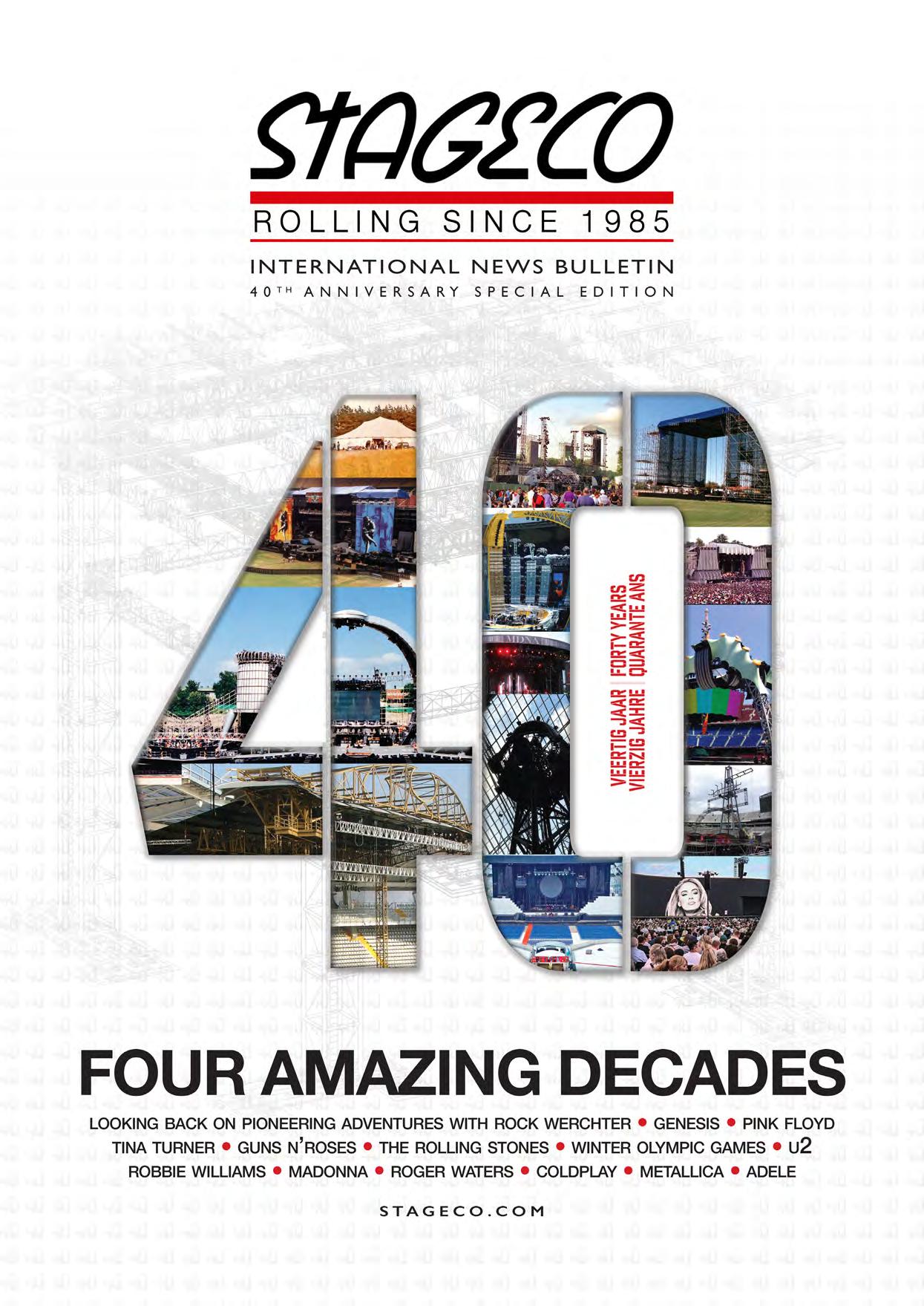

CELEBRATING 40YEARSOF INDUSTRY-DEFINING ACHIEVEMENT

* A SPECIAL EDITION *

Forty years is a long time and the knowledge, skills and lessons learned will serve Stageco well for another 40 or more!

A truly international business, Stageco now operates from offices in the US, France, Germany, The Netherlands and, of course, our headquarters in Belgium, where we now trade from an extraordinary new base.

The purchase of a 16-hectare site has resulted in Stageco’s new ‘Hedco’ in Tildonk, which has been designed with efficiency and sustainability prioritised throughout the spacious offices and warehousing. No less than 3,400 solar panels on the roof of the warehouse generate enough power to run the entire operation.

The industry shutdown that came as a result of the COVID-19 pandemic was a massive test of resilience for

everyone, but Stageco came through it in good shape because the bountiful years had provided a dependable financial buffer. The company is now working at full strength with new blood and a solid vision for the future.

Over the following pages, we look back on a selection of projects that, over the last 40 years, have contributed to the growth of Stageco and, by doing so, helped to shape modern live event production.

We offer our deepest thanks to our many clients and partners. It is due to them that Stageco is where it stands today. Naturally, we also extend our gratitude to our staff, past and present, for the roles they have played in building the Stageco name.

With best wishes from the STAGECO EXECUTIVE COMMITTEE

Wouter Van Mierloo

Peter Schillebeeckx

Dennis De Graaf

Lauenstein

Micah Catterson

Katleen De Meyer

Hedwig De Meyer

Where it all began

In 2025, Stageco is proud to celebrate 40 adventure-packed years as the live event industry’s premier staging solutions provider. Although 1985 was the official year of its incorporation, this well-established Belgian company has a fascinating prequel.

