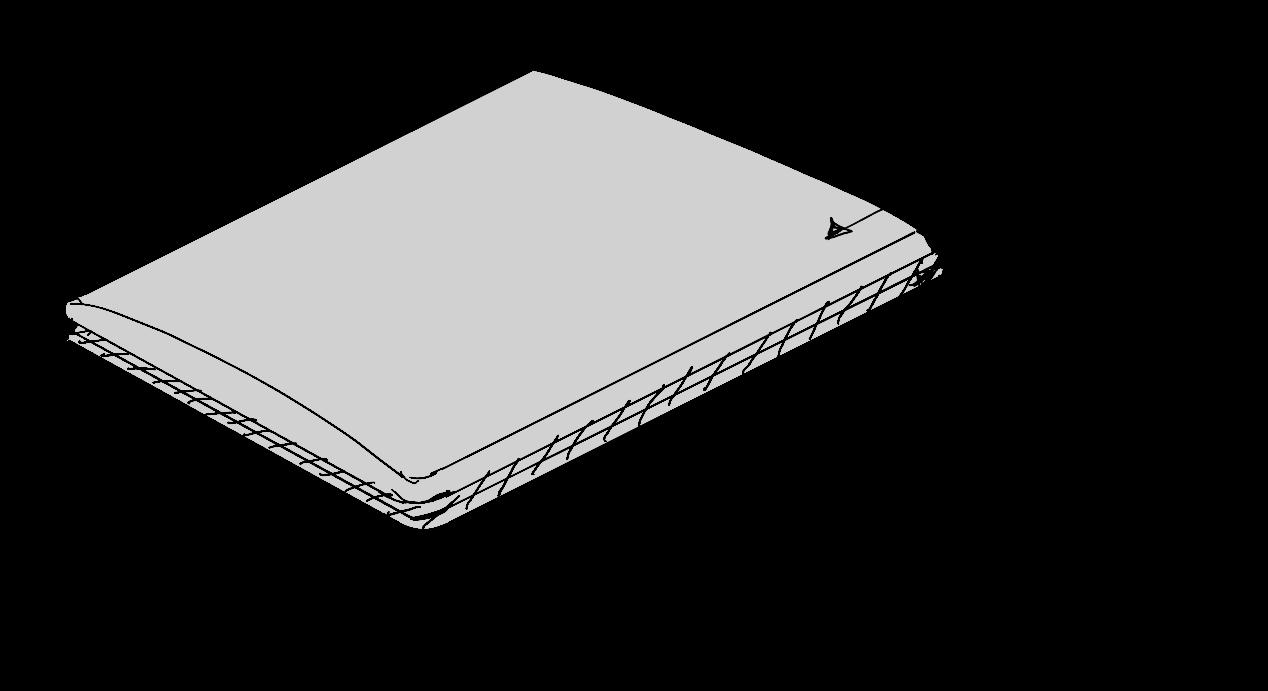

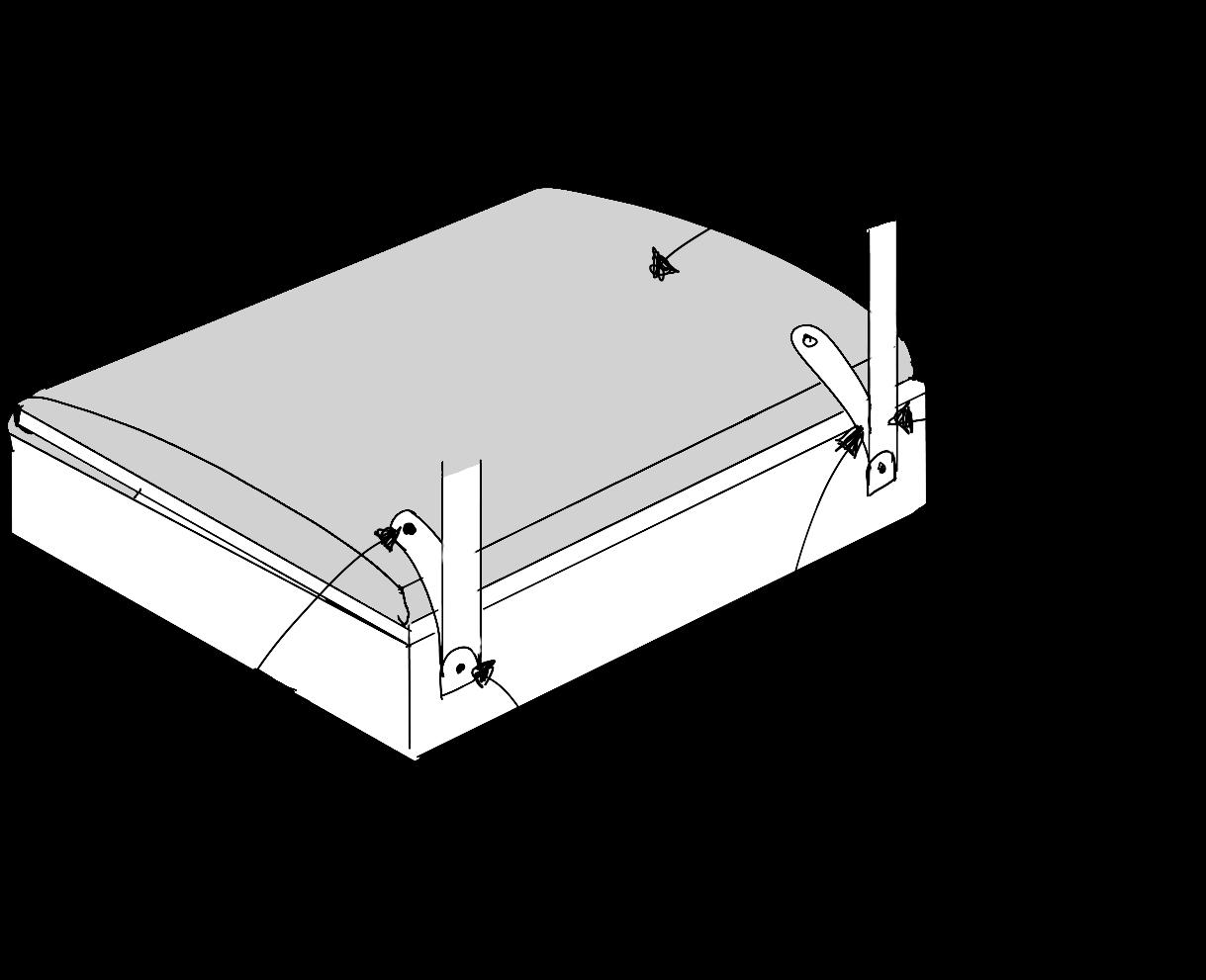

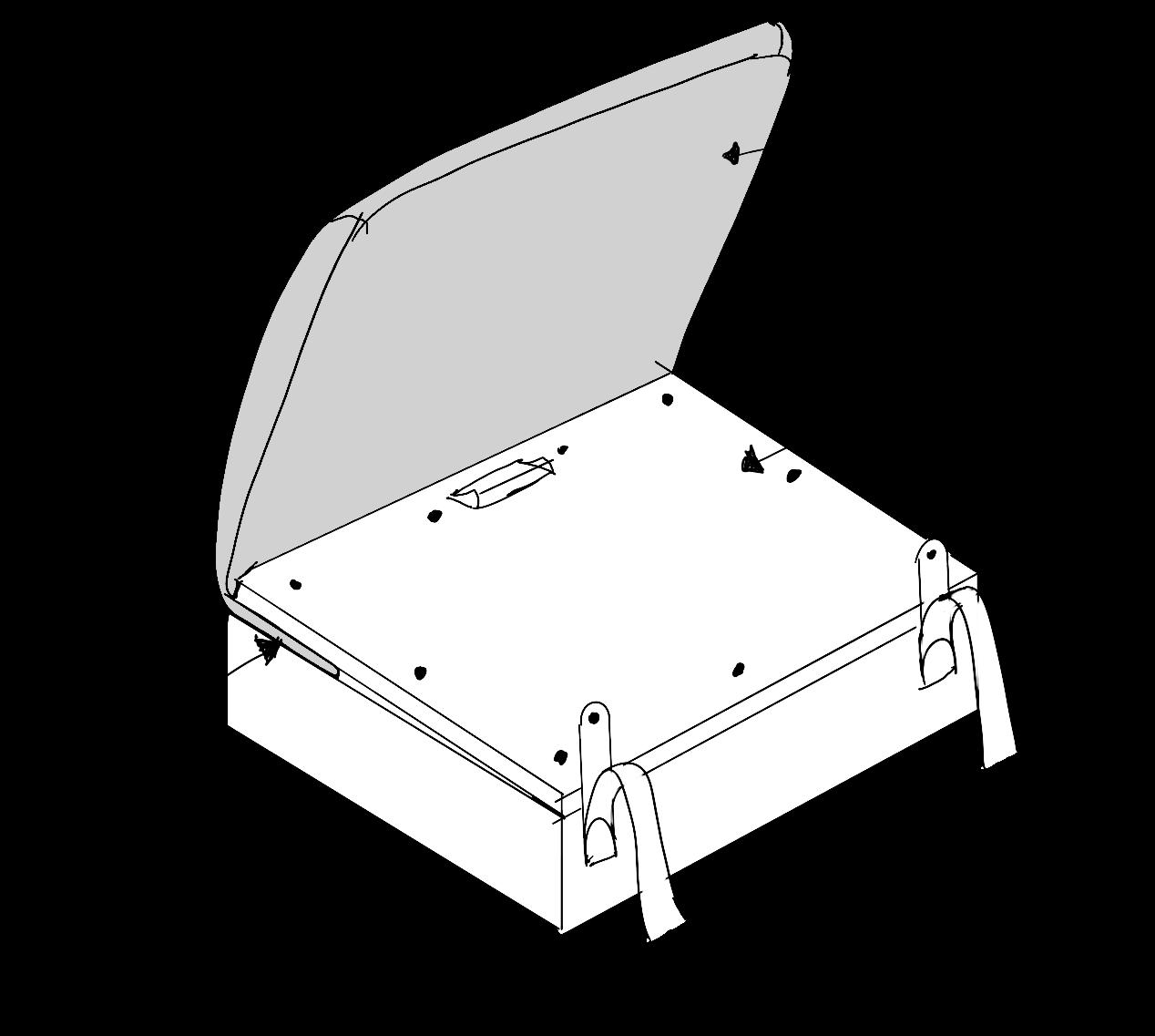

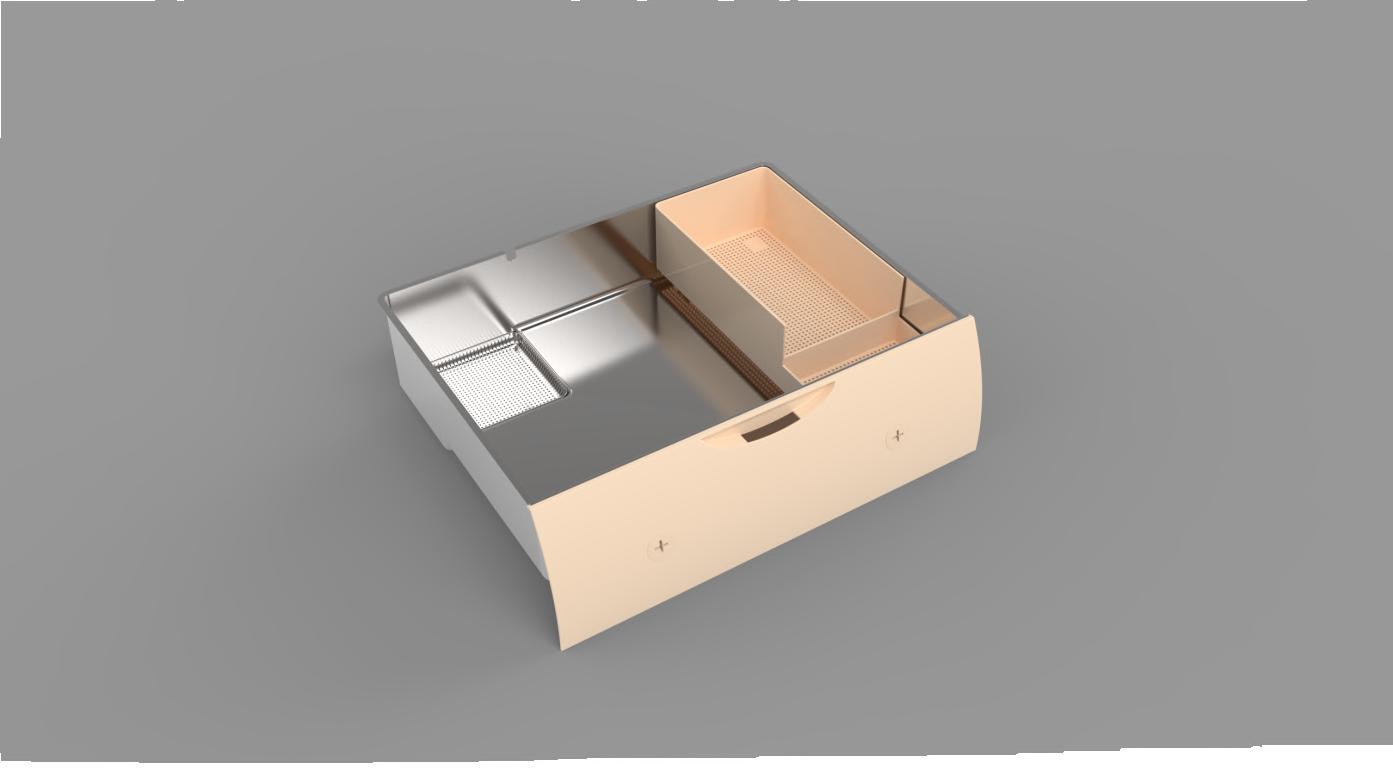

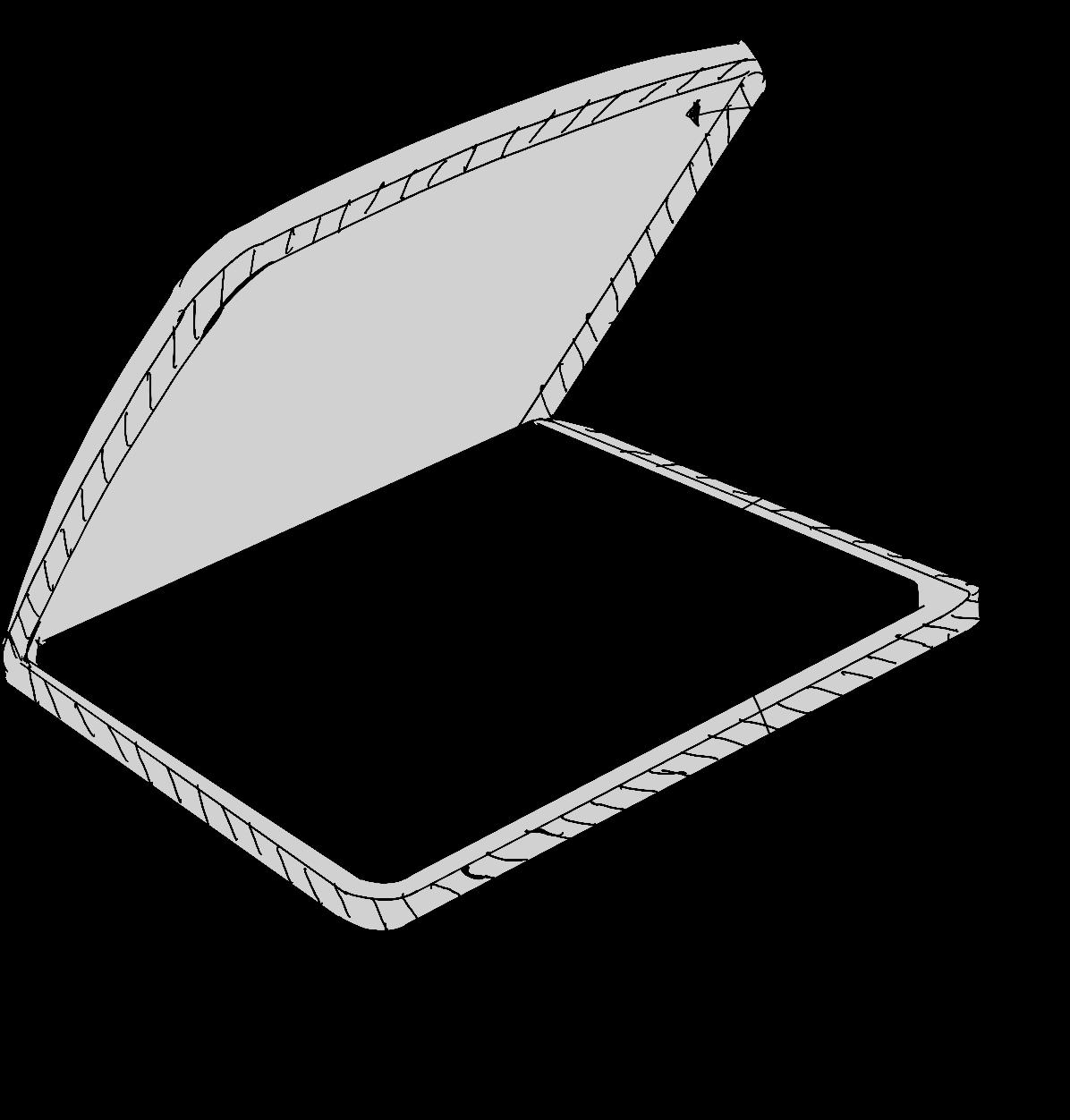

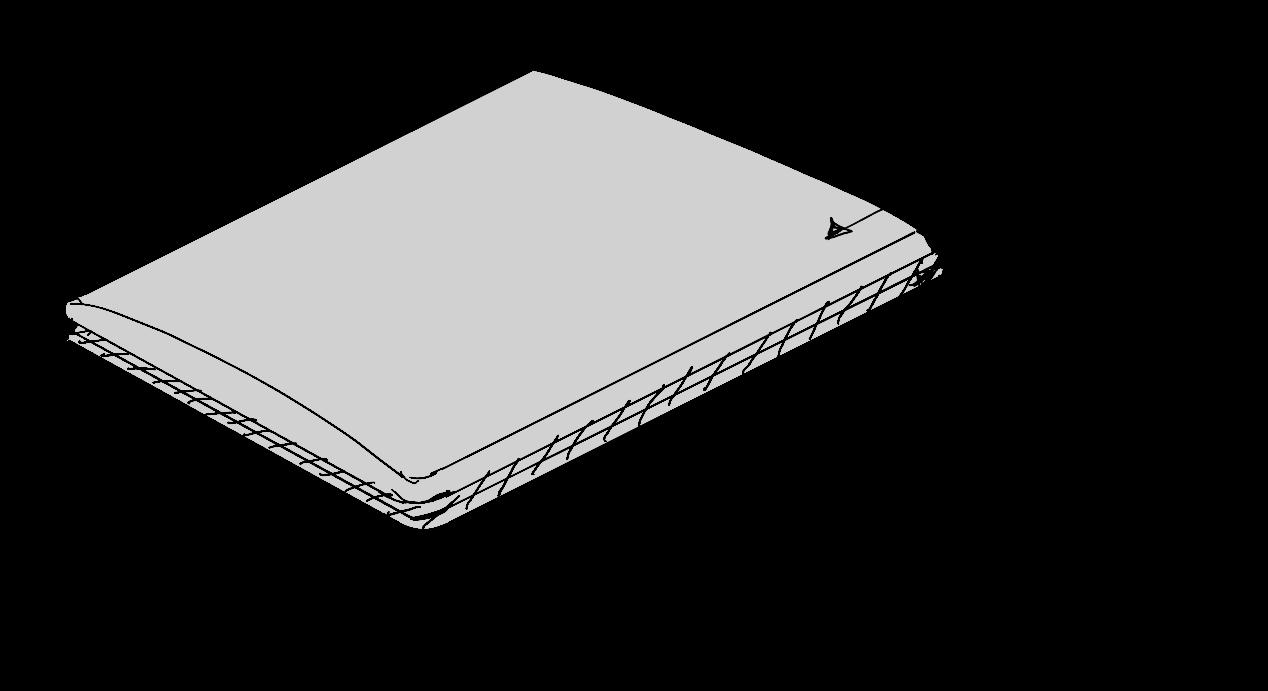

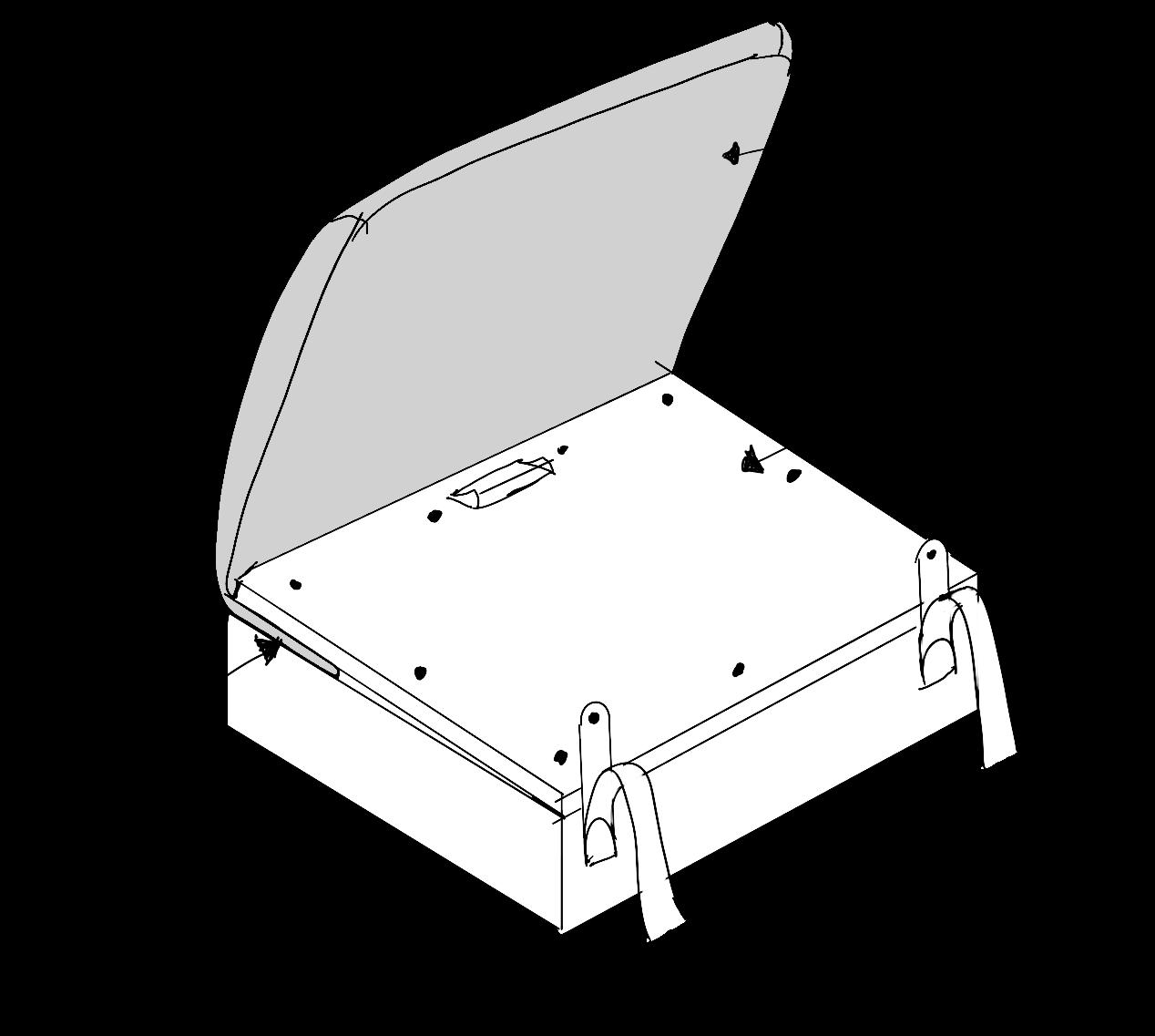

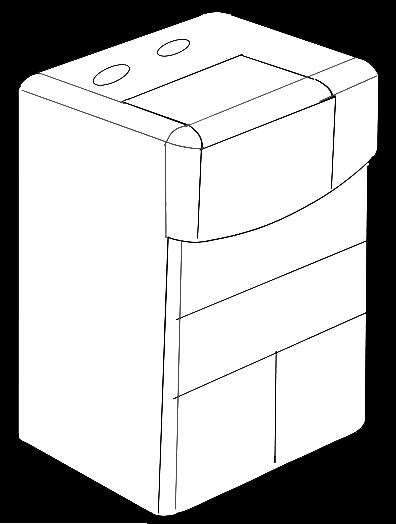

