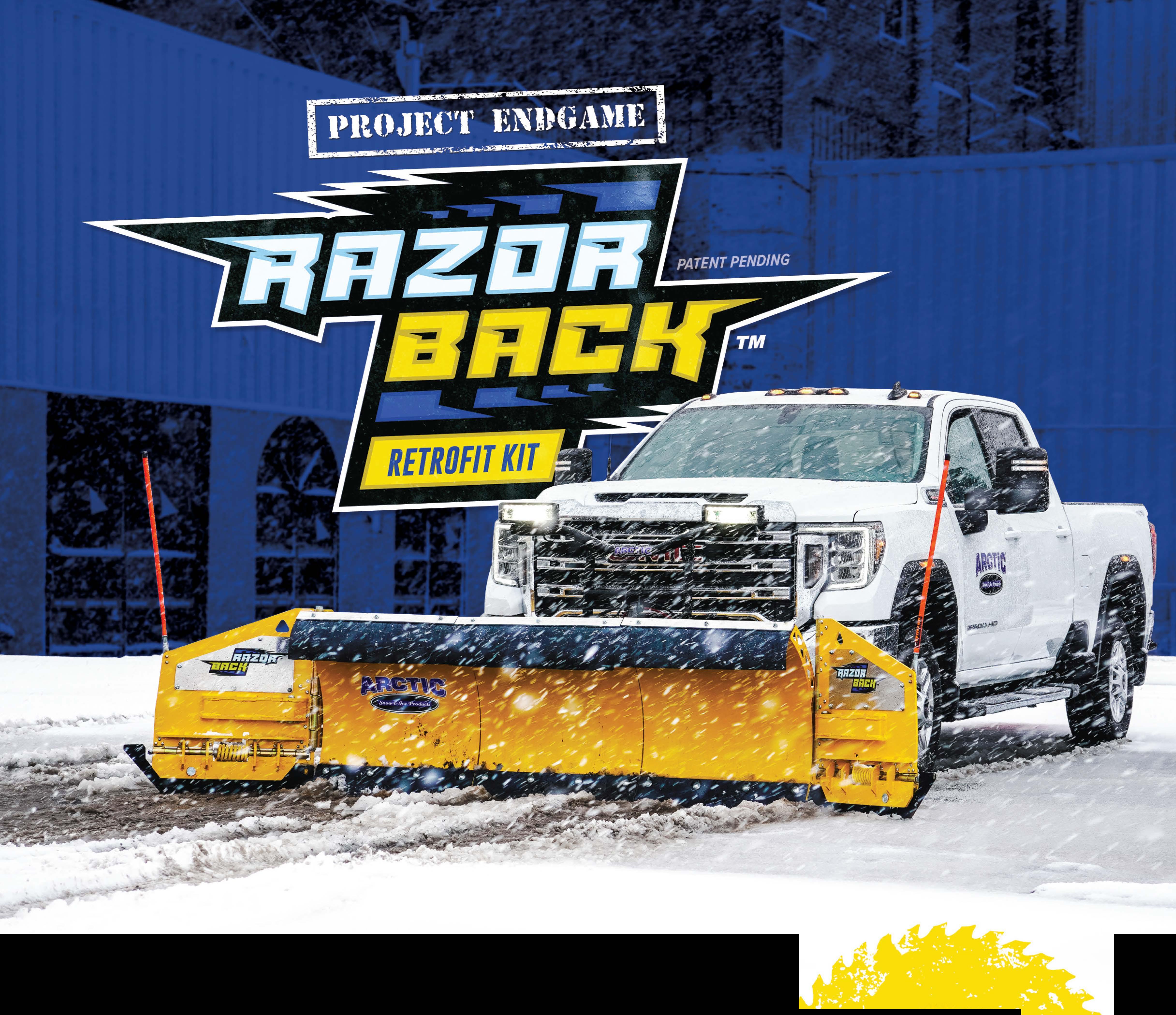

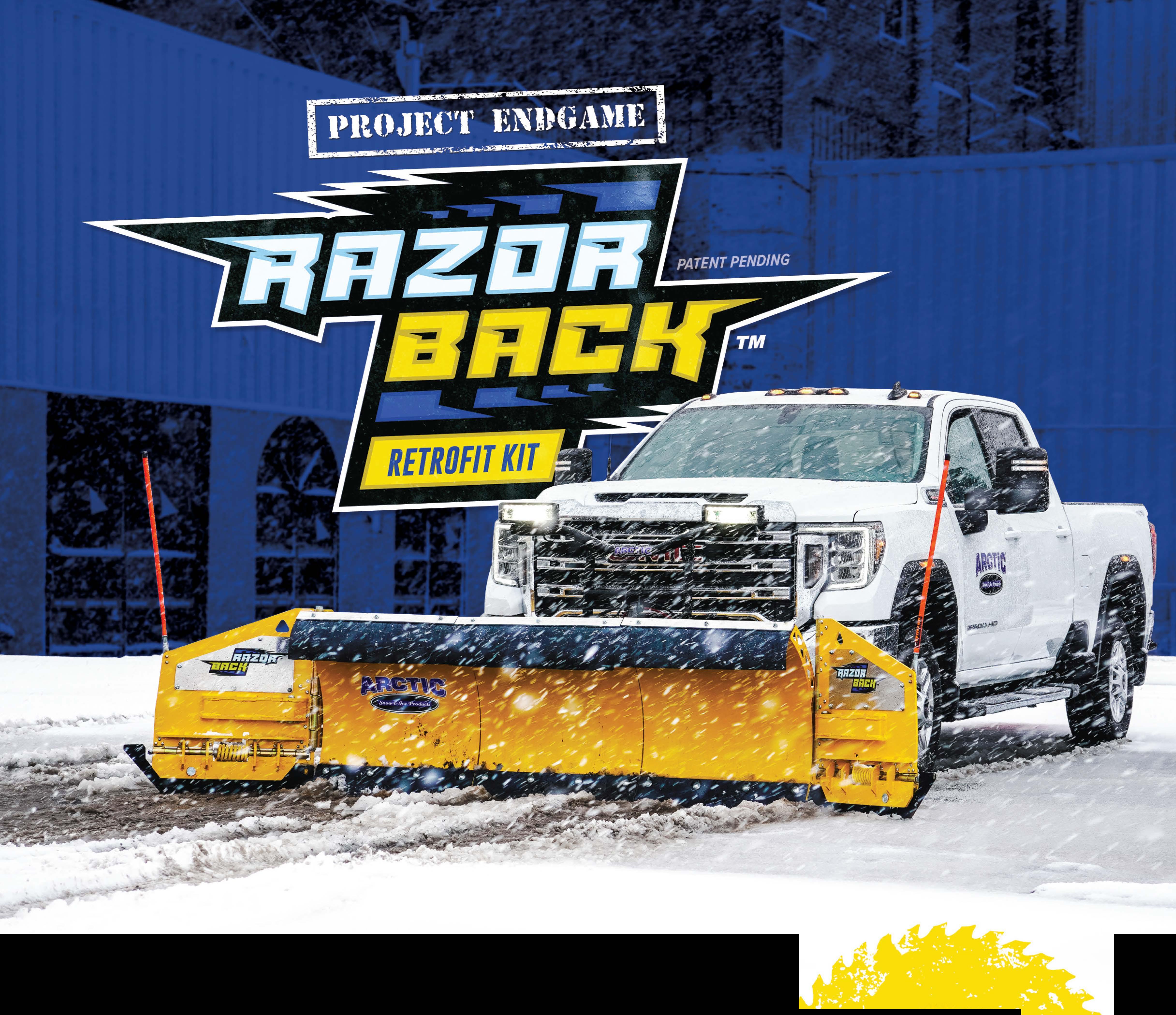

Finally,afterfiveyearsinthemaking,theNEWRazorBack'"RetrofitKitbringsthe bestoftheoriginalArcticSectionalSno-Pusher™ andtheSectionalSno-Wing™ to yourpickuptruck.

Withindependentsectionalmoldboards,impactabsorbingpolyblockdesign,AR400 trippingcuttingedgesandfreefloating,hydraulicallyadjustablewings,the RazorBack'"isjustasforgivingastheSectionalSno-Pusher™ -andbuilttolast,too.

By MIKE McCARRON

Now that COVID-19 is officially behind us, it was nice to see this year’s Snow & Ice Symposium in full swing with people conversing and exchanging ideas in person. After the Symposium, our team sat down and shared the information we gathered, from speaking with vendors to notes we took during the education seminars. The amount of valuable knowledge and amazing nuggets of information we gathered was impressive.

Labor was one of the most often discussed concerns. This was a universal concern in every market.