A graduate of NARAFI College in Brussels, with a degree in electronic engineering and a firm grounding in civil and structural engineering, Hedwig De Meyer’s love of music encouraged him to work as a rock DJ with his self-styled Flash Experience disco bar. Bookings came in from far and wide, and in 1973, Hedwig’s plan to organise a summer party for 2,000 people, demonstrated his successful ambitiousness.

Hedwig’s future began to unfold two years later when Guy Mortier from TV and radio magazine Humo encouraged him to organise a concert in Werchter, the day after Hedwig’s third annual summer party.

Driven by the need for additional income as a newly-married man (to Ria), Hedwig took up this opportunity, and on July 13, 1975, the first Werchter Rock & Blues Festival took place indoors with a bill of well-known local acts.

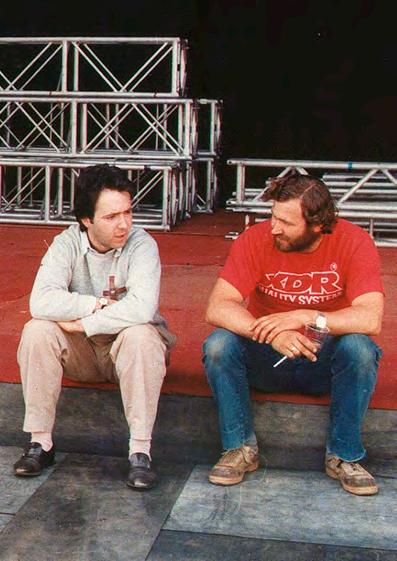

Twelve months later, the audience figures tripled and when Hedwig ran into local promoter and Muziek Express journalist Herman Schueremans that summer, he soon realised that his life was about to radically change. As Hedwig once said: “Herman ran small events and it was obvious that our individual skills would complement each other very well, so we joined forces. While I organised the logistics of the festival, Herman handled artist bookings, contracts and general promotion.”

The rapid growth of Rock Werchter (as it later became known) forced its move to a new open-air site where major acts played to a sold-

out crowd. Notably it was effectively the birthplace of Stageco, as Hedwig explained: “The festival soon grew out of its original marquee tent and with a larger one proving impossible to find, we moved completely outdoors to a new site.

“We couldn’t find the staging infrastructure and the only one that existed was in England and it was built from scaffolding, so we were forced to build our own stage with a pole at the front to support the roof, and a covered platform on both sides to accommodate the PA. I was more interested in the technical aspects of concerts and festivals, so I took care of that.

“What we came up with was very primitive, but we learned a great deal over the next few years and we rapidly improved the standards. Promoters visiting Rock Werchter noted our unique approach and began asking if similar solutions might be available for their own events. This was the start of what became Stageco.”

21st CENTURY WERCHTER

Stageco has been proud to remain the exclusive staging supplier for Rock Werchter since its early days. Extending to four days and attracting around 350,000 each year, the festival has multiple awards as one of Europe’s longest-running and most successful festivals, and also become a showcase for Stageco’s most up to date and ingenious technical solutions, including its impressive Superroof, XXL-Roof system, originally developed for Madonna’s MDNA world tour – see page 16.

The company is also responsible for other key elements of the festival infrastructure, including loading docks, video screen supports and portals, mix towers, PA and spot towers, front of house risers and many other structures.

L-R: Herman Schuermaons and Hedwig De Meyer discuss their work on Rock Werchter in 1981.

Row 1: The original 1975 Werchter Rock & Blues Festival tent; the 1979 Werchter stage. Row 2: The build underway in 1980... and ‘81. Row 3: The 1981 festival in action; growing up in 1995. Above: Into the 21st century.

GENESIS: INVISIBLE TOUCH (1986-87), WE CAN’T DANCE (1992) & TURN IT ON AGAIN (2007)

One of rock music’s most visually spectacular bands, Genesis is among Stageco’s oldest clients. In the mid-’80s, the company branched out into international touring when the band used one of its stages for the Mama tour. In those days they just used scaffolding with a standard festival roof.

For the next Genesis tour, Invisible Touch, Hedwig decided to leave the traditional scaffolding stage approach behind, and developed a tower system, based on crane technology – the use of such towers requires less labour, results in more rigging capacity and offers a safer work environment.

Genesis’ We Can’t Dance tour of 1992 took Stageco to the United States for the first time. This marked the first tour where the company worked in close co-operation with an architect, and where the outdoor stage design became part of the production design.

Returning in 2007 with the Turn It On Again world tour, Genesis worked with designers Mark Fisher and Jeremy Lloyd, and opted for a sculpturally ornate structure built from truss. Stageco was the clear choice when it came to manufacturing this construction. The firm created a bespoke stage designed entirely around the lighting and video production.

Around 60% of this stage was custom built, as Stageco needed to translate the Mark Fisher Studio drawings into a portable structure.

Clockwise from top left: The Invisible Touch stage; We Can’t Dance ; the sprawling industrial look of Turn It On Again

PINK FLOYD: A MOMENTARY LAPSE OF REASON (1987-89) & THE DIVISION BELL (1994)

Based on his positive experience of working with Stageco on Invisible Touch, production manager Morris Lyda commissioned Stageco for Pink Floyd’s A Momentary Lapse Of Reason tour in 1987, which saw the band perform 199 shows to a worldwide audience of 5.5 million, with what was then the largest production ever taken on the road.

Morris requested that the company take on the staging for entire world tour, leading to Australia, New Zealand and Europe. Such a high profile project, it instantly put the company on the map as an alternative for the traditional (weaker and more labour intensive) scaffolding stages.

