AMBIENT FUME & DUST DUST COLLECTION

WELDING SMOKE & FUME MACHINE MIST COLLECTION VEHICLE EXHAUST REMOVAL

IVEC

Designed to get the most from your process ventilation equipment by monitoring fume exhaust and dust loads, then automatically adjusting the fan speed to provide optimum ventilation. IVEC gives you the power to cut costs, maximize resources and gain a competitive edge.

FUMEVAC’S FV-190 is a portable, continuous duty unit for weld fume extraction applications

FUMEVAC’S ERGOBOOM maximizes weld fume gun usability

SYSTEMSTHE POWER OF SMART VENTILATION

SYSTEMSTHE POWER OF SMART VENTILATION

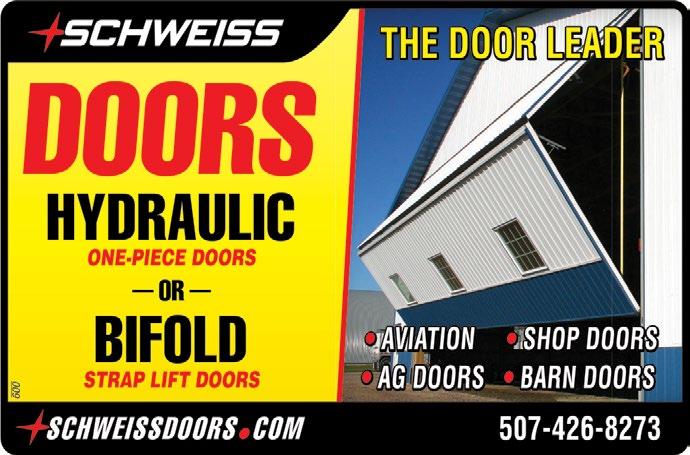

Cut 4 to 5 times faster than a conventional band saw with a clean surface finish that seldom requires a secondary operation. Standard features on all HYDMECH CSNC-Series high production circular saws include:

• automatic bar loading magazine with adjustable incline

• mist fume exhaust system

• automatic lubrication system for all moving parts

• programmable part cut length and trim cut length

• automatic sorting of trim cuts, remnants, and cut parts

• automatic chip auger

• mist blade lubrication system

• remote diagnostic service

North America’s Manufacturing Resource for Industry Professionals Since 1986

SERVING AMERICAN MANUFACTURERS FOR OVER 38 YEARS

William C. Strickland iii, publisher william.strickland@indmacdig.com 800-366-0676 ext. 103 | Fax: 866-826-5918

Adrienne Gallender, Associate publisher/Media Advisor agallender@indmacdig.com 847-612-1572 | Fax: 847-559-2909

Brian Self, Associate Editor brian@indmacdig.com 800-366-0676 ext. 104 | Fax: 866-826-5918

Shane Bell, Creative Director sbell@indmacdig.com

SALES

lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland iii, National Sales 205-903-9178 | fax 866-826-5918

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

iMD, 3590-B Hwy 31 South, Suite 233, pelham, Al 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com

As we step into a new era where digital transformation reshapes the backbone of the manufacturing industry, this issue of industrial Machinery Digest is themed around "Augmented reality - The impact of the Digital Environment". Our journey through the realms of CAD/CAM, CiM & robotics, Material Handling & Warehousing, Joining & Metalworking, Composite Machining & EDM, and Fabrication, Cutting, Sawing, Finishing, is guided by the innovative strides made by industry leaders and emerging disruptors alike.

The collaboration between Velo3D and Bechtel plant Machinery inc., utilizing metal additive manufacturing for the U.S. Navy, epitomizes the shift towards integrating digital fabrication to enhance traditional manufacturing. This partnership not only streamlines production but also reflects a broader trend of adopting advanced manufacturing methods to maintain operational readiness and efficiency.

The formation of the TSM Group, heralding a new era of manufacturing solutions, and Neugart's strategic management realignment, aimed at bolstering digitalization and global competitiveness, both signify the industry's momentum towards embracing integrated and innovative approaches.

Highlighting the practical applications of these advancements, Westinghouse Electric Company’s milestone in additive manufacturing for nuclear fuel components illustrates the critical role of digital technologies in serial production. Meanwhile, Wauseon Machine's showcase at the Design 2part Shows emphasizes the wide-ranging capabilities that precision machining and fabrication offer to the industry.

As we look forward to our Tradeshow Coverage at pacific Design & Manufacturing, we remain focused on the symbiosis between augmented reality and manufacturing processes. This convergence is not merely an enhancement but a fundamental shift towards a more innovative future.

As we navigate through these developments, our focus remains on how augmented reality and digital environments are influencing the very fabric of industrial machinery and manufacturing. The convergence of physical and digital realms opens new avenues for innovation, efficiency, and sustainability.

We are at the cusp of a new dawn in manufacturing, where augmented reality, alongside advanced manufacturing processes, is not just an enhancement but a necessity. let's embrace this digital transformation, explore its potential, and lead the charge towards a more dynamic, efficient, and innovative future.

Warm regards,

William Strickland publisher, iMD William Strickland

Hydraulic Shears:

1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

Ambassador: lena risse

lena risse's journey from uncertainty to becoming the inaugural ANCA Female Machinist of the Year is a narrative that defies conventional career paths and challenges gender norms in the tool grinding industry. initially dabbling in media technology and event support, lena found her true calling in tool grinding, a field closely associated with her family, particularly her father Horst risse's business, risse Werkzeugtechnik GmbH. Despite the male-dominated nature of the field, lena’s foray into tool grinding was not just a leap of faith but a return to familiar roots, with her involvement in the family business transitioning from minor tasks to handling sophisticated ANCA machines.

Her apprenticeship was a blend of practical work and theoretical learning, leading to her full qualification as a machinist and eventually taking on significant responsibilities within the company. lena's contributions extend beyond daily operations to innovations that enhance productivity and efficiency, such as the invention of a dead stop for an automatic chuck and programming a probing routine for ANCA's iGrind software.

looking ahead, lena aspires to continue her growth alongside her father, potentially taking on an apprentice and expanding her teaching role. Her story stands as a testament to the idea that tool grinding and the broader field of machining are realms where women can excel and innovate. lena’s success not only challenges stereotypes but also highlights the importance of passion, precision, and problem-solving in manufacturing.

EXAir's innovative solutions for industrial challenges have taken a leap forward with the launch of their fully digital and interactive Catalog 35 on EXAir .com. This digital catalog makes accessing information on EXAir's extensive product range, including solutions for conveying, cooling, cleaning, and more, more accessible than ever. With intuitive navigation features, users can effortlessly find product specifications, models, and application data, enhancing the customer experience significantly.

The digital transformation of Catalog 35 is part of EXAir 's commitment to providing valuable resources to its customers, complementing their existing offerings like Augmented reality, 3D models, and case studies. This digital initiative not only simplifies the process of finding the right industrial solution but also aligns with modern

demands for quick and easy access to information. Through this digital catalog, EXAir aims to further its mission of conserving compressed air and increasing personnel safety, by making its innovative products more accessible to a broader audience.

Fixtureworks is set to display its comprehensive range of clamps, fixturing accessories, and machine tool products at the AUTOMATE Show 2024, highlighting its role as a leading supplier in the automation and manufacturing industries. Visitors to Booth 4231 will have the opportunity to explore a variety of workholding products, including pneumatic clamps, One-Touch Fasteners, and Flex locators, demonstrating Fixtureworks' commitment to providing innovative solutions that enhance productivity and efficiency.

This exhibition at the McCormick Center in Chicago is a reflection of Fixtureworks’ dedication to excellence and innovation in the field of automated manufacturing. By featuring their extensive product line, including the Fairlane® products line of grippers and Swivots®, Fixtureworks aims to cater to the diverse needs of the industry, emphasizing the importance of reliable and high-quality fixturing in achieving operational success. The AUTOMATE Show, organized by the Association for Advancing Automation (A3), serves as the perfect platform for Fixtureworks to connect

with industry professionals and showcase their expertise in advancing automation technology.

HAiMEr has announced a strategic advancement in tool management by acquiring a 25% stake in WinTool AG and partnering with the TCM Group, marking a significant move towards integrating digital solutions in tool management. This collaboration aims to enhance HAiMEr's offerings with the WinTool software and Toolbase dispensing systems, which have proven their value in HAiMEr's own production facilities. The partnership signifies a mutual commitment to providing comprehensive tool management solutions that combine physical tool holding, shrinking, balancing, and presetting machines with innovative digital technologies.