Year-round recruiting. Several people that we talked to said they were recruiting year-round, regardless of the size of their operation. In the past, they advertised for staff in the early fall. Now, many strive to be fully staffed before the first snowflake falls.

New marketing approach. Apps help with advertising to younger generations that prefer using apps to phone calls, job listing boards and personal interviews. Most companies agreed that using apps to advertise openings is the way of the future.

Technology is becoming more available for our industry on many fronts, and amazing new technology and equipment are being embraced by more and more companies every day.

Site cameras. Information is power, and information-gathering technology is a powerful tool. For example, onsite cameras can transfer valuable realtime images and data to contractors and building owners. Now that pricing and availability are within reach of most companies, these cameras will likely become very popular.

Site measuring. The other nice type

of software we saw was the site measuring tools like parking lot measuring systems, site photos and placement markers. These tools help production teams assess damage and other areas of concern. On display were also full site overlay and map coloring systems for each division within our industry to help manage everything from large loaders to sidewalk and icing crews.

Training. We learned that a new trend, thanks to the popularity of platforms like TikTok, is 15- to 30-second training videos to help people more easily learn and retain information before going out to job sites. Some companies have had success with this quick training style. We will be bringing this practice into our organization.

As is usually the case at in-person conferences, a tremendous amount of informal “learning” goes on outside of the classroom sessions. This conference did not disappoint. Casual conversations during lunch and dinner were crazy! The conversations went from one extreme to the other. One discussion centered on how some areas had record-breaking snowfalls but some areas had no snow, and we weighed the pros and cons to both situations.

The feeling of camaraderie among the attendees was palpable. So many business owners and managers told others to “just call if you ever need anything.” It is heartwarming to

know that 99% of people are willing to help each other when they are not in direct competition. (Although, I got the sense that these folks would help each other even if they were in direct competition.)

Some of my direct competitors were at the conference, and I enjoyed seeing that they are striving, as we all are, to up their game. It only serves to help our industry when companies work to do better and raise the bar for service in their areas.

If you attended, follow up with the connections you made. Reach out to those people who talked to you, helped you, and gave you even a tiny nugget of information. The time we spent at this event away from our businesses and families learning, sharing and connecting with others is valuable, and will absolutely help you further your business. But only if you use the information and follow up with the contacts you made! I hope you had as much fun and learned as much as I did. And if you didn’t attend, it’s not too early to start planning for Pittsburgh, June 25-28, 2024!

Mike McCarron is president and founder of ImageWorks Landscape Management, a commercial landscape maintenance and snow removal firm in the Northern Virginia market. He has 20+ years of industry experience. Email him at mike@imageworkslandscaping.com.

EDITORIAL

Director of Education & Content

Cheryl Higley // 262-236-9972 // cheryl@sima.org

Design & Production Director Lisa Lehman // 216-798-1853 // lisa@sima.org

ADVERTISING SALES & MANAGEMENT

Senior Manager, Engagement and Business Development

Kerri Joseph // 614-557-3948 // kerri@sima.org

DIGITAL MEDIA & MARKETING

Manager, Marketing & Communications

Stephanie Orvis // 262-236-9948 // steph@sima.org

SUBSCRIPTION

Subscription changes/updates: https://www.sima.org/subscribe

EDITORIAL ADVISORY COMMITTEE

Charmaine Allen Allen Builders & Landscape

Nichole Ashton, CSP North Country Snow and Ice Management

Jim Hornung Jr., CSP

Elbers Landscape Service

Tyler Jabaay Priority Landscape & Maintenance

Rick Kier, CSP Forge Ahead Consulting and Software LLC

Bob Marks, CSP, ASM emi landscape

William Moore, CSP, ASM

Executive Property Maintenance

Dean Outhouse, CSP, ASM Piscataqua Landscaping

10140 N. Port Washington Road, Mequon, WI 53092 414-375-1940 // info@sima.org // www.sima.org

Chief Executive Officer

Martin Tirado, CAE // martin@sima.org

Chief Operating Officer

Brian Birch // brian@sima.org

Director of Events

Heather Carew, CAE // heather@sima.org

Manager, Education & Credentials

Ellen Lobello // ellen@sima.org

Senior Manager, Membership Evan Newman // evan@sima.org

Jason Ostrander, CSP East End Group

Thomas Skuta, CSP USM

Robert Young K.E.Y. Property Services

Michael Wagner, CSP, ASM Colorado DesignScapes Co.

Manager, Finance & Operations

KC Hallgren // kc@sima.org

Manager, Billing & Member Services

Aimee Krzywicki // aimee@sima.org

Office Manager & Executive Assistant

Nikki Luedtke // nikki@sima.org

Business Process Analyst

Nakishia Lee // nakishia@sima.org

SIMA OFFICERS & DIRECTORS

Board Chair: Mark Arthofer, CSP, Skyline Construction

Immediate Past Chair: Jonathan Crandall, CSP, JC Grounds Management

Vice Chair: David Wescott, CSP, Transblue

Secretary / Treasurer: Chris Hinton, CSP, GRM Inc.

Ruben Diaz, ASM, Diaz Group LLC

Connie Gaul, ASM, Brightview Enterprise Solutions

Jeff Heller, CSP, Innovative Maintenance Solutions

Patrick Kane, CSP, Evercor Facility Management

Danny Milligan, ASM, Strathmore Landscape Contractors

William Moore, CSP, ASM, Executive Property Maintenance

John Janes, CSP, ASM, Caterpillar

Debora Babin Katz, TrucBrush Corporation

Snow Business (5730) (ISSN 2155-2576) Copyright © 2023 by the Snow & Ice Management Association, 10140 N. Port Washington Rd., Mequon, WI 53092 is produced and published February, April, June, August, September, October, December by the Snow & Ice Management Association. All Rights Reserved. No part of this publication may be reproduced or transmitted by any means without permission of the Publisher, SIMA – Snow & Ice Management Association. Subscribe at SIMA.org/subscribe. Periodicals postage prices is paid at Mequon, WI, and additional entry offices at 11716 S. Preston Hwy, Lebanon Junction, KY 40150-9998. POSTMASTER: Send address changes to SIMA - Snow Business – PO Box 8818, Lowell, MA 01853

When winter weather is in the forecast, you need to launch a full-on assault. The all-new MARAUDER™ line of stainless steel hoppers from Western Products does just that. The line includes seven capacities and your choice of delivery system—conveyor or all-new HELIXX™ auger technology—so your operation can select the right hopper based on vehicle application and deicing material. MORE JOBS.

In its third year, the 2023 Leadership Forum reached record attendance!

The first day’s keynote speaker, Don Yaeger, touched on key concepts from his book “What Makes the Great Ones Great” as he told his personal stories of playing 1 vs. 1 basketball with Michael Jordan and his emotionally powerful story of former NFL running back Warrick Dunn’s message on forgiveness.

The day-two keynote, David Rendall, covered his concepts of the Freak Factor and Pink Goldfish that guide us to discovering our unique characteristics and using perceived weaknesses as incredible strengths. The warm Florida sun was made cool by the ocean and relaxing pools at the Ponte Vedra Inn & Club. This is not just a review of an event you can no longer attend … consider this an invite to the 2024 Leadership Forum!

Mark your calendars for August 12-13, 2024, and Join SIMA and our growing list of leaders and snow professionals in Vail, CO!

VariTech Industries is a leader of automatic salt-brine production, liquid storage, transfer and mobile application systems. Our automated brine production and blending systems provide an ef cient, cost-effective solution, allowing you total road control.

Thanks to this year’s sponsors: Western Snowplows, Fisher Engineering, SnowEx, ProTech, BOSS Snowplow, WeatherWorks, Yeti and the SIMA Foundation.

SIMA’s Financial Benchmarking Tool for Snow Contractors debuted in the spring to help companies measure their numbers against different competitive sets (e.g., company size/type, revenue, location, etc.) in the industry.

The tool can answer questions like:

• What is the average rate for a loader in my region?

• For companies with $100,00 to $250,000, what’s their average profit margin?

SHARE YOUR DATA: Access the tool and submit your data (anonymously) at sima.org/benchmark

• For companies that aggregate service, how do their expenses compare to mine?

• For smaller companies, what is the breakdown in contract types?

We need your help to continuously grow the data included in the competitive sets. The more companies who contribute, the better the tool becomes.

DO IT ALONE.

Customizable training ensures that your staff is equipped for the future.

Our professional network can help grow your business, identify trends, and assist in navigating industry challenges.

Rely on our expansive resource library and industry partners to elevate your business.

The business climate is challenging. We work to make sure you are seen! Our marketing kits, online directories, and standards elevate the industry.