To follow the hugely successful opening leg in North America, Morris Lyda hired Stageco to ship a staging system and a young eight-man crew to Australasia where the Floyd played 23 dates in January and February 1988. While it included many classic Floyd elements, the production was governed by the need to load in and out quickly enough to achieve one-nighters in stadiums without the luxury of set-up days.

To fulfil set designer Paul Staples’ vision of a ‘black box’ that would contain Marc Brickman’s magical lighting and effects, Stageco built its biggest ever stage – one that was based on the tower developed by the company for Genesis, but with a 26m wide front. The side wings used Layher scaffolding to form a gigantic, 20m high structure that was 10m wide and 16m deep at the base. Stageco also constructed the scaffolding structure behind the FOH tower, from which the Floyd’s scale model aeroplane flew on to the stage.

The excellent weather protection afforded by Stageco’s systems came into their own when Morris Lyda commissioned the company to take care of the three leapfrogging stages for the following two European legs. By introducing aluminium tent technology into outdoor staging roofs and sheeting, Stageco was able to minimise the damaging effects of heavy rain at some of the shows.

To this day, it surprises Hedwig De Meyer that such a tour existed without cell phones, Skype and the Internet. “All we had was fax and landline telephones,” he smiles. “Can you imagine that today?”

When Pink Floyd followed this up with The Division Bell (a.k.a. Pulse) tour in 1994 – one of the genuine benchmark touring productions of the ’90s – Stageco was back to build three colossal, leapfrogging stage sets, measuring 60m wide x 22m deep x 23.5m high, incorporating 700 tons of steel. Based on the dome of the famous Hollywood Bowl, each stage took three days to build, 18 hours to set up, seven hours to break down, and two days to fully dismantle and exit.

Top: Pink Floyd’s A Momentary Lapse Of Reason touring stage, designed by Paul Staples. Above: The Hollywood Bowl provided the inspiration for Mark Fisher’s The Division Bell show design.

TINA TURNER: FOREIGN AFFAIR – THE FAREWELL TOUR (1990)

Fresh from scoring mega-hits with ‘The Best’, ‘Steamy Windows’ and other hot tracks from her latest album, Foreign Affair, the undisputed Queen Of Rock’n’Roll, Tina Turner made the surprise decision in 1990 to retire from the concert world and concentrate on her acting career. She then decided to make the decision to bow out in style with the European exclusive Foreign Affair: The Farewell Tour

An unparalleled success at the time, the tour attracted 3,000,000 spectators and set a new record for Europe. Although they were no strangers to each other, this marked the first time that Hedwig De Meyer and set design legend Mark Fisher worked together as a strong, bonded unit.

This was a turning point for live music. From this tour onwards, a stage was more than just a piece of iron. It became an integral part of the show, marking the beginning of the incorporation of decorative elements into the structure of the stage. Consider, for example, the large shells on this tour’s stage roof.

Ever the innovator, Mark Fisher was someone who could motivate and challenge Stageco to try new ideas every time. Many more wonderful collaborations and extravagant stages would follow, wowing audiences every time.

Tina Turner soon made a momentous live comeback in 1993 with her What’s Love? tour, the first of four hugely successful tours that helped to re-establish Tina’s legendary status as a legendary live performer before her sad passing in May 2023.

Tina Turner’s Foreign Affair production at Woburn Abbey in July 1990.

