0700 SRM 1595

Cooling System

Clutch engagement is also influenced by actual viscosity of the viscous oil. Engagement is higher at lower temperatures. Engagement is lower at higher temperatures. The ECM compensates for differences in engagement, but at extremely cold temperatures the normally lowest engagement of 30% may remain at a higher level because of the higher viscosity. The reaction time for a changed engagement depends on actual viscosity and rotor speed (engine speed). This is particularly noticeable when comparing the start of a cold engine and a warm engine. After cold starting the engine, it will take at least 30 seconds at high idle before the oil at the rotor has disappeared, disengaging the clutch. The fan clutch of a warm engine will disengage in less than 20 seconds after the engine has been started.

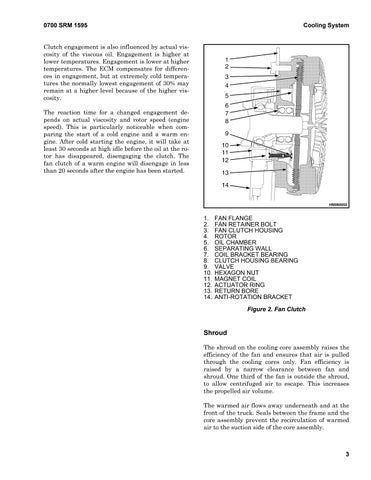

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

FAN FLANGE FAN RETAINER BOLT FAN CLUTCH HOUSING ROTOR OIL CHAMBER SEPARATING WALL COIL BRACKET BEARING CLUTCH HOUSING BEARING VALVE HEXAGON NUT MAGNET COIL ACTUATOR RING RETURN BORE ANTI-ROTATION BRACKET Figure 2. Fan Clutch

Shroud The shroud on the cooling core assembly raises the efficiency of the fan and ensures that air is pulled through the cooling cores only. Fan efficiency is raised by a narrow clearance between fan and shroud. One third of the fan is outside the shroud, to allow centrifuged air to escape. This increases the propelled air volume. The warmed air flows away underneath and at the front of the truck. Seals between the frame and the core assembly prevent the recirculation of warmed air to the suction side of the core assembly.

3