When we show up together, we can strengthen our industry. Join today at www.sima.org/join.

Your contracts for the 2023-24 winter should be signed. There is a lot to do between now and when the first event is on the radar to ensure your team is prepared and ready for service. Thorough preseason preparations will be worth the time and effort, so don’t skip over the key to-dos, including account management, team training, equipment and site preparation, and communication details.

Selling snow services can’t exist in a silo — especially as you seek to grow your business. The operations team will have valuable insights to make sure that what is being sold can successfully be achieved. Don’t wait until the contracts have been signed to bring operations into the mix. Establishing a process of partnership will result in a smoother transition between sales and operations that will hopefully result in more satisfied customers.

Salesperson meets with the prospective client to ID level of service expectations and any pain points.

1 2 5

Operations allocates resources (labor, material, equipment) for the sites and adds customers into the overall service plan.

Sales brings discovery data to the person who will bid the project to create a service plan. They also consult with operations for insight on the size, complexity and level of expectation.

4

The handoff to operations takes place, starting with a site visit that includes operations and sales team representatives as well as the client.

3 6 7

Ops team executes the winter service plan. Sales team checks in with customers.

Sales finalizes the contract and conducts a preseason walkthrough.

Sales and ops team representatives meet with customers at the end of the season to debrief and plan for next season.

Source: Winter Services, Compass Network presentation. Members can view the presentation at train.sima.org.

Snow businesses face unique challenges related to staffing, training and controlling operations. One of the best ways to address these challenges is to conduct an annual snow kickoff meeting.

Everyone involved in snow operations, including field teams, supervisors, managers, dispatchers and administrative personnel. Hold a separate meeting for service providers so that a clear employee/sub distinction is maintained. Senior managers and owners should attend to send the message that these meetings are important.

When should it be held?

Most snow kickoff meetings should be held in late October or early November (depending on when winter events in your market typically begin). Do it too early and you risk memory loss; too late and you risk being unprepared for the first event (especially if it’s a surprise early storm).

Where should it be held?

If presentations or videos are to be shown, make sure everyone can see and hear clearly. If training or demonstrations are planned, equipment should be prepared and available.

Make time for new hires.

Another reason for the meeting may be to complete new hire paperwork and orientation. Conduct this before or after the team convenes for the kickoff meeting.

Make it fun.

An effective kickoff meeting will not only be a productive learning experience, but will also be fun. This meeting is an opportunity to celebrate past successes and enjoy each other’s company before winter operations begin.

Save plenty of time for questions and create an environment in which people are comfortable asking questions. Having smaller groups will make a big difference in this regard.

In previous issues of Start Up, we shared the benefits of training your team. As you get closer to the season, it’s time to ramp up your efforts. Site-specific training without the pressure of a storm bearing down can identify any issues with your winter operations plan and leave time for additional training.

Each company’s kickoff meeting will be a little different, but there are some common topics that should always be included:

Contact information & communication tree

On-call expectations / event mobilization

PPE

Accident / incident procedures & reporting

Documentation standards & processes

Service data submissions, including use of any third-party or client-required apps

Payroll procedures

Equipment & routing assignments

Snow clearing, sidewalk & deicing/anti-icing techniques

Training includes everyone. Train or retrain each team member (yes, even veterans) to operate the equipment they’ll use on their site(s) safely and properly.

Conduct site walkthroughs. Using the site map as a guide, operations managers and their teams should visit each property to visualize operations and identify hazards that may not be visible once snow is on the ground. Each team member should understand not only their specific role but also how the team should work together for safe, efficient and effective operations. Discuss the level of service; review onsite equipment, vehicle and tool usage; review safety procedures and practices; and discuss how you will complete the job from start to finish.

Conduct a mock storm dry run from start to finish. Putting the team in realistic conditions can be a very effective way to make sure people and processes are aligning properly before the first snowfall. A live drill will show any cracks in the plan that can be ironed out before a real event. Sites look different in the dark so call the team out at 2 a.m. and observe how the event runs. By putting the equipment under load, you can ensure equipment is operating as it should and that the assigned team members are operating properly and following the engineering plan.

Mother Nature doesn’t wait for you to be ready. Establish a schedule for your preseason equipment roll out. Preseason checks, annual services and pre-, during- and post-event checks are all part of a good preventive maintenance plan.

Preparation starts in late summer when you dust off your snow and ice control equipment and perform operation and serviceability checks. Don’t be the one who waits until they see snow on the ground before connecting their snowplow and/or spreader. Poorly maintained equipment will cost you in repair expenses and downtime. Follow these tips to prepare your equipment fleet for winter:

CREATE A READINESS SCHEDULE. If you don’t already have a fleet readiness schedule, make one. Identify your company’s snow season kickoff date and calculate the time you need to get your equipment ready. Leave plenty of time, knowing that current season maintenance and breakdowns may temporarily derail the schedule. If you perform other services and can’t do a complete switch over to winter operations, use a phased approach. Prepare one or two trucks with plows and spreaders as soon as possible in the event of an early storm and add more equipment as winter nears.

STAGE EQUIPMENT. Work with clients to stage equipment and materials onsite early. This cuts down on deployment time when the first event starts.

PREPARE FOR BREAKDOWNS. You’re eventually going to need to make a repair; and Murphy’s Law says you’ll need to execute that repair at the worst part of the storm in the middle of your route. Keep an equipment “first aid” kit handy. At minimum, every truck should carry basic hand tools and a hydraulic hose repair kit as the first line of defense in the event of a breakdown.

ORDER PARTS EARLY. The closer you get to the start of the season, the better the chance that parts will be on backorder. Early on, stock major parts, such as plow pumps, spreader motors, etc., that may be hard to find in the middle of a storm. Maintaining a great relationship with your dealers is important when it comes to parts availability. Let your dealer know your service needs as well as your snow and ice control equipment density to help them stock the appropriate parts you’ll need in the future.

ESTABLISH BREAKDOWN PROCEDURES. Ensure your drivers and site managers follow protocol, including how to report problems and any required documentation.

When you commit to clearing a lot, you mean it. No snow left behind. With TRACE™ edge technology that contours to the plowable surface, the all-new POWER PUSHER™ plows move massive amounts of snow—scraping down to the pavement—so you can save time and money with less salt usage.

MAKE YOUR MARK.

During the Snow & Ice Symposium in Hartford, SIMA recognized several companies and team members for their commitment to culture, professionalism and dedication to their organizations and the industry at large.

Congratulations to this year’s honorees!

Of the many complex, high-stress jobs in the snow and ice profession, the role of dispatcher may reign supreme. The position involves trying to organize chaos – making plans and then having to change them as conditions shift; prioritizing in some cases and triaging in others. So, the fact that Aaron Schrot is a Snow Ops Employee award winner in his first year as dispatcher is all the more impressive. And he did so by taking on responsibilities far beyond the usual role of dispatcher.

In 2022 alone, Schrot helped to expand From the Ground Up’s out-of-town operations from $50,000 in sales to over $1 million by becoming heavily involved in snow sales. “He also ran a supervisory route and expanded our use of liquid and was in charge of when to pre- and post-treat and at what rates, to ensure we weren’t being wasteful,” explains CEO Mitchell Mulert, CSP. “Since Aaron has been in charge of dispatching, we have implemented the use of liquid on all sidewalks when appropriate

and have added two trucks to pre- and post-treat with brine to cut back on salt usage.” He’s also researched products and application methods, which have increased efficiency, Mulert notes.

But it’s Schrot’s commitment to customer service that has been the biggest driver behind his success. “The customer is always first with Aaron; he prides himself on never resting until every site is serviced

to the standard we expect and sell our customers,” Mulert says.

Just as notable is Schrot’s dedication to the company and the industry. “Aaron shows up every day with the same passion for this industry as the day he decided to make it his lifetime career,” says Mulert. “Aaron’s the first one in and last one to leave in a snowstorm… In today’s world, leading by example is one of the most important things to building a strong team, and Aaron does just that.”

Schrot’s 10 years in the industry and two with From the Group Up have given him an understanding of both snow operations and the capabilities of his company and coworkers. “Aaron is an all-around great person who knows the name of every single employee and subcontractor, and you will always find him in the breakroom before each storm, greeting each and every person who walks through the door,” states Mulert.

“Aaron always has a smile on his face and is known for being our ‘can do’ person. The employees truly respect Aaron’s authority and how much he cares about his job and our customers.”

Elizabeth Ramirez’s rapid rise to the position of site supervisor is a testament to the potential for motivated and talented team members to advance in the snow and ice industry. And Markham Property Services (MPS) showcases just how companies should be looking to advance those with the same qualities exhibited by Ramirez: natural leadership, a commitment to learn, dedication to the job and excellent communication skills.