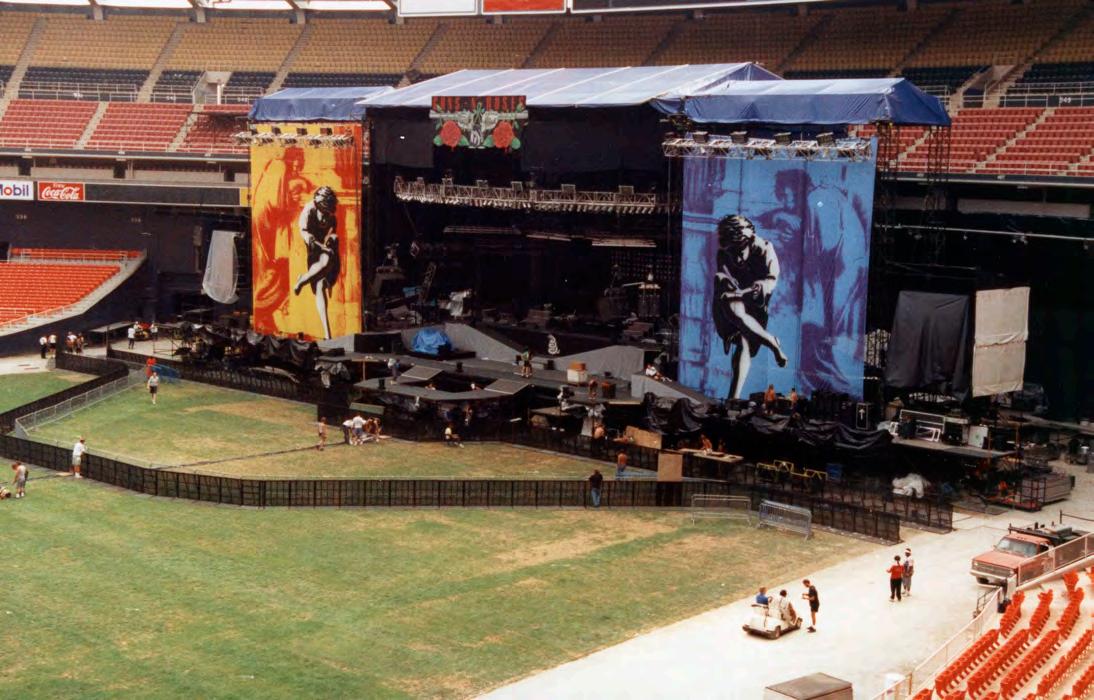

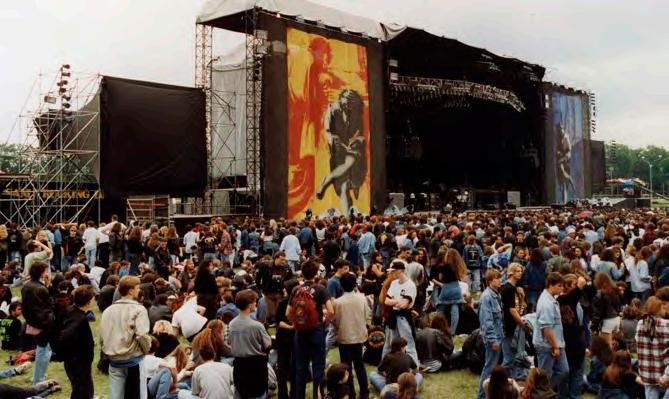

GUNS N’ ROSES:

USE YOUR ILLUSION (1991-93)

By the early ’90s, American rockers Guns N’Roses had become globally notorious as the new bad boys of the music biz. Anthems like ‘Sweet Child O’ Mine’ and ‘Paradise City’ paved the way for what would not only be the band’s longest tour, but also one of the longest in rock history, spanning 194 shows in 27 countries between January 1991 and July 1993.

It was during this tour that Hedwig De Meyer met Mary Lou Figley and Steve Thomas, and fate lent a helping hand. Although the original plan was to ship the tour equipment back to Belgium, Hedwig asked these two Americans if they knew of a location that could accommodate the equipment during the winter, because if Stageco was hired to work again in America during the summer, it would be readily available.

With the much-fabled antics of frontman Axl Rose regularly making headlines, it was no surprise that this tour, Use Your Illusion, organised in support of their new, multi-platinum twopart album would further contribute to the GN’R legend.

This time, it was with the support of Stageco which, for the first time in America, was responsible for a complete stage set-up, providing the roof, black steel, flooring and much more.

Just over a year and a half into an already highly eventful schedule, the tour morphed into a monster, as GN’R were joined by Metallica. In July 1992, these leading hard rock and metal bands kicked off a co-headlining leg in Washington D.C. Musically, it was a perfect storm.

As it turned out, work did come in and this was the catalyst behind Mary Lou helping Hedwig establish Stageco US in 1992 – all as a result of this tour.

Guns N’ Roses in 1991: loaded in, built and ready to rock.

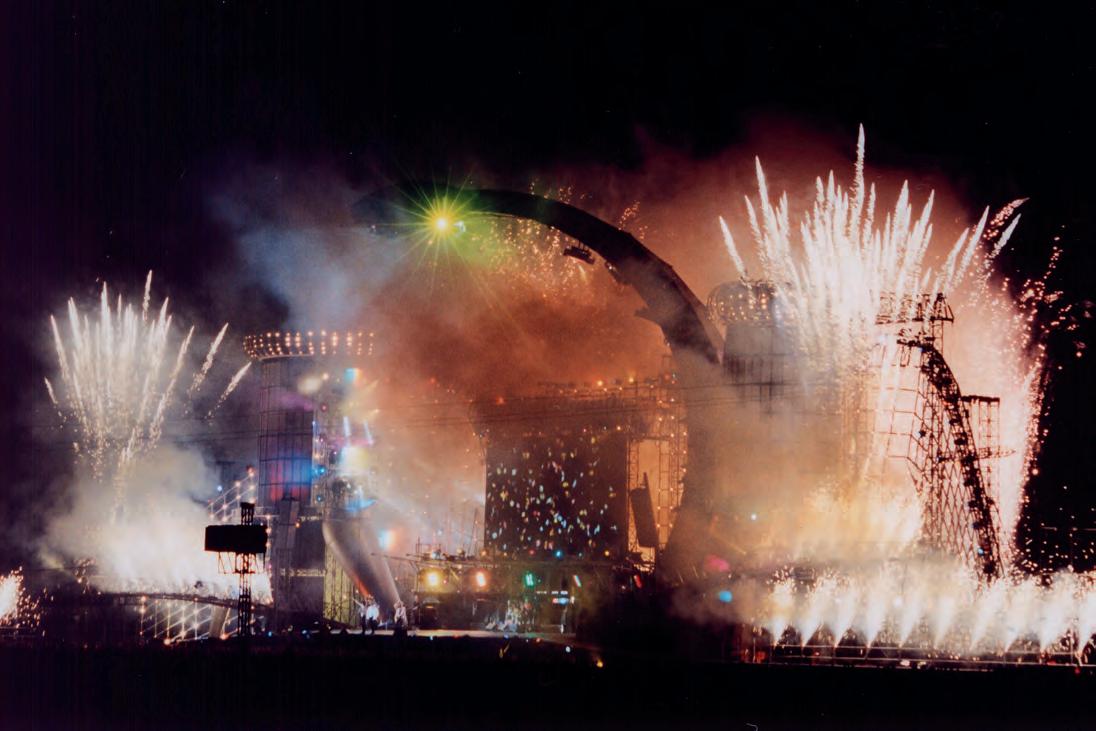

THE ROLLING STONES: VOODOO LOUNGE (1994-95)

Over many years, Stageco has been proud to have a close association with the world’s greatest and most enduring rock’n’roll band, The Rolling Stones, whose Voodoo Lounge tour has gone down in history as truly iconic.

