KO-YANG HSU

pixel loop In the mind

As a designer with interdisciplinary experience in the op�cal industry

pixel loop In the mind

As a designer with interdisciplinary experience in the op�cal industry

As a designer with interdisciplinary experience in the op�cal industry

I am a technology integra�on AOI op�cal engineer where serves in GSEO for a year. How to lead VR lens, flash and small lens to MP state are my core work criteria in Research and Development Department. In par�cular, AOI light module design and vision system build-up. On the others hand, I am not only an AOI designer also be a quality assurance engineer. In other words, AOI is an integra�on project which includes so�ware, light technology and quality assurance theory. Therefore, NPI became most of the content that I par�cipated in. From my educa�onal background, I obtained a Master's Design degree from Goldsmiths, the University of London in 2019. The major issue in this MA is how to be an interdisciplinary designer. During this two years course, developed my own capability and experience in mul�ple cultures and industries was the main orienta�on for students to progress. The first challenge for me is study innova�on and services topics. This is a theory that gathers all of the human knowledge and prac�ce experience. The result is produced by crea�vity and shows people a new form of lifestyle. This profile will show mul�ple fields of design projects and how I par�cipate in them.

GENIUS ELECTRONIC OPTICAL CO.,LTD JUL. 2020 - Now`

玉晶光電股份有限公司 研發工程師

R&D: Research and Development NPI Optical Engineer

MA DESIGN: EXPANDED PRACTICE

Goldsmiths University of London SEP. 2018 – Dec. 2019

DIPLOMA: DIPLOMA IN DESIGN

Goldsmiths University of London JUL. 2017 – JUN. 2018

2021 -GSEO VR lens op�cal mass produc�on experience.

2021 -GSEO VR AOI machine Op�cal inspec�on development

2021 -GSEO VR AOI system Import

2020 - Product design, cooking machine design case

2019 - Graduated from Goldsmith in December

2019 - Join a summer short course at the Royal College of Art Course name: Destruc�ve market innova�on through design

2018 - Started the MA main course in September

2018 - Par�cipate two months Autodesk Alias 3D workshop

2018 - Finish the Graduate Diploma course at Goldsmiths in June.

2017 - Finish the pre-sessional language course at Goldsmiths in September

2017 - Started study at Goldsmiths University of London

2017 - Graduate from Chaoyang University of Technology

2017 - Xiamen and Taiwan, Straits Industrial Design Compe��on, Three wheels scooter design, Finalist Award

2017 - Taiwan, Young Designers' Exhibi�on, Finalist Award

2016 - Malaysian Inven�on Exhibi�on Silver Medal Award

2016 - Interned in Chih Kang Material Company Ltd. Work content: Mechanical drawing and Steel material tes�ng

2016 - Par�cipate Red Dot design concept compe��on. Three projects into Finalist Award. Be responsible for 3D modeling and rendering in the team

2016 - Par�cipate iF design concept compe��on Be responsible for 3D modeling and rendering in the team.

2015 - CNC workshop assistant Opera�ng so�ware and machine control

2014 - Industry-Academic Coopera�on Project (DC fan design) Yow-Lih-Shyang Industry Co., Ltd

2013 - Started study at Chaoyang University of Technology

Adobe Illustrator

Autodesk Inventor

Adobe Photoshop

Autodesk Alias Autostudio

PTC creo/ ProE

Ca�a V5 R21

Power Point

Word

Excel

Mechanical Auto CAD

Autodesk Fusion 360

3D prin�ng

AOI Image processing, Python

Teamwork

Communica�on

Decision Making

Time Management, Self-mo�va�on

Adaptability

Crea�vity

Detail-oriented

Flexible

Quick Learner

Cri�cal thinking

Philosophy

A meniscus transparent glass use AOI to distinguish on the surface dot, inner glass dot and bottom face dot. This project will show how I do investigations and how to solve problems. Consequently, giving different proposals.

This is an unfamiliar op�cal field for me but as a MA degree designer with an engineering background. This is a good experience for me to study and research the different possibili�es. This also echoes my MA course: expanded and prac�ce. Exploring and finding a method in a field that I am completely unfamiliar with is the core skill that the master's program gave me.