The integration of WinTool and Toolbase into HAiMEr ’s product lineup addresses the growing importance of efficient tool management in manufacturing. By offering a unified system concept that bridges analog and digital tool management processes, HAiMEr aims to empower customers to increase productivity on the shop floor. This

initiative is a testament to HAiMEr 's strategic vision to deliver a complete solution for tool room efficiency and productivity, demonstrating their leadership in the evolution of manufacturing technologies.

Kardex introduces Kardex FulfillX at MODEX 2024, an innovative warehouse execution system designed specifically for AutoStore systems empowered by Kardex. This new development aims to expedite the go-live process of new AutoStore systems, enabling them to ramp up faster and achieve business outcomes in as little as six months. Attendees at MODEX will have the opportunity to experience the latest in automation software and witness live demonstrations of Kardex’s intuitive

pick Assistant, which facilitates ergonomic and error-free picking by projecting picking information directly onto access openings.

Kardex's participation in MODEX 2024 also includes presenting two live seminars focused on transforming warehouse operations with ASrS automation and how AutoStore, empowered by Kardex, has revolutionized omnichannel business for Cutter & Buck. Additionally, Kardex’s role as a global AutoStore partner highlights their commitment to providing space-saving solutions for efficient small parts order processing. The introduction of Kardex FulfillX is anticipated to set new standards in warehouse execution systems, offering unprecedented operational efficiency and productivity.

Mazak proudly announces the formation of The Shelton Machinery (TSM) Group, a merger that solidifies one of the manufacturing industry's largest solutions providers. By acquiring Concept Technical Sales, inc., now Concept Machinery, and Municipal Tool & Machinery, now Municipal Machinery, TSM Group emerges as a powerful conglomerate serving the metalworking sector across indiana, Kentucky, southern illinois, Missouri, and Kansas. This strategic expansion not only strengthens Mazak's distribution network but also amplifies its commitment to delivering exceptional sales, technology demonstrations, service, and support through its certified distributors.

This union signifies a significant leap towards enhancing Mazak's direct sales and distribution model in North America, ensuring unparalleled access to advanced manufacturing solutions and support for customers. The creation of TSM Group marks a pivotal moment in Mazak's history, underlining its dedication to continuous improvement and customer service excellence. With a rich heritage and a forward-looking approach, TSM Group is poised to redefine manufacturing solutions delivery, fostering innovation and driving success in the metalworking industry.

Neugart, a renowned gearbox specialist based in Kippenheim, Baden, has ushered in a new era by reorganizing its management structure, appointing Swen Herrmann and Holger Obergföll as managing directors. This pivotal move, a first in the company's nearly century-long history, sees leadership beyond the owner families, signaling a strategic pivot to address the challenges of the international mechanical engineering industry.

The restructuring, effective from the beginning of 2024, positions Neugart to leverage Herrmann's and Obergföll's expertise, accumulated through years within the company, to steer Neugart towards global market leadership. The introduction of a nine-person leadership Team further streamlines operations, ensuring agility and innovation in delivering high-quality products worldwide.

As Neugart strengthens its home base in Kippenheim and expands globally, this new leadership framework, coupled with the strategic direction from Neugart Holding, aims to secure the company's legacy and foster growth amidst digitalization and internationalization. This bold step reinforces Neugart's commitment to excellence and innovation, setting a robust foundation for future endeavors.

rEGO-FiX, enhancing its focus on the aerospace, defense, and space sectors, welcomes Sherman D’Souza as its Global Aerospace Specialist. D’Souza, with over a decade of aerospace manufacturing expertise, will bridge rEGO-FiX's innovative tool holding solutions with the dynamic requirements of global aerospace customers. His appointment underscores rEGO-FiX's commitment to advancing aerospace manufacturing through cutting-edge technology and specialized support.

D’Souza's extensive background in engineering and manufacturing, coupled with his project management experience, equips him to foster collaborations that drive the aerospace industry forward. rEGO-FiX customers are set to benefit from his unique insights, ensuring that the demands of the aerospace sector are met with precision and innovation. This strategic move positions rEGO-FiX as a collaborative partner in aerospace manufacturing, ready to tackle the industry's complex challenges.

l azer Sport NV, a leading cycling helmet manufacturer, has adopted the Siemens Xcelerator portfolio to develop KinetiCore, a groundbreaking cycling helmet technology. This collaboration marks a significant milestone in enhancing rider safety and comfort while emphasizing sustainability. KinetiCore, integrated into 20 helmet models by the end of 2024, represents a decade-long pursuit of

innovative protection, featuring EpS foam blocks designed to absorb impact energy and protect cyclists.

The partnership with Siemens Digital industries Software enables l azer Sport to leverage NX™ software for product engineering and Simcenter™ 3D software for digital simulation, streamlining the development of complex designs and ensuring robust testing and verification. The Siemens Xcelerator portfolio facilitates a seamless design-to-production process, allowing l azer Sport to meet the evolving needs of cyclists with helmets that are lighter, cooler, and more environmentally friendly.

This initiative showcases l azer Sport's dedication to pioneering safety technologies that align with the cycling industry's sustainability goals.

Bechtel plant Machinery inc. Adopts Velo3D's Advanced Metal printing for U.S. Navy Bechtel plant Machinery inc. (BpMi) has embraced Velo3D's metal additive manufacturing solution, selecting the Sapphire XC large format printer for creating parts for the U.S. Naval Nuclear propulsion program. This initiative, carried out in collaboration with ATi at its new facility in Florida, is set to revolutionize the production of parts that were previously cast, streamlining the supply chain and significantly reducing lead times for mission-critical components. Velo3D’s innovative technology enables the creation of complex geometries without the extensive need for support structures, a common limitation in conventional 3D printing.

This partnership represents a strategic move towards enhancing the U.S. Navy's maintenance and operational capabilities, addressing the challenges of maintaining an aging fleet with cutting-edge additive manufacturing.

The technology's scalability across multiple machines and locations promises a transformative impact on the Navy's supply chain, ensuring the availability of parts with reduced lead times and fostering innovation in part design. This collaboration underscores the potential of metal 3D printing in advancing the manufacturing industry, offering new solutions for defense and aerospace applications that were previously unattainable.

Wauseon Machine announces its participation in the upcoming Design 2part Shows (D2p) in irving, Texas. As a premier event for design and contract manufacturing services, D2p offers a pivotal platform for Wauseon Machine to showcase its extensive capabilities in precision machining and fabrication. Boasting over 100 CNC machines and a network of metal fabrication partners, Wauseon Machine is positioned to deliver comprehensive services ranging from laser and die cutting to welding and assembly, addressing both low and high-volume production needs.

The D2p conference presents an exclusive opportunity for Wauseon Machine to engage with industry professionals, demonstrating how its expertise can contribute to the success of future projects. Situated in the accessible irving Convention Center, the event promises

to facilitate meaningful connections and collaborations among attendees. Wauseon Machine's presence at booth #203 will be a highlight for those seeking innovative manufacturing solutions in the region.

Westinghouse Electric Company has achieved a groundbreaking milestone by manufacturing its 1,000th additive manufacturing (AM) fuel flow plate for VVEr-440 fuel assemblies. This marks a significant achievement in the nuclear industry, showcasing the transition of AM from prototyping to serial production. The AM flow plates contribute to a redesigned assembly bottom, enhancing robustness and performance.

This milestone underscores Westinghouse's pioneering role in incorporating AM technology to improve safety, efficiency, and sustainability within the nuclear sector. The company's dedication to innovation is evident in its history of AM deployments, including the first material irradiation study of AM nuclear components and the installation of the first-ever safety-related AM component in an operating reactor. Westinghouse's commitment to advancing carbon-free energy through cutting-edge technology continues to set industry standards, reinforcing its position as a leader in nuclear and clean power technologies globally.

in a world where unpredictability has become the norm, the last few years have served as a stark reminder that anything can happen. reflecting on the challenges of the past year, one thing remains clear: the need for business resilience has never been more pressing. This is where the role of solutions already present in manufacturing operations could play a significant part in navigating the uncertain road ahead.

The shift towards extracting the maximum value from every existing asset has emerged as a clear response in fortifying businesses against unforeseen disruptions. Whether grappling with supply chain disruptions, market fluctuations, or global crises, a business’s resilience can be largely swayed by its capacity to derive optimal value from its resources, including operations, labour and sustainability.

preparing your business for the future can often feel like solving a complex puzzle. By consolidating information into a unified platform, businesses can simplify decisionmaking processes and gain a clearer perspective on how to maximise their rOi

The missing piece of the puzzle

Central to any business strategy lies an often-forgotten piece of the puzzle: data. The raw data collected across various facets of the production process is often an untapped resource waiting to be harnessed. Many manufacturers find themselves with a treasure trove of data but lack the processes to extract its full potential. This gap between data capture and effective utilisation is where businesses often falter.

in the journey towards resilience, recognising data as the cornerstone and implementing structured processes to harness its power becomes the catalyst for informed decision-making and operational single source of truth. Overall Equipment Effectiveness (OEE) is a measurement used to harness this data, offering the ability to identify the highest impact opportunities for productivity gains on your production lines.