A local temp agency assigned Ramirez to MPS in 2021. She worked as a shovel crew leader and Ken Jorgenson, CSP, ASM, health and safety training manager/winter operations dispatcher, says that Ramirez quickly stood out. “Elizabeth demonstrated excellent leadership skills and an ability to provide quality service.” In spring 2022, the company hired Elizabeth as a direct employee and she became a grounds maintenance leader.

Jorgenson. While the site has extremely high service standards and high liability potential, Ramirez was up for the challenge. “Undaunted, Elizabeth engaged 100% in our supervisor and leadership training sessions, time and asset management training, and plow operations training – quickly demonstrating that our confidence in her abilities was not misplaced,” Jorgenson notes.

OVER $5 MILLION 2023

During the winter of 2022/23, MPS was so impressed by Ramirez that it made her a site supervisor on one of its most challenging accounts: a 21-acre college campus with multiple facilities and residence buildings.

“Despite never having plowed snow or driven a plow truck or loader, the management group at our company had confidence in Elizabeth’s ability to learn quickly,” explains

As a “hands-on” site supervisor, Elizabeth managed a team of three loaders and plows, two sidewalk tractors and two three-person shovel crews. This included coordinating salting operations, scheduling snow removal operations poststorm to quickly free up the college’s valuable paid parking spaces, and completely managing the 24/7 needs of the site (for example, prioritizing early day care areas in the morning and classroom buildings in the evening so night classes could take place).

Within MPS, Ramirez assisted in the company’s weekly tailgate training by leading the Spanish language group sessions to ensure that all team members understand the important safety and operational information being presented. Jorgenson states: “In a very short time, Elizabeth has

become a very valuable and trusted member of our company team.”

Jorgenson adds that the results of Ramirez’s hard work were very tangible. Despite the area experiencing three significant/historical snow events, “the college’s level of satisfaction was evident as we recorded 20% fewer calls/concerns compared to the previous year; property damage incidents were halved; and not once were classes canceled due to our timeliness or lack of service.” In a very competitive environment, MPS was the successful bidder for the account again next year “due mainly to the quality and customer satisfaction demonstrated by the excellent work of Elizabeth and her team,” he adds.

As office administrator at Green Earth, Rosa Peña has a wide range of responsibilities: accounting/ bookkeeping, billing, contract management, customer service and general office paperwork. Oh, and add to that marketing and communications, subcontractor management and documentation.

“In the two years she has been in this role, Rosa has shown a willingness to do anything to help grow and advance our company,” says Jason Fassler, CSP, ASM, operations manager for Green Earth.

Fassler points to several key areas where Peña has worked to improve company operations, including

streamlining service provider onboarding and the contract process by minimizing the steps involved and maximizing data being captured. “Rosa also took on a large bookkeeping role that has allowed the team to be more

informed on company financials, while also organizing the company P&L and other financials,” he adds. Additionally, Peña helped to streamline Green Earth’s billing and collections efforts by keeping a constant open line of communication with customers. She has even taken on the role of customer contact before snow events to advise about storms plans; and during operations she handles many inbound calls from customers.

“She knows exactly how to handle and dispatch teams as needed. Rosa makes sure the customers are kept up to date on any issues they may have,” Fassler notes, adding that Peña has a real passion for snow and jumps in to help operations managers any way she can.

Finally, Fassler says that Peña’s Spanish language skills have helped to overcome any communication and information-sharing barriers within the company.

A family of solutions to help you manage, measure, and grow.

Optimize operations, measure and bid more consistently, and make data driven decisions to increase profits.

Manage operations more efficiently with instant access to accurate job costing data, streamlined workflows, and real-time communication tools.

Measure job sites accurately and create winning estimates fast using PropertyIntel's precision measuring tools and aerial imagery.

Grow and scale profitably by harnessing the industry's top solution for evolving businesses.

BRILAR / FARMINGTON HILLS, MI

Not even the best-performing snow company can survive if it doesn’t get paid. That makes “accounts receivable and collections specialist” an incredibly important job; it’s one that Stephanie Beckwith excelled at in her first year at Brilar.

When Beckwith started, the company had over $1 million in overdue receivables, “which was unfortunately not unusual,” wrote Michael Voories, CSP, who nominated Stephanie before departing as president & CEO of Brilar. “In just a year Stephanie reduced past-due receivables to below $60,000.” Now, few clients have outstanding balances, which made a tremendous difference for the

company by improving cash flow and saving considerable monthly credit line expenses.

Voories noted that Beckwith made these strides without a heavy-

handed approach: “Stephanie has the ability to collect past due money and prevent reoccurring delinquencies while actually enhancing relationships with those same clients. It’s quite remarkable.”

Much of the reason Beckwith has been successful is because of the systems she has put in place, Voories wrote in his nomination essay. “Stephanie created a system where she reminds clients when invoices are coming due and when they are late, and she knows exactly when to pick up the phone instead of waiting.”

Voories praised Beckwith’s ability to stay focused on her main mission without being distracted by her other responsibilities, and to do a tough job with a smile. “Stephanie is always polite and friendly – everyone in the office loves working with her,” he said. “Stephanie is, without question, the type of business professional anyone would be fortunate to have on their team!”

Maria Sanchez’s primary role is working in human resources at Tricon Group, but she sees it as her job to help the company succeed in any way she can. “Maria really stepped up this season to help out with snow,” says Madeleine Manas, Tricon’s social media and marketing coordinator. “Not only was she responsible for handling daily HR tasks, but Maria helped with the onboarding process for our workers, their training, setting them up on Yeti, and even took on the role of a dispatcher since we were short-staffed.”

Manas says that final role – as dispatcher – wasn’t something that Sanchez muddled through as a fill-in, but rather something that she excelled at: “Maria really

learned how to dispatch in one day and was already an expert by the following storm. Maria has become one of the main points of contact for many of our workers and has been able to translate and quickly communicate with all teams.”

When a surprise storm hit and the company needed to get ahold of crew

members, some of whom are not fluent in English, Sanchez stepped up – from home – to track down a few employees and ask them to start spreading the message. “Maria was able to communicate with them in time for them to be ready to service their sites before businesses were open. It was Maria’s quick-thinking and resourcefulness that helped ensure customers’ properties were serviced in time,” says Manas.

Managing a wide range of responsibilities makes her an invaluable team member, says Manas. “Maria is seen throughout the company as dependable as she gets tasks done in a timely manner and is always able to answer any question or address any issue quickly. We know that no matter what we ask of her, Maria will exceed our expectations.”

Success in sales is relatively easy to spot simply by looking at topline numbers. That’s certainly the case for Jason Hall, senior commercial account manager at EMI. He is one of the company’s 11 sales reps, yet his accounts represent 23% of the company’s overall snow revenue.

But to truly understand Hall’s success, and value to EMI, you have to dig a little deeper. Do that and you’ll see that Hall is not just selling clients but maintaining them over time. “Jason had 100% renewal for his contracts for 3-5 years, which allows the team to plan for staffing and equipment,” explains Annabelle Weisgerber, EMI’s marketing manager. This is a function of understanding that sales is not a one-time event. “Jason consistently receives exceptional reviews from customers,” says Weisgerber. “He focuses on open and effective communication. Initial client meetings, site walks and understanding expectations are important to creating a relationship with the client.”

OVER $5 MILLION

And Hall takes a hands-on approach to ensuring his clients receive the service he has sold, communicating with the company’s 24-hour dispatch team during snow events and actively participating in snow events by monitoring conditions with crews and filling out safety and site inspections.

Weisgerber also notes Hall’s role in growing EMI’s snow business. Just this past year, for example, he added an important new client that accounts for 3% of company-wide snow revenue. And when that

“Jason had 100% renewal for his contracts for 3-5 years, which allows the team to plan for staffing and equipment.”

—ANNABELLE WEISGERBER, EMI’S MARKETING MANAGER

client realized early in the season that the zero-tolerance service it had requested was costing more than it had expected, Hall worked with them and EMI’s operations team to reshape the scope of the contract. “Together they were able to make some areas of the property zero tolerance while other areas were bumped up to reduce the cost,” explains Weisgerber. “The client was thrilled with the changes and happier with their bills on the last few snow events of the year. This focus on customer experience is a key to Jason’s sales approach.”

Hall is a true leader on the EMI sales team, Weisgerber emphasizes: “He consistently offers knowledge and experience to sales representatives who are new to the team, joining them on client meetings and teaching them his strategy. He is passionate about educating the client, exceeding expectations, and helping the company provide the best service possible. And he also regularly interacts with our crews and shows his appreciation for their efforts.”