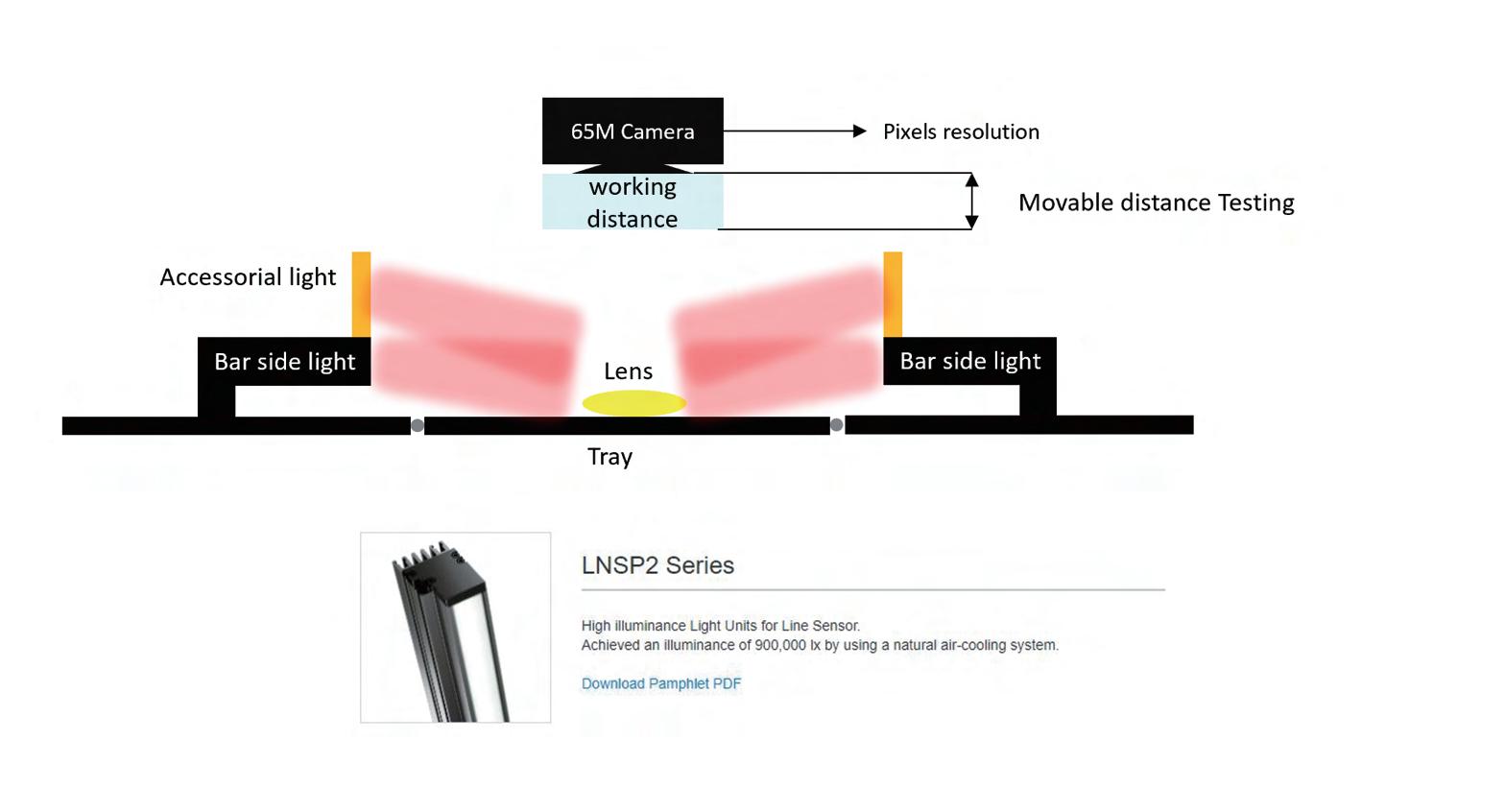

On the Hardware side, Understanding the camera principle will be the first part to assist us to find a good result. The next part is to select the reasonable pixel resolution, Fov and Dof.

For this experiment, I choose the DOF 2mm for identifying. If I choose the deeper Dof in the case, all dots at different depths will be in focus in same layer. This phenomenon makes the contrast can not ditengish in focus or defocus.

There have two aspects to think about how to achieve this goal with accurate and consistent detectability. The first idea comes from applying algorithm development to make it come true. Another idea is thought illuminance intensity and contrast to distinguish surface 1, inner and surface 2.