Prompted by the rise of the Internet, the tour had the working title of Gigabyte City, as the design presented the audience with a vision of an alternative future.

Designed by Mark Fisher, in partnership with Charlie Watts, Mick Jagger and Patrick Woodroffe, the Voodoo Lounge tour scenic design marked the Stones’ foray into the world of seriously over-the-top staging.

A massive, neon-lit jungle gym in which Mr Jagger and co. could strut their stuff, it was an enormous, spiralling, multi-level structure with ramps, towers and giant, inflatable effigies of a sneering Elvis Presley, a six-armed Hindu goddess, the Virgin Mary and much, much more... and Stageco was there all the way, ensuring that the staging was as robust as the band’s enviable legacy.

THE TURIN WINTER OLYMPIC GAMES (2006)

torino ’ 06

Stageco is no stranger to the greatest sporting event in the world, the Olympic Games. After working on the Medal Plaza in Salt Lake City in 2002, Stageco was welcomed back to contribute to the ‘Tree of Life’ construction at the opening of the 2004 Special Olympics in Athens. The Turin 2006 Olympic Winter Games, however, was an opportunity for the company to really shine.

“Turin showed that we had grown up,” recalled Hedwig De Meyer. “We made our expertise available to other clients in other areas, and were able to handle projects for institutional clients such as UEFA, FIFA and the IOC.”

Through an open tender, Mark Fisher was selected to design a grand, classical-inspired stage in the bleacher at Stadio Olimpico Grande Torino, and enlisted Stageco to handle the structural implementation. Above the five enormous Olympic rings, the top of the stage immediately caught the eye with its gleaming custom-made

fronton, packed with clever technical gadgetry. The towers supporting the roof and the fronton were 1m towers, sprayed gold. The roof cover was composed of aluminium panels to offer increased support for the weight of the snow.

Unlike most projects that have tight deadlines, Stageco had the luxury of long lead times, though the job did have problems to overcome. While a crew had already begun work in the mountains on video structures the previous October, the stadium construction took two weeks. Although loading in was not a challenge, the long wait for critical information proved frustrating.

Said Hedwig: “As the construction had to be anchored to the bleachers, our engineers needed to know the construction characteristics. It took weeks to get these details.”

As a consquence of its Olympic exposure, Turin has become one of Italy’s primary tourist destinations and has been established as an important European sport centre. Turin 2006 will always be remembered for its official motto, “Passion lives here” – a statement that is completely understood in every corner of Stageco’s business at home and abroad.

ROBBIE WILLIAMS: CLOSE ENCOUNTERS WORLD TOUR (2006)

Following a number of previous tours with the best-selling artist, Stageco was commissioned to design, fabricate and operate the structural elements for Robbie Williams’ Close Encounters world tour of 2006.

Another impressive production managed by Wob Roberts, it saw Stageco project manager Dirk De Decker working in partnership with the company’s engineering team, architect Mark Fisher and his team at Stufish, and technical co-ordinator Jeremy Lloyd.

Planning began in early 2005 and the first sketches were made in the December, with the delivery date set for two identical (leapfrogging) structures in early May 2006. Very early in the design process, a calculation model was created to assess the influence of the overhang, use loads and wind loads on the overall stability and to determine which profiles would have to be used. Specific constraints to the structure were that it should be possible to build it within 24 working

hours and to dismantle it and load it on 14 trucks in 12 hours. This very tight schedule was needed to assure a smooth flow of each and every concert.

Structural calculations, together with the first CAD drawings, allowed Dirk De Decker’s project team to present a budget. Said Dirk: “Numerous extras and modifications had to be taken into account, which is quite normal. For example, an outrigger for the main PA cluster had to be integrated within the Scorpio [the huge, curving pair of towers], but it speaks for itself that it had to fit into the overall look of the main structure. We also had to find a way to get Robbie up on the Scorpio, so a single-person elevator, a complementary staircase and catwalk were designed and integrated.”

The Scorpio structure was designed to carry a rigging load of nine tons and withstand a wind speed of 72 km/h in use and 130 km/h out of use. The complete package of calculations and drawings was sent to the German TÜV for final approval, and at the beginning of May 2006, a complete test build hosted at a Stageco site preceded a tour that would play around 50 shows for a total audience of more than 2,000,000.

U2: 360° (2009-11)

At the heart of U2’s stunning 360° show, attended by a stunning 7.3 million fans at iconic venues across the world was the giant in-the-round stage, built by Stageco, supporting 170 tons of video screens, audio and lighting.

U2 360° began at Camp Nou Stadium in Barcelona on June 30th 2009, and took the stage and our crew to locations in North America, South America, Africa, Europe, Australia and New Zealand until it finally loaded out in Canada on July 30th 2011.

This remains one of the largest stages ever toured in any field of entertainment. Nicknamed ‘The Claw’, the structure’s central grid was raised 28m high, with legs traversing the width of the famous pitches, while a central antenna reaches as high as 51m.

The stage’s four legs arched out gracefully to embrace the audience, giving unprecedented and extensive access to the superstars, while its gargantuan proportions echoed those of the legendary stadia in which it sat, carrying the band’s performance to every single person in the house.

Stageco’s steel structure weighed 220 tons, excluding both the 90 tons of steel ballast that travelled with each system and the rigging loads. Stageco produced three identical systems for the band’s world tour, each one taking a specialist Stageco team five days to erect (four days of Stageco building plus one day of production) and another two days to dismantle, before being packed on to 38 trucks for transportation to the next venue.

