Patrick White // Photography by Cristin Powers

Patrick White // Photography by Cristin Powers

By JON CRANDALL, CSP

What an awesome year! SIMA has grown by leaps and bounds. We got to go to SIMA’s hometown of Milwaukee, and the Symposium was off the charts! The Leadership Forum in Austin had some of the highest-rated speakers in our history; and the SIMA Foundation funded and produced its first research project to provide top-notch benchmarking data to our members.

The SIMA staff is working on some huge initiatives geared toward strengthening our members. The initiatives include:

• Educating our members in best practices for obtaining correct and competitive insurance;

• Seeking potential synergies between commercial snow fighters and municipal snow fighters to raise all ships; and

• Expanding membership, which will grow our combined knowledge as peers and expand our resources to further strengthen and support our member-driven

initiatives. Being a small part of this journey through such interesting times has been an awesome experience.

And 2023 promises more great opportunities for business growth through SIMA. From June 13-16, our annual Snow & Ice Symposium will be in Hartford, CT, allowing us to learn and prepare for the next winter season.

Our Leadership Forum returns to the Florida coast at the beautiful Ponte Vedra Inn on August 7-8. Snow company leaders and those wanting to grow and network with the best in the business will want to attend. SIMA also plans options for those interested in virtual learning or pursuing online education at their own pace.

As winter maintenance workers and business owners, we do some amazing things. We are emergency responders and are relied upon to keep properties safe and passable; and we are collectively responsible for ensuring that businesses generating billions of dollars in revenue can go on during winter events. We miss holidays so others can safely have theirs. What we do as a community is amazing. Continuing to grow and learn to better our abilities and provide more value to our teams and customers will enrich the lives of us all.

I encourage all of us to tell the stories of the value that we bring to the communities we work in. If we stop doing our essential work, then transportation stops. Our local economies would slow down and that would affect the critical supply chain of our economy. If we don’t communicate our value to our customers and the public, then who will?

Our collective voice is more powerful than we are as individuals. Let’s give ourselves the appropriate credit we deserve. Many of us are facing shortages of people willing to work in snow and ice. If we talk to our personal contacts about the opportunities that exist in our business, that will hopefully spread and be used to provide others entry into the work we do. Now is a great time to inform, recruit, train and retain.

I am excited for Mark Arthofer, CSP, to jump in as our SIMA chair and for him and the Board of Directors to continue to forge forward. Have an amazing winter season and thank you all for the opportunity to serve as your board chair this past year.

Jon Crandall, CSP, is chief visionary for JC Grounds Management and is 2022 chair of the SIMA board of directors. Email him at jon@jcgrounds.com.

Catch up on SIMA’s 2022 recap and plans for 2023. View the entire presentation or catch the highlights at www.sima.org.

A Publication | www.sima.org

EDITORIAL

Director of Education & Content

Cheryl Higley // 262-236-9972 // cheryl@sima.org

Design & Production Director

Lisa Lehman // 216-798-1853 // lisa@sima.org

ADVERTISING SALES & MANAGEMENT

Senior Manager, Engagement and Business Development

Kerri Joseph // 614-557-3948 // kerri@sima.org

DIGITAL MEDIA & MARKETING

Manager, Marketing & Communications

Stephanie Orvis // 262-236-9948 // steph@sima.org

SUBSCRIPTION

Subscription questions/cancellations: cs@e-circ.net

Subscription changes/updates: sima.org/magazine

EDITORIAL ADVISORY COMMITTEE

Charmaine Allen Allen Builders & Landscape

Nichole Ashton, CSP North Country Snow and Ice Management

Erin Faupel, ASM ULS Landscaping

Jim Hornung Jr., CSP Elbers Landscape Service

Tyler Jabaay Priority Landscape & Maintenance

Rick Kier, CSP Forge Ahead Consulting and Software LLC

Bob Marks, CSP, ASM emi landscape

William Moore, CSP, ASM Executive Property Maintenance

10140 N. Port Washington Road, Mequon, WI 53092 www.sima.org

Dean Outhouse Piscataqua Landscaping

Jason Ostrander, CSP East End Group

Thomas Skuta, CSP USM

Robert Young K.E.Y. Property Services

Michael Wagner, CSP, ASM Colorado Designscapes Co.

