PORTFOLIO SOFIA FERRAZZI

The italian industrial revolution most strongly impacted the Northern and Central areas of the nation, leading d to a transformation of the Italian landscape with the construction of industrial poles with their tall brick chimneys, large steel warehouses, and railway and canal connections appearing throughout the territory. By 1911 Italy was the seventh industrial country in the world. What followed is the transition from a industry based economy and society to the favouring of tertiary sector growth known as deindustrialization. This lead to the abandonment of many industrial systems and the decline of said areas into industrial archeologies. The sites which have remained abandoned without being repurposed to welcome new functions are exposed to many vulnerability factors as their neglect on behalf of the community continues.

Industrial sites fascinate me in their ability to suspend time, lending themselves well to a reflection on the historical stratification and the memory of industrialization, growth and decline which envelops these areas. The projects collected in this portfolio were developed within ex-industrial sites in Lombardy. The use of colour and of material is crucial in defining each project and in creating a dialogue between the historical and cultural layers intrinsic in our territory.

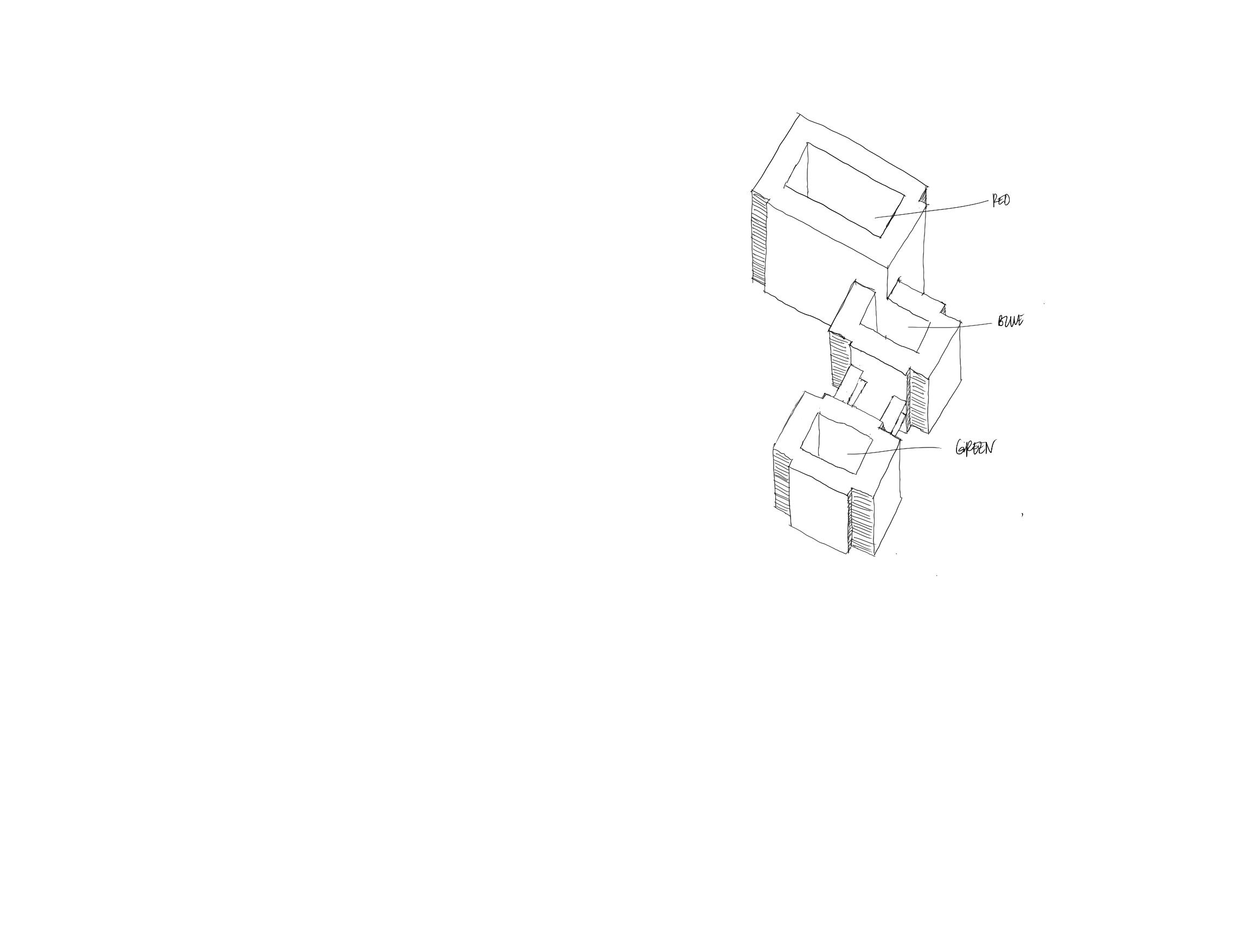

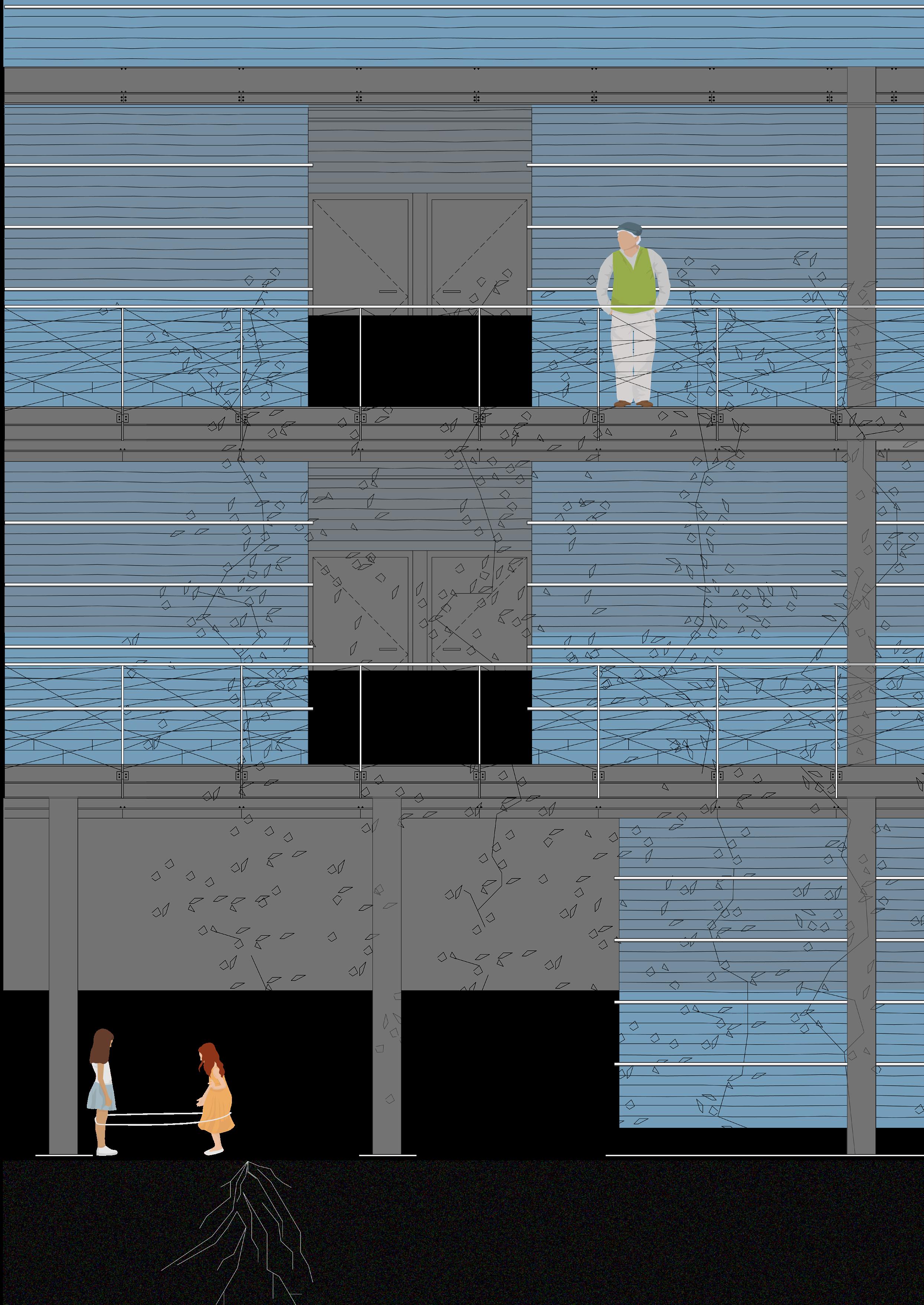

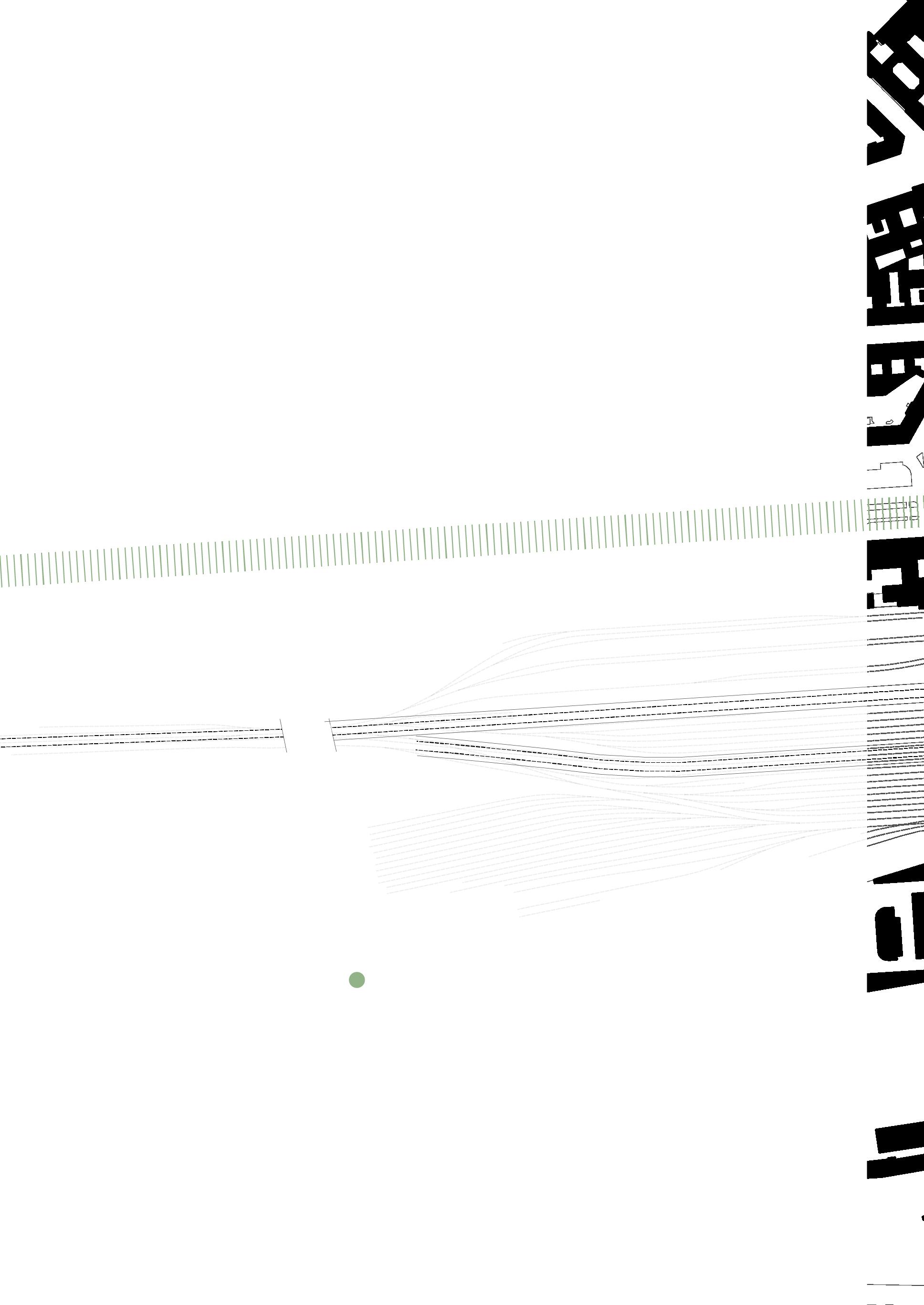

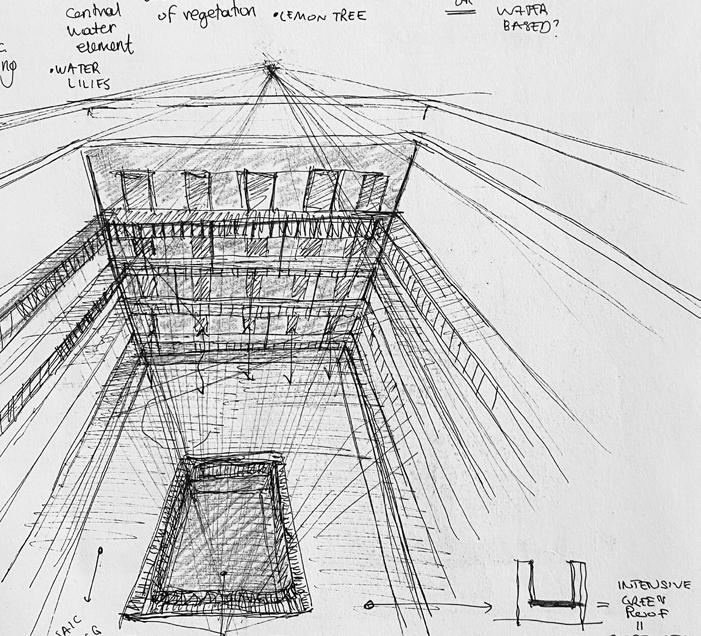

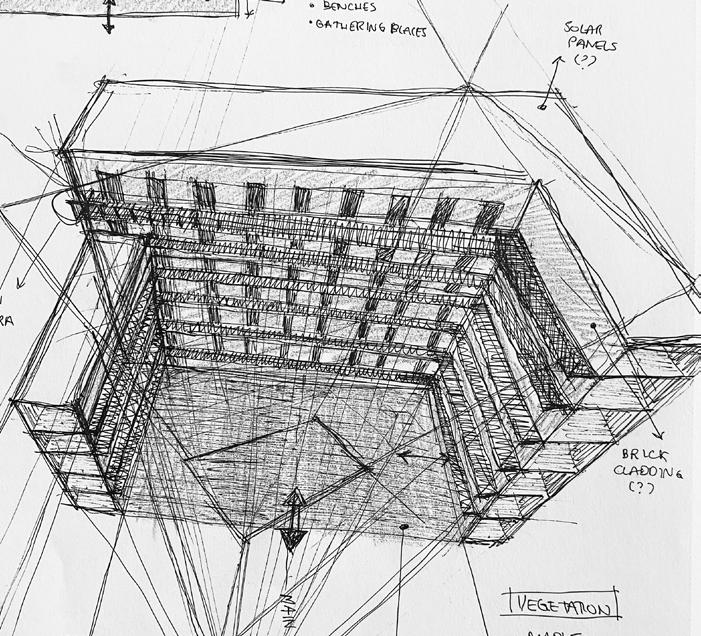

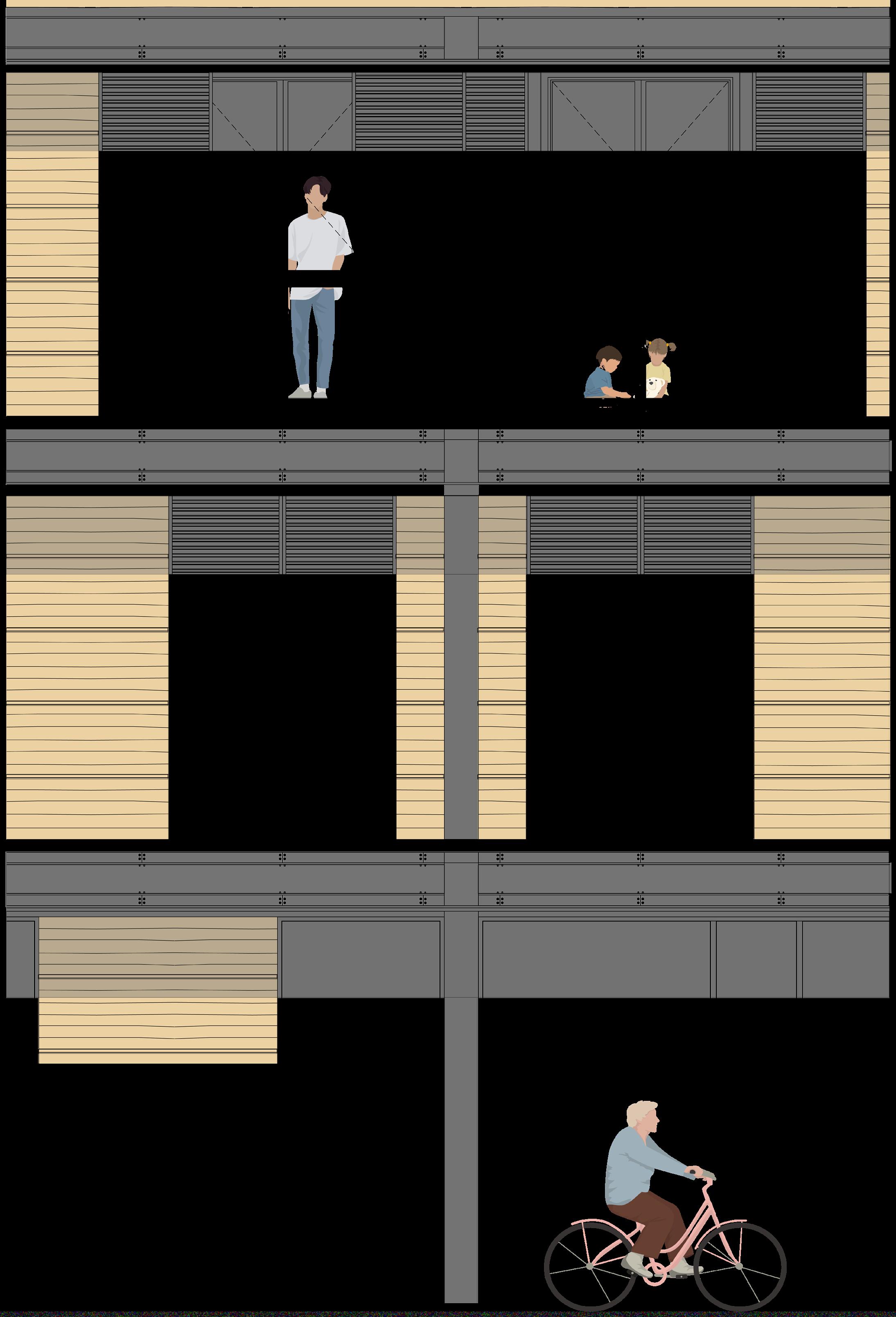

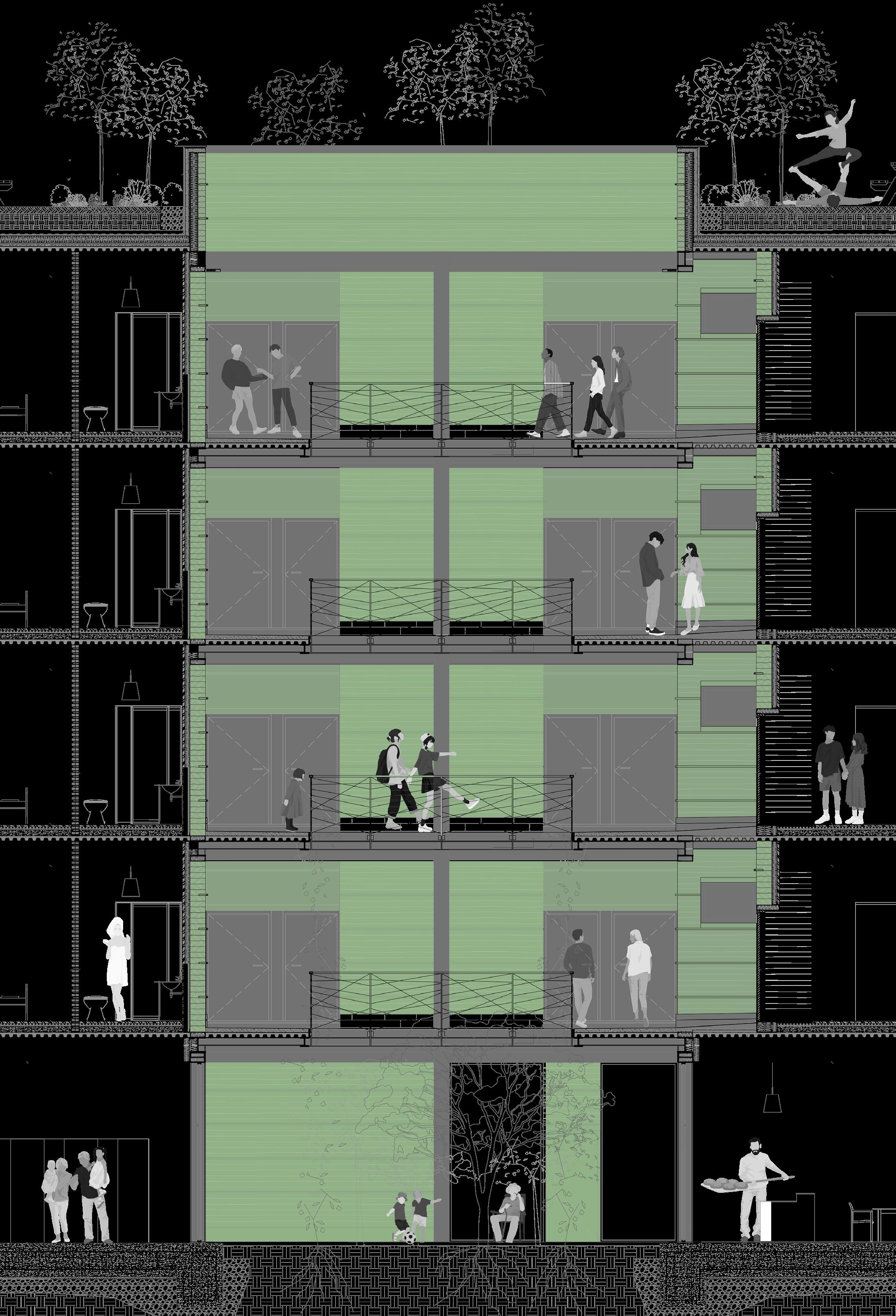

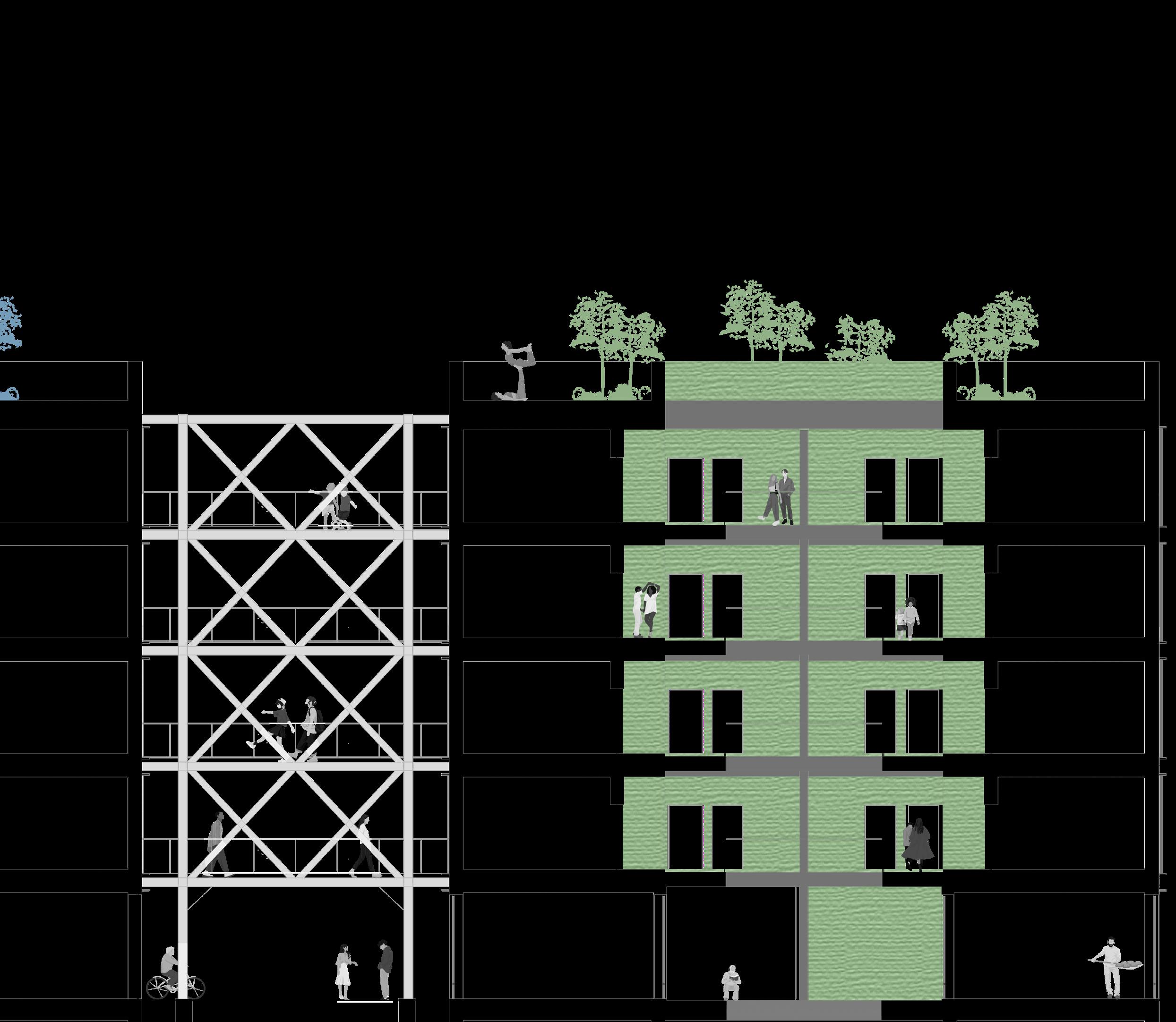

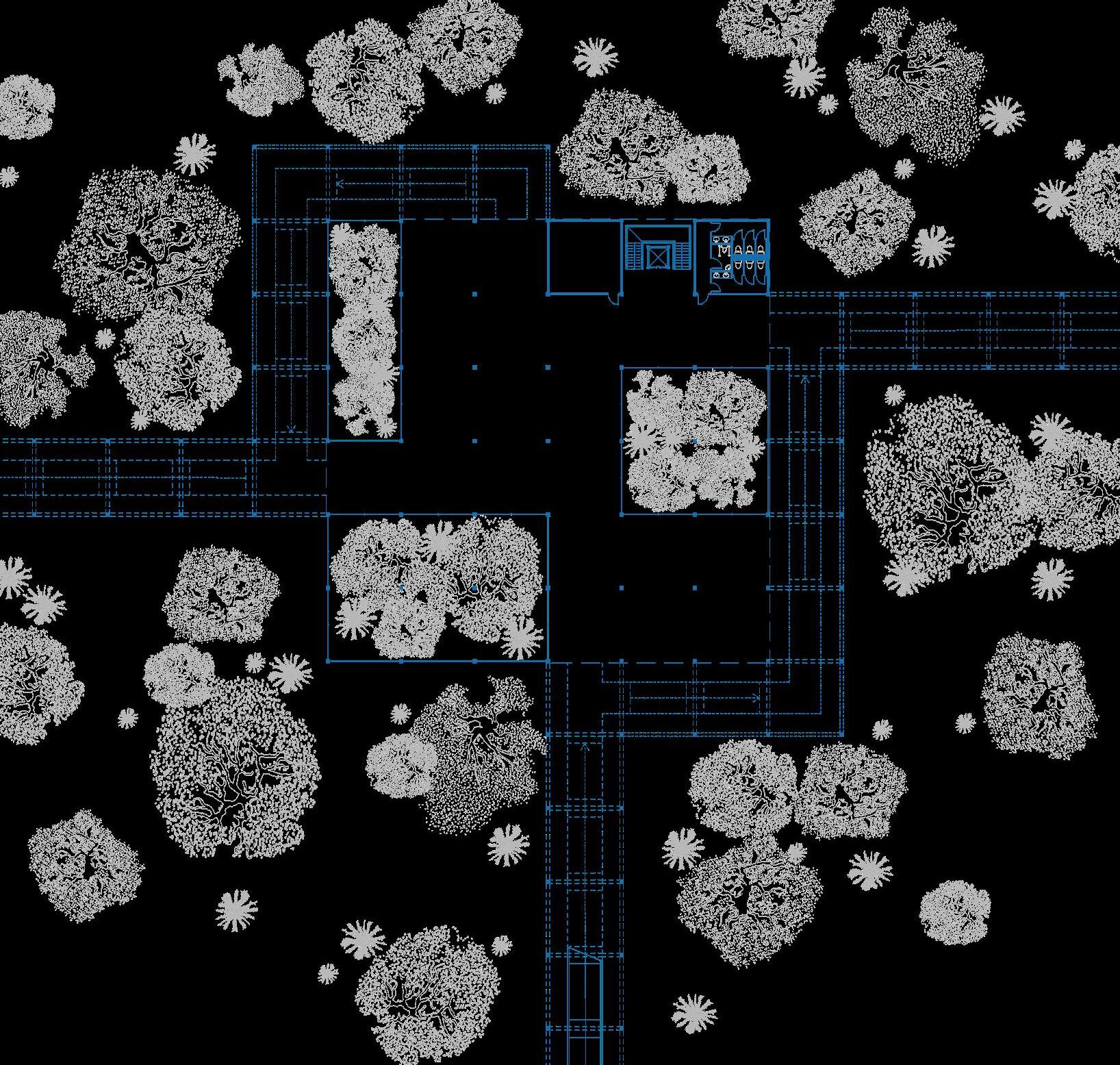

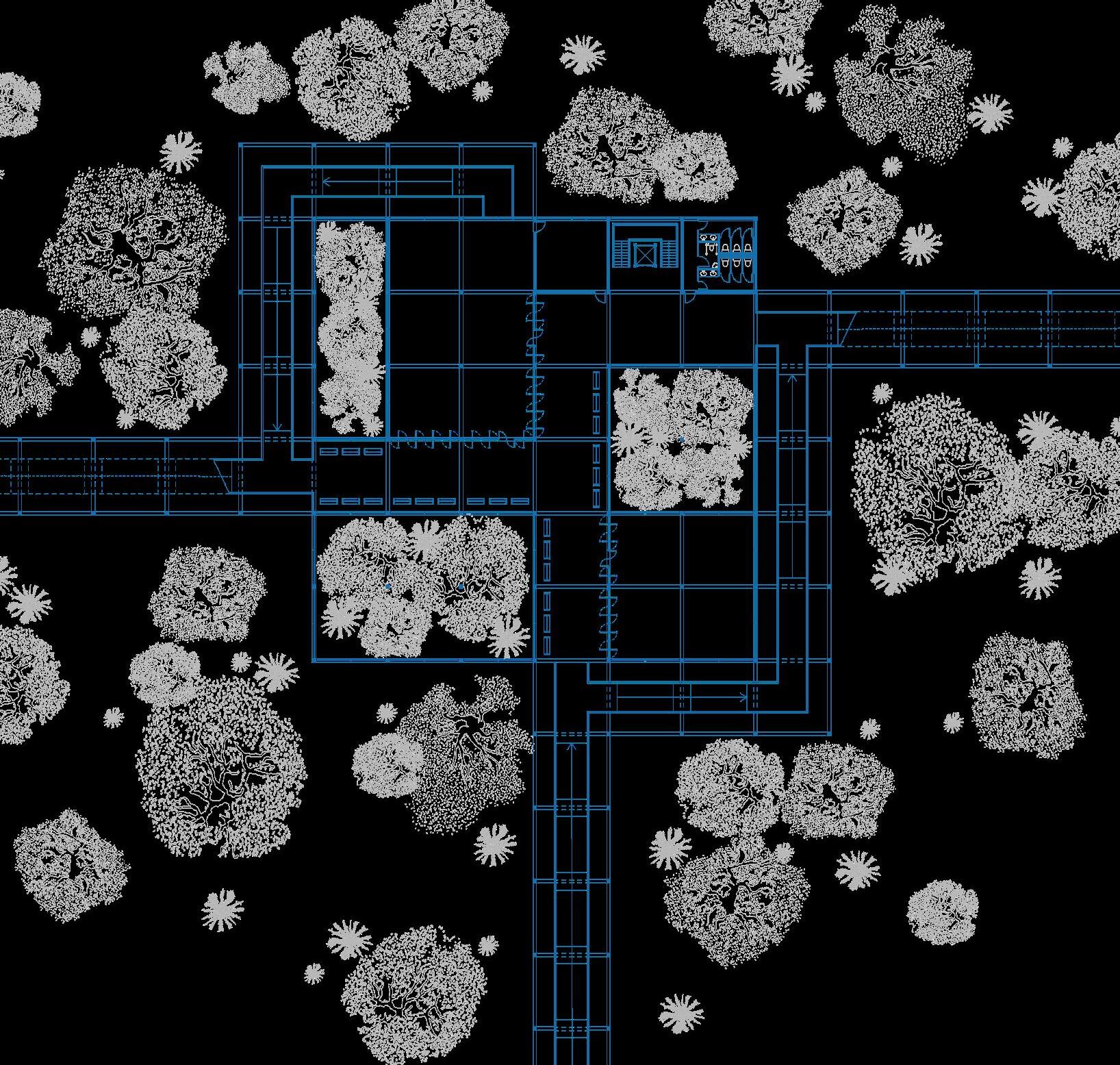

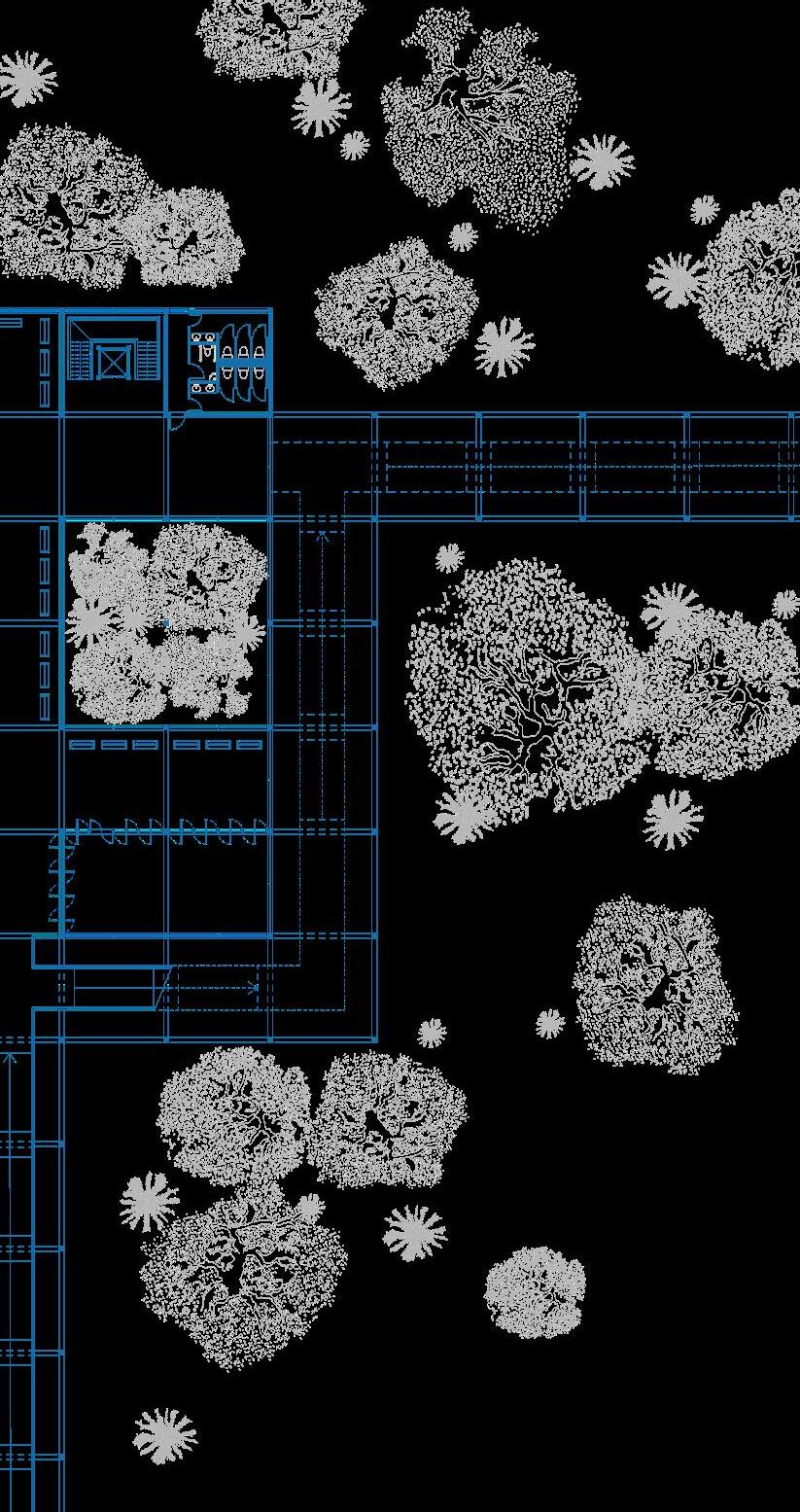

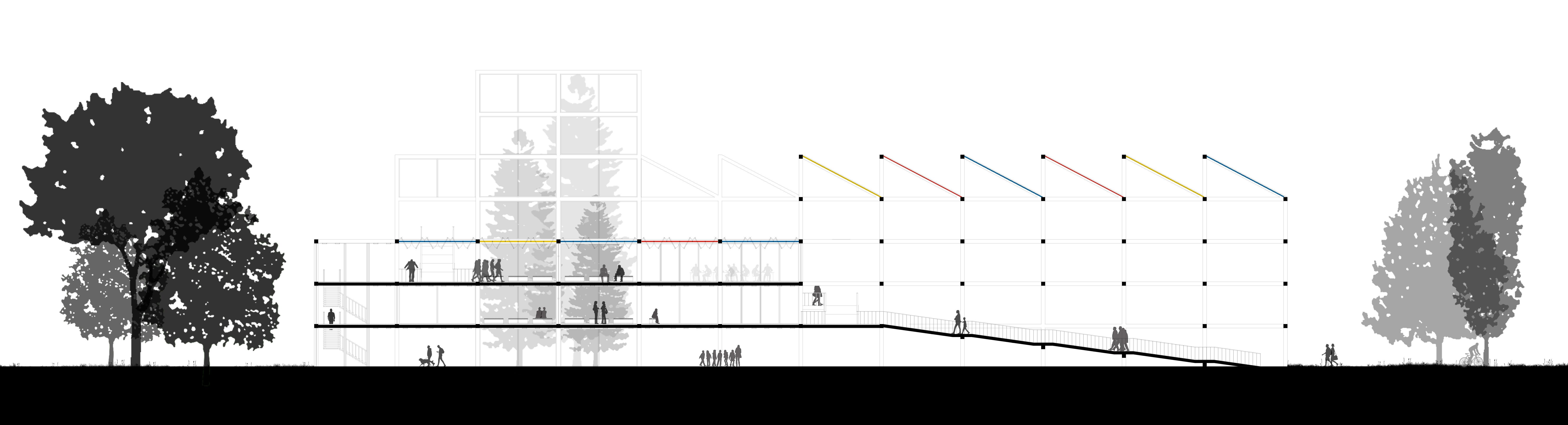

Milan is set to host the 2026 Winter Olympics: for the event the “Scalo Romano” railway junction will become site of the Olympic Village, transformed after 2026 into a student residence. The project concentrates on a part of the large plot, developing three residential buildings with public functions on the glazed ground floor open