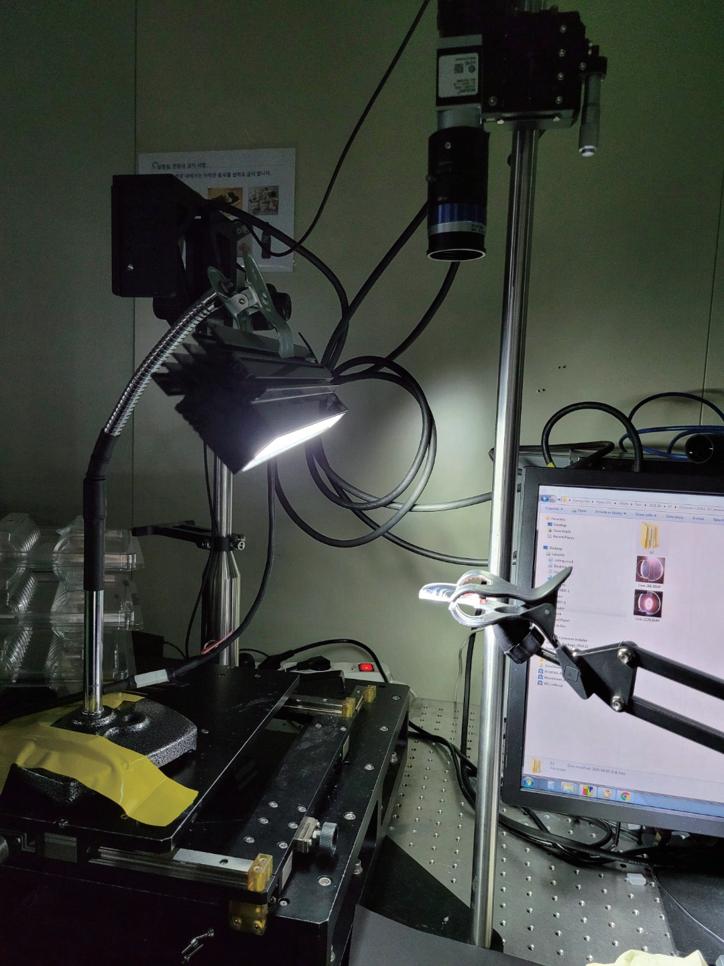

The testing process is to find a great solution for how we separate S1 and S2 defects by diverse light modes and small DOF. During these complex light testing flows, we will obtain a core recipe for making a dramatic contrast and intensity between S1 particle and S2 particle.

According to the left-hand side image, there have some checkpoints that we can do investigate. The first phenomenon is that particles in different depth of view shows differentiation between in-focus and defocus. For example, "in-focus" display a clear delineation, in contrast, "de-focus" display an annulus. This contrast can help the algorithm to identify S1 and S2 defects.

Meanwhile, the exposure time and working distance also become core factors to determine whether S1 and S2 defects can be identified. On the left down image, we can figure out that S2 defects are unobvious and unclear, however, S1 defects are distinct.

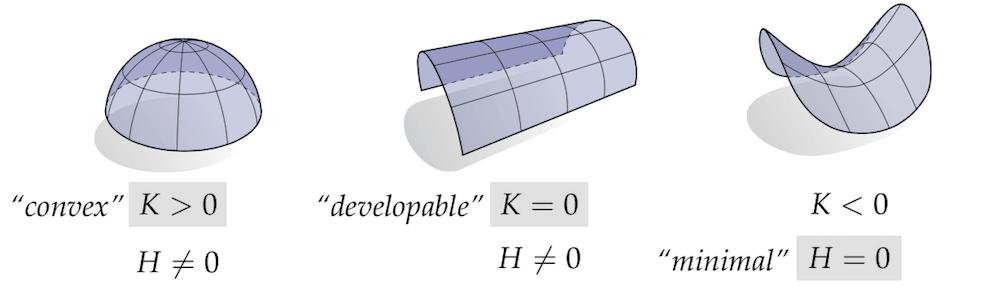

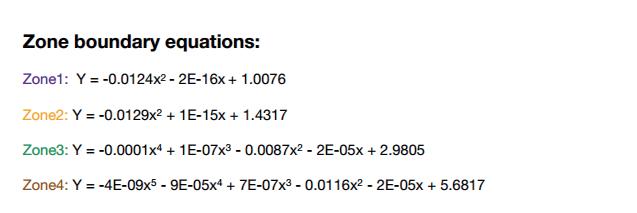

A�er the ligh�ng experiment, we obtain an idea with fundamental knowledge. The concept for how to separate S1, inner and S2 par�cle is based on Math. The crave func�on will be a core direc�on for helping us to detect different layers of defects. Fit theory, Polynomial curve and Gaussian curvature fun�on are the main factors to make an algorithm system accurately.

According to PTC Creo(3D so�ware), we are able to obtain these curvature func�ons. These data can help me to do the development of an algorithm.

Red number = Surface 1

Blue number= Surface 2

Green number=Inner

The algorithm developed is successful because the ligh�ng mode can separate different layers of defects. In the grey colour image, we can clearly see that defects can be dis�nguished into different layers by different colours. Consequently, crea�ng the best ligh�ng module is the main core issue for how we make it accurate. The next step is to generate a logical curve func�on for prac�sing whether my result matches for real lens or not.

INFLUENCE LEVEL CROSS CHART

Exposure Time

Light Working Distance

Algorithm S1 Under S1

Different Light Mode

S1 And Under S1Influence Factors

Exposure �me > Light working distance > Different light mode> Algorithm

How objective lenes can perform like human eyes?

0.3360.2860.2740.284 0 .282 .3110.350.3450.4350.5180.5220.4770.5470.4870.529 0 .4470.4730.4220.2910.285 0 .3260.3120.2750.291

0.2810.2490.2510.295

0.3010.2880.3260.306

0.3350.3420.3250.326

0.3720.3560.3140.377

0.3370.3410.3990.415

0.3840.4390.4710.462

0.470.4790.4720.486

0.4750.4880.4820.488

0.4620.4760.4890.525

0.4480.5020.5030.519 0 .516 .5390.5740.5320.5650.5480.5640.5460.5510.570.576

0.4950.4450.4840.44

0.4820.4960.4920.473

0.4360.4480.4510.493

0.4040.3810.3910.405

0.3880.4140.3950.412

0.3440.2970.2940.281

It can be seen that the photo effect of this picture is to imitate human eyeball vision. The center of the lens has a convex curvature if this lens is assembled into a module and put on the VR headset after installation. The user will see these defects on the virtual image