Manager, Finance & Operations

KC Hallgren // kc@sima.org

Manager, Billing & Member Services

Aimee Krzywicki // aimee@sima.org

Office Manager & Executive Assistant

Nikki Luedtke // nikki@sima.org

Business Process Analyst

Nakishia Lee // nakishia@sima.org

SIMA OFFICERS & DIRECTORS

Jonathan Crandall, CSP, JC Grounds Management

Wayne Michalak, CSP, cutmytreedown.com

Mark Arthofer, CSP, Skyline Construction

David Wescott, CSP, Transblue Ruben Diaz, ASM, Diaz Group LLC

Connie Gaul, ASM, Brightview Enterprise Solutions

Patrick Kane, CSP, Evercor Facility Management

Chris Hinton, CSP, GRM Inc.

Danny Milligan, ASM, Strathmore Landscape Contractors

John Janes, CSP, ASM, Caterpillar

Debora Babin Katz, TrucBrush Corporation

(5730) (ISSN 2155-2576) Copyright © 2022 by the Snow & Ice Management Association, 10140 N. Port Washington Rd., Mequon, WI 53092 is produced and published February, April, June, August, September, October, December by the Snow & Ice Management Association. All Rights Reserved. No part of this publication may be reproduced or transmitted by any means without permission of the Publisher, SIMA – Snow & Ice Management Association. Subscribe at SIMA.org/subscribe. Periodicals postage prices is paid at Mequon, WI, and additional entry offices at 11716 S. Preston Hwy, Lebanon Junction, KY 40150-9998. POSTMASTER: Send address changes to

Our journey as a small-staff national association is not all that different from many of yours, believe it or not! With just over a dozen people, we provide a wide array of events, programs and services that we hope make the lives of our members safer and better over time. But we know we aren’t perfect; and we strive to improve each year.

Customer service at the national scale (with over 1,500 members), is

sima welcomes new membership manager

Senior Manager of Membership Evan Newman joined the SIMA staff in late November. He will lead the development, implementation and evaluation of membership growth strategies as well as day-to-day member engagement. Prior to joining SIMA, Evan worked for the Ohio Trucking Association.

“As a membership-based organization, SIMA’s intent is to continually invest in, and increase, the value of membership. Having a professional with an association background will help SIMA increase the resources and value that coincides with being a SIMA member,” says SIMA CEO Martin Tirado.

Thank you to the following

a challenge for us. In the past year, we really dove headfirst into this and made major changes that we think will make it easier to connect with us and get the help you need, whether it’s as simple as renewing your membership or a major business challenge you may be facing.

We’ve built several processes into our operations to be as accessible as possible:

Virtual Office Hours: SIMA provides 2 hours of open office hours every Thursday (non-holidays) from 10 a.m. - Noon EST. You’re welcome to jump in and get help, renew your membership, ask questions and more!

Membership Valet Service: If time has been a barrier to joining SIMA, we’ve made it super easy to join. Potential members can

spend 5 minutes providing a little information, and SIMA will send an invoice within 1-2 business days, including a no-login payment link.

SIMA web chat + support tickets: In early 2022, we launched a web chat and ticket support system to help customers and members get in touch with SIMA more effectively and to help SIMA centralize customer and member service and support.

24/7 Help Center: The association launched help.sima.org/knowledge as an interactive, searchable FAQ for anyone interested in membership and our products and services, so they can get key details even when staff are unavailable.

We are always open to feedback. Please let us know if you have suggestions for ways SIMA can support our core customers and members! Email us at info@sima.org.

SIMA’s Snow & Ice Awards application portal is open! We want to give you as much time as possible (especially if it hasn’t started snowing yet) to submit nominations for the 2023 awards:

• Best Companies to Work for in Snow & Ice

• Snow & Ice All-Stars

- Sales Professional of the Year

- Business Professional of the Year

- Snow Operations Manager of the Year

- Snow Operations Employee of the Year

SIMA Foundation scholarships

The SIMA Foundation also offers two scholarships tied to the Snow & Ice Symposium:

• The Alan Steiman Symposium Scholarship

provides smaller-revenue companies an opportunity to attend the Symposium for free.

• The Dean Fisher Innovation Scholarship is presented to a company that has an innovative product or service to offer the industry. The winner receives a free booth at the show plus advertising support in Snow Business magazine.

The awards portal closes April 7 to ensure judging can be completed in time for the Symposium. Winners will be recognized during the awards breakfast on June 14, 2023. Visit www.sima.org/awards to download the application guide and submit your nominations. Questions? Email info@sima.org.