to a portion of the Olympic Piazza. The Milanese “Casa a Ringhiera” typology was selected for its intrinsic qualities of both privacy and community building with the idea that athletes and, in a second moment students, would collect in the central courtyards. Each residential floor is characterized by different room typologies, with corners fitting vertical connections and a shared kitchen. In the exterior, a sliding shading system was developed to create a dynamic facade controlled by the inhabitants themselves. The materiality was equally important in defining the project. The use of rammed earth, with its insulative properties, opened the possibility of using coloured pigment to define the three different cores (red, blue and green) reinforced with specific choice of vegetation for each, while its natural colour was left in all facades.

The site is highly connected with public transport, two entrances were placed in accordance to a bus stop in Via Isonzo and the metro stop in Piazza Lodi. These determine the main longitudinal circulation, whilst a secondary route crosses the plot perpendicularly. Distribution of greenery and building height was set by the desire to shield inhabitants and the central square from the high-traffic Via Isonzo, north of the site, and open to the requalified southern plot and Fondazione Prada.

The local typology: the “casa di ringhiera”.Developed during the urbanization of the second industrial revolution, characterized by a central courtyard vertically surrounded by open air circulation routes is adopted for the project for its connotations of community and privacy essential for olympic athletes and, later, the students that will inhabit the residential complex.

Scalo Romano

Via Isonzo

Scalo Romano

Via Isonzo

on this page (top down):

Ground Floor Plan

Residential Type Floor Plan

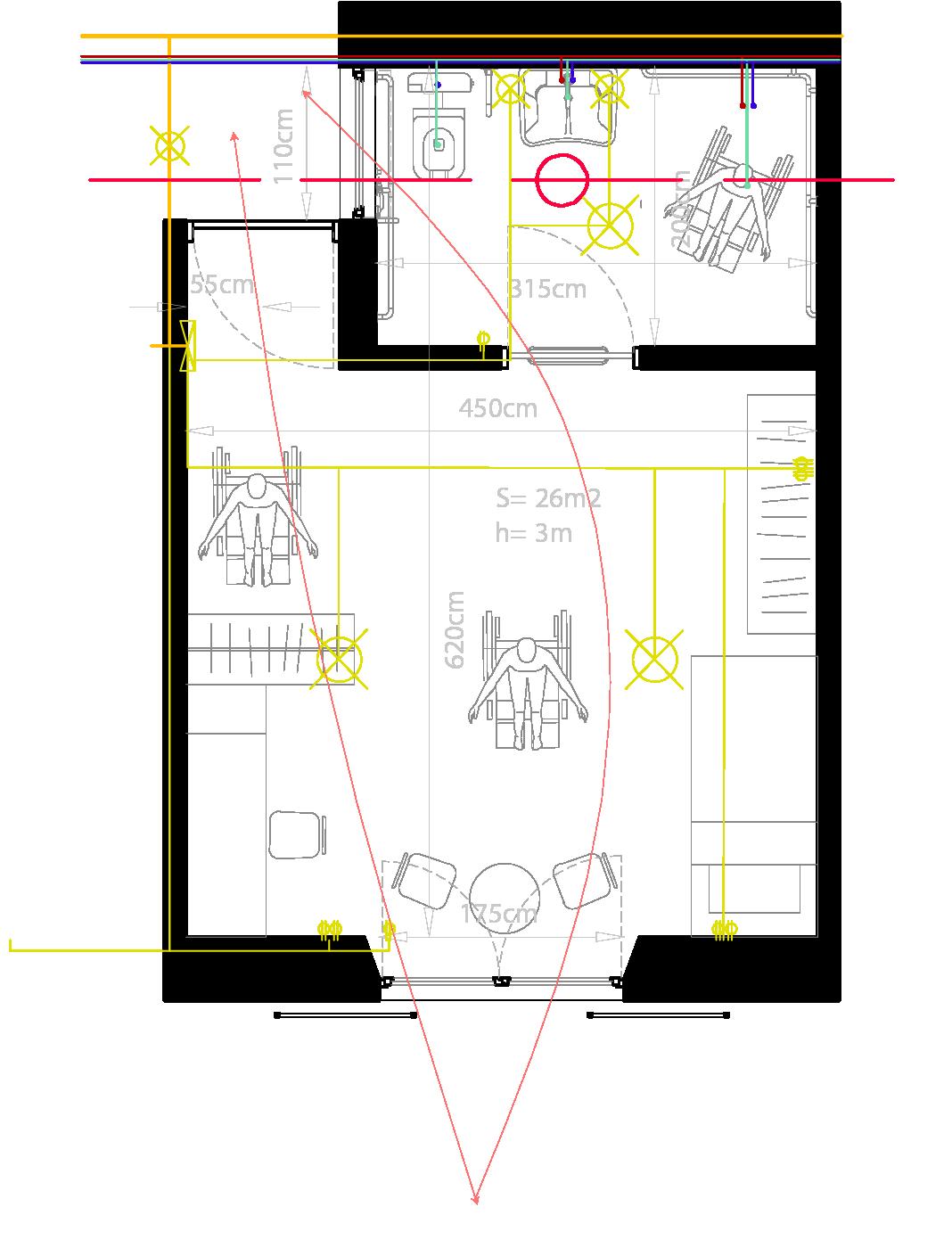

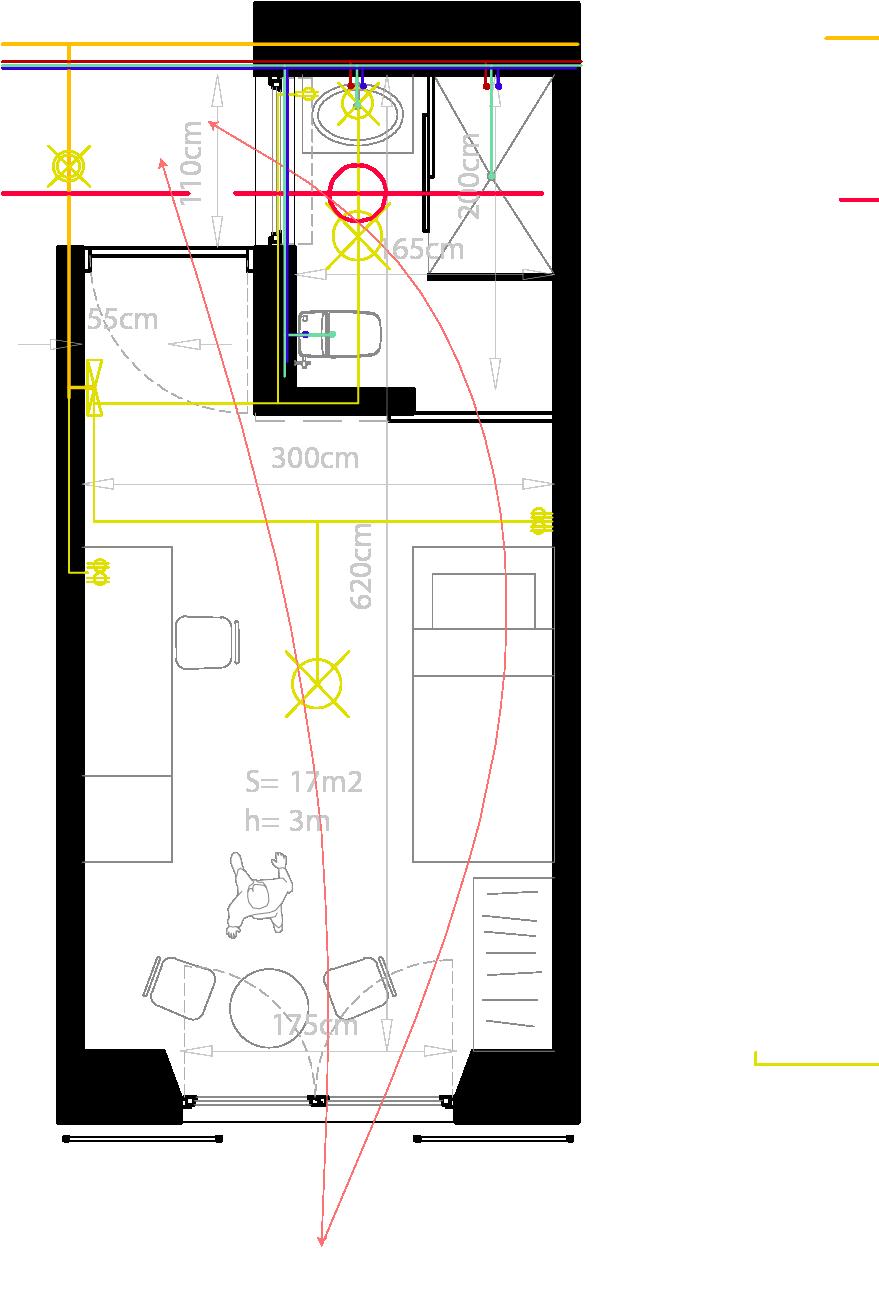

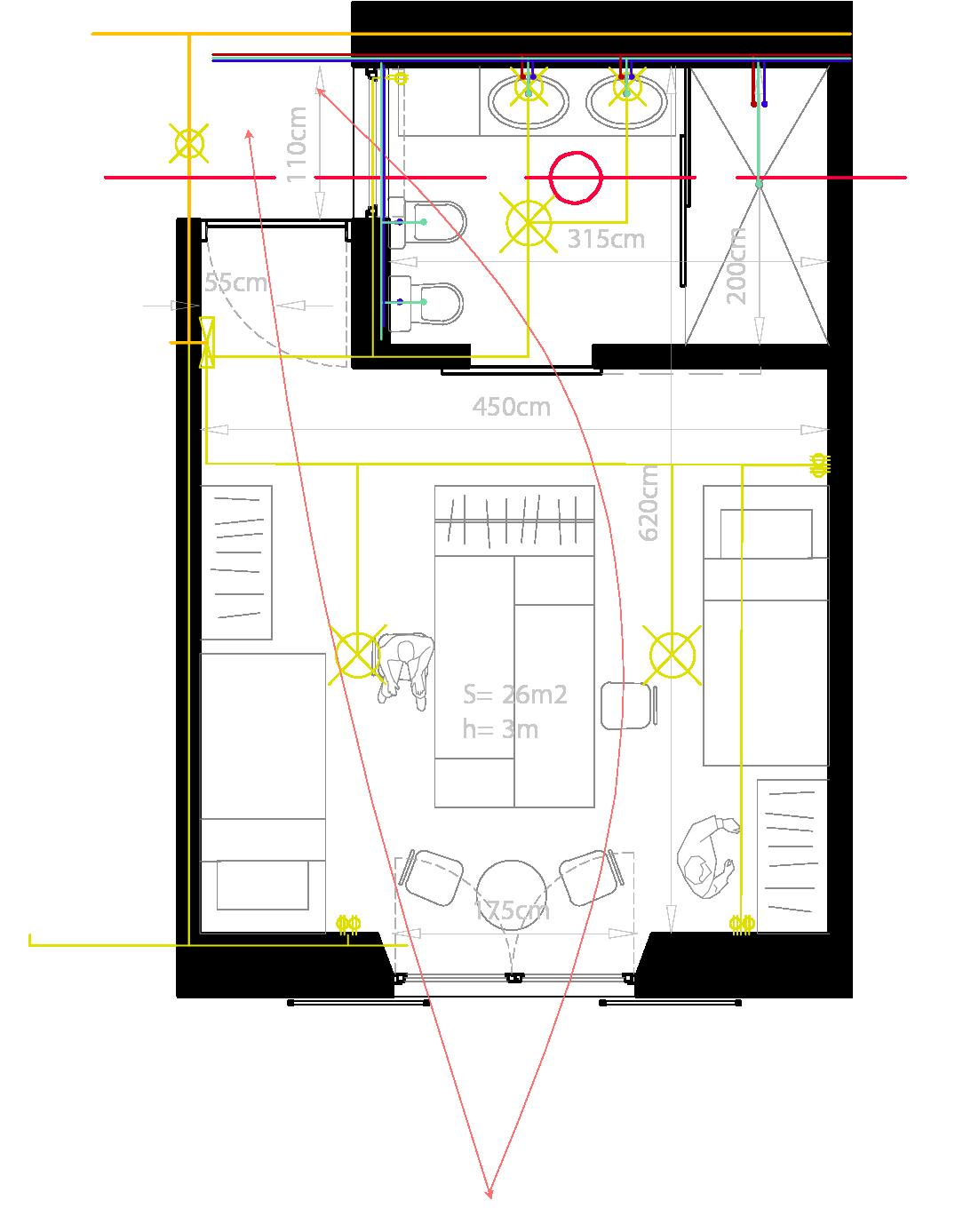

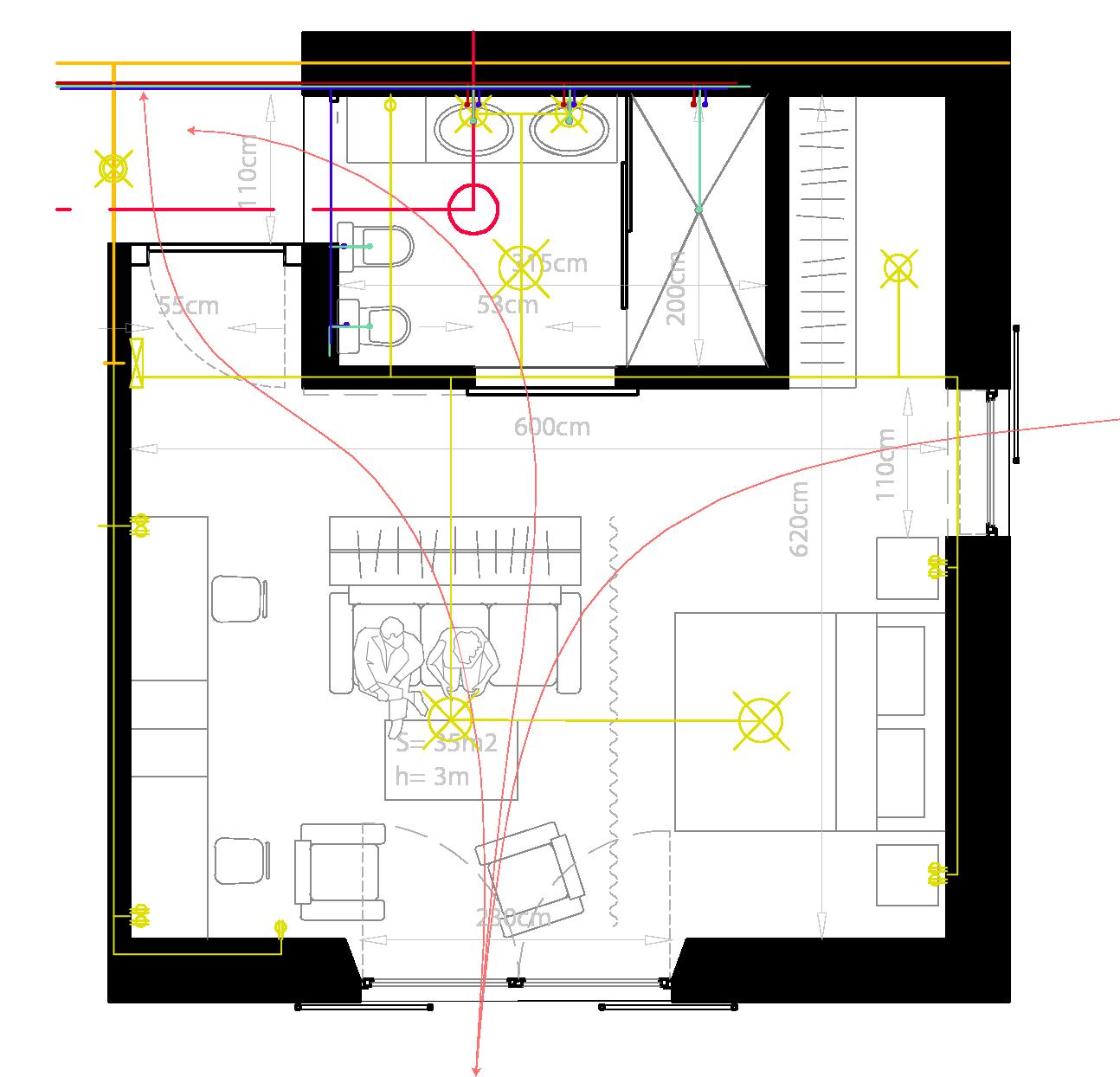

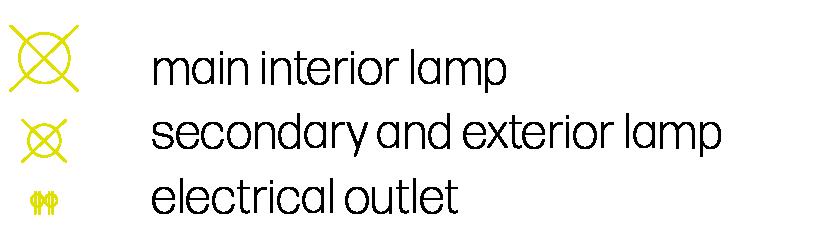

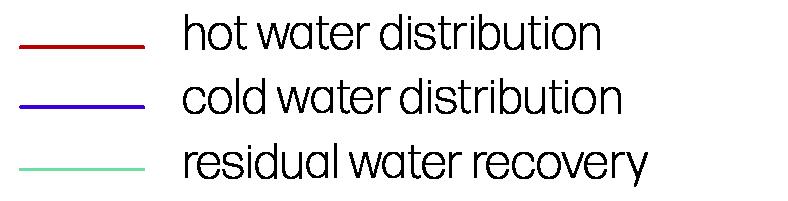

opposite: Floor Plans of Room Types with electrical, ventilation and water systems