OEE, a key metric for measuring a manufacturing process's effectiveness, takes into account machine availability, performance, and quality to provide a holistic view of a production line's efficiency. By determining performance against equipment capability, tracking OEE can empower businesses to be prepared for the challenges facing the food and drink manufacturing industry. We explore three of these key challenges below.

in the aftermath of Brexit and the coronavirus pandemic in 2020, the food and beverage manufacturing industry has grappled with unfilled positions and lack of skilled workers in the face of significant labour shortages.

Against this backdrop, maximising team time becomes not only a necessity but a strategic imperative. it's important for businesses to recalibrate their approach, ensuring that people continue to play an indispensable role in the manufacturing process. By implementing OEE monitoring, not only can operations achieve increased efficiency, but they can also optimise labour utilisation by employing streamlined processes. This approach minimises unplanned downtime and reduces the need for staff overtime, ultimately enhancing overall staff productivity through more efficient workflows. By leveraging technology, automation, and optimised workflows, the industry can navigate labour challenges, ensuring that every team member contributes meaningfully to the overall production process while offering positive returns on rOi

Operating in the face of global supply chain disruptions and the threat of a global food crisis, with raw materials shortages creating price hikes across sectors, making the most of every asset becomes priority. Every business is now under pressure to produce more products faster and with higher quality, but with fewer resources. Often working with low margins, operators must put a stronger focus on maximising asset utilisation and increasing line efficiency to achieve increased productivity, reduced downtime and reductions in waste.

By monitoring OEE, businesses can quickly identify areas of inefficiency, getting ahead of unplanned downtime and maintenance while ensuring every resource is exploited to its full potential for more resilient and robust operations.

reducing operational emissions in the face of rising energy costs and increasing pressure to reduce carbon emissions, the need for more sustainable operations is imperative. positive momentum can be seen across industry to adopt initiatives such as sustainable packaging however, the opportunity to reduce the environmental impact of running production lines must not be forgotten. For some, taking a stronger focus on reducing waste – such as water - and producing units with the most efficient use of resources – including minimising the energy required - may feel like an obvious objective but it is one often overlooked. By continuing to consider this challenge through an increased efficiency lens, production lines that are not operating effectively can see materials wasted and increased loss through the production of poor-quality products.

Efficient manufacturing minimizes waste and resource usage, reducing energy consumption and promoting sustainability. This leads to a lower carbon footprint per unit compared to end-of-production interventions. Maximizing Overall Equipment Effectiveness (OEE) facilitates this transition, enhancing business resilience, and unlocking additional capital expenditure (CA pEX) for sustainable operations.

The food and beverage manufacturing sector faces a difficult challenge, finding itself at the intersection of labour shortages, rising operational costs and the threat of a global food crisis, not to mention low margins in an already challenging operating environment. Working towards improving OEE is a no brainer, in theory, but piecing it together, in practice, can become a challenging and often daunting feat.

End-to-end connected shop-floor monitoring and analysis systems, like lineView’s, offer a helping hand towards reaching this goal. Serving as an essential step to first understand all plant processes – from line monitoring to machine downtime tracking – before identifying the areas in need of adaptation to achieve optimum output while reducing wasted resources. By adopting software that essentially removes the burden of thought, and improves OEE, manufacturers can tap into the goldmine of data that is often left unexploited. real-time data, which can facilitate enhanced use of team time, more efficient production and transparent reporting on sustainability initiatives.

Ultimately, working with a smart factory solutions provider like lineView to implement solutions that can help piece the data puzzle together for you, will empower your business to focus on the areas that allow you to maximise and build a more resilient future.

www.itwprobrands.com/brand/dykem

Whether your customer needs to permanently mark metal, wood, glass, rubber, cardboard, or ceramics, DYKEM Brand marking products and layout fluids are proven performers. Carefully formulated and manufactured to deliver vivid color and durable identification marks and color-coding, the DYKEM family of products is an ideal companion for professionals who need quick and effective detection and protection against tampering and changes in settings or controls.

Our mast design is a game-changer, maintaining the load's center regardless of the lift height

FEATURING:

TALKING SHOP WITH: Anthony rooney and Co-Founder & CEO Martin McVicar — Combilift

introducing the latest innovations from Combilift: the COMBi-CB70E. As the Sales Director for USA, UK, & ireland, Anthony rooney takes us through this groundbreaking addition to the North American market. Designed to handle long loads with ease, the COMBi-CB70E boasts a remarkable 15,500 pounds capacity, ensuring safety and efficiency in product delivery across industries. Featuring all-electric power and multi-directional capabilities, this versatile machine excels both indoors and outdoors, promising seamless maneuverability even in tight spaces. Join us as Anthony rooney and Co-Founder & CEO Martin McVicar shed light on the inspiration behind this innovative design, the unique load handling advantages, Combilift's battery technology, and the array of options available to optimize warehouse operations.

Anthony, as the Sales Director for USA, UK, & ireland, can you introduce us to what's innovative at Combilift for the North American market?

Anthony rooney: i'm thrilled to talk about our latest innovation, the COMBi-CB70E. it's designed with a 15,500 pounds capacity, catering specifically to industries that handle long loads, enhancing safety and efficiency in product delivery. This all-electric machine is versatile for both indoor and outdoor use, boasting multi-directional capabilities for easy maneuvering of long loads.

Martin, as Co-Founder & CEO, what inspired the design and functionality of the COMBi-CB70E?

Martin McVicar: Our inspiration came from understanding the nuanced needs of our clients. The design, especially the multi-directional capability and the ergonomic and aerodynamic cab, is influenced by our commitment to operator comfort and safety. We borrowed the suspension concept from the agricultural industry, applying it to this industrial vehicle to ensure it performs exceptionally well, even on unpaved job sites.

Anthony, how does Combilift's battery technology stand out in the market?

The COMBi-CB70E is equipped with a battery system that supports a full 10-hour shift, surpassing many competitors

in efficiency and operational longevity. it's designed for easy battery changing, ensuring minimal downtime and maximum productivity.

Martin, can you elaborate on the unique load handling and operational advantages of the COMBi-CB70E?

Our mast design is a game-changer, maintaining the load's center regardless of the lift height, which significantly reduces strain on the machinery and increases safety. With features like the side shift on brass bushings and hydraulic fork positioner, it's tailored for handling heavy and awkward loads more efficiently than standard forklifts.

Anthony, beyond the CB70E model, what other options does Combilift offer?

We have a diverse range, including the more compact Combilift CB and C-Series, catering to different capacities from 6,000 to 55,000 pounds. These models retain the key feature of multi-directional movement, essential for safe and efficient handling of long loads across various industries.

Martin, how does Combilift help optimize warehouse operations?

Our AisleMaster model, for instance, is designed for maximizing storage density, capable of operating in

narrow aisles and increasing pallet storage within the same warehouse footprint. We also offer a free warehouse design feedback service, showing clients how our equipment can enhance their storage capacity and, by extension, their operation's efficiency and cost-effectiveness.

Combilift, a leading provider of innovative material handling solutions, has been at the forefront of revolutionizing the way businesses handle their goods since its inception. Established in 1998 by Martin McVicar and robert Moffett, Combilift has rapidly grown to become a global leader in the industry, renowned for its cutting-edge products and unparalleled customer service.

Specializing in the design and manufacture of multidirectional forklifts, Combilift offers a diverse range of solutions tailored to meet the unique needs of various industries. From compact electric models for indoor applications to robust diesel-powered units for outdoor use, Combilift's versatile fleet of forklifts ensures efficient handling of long, bulky, and heavy loads in confined spaces and challenging environments.

What sets Combilift apart is its commitment to innovation and customization. With a team of skilled engineers and designers, Combilift collaborates closely with customers to develop bespoke solutions that address specific challenges and enhance operational efficiency. Whether it's optimizing warehouse layouts, improving storage density, or streamlining material flow, Combilift's tailored solutions empower businesses to overcome obstacles and maximize productivity.

Moreover, Combilift's dedication to sustainability is evident in its eco-friendly designs and initiatives. By incorporating advanced technologies and energy-efficient components, Combilift strives to minimize environmental impact while delivering exceptional performance and reliability.

With a global presence spanning over 85 countries and a network of authorized dealers and service centers worldwide, Combilift is committed to providing unparalleled support and service to its customers. Whether it's initial consultations, onsite training, or ongoing maintenance, Combilift ensures that customers receive comprehensive assistance every step of the way.