Our Valet Service and Virtual Office hours concepts caught the attention of the national magazine for association professionals! Scan the QR code or enter this link to read! https://qrco.de/bdSZYb

By MARTIN TIRADO

If you have ever considered how your snow and ice company compares to others, you now have access to SIMA’s first profitability and benchmarking report. Sponsored by the SIMA Foundation, the Profitability and Benchmarking Report gives company owners, chief financial officers and senior managers a tool to:

• compare financial and operational benchmarks against other snow and ice companies

• measure performance ratios

• identify potential areas for improvement

• strategize and make recommendations for changes and improvements

More than 100 companies provided a breakdown of company costs, profitability, contract type, portfolio mix and employee categorization. The diverse mix of responses make the results valuable to any size organization.

In 2023, SIMA will launch

dashboards where companies can input their own data to measure how they compare to companies of similar size, revenue, location, etc.

An additional research project was an update to SIMA’s 2016 Snow Industry Impact Report. The 2022 Impact Report can be used to show consumers, financial institutions, investors and others the size and scope of the industry. The report provides the number of snow and ice companies, total employees, revenue percentage compared to other parts of the business, and projected growth.

Both of these reports are free to the industry. Download them at www.sima.org/foundation

Plans for the 26th Annual Snow & Ice Symposium in Hartford, CT, are underway; and two speaking opportunities are available for SIMA members:

• Session speakers are needed for 15+ main education sessions June 14-16

• A new event at the 2023 show will be the Breakfast Jamboree, featuring mini-sessions covering more than 40 topics. This is a volunteer opportunity that is open to all SIMA member companies (contractors and suppliers).

To learn more and submit speaking proposals, visit www.sima.org/show

The Snow Business team is seeking new contributors for 2023. You don’t have to be a perfect writer to share your insights and stories with your peers. If you have topics you’d like to write about (or recommend to the content team), email Director of Education & Content Cheryl Higley at cheryl@sima.org.

Allen Builders & Landscape tailors operations to fit the company’s size and rural location

BY

ANYONE WHO’S LISTENED to current political commentary (or read “City Mouse, Country Mouse”) knows that there are differences between urban and rural. That also applies to the snow and ice business. What works in high-population metropolitan areas doesn’t always make sense in small-town environments. Allen Builders & Landscape has worked hard to take some of the tools and approaches used by large, urban snow companies and translate them into a model that works for their smaller company’s more rural service area.

Allen Builders & Landscape is in Hamlin, PA – a bit east of Scranton and not far south of the New York border. The four-season service firm was founded in 1997 by Matthew Allen, who emphasizes that it was winter rather than summer work that inspired his start: “I really started with snow. When I got my first truck, my goal right away was to get a plow.” His love of snow work actually began much earlier, riding along at the age of 6 when his grandfather was plowing. “He had a 1973 F250 – with the Ranger package – and a Western plow,” Allen recalls vividly.

Continued on page 10

Allen Builders & Landscape provides a complete array of landscape services (from hardscape and outdoor kitchens to lighting and water features); interior services (such as painting, flooring and door/window installations); and even a retail store that sells everything from candles to stone/mulch to Amish-built sheds.

With the wide mix of services that the company performs, snow is the most profitable and accounts for the biggest portion of income. For that reason, and because it’s where he got his start, Matt says: “If there was one part of the business that I would never give up, it would be snow.”

While the company started as a oneman operation, it has grown as its service offerings expanded. There are now 6 to 10 field staff crew members, as well as a dedicated office staff of 3 full-time and one part-time employees. The most crucial staffing addition came in 2003, when Matt married Charmaine (she actually began plowing with him a couple years earlier). Since then, the Allens have operated the business as a couple, and have found some success in maintaining their relationship while also working together.

Charmaine deals with the accounts and routing and scheduling; Matt

handles the equipment and operations side of the business. The couple says that this division of duties has helped keep things running smoothly in a family business where husband and wife are working closely together.

“That wasn’t always the case. It used to be that we would always be in one another’s business,” Charmaine says. Each of them was doing a little bit of everything, and that proved not to be efficient or effective. By dividing duties and focusing mainly on their specialized areas, efficiency has improved and the chance for

duplication or disagreement goes down. “We still argue sometimes!” jokes Charmaine, “but this approach has proven to be a lot better.”

Their daughters are also involved with the business. Taylor Haggerty is chief operating officer, but she started on a sidewalk crew and is a leader when it comes to jumping into a plow or a skid steer or doing whatever is needed. On occasion a new employee will come in with the assumption that, as a young woman, Taylor is not cut out for the difficult job of snow work. They soon learn differently.