Talk about no rest for the weary. As shop manager at Outdoor Pride Landscaping & Snow Management, Nate Klaver’s preseason is busy as he manages a team of four to service and repair machinery, install new equipment and fabricate items. “This past season, they had our snow fleet ready to redeploy in record time – August 15,” marvels Degen Kelly, ASM, the company’s director of operations.

Klaver took a methodical approach to getting everything ready early: not only taking detailed notes on all equipment repairs that were at the end of the prior winter season, but also putting together a presentation on the most common, preventable damages incurred and presenting ideas to the operations team on ways to prevent them. He also established a standard operating procedure for onsite breakdowns, which is now followed by the entire company.

Klaver sees education as a big part of managing the shop, says Kelly: “Nate plays a critical role in not only developing training for the team, but leading training events.” Finally, Klaver’s equipment knowledge is put to good use as he played a pivotal role in revamping Outdoor Pride’s asset management program to ensure that every new asset is allocated properly.

Klaver’s workload intensifies once the season starts and he takes on the additional role of winter operations manager, in which he manages two hospitals that utilize 15 pieces of equipment and dozens of walkway staff. “These are our trickiest accounts and Nate manages them with ease,” says Kelly. “Thanks to his initial kickoff training event with the operators and his continuous training throughout the season, Nate’s team is always dialed in. If an issue arises, Nate ensures the entire team is aware so that it won’t happen again. And he does all this while also taking phone calls to assist team members in other areas with equipment troubleshooting.”

Klaver’s hard work and talents are recognized outside the company

as well. “He ‘wowed’ one of his hospital accounts so much that when their self-managed grounds crew dissolved, we were their first choice to take over operations ‘as long as Nate was involved,’ ” reports Kelly. Even a visitor was impressed by the attention to detail: “After an 8-inch event of wet, heavy snow, many vehicles of long-term residents at the hospital, doctors and nurses were heavily snowed in. Nate ensured that their walkway team shoveled between all these vehicles so none of them would have the burden to do so after a long stay or shift. A hospital patron actually took a picture of this and posted it on their social media, which was then shared by dozens of others.”

Kelly uses words like “can-do attitude,” “organized,” “selfless” and “innovator” to describe Klaver but says one word perhaps best sums him up: leader. “Nate leads by example and never asks anyone to do something he wouldn’t do himself….And he is always trying to pass on wisdom he has learned over his career to others so they can be just as successful.”

LANDSCAPE AMERICA // WRENTHAM, MA

Kyle Correia, CSP, ASM, has been production manager at Landscape America for nine years (and with the company for 14), and over that time has amassed huge responsibilities – like overseeing a portfolio of more than $1.5 million in snow revenue. But he remains a very hands-on leader, says company President Doug McDuff.

Correia’s work begins long before the storm as he monitors weather forecasts and fine-tunes a plan of attack, which he communicates with a large team of machine operators, plow truck drivers, salt truck drivers, sidewalk crew members and service partners, to make sure they are all ready. “Despite managing a very large portfolio of work, Kyle does all that prep work for his area and then gets out of the office and works a snow event alongside his team,” McDuff notes. “Kyle drives a truck with a plow and has a snowblower as well. He will help plow a site and then jump out of the truck and help the sidewalk crew. Then he moves to another site and does the same for them. The whole team rallies around Kyle for this – it creates an environment where Kyle’s team does not want to let him down.”

McDuff says that Correia is always willing to go the extra mile to help Landscape America succeed, whether that’s rolling up his sleeves to repair a piece of equipment, helping devise quick-fixes for account managers during crunch time, training a new employee, helping other district managers get caught up during a major event or even devising solutions for software problems. McDuff says that this selflessness does not go unnoticed. “Kyle is very good at leading up and down the organization – he conducts himself in a very professional manner that radiates through his team as well as the other managers and to upper management.”

Correia has been a key member of the Landscape America leadership team for five years, “and has played a pivotal role in our growth, both in revenue and culture,” says McDuff. Correia has been instrumental, for example, in helping the company successfully implement a brine program, develop and implement open book management, and helps to develop the company’s preseason and midseason training programs. Currently he is leading the company’s efforts to implement Lean Management. Perhaps most telling, McDuff says Correia was also “one of the select few who developed our core values and helps us make sure our team is living by those values daily.”

“Despite managing a very large portfolio of work, Kyle does all that prep work for his area and then gets out of the office and works a snow event alongside his team.”

—DOUG MCDUFF, LANDSCAPE AMERICA’S PRESIDENT

Subzero Snow Pushers is one of the leading manufacturers to offer high quality snow pushers manufactured in the USA. Our patented cutting edge and shoe design allows our snow pushers to scrape the pavement clean, reduc-ing salt use. Unlike conventional plows, our snow pushers are designed to contain and move forward large amounts of snow, allowing you to move more snow in less time.

Contact us now for the lastest top of the line snow plows to level up and expand your business.

www.subzerosnowpushers.com sales@subzerosnowpushers.com 207-709-1002

The Best Places to Work in Snow & Ice award recognizes companies that are focused on empowering their workforce and promoting our industry as one in which you can build successful and rewarding careers. This annual award is bestowed on companies that meet or exceed certain criteria related to company culture, leadership, training and personnel support and engagement.

SNELLER SNOW & GROUNDS

Byron Center, MI

Palatine, IL

Menomonee Falls, WI

WINNERS NOT PICTURED:

DeHamer Landscaping, Grandville, MI

MSNW Group, LLC, Ferndale, WI

Pro Snow Solutions Ltd., Abbotsford, British Columbia

York Property Services Ltd., Vaughan, Ontario

By DAVID GALLAGHER

Ihad the pleasure to introduce a newcomer to the industry at this year’s 26th Annual Symposium. GreenerConcepts Lawn Care Solutions owner Jacob Peffer is a local business owner who I met at the gym. At 22 years young, he has the energy and drive you would expect, which drew me to begin helping him with his business. Initially, Jake was unaware that it was my chosen profession to help snow and green businesses be more successful; and most of our interactions happened during our morning workouts. Eventually, I asked him to do some work at my house; and he figured out what I actually do for a living.

Jake is only in his second year in business and is still very much in learning mode. His desire to learn and to grow his business has been refreshing and, frankly, good for me. As a member of the SIMA Foundation Board of Directors, I have the responsibility to promote the Foundation and to help our industry understand how it gives back and furthers the cause of the professional snow and ice management industry.

In early 2023, I suggested Jake apply for the Alan Steiman Scholarship. Pushing Jake to apply for the scholarship was a way to promote the Foundation but also to honor Alan Steiman’s legacy.

In the early 2000s, Alan encouraged me to follow my dreams and get involved with a budding business making a big impact on snow and ice management. He also encouraged me to get more deeply involved in SIMA. Alan always had a knack for being right there when you needed him; and he was always willing to tell you what he thought, even if it wasn’t what you wanted to hear.

Alan passed away after a courageous battle with cancer in 2010. SIMA and the family established the Alan Steinman Scholarship

(From left) Nick Steiman honored his late father Alan by awarding the Alan Steiman Scholarship to Reed Martindale of EPM of Michigan and Jacob Peffer of GreenerConcepts Lawn Care Solutions at the 2023 Snow & Ice Symposium. SIMA Foundation Board of Directors Chair Paul Vanderzon, ASM was also on hand to congratulate the winners.

to provide full Symposium access and travel support for a first-time attendee. The scholarship is now part of the work of the SIMA Foundation.

Reed Martindale from EPM of Michigan also was awarded a scholarship. Having the opportunity to meet Reed and expose him and Jake to an event and organization that has meant more to me than I can measure was an amazing experience.

After he returned home, Jake told me he had no idea how important snow and ice management was and the impact it could have on his business. He’s been keeping me on my toes planning for this winter. I can think of no better way to spend my time; and I know that Alan did exactly the same thing for countless others.

I hope you had a chance to meet Jake and Reed. I hope you knew Alan and had the opportunity to take in his awesome personality and devotion to helping others. If not, I hope you got a chance to meet his son Nick Steinman at the awards ceremony.

I hope you’ll support the SIMA Foundation in its mission to provide scholarships, crucial industry research, and funding for dedicated branding and awareness for the professional snow and ice management industry. Learn how you can support the Foundation and the work it is doing at sima.org/foundation.

David Gallagher is principal for Spiritus Business Advisors and a member of the SIMA Foundation Board of Directors. Email him at david@spiritusba.com.

The Reach Right USA team received the 2023 Dean Fisher Innovation Scholarship for their ergonomic handle that quickly and easily attaches or detaches to long-handled tools to reduce the strain of using them.