As Combilift continues to push the boundaries of innovation and excellence in material handling, it remains steadfast in its mission to empower businesses with smarter, safer, and more efficient solutions for their operational needs. With Combilift as their trusted partner, businesses can navigate the complexities of material handling with confidence and success.

Combilift announced its move into the offshore wind sector today with the launch of a new product designed to meet the load handling demands of large scale offshore wind manufacturers. The Combi-lC, designed at Combilift’s HQ and Manufacturing plant in ireland, in collaboration with Siemens Gamesa, allows for the movement of wind turbine blades and towers through production stages and on to storage locations.

Deliver long loads in narrow aisles safely and reliably, around the clock, with the new Combi-AGT Autonomous Guided Forklift Truck. Our autonomous truck solutions combine sophisticated innovative technology to provide the highest levels of productivity and safety. The Combi-AGT can operate autonomously in guided aisles and free-roaming while also featuring a manual driving option.

Combi-Connect is a telematic software product that provides customers with greater levels of insight into fleet management and usage, providing real-time data on fleet

performance, including location tracking, usage analytics, and maintenance alerts. With this invaluable information at their fingertips, businesses can improve and enhance operational performance.

For more information, please visit our website at combilift.com.

ABB, a global leader in robotics and automation, has inaugurated its revamped U.S. robotics headquarters and manufacturing facility in Auburn Hills, Michigan. This initiative underscores ABB robotics' dedication to spearheading the development and production of cutting-edge robotic solutions tailored for the American market and the Americas region. The refurbished facility aligns with ABB's long-term growth strategy in the United States, anticipated to mirror the robust global robotics growth trajectory of 8% CAGr*, and reflects the company's substantial investment to bolster robotics and automation capabilities while generating highly skilled employment opportunities.

Sami Atiya, president of ABB's robotics and Discrete Automation Business Area, emphasized the significance

of this milestone, stating, "The opening of our refitted state-of-the-art US robotics headquarters in Auburn Hills, Michigan is a significant part of our global growth story, reaffirming our commitment to industry leadership in the US." Atiya underscored the pivotal role of robotics and Ai in addressing critical labor shortages, localized supply chains, and the imperative to operate sustainably. The enhanced facility, with its advanced Ai-driven software and hardware, is poised to make ABB's robots more accessible to a broader spectrum of businesses, empowering them to bolster resilience and competitiveness.

Governor Whitmer commended ABB's $20 million investment in Auburn Hills, emphasizing its contribution to job creation and Michigan's advanced manufacturing landscape. The investment, expected to generate over

70 high-skill jobs, underscores ABB's dedication to local workforce development and education.

The upgraded Auburn Hills facility, boasting a 30% increase in space, positions ABB as a premier strategic robotics partner for its expanding clientele. Equipped with a state-of-the-art Customer Experience Center, the facility showcases ABB's leading-edge hardware and software solutions, facilitating collaborative exploration of the latest digital and Ai-powered automation technologies. Furthermore, the facility includes a training center aimed at educating over 3,000 workers and students annually, nurturing a skilled workforce primed for the Ai-powered automation era.

John Bubnikovich, president of ABB United States robotics Division, expressed enthusiasm for the facility's expanded capabilities, stressing ABB's commitment to pushing technological boundaries and fostering a more productive, sustainable future.

ABB's investment in Michigan underscores its unwavering focus on the U.S. market and commitment to continued growth in the region. Supported by a $450,000 Michigan Business Development program grant, the expansion is anticipated to create 72 highly skilled jobs and capitalize on the region's technical talent pool. Additionally, ABB remains dedicated to providing upskilling and career opportunities, enabling individuals without prior experience or degrees to thrive in the robotics and automation industry.

This initiative represents part of ABB's broader commitment to invest in its electrification and automation businesses across the United States, with a focus on driving industrial transformation and advancing sustainability.

ABB is at the forefront of technology-driven electrification and automation solutions, aimed at fostering a more sustainable and resource-efficient future. With over 140 years of excellence, ABB's innovative solutions empower industries worldwide, connecting engineering expertise with cutting-edge software to optimize manufacturing, mobility, energy, and operations.

For more information, visit www.abb.com.

1.1 billion cutting tools and counting have shaped the world around us for 50 years

Family, fulfillment, and a fascination with technology are all part of a formula that has seen ANCA lead the demanding niche of CNC tool and cutter grinders for a half-century.

in its time, the Australiabased global business has made an enormous yet largely hidden contribution to the world, selling over 10,000 5-axis CNC machines to over 2,500 customers. Around 1.1 billion tools have been created using ANCA’s grinders.

“You would be very unlikely to find any bit of advanced equipment, anywhere in the world, that hasn’t been touched by a cutting tool which has been manufactured on one of our machines,” explains co-founder pat Boland, whose company’s customers include Boeing, rolls-royce, iscar, Sandvik, Sutton Tools and many other household names.

Boland and pat McCluskey – then an electrical engineer and an industrial electronics tradesman – met at a government-owned munitions factory in Melbourne in 1968. The two pats started ANCA in 1974 in a spare room at Boland and wife libby’s home.

“it wasn’t about money in the beginning, and for me it’s not about money now...i get my kicks out of designing new machines,” explains McCluskey. “Even before we started ANCA, pat and i have always been driven by simply wanting to get machines to do things better. My enduring philosophy in business is if you always do what you’ve always done, you’ll always get what you’ve always gotten. New ideas and new thinking are the basis of our business.”

ANCA’s highly sophisticated CNC grinding machines are exported around the world, with 98 percent of its revenue being generated by exports. The ANCA Group also makes associated equipment and software, including robot arms, software, and control systems, and offers automation services and technology to OEM machine builders.

leading the incredibly demanding tool and cutter market – where nanometer-level details matter – means a reinvestment of roughly a tenth of revenues back into r&D.

A near-obsession with solving customer problems has seen ANCA contribute a collection of world firsts to its industry, including the first probe for digitizing tools, first modem for support and diagnostics in a machine, first full and true 3D simulation of the grinding process, and many more.

Martin U. ripple, who has been at the helm of ANCA as CEO since November 2022, reflects on the company's enduring legacy. “in all my interactions, i've observed a consistent threadour customers invariably share fond recollections of their encounters with ANCA dating back to the ‘70s, ‘80s, and ‘90s. it's evident that there's a deep-seated loyalty and trust towards our brand,” he notes.

ripple, always keen on uncovering the unique elements that set a business apart, asks, 'What is the secret ingredient that differentiates us from our competitors? What makes ANCA exceptional?' His answer is the involvement of family in the business, a fervent passion driving the company forward, and a steadfast commitment to providing customers with the most innovative products. This blend, according to ripple, is the essence of ANCA's success and longevity."

Edmund Boland, son of pat and ANCA CNC Machines’ General Manager, values ANCA’s agility as a privately owned company which enables swift decisions to support ANCA’s people and customers.

“ANCA has always endeavored to stay ahead of the curve, anticipating market trends and delivering cutting-edge solutions which enable our customers to thrive. With 50 years of innovation behind us, our product and technology portfolios are perfectly placed to meet the challenges of the future.”

The delivery of technical and practical excellence has required a sharp focus on both vertical integration –creating everything from the machines’ motors to their polymer concrete bases to their sheetmetal canopies – and both trade and university-taught skillsets.

ANCA has trained more than 60 apprentices and established its formal apprenticeship program in 2011. McCluskey enthusiastically wrote the course material for this.

While being very particular with skill and technology development is one way to look at ANCA’s story, pat Boland also likes to zoom out to a very general view.

The ANCA era runs 50 years and counting, touching countless lives, operating in the background.

it’s shorter than, but has similarities to the overall story of toolmaking: critical to industrial progress, even if it needs pointing out every now and then.

“For the vast sweep of history, the only evidence of homosapiens and our predecessors are cutting tools,” says Boland.

“And a number of the broad eras of human life are really named after cutting tools. So the stone age, the bronze age, the iron age. What we’re talking about is the technology of cutting tools as much as anything.”

Celebrating a golden achievement across the globe

To mark the occasion of ANCA’s 50th anniversary, the company is hosting a series of open houses, seminars, events, and attending tradeshows worldwide. As innovation has motivated ANCA throughout the company's history, new products and developments will be at the center of the 50th year celebrations.