“When we’re in the midst of a 36hour storm, and some employees are completely worn out just six hours

Allen Builders & Landscape emphasizes to its employees that details make the difference. In fact, the company’s mission is focused on DETAILs:

The company works to keep employees feeling rewarded and engaged using these principles and believes that clients will notice the difference that details make in the work they perform.

Charmaine Allen says that’s true not only in the summer (a new patio or outdoor kitchen or painting job is obviously dependent on a lot of fine details), but also in the winter. “People don’t realize it, but there’s a lot of detail involved with snow removal.

Knowing where the drains are, where the curbs are, where the snow goes, sidewalk work,” she explains. “That’s why we have employees walk rather than drive the sites after they’re done – you pick up a lot of things when you’re walking that you don’t when you’re in a vehicle.”

in, she’s the one who keeps going,” Matt marvels. “She understands the importance of doing a good job for the clients, and how that reflects on the company.” Taylor’s sister, Courtney Haggerty, has worked at the company; she was on a sabbatical last winter but still came back and plowed when needed.

In the early years, the business focused on residential driveways. But Matt says that in their area, many driveways are gravel and many residents are gone in the winter, so that market is tough. “It’s better for someone just getting started. That’s where I once was, so I understand that.” The company’s winter focus now is on local commercial accounts.

There aren’t a lot of big box stores in their area, but there are a growing number of large warehouses and distribution centers. None of those holds a lot of appeal for them. “We would need bigger equipment, and to find employees capable of running that big equipment is difficult in this area,” Matt says. “And from what I hear in the industry, the prices are being driven down more and more on those kinds of accounts.”

“We also like the loyalty of working with local business owners. There isn’t always a lot of loyalty when you’re working with chains,” Charmaine says. That philosophy extends to their desire to buy from smaller businesses and American-owned companies, like Stork’s Plows, whenever possible. In town, the Allens have become good friends

Continued from page 11

with local owners whose businesses they patronize and who in turn use them as snow service providers.

One of the limitations of working in an area with fewer people is that recruiting employees is that much more difficult. “Finding employees has always been a challenge in this area,” Matt says. “That challenge has only intensified.”

Finding “bodies” isn’t even the biggest problem; it’s finding people who can do good work, he says.

To help overcome the shortage of employees, Allen Builders & Landscape found that upgrading its equipment fleet, which now includes skid steers, for example, has allowed them to get more work done with fewer people. “If you can do a job

with one person that used to take two, that’s a good piece of equipment to invest in,” Charmaine says.

Matt says equipment investments have paid off in other ways. “We try to have trucks that are newer, and to make sure they look good,” he explains. “If you show up at a client’s property and have a truck that looks like the door is falling off, or that it’s backed into things a hundred times, they’re going to think, ‘If that’s how they take care of their own trucks, how are they going to take care of my property?’ ”

Some years back, the couple sat down to analyze equipment expenses. They looked at the costs of repairs to older equipment.

“Matt can fix anything, but we had to stop to consider how much it was really costing us to have him fixing a truck rather than out there working and gen-

Allen Builders & Landscape’s headquarters was once home to Brad’s fruit stand, which was established in 1968 by Matt’s uncle Brad, who battled multiple sclerosis. After he was no longer able to operate the fruit stand, Brad’s parents took over the stand. “Brad was the soul and energy of Allen Builders and Landscape,” Matt says. The “Brad’s Fruit Stand” sign still hangs in the company’s retail store and Brad’s influence and example continue to be felt, Matt states.

erating money,” Charmaine says. Even when equipment was brought to a service shop, the costs were unpredictable. In the end, Charmaine says she realized that “I can budget for a monthly payment, but I can’t budget for endless repairs on older equipment. It was scary, making those investments as a smaller company,” she says. “But it has paid off.”

Matt agrees that this was an important decision, financially and operationally: “In attending SIMA workshops and hearing even from really large companies that some had switched from having their own crew of service technicians to simply taking the equipment in for maintenance and repair. I realized that we needed to focus on doing what we do well and be out there performing services for clients and generating income.”

He adds that newer equipment is more likely to work well and be ready when snow comes. “Even new equipment can break. We still have repairs that need to be done. But if you can minimize the chances of breakdowns as much as possible, it’s a huge advantage.”

Just as equipment advances have

SMART DECSIONS: As a smaller company, Matt and Charmaine Allen have chosen to invest wisely in technology and new equipment to maximize their small staff’s time, improve efficiency and save costs.

helped the smaller company improve efficiency, adopting technology has also been vital. “We’ve tried to make as much of a leap forward as we can,” Matt says. The rural area lends itself to a lot of dead areas for cellphone coverage, but the company equips employees with smartphones and uses a variety of apps and programs to run its operations. “We’re not a $10 million or $100 million a year company that can afford to build its own app; but we have found technology that works for us,” he adds.