KOMPACT is a portable and an all-in-one cooking unit that features an induction cooktop, storage, a sink with water supply and foldable work surfaces.

The countertop doubles as storage.

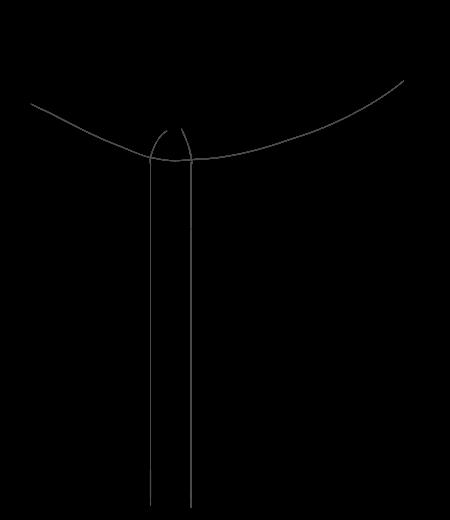

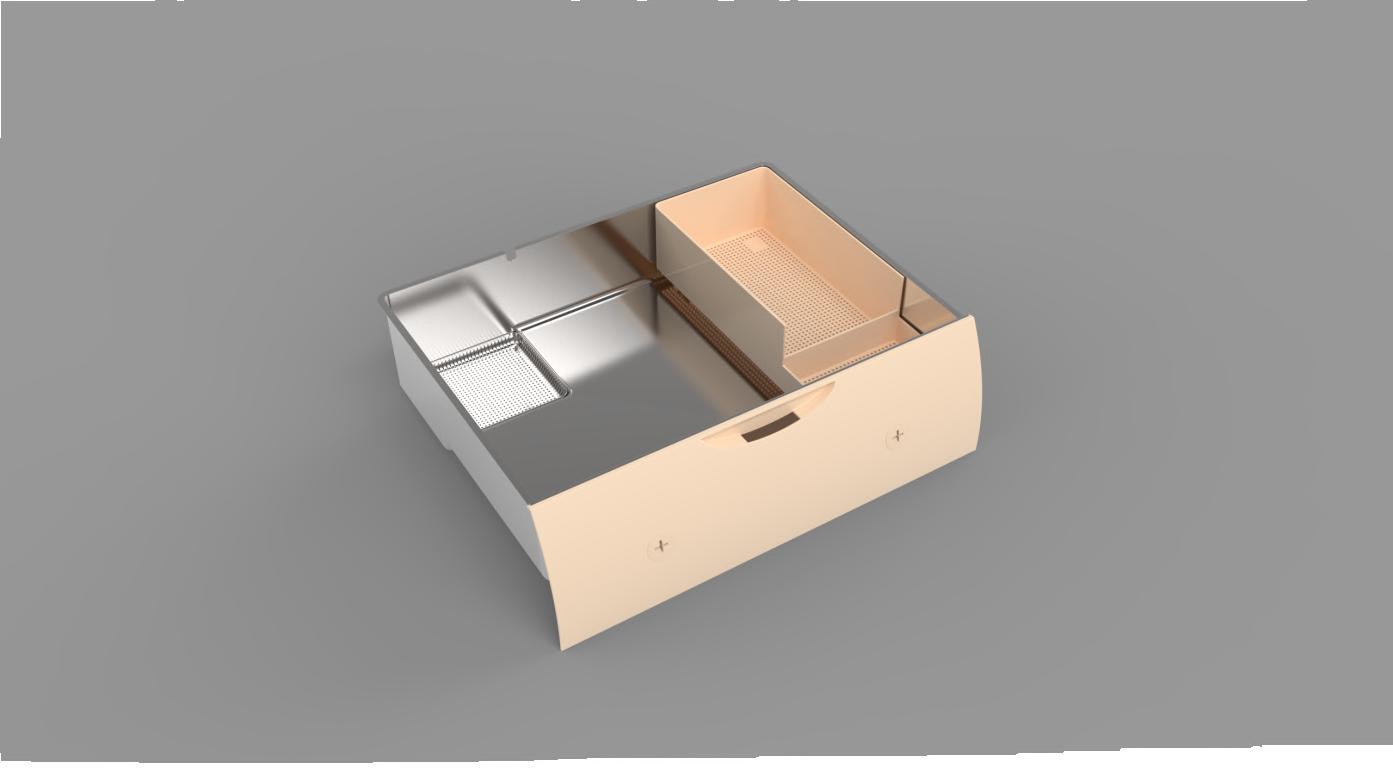

The sink is a pull-out drawer featuring a refillable water drum, controlled by an electric pump and foot-operated switch.