At global tradeshows and ANCA Open House events, precision manufacturers can experience new hard- and software for micro tool and gear tool manufacturing, edge preparation, closed loop manufacturing and automation.

russell riddiford says: "Our large and experienced group of engineers and developers is continuously presenting new solutions to meet customers’ needs. Highest quality tools and lowest cost per part are the guiding principles leading to groundbreaking, real-world innovations. Examples are our new MicroX CNC grinding machine, using nanometer control technology and ANCA Machine intelligence to produce micro tools of unseen quality, or our AiMS system, the world's first and only autonomous system for tool manufacturing."

ANCA is a market leading manufacturer of CNC grinding machines. it was founded in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA has offices in the UK, Germany, China, Thailand, india, Japan, Brazil and the USA as well as a comprehensive network of representatives and agents worldwide.

ANCA CNC grinders are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

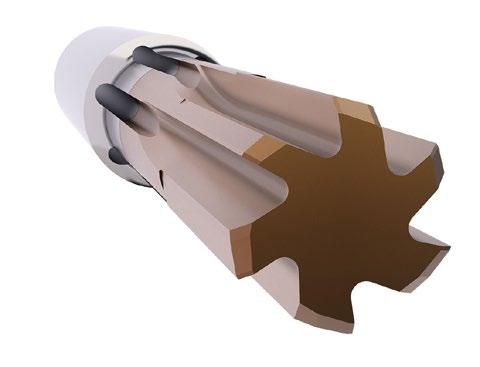

in the realm of manufacturing and design, the quest for precision, versatility, and eco-friendliness leads us to a standout technology: waterjet cutting. This cutting-edge method uses a high-velocity stream of water, sometimes mixed with abrasive particles, to cut through a myriad of materials. Unlike its thermal counterparts, waterjet cutting does not introduce heat, making it a unique choice for a wide range of applications.

Waterjet cutting is akin to carving with liquid precision. it operates on a simple principle: directing a high-pressure stream of water, often combined with an abrasive substance, through a narrow nozzle to cut material with unmatched accuracy. This technique stands out for its ability to cut without the heat-affected zones, preserving the integrity of the material being cut.

Understanding the waterjet cutting process illuminates why it's favored for diverse applications. The journey from raw material to finished product involves several stages:

» preparing the material: positioning and securing the material to ensure precision cutting.

» Generating the high-pressure water stream: Water is pressurized to an intensity that can slice through materials.

» Mixing abrasive materials (when necessary): For harder materials, an abrasive substance is added to the water stream to enhance cutting power.

» Cutting the material: The high-velocity water or abrasive mixture makes its precise cut according to the design.

» post-processing steps: includes washing and finishing the cut edges as required.

The benefits of waterjet cutting are manifold, making it a preferred choice in various industries:

» precision and versatility: it can create intricate designs and patterns on a wide range of materials.

» Cold cutting process and no heat-affected zones: This ensures the material's properties remain unaltered.

» Ability to cut a wide range of materials: From metals to composites and beyond, waterjet can handle it all.

» Minimal material wastage: The precision cutting translates to more efficient material use and less waste.

Yes, waterjet cutting excels in producing complex geometries that other methods might struggle with. This adaptability stems from its precision and the ability to cut without introducing heat or mechanical stress, preserving the material's original characteristics.

The green credentials of waterjet cutting are significant:

» Water recyclability: The water used can often be recycled and reused.

» Absence of hazardous waste: Unlike some cutting processes, waterjet cutting does not produce harmful by-products.

» reduced material wastage: Efficient use of materials means less waste.

Waterjet cutting's versatility is showcased in its ability to handle diverse materials:

» Metals: including Stainless Steel, Aluminum, Brass, and more.

» Composites: Such as carbon fiber and fiberglass.

» Glass and ceramics: For intricate designs and shapes.

» Stone and tiles: ideal for custom architectural elements.

» plastics and polymers: Offering clean cuts without melting.

» rubber and foam: For precise shapes and sizes.

While waterjet cutting is remarkably versatile, the thickness it can handle varies by material type. Generally, it can cut up to several inches thick, but this capacity can be material-dependent.

The adoption of waterjet cutting spans numerous sectors, each valuing its specific advantages:

» Aerospace and Aviation: For precision parts that require tight tolerances.

» Automotive: For cutting complex parts efficiently.

» Manufacturing and Fabrication: For its versatility in materials and shapes.

» Electronics: For delicate components that must avoid heat damage.

» Art and Architecture: For creating intricate designs in a variety of materials.

» Energy Sector: For cutting components used in harsh environments.

in aerospace, the precision and ability to cut high-strength materials without compromising their integrity are crucial. Waterjet cutting meets these requirements, making it invaluable for creating parts with tight tolerances and complex shapes.

Why is Waterjet Cutting ideal for Manufacturing and Fabrication?

its versatility and precision make waterjet cutting a go-to for manufacturers seeking to reduce material waste, ensure part accuracy, and maintain the integrity of the materials they use.

Comparing Waterjet to Other Cutting Technologies

When pitted against other cutting technologies like laser, plasma, and mechanical cutting, waterjet stands out for its versatility, precision, and material-friendly process.

Waterjet vs. l aser Cutting: Which is More Versatile?

While laser cutting is precise and fast, it introduces heat, limiting its use with certain materials. Waterjet, with its cold-cutting advantage, can handle a broader spectrum of materials without heat damage.

Waterjet vs. plasma Cutting: Why Choose Waterjet for precision?

plasma cutting is suited for metal and is faster for thick materials. However, waterjet offers superior precision, especially for complex shapes or materials where heat damage is a concern.

Key Considerations When Choosing Waterjet Cutting

Selecting waterjet cutting involves evaluating several factors:

» Material type and thickness: Assessing the compatibility

and optimal cutting method.

» Cutting precision and quality requirements: Ensuring the method meets the project's precision needs.

» project budget and operational costs: Balancing cost-effectiveness with quality. Water jet cutting systems can have lower costs and save money with optimal waterjet software.

» Environmental and safety considerations: prioritizing eco-friendly and safe processes.

Design optimization for waterjet involves several strategies:

» Minimizing material use with nesting techniques: Efficient layout reduces waste.

» Designing for cutting efficiency: Simplifying designs where possible to reduce cutting time and costs.

» Avoiding certain geometries that increase cutting time and costs: Streamlining designs for optimal cutting efficiency.

Ensuring safety during waterjet operations is paramount:

» personal protective equipment (ppE) requirements: protecting operators from potential hazards.

» Handling high-pressure equipment: Ensuring safe operation and maintenance.

» Safe material handling practices: Avoiding injury during material loading and unloading.

The cost of waterjet cutter is influenced by several factors:

» Material type and thickness: Different materials and thicknesses can affect operational costs.

» Complexity of the design: More complex designs may require more time and resources.

» Quantity and size of the parts: l arger or more numerous parts may increase costs.

project cost estimation involves considering material costs, operational expenses, and the time required for cutting. Accurate estimations ensure projects stay within budget while achieving desired outcomes.

innovations in waterjet technology continue to enhance its capabilities, with automation and artificial intelligence playing increasing roles in optimizing cutting processes and efficiency.

The preference for waterjet cutting in various industries is clear. its unparalleled precision, versatility, and eco-friendly nature make it an indispensable technology in modern manufacturing and design. As we look to the future, waterjet cutting's role is poised to expand, driven by ongoing innovations and its ability to meet the evolving needs of industries worldwide.

CHECKBALL PISTON PUMPS… Dynex high pressure hydraulic pumps with positive-seating checkball valves provide better wear and high volumetric efficiency. Pumps operate at pressures to 20,000 psi. Checkball pumps are ideal for hydraulic systems with demanding conditions and accommodate more force in a smaller package. At lower pressures, they provide the life and performance margin essential in critical environments. Checkball fixed displacement pumps offer flows from 0.22 to 60 U.S. gpm at 1800 rpm.

• HP Pattern Spool Valves — Simple spool valves eliminate complex valve circuits for fourway control in high pressure systems. HP03 pattern valves are rated for 15 U.S. gpm at 10,000 psi, HP05 pattern rated from 5 to 25 U.S. gpm at 8000 psi.

• NFPA/ISO Pattern Valves — Smooth spool movement with four-land design offers low pressure drop with large internal flow passages. 5000 psi valves rated to 165 U.S. gpm.

• VST Series Seated Valves — High pressure with low leakage. Reliable shifting with non-silting ball-on-seat design.

• Explosion Proof Option — Solenoids with special enclosures designed for use in hazardous locations. UL and CSA approved.

• Accessory Sandwich Valves — Mounts under directional valves, saves space, reduces weight and provides flexibility locating valves.

For a view of the STEM classroom of the future – and to learn about careers available today – educators, school administrators, students, and parents can visit the Smartforce Student Summit at iMTS – The international Manufacturing Technology Show, which runs Sept. 9-14 at Chicago’s McCormick place. registration is now open for the Smartforce Student Summit and includes access to the iMTS show floor, where more than 1,600 exhibitors will represent the breadth of manufacturing technologies.