Each stage deployed high-pressure, state-of-the-art hydraulic systems. These were used for the first time ever to assemble and dismantle the high-tonnage structure. Stageco designed a unique system, based on Enerpac’s Synchronous Lift System, to raise the modular construction to a height of 30 metres in an efficient and effective manner.

The Claw has earned itself a second life. Originally built and tested by Stageco in Werchter, it has found a new home in the Utah desert at the Loveland Living Planet Aquarium. Renamed the EECO, the 200 tons of steel is once again rising majestically like a phoenix to form a spectacular centre piece for the Aquarium, which champions wildlife conservation and environmental awareness.

MADONNA: MDNA WORLD TOUR (2012)

Stageco developed, manufactured, supplied and constructed an innovative XXL stage system for Madonna’s 2012 MDNA world tour, whilst also providing full logistical support throughout the journey, which began in May 2012.

The touring production included a significant amount of state-of-the-art moving video and LED technology, which required large and clear visual spans within the stage in order to achieve the desired impact. No existing stage roof served show architect Mark Fisher’s requirements with regards to sight lines and weight loadings across wide spans, however, this new system offered designers a different canvas.

More than 60 tonnes were suspended in the roof for MDNA. Flown PA and video areas were incorporated within the single stage roof, which spanned 57m and was 27m deep at the widest central point. The heavy duty truss

that stretched the width of the roof formed a central spine, giving the roof additional strength over traditional systems.

The curvature of the XXL stage design also featured an ingenious flat roof, which minimises wind loading pressures applied to the stage through reducing its horizontal surface areas. Pressurised air cushion roof panels created an angled roof for water to run off into gulleys and hoses, moving water away from the stage.

The cluster tower support infrastructure was another unique element of this XXL stage, which used the company’s hydraulic lifting system to enable an efficient build and de-rig.

Stageco manufactured four MDNA tour roofing systems, each being transported in 21 trucks and joined by three specialist crews that took four days to build the system and two days to dismantle. Madonna began the tour in the challenging locations of Tel Aviv, Abu Dhabi and Istanbul, then crossed into Europe before moving on to the Americas.

ROGER WATERS: THE WALL LIVE (2010-13)

From South and North America, and through Europe, until the final show, Stageco was proud to support Roger Waters’ iconic The Wall Live tour all the way. By the time it ended at Stade de France in Paris, in September 2013, it had become the highest grossing tour ever by a solo artist, and the third highest grossing of all time.

Having supplied a specially modified Superroof system across the Stateside shows, Stageco worked with promotors and tour production to introduce the company’s larger, recently launched XXL-Roof. The challenge was to accommodate the sheer scale of this spectacular visual production in line with the artist’s and production manager Chris Kansy’s aspirations as the entourage arrived into some of the largest stadia in Europe.

The XXL offered excellent sight lines and the desired deeper performance area, courtesy of a 12m cantilever in front of the downstage towers. The projection on to the Wall itself, built across the width of the stadium, was a central element of the show, so Stageco had to provide an extended roof hang of 25m (h) to raise the PA out of the projection lines.

Crew scheduling was meticulously detailed as this was an incredibly tight touring schedule, particularly for this scale of show. Decades of experience were drawn on to achieve a schedule that saw three crews of 14 supported by nine working drivers and an additional two teams of drivers working shifts to traverse Europe. The XXL-Roof’s new hydraulic build technology not only enabled efficient build and dismantling, but also improved the safety for the crews handling the large steel.

COLDPLAY:

MUSIC OF THE SPHERES (2022-)

Four separate systems were devised by Stageco for Coldplay’s Music Of The Spheres – one of today’s few genuinely extensive, ongoing world tours, and one that has been praised for minimising CO2 emissions and prioritising sustainability across all of its tour operations, from set building and travel, to freight, power and audio.

Two of those systems have travelled around Europe while, to avoid shipping across the Atlantic, the other two have been based in the United States. Each system is contained within 15 trucks and includes the materials to build each iconic part of the scenery, such as the stunning Moonrise Arch.

Appearing behind the band, this very specific item relies on Stageco’s own distinctive scaffolding equipment. On-site, Stageco’s crew build a 50m upstage arc, two 23m high, 12-tonne ‘pylons’ at left and right to support video screens, and a pair of custom sound towers, each with a large cantilever, that were designed in collaboration with Coldplay’s head of audio.

It’s a 72-hour build with a single day loadout. All of the elements constructed by Stageco are unconnected.

Stageco project manager Dirk De Decker explained: “No individual element depends on another, therefore, if the crew encounter a problem with a pylon, they can continue working on another part. This makes things very smooth and offers flexibility.”

At the most recent count, the total audience attendance across 225 shows on Coldplay’s Music Of The Spheres world tour has been in excess of 12.3 million. With set design by Misty Buckley, the tour has pledged to plant one tree for every ticket sold, with a portion of the proceeds earmarked for a variety of global green initiatives.

Dirk applauds Coldplay’s efforts toward creating a greater awareness of climate change. He said: “Logistically, it’s been a major operation as we have planned the most eco-friendly routes for supplying our equipment in all territories.

“The production team assess which local services can be called upon to meet the design’s brief and we provide the irreplaceable custom elements.”

METALLICA: M72 (2023-26)

Heavy metal powerhouse Metallica is another of Stageco’s most valued, longtime clients, with whom the company has embarked on a large number of memorable world tours. Every time, the band has delivered an interesting challenge, however, M72 was certainly among the most challenging, with Stageco continuing its central role in the realisation of a thrilling new show design.