Cutting surface

Additional

Wire mesh for stability

Induction surface

ap for more workspace

Foot switch

Drain water drum

ap for more workspace

Foot switch

Drain water drum

Control panel

Drawer for storage

Fresh water drum

Sink Hooks for hanging rags/napkins

Fresh water pipe

Fresh water pipe

Tap

Drain water pipe Water

Flow

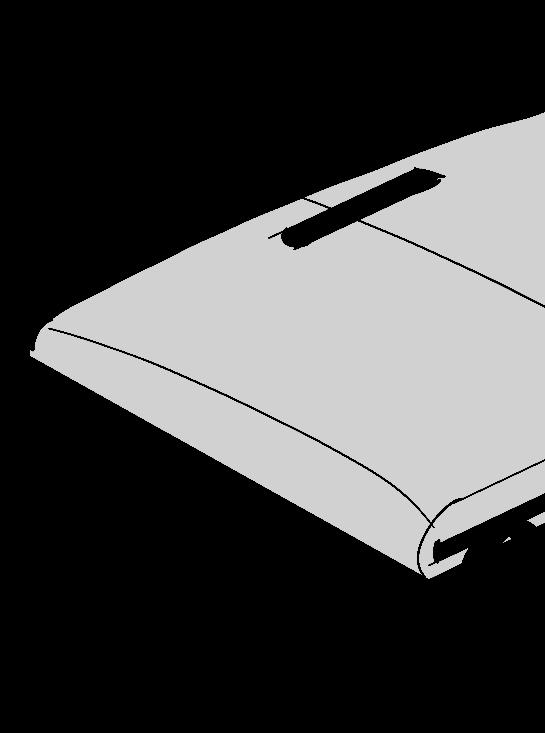

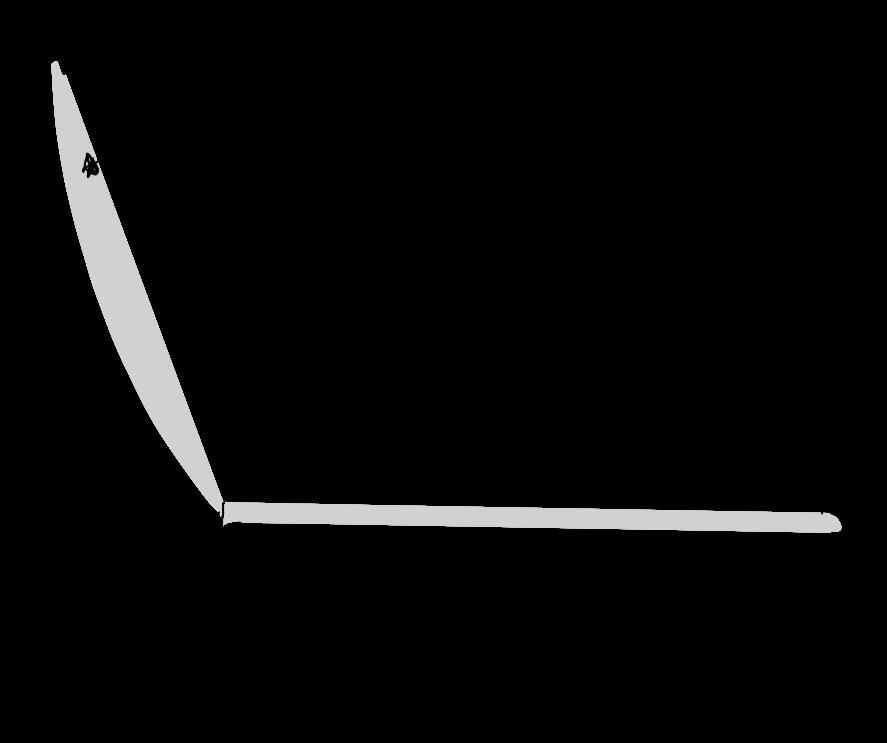

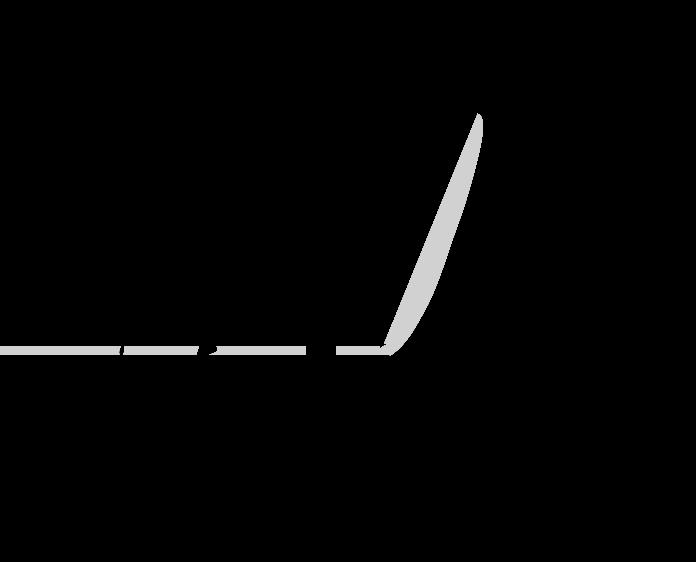

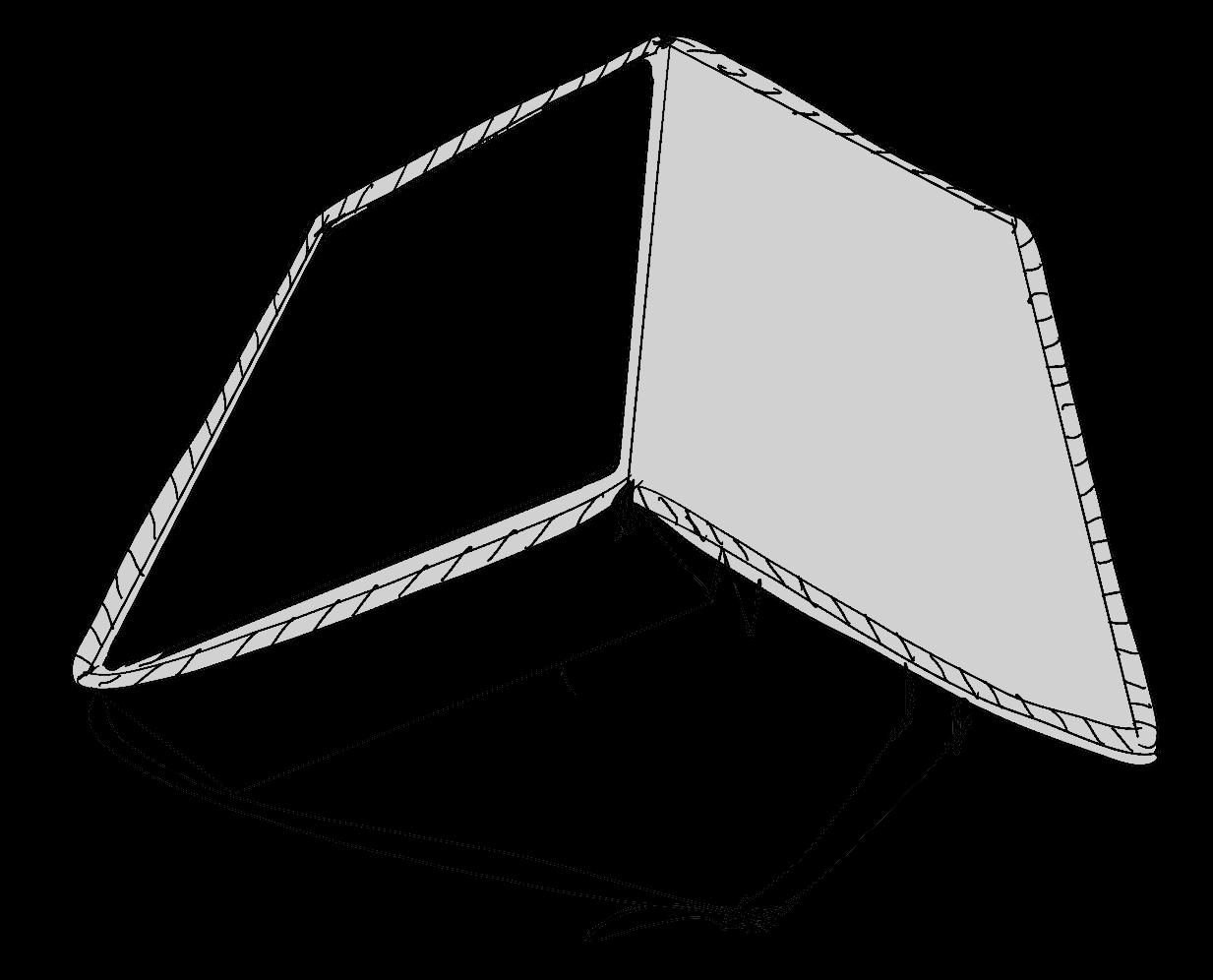

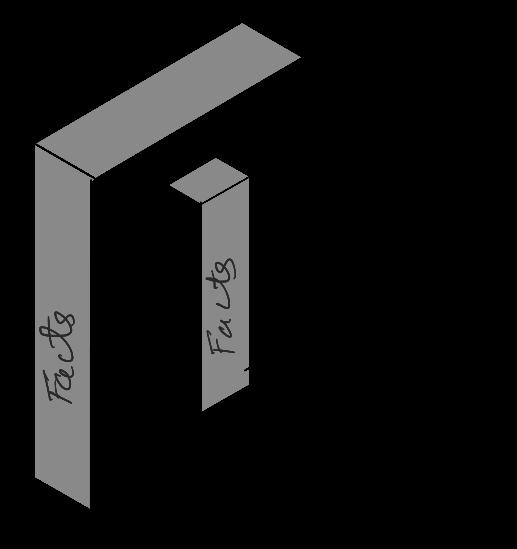

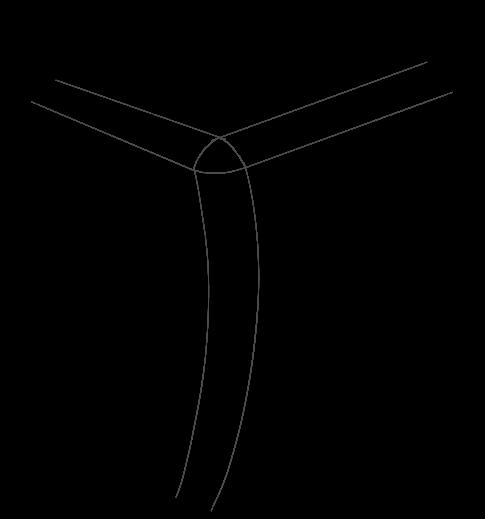

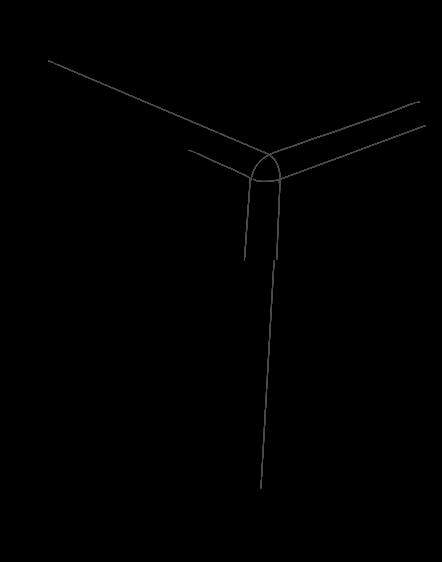