The Smartforce Student Summit at iMTS 2024 enables students to explore STEM education and career pathways through interactive exhibits.

The Smartforce Student Summit at iMTS 2024 enables students to explore STEM education and career pathways through interactive exhibits.

The Smartforce Student Summit exhibits emphasize interaction, heavily focus on digital manufacturing technologies, and appeal to students ages K-16. Nearly 70 exhibitors have created education-oriented booths and interactive events for students, which will be held on level 2 of the East Building of McCormick place.

“We have always focused on the manufacturing

technology classroom of the future,” says Greg Jones, director of strategic programs and partnerships, SME. “This year, we designed the experience to provide students with a sense of belonging in our industry, providing them with engaging, hands-on exhibits that will encourage them to seek an education in STEM and career pathways in our industry.

“The Smartforce Student Summit will help students to understand what an education in design, mechatronics, or machining means and how it opens the door to careers as technicians, engineers, entrepreneurs, and more.”

New in 2024, the Smartforce Student Summit is now co-produced by AMT – The Association For Manufacturing Technology, which owns and produces iMTS, and SME, the largest workforce development organization in the manufacturing industry.

"You don’t know what you don’t know about the opportunity that a career in the manufacturing industry can present to you if you don’t experience it yourself,” says Carmen Mahon, Citywide STEM initiatives manager for Chicago public Schools. “The best place to do that is right here in Chicago at the Smartforce Student Summit at iMTS 2024 at McCormick place. Having had the opportunity

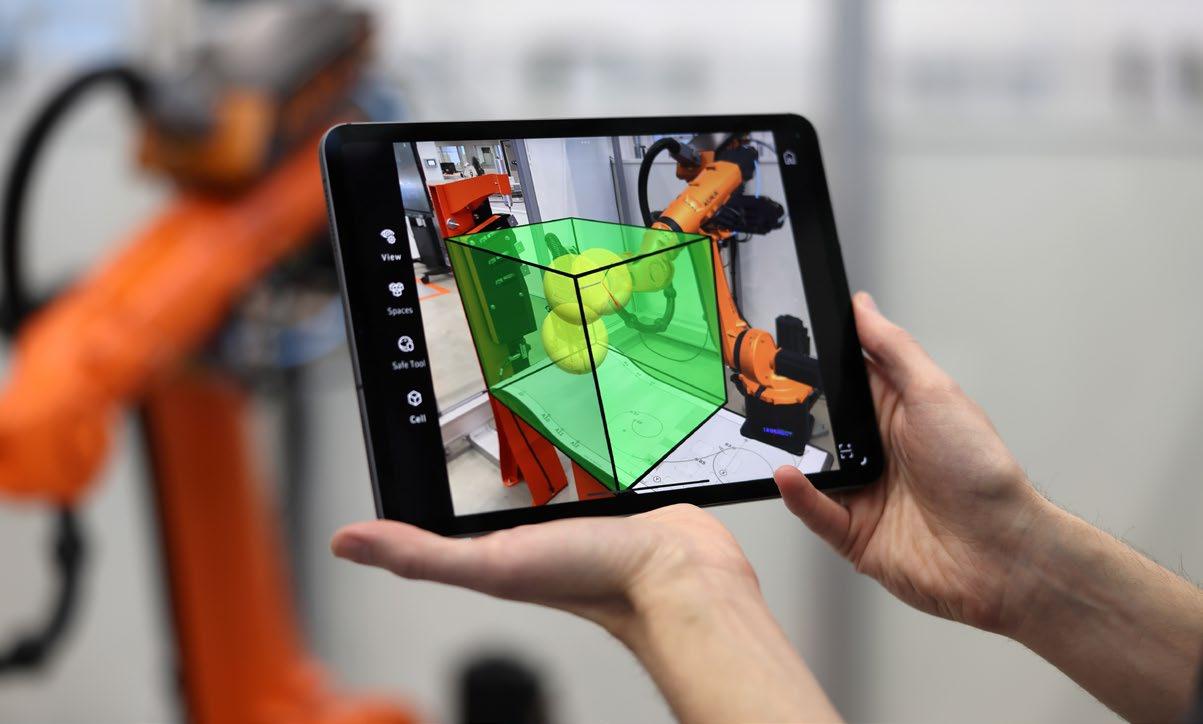

Employing the power of smartphones and Augmented reality (Ar), KUKA has launched its new KUKA.

Mixedreality software that allows users to visualize the environment of robot cells live on their smartphones to support fast, safe and intuitive robot startups. The free mobile app displays tools and interference geometries for early detection of potential hazards that can then be eliminated before a robot even starts to work.

Ar enables such intuitive robot startup assistance capability, connecting the real and virtual worlds to enrich the environment of robotic cells with clear, uncomplicated digital information. By quickly detecting and correcting errors, facilities accelerate installation and boost safety.

For example, the software will simulate robot motion along with a virtual gripper and detect any potential collisions that arise in the Ar environment. These are then resolved at an early stage in the real environment so that neither the robot nor the gripper is damaged.

"Augmented or mixed reality is a future-oriented topic that also offers promising opportunities in robotics,” said roland ritter, portfolio Manager Simulation at KUKA. “KUKA. Mixedreality makes robot installation more user friendly and safe. This benefits customers at all levels of experience in the field of automation.”

The KUKA.Mixedreality Assistant app graphically displays all relevant variables directly for the robot in real time, including Cartesian or violated monitoring spaces, safety-oriented tools and tool spheres. Users can also view the corresponding configuration parameters of the spaces or tools.

KUKA.Mixedreality is easy to set up and operate. Users simply install the KUKA.Mixedreality Assistant on their smartphone or tablet via the Apple App Store or Google play Store. All relevant information about the robot transmits directly to the mobile end device via Wl AN through a router or access point – not a KUKA product – and displays

visually on the mobile device. Ar headsets or additional hardware are not required, and a KUKA.Mixedreality Safe technology package installs in the robot controller as a data source, along with one of the KUKA.SafeOperation technology packages to use with the Safe functions.

Those interested in KUKA. Mixedreality can download and test the application for free at my.KUKA.com. An integrated demo mode enables function testing without a real robot.

KUKA is a global automation corporation with sales of around 3.3 billion euro and roughly 14,000 employees. The company is headquartered in Augsburg, Germany. As one of the world’s leading suppliers of intelligent automation solutions, KUKA offers customers everything they need from a single source: from robots and cells to fully automated systems and their networking in markets such as automotive, electronics,

in the quest for optimal performance in welding manufacturing, two critical factors stand at the forefront: precision and efficiency. Yet, a pervasive challenge across production lines, known as part deviation, threatens these very benchmarks. This article explores the transformative role of Ai-enhanced welding robots in mitigating part deviations, thereby elevating both efficiency and precision in industrial operations.

The Challenge of part Deviation Understanding the nuances of part deviation in welding is

crucial for maintaining the integrity and quality of welded components. part deviations refer to the discrepancies that arise from the intended design specifications, dimensions, or properties of welding components. These deviations, influenced by a multitude of factors, can significantly impact the final product. let's explore some of the primary contributors to part deviations in welding.

The composition, thickness, and surface condition of materials play pivotal roles in the welding process. Variations

in alloying elements, impurities, and surface treatments can directly influence weldability, potentially leading to inconsistencies in weld penetration and joint quality. Materials with inconsistent properties may exhibit varied thermal behaviors, causing uneven heating and cooling that contribute to part deviations.

The parameters set during the welding process, such as heat input, welding speed, and electrode orientation, are critical determinants of weld quality. Deviations in these parameters can introduce welding defects including porosity, incomplete fusion, excessive spatter, and irregular bead formation, all contributing to part deviations. Tailoring welding parameters to suit specific material and joint configurations is essential for minimizing such deviations.

The localized heating and cooling inherent in welding lead to material expansion and contraction, potentially causing significant distortion and warping. These thermal effects can divert the welded components from their intended design dimensions. Moreover, the cooling phase can introduce residual stresses, which may result in material deformation or component misalignment, further exacerbating part deviations.

Achieving a high-quality weld heavily relies on the joint design and the precision of part alignment before welding. inadequate joint design or improper fit-up can create challenges in achieving uniform weld penetration and formation, leading to gaps, overlaps, or misalignments. Such issues not only weaken the welds but also result in deviations from the desired part dimensions and tolerances.

in scenarios where welding is performed manually, the skill level and consistency of the operator become crucial. Variability in welding techniques, including fluctuations in welding speed, arc length, and travel angle, can lead to inconsistent weld quality. Additionally, factors like operator fatigue, inexperience, or insufficient training can further contribute to part deviations. Ensuring comprehensive training and adherence to consistent welding practices is vital for mitigating these deviations.