Aside from band members Hetfield, Ulrich, Hammett and Trujillo, the audience’s eyes are regularly drawn to the show’s iconic eight ground-supported cylindrical towers that encircle the stage and soar at 100 feet in the air, dominated by the LED video screens, PA hangs and lights that they carry. The bold, new stage design now relocates the band’s famous Snake Pit to centre stage, giving fans uninterrupted 360° views.

A workforce of 16 worked with one set of Camemberts (the upper round parts of the towers), delivered in up to eight trailers, and two sets of towers and platforms that were tipped off a maximum of 20 trailers.

“The requirement was to be as small as possible at the base [of each tower], but

it needed to take all the load. That was where we started the design and then do the engineering and manufacturing,” said Stageco’s US project manager, Tom Frederickx.

The in-the-round stage, imagined by creative director and scenic/production designer Dan Braun, provides an immersive, high-energy performance environment for both Metallica and their fans. “Dan knows what he wants and we really appreciated how they spent time and effort to do a full test build at our site in Belgium, because it gave everyone so much more confidence,” said Tom, who was partnered across the Atlantic by European project manager Tom Mariën.

“They really took care on the preparation side. There was a whole cycle of testing and checking that was so appreciated due to the specific design and all the different companies involved. The co-operation was really great.”

Described by rock magazine Metal Hammer as “the world’s biggest heavy metal party,” the first North American leg successfully came to a close in November 2023, Dan reviewed the design’s effect on the ticket buyers. “Even though it is in a stadium, it feels more intimate; the fans have been brought into the circle.

“Everybody who comes to the show has their own experience, wherever they are seated or standing. Maybe you experienced something that the guy 10 seats over didn’t. When they look through the band, they’re looking through at the rest of the Metallica family, because it’s one show. That’s very much something I tried to put into the design.”

When a tour is in full flow, Dan considers his suppliers as partners rather than vendors. He went on to tell PLSN magazine: “Stageco… have helped us make the dreams come true. Their support is unbelievable and ongoing. We’re together still trying everyday to make load-ins go better and, they don’t stop when the tour starts. That goes for all our partners in lighting, video, audio, etc – they are all working with us and doing great work.”

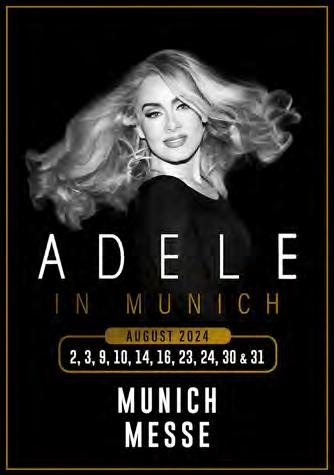

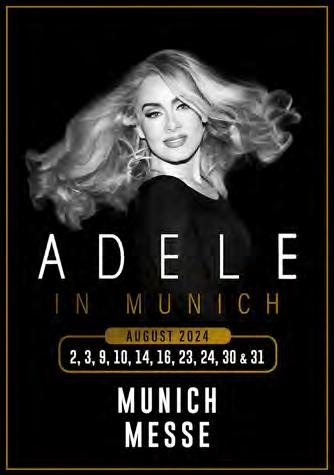

ADELE IN MUNICH (2024)

In August 2024, the artist residency genre was taken to a dazzling, new level when 16-times Grammy Award-winning sensation Adele gave 10 unforgettable sold-out performances at an innovative, 80,000-capacity temporary outdoor arena in Messestadt Riem to the east of Munich, Germany, as Stageco helped her production team establish a new GUINNESS WORLD RECORD™

No stranger to concert residencies, over the course of a year, the star had played

100 Weekends With Adele shows at the Colosseum at Caesars Palace, and this inspired promoters Klaus Leutgeb and Marek Lieberberg to pitch the idea of an “impermanent stadium” in the heart of Central Europe.

Adele In Munich was essentially a collaboration between the pair and Live Nation, production designer Florian Wieder, creative director Matt Askem and Stufish Entertainment Architects. It was Stufish that developed the design for the stage and the well-publicised “big scroll” concept of the super-wide LED video screen. This visual

wonder comprised of 4,625m2 of ROE Carbon 5 Mark II LED panels, ensuring precise visual quality. Spanning no less than 244m in width and 18m in height, and flanked by cylindrical towers to resemble a gigantic analogue film reel, the curved video wall earned the GUINNESS WORLD RECORDS™ title for the Largest Continuous Outdoor LED Screen (temporary). This honour was presented to Adele by Joanne Brent, the Official Adjudicator for Guinness.