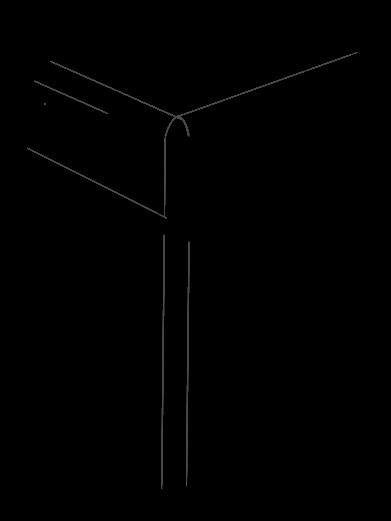

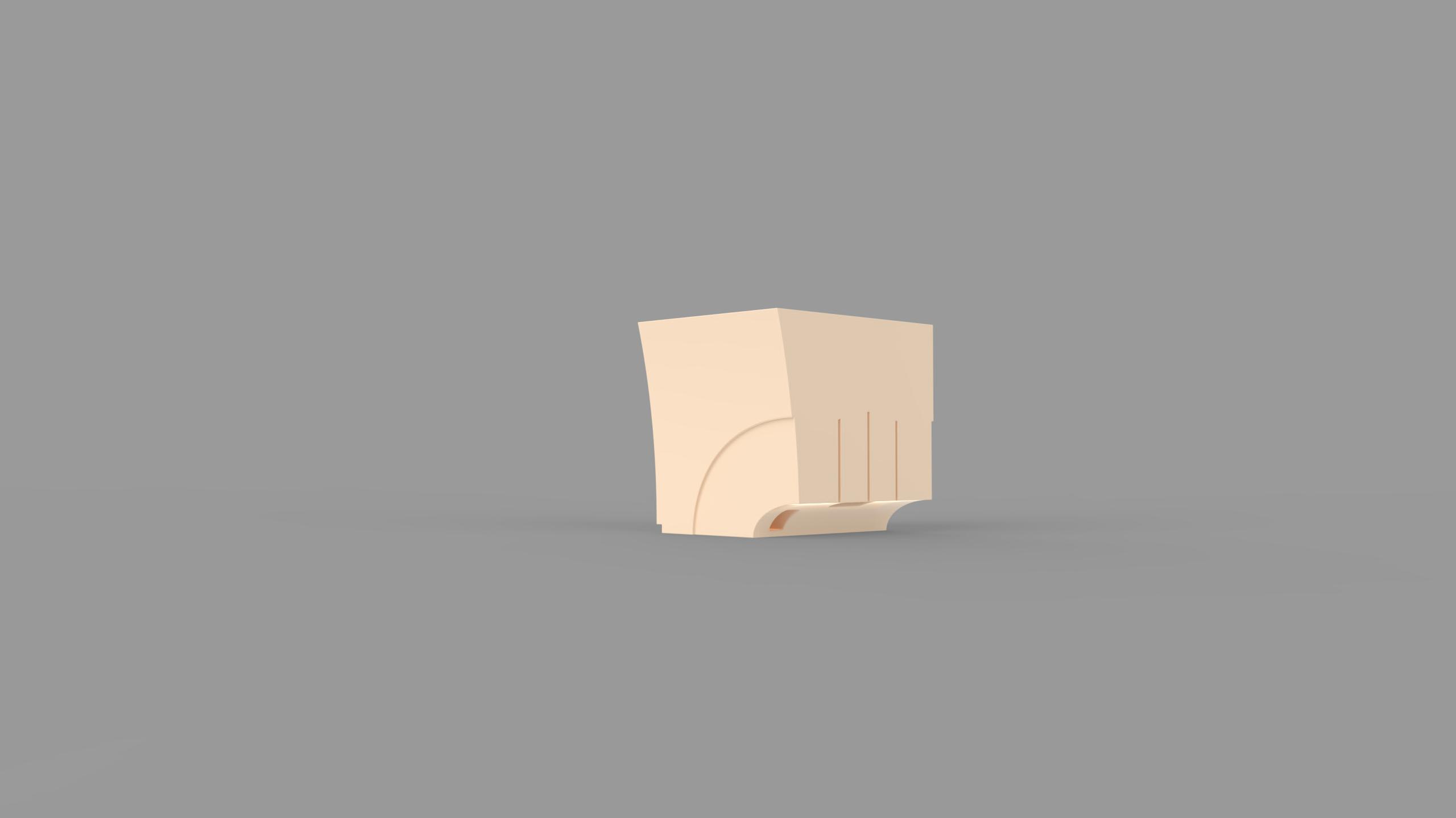

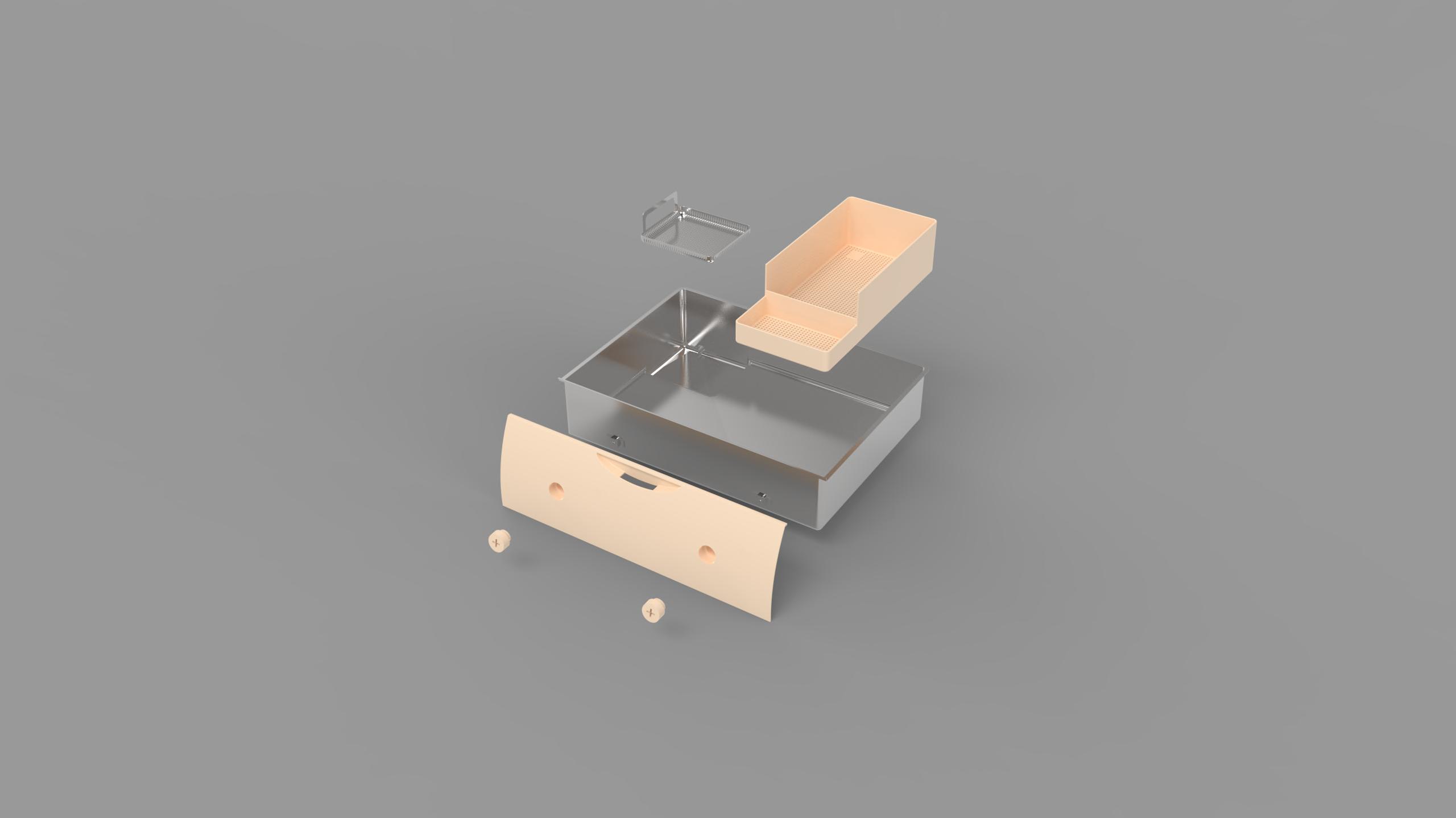

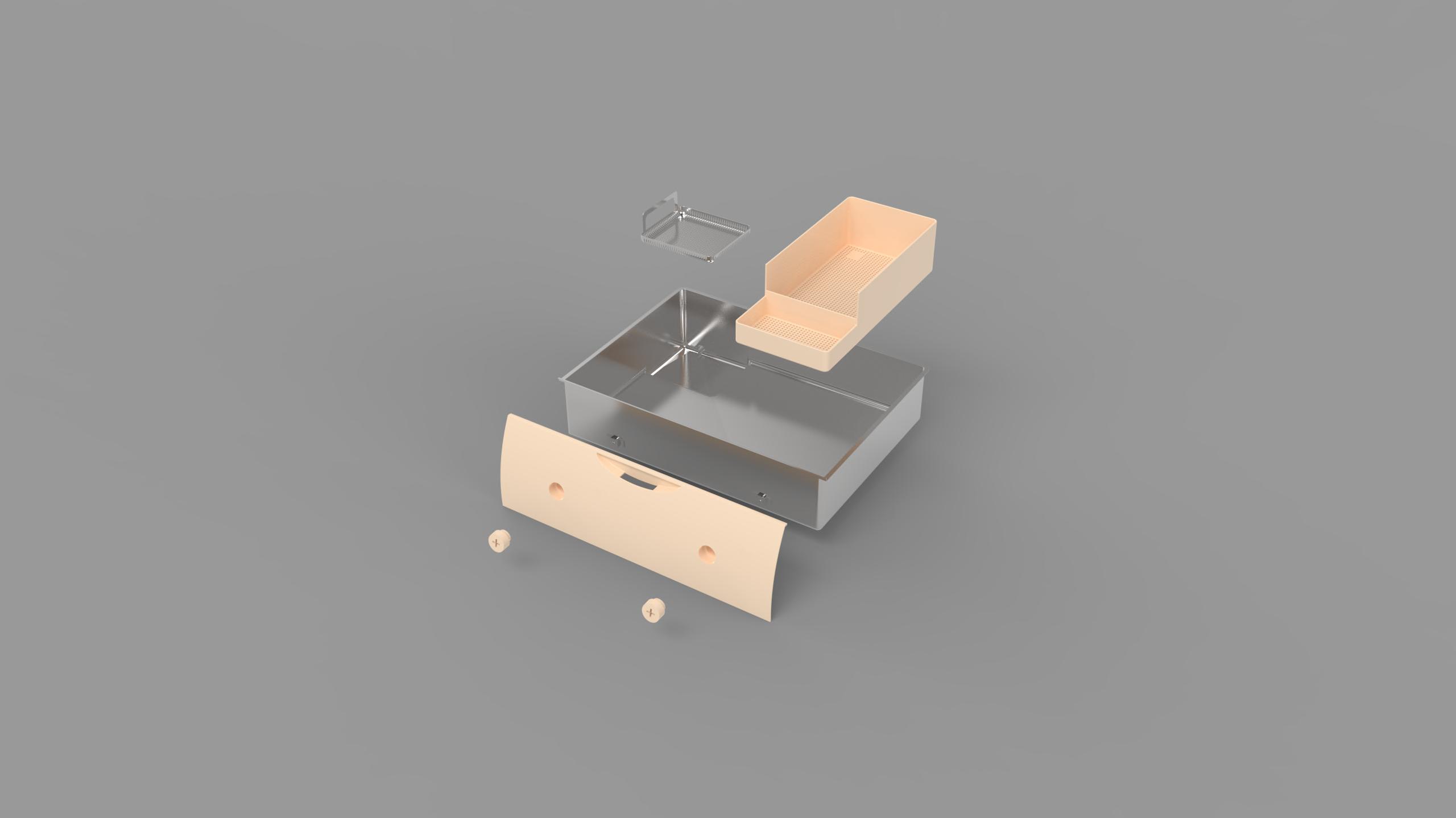

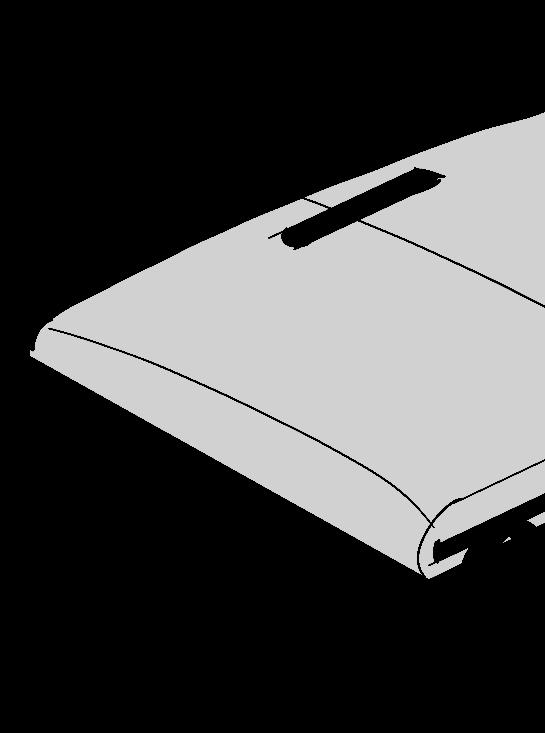

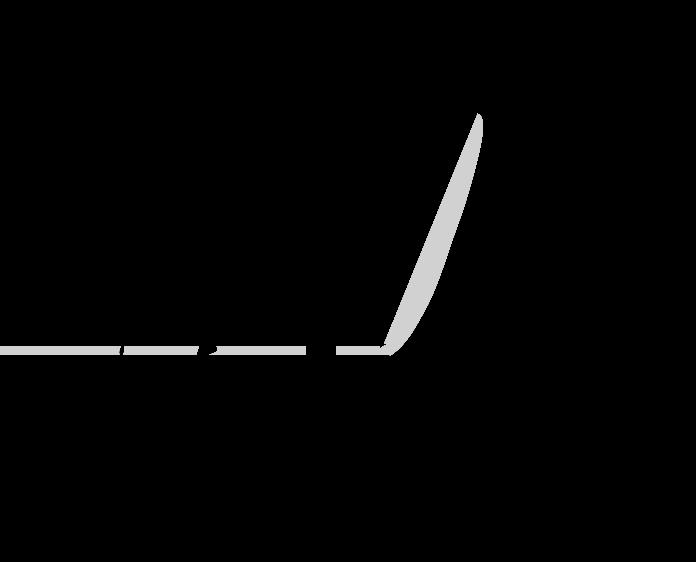

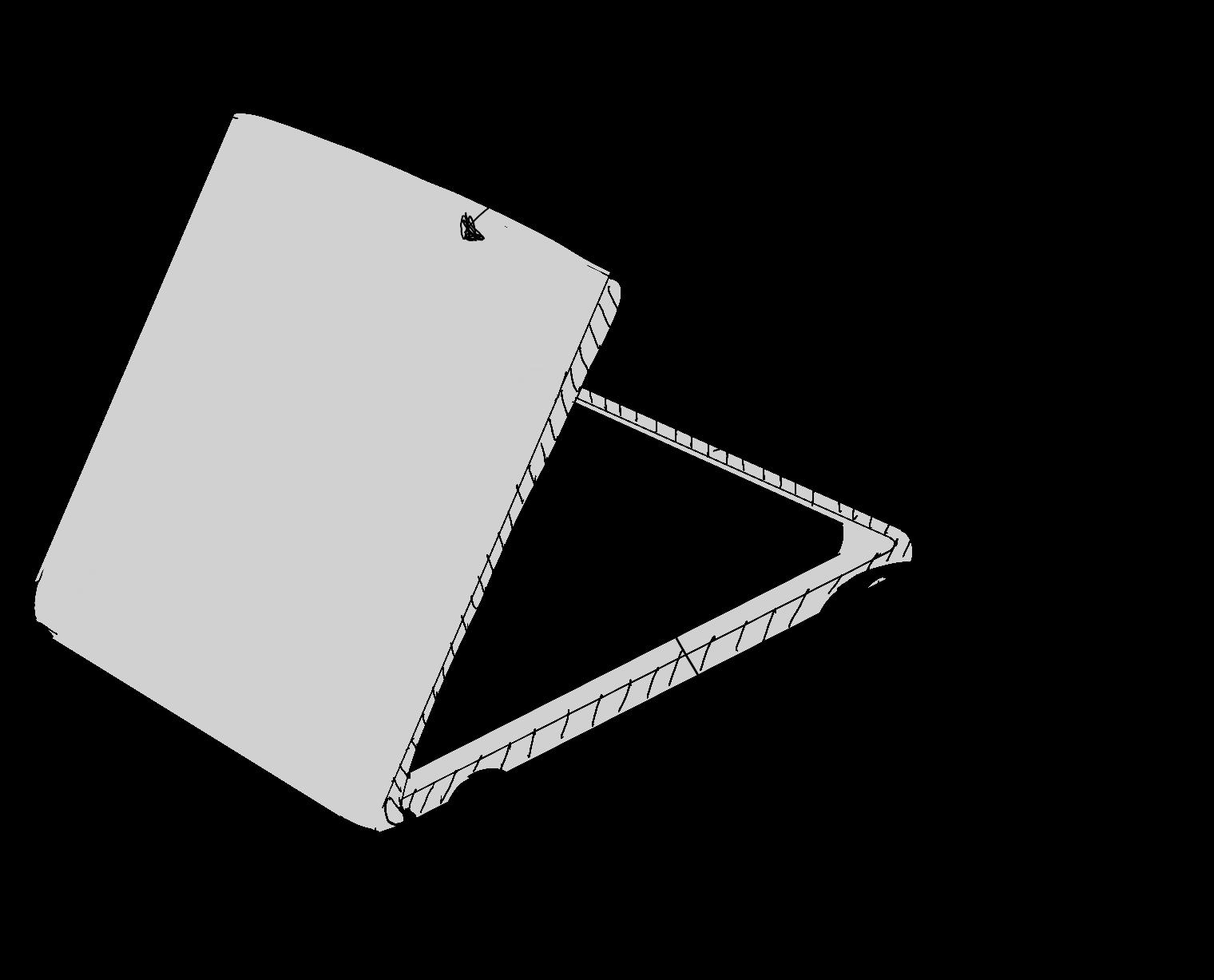

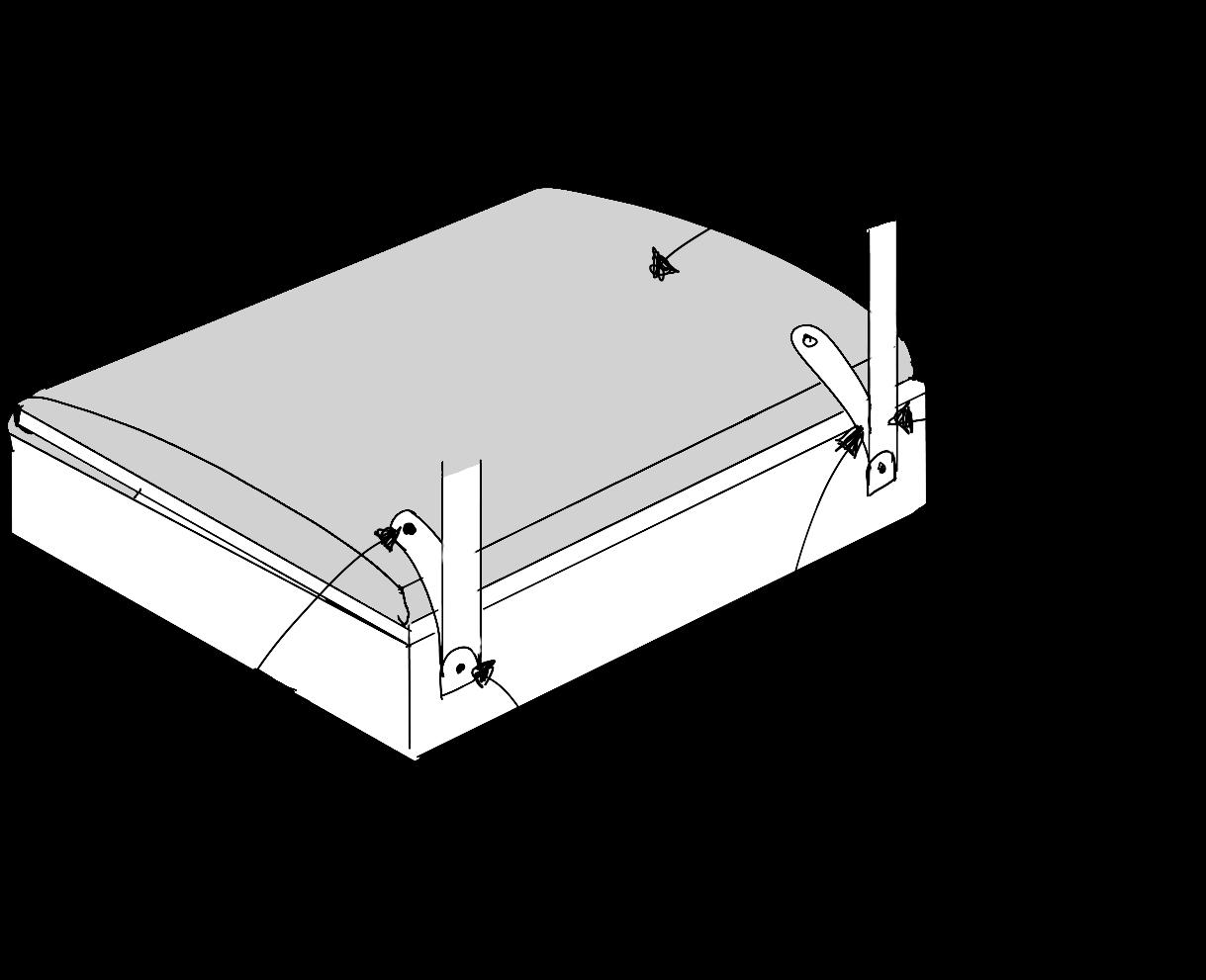

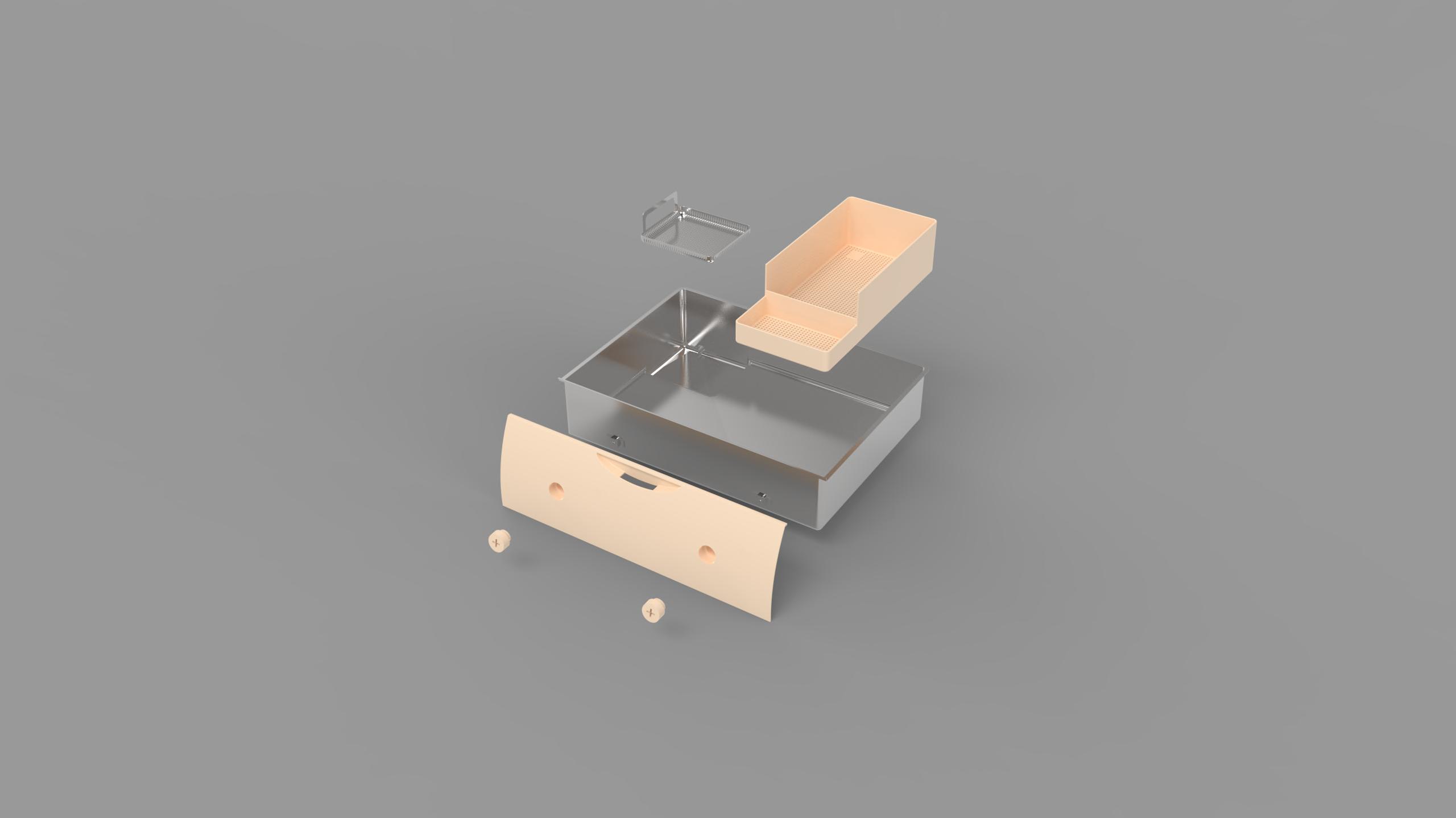

The unit’s housing consists of 5 parts which will be screwed together.

The back, right, left and bottom housings will be made of ABS plastic by injection moulding.

The top surface will be made of Corian material as it is more durable and suitable for cutting.