BY

CULTURE CHANGE: ImageWorks Landscaping owner Mike McCarron (far right) and Operations Manager Angel Campos-Chavez have worked together to build an inclusive culture for its diverse team.

+ PAVING A LEADERSHIP PATH Angel Campos-Chavez stepped up to show he could lead and is helping other Latino team members see the possibilities. Page 28

It’s no secret that much of the workforce in the green and white industries is Spanish speaking. The U.S. Bureau of Labor Statistics reports that, nationally, just over 44% of those working in “landscaping services” are Hispanic or Latino. In some areas of the country, that figure is much higher.

For companies hiring these employees, there can be barriers – both in language and culture – to overcome. Successful businesses take the approach that overcoming these barriers is critical; and they make it a priority to do so, devoting the time and resources needed, just as they would to solve any other business challenge.

One great example is ImageWorks Landscaping, which services the northern Virginia market. Owner Mike McCarron and Operations Manager Angel Campos-Chavez have been partners in that mission.

McCarron started ImageWorks Landscaping in 1998 as a residentialonly company. Today, that number has shifted to 80% commercial and 20% residential but only provides snow services to commercial clients. The company has about 25 employees yearround, with that number swelling to as

many as 60 in the winter, with between $2 million and $3 million in annual revenue.

The client base isn’t the only thing that’s changed over the last twoand-a-half decades. When he formed ImageWorks, McCarron’s early workforce was less than half Hispanic. “It’s grown to be way more than that now, maybe 80 percent,” he says. While the majority of the office employees, including the sales and contract personnel, are native English speakers, most of those on the production side, from management to those working in the field, come from Spanish-speaking backgrounds.

As the ethnic makeup of the company diversified, communication challenges arose. “Sometimes words, even when translated, mean different things in different languages. Adjectives and descriptions can mean different things. We started getting a little bit of distortion in the company as far as training and understanding,” McCarron says.

Committed to keeping the company one cohesive unit, McCarron looked for solutions. He credits the key role

DUAL-LANGUAGE MEETINGS: PowerPoint presentations with photos, as well as both English and Spanish explanations, have minimized miscommunication.

Campos-Chavez has played in that mission (see “Paving a Leadership Path” for more on his growth within the company). “For many employees, their English is really rough; so, I try to always be around during the trainings, because we have had issues when sometimes the language barrier is really big,” says Campos-Chavez, who was born in El Salvador and is bilingual.

Campos-Chavez says overcoming the language barrier benefits both the employees and the company. “We use all the technology we can to help with that; we use tablets and software to make sure that everything that comes from the office is translated in both English and Spanish. When we have meetings about big projects, we are always running them in both languages. I think we do a pretty good job with that.”

Continued on page 30

Maneuver like never before with the responsive XRS™ skid-steer plow. Designed specifically for skid-steers, the XRS operates with existing skid-steer controls. Positioned straight ahead, it carries the load in scoop mode. Fully angled, the inside wing automatically retracts for efficient windrowing. Plus, the oscillating mount follows contours to improve scraping and cutting edge wear while reducing surface damage.

Angel Campos-Chavez joined ImageWorks Landscaping in 2009 as a driver. Since then, his aspirations and leadership skills have helped elevate him to his current role as operations manager.

“I noticed early on that Angel had more capacity, and he had more drive than other people,” says ImageWorks Landscaping owner Mike McCarron. “Some people have no desire to go up another level; they want to be a laborer or a foreman or a crew leader, and they want to stay at that level, and that’s fine. But to grow a company, you also have to find people who want to take it to the next level.” That’s exactly the spark that McCarron noticed in Campos-Chavez: “I knew he wanted more responsibility than what I was offering him at first,” he states.

Around that time a manager left the company and CamposChavez realized he had prior industry experience in some of the areas that that manager was in charge of, so he decided to take the initiative. “I thought, ‘I can do that,’ so I asked Mike for the opportunity. I told him I would need more training on certain things, so he helped me get that training and that’s how it started.”

McCarron provided him with many opportunities to learn professionally and be exposed to the industry. “We started locally with some seminars and visits to equipment dealers,” Campos-Chavez recalls. “Then he started taking me to the SIMA annual conference, the GIE show, the NALP Elevate Conference. That’s been a lot of opportunity for me; I know my company is putting a lot of money into my career. And the relationship I have developed with Mike is more important than going to look for another job.”

As Campos-Chavez began moving up and assuming more responsibility, McCarron says they discovered a common bond: “We found out he had computer skills in addition

to everything else, which was a total blessing – he is a tech junkie, kind of like I am. And so that made our relationship mesh even more, because I could talk about technologies and he was right there with it.” Campos-Chavez was also able to translate and explain to the Spanish-speaking crew members just what the various technologies could do.

McCarron says that Campos-Chavez’s continued growth has created a cascading positive effect that has benefited both the company and the employees. “It’s helped us to start promoting within our own organization. Now that Angel understands what the growth pattern looks like, he has been able to help guide others and tell them, ‘Hey, there’s more opportunity; all you have to do is raise your hand and say, ‘I want to earn more. How can I get to the next level?’ And Angel really launched this for us.”

McCarron says his relationship, both personal and professional, with Campos-Chavez has reinforced for him

the importance of business owners truly investing in their employees. “Angel purchased a home just a little over a year ago – that’s sort of the American dream,” says McCarron. “And now I’m personally trying to help make sure both of his kids get through the college admissions process, which can be daunting.”

That type of relationship building extends throughout the company. McCarron has also helped team members learn how to navigate the U.S. banking system, resolve landlord disputes, and connect with community groups that can help with housing, affordable food sources, and even learning to speak, read and write English.

“We focus so much on training and supporting our teams in their professional roles; but giving them the tools to succeed off the field can yield powerful results, too,” he says. “In our company, we believe that taking the time to help our team members become more educated about things outside of work that they may not fully understand builds trust and, ultimately, a stronger team at work.”

— Patrick White

Continued from page 26

The company also started conducting company-wide, duallanguage meetings every Monday morning. “Once we started doing that, it started taking away a lot of the miscommunication,” says McCarron. The meeting is conducted in both languages using PowerPoint presentations that include photos, which McCarron says can often help to clarify things. “When we figured that out, it started bringing everybody onto the same page,” he notes.

A unified, bilingual approach McCarron has also worked to develop his own Spanish-language skills. “I speak to the employees in Spanish as much as I can,” he notes. “It’s something I’ve picked up over the years. It’s a benefit to be able to do that, and it also shows them that you’re trying.”

Campos-Chavez says it really helps employees to hear the owner, as well as himself as the manager, speaking in Spanish. “This way, the guys understand that language isn’t a barrier – it makes them feel safe, at home,” he notes. “If they have something they want to ask, they can hear the answer in both English and Spanish, coming directly from the owner and the manager, so they don’t

have to question it; the information is coming from the top. They feel like they’re really safe in that.”

Conversely, if all they ever heard in Spanish was instructions by a foreman on a site, they might wonder what important company information they were missing and not feel truly included in company operations. After all, the goal isn’t simply to ensure that employees understand their jobs, but that they’re able to be active, integral parts of the company. “There are no people being held back here because of the language barrier – that’s what we try to make sure of,” Campos-Chavez says. That includes advancement in their careers. “Language is not a barrier to advancing because everyone has access to all the job details and job descriptions in Spanish,” says CamposChavez. If they show a work ethic and potential, there are opportunities, he emphasizes. “If you see they are not willing to show leadership, it’s not because of the language – it is something else.”

Campos-Chavez says that while he is fluent in the native language of the Spanish-speaking employees, there are still cultural differences since the team hails from Mexico, Guatemala, El Salvador, Honduras and Nicaragua. “All those people, they have some different cultures. And I learn a lot about that all the time,” he says. Regardless of their country of origin, one cultural aspect seems to

be universal among the Latino team members: “They like to feel like family all the time. They understand their job as a second home, and they’re so proud of that.”

Campos-Chavez does much of the hiring for his operations team, so he makes it a point right from the initial interview to try to learn about

the employee, and to convey that the company culture within ImageWorks Landscaping is one of family. But he says that must be a continual commitment, not a one-time hiring pitch. And he says one of the most successful ways of building a culture of family within the company started

Continued on page 32

Continued from page 31

several years ago when McCarron began cooking for all the employees on alternating Fridays.

“I’ve found two things that the Spanish community really appreciates, and that’s food and family,” says McCarron. “When we started cooking, it really changed the dynamic here. It started tightening up the group and made everyone feel like a family.” The company’s annual food budget is significant, “but the benefits are definitely worth it,” he says.