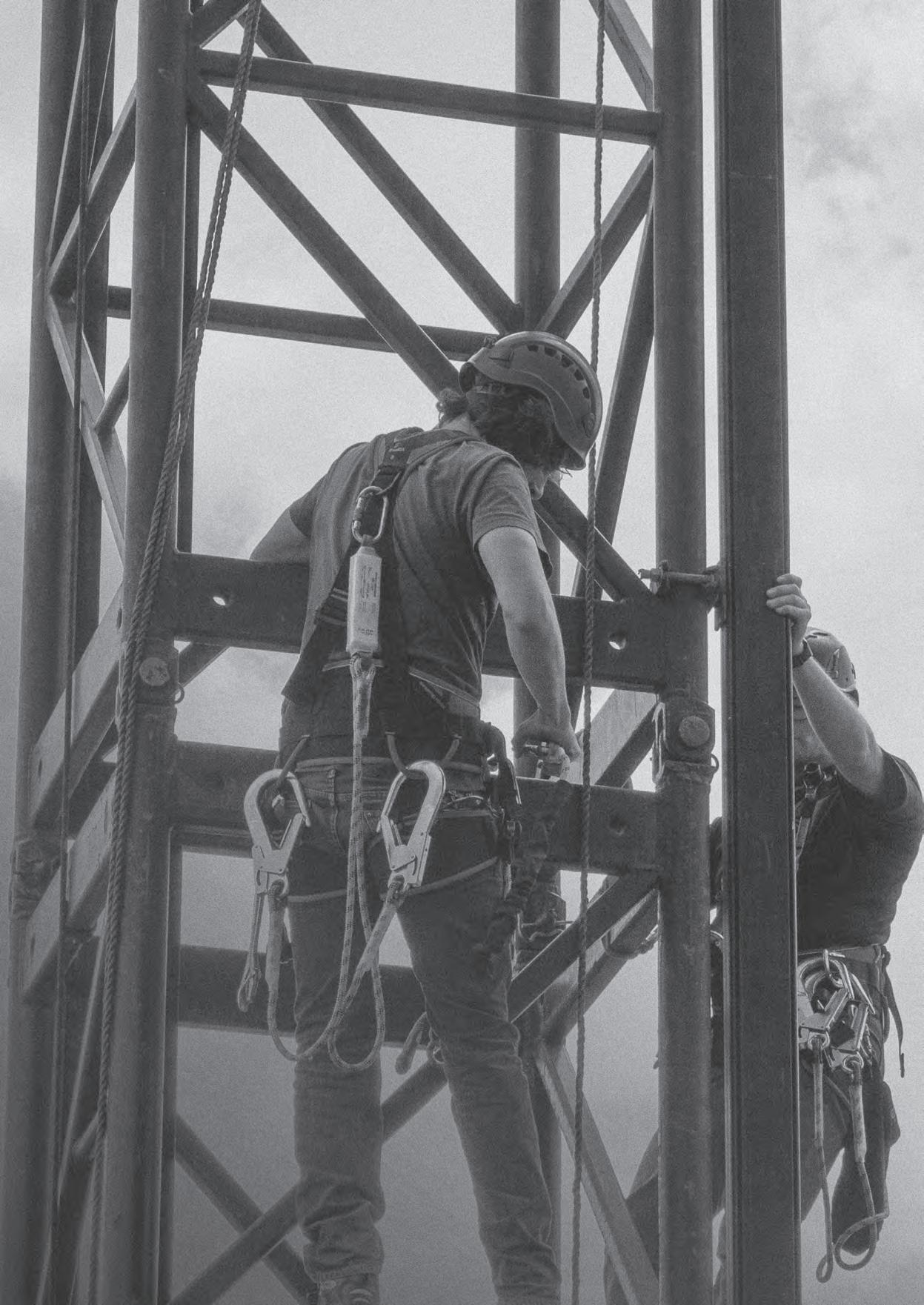

Aided by a profound effort on the part of the company’s R&D department, Stageco’s involvement – managed by Dirk De Decker

and Christof Duarte Da Cruz, in liaison with Adele’s production manager Paul English – was critical to the success of the LED screen, which was supported by a complex foundation system constructed by four Stageco teams over three weeks, concealing all rigging to present a flawless, infinity-like appearance. The combined crew also laid 3,000m² of stage floor, and built the delay towers and FOH platform.

An innovative custom lifting system was designed to raise and lower the video screen which had to be raised at 96 points. The crew lifted it in sections, each of which

had to align perfectly. Christof Duarte Da Cruz explained: “We developed an almost continuous adjustment system to approach this point as accurately as possible. More importantly, it will ensure future flexibility if this point needs to be repositioned for another project – the lifting beams can be moved almost continuously in both directions.”

R&D team member Koen Vandeweerdt added: “This was a stroke of luck because, due to certain circumstances, we had to move a number of beams. It would have been much more complex if we had chosen a welded connection. They start with one panel, which they place on our floor. They lift it using a motor with a long cable that runs over our lifting beams.

“Lifting it in sections, building the screen up from below until it reaches a height of 18m, the crew start with one panel, which is placed on our floor, then they lift it using a motor with a long cable that runs over our lifting beams.”

In total, 68 trucks arrived on site to deliver materials including approximately 1,800m of black steel, 500m of trussing, 6,000m of staging uprights, and 18,000m of staging beams, which came to Munich from four different countries.

“Ensuring all this equipment arrived during the busiest time of the year was our biggest challenge,” said Christof.

For both the construction and dismantling phases, Stageco’s work required up to 82 site crew. The week-long load-out was subject to a tight deadline in order to prepare the site for an international trade fair.

STAGECO Belgium N.V.

Klein Terbankstraat 65

3150 Tildonk

Tel: +32 16 60 84 71 info@stageco.com

STAGECO Nederland b.v. Aalsvoort 14

7241 MA Lochem

STAGECO Deutschland GmbH

Schäfflerstrasse 13

86343 Königsbrunn

Tel: +49 8231 98 96 80 info.deutschland@stageco.com

Tel: +31 573 25 63 02 info.nederland@stageco.com

STAGECO Deutschland GmbH

Herzbergstrasse 120 10365 Berlin

Tel: +49 30 54 98 72 40 info.berlin@stageco.com

STAGECO U.S. Inc 8755 Vollmer Road Colorado Springs, CO 80908

Tel: +1 719 495 9497 info.us@stageco.com

STAGECO France sarl 158, Le Petit Palais

84800 L’Isle sur Sorgue

Tel: +33 4 90 20 90 90 info.france@stageco.com

STAGECO U.S. Inc Manheim 181 E. Stiegel St. Manheim, PA 17545 info.us@stageco.com