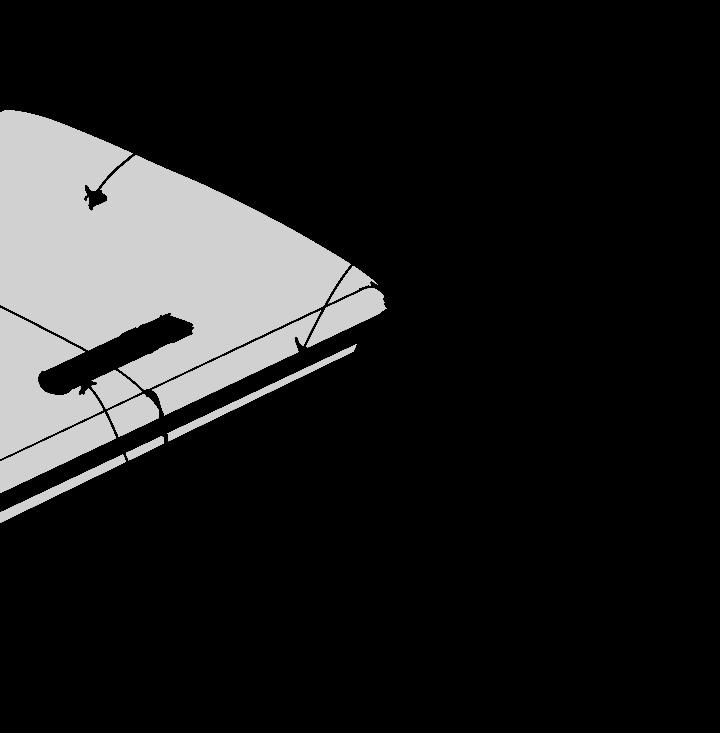

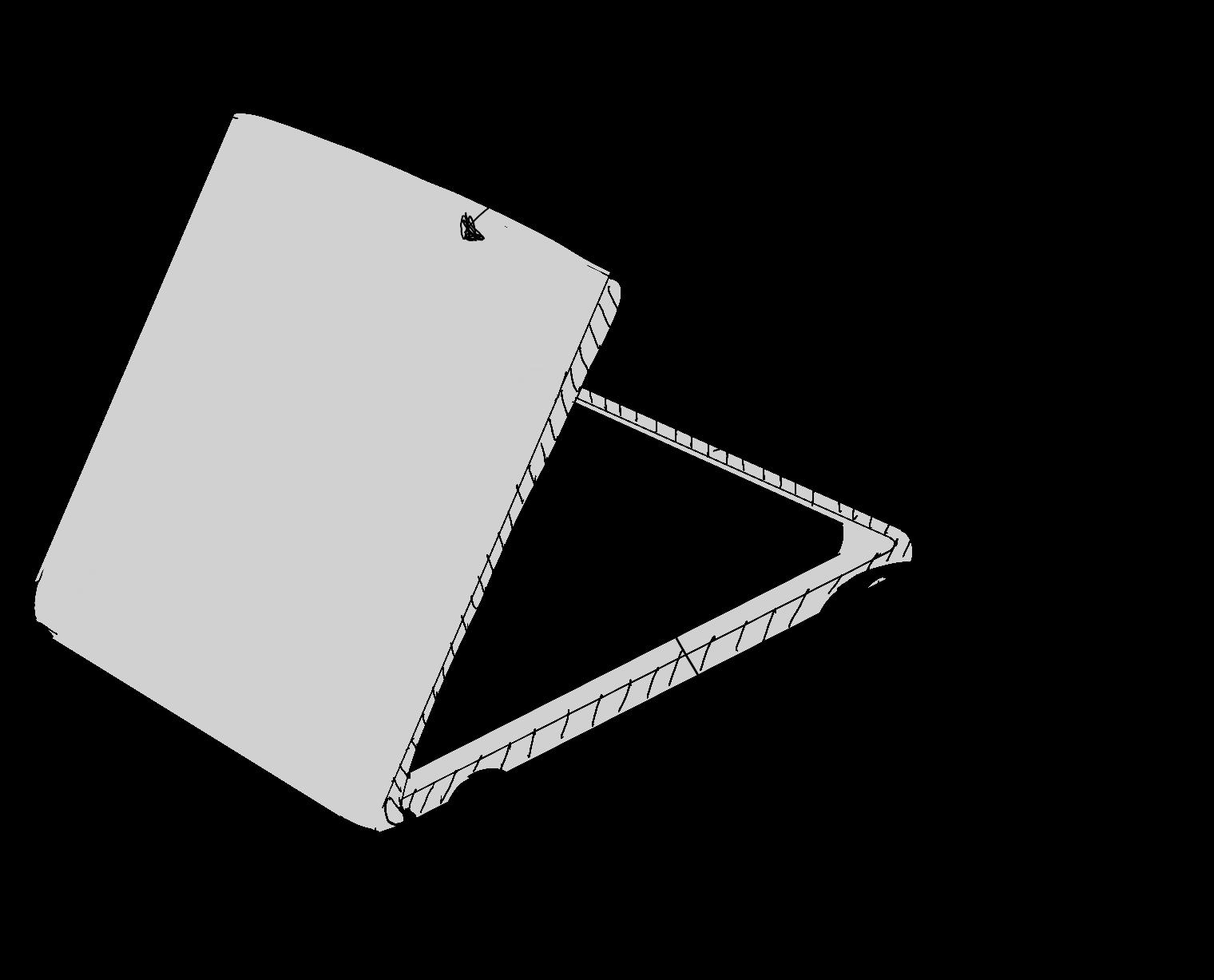

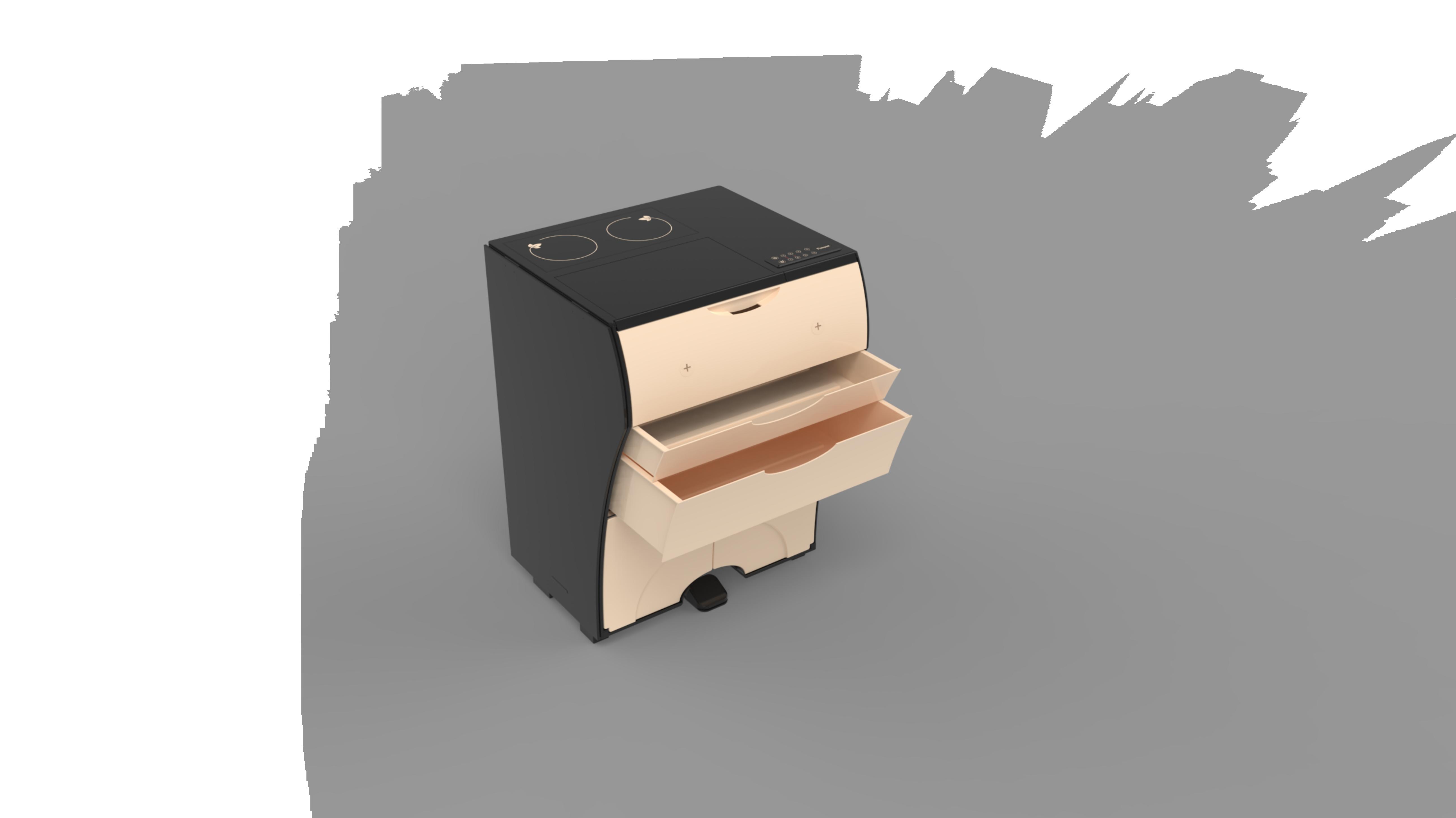

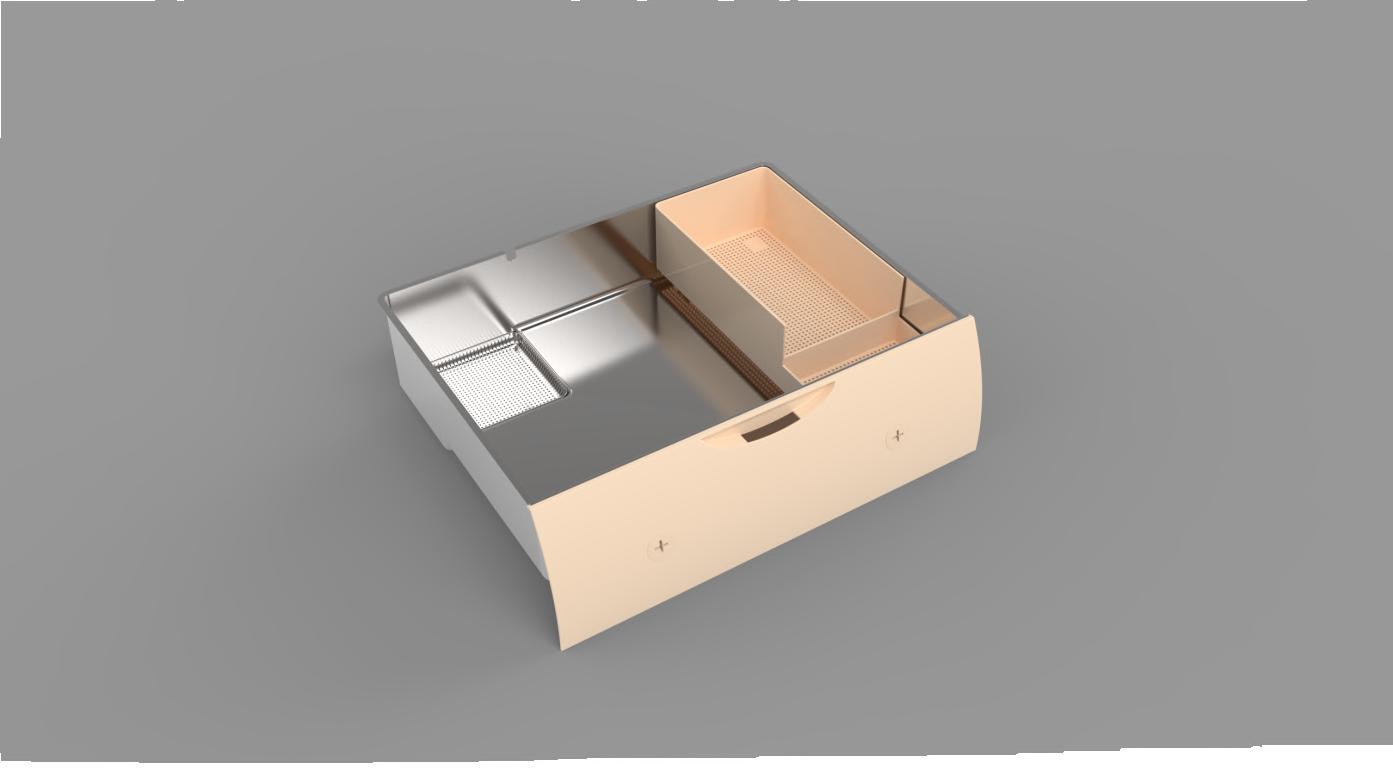

For quick rinses, the cutting surface doesn't have to be opened.

For full washes or larger items, the cutting surface has to be opened along with the sink.

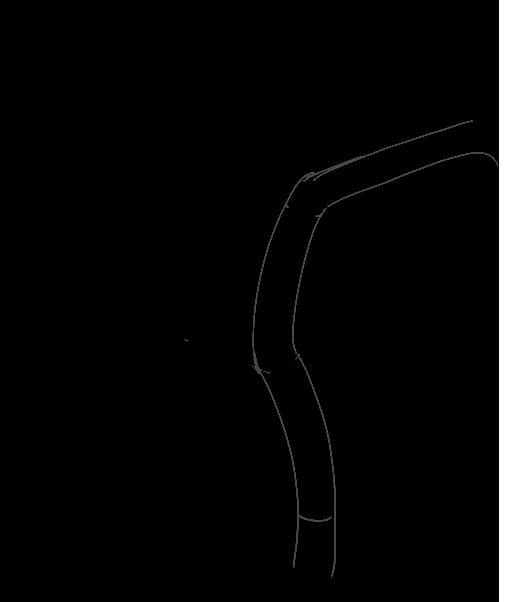

The unit features a foldable flap, customizable on the right, left, or not included based on the purchase option. It also includes a smaller sliding work surface board.

Handle to lift the drum

Slot for ngers to pull the drum out

Handle to lift the drum

Slot for ngers to pull the drum out

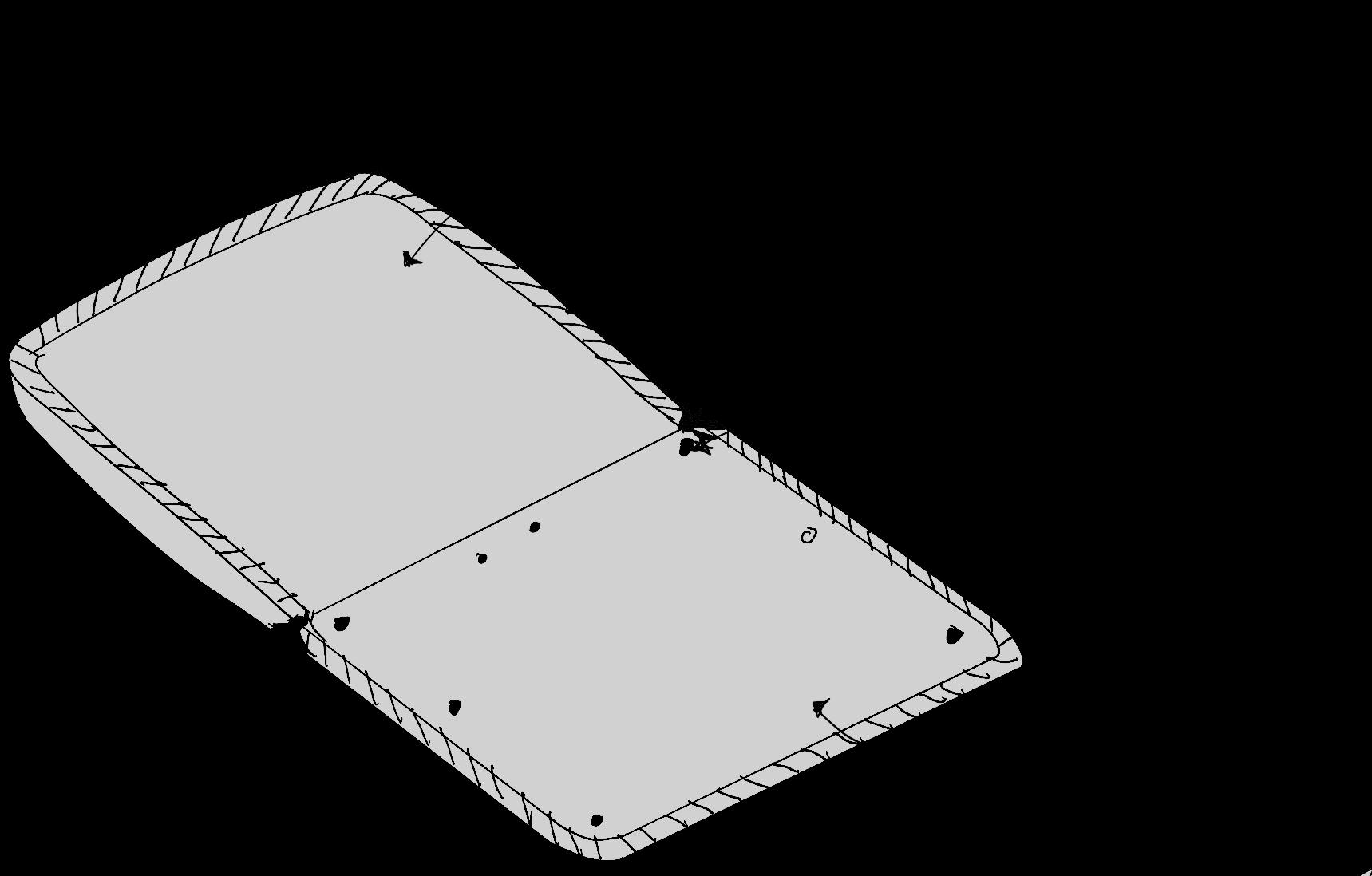

The sink has two rubber hooks for hanging rags, a plastic basket for soaps and scrubbers, and a drain basket for collecting waste during washing.