Single | Couple

Double | Disabled Accessible

on this page: East Elevation

on next pages: Facade / Courtyard Details

1.ConcreteScreed20mm

2.ConcretePerimeterpavingtoprotect edgesoftheraftfromweatheringand frost100mm

3.ConcreteRaftwithreinforcement runninginbothdirections

4.DampProofMembrane30mm

5.Concretebindingcreatingalevel

Intensive green roof

1. Rooflite intensive 130mm

2. Rooflite intensive base 320mm

3. Filter layer

4. Drainage layer

5. Geotextile protection

6. Root resistant

7. Waterproof membrane

8. Insulation layer

9. Vapor barrier

10. Screed to falls

11. Structure: concrete slab, corrugated sheet and HEB 300 beam

Massive wall

1. Clayboard finition Eco Building Boards + KEIM Ecosil-ME surface finish highly abrasion-resistant 1100x625x22mm

2. Rammed earth inner wythe (for closing the steel frame structure, support of technical shafts) 35mm

3. Acoustic insulation 5mm

4. XPS thermal rigid insulation 5mm

5. Rammed earth outer wythe in layers 300mm

6. Brick erosion checks with integrated weather moulding (each 6 layers)175mm protruding 45mm

7. HEB 300 primary beam 300X300mm (11mm and 19mm)

Floor

1. Ceramic tile Otto 800x800x9mm

2. Rammed earth screed including heating system 100mm

3. Ashlar isolating panel PaviPlus and radiant floor 58mm- 30mm

4. Heating pipe

5. Supporting fold 1mm

6. Cement screed with canalizations for systems

7. Concrete subfloor

8. Corrugated sheet: SAND A55, Sandrini metalli, 750mm long

9. HEB 160 secondary beam 160X160mm (8mm and 13mm)

10. HEB 300 primary beam 300X300mm (11mm and 19mm)

Massiverammedearthwallandbalconyelevation Avibratingeffectoftheretreatedroomentrancesinacontinuedlayered textureoftherammedearth

11. Plaster ceiling Casoprano Casobianca, 600x600x8mm

Fixed window triple tickness

1. Insulated steel box as support

2/3. Fixed steel window frame and skrews

4. Neoprene of protection of glass

5. Triple glass layer

6. Air interstice for better thermal insulation

Balustradedetail:

1.Woodenhandrail60x30mm

2. Verticalsteelbar1400x20x20mmand cables

3. Verticalplate1mmand4metal screwstofixittothestructure

4.EnclosingCsteelelement17mmhigh, 1mmthickfixedtothereceptionbeam

Fixedwindowtripletickness:

1.Insulatedsteelboxassupport

2.Fixedsteelwindowframe

3.Fixationscrews

4.Neopreneofprotectionofglass

5. Tripleglasslayer

6.Airintersticeforbetterthermal insulation

Massiverammedearthwallandbalconysection Scale:1/20

1.Clayfinish+KEIMRoyalan®-Grob surfacefinish(silicatemineralcoat)

2.Rammedearthscreedin1%slope apourbarrier10mmandbrickcheck

6.Corrugatedsheet:SANDA55,Sandrini metalli,750mmand500mmlong

7.HEB160canteleeveredsecondary beam160X160mm(8mmand13mm)

8.HEB180receptionbeam180X180mm

Foundation

1.ConcreteScreed20mm

2.ConcretePerimeterpavingtoprotect edgesoftheraftfromweatheringand frost100mm

3.ConcreteRaftwithreinforcement runninginbothdirections

4.DampProofMembrane30mm

5.Concretebindingcreatingalevel platformandsealingtheraft50mm

6.Gravel 7.Earth

Balustradedetail:

1.Woodenhandrail60x30mm

2. Verticalsteelbar1400x20x20mmand cables

3. Verticalplate1mmand4metal screwstofixittothestructure

4.EnclosingCsteelelement17mmhigh, 1mmthickfixedtothereceptionbeam

eMassiv lstee dan dramme

Accessible / non-accessible extensive green roof

1. Rooflite intensive 150mm

2. Filter layer

3. Drainage layer

4. Geotextile protection

5. Root resistant

6. Waterproof membrane

7. Insulation layer

8. Vapor barrier

9. Screed to falls

10. Structure: concrete slab, corrugated sheet, HEB 300

Balcony Floor

1. Clay finish + KEIM Royalan®-Grob surface finish (silicate mineral coat) 5mm

2. Rammed earth screed in 1% slope 70mm

3. Supporting fold 5mm

4. Vapour barrier 10mm and brick check for wall foot protection

5. Concrete subfloor

6. Corrugated sheet: SAND A55, Sandrini metalli, 750mm and 500mm long

eMassiv lstee dan dramme

Massiverammedearthwallandbalconyelevation Avibratingeffectoftheretreatedroomentrancesinacontinuedlayered textureoftherammedearth

7. HEB 160 canteleevered secondary beam 160X160mm (8mm and 13mm)

8. HEB 180 reception beam 180X180mm (8.5mm and 14mm)

Balustrade Detail

1. Wooden handrail 60x30mm

2. Vertical steel bar 1400x20x20mm and cables

3. Vertical plate 1mm and 4 metal screws to fix it to the structure

4. Enclosing C steel element 17mm high, 1mm thick fixed to the reception beam

Particulardetails Scale1/10

Fixedwindowtripletickness:

1.Insulatedsteelboxassupport

2.Fixedsteelwindowframe

3.Fixationscrews

1. Steel overhanging plate fixed with bolts to steel box and C profile

4.Neopreneofprotectionofglass

5. Tripleglasslayer

2. Insulated steel box fixed to HEB 300 beam

6.Airintersticeforbetterthermal insulation

3. 2 fixed rails to the overhanging

4. Sliding shutter

5. Wooden lamels

6. Steel sheet for rain flap

7. Steel overhanging plate fixed with bolts to steel box and C element

8. Insulated steel box fixed to HEB

9. Steel overhanging plate stabilized with small bolts to window bottom steel box

OlympicvillageinMilan

Technicaldetails:innercourtyardfacade

PolitecnicodiMilano 2022

Foundation

1. Concrete Screed 20mm

2. Concrete Perimeter paving to protect edges of the raft from weathering and frost 100mm

3. Concrete Raft with reinforcement running in both directions

4. Damp Proof Membrane 30mm

5. Concrete binding creating a level platform and sealing the raft 50mm

6. Gravel

7. Earth

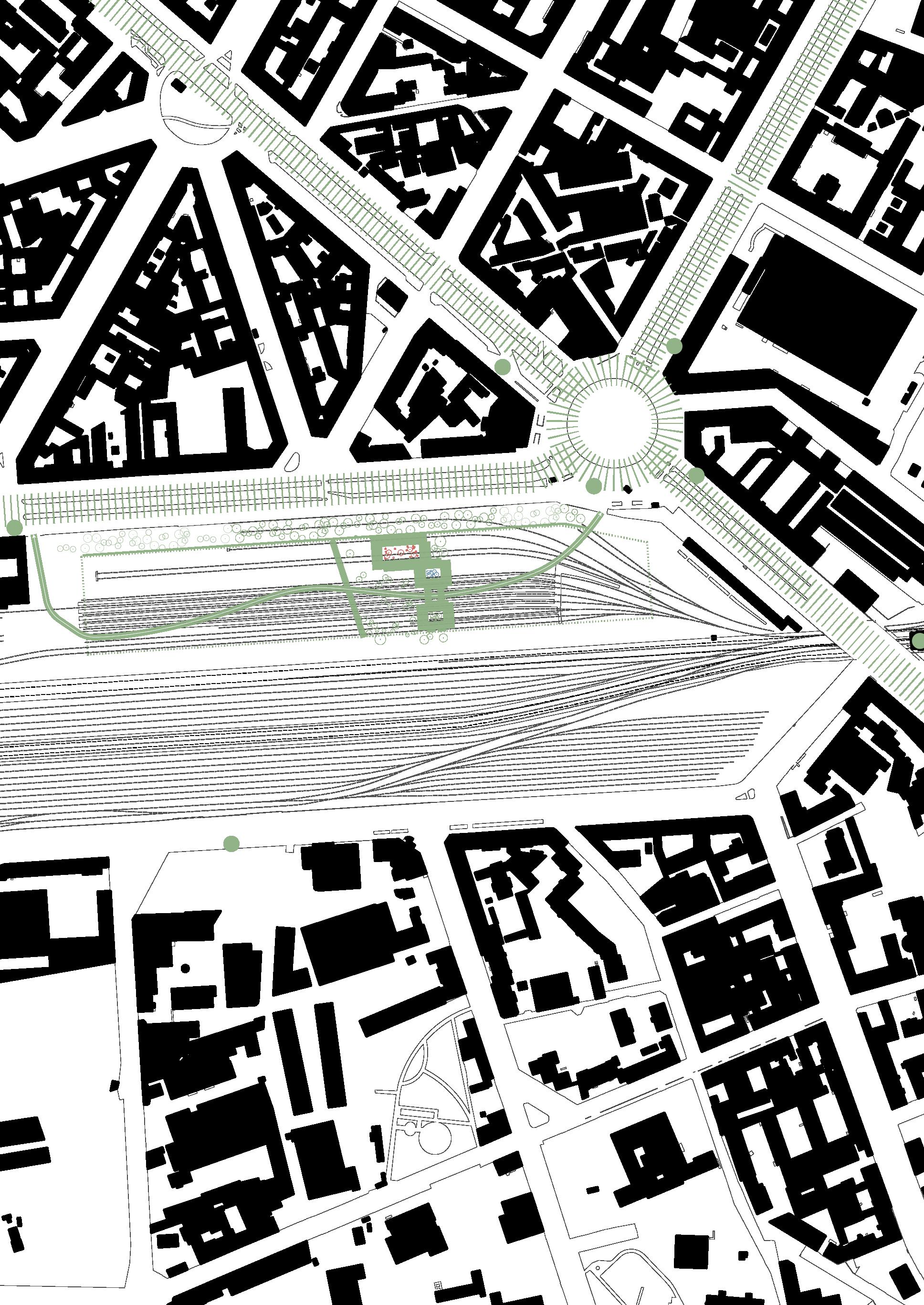

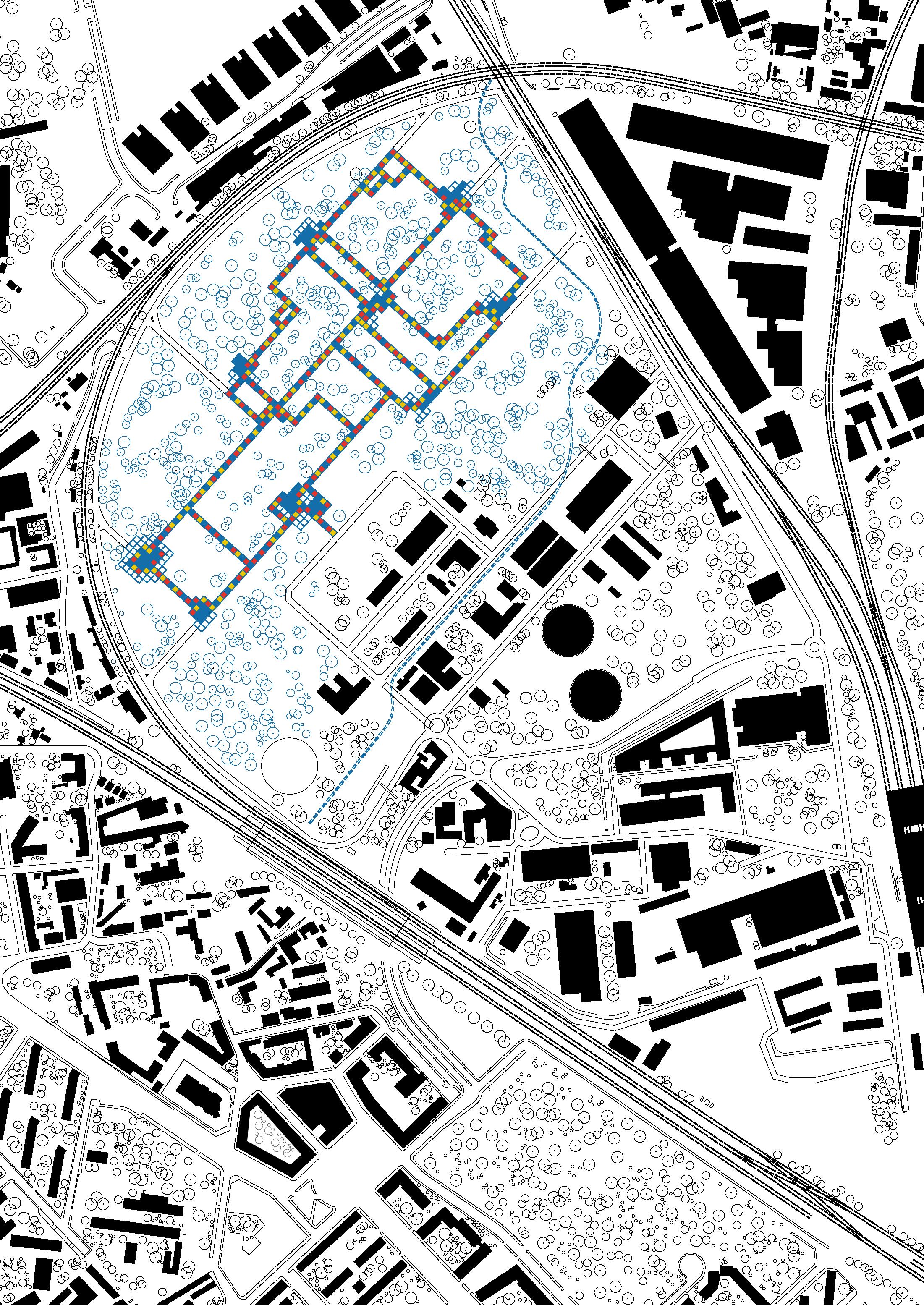

La Goccia di Bovisa, MI

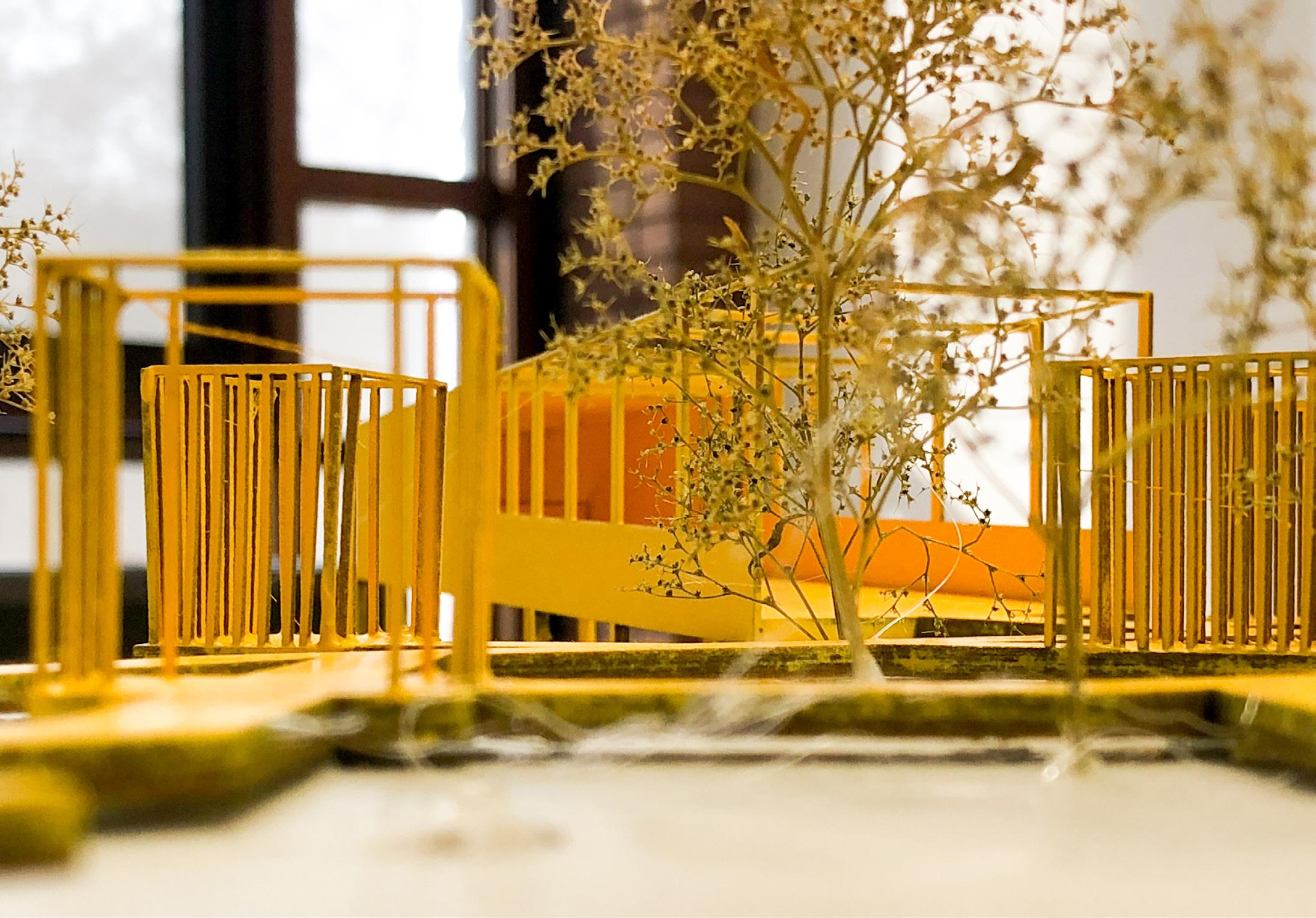

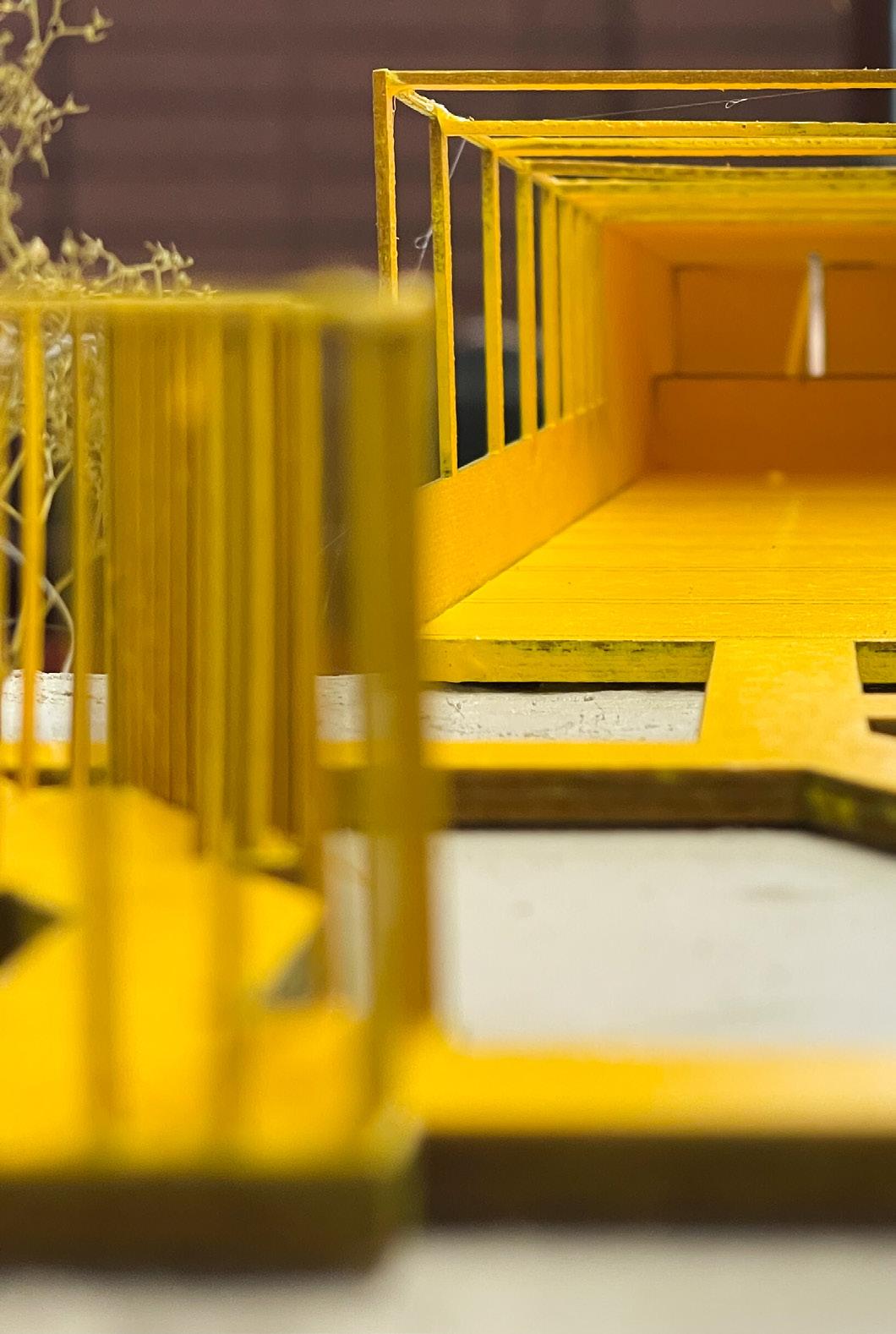

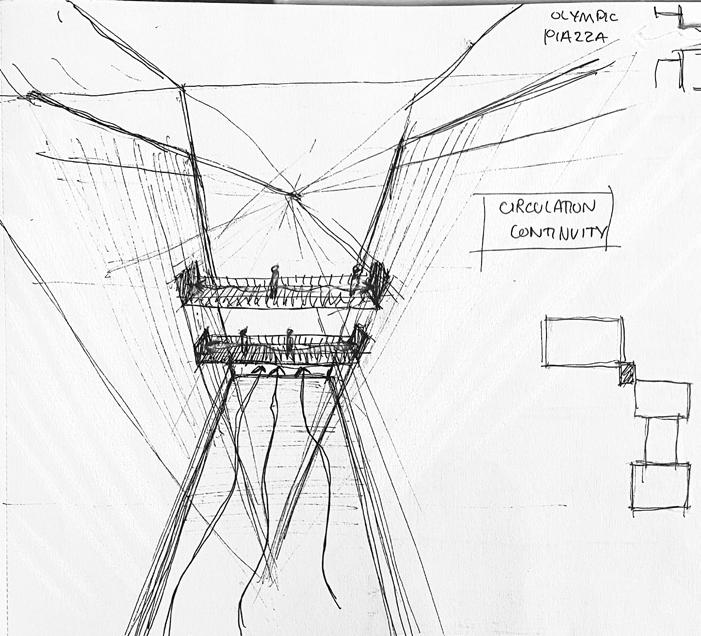

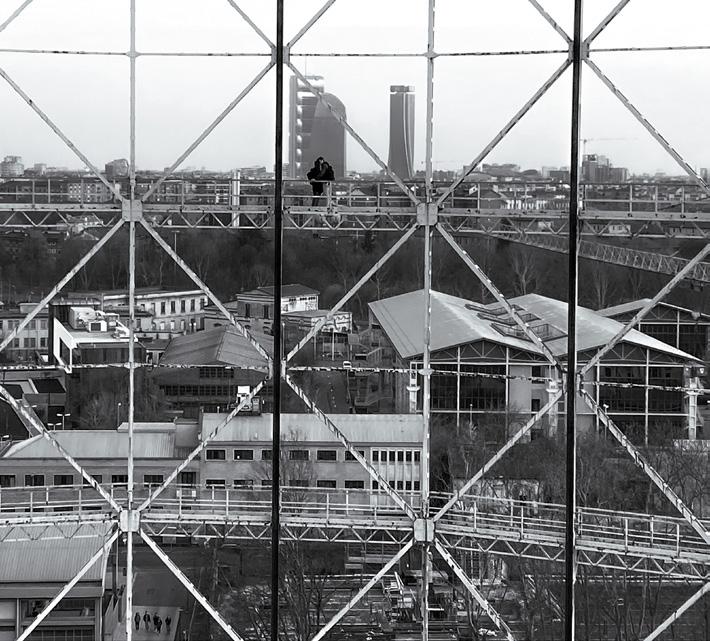

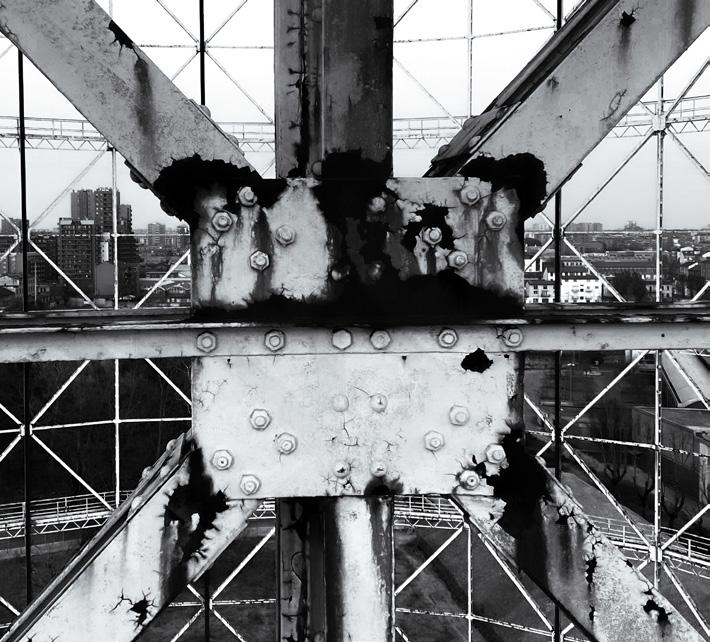

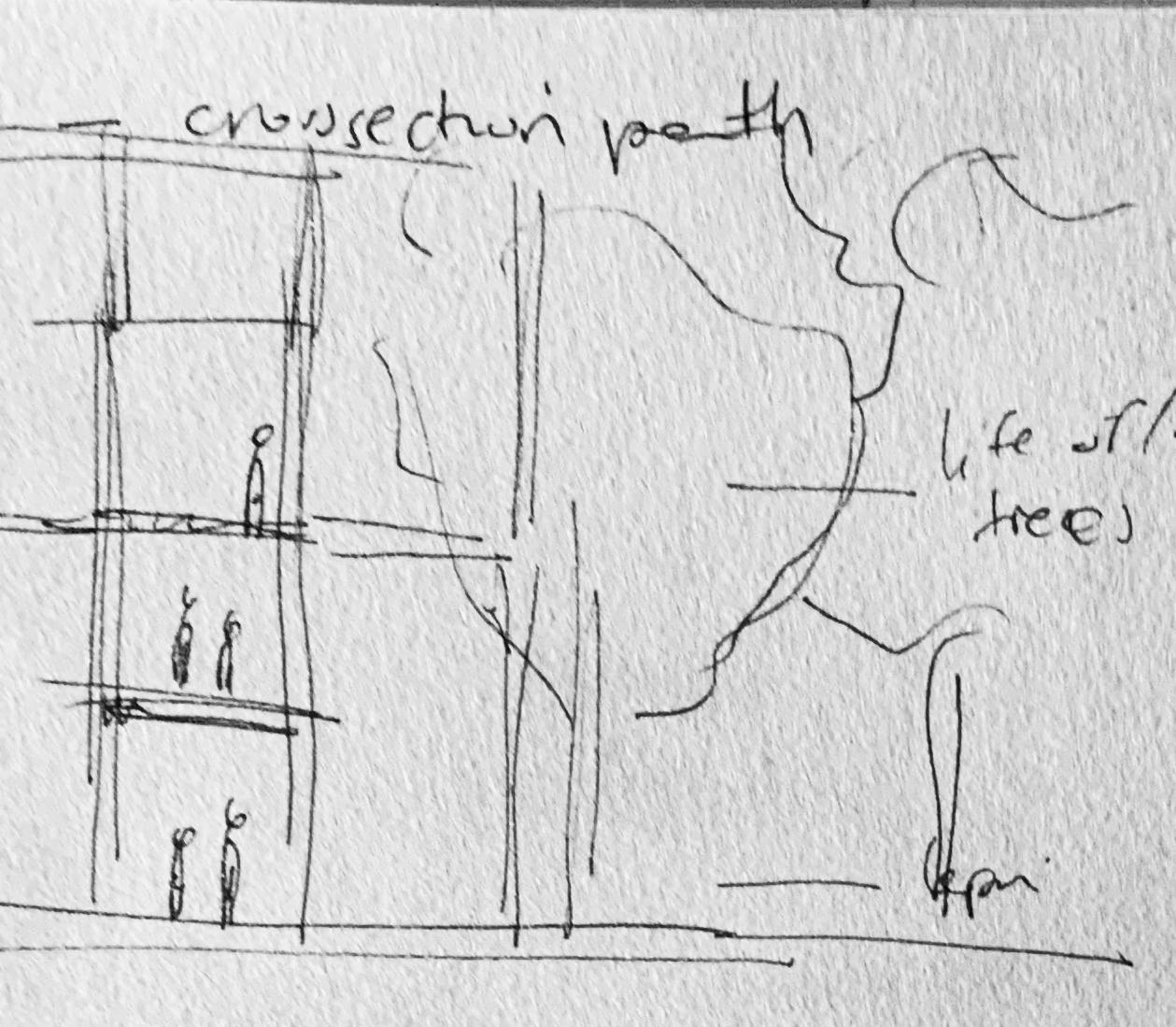

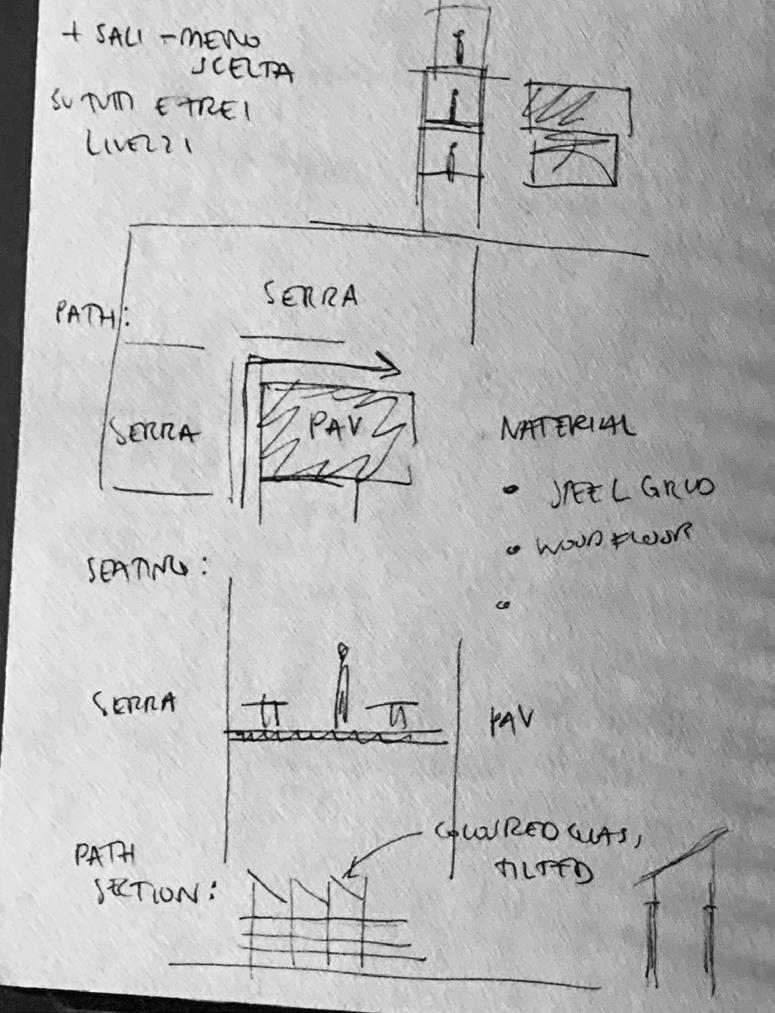

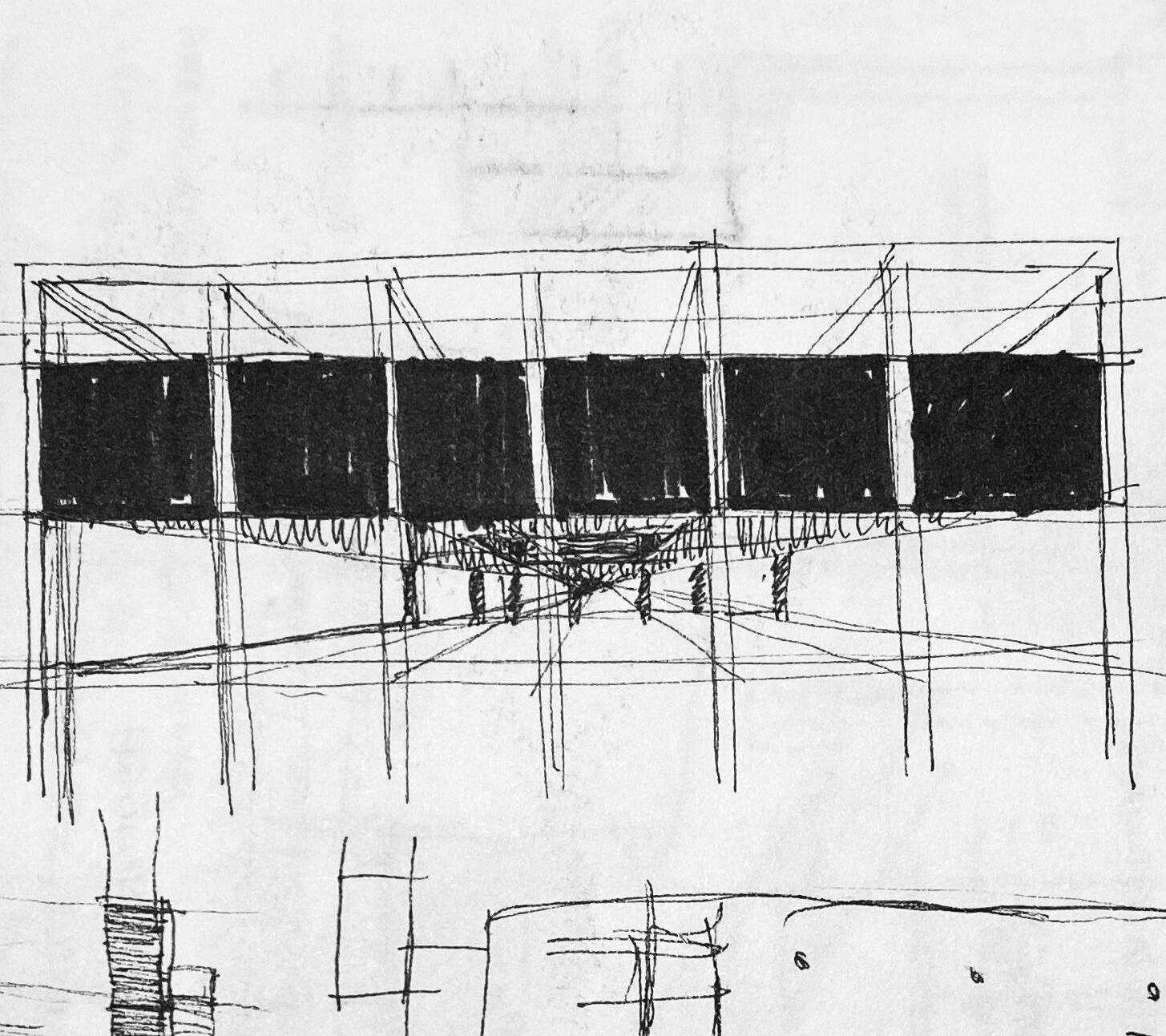

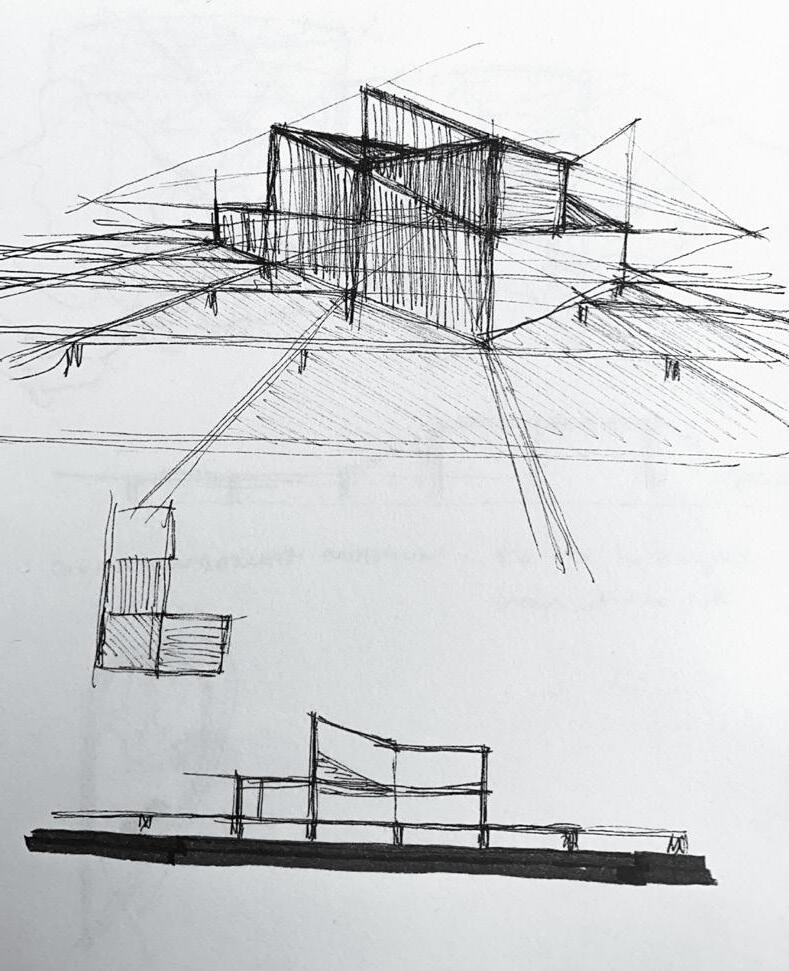

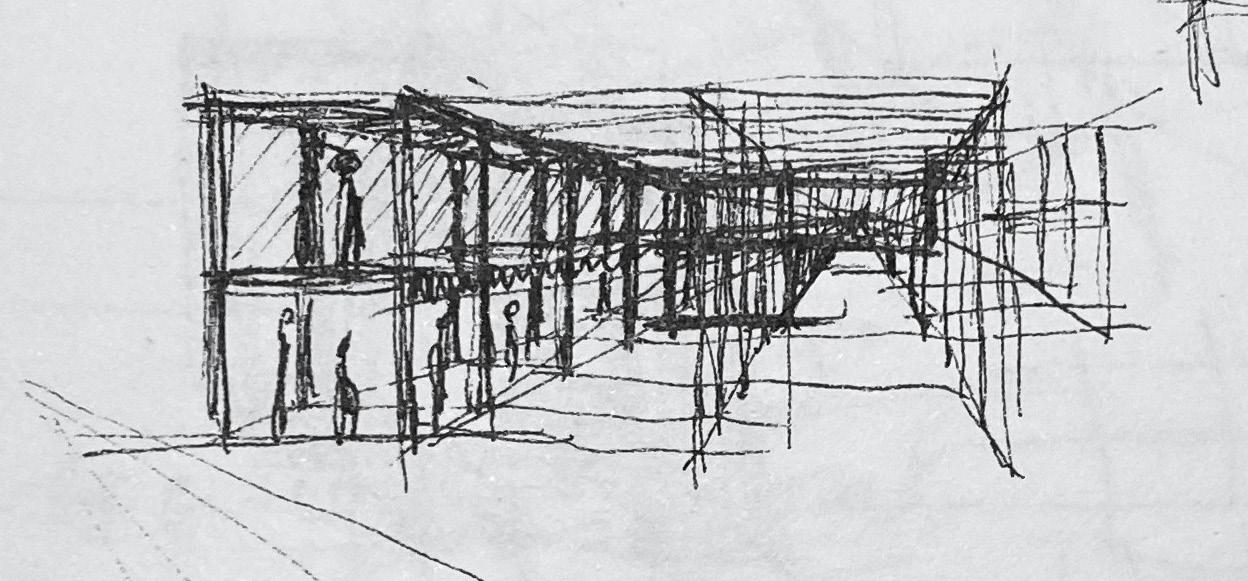

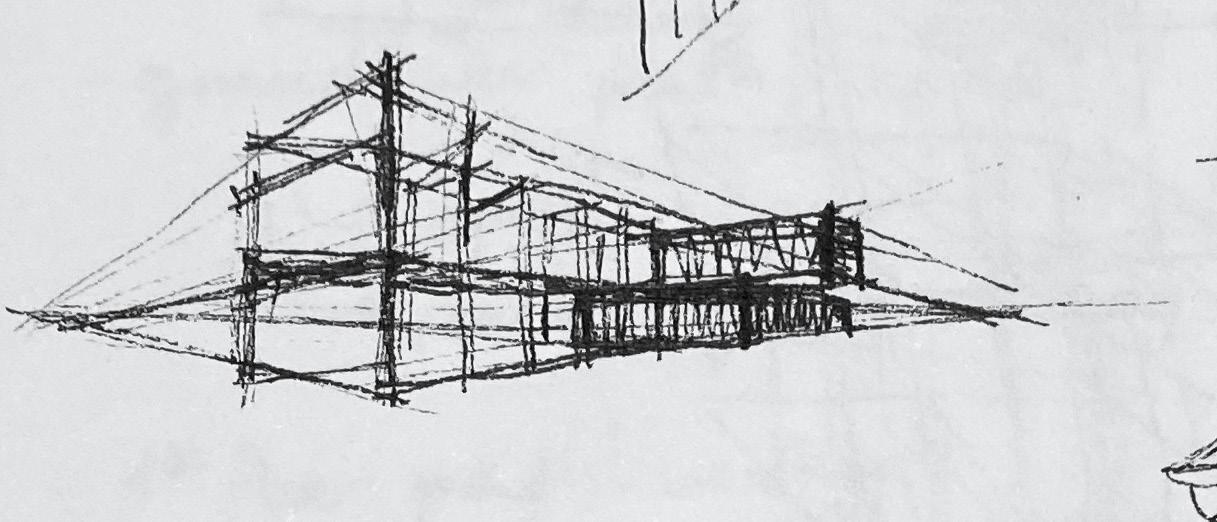