When welding, part deviation poses several difficult problems that can affect the final product's quality, the effectiveness of production, and the cost of manufacturing. These difficulties result from the fundamental nature of manufacturing procedures, the complexity of welding, and the possibility of mistakes or discrepancies at different production stages. Here, we go into the specifics of part deviation's challenges and how they affect the manufacturing sector.

Compromise in structural integrity is one of the biggest problems caused by part deviation. The total strength and load-bearing capability of the finished product can be decreased by weak spots in the structure caused by welds that are not in line with the original design. Any reduction in structural integrity caused by part deviation can have major repercussions in sectors like construction, aerospace, and automotive where safety and dependability are top priorities.

part deviation might make it challenging to precisely assemble components. When assembled, welded parts may not fit together perfectly if their dimensions differ from those specified in the design. This may result in manufacturing line bottlenecks, longer assembly delays, or even the requirement for manual alterations or revisions to guarantee a good fit.

Even tiny part deviations can cause products to appear inconsistent or unattractive in markets where aesthetics matter a lot, such as consumer electronics and luxury goods. As a result, brand value, consumer satisfaction, and market competitiveness may all suffer.

rework is frequently necessary to address part deviation, which not only eats up important time but also raises manufacturing costs. Material wastage can happen in traditional manufacturing settings where manual changes are performed to remedy deviations due to trial and error methods. This waste results in increased material costs and a less environmentally friendly manufacturing process.

part deviation increases the complexity of quality control and inspection procedures. To make sure that each welded component complies with design requirements, manufacturers might have to spend more money on examining and validating each one. The likelihood of problems evading inspection can rise because of production being slowed down.

The integration of advanced Ai into industrial robots marks a transformative era for the manufacturing sector, significantly enhancing the capabilities of traditional robots. This advancement enables robots to undertake more intricate tasks and adapt to evolving environments, ultimately boosting both efficiency and productivity. Central to these enhancements is the robots' ability to deliver precise and consistent welding, effectively mitigating the adverse impacts of part deviation. Below, we delve into the specific roles these Ai-equipped welding robots play:

Equipped with sophisticated vision systems, Ai-integrated welding robots excel in identifying various joint configurations. They adeptly adjust their welding strategies to suit different geometries and orientations, significantly minimizing the likelihood of weld defects and part deviations.

Ai-driven systems are adept at tailoring welding parameters to accommodate material variations, such as thickness, composition, or surface conditions. Through meticulous analysis of data from each welding operation, Ai algorithms fine-tune the welding process for each unique scenario, guaranteeing superior weld quality even in the face of material inconsistencies.

Ai-integrated welding robots leverage machine learning algorithms to glean insights from every welding task they perform. This continuous learning process allows them to refine their welding parameters, enhancing both the quality and efficiency of their work over time.

The power of Ai enables these welding robots to execute real-time modifications during the welding process. By interpreting data from sensors, such as those in vision or laser-based systems, the robots can identify and rectify any deviations from the predetermined weld path or penetration depth, ensuring precision in each weld.

A i-integrated robots stand out for their ability to consistently replicate precise welding parameters—such as speed, angle, and distance—across numerous parts. This capability starkly contrasts with manual welding, which is prone to variations due to human error or fatigue, thereby significantly diminishing the chances of part deviations.

Ai-integrated welding robots, pioneering innovation in manufacturing, tackle part deviation with precision and adaptability. By merging robotic welding consistency with Ai 's dynamic learning, these systems enhance efficiency and product quality. As Ai evolves, so does the promise of groundbreaking advancements in robotic welding, leaving part deviation challenges behind.

Daryl lim, Co-founder and CEO of Augmentus, drives innovation in autonomous manufacturing by pioneering intelligent computer vision and Ai robot motion planning systems to enable truly autonomous manufacturing even in high-mix and complex applications.

Global distributor Wesco and Siemens team up with local integrator to enable major Tennessee tire manufacturer achieve consistent tension, save money

As Chad Garner, a Nashvillebased application engineer with distributor Wesco, relates, “We were presented with a significant challenge by one of our great customers, a tire manufacturer in the area. They needed to upgrade their multiple wire drawing machines for tire cord production in the plant.”

Garner goes on to explain in detail. “They were faced with very specific challenges. The machines needed to hold a very tight and consistent tension to meet the wire specifications. The company was using a ‘black box’ solution that had been custom-developed for them by a small local company that was no longer in business. The black box, in this case, originally allowed the user to dial in the tension on the wire without making any adjustments to the drive parameters. However, the system was now only able to hold +/- 500 grams of tension on the line, even after the customer had tested nine different control schemes to find a solution. ideally, their goal was to replace the black boxes with off-the-shelf products, but their current drive and control supplier was not able to help satisfactorily. Wesco, in tandem with a local integrator and Siemens, was able to devise a solution, using standard Siemens components for the first line.”

This wire line was running at a maximum speed of 1000 meters per minute. The target wire tension requirements were 600-2000 grams, +/- 50 grams. Typical wire diameters on the line were 0.15-0.3 mm. The tire manufacturer and integrator first tried using their default drives and plC platforms, supplied by another manufacturer, to solve the problem. However, it was determined that the manufacturer could not meet the tension specifications needed for the job. As a result, Wesco and Siemens were jointly asked

if they might have a better solution. Wesco specified the drives and motors required, then provided a combination package of Siemens products to the integrator for onsite testing. During the initial testing period, the legacy plC was used with the Siemens drives and motors and the solution was proven acceptable. Upon meeting and exceeding the desired specification, it was finally determined that a full Siemens solution was the most efficient and cost-effective answer for this tire manufacturer on the first wire draw line.

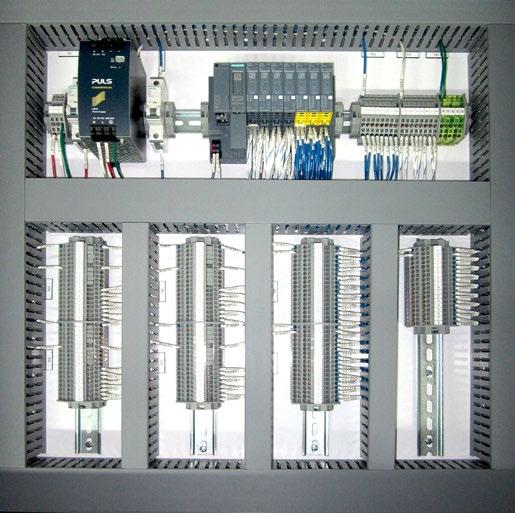

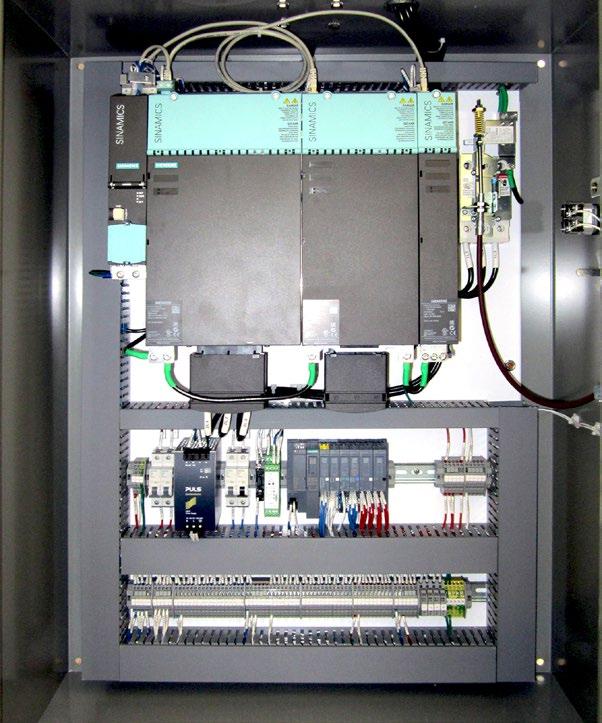

The full solution to this challenge comprised a SiMATiC S7-1500 plC plus remote i/O racks, SCAl ANCE wireless switches, SiMATiC HMi panels and, the heart of the solution, the SiNAMiCS S120 drive system, running 30 axes of motion control, plus various servo motors and other control products. All these components were supplied as a total solution to the integrator and the tire cord manufacturer by Wesco.

Thanks to the success on the first machine, three more wire drawing lines at the facility were upgraded with the Siemens solution, with more planned for future installation. A total of 120 axes of motion run by the SiNAMiCS S120 drives are currently in operation. The key to success here was the tight tension control programmed into the S120 drive control unit.