Plastic basket

Drain basket

Hooks for hanging rags

Hooks for hanging rags

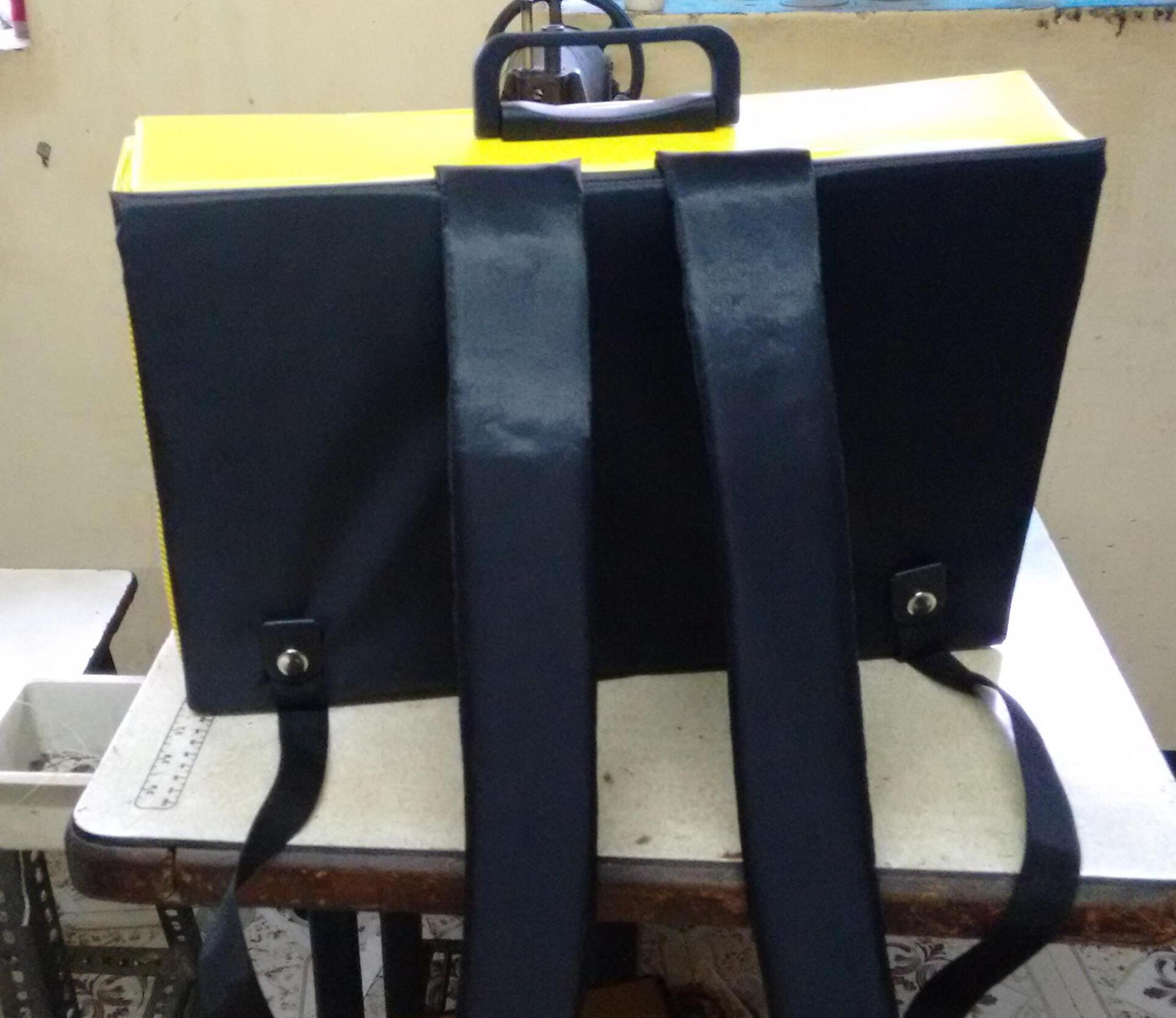

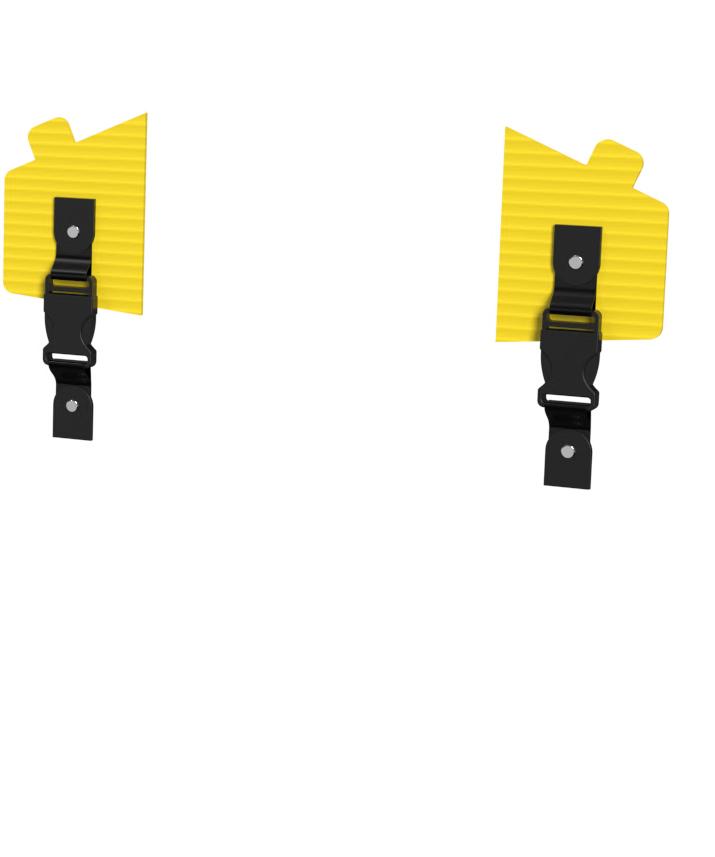

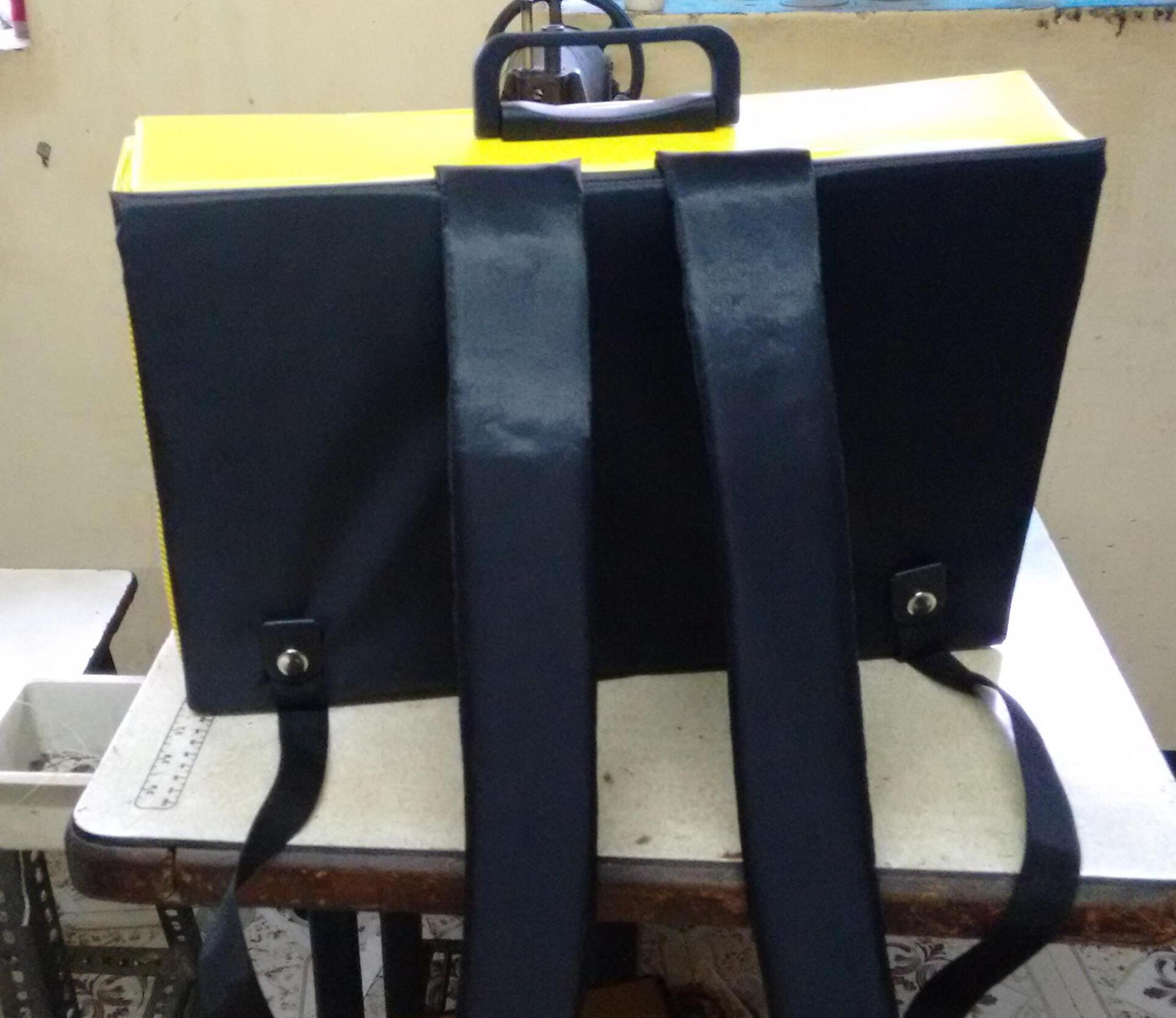

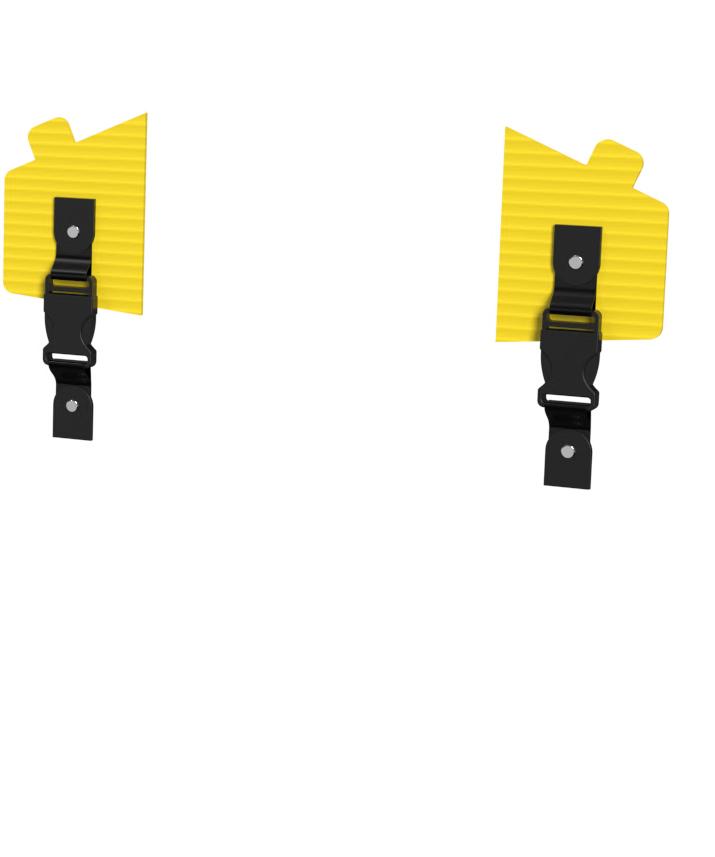

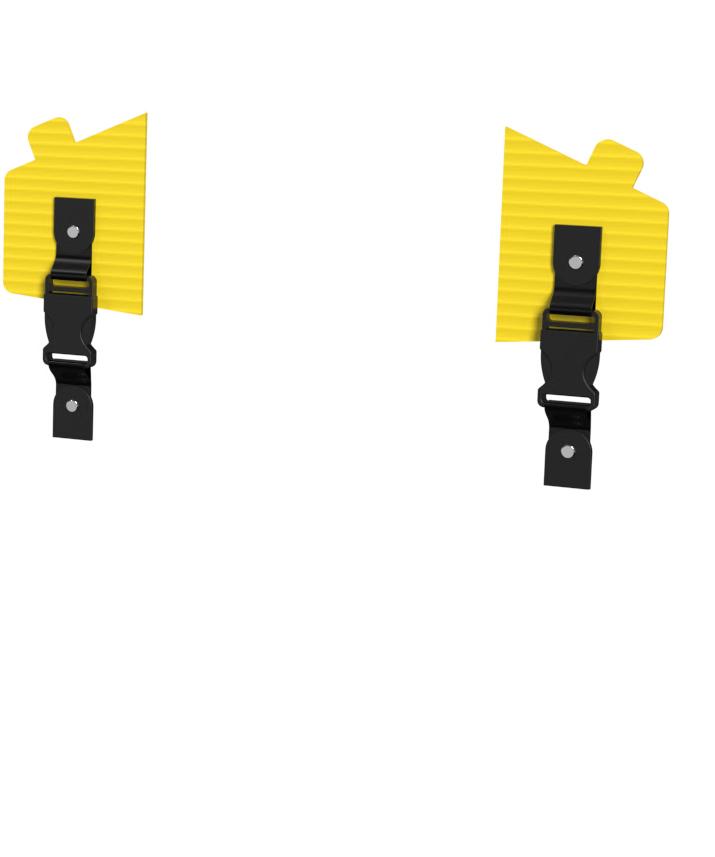

A dual-purpose sling bag made from corrugated plastic sheets serves as portable desks for rural Indian schools lacking traditional furniture.

Prayas Innovations, India. But are sling bags comfortable for long-distance walking?

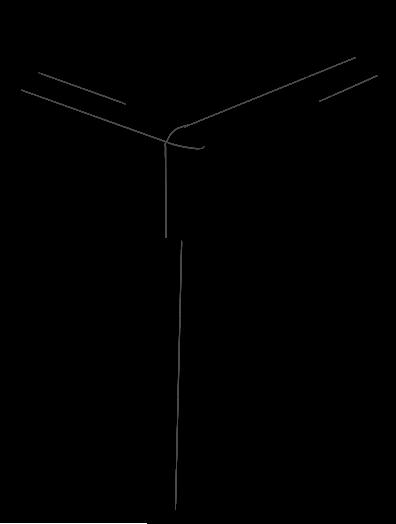

Ideation - For the soft back padding

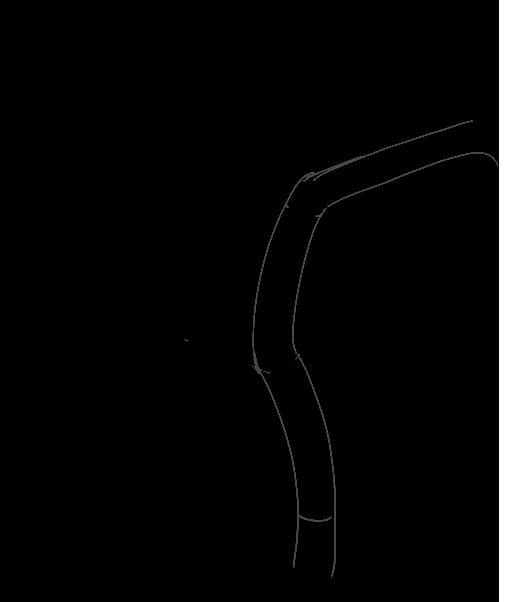

The original design featured a sling handle, which proved inconvenient to carry longer distances. The bag was upgraded to a comfortable backpack with two padded straps for added comfort. Further improvements included the addition of soft padding on the back, ensuring optimal comfort for the child.

Final Design

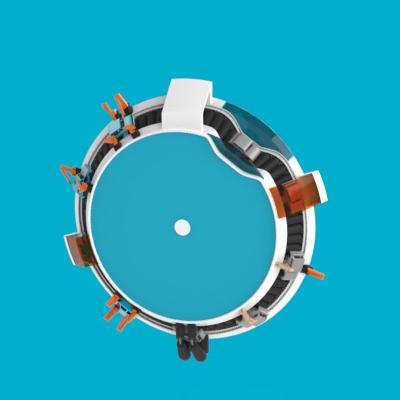

MINI Paint Shop WalkThrough

Live project (Coventry University with BMW MINI Plant, Oxford), involving collaboration with an Interior Design student.

The BMW MINI factory tour features the Body Shop, Assembly Line and Museum but excludes the crucial Paint Shop due to restricted public access.

How can we include the closed paint shop, vital for MINI production, in the existing factory tour?

Why the MINI Paint Shop Walk-through?

The existing tour takes groups of 15 people each through the...

Body shop

Paint Shop?

Assembly Line Museum

It is not mentioned on the tour.

It is closed to the public.

But it is the most important and biggest step in making a MINI.