McCarron says that being able to share a nice meal, often with some of their native flavor to it, gives everyone a chance to sit down and hang out as buddies. Conversations tend to be more open. “And you hear some crazy stories!” he adds. “You start learning about their kids and their family and their brothers and their sisters. When you start taking an interest in their family, it really helps develop relationships.”

“You start learning about their kids and their family and their brothers and sisters. When you start taking an interest in their family, it really helps develop relationships.”

— MIKE McCARRON

Campos-Chavez agrees that bonding happens more naturally with a group meal. “That’s when we’re joking around and learning about what they like, their favorite foods, their home countries – all of that. Once you get involved in that kind of stuff you make it personal; they see that this guy is really interested in learning about me.”

And the benefits extend even beyond building rapport with current employees. When they see and experience that type of family culture at work, they are more likely to recommend the company to friends and relatives. McCarron says this is how the company finds most of its new employees. And, as an added bonus,

The first winter tire for tractors, Nokian Hakkapeliitta TRI , makes sure your winter contracting has all the grip and control you need –with or without studs.

these new employees tend to be high quality. “The current employees usually only recruit the type of people that they would want to invite into this family atmosphere,” he notes.

McCarron says he’s had people join his company for less than they were making elsewhere due to the company culture and opportunity for advancement. He’s also occasionally had employees leave for less money somewhere else. But as a general rule, he’s learned, “if you treat people like family, and you pay them correctly, you won’t have a high turnover rate.”

Patrick White has covered the landscape and snow and ice management industries for over 25 years.

The first winter tire for wheel loaders, Hakkapeliitta Loader, offers you speed, stamina and control. Unmatched grip and durability in the market –both winter and summer.

OCTOBER 23-27, 2023

Winter is coming … is your company ready?

SIMA’s Winter Boot Camp will feature a week’s worth of tips and best practices, from videos to downloadable resources and more.

Sponsorships available

Plan to join us and get winter ready! To learn more scan the QR code or visit www.sima.org/bootcamp

TRAINING UP. ELM’s Employee Relations Coordinator organizes a training for those who are new to the United States and need help learning about the tools and work requirements.

ABy CINDY MONZON

s an employee relations coordinator, I handle various employee-related tasks such as recruitment, support, employee concerns, orientation, and an employee recognition program. Most

importantly, and my personal favorite, I help develop a relationship between the employee and the employer.

ELM has a large number of Hispanic employees, and I’ve made it my personal goal to help break the ice between them and the company. Helping to interview those who don’t speak English is very important as I aim to gain their trust and to help them see that ELM is not just looking for workers … we are looking for

employees who can be trusted and want to become part of our ELM family by helping our company and themselves grow.

As a Hispanic person, I know it’s hard to come to a country where you don’t know the language or culture, but nonetheless need to establish a life.

Even though the landscape and snow industries involve outside work,

Being visible in the Hispanic community is important to ELM. In this photo, a woman paints faces at a community event for low-income families that the team participated in.

there is always the potential for a wall between an employee and a manager –and it all comes down to the language. Many employees are afraid to speak up because they don’t know how.

Since it is out of their comfort zone, I’ve made it my duty to welcome them to a relatable environment and to break the wall between the languages by translating and helping them more freely communicate with their managers. It’s been my pleasure to help them and make that possible at ELM.

It has become very important to ELM to help our Hispanic community. We’ve done partnerships with great communities, helping those who have just come to the country by providing support, orientation and even bringing a smile to their little ones. We have done work training for those who just came from their countries needing a little push toward a job opportunity.

The most important value in Hispanic culture is family. ELM values their families with great honor and has made sure that our employees feel at home. I always make sure they know that and help them with guidance, support and with any work-related or personal concerns they may have.

It is very important to me to guide my Hispanic community to a better workplace by providing information on the job, helping them understand the laws, the employee handbook, the rules and everything these involve.

This will help them better understand the work environment that we provide, while also clarifying what we are seeking from them. Hispanics are hardworking people; and we are very proud of the Hispanic community

we have at ELM. I help our employees understand that we are a team player, but they end up showing us that in the long run we become a family.

Our fleet of interchangeable truck bodies and WorkReady™ subframes will transform your truck from season to season in just 3 minutes.

• One Truck, Multiple Bodies

Multi-Seasonal Use

Non-CDL Trucks

ABy JASON OSTRANDER, CSP

dmittedly, I am a “bells and whistles” kind of guy. While walking through the trade show floor at this year’s Symposium I was like a kid in a candy store. I was amazed by the innovation that currently supports our growing industry. The amount of data that can now be collected during a storm and the realtime feedback that we can receive as snow contractors is at an all-time high. I am excited to see how all of this continues to shape the future of our industry. That being said, I had a couple of conversations in Hartford that gave me pause. There seems to be a growing reliance on what I would call the “supportive layer” of the snow and ice industry, instead of focusing on the basics of good service. As we head into the winter months, here are a couple things to keep front and center with your team.

How do you grade out with each of your clients?

Maintaining a strong client relationship is crucial for a successful snow and ice management business. Open communication, responsiveness to client needs, and demonstrating reliability builds trust and loyalty. Satisfied clients are more likely to retain your services in the long term and may refer you to others, contributing to business growth. What is your strategy for client relationships? Do you look at it as a business-to-business connection or more like a working partnership? If it’s the latter, which is most ideal in our industry, how do you grade out with each of your clients?

Is there a single knowledge base where everyone on your team can go to know what to do before, during and after a storm?

Effective execution during a snowstorm is essential to ensure safety and minimize disruptions. Timely deployment of snow removal and deicing crews, monitoring weather forecasts, and having welldefined action plans are critical in any weather event.

Being prepared for varying snowfall intensities and having contingency plans in place helps to efficiently manage snow and ice accumulation. As an owner or manager, you probably have a good plan in mind for when a storm hits, but how well does the rest of your team know your plan? Having a plan is good, but communicating that plan is even better. Is there a single knowledge base where everyone on your team can go to know what to do before, during and after a storm?

What is your strategy for updating contract language?

Clear and comprehensive contracts are vital to the future of our industry. Proper wording throughout all your documentation will help to avoid misunderstandings and potential disputes.

A proper snow contract should outline services provided, pricing, snow thresholds and the responsibilities of both parties. Specific terms related to timing, service limitations and payment schedules ensure a solid foundation for a successful working relationship.

Additionally, taking the time to walk each of your clients through their contract before the first snowflake falls can alleviate multiple issues that

usually surface during a storm. What is your strategy for updating contract language? Contract renewal season is the best time to look at the wording and make changes where appropriate.

What are the 3-5 things that you’d like to get feedback on as a snow contractor?

After the winter season, it's essential to conduct a thorough evaluation of the services provided. Seek feedback from clients to identify areas for improvement and to gauge their satisfaction. Address any concerns promptly and use the feedback to refine your approach for future seasons.

Proactive follow-through helps you maintain a positive reputation and retain clients for the upcoming winter. If done properly, you can also use the postseason meeting as an opportunity for contract renewal, or to upsell clients for a more robust service offering (e.g., snow hauling, site monitoring between storms, etc.). Heading into the long postseason with clients is made easier if your final interaction of the winter season was a positive experience. What are the 3-5 things that you’d like to get feedback on as a snow contractor? Who could you assign as a “postseason account manager” to ensure you get that necessary data?

In an era with lots of tech and innovation, it’s important to remember that while the “bells and whistles” give us valuable information that can enhance our businesses, there is no replacing client relationships, proper execution, well-worded contracts and consistent follow-through.

Jason Ostrander, CSP, is chief operating officer for East End Group, and a member of the Snow Business Editorial Advisory Committee. Email him at jason@eastendgroup.net.

Innovative’s ProMelt™* line of liquid de-icers offer an attractive price to performance ratio delivering the best solutions for all of your winter road maintenance needs.

Did you know we are donating to the LGA or Swim Drink Fish, for every person who registers to learn more about chloride reduction? Topics Covered

• Winter maintenance best practices.

By LISA ROSE, CSP

Think of each annual cycle in the snow services profession as a story. The way you tell your story will determine how vulnerable you are to lawsuits that could cost you and your business significant amounts of money. Like any story, there is a beginning, a middle and an end – all of them important in determining how the story turns out.

All the work you do before the season – from contracts to site planning to training – sets the tone for your story. Performing and documenting these important items will help close any plot holes once the season starts. Contracts / subcontracts. Have a current, written contract with each customer. It is easy to let rollover contracts expire.