Chad Garner of Wesco further observes, “A major financial aspect of this project was the amount of money invested in the controls cabinet on each machine. The legacy plC and Ethernet cards, if purchased from the previous supplier, would have cost approximately $30,000 and we were able to supply our better solution for about one-third that amount. This was not only a significant reduction in cost from the previous solution, but it also resulted in component reduction, as we were able to combine functions in fewer parts. The Siemens solution offered the customer integrated Ethernet on the plC, so there was a reduction in expensive hardware, also achieving a smaller footprint in the plant.”

Matt Wagner, a Drives and Motion Consultant on the Siemens team, comments, “By replacing the old black box solution for tension control on these wire drawing machines at the tire manufacturer, our team, working in tandem with Wesco and the local integrator, was able to achieve all the required wire draw specs and do it with off-the-shelf solutions from the Siemens product lines. it’s exciting when we can exceed the goals of the customer, retrofit a substantial part of the manufacturing operation and save them a lot of money in the process. Can’t do much better,” he mused.

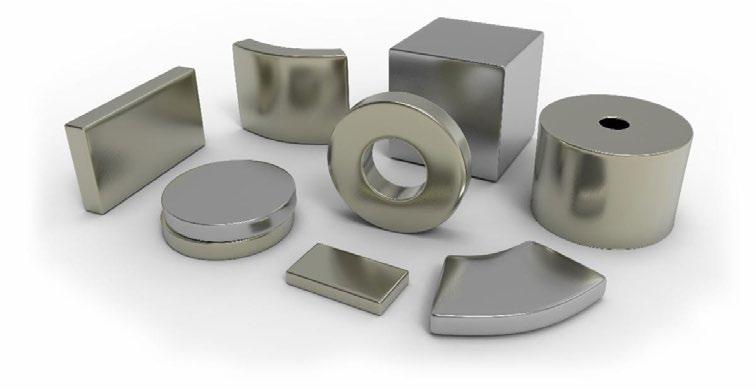

Arnold's NDAA Compliant NdFeB Magnets for Aerospace

Arnold Magnetic Technologies presents its Neodymium iron Boron (NdFeB) magnets, compliant with the John S. McCain National Defense Authorization Act, for the aerospace and defense industries. renowned for their high energy storage and transfer capabilities, these magnets are ideal for applications requiring high-performance materials, such as motors and sensors. Arnold ensures a secure supply chain for these NDAA-compliant magnets, promising uninterrupted supply. Additionally, they offer corrosion-resistant coatings to counteract the inherent corrosive potential of NdFeB, ensuring longevity and reliability in critical applications.

Beamcut Systems introduces the BC25, an automated 6-axis beam cutting robotic system designed for precision metal cutting across structural steel shapes. Equipped with high-definition Hypertherm plasma technology and Fanuc robotics, the BC25 enhances manufacturing efficiency by eliminating layout work and post-cut grinding. Features like the photo-l aser Measuring Device and Windows-based Operator Control System simplify operation. The BC25 represents an affordable, automated solution, promising a swift return on investment and robust aftermarket support, encapsulating 20 years of Machitech Automation Group's experience in CNC and robotic systems.

Delta's M∞Vair 30 kW Wireless Charging for industrial E-Vehicles

Delta introduces the M∞Vair 30 kW Wireless Charging System, an efficient, contactless power conversion system for large industrial electric vehicles like forklifts

and AGVs. Approved by the FCC and METus certified, this system boasts 95% power conversion efficiency, supporting the logistics and manufacturing sectors' push towards electrification. Utilizing WiTricity's licensed technology, the M∞Vair Series facilitates easy integration into existing projects, enhancing productivity and energy efficiency with its innovative wireless charging capabilities.

E-Z lok launches E-Z Hex™ (Hex Drive) inserts and accompanying kits for reinforcing threads in softwoods, offering a cost-effective, robust solution for assembly and disassembly applications. The hex drive design ensures efficient torque transfer and installation simplicity, with options for flanged and flush designs. ideal for furniture, display cases, and various wood applications, E-Z Hex™ inserts demonstrate versatility and reliability for softwood thread reinforcement.

FipA GmbH introduces the Cobot Smart Gripper CSG, tailored for cobots in low-payload automation processes. Available in three versions, including an innovative electric vacuum pump model, the CSG adapts to various applications without requiring compressed air. Compact and intelligently controlled, the CSG is compatible with leading cobot brands, offering flexibility in pick and place, assembly, and mechanical processes across industries.

Fairlane products unveils metal-backed rectangular and square bumpers, offering added durability and strength for protecting workpieces. Molded from urethane or neoprene and bonded to metal plates, these bumpers are designed

for stops, guides, and protective applications. Available in standard and custom sizes, Fairlane's bumpers provide an economical alternative for applications requiring robust impact resistance and durability.

Fixtureworks introduces a line of adjustable torque handles and knobs designed for precise clamping and torque applications where rotation space is limited. These tools allow users to set specific torque to avoid over-tightening, ideal for applications requiring consistent force or where damage from excessive force must be avoided. The handles offer a torque range of 1-8 Nm, with a clicking mechanism for torque achievement indication, and come in various lengths, heights, and thread options. The torque knobs provide preset torque options of 2Nm or 3Nm, with audible and tactile click feedback when the set torque is reached, available in steel with stud or tapped versions, and made from durable polyamide with nickel-plated steel components.

Hemco's Stainless Steel Canopy Hoods & Back Draft Hoods

Hemco presents Stainless Steel Canopy Hoods designed to collect and exhaust corrosive vapors, heat, steam, and odors, available in wall or island models. Made from 16-gauge type 304 stainless steel, these hoods can be wall-mounted or ceiling-suspended, featuring optional panels for enhanced airflow control. Additionally, Hemco introduces the Back Draft Fume Hood, utilizing Back Draft technology to remove hazardous fumes and odors in laboratories with limited space, offering a selection of accessories and components for customization. Both

products are designed to provide efficient and durable solutions for air quality management in various professional settings.

HWArobotics unveiled its shuttle automated storage and retrieval systems (ASrS) at MODEX 2024, aiming to expand its North American customer base. The company showcased four key product lines, including tote and pallet shuttles, emphasizing reliability, efficiency, and customization for diverse industry sectors. With over 20 years of experience, HWArobotics' systems boast system availability of over 99%, showcasing high-quality components from European suppliers. The Sl S300, Sl S400, and Sl S600 tote shuttles alongside the Fp SS1500 pallet shuttle, demonstrate HWArobotics' commitment to innovative warehousing and logistics solutions, aiming to enhance competitiveness with their shuttle ASrS technology.

Jamco America announces its comprehensive testing capabilities for the aerospace, automotive, space, defense, and marine industries, serving as an FAA-accepted dynamic test facility. The facility is equipped to test mechanical, static load,

fire, ballistic, and environmental properties. With expertise in evaluating products throughout the design cycle, Jamco America supports a range of tests from passenger seats to galleys and more. As an FAA Organization Designation Authorization (ODA) Office, Jamco also provides consultations for FAA certification tests. Their materials testing lab is ideal for early design phase evaluations, equipped with advanced technology for detailed data generation and analysis, including fire properties, acoustic, static load, ballistic, and lifecycle testing.

Kawasaki robotics partners with Olis robotics for

Kawasaki robotics collaborates with Olis robotics to introduce remote monitoring and error recovery capabilities for industrial robots, aiming to minimize unplanned downtime. This partnership allows customers to restart production faster, significantly reduce downtime costs, and access expert support swiftly. The integrated solution, showcased at MODEX 2024, demonstrates a Kawasaki rS007l robot equipped with Olis' software, enabling remote error recovery. This collaboration promises a transformative impact on the market, offering secure connections without

cloud dependencies and ensuring safety compliance with robot controller restrictions.

Mitsubishi Electric Automation's loadMate plus™ revolutionizes Tl Aerotek's production Tl Aerotek, a milling shop, leveraged Mitsubishi Electric Automation's loadMate plus™ machine tending solution to meet growing demand, tripling output. The solution, integrated with an existing Mitsubishi Electric M8 Series CNC, automates material loading and unloading, allowing 24-hour unattended operation. This plug-and-play system, featuring an rV20 six-axis robot arm, demonstrates Mitsubishi Electric's commitment to support, performance, and reliability, significantly enhancing Tl Aerotek's productivity and efficiency.

OMrON announces the launch of its mid-range autonomous mobile robots, the MD-650 and MD-900, integrated with rOEQ's lifter and roller modules, targeting the U.S. and Canada. These solutions, equipped with