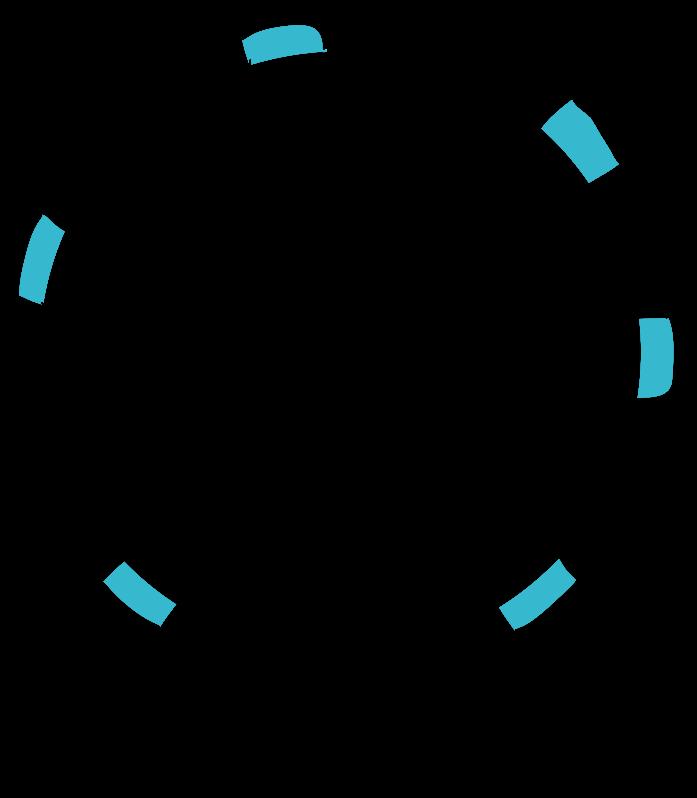

Ideation

Ideation

Group of 15 visitors

Tour guide explains the process

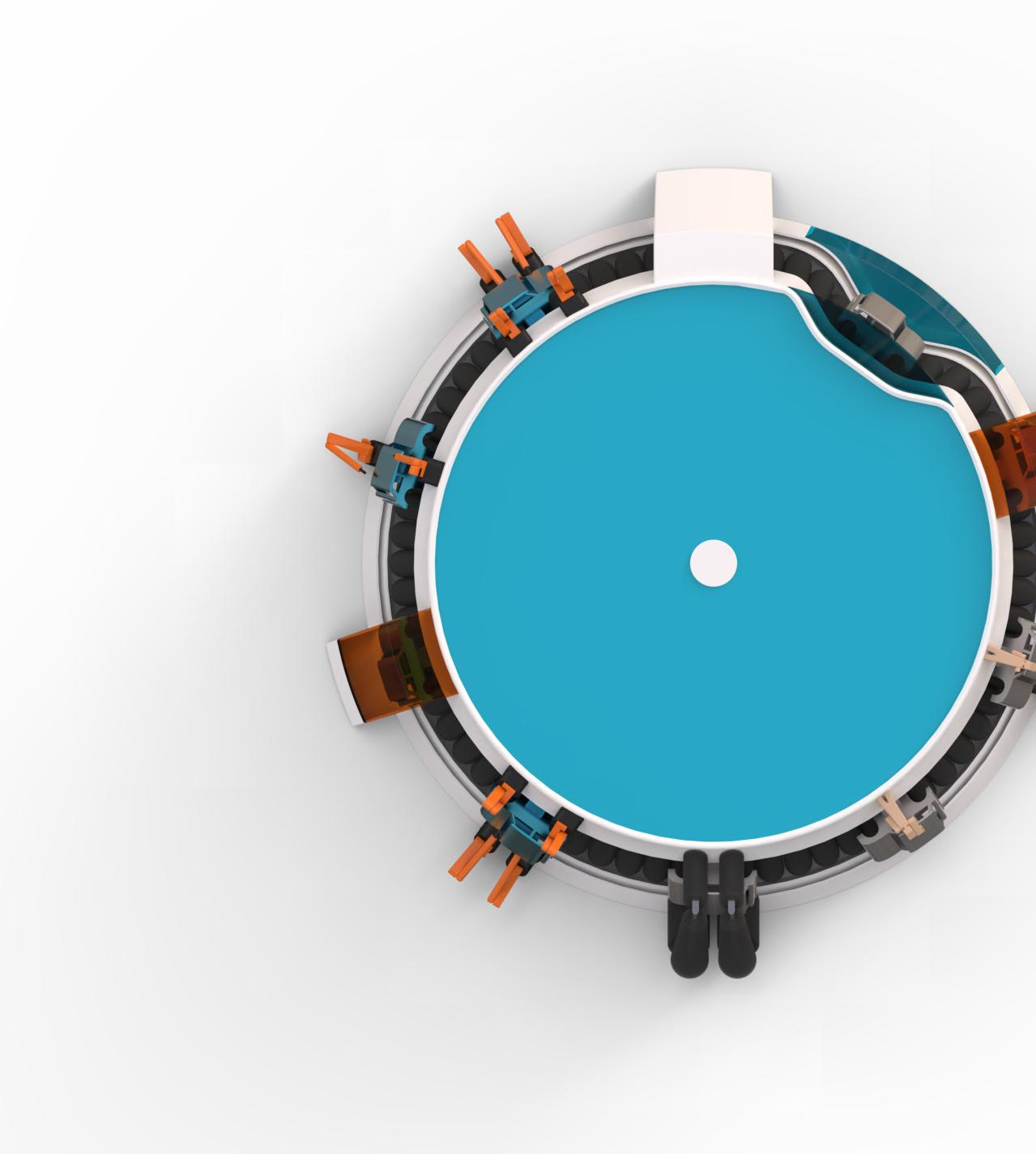

Final Design

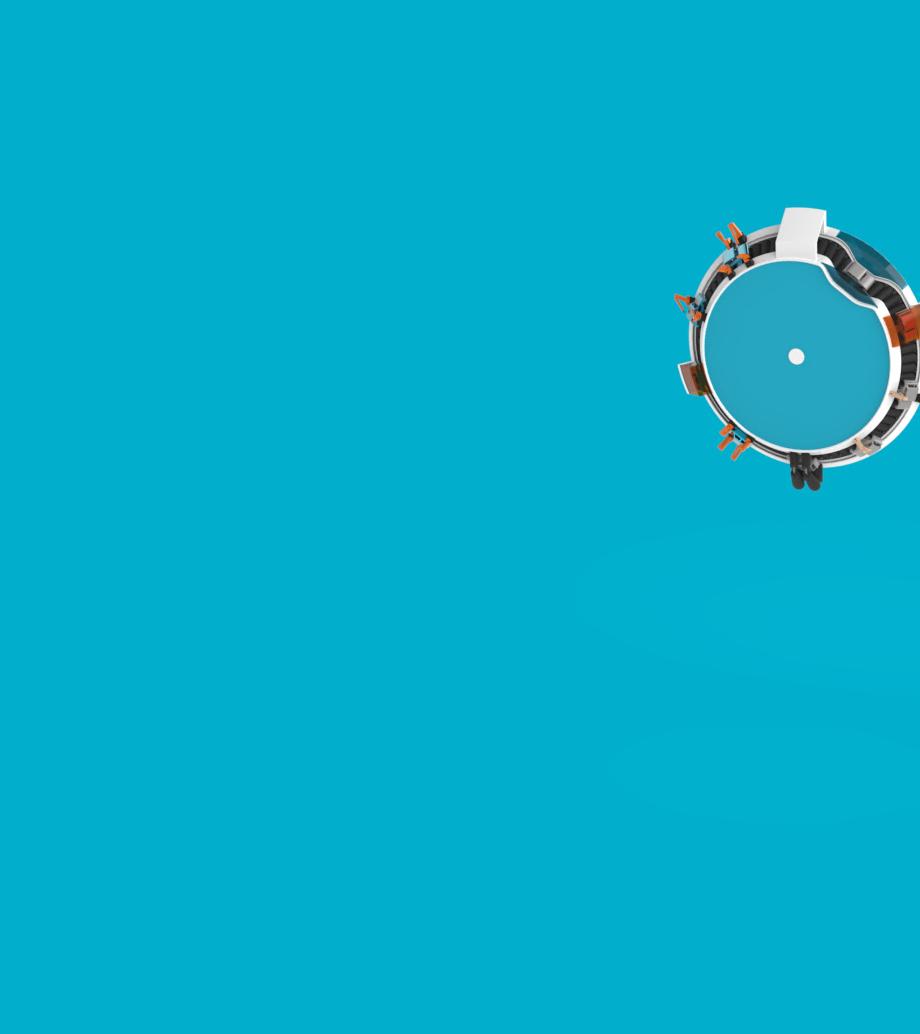

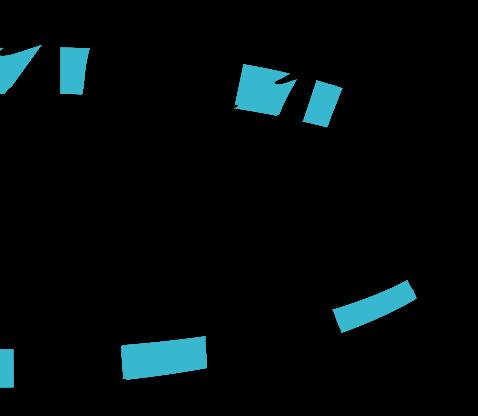

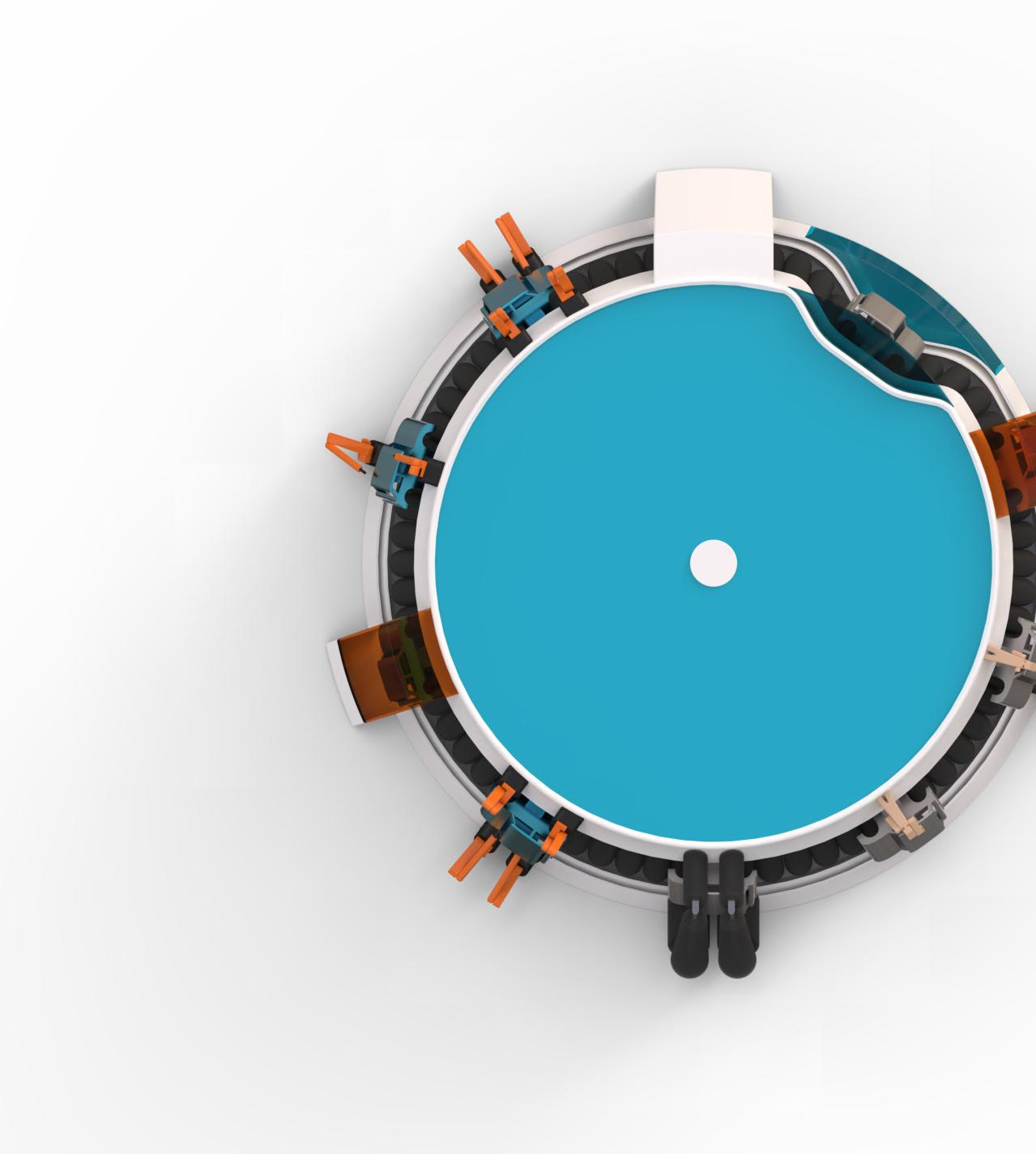

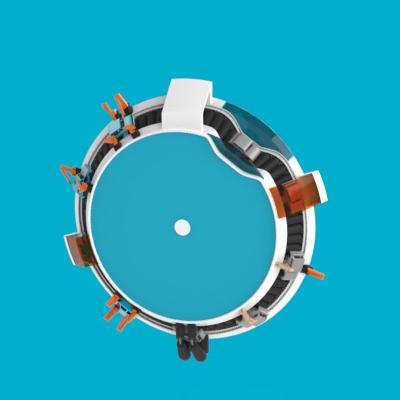

The MINI Paint Shop Walk-through gives you a brief overview of the stages of painting a MINI.

It is placed at the entrance of the Assembly line building on the wall graphics by the Interior Design student.

The display suggests starting the tour at the Body Shop as usual, followed by a pause before entering the Assembly Line building to learn about the paint process.

Entrance / exit point

Cavity waxing

Roof painting

Heat treatment

Color coat and clear coat

Feather duster machine

Series of chemical bath and E-coat

E-coat oven

Seam sealing manually and by robots and underbody coating

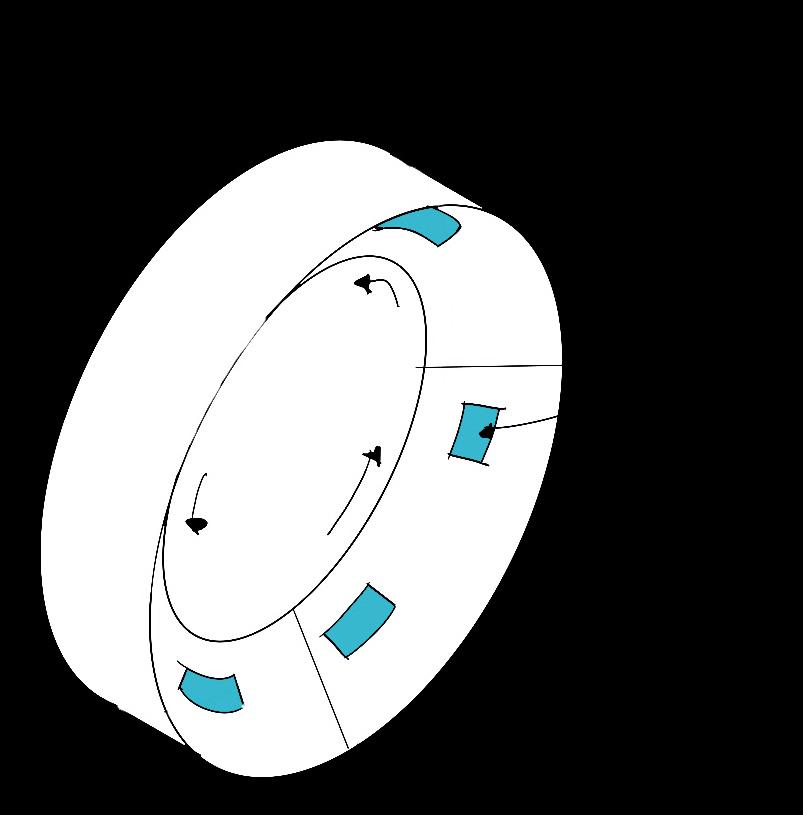

Working

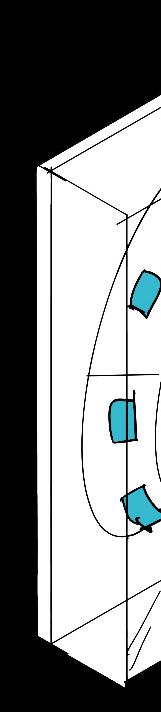

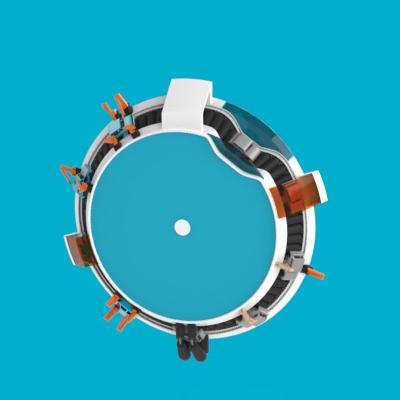

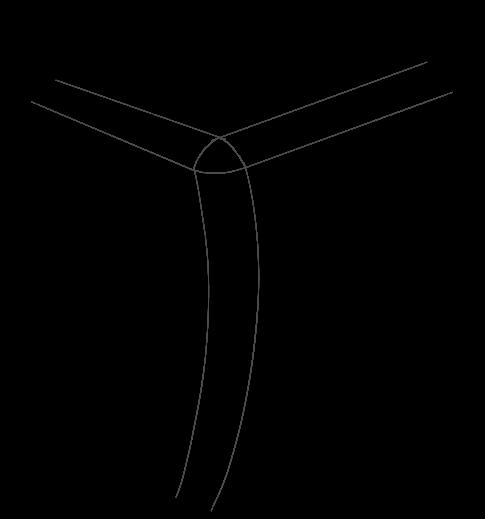

The carousel-like display features cars moving continuously on a roller conveyor belt, marking entry and exit points for the bodyshell at the top.