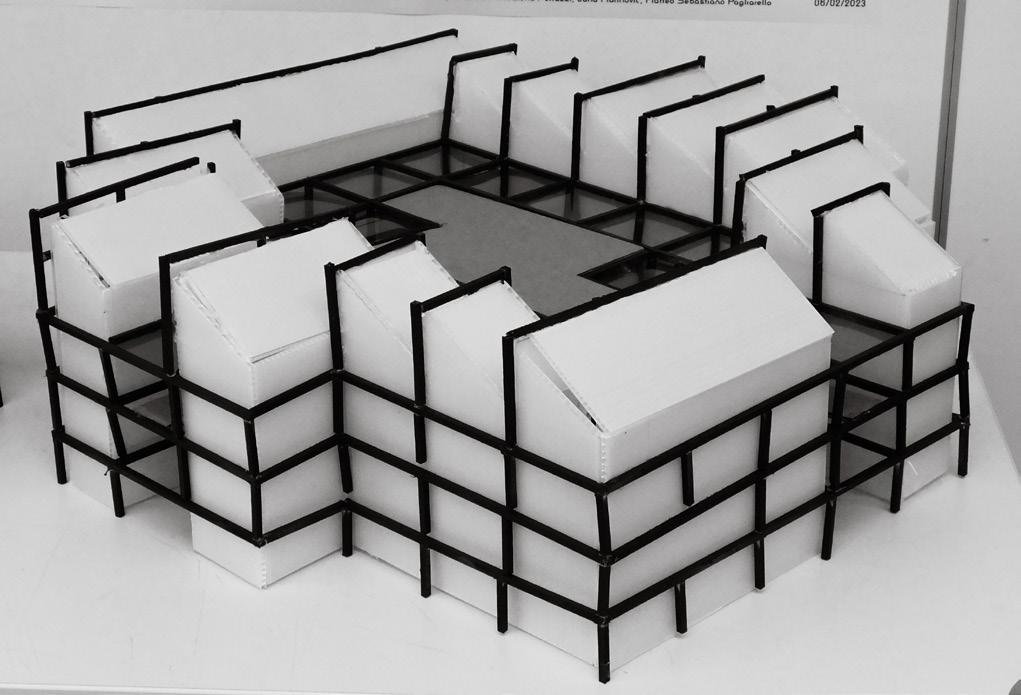

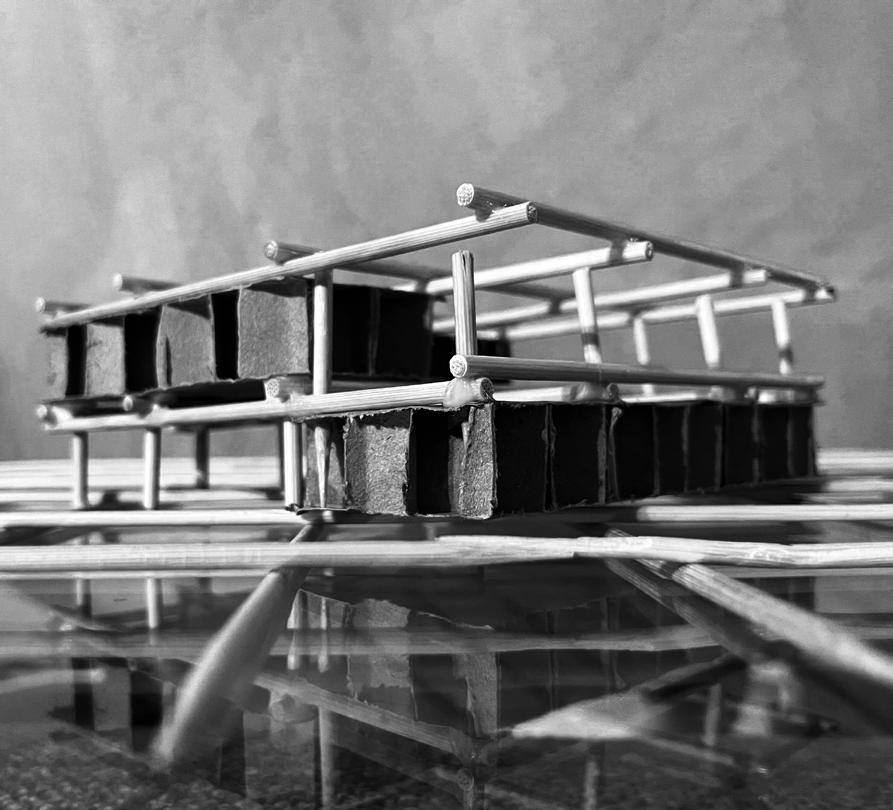

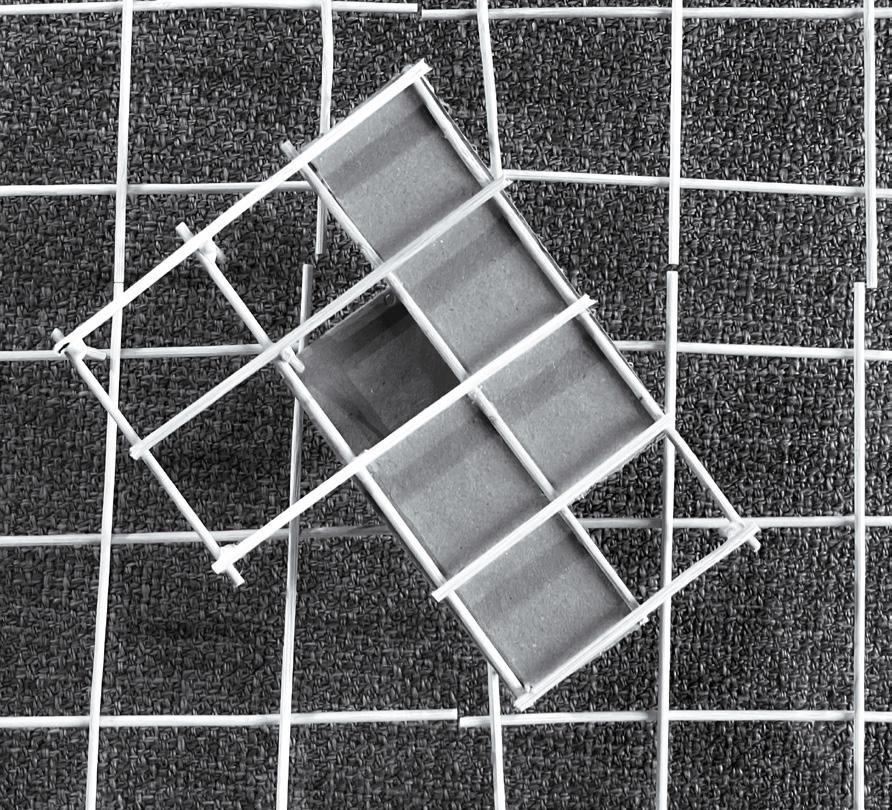

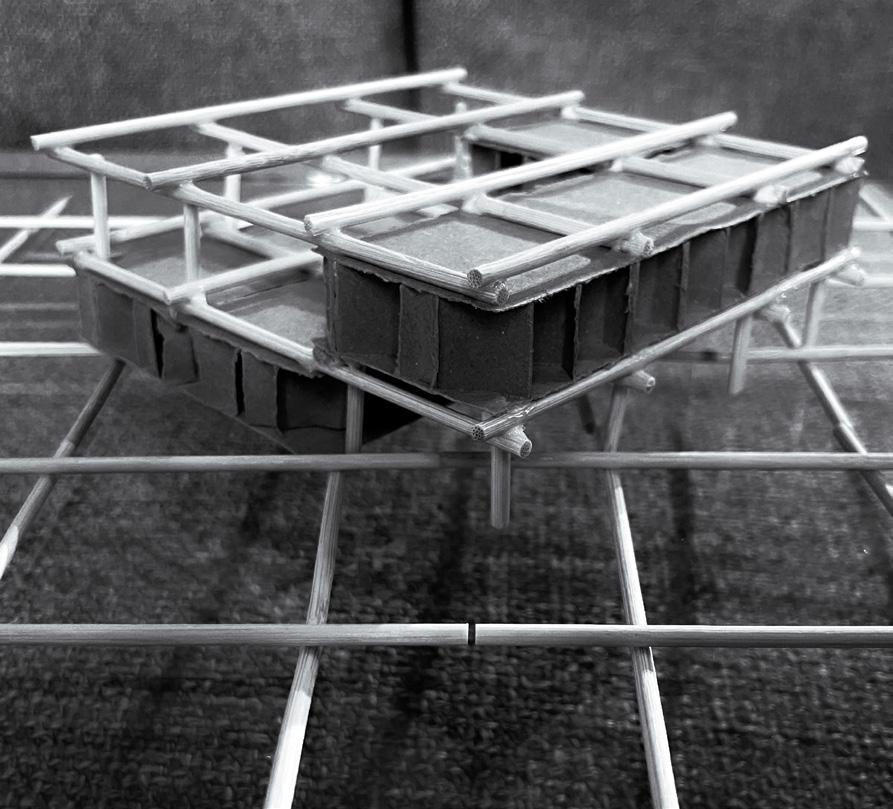

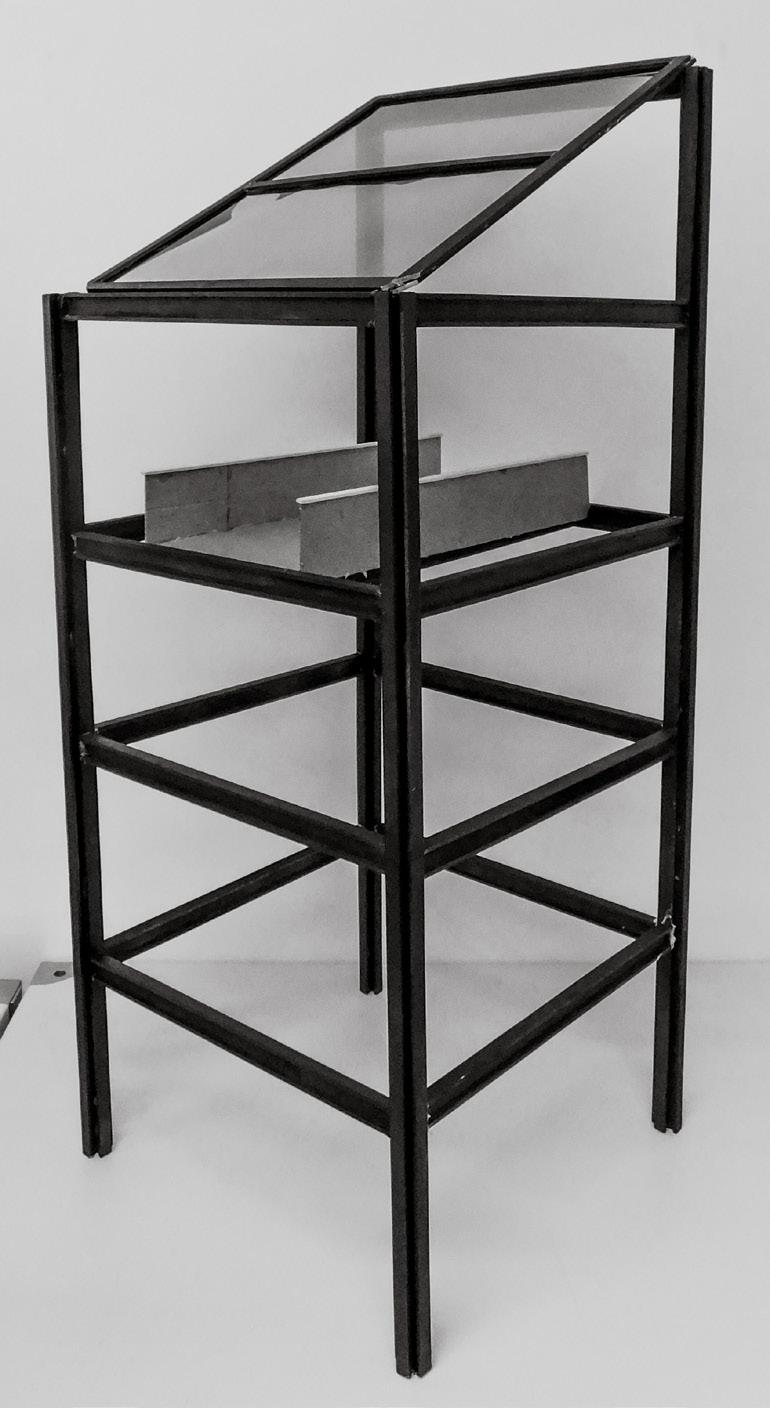

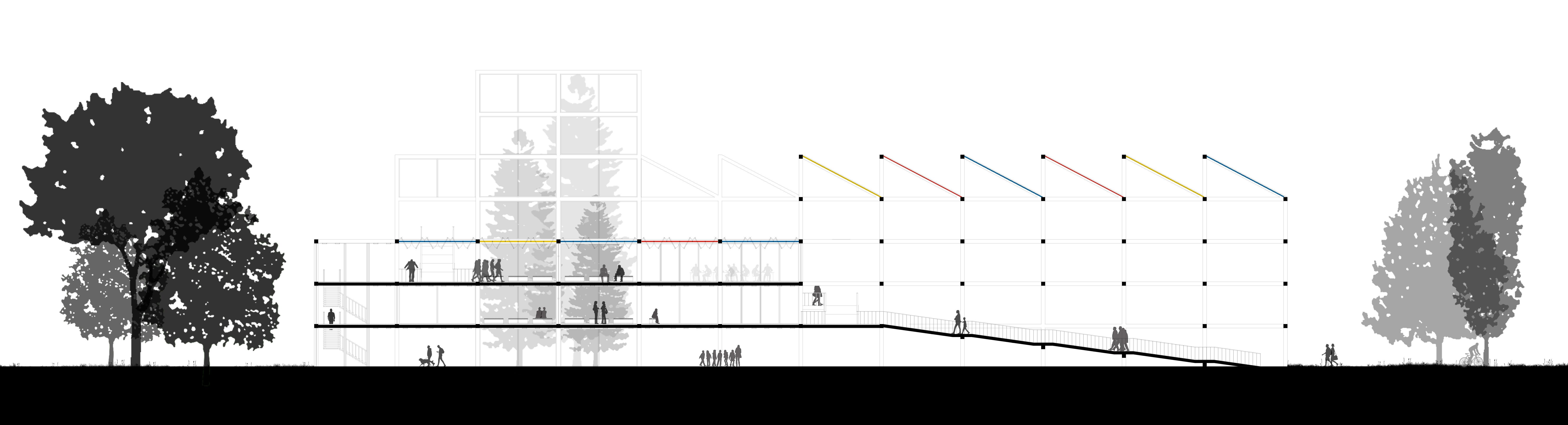

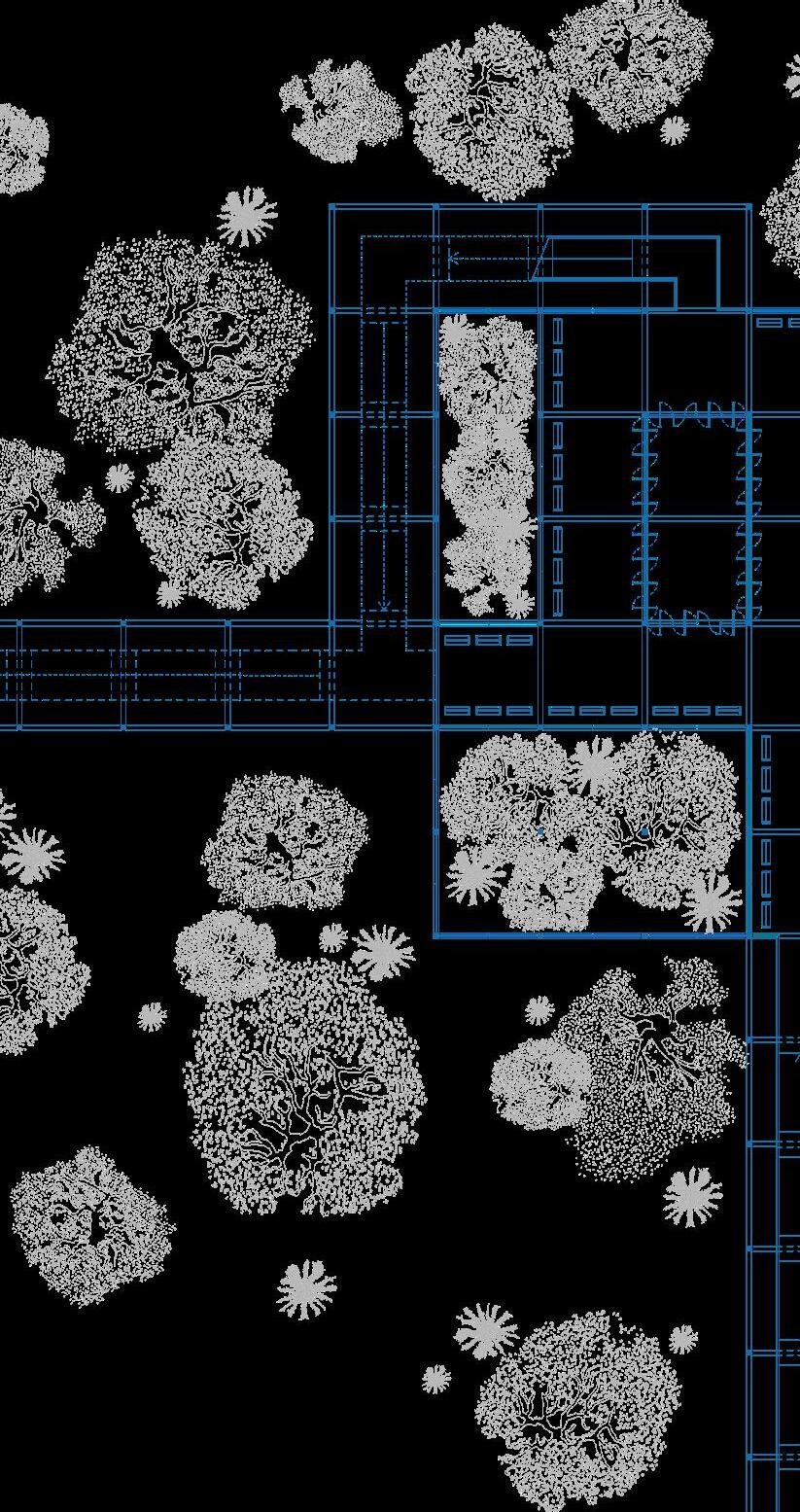

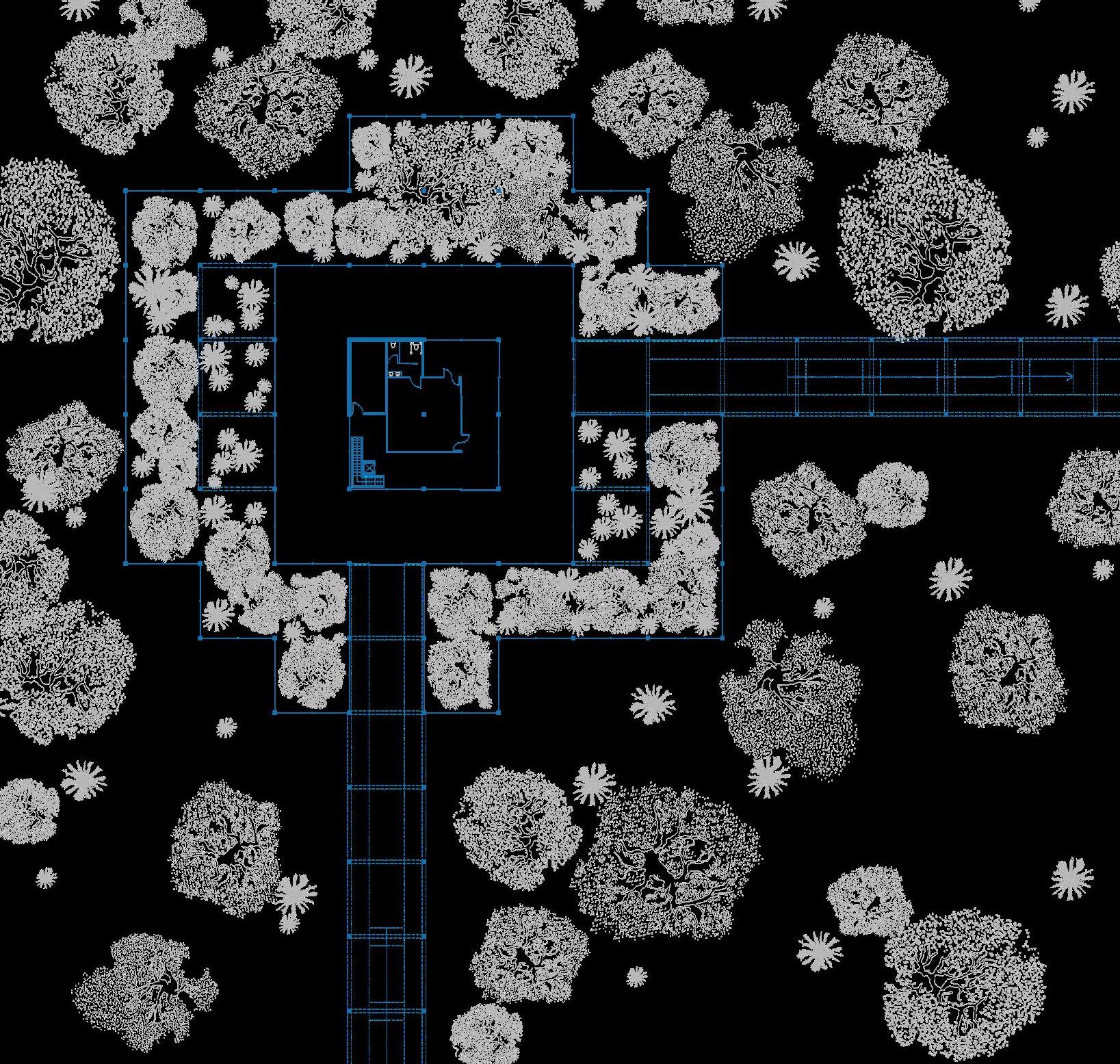

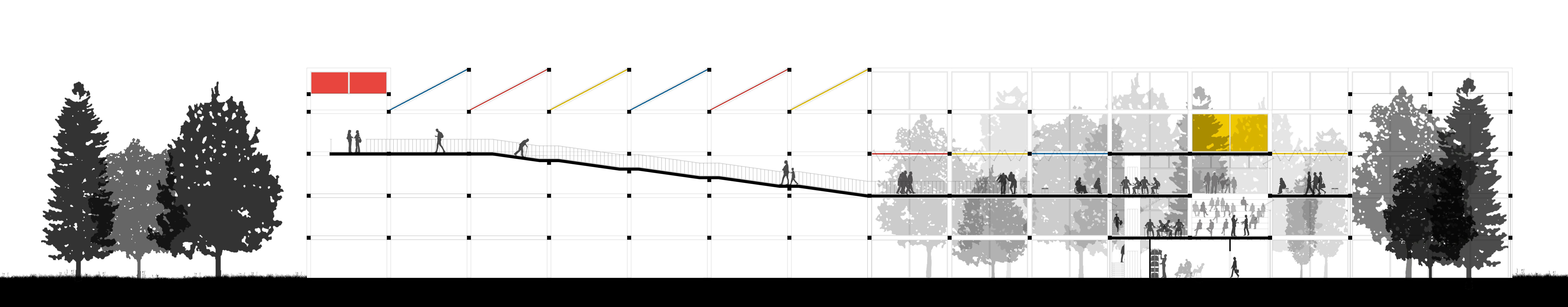

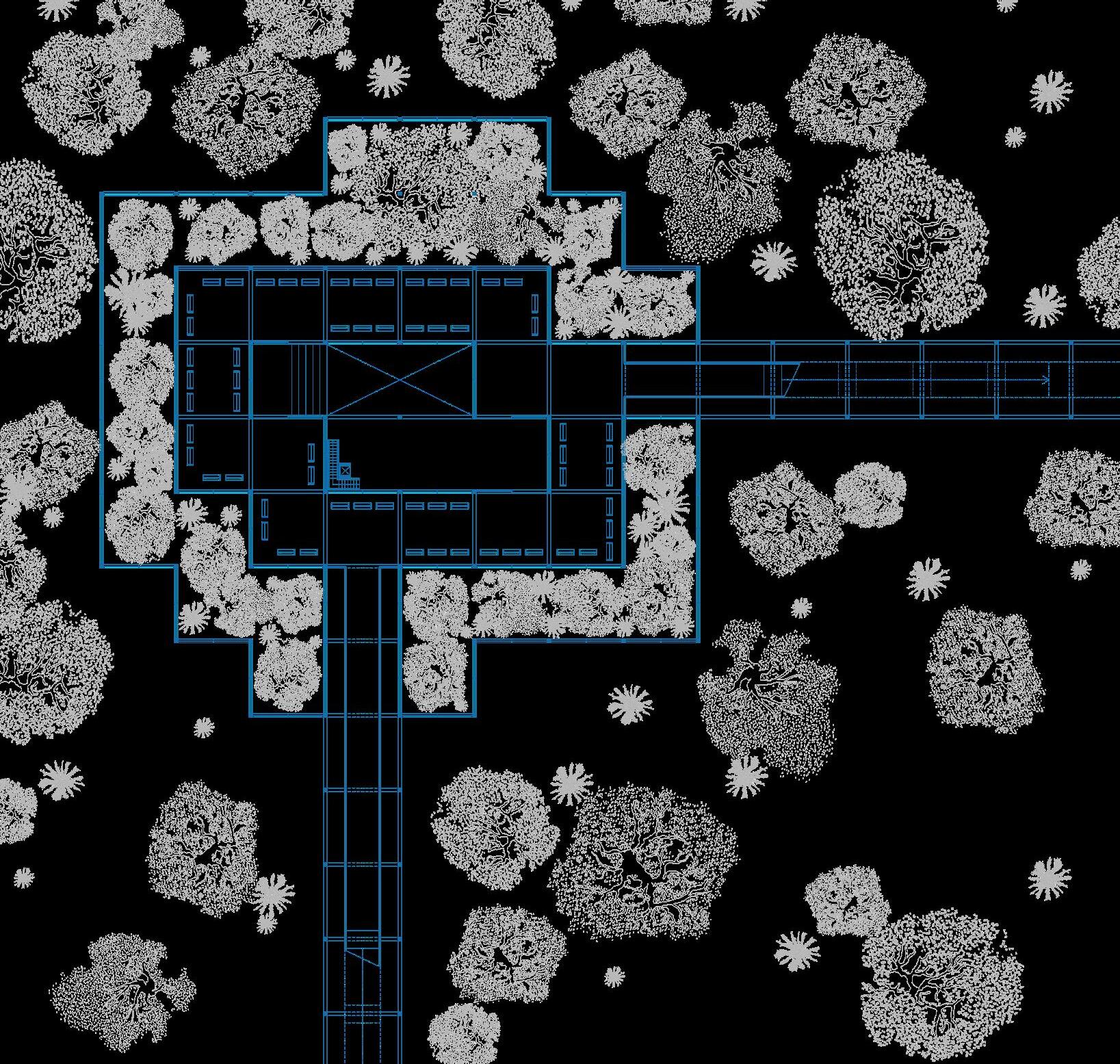

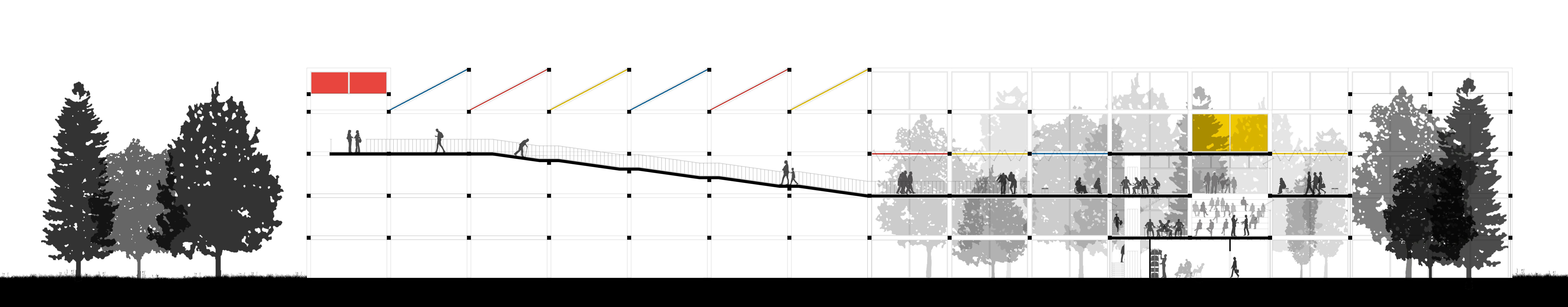

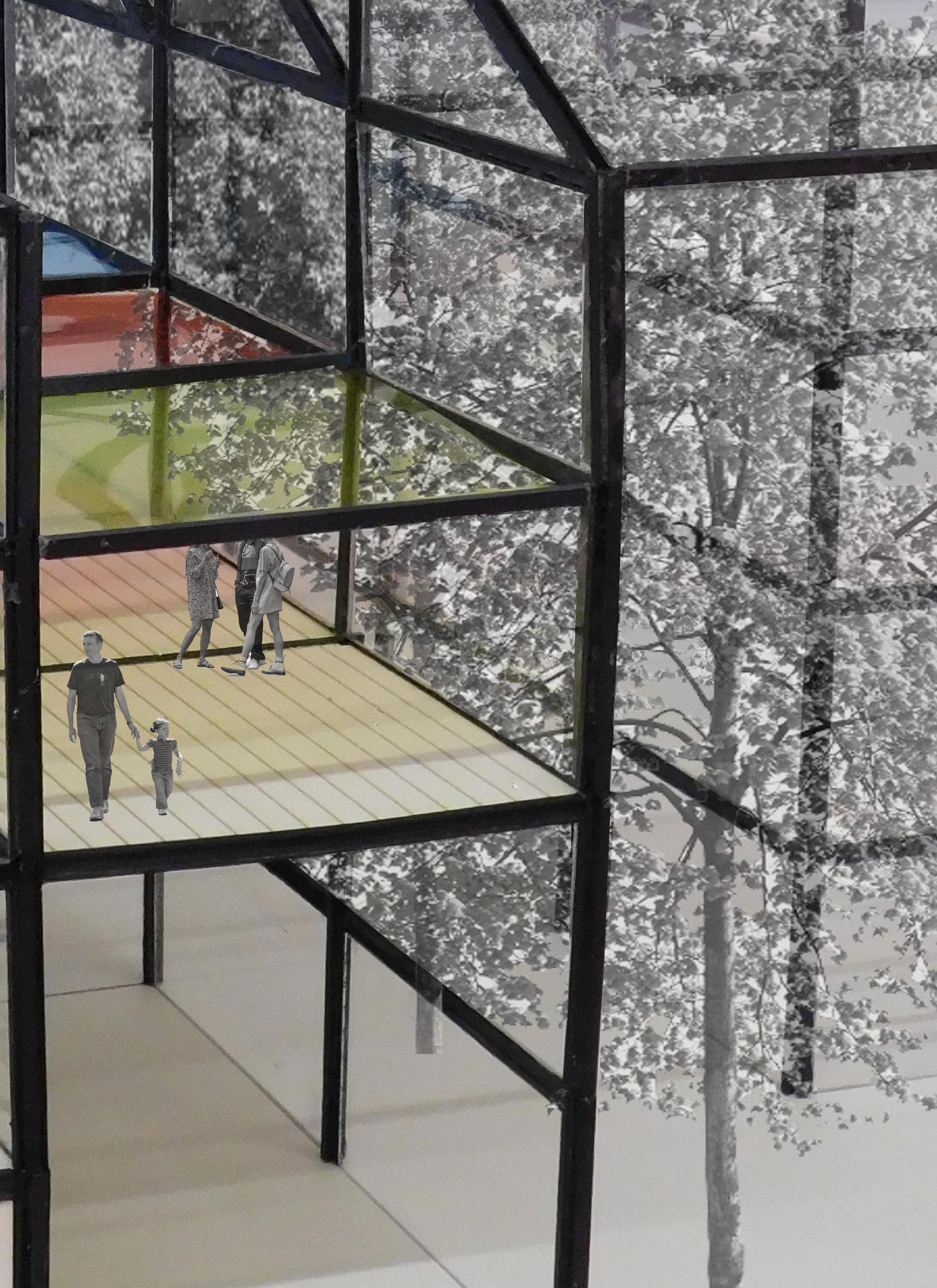

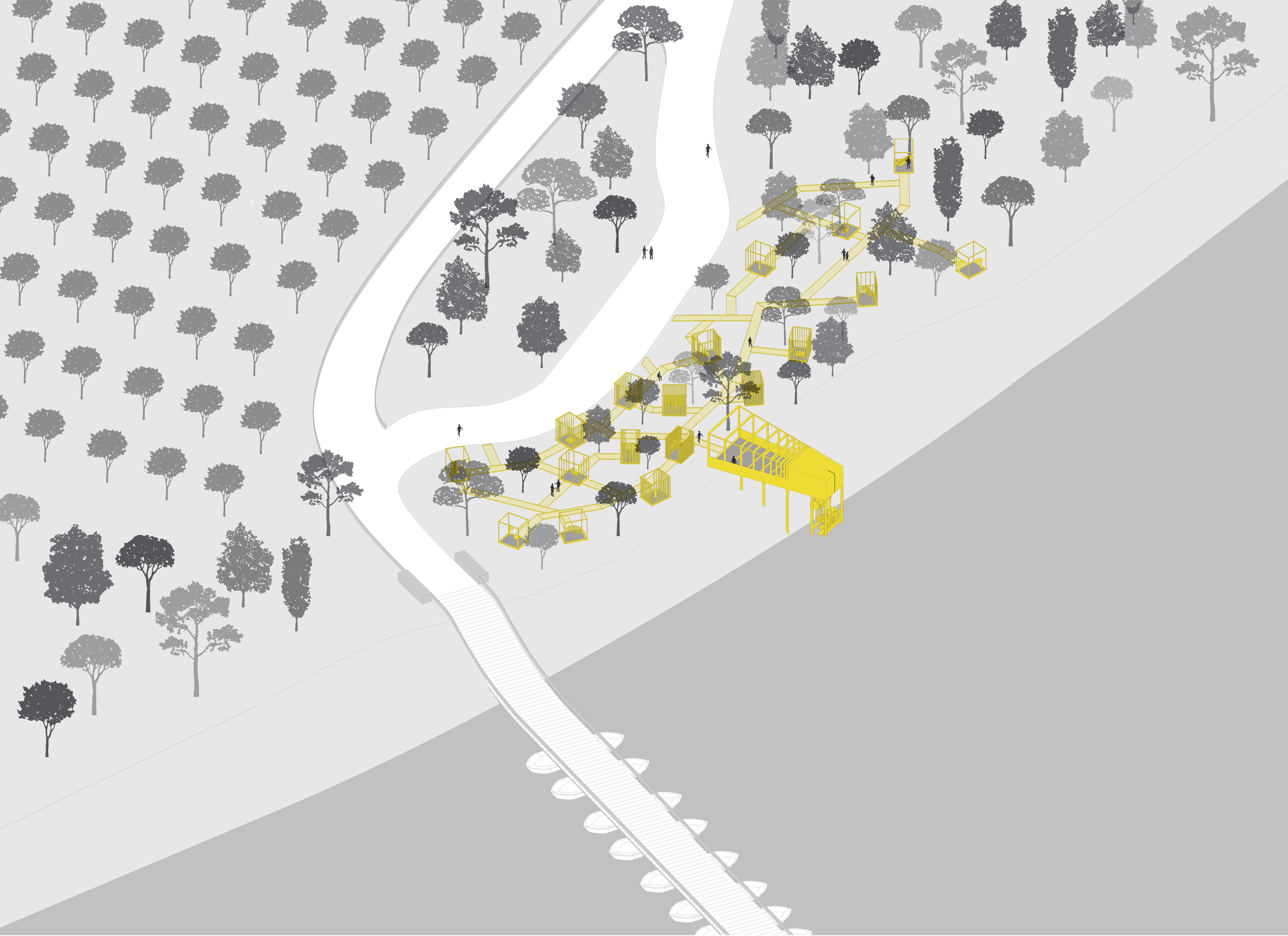

The Factory of Prototypes is set to become an extension of the Bovisa Campus of the Politecnico of Milan to be developed in a reclaimed industrial area known as the “Goccia” for the drop-like shape created by surrounding railways. The functional program includes 8 technical pavillions where distinct spaces between visitors and students were needed and a completely public exhibition pavillion to be inserted within the urban forest that has rosen naturally in the “Goccia”. The pavillions are characterized by a steel structural grid within which technical or exhibition spaces alongside glasshouses. The grid also allows us to create modular steel elevated pathways connecting all pavillions and providing a different experience of the woods. Key elements in the design is the use of coloured glass as covering in spaces for visitors giving a new perception of space and light; and the the juxtaposition of technology and nature both in the pathways and the buildings.