Site visits / site plans. The agreement should include an annual preseason site inspection report detailing the property and how it will be serviced. Each visit with a representative from the property and snow management company should include a review of:

• A detailed property drawing or picture (including current damage)

• Services to be performed

• Operating hours

• Potential risk areas

• Placement of snow piles

• Snow hauling timelines/procedures

Employee training documentation. Having the best training materials/ presentations doesn’t do any good if you can’t document what was shown to whom and when.

In addition to equipment and safe operations training, educate employees on how to document when the customer handles a portion of the mitigation that

may impact areas of the contractor’s responsibility. For example, if a retailer handles sidewalk clearing but pushes the snow off the edge/curb into the lot or between the walk and the tire stops, that snow placement could impact the parking lot’s condition when there is melt/refreeze. Identify, discuss and document who is responsible for rectifying that scenario. Document if the established protocol is not being followed.

middle: during the season

Winter services are action-packed … and where many pitfalls lie. Unclear or missing documentation will almost certainly cost you if a lawsuit is filed.

Weather services. Use a professional weather prediction service and maintain the data. Document and place it in a folder organized by customer, location or ZIP code. Part of the story is to explain why your company did (or did not) service the site.

Customer communications.

Document and save all communications between your company and the customer during an event. There are many modes of communication. Determine who will maintain the

documentation and how. Texts not captured will not support your story of what transpired. Take photos or screenshots and email them to the office. Consider establishing a designated email for customer communications or using cloud-based storage.

In-event documentation. Following the 5 “Ws” (who, what, where, when and why) will result in a comprehensive retelling of the event. In-event documentation should include:

• Arrival and departure time of crews

• Who serviced and/or was on the site

• Property conditions (this works in conjunction with your weather data)

• Services that were performed

• Areas serviced and not serviced. For example, if you have a contract to clear a retailer’s parking lot that is

closed overnight but a restocking crew is parked in the lot, document and/or take a photo.

• Incidents that may have occurred

Site monitoring. A site inspection during and/or after an event should answer these questions:

• Are the crews doing their jobs?

• What does the site look like once they are done?

• Do they need more training?

• Do they need another walk-through to understand what they are not doing correctly?

• What were their struggles?

• What worked well?

• What did they notice?

Melt and refreeze. Determine how melt and refreeze will be handled since these conditions can continue for days or even weeks. Use your documentation processes and/or technology for a check-in/site inspection at no charge if included in your pricing. Site inspections provide documentation. Determine who will monitor the weather and the site to determine the need for services. Even if the contractor is not responsible for melt and refreeze, they could initially be included in a lawsuit.

The final chapter should reveal whether your documentation will tell a complete story. Perform a postseason analysis by checking with inside operations to see how effective the written documentation was and if it was legible, complete and appropriately filed. If using technology, determine whether the complete story has been captured and the app has worked well.

Postseason follow-up includes:

• Review contract to determine what worked well and what didn’t.

• Visit the site to inspect for damages and pulling stakes/markers.

• Review the site map to note any site issues/nuances.

• Communicate with the customer to determine what worked well or didn’t for them.

Don’t miss the opportunity to tell your story – beginning, middle, end – in order to defend you and your business from a slip-and-fall lawsuit.

By MICHAEL WAGNER, CSP, ASM

In snow and ice management operations, an integral success factor is the healthy operation and utilization of vehicles and equipment. Keeping equipment maintained, cleaned and functional contributes massively to your ability to provide an exceptional level of service (LOS) to client properties and the community. Also, consider how proper maintenance can positively affect employee productivity, morale and company profitability throughout the snow season. Let’s talk shop management and identify best practices for yearover-year success.

The shop is an internal service component of most organizations and provides a variety of support services depending on operational needs. Key responsibilities of a shop include:

• Performing preventive maintenance in the off-season (or during landscaping season)

• Maintaining a reliable parts inventory and supplier relationships

• Determining proper personnel needs (count and quantity of hours)

• On-call schedules for working through the winter season

• Performing quality repairs and not cutting corners

Not all organizations have a dedicated shop manager, but most will at least have an employee who is responsible for overseeing mechanics and yard personnel. A shop manager must be diligent in proactively planning to be sure that company operations

staff have the vehicles, equipment and tools to perform their jobs.

The shop manager must also be a strong and professional communicator with their staff, as well as the rest of the organization.

In the fleet and shop environment, preventive maintenance is a must! A shop should develop a preventive maintenance plan for all its assets, and also communicate the importance to the organization of staying on schedule with preventive maintenance services.

As you can see in the sample graphic on page 41, preventive maintenance schedules can vary drastically, depending on the asset. Vehicles and equipment that must be used during the offseason receive regular maintenance throughout the entire year, whereas assets primarily designated to snow will see much

Set up a preventive maintenance plan for your winter assets to avoid unnecessary downtime. Each asset will have a unique plan depending on its type and use.

more robust preventive maintenance during the offseason.

The reason it is done this way is because it focuses on reducing the downtime of assets, which is time the assets cannot be used and are “out-of-service.” The effects of a solid preventive maintenance plan are realized when you reduce overall downtime of assets. When you perform timely preventive maintenance and stay on schedule, you reduce the possibility of unexpected breakdowns that place constraints on your operations.

In the snow and ice industry, what we do can be considered an emergency operations service. One of the worst things that can happen is untimely equipment breakdowns in the middle of a storm when the issue could’ve been prevented by properly maintaining assets.

Managing your parts and inventory is vital to the success of a shop and fleet. Not every organization has the resources to house a large inventory of parts, so here are a few tips on how you

can reduce your inventory costs and speed up repair times.

Track your common parts failures. This can be done in shop software, Excel spreadsheets or even a notebook. You want to find out what parts fail most often and carry a manageable stock in the shop. Typically, these are tires, hoses, filters, lights or common wear items like plow edges, hardware, brakes, belts, etc. Many of these parts aren’t your most expensive inventory, so sometimes you can have larger supplies of them on-hand.

Review expensive parts. Next, look at your more expensive parts that are prone to fail and may cost you moderate downtime if you don’t have spares readily available. These could be electrical sensors, controllers, joysticks, sprayer nozzles and systems, chains, augers and more. Look at your inventory and your previous parts usage. A good rule of thumb is that if you use a particular type of part three times or

Continued on page 42

Continued from page 41

more in a year, you should carry an inventory of that part. Make your best judgment of how many you think you need on your shelf going into the winter season. If you used 10 last season, you may want to stock at least three or four at all times. If you only used three during the whole season, it may be sufficient to keep one on the shelf.

Identify your least common failures. Typically, these will be more expensive parts. Without them, you run the risk of severe downtime or putting an asset out of commission for an extended period. While you may not necessarily stock these parts, you should work closely with vendors to determine who can supply the part as quickly as possible. Don’t wait until the part fails to start looking for a supplier. Be proactive so you know who you can get it from, an estimated cost, and a general estimated time of arrival. In some cases, if you have a strong relationship with vendors, they may be willing to stock parts for you and keep it in their inventory since they know there’s a possibility you or their other customers may need it.

To recap this section, consider the options for parts and inventory management; and really focus on building those strong vendor relationships for dependability and predictability.

Setting up a shop for efficiency and consistent workflow is important. Consider your shop facility design, number

of mechanics, number of assets, parts inventory, and how you want equipment to flow in and out of the shop. Most importantly, you want mechanics to be able to repair assets as quickly as possible while keeping quality at the forefront of their mind to reduce comebacks (repeat failures due to lack of workmanship).

Work with the mechanics to lay out the shop plan. The most important components within the shop include:

• Toolboxes

• Lifts and racks

• Parts and inventory shelves

• Lubrication tanks, pumps and reels

• Nuts, bolts, and all other expendables

• Drains, vents, hose reels and all other fixtures

Ensure that the most used components are the closest and most accessible to their workstations and that the shop and all supplies stay clean and organized to reduce safety hazards and improve mechanic workflow through the shop.

It is helpful to draft a design/layout of the shop that designates where all items go, as well as a plan to keep everything organized. All shop personnel must keep an orderly operation, so make sure everyone understands their responsibilities and the benefits of keeping the shop organized.

Another consideration in the shop is the mechanics and how equipped they are to successfully perform their jobs. You must think of the resources they have at their disposal and what they might need, as well as their level of proficiency with different assets.

TRAINED TO MAINTAIN: Make sure the shop team is trained to service and maintain assets and that they have the equipment and tools needed to efficiently repair or maintain the fleet.

Following is a list of the most important considerations for shop personnel when it comes to preparing your organization for snow and ice operations.

• Do you have enough mechanics to service and maintain all assets?

• What is their level of experience with different assets?

• Do they have the hand or power tools to perform their job?

• Are there specialty tools that should be purchased?

• Do they have the proper training to work on specific equipment?