Starting with grey, the bodyshell progresses through pretreatment stages to the colour coat stage, where for visual purposes it changes colour using thermochromic paint.

Imperfection check and cleaning with a sticky cloth

A heating device turns it blue, while a cooling system reverts it to grey, symbolizing new bodyshells entering the Paint Shop.

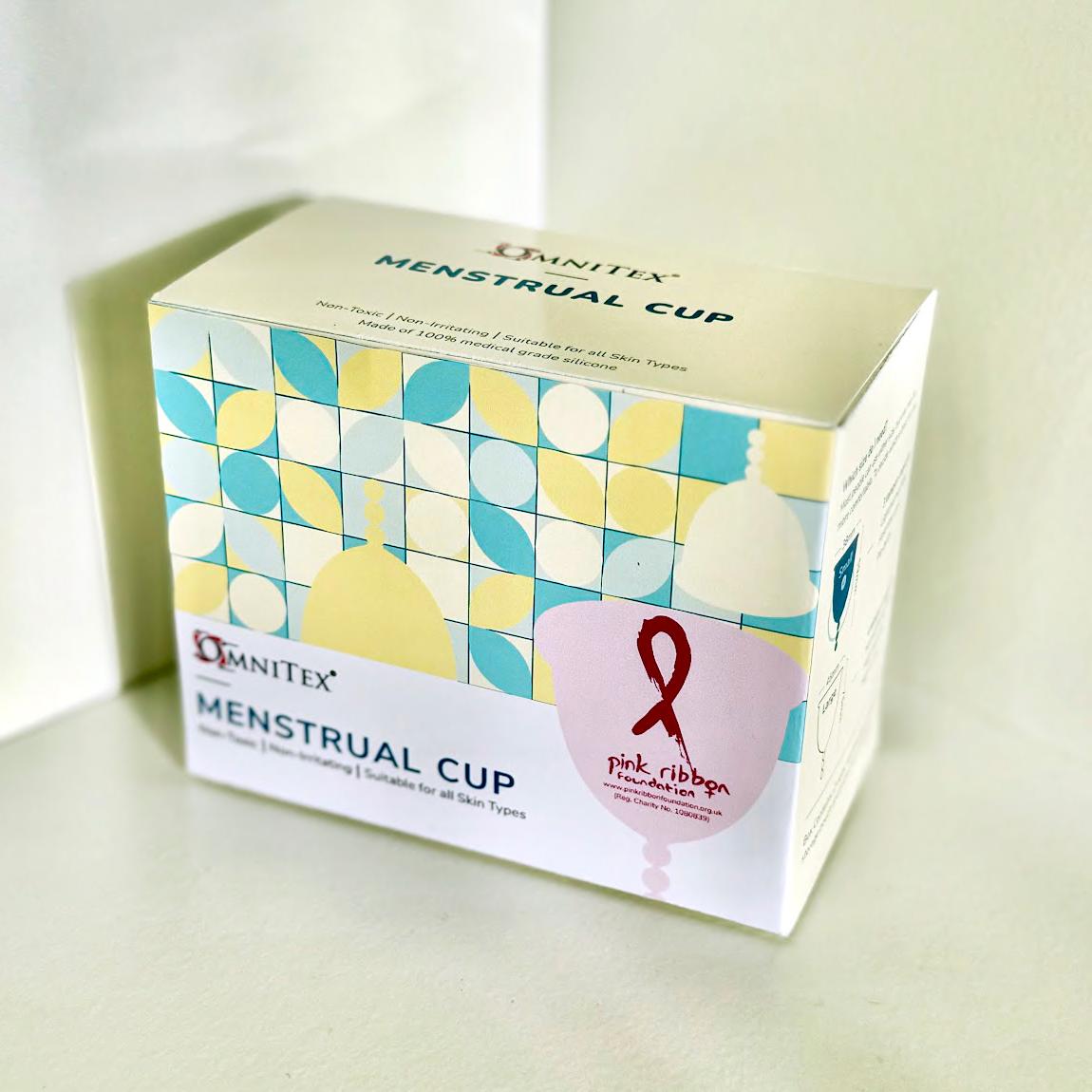

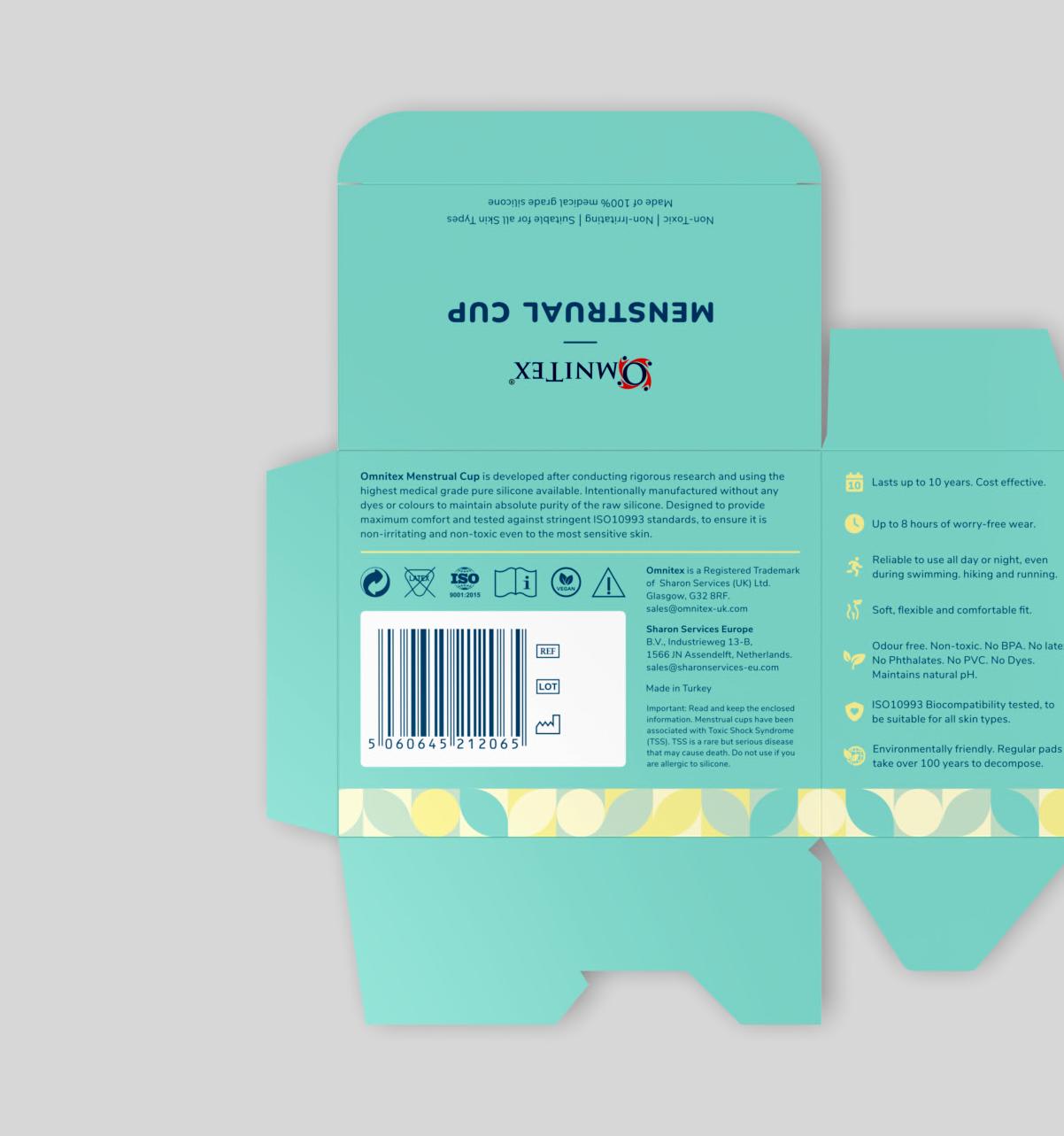

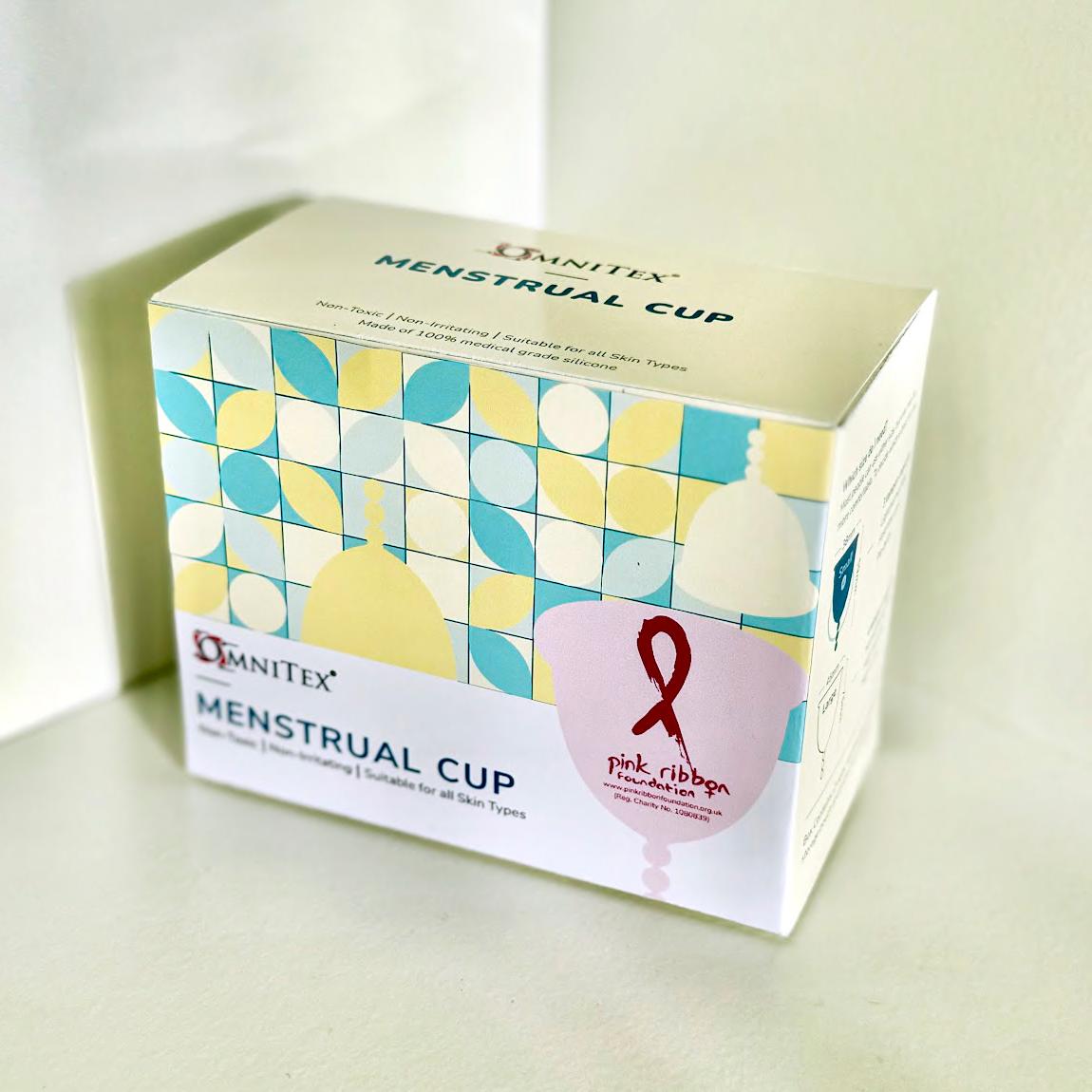

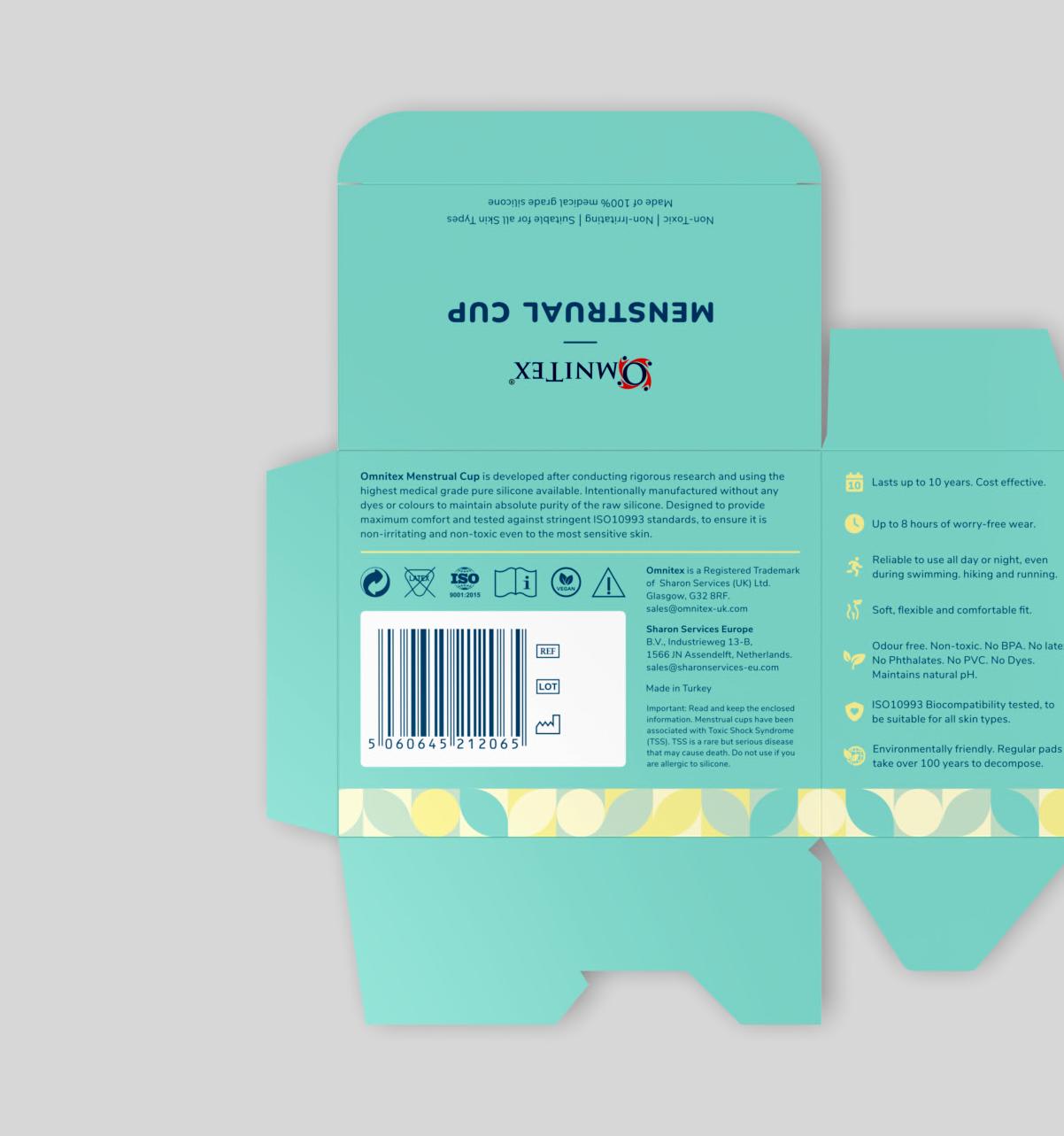

Elevating Menstrual Cup Packaging by Infusing Peace and Calm

Sharon Services UK Ltd.

Ideation

Selected design

Ideation - Further development

Final Design

Calm Peaceful Boost positive mental energy

Cheerful Energetic Sparks happiness and optimism

Health Nature

Services

Packaging Sharon

ackaging Design Services UK Ltd.

Product Renders

Sharon Services UK Ltd.

Product models and renders for the company’s catalogue and websites.

Thank You

Stef Fernandes Industrial Designer

Stef Fernandes Industrial Designer

House 1 - Cooking preparations

House 2 - Cooking preparations

House 1 - Cooking preparations

House 2 - Cooking preparations

Working mock up to test the

Food preparation space

Induction cooktop Sink

Working mock up to test the

Food preparation space

Induction cooktop Sink

ap for more workspace

Foot switch

Drain water drum

ap for more workspace

Foot switch

Drain water drum

Fresh water pipe

Fresh water pipe

Hooks for hanging rags

Hooks for hanging rags