Until a few years ago, the company was paper-only. It is now largely digital but still maintains paper backup records.

It took some trial and error (“we tried a lot of apps, and they all failed for one reason or another,” Charmaine says), but eventually the company found an app that worked for them. The main digital technology it uses is CompanyCam, which Charmaine says has worked well for them on both snow and landscape accounts.

“It does things like geotagging and time-stamping on pre- and post-work photos that the field crew takes; it allows them to draw on the photos, or add notes if there were cars parked in a corner that they couldn’t service, for example,” she explains. And if service isn’t available at a particular property,

or due to storm conditions, the photos can be stored and uploaded later.

Charmaine says she doesn’t foresee a time when the company will ever move completely away from paper, but digital technology will likely be an increasing part of the company’s operations moving forward:

“We’re always trying to grow, and

the technology will help us with that. But growing doesn’t always mean getting bigger; it can also mean getting better.”

Patrick White has covered the landscape and snow and ice management industries for a variety of magazines for over 25 years. He is based in Vermont. Contact him at pwhite@meadowridgemedia.com.

Despite our best intentions, planning and training, incidents that lead to personal or property injury happen. Companies can do their best to prevent these occurrences through proper training and operational best practices.

In the event that one occurs, having a reporting and investigation plan in place is vital to hopefully preventing a repeat performance by identifying workplace hazards and safety program weaknesses. It’s not enough to stop at the surface reason an incident occurs (e.g., a plow driver backed into a light pole in the parking lot). Find the facts and not the fault; this will help you to refine your operating procedures and training programs.

Trustworthy companies consistently respond to claims that their employees and/or services caused damage, and when appropriate, make repairs or compensate property owners for reasonable damage.

Whether you knock down a

☑ Document and train your management team and supervisors on incident protocols.

☑ Make sure everyone understands how to handle medical emergencies and jobsite injuries as well as property damages.

☑ Create an employeemanagement team for investigating incidents. Create a safety committee that identifies risks, reviews incidents and establishes goals for reducing incidents.

telephone pole or bump into a stop sign, be proactive with your customer. Immediately document, report and address it.

In addition to having a process for in-season damage reporting, before and after the season are just important.

PRESEASON

Document site conditions to help your team identify issues before they become a problem. You might discover heaved pavement, raised drainage structures or manhole lids that could damage your equipment or injure an employee. By cataloging current site conditions or documenting existing damage, you are better prepared to defend yourself against future damage claims. Clients who are not aware of critical damage issues that may affect service will appreciate knowing about problems that need corrective action.

☑ Investigate close calls, which can identify a process flaw before something occurs.

☑ Regularly review your program with all employees and especially with new employees as part of the onboarding process.

☑ Ensure your reporting standards and procedures are reasonable and do not discourage reporting. Team members who don’t feel comfortable reporting could cause a faulty procedure to go undetected.

RESOURCE: A sample incident reporting form is available for download at my.sima.org

POSTSEASON

At the end of the season, assess your sites for damage that needs to be repaired. During the assessment, catalog current site conditions. This may prove helpful if damage occurs after the season and a property manager claims in May or June that your company

caused the damage in the winter and needs to address it. The property manager may be drawing a logical conclusion that damage was caused by your company, particularly if they have not seen the site since the end of the season.

As you grow your snow business, supplementing your portfolio by working as a subcontractor for larger companies is common. At some point you may decide to grow by hiring subs instead of being one. Regardless of the path, it’s important to follow insurance, legal and operations rules and best practices.

• Ability to take on additional business without assuming labor, equipment and overhead costs

• Access to larger or specialized equipment you don’t have

• Expansion into new markets

• Do not have to provide insurance or pay taxes

• Possibility of federal and state tax and worker’s compensation audits. (Learn more on page A2)

• Restrictions on training and oversight

• Quality may be subpar and open you to unhappy clients/damaged reputation

• Cannot manage or supervise the subcontractor’s work

• Restrictions on right to fire PROS

• No sales and marketing costs

• Add properties to close routing gaps

• Expand your book of business

• Build relationships with contractors who can share knowledge

• Keep your team working during the winter

The subcontractor(s) you hire are a direct reflection on your company. They’re working on your behalf, but you’ll be the one left holding the bag if they fail. Here are some tips for hiring subcontractors:

Set up a meeting at their facility to see