Union des Gas

Union des Gas

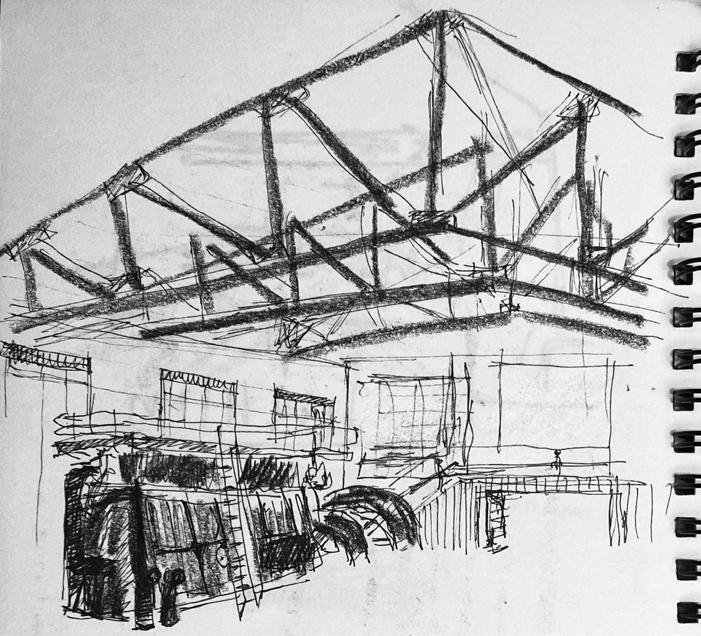

The “Goccia” developed as an industrial center north of Milan in the late 19th century. Iconic in the local landscape is the railway defining the drop-like perimeter and the two gasometers which tower over the industrial heritage brick buildings and urban forest to the north and Politecnico’s Bovisa Campus to the south. The exposed steel framework of the gasometers was crucial in the design process: initially re-interpreted as a continuous grid spreading through the forest, to finally morph into the clusters of vertical modular spaces connected by elevated steel pathways.

Exhibition Pavillion

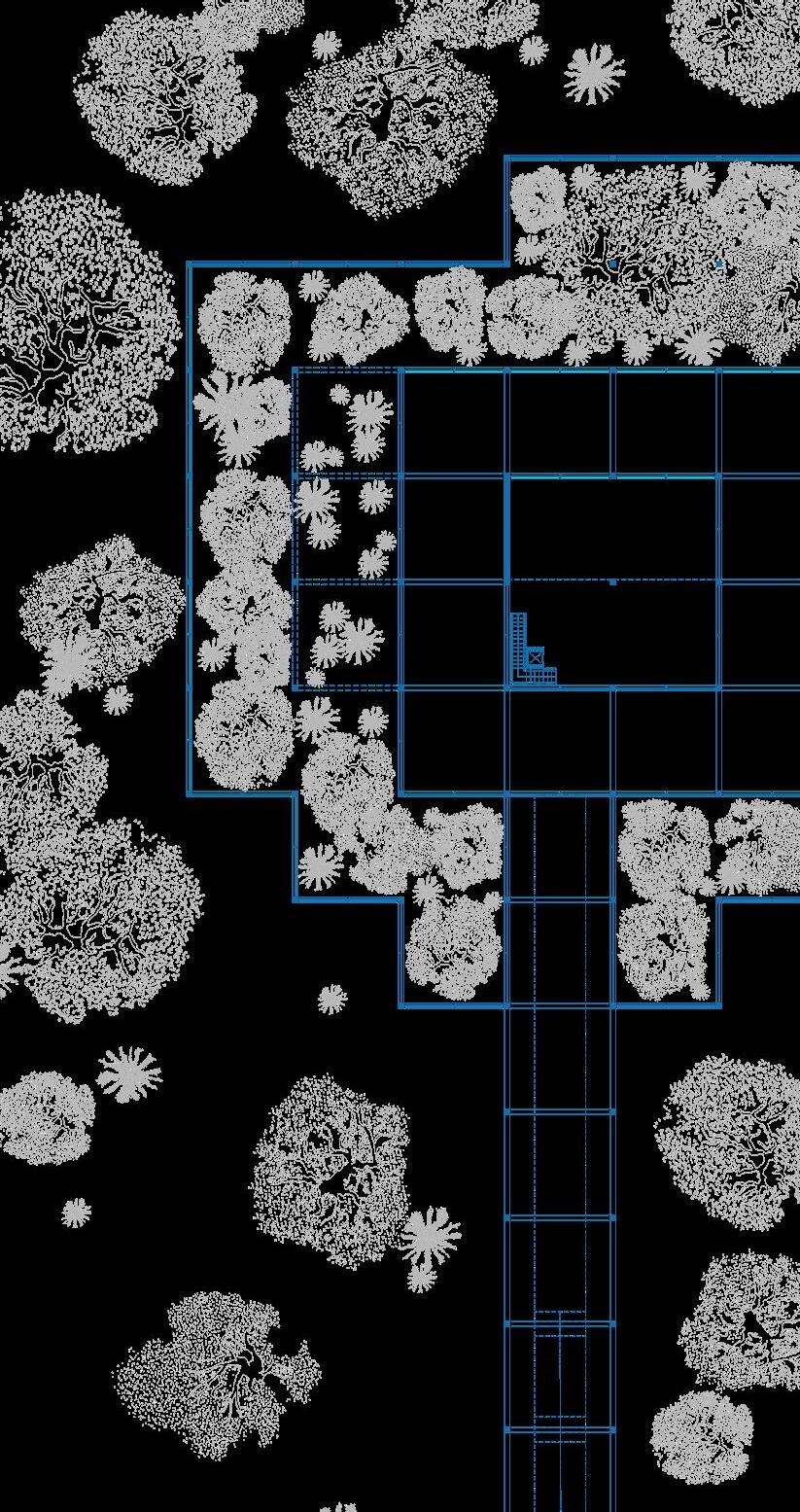

Ground, First and Second Floor Plan

below: Exhibition Pavillion Vertical Section

right to left:

right to left:

on this page:

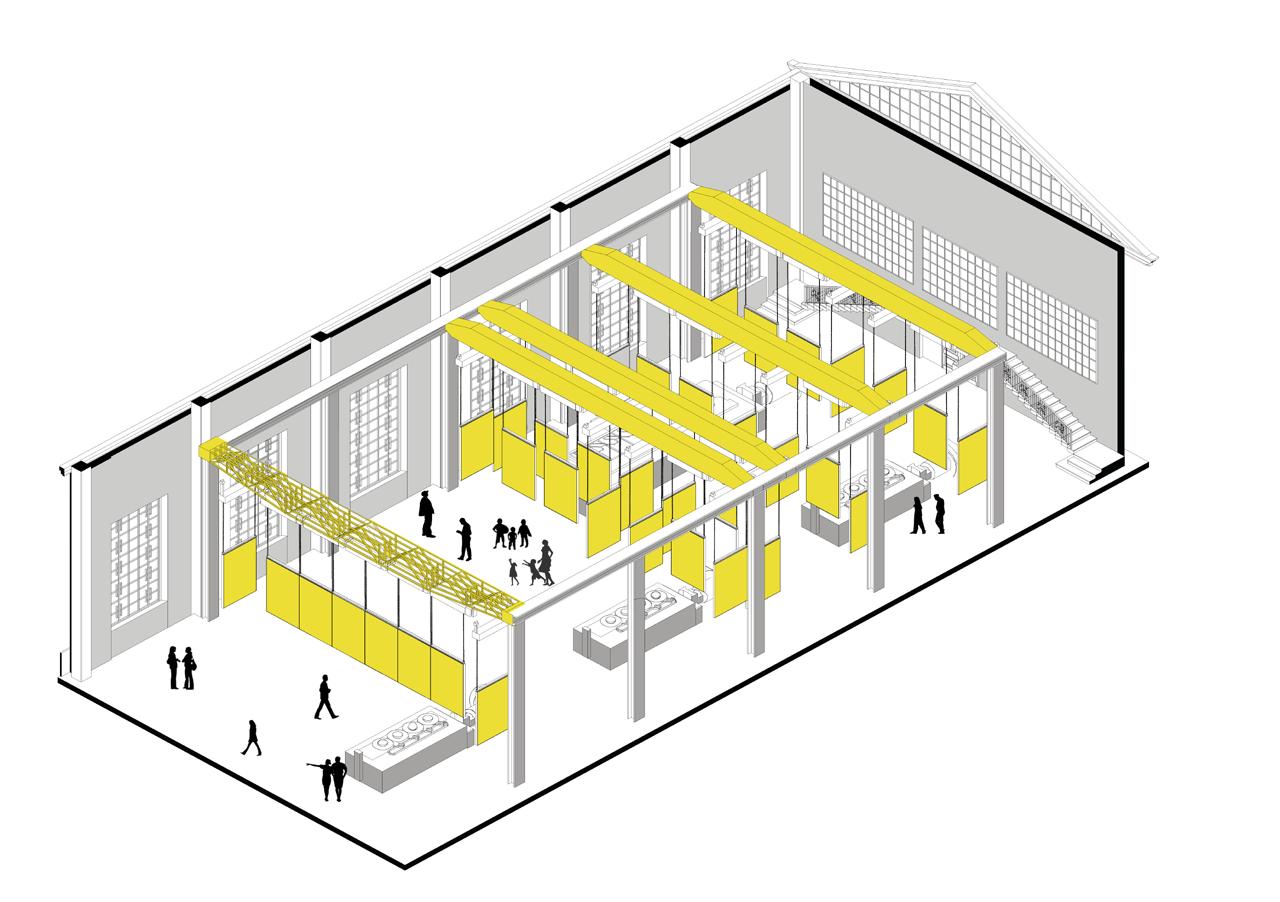

Exhibition Pavillion Close | Open Configuration

opposite: Exhibition Pavillion Detail Section

right to left:

Technical Pavillion

Ground, First and Second Floor Plan

below: Technical Pavillion Vertical Section

on this page:

Technical Pavillion

Close | Open Configuration

opposite:

Technical Pavillion

Detail Section

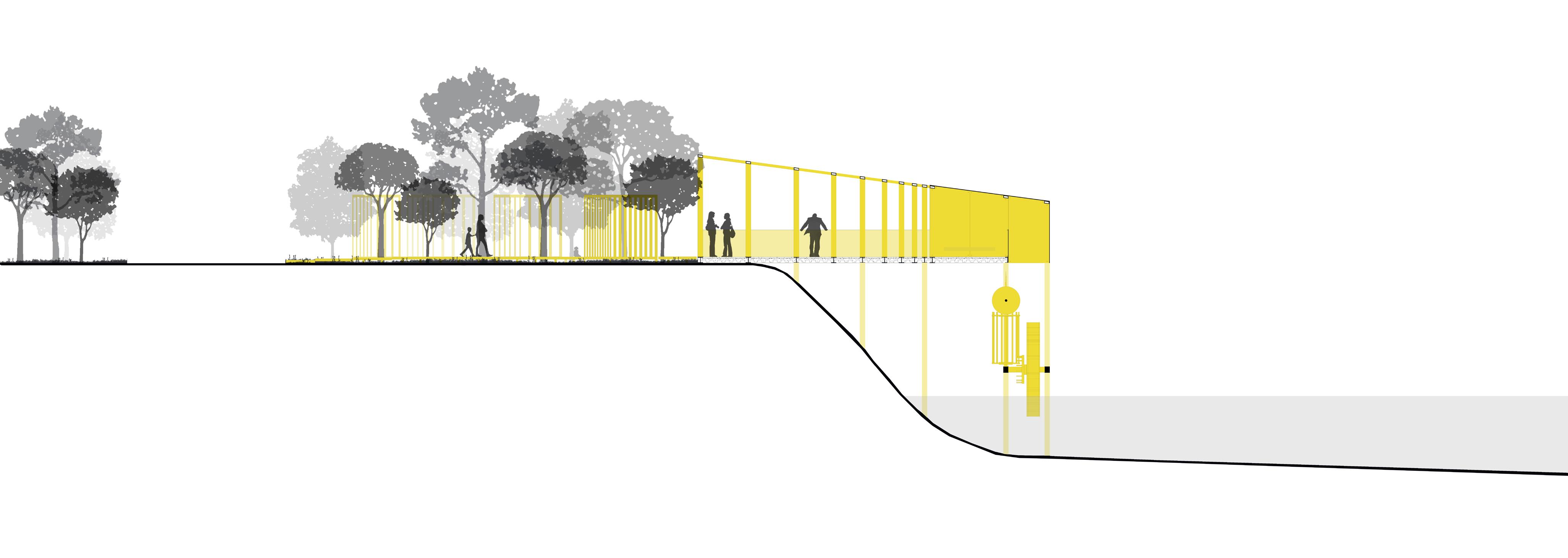

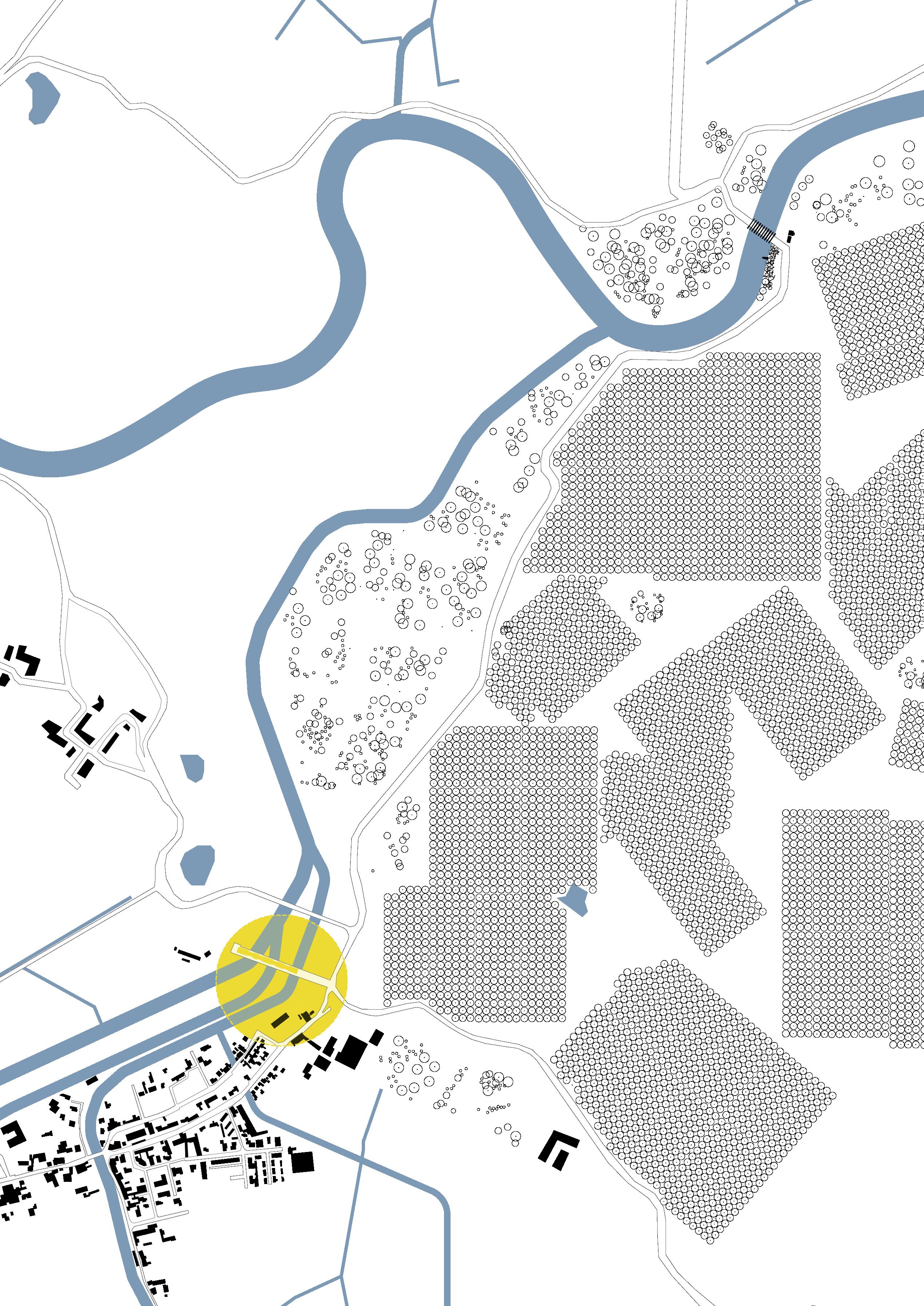

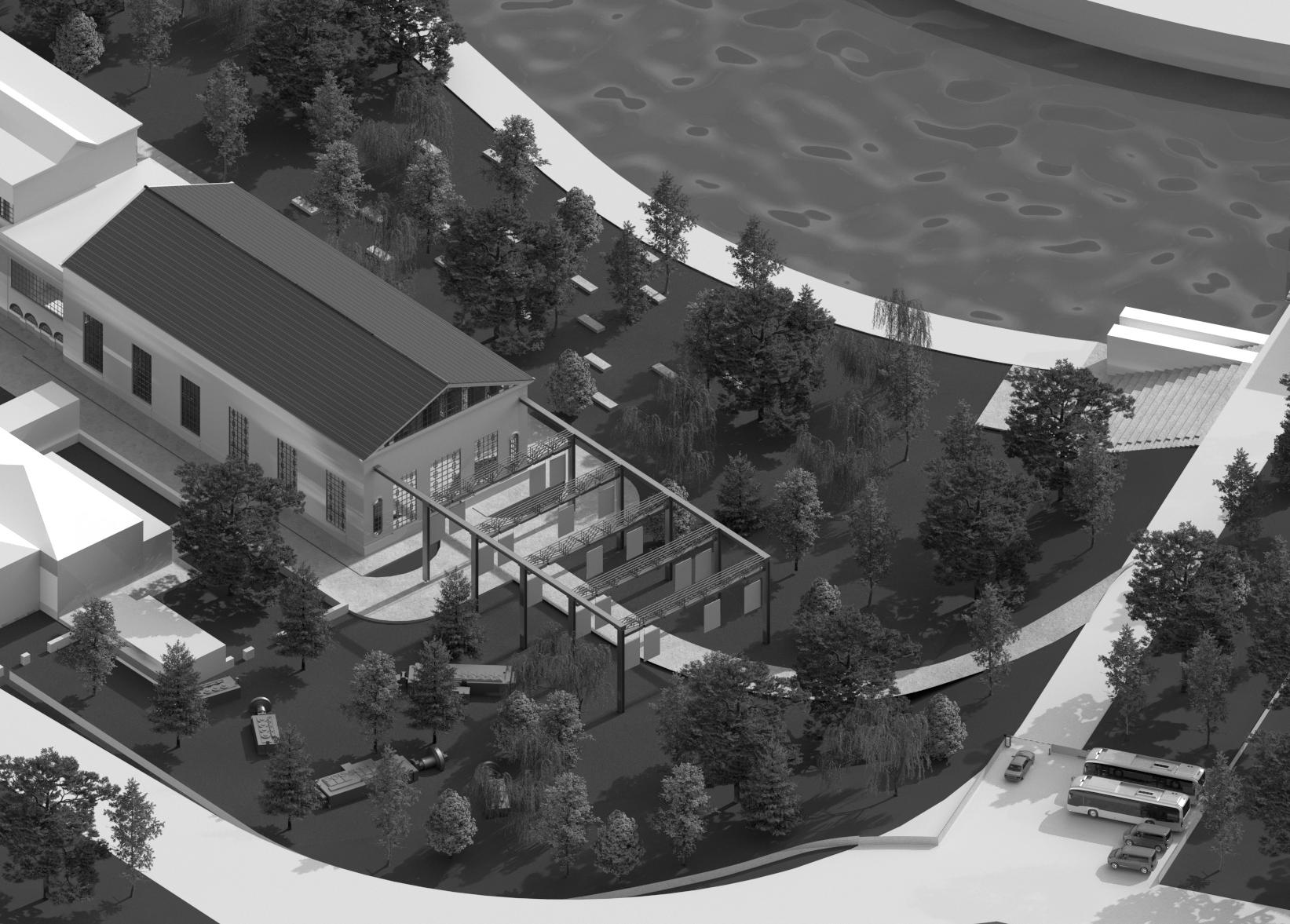

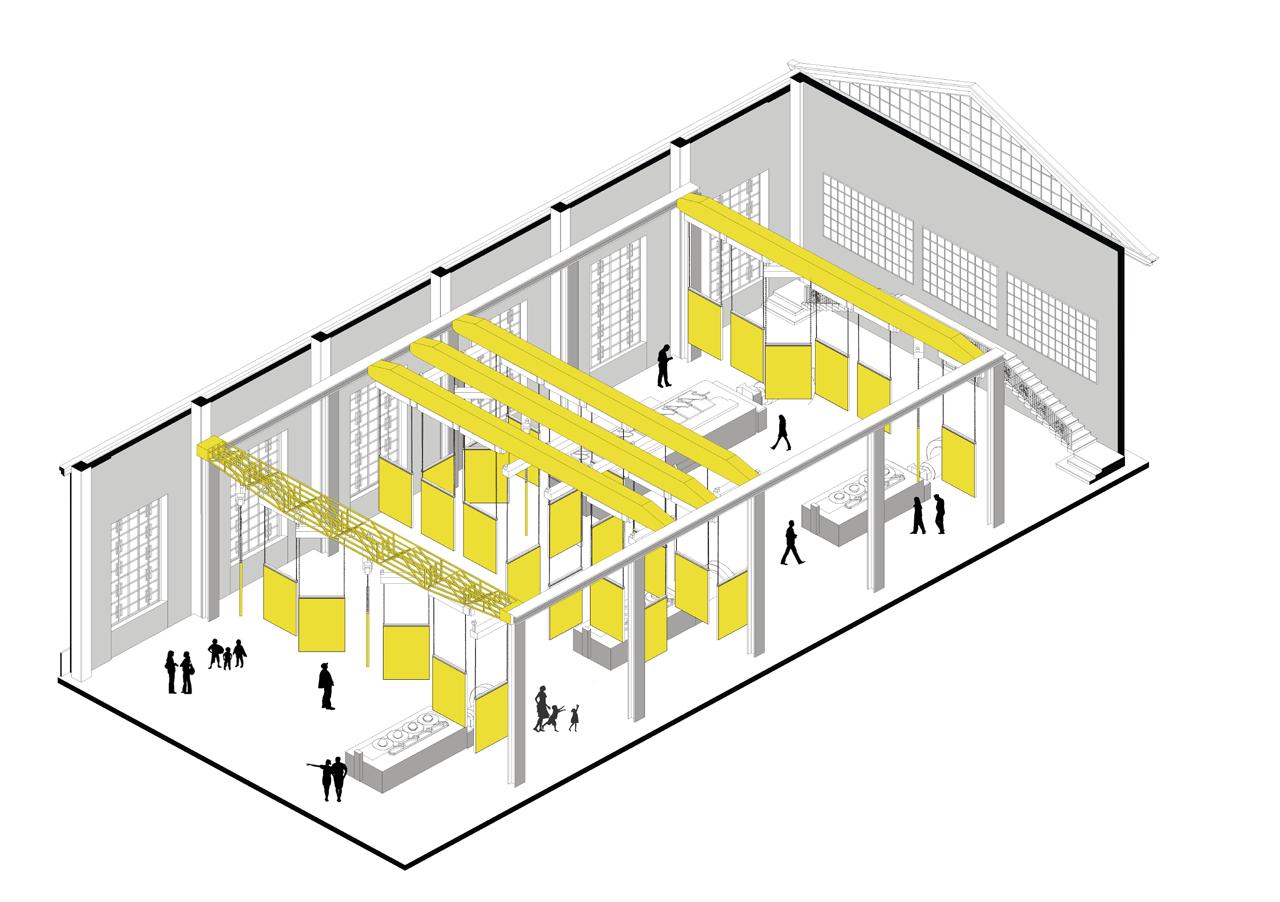

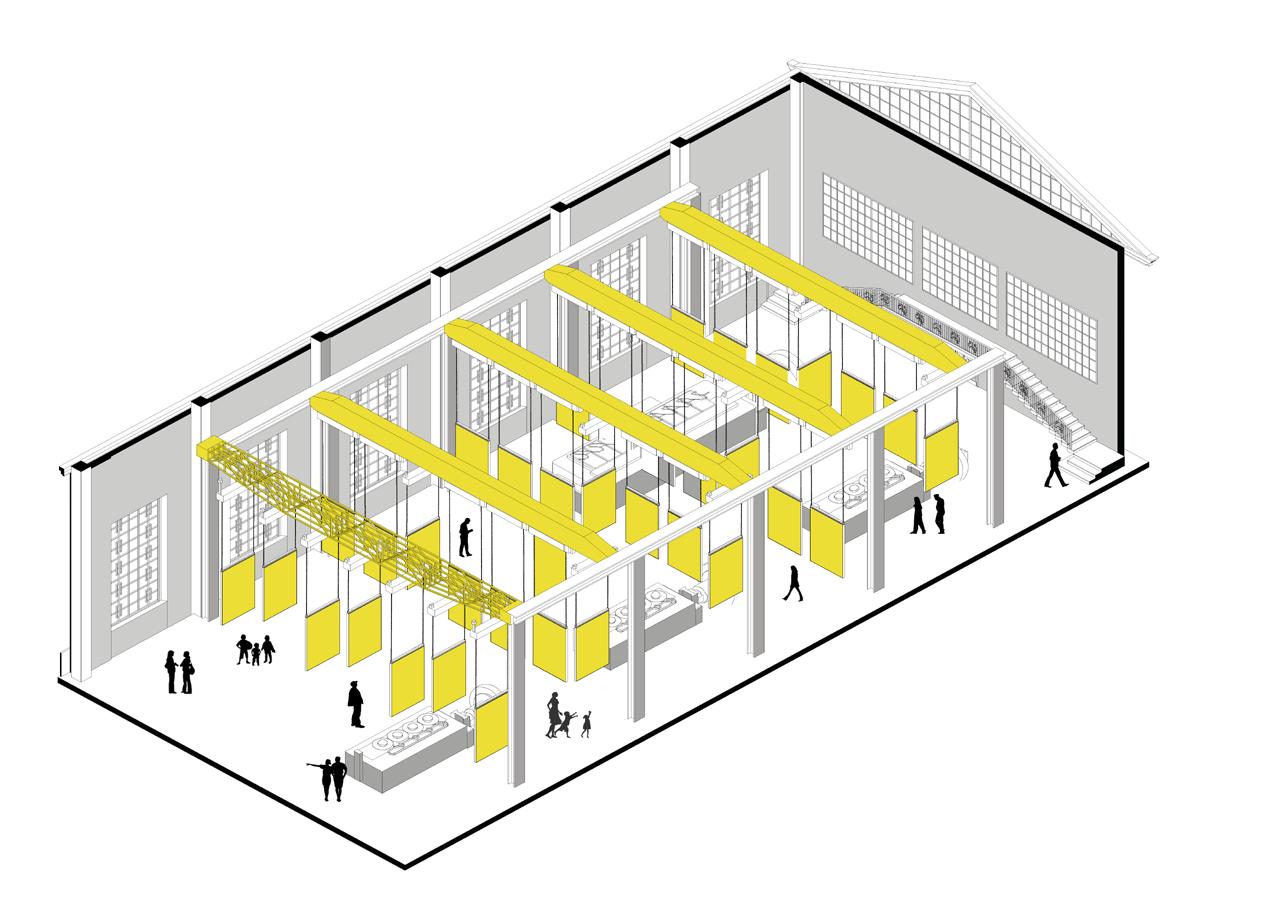

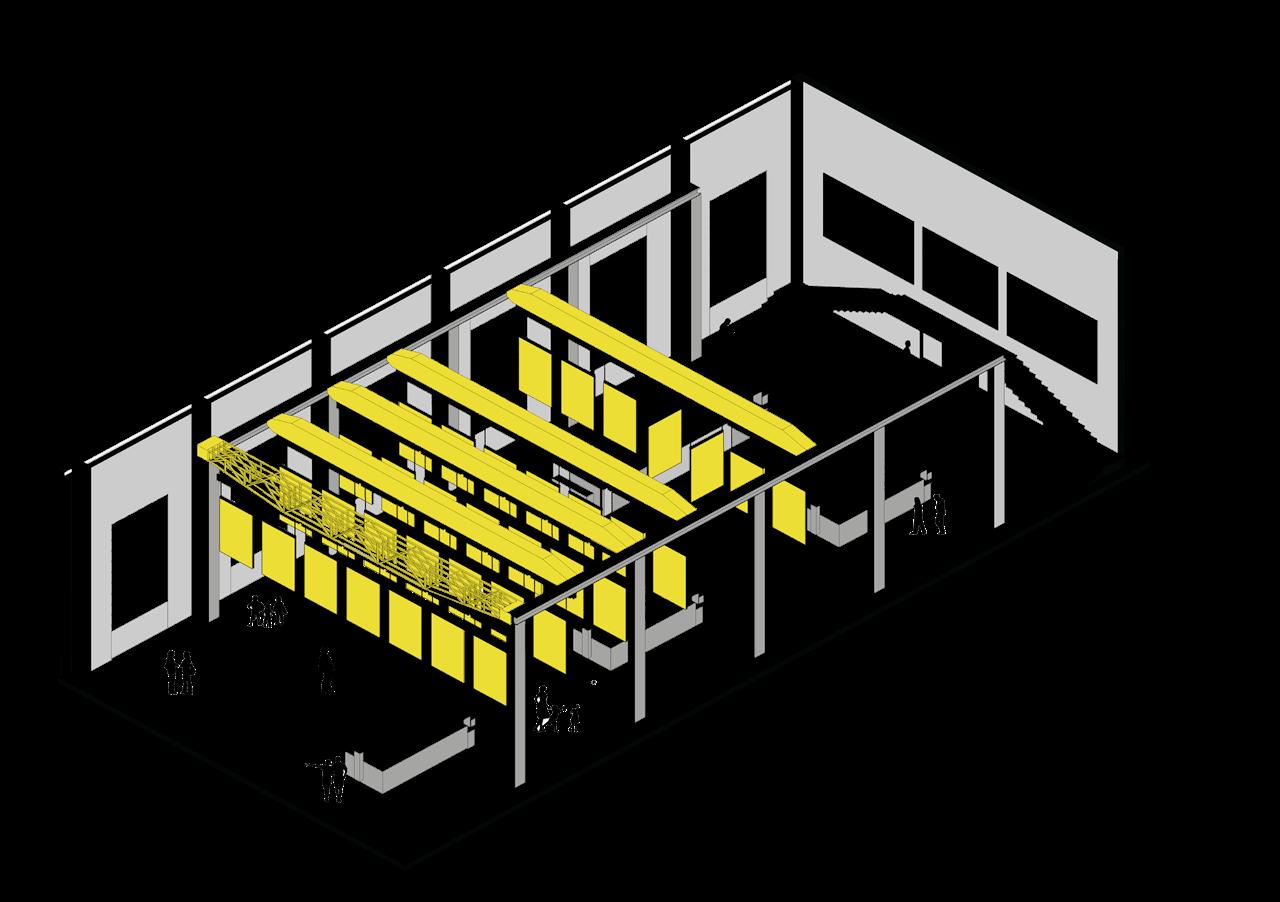

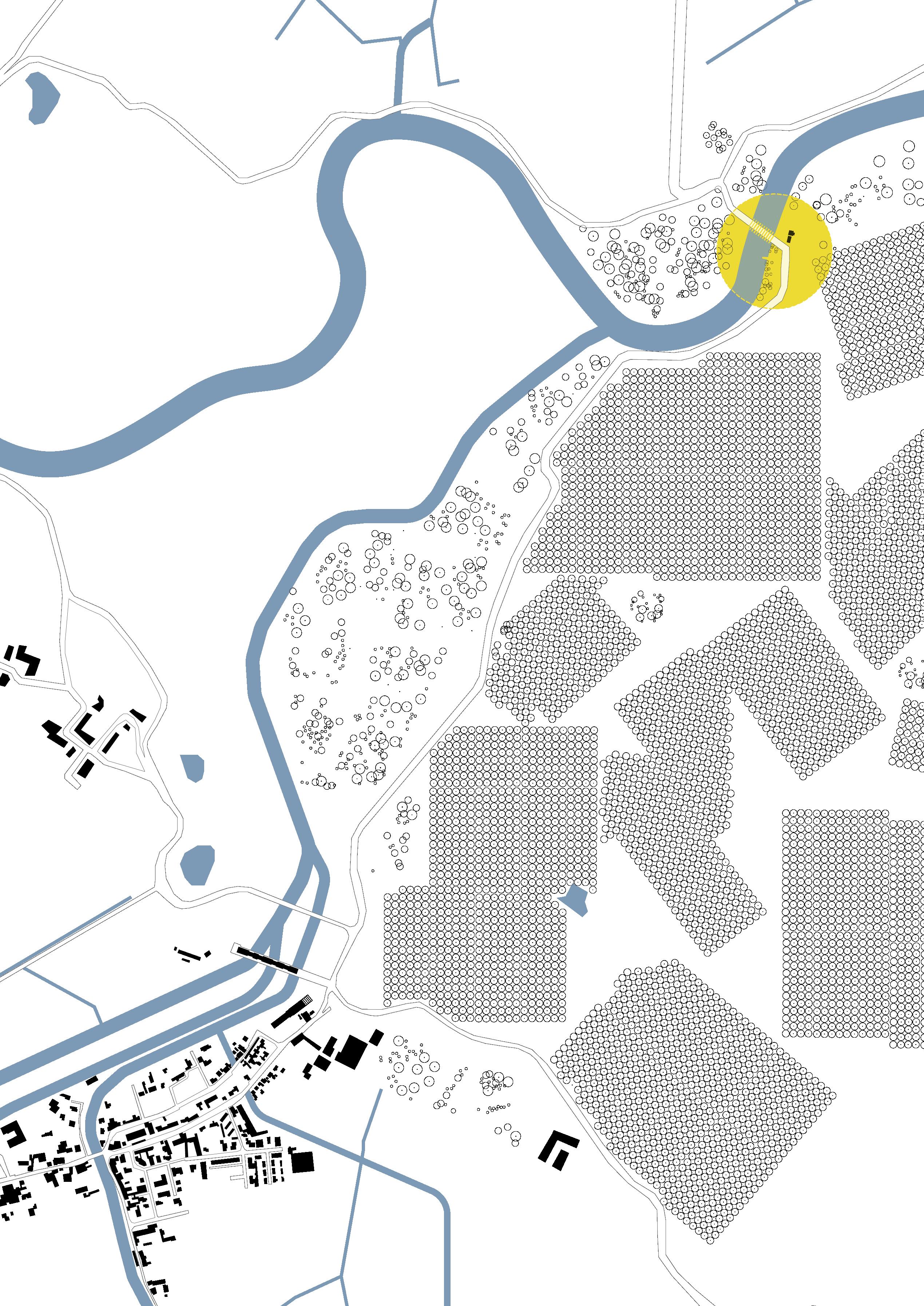

San Matteo delle Chiaviche, MN

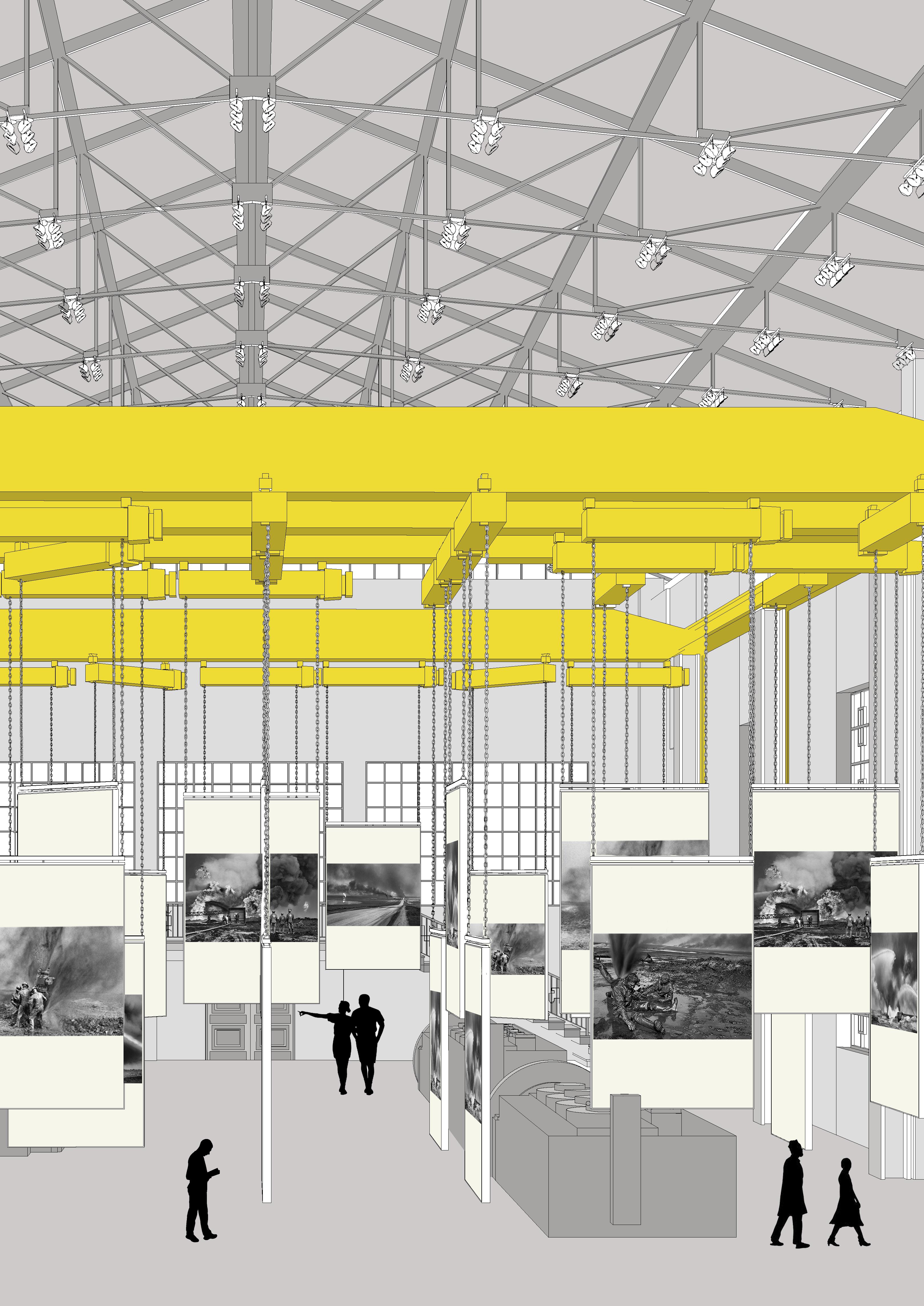

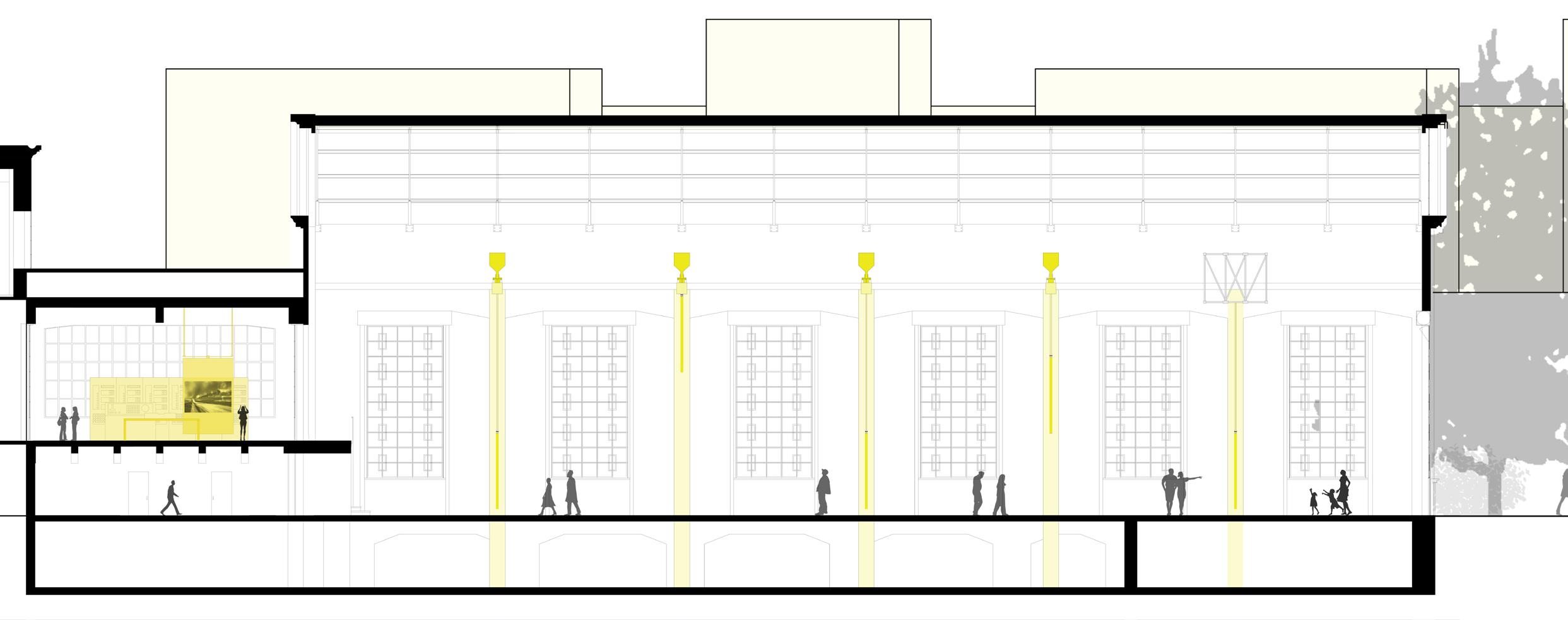

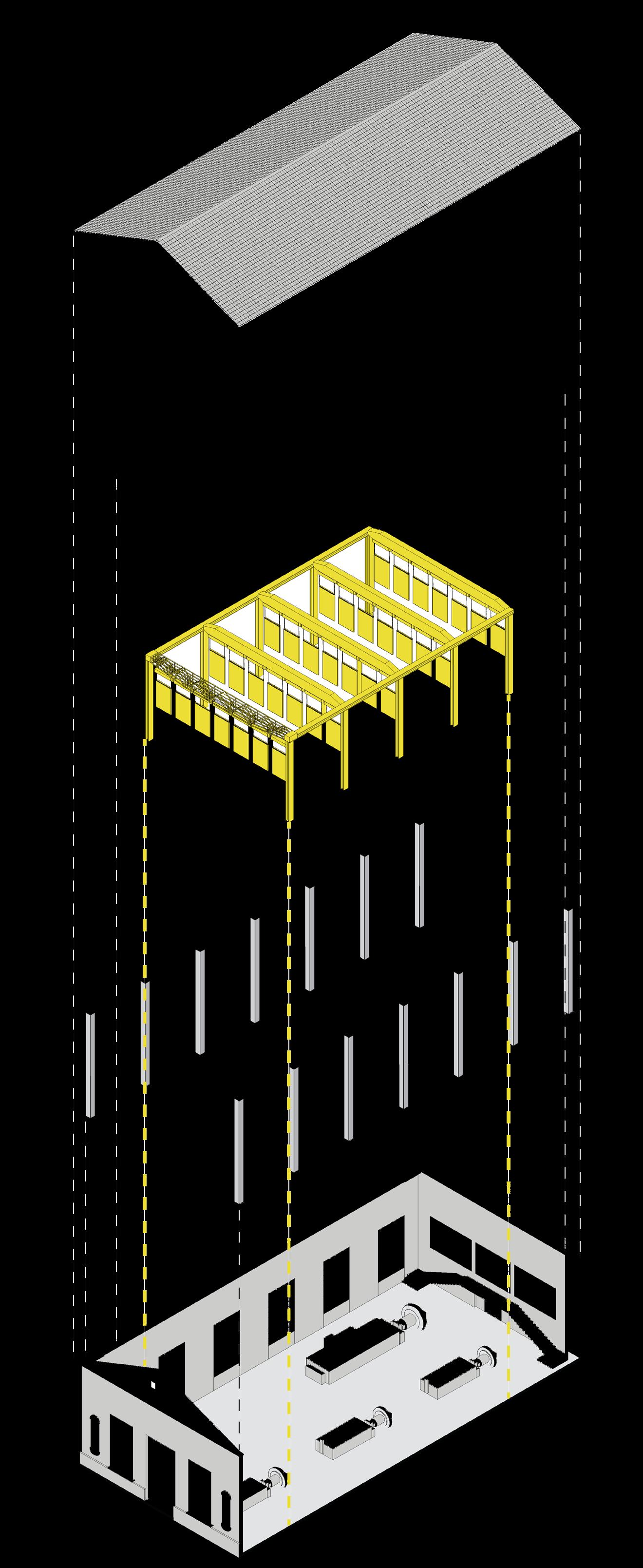

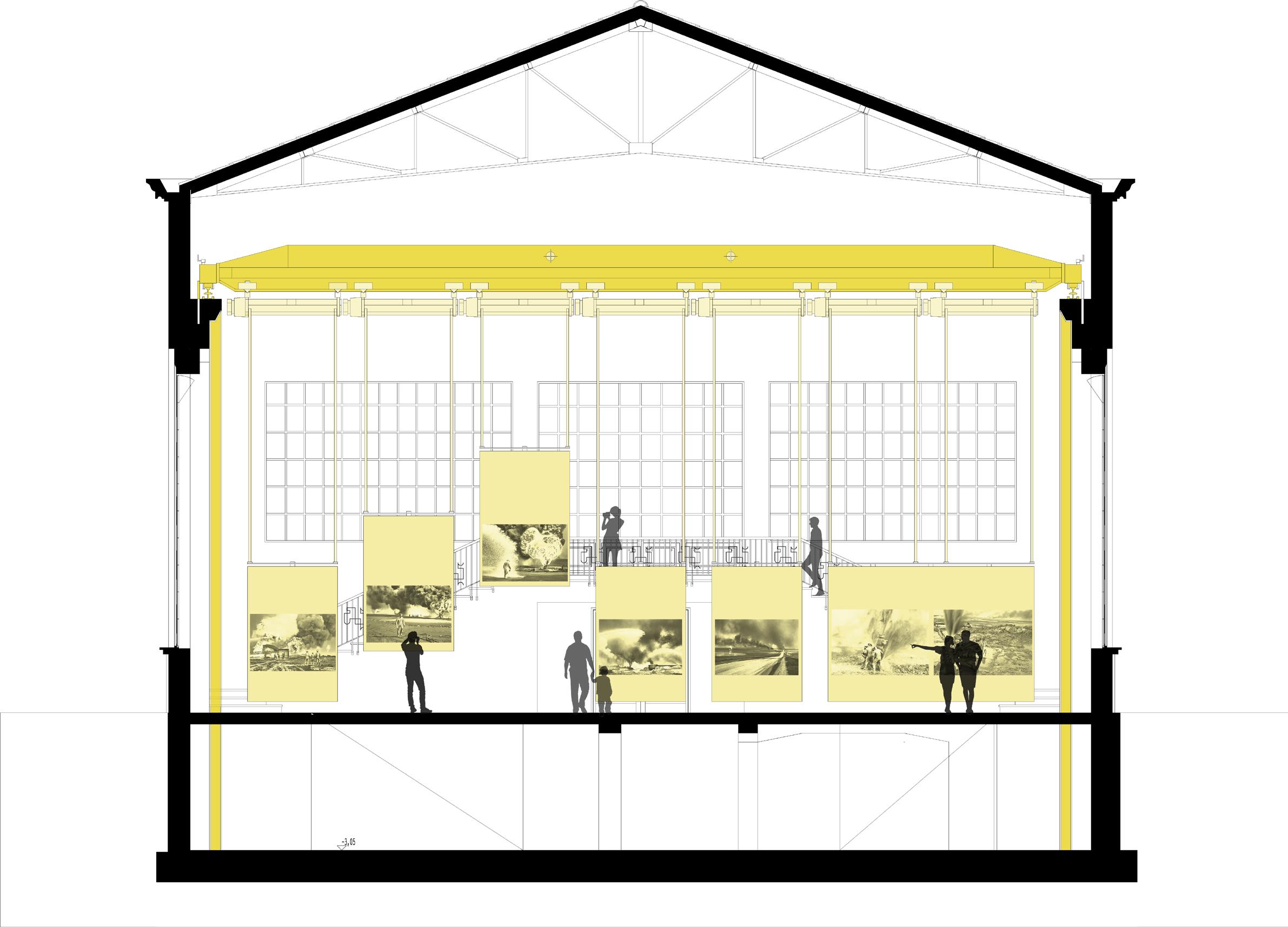

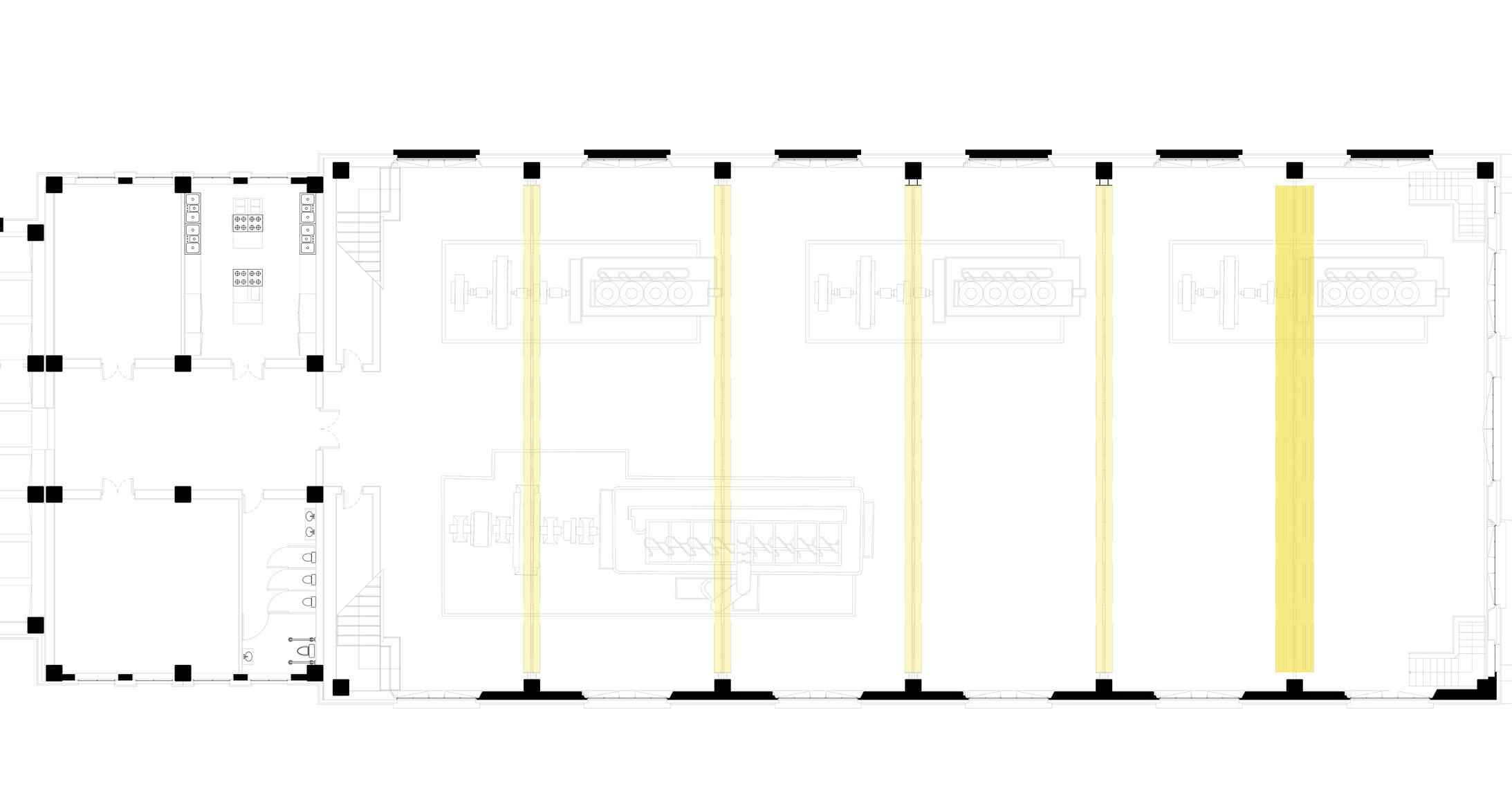

The project rises within the Centrale Termoelettrica designed by Piero Portaluppi, along the river Po. Our vision for the Ecomuseum was that of creating an inclusive space for art and for social gatherings, whilst still communicating the previous identity of the site. The exterior is organized in three zones: the slope leading to the site is used to create an open air auditorium, along the riverside benches provide seating within the vegetation and a small grass path leading the visitor through a series of “industrial machine ruins” belonging to the Impianto Idrovoro, developing across the river just above the Centrale Termica. The use of the carroponte, central element in the intervention, is first seen in the external space where a sequence of 5 fixed bridge cranes frame the main entrance. In the main hall, the fixed pre-existent carroponte is combined with 4 movable new carroponti, distinguished through bright yellow coating, all carrying a series of detachable panels to be used for the exposition of artworks, but also for the subdivision of the main space. The panels can rotate along their central axis and move vertically along the plane thanks to the use of chain hoists giving flexibility to the space.

RiverOglio

San Matteo delle Chiaviche

RiverOglio

San Matteo delle Chiaviche

from

left to right: Masterplan and Render below: Longitudinal Section

left to right: Masterplan and Render below: Longitudinal Section

above:

Ground Floor Plan

below:

Cross Section of Main Exhibition Hall

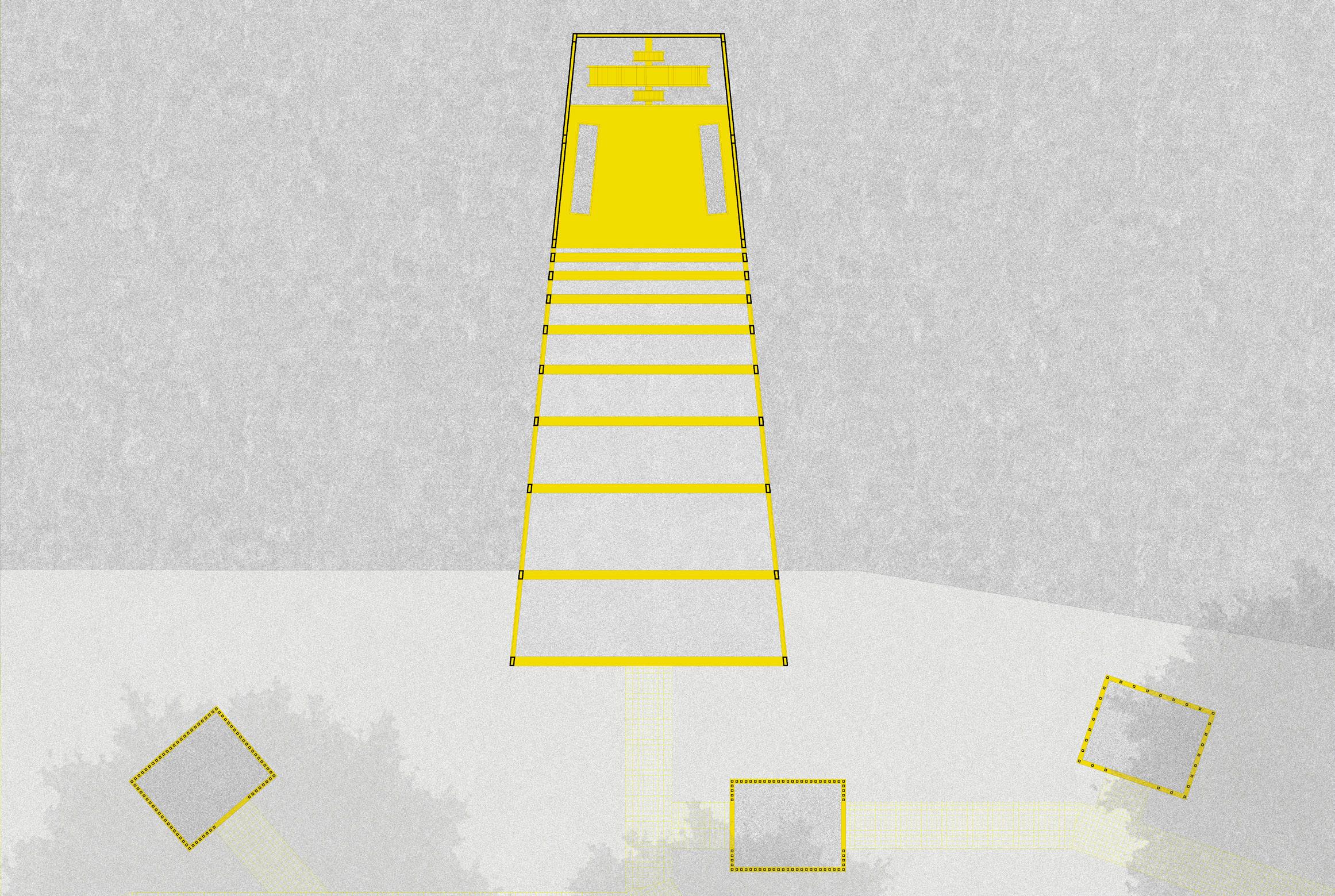

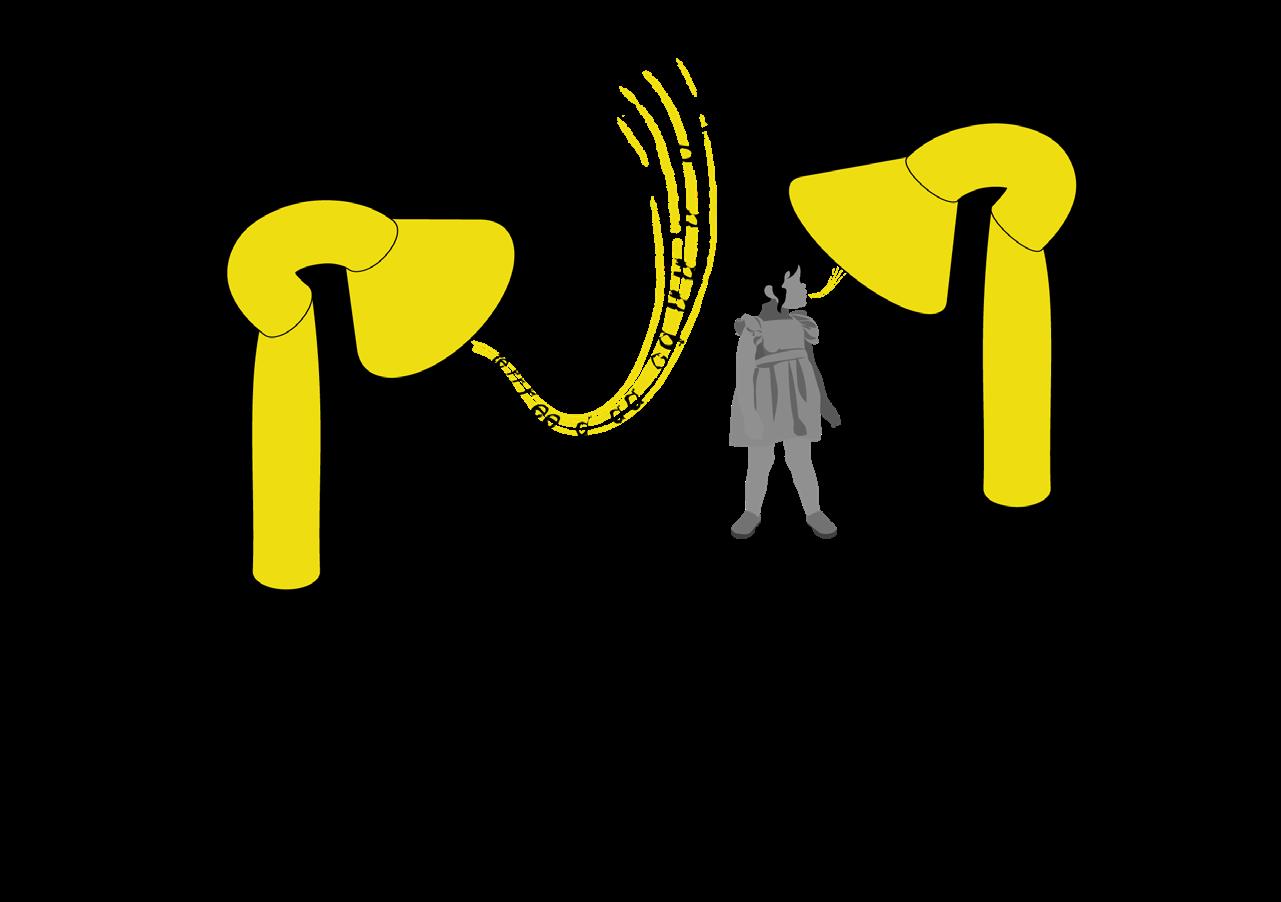

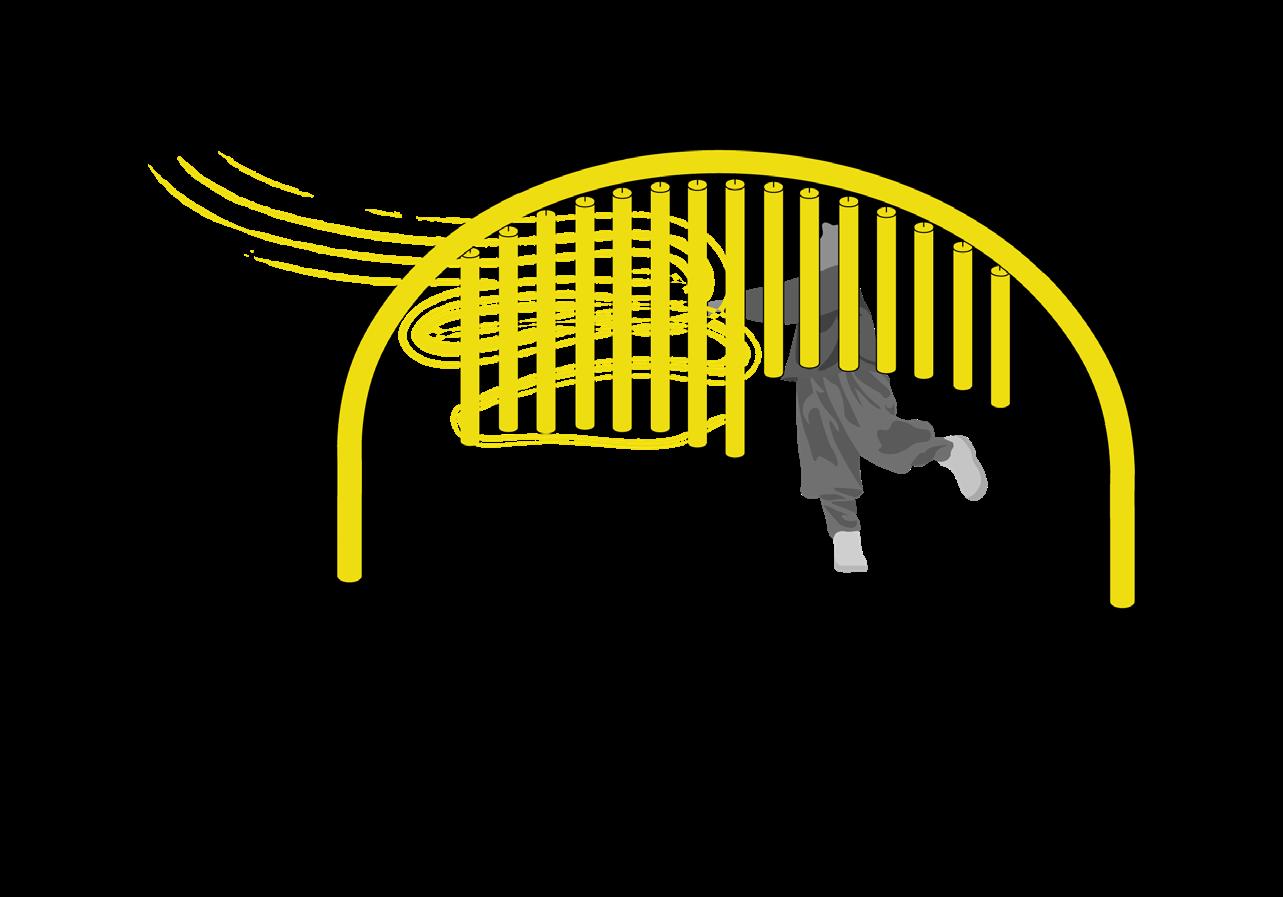

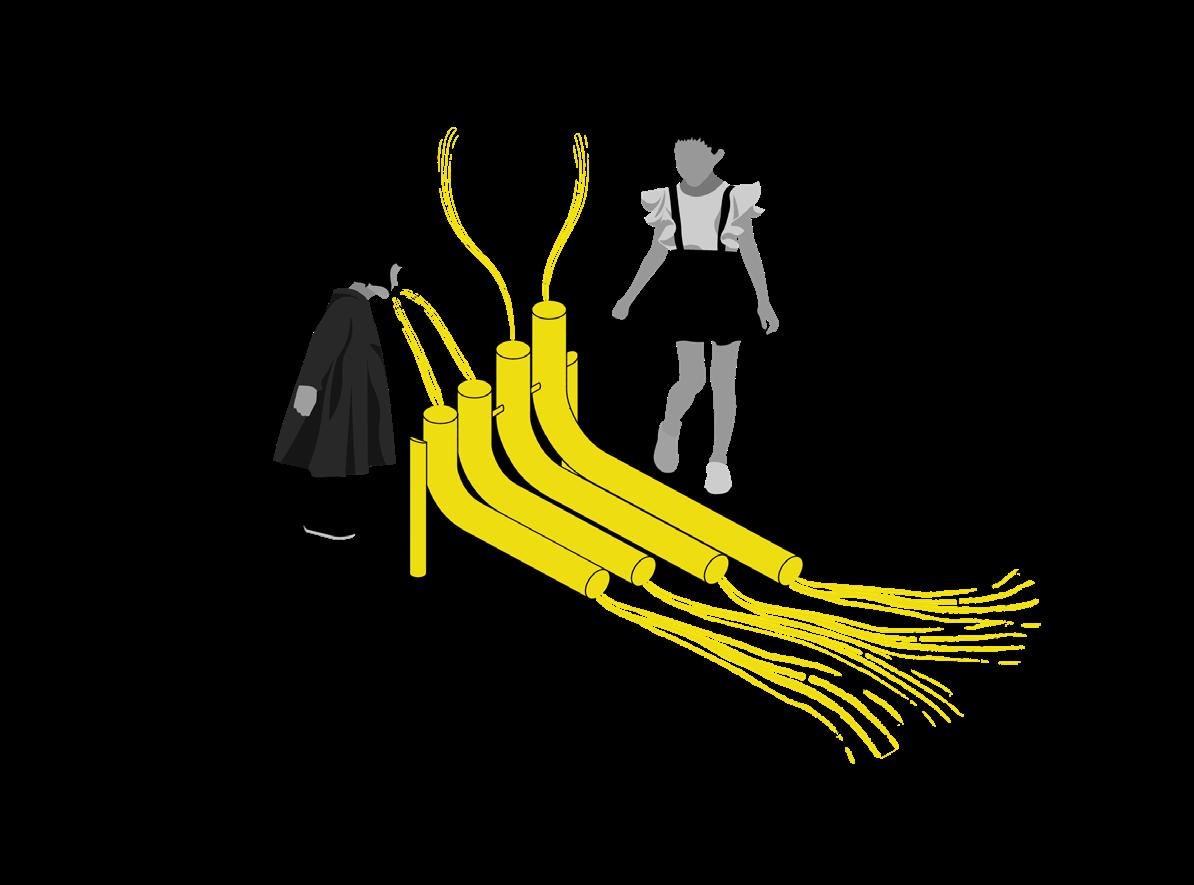

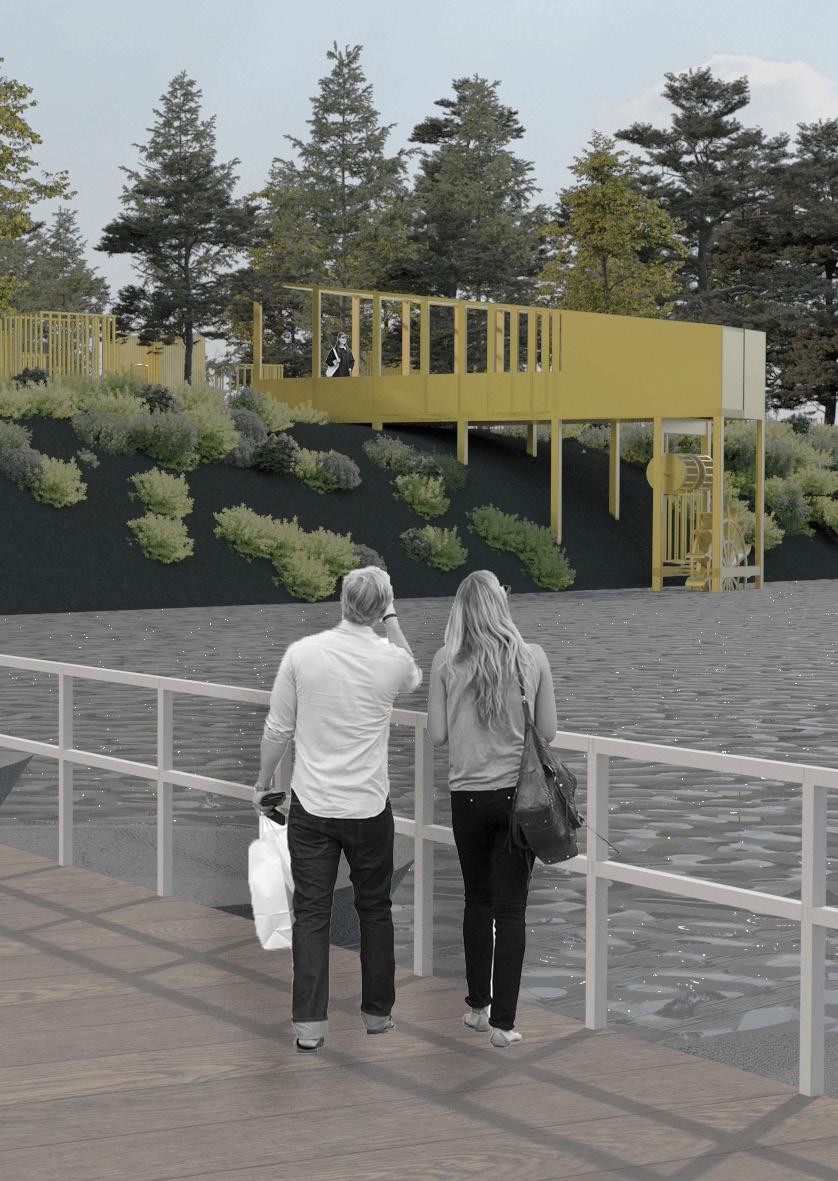

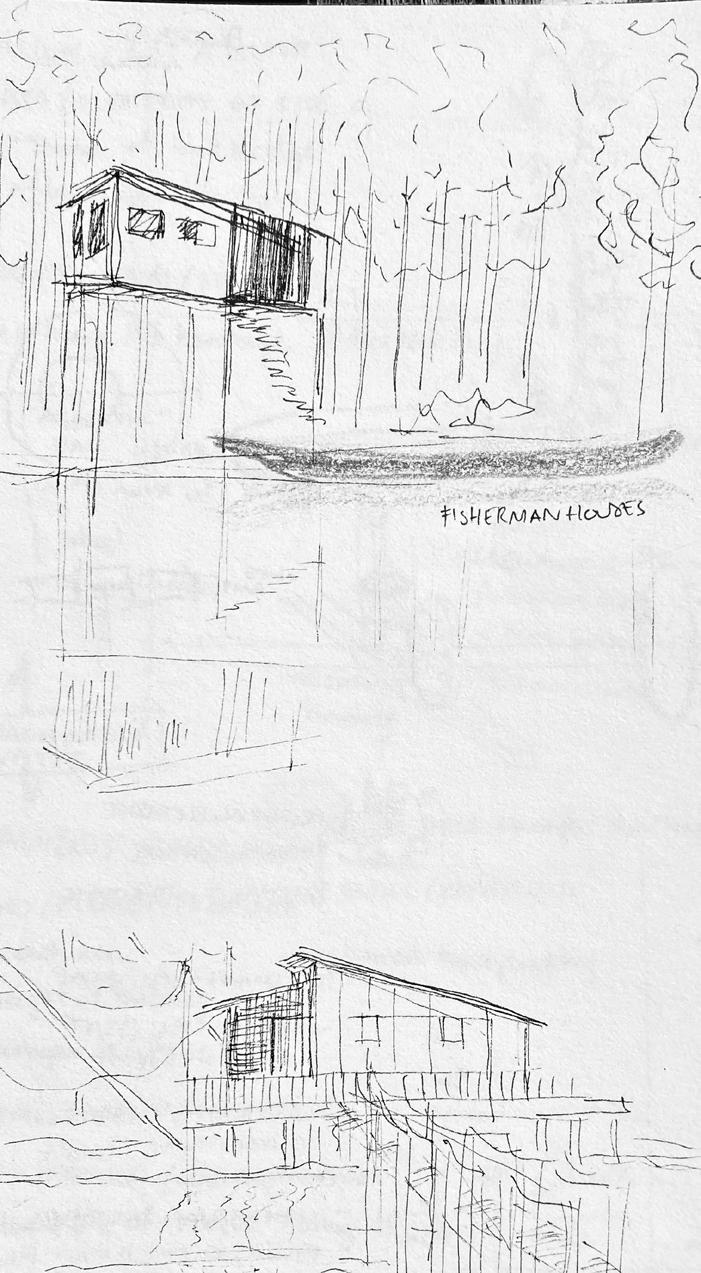

The acoustic and visual landscape is at the core of our pavilion design. Instead of viewing the noise of the boat bridge as an obstacle a sound pavilion and sound garden was designed to complement and enhance the heritage represented by the boat bridge. Sound and the colour yellow, the visual queue for all our interventions, dominate the site. The main pavilion expands onto the water, suspended above the river much like the temporary fishermen’s houses scattered along the Oglio river. A vertical slit becomes the only keyhole to the external landscape, and invites the visitor to look downwards, where a system much like that of a watermill gives voice to the river. The site surrounding the main pavilion becomes, through cubicle structures, each with their individual instrument, a sound garden and playground where visitors can contribute to the acoustic landscape in an experience which looks to briefly merge “musician” and environment.

Ponte di Barche sull’Oglio, MN

Ponte di Barche sull’Oglio, MN

RiverOglio

San Matteo delle Chiaviche

RiverOglio

San Matteo delle Chiaviche

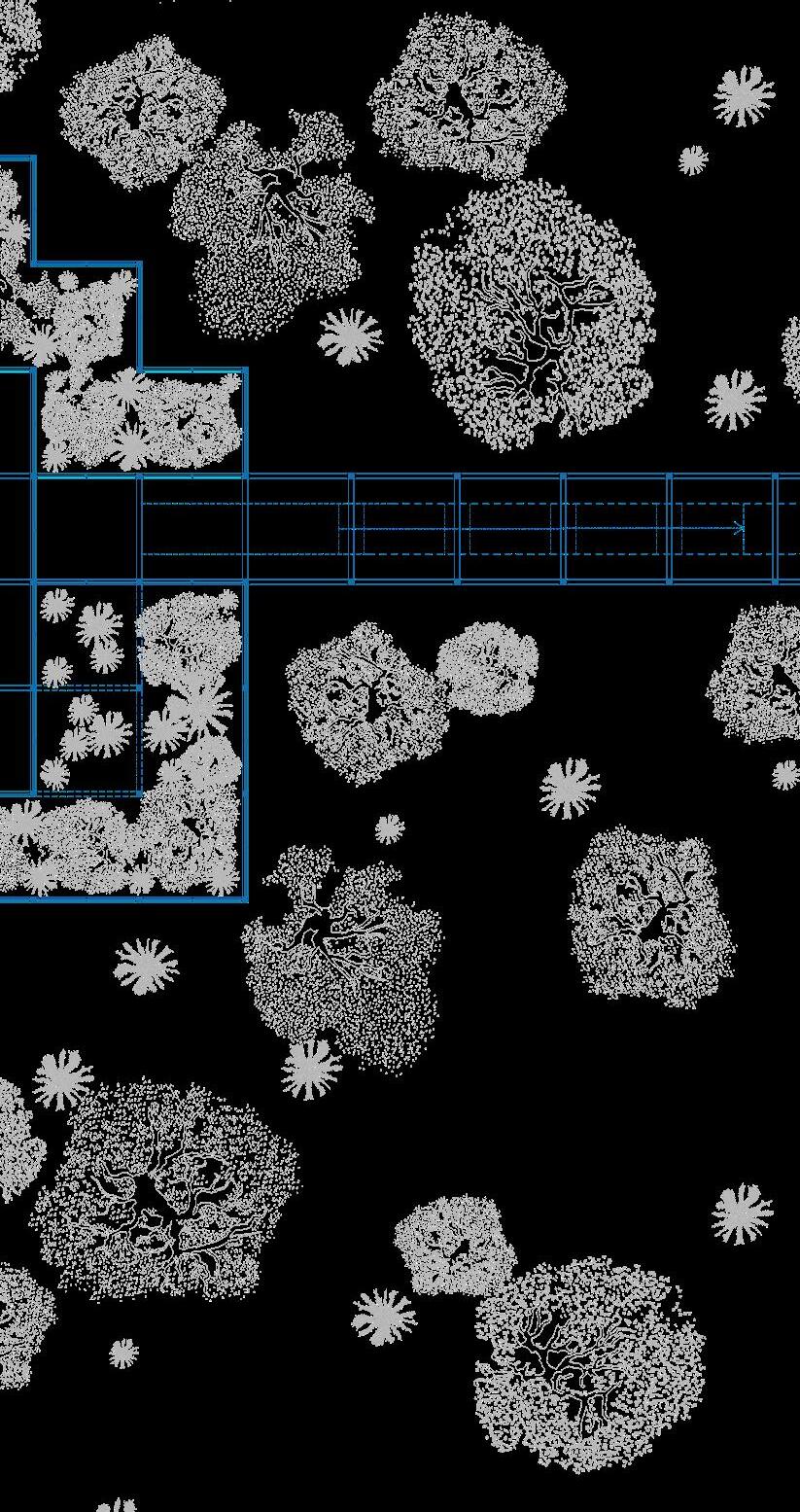

opposite : Masterplan with Sound Garden

above : Pavillion Plan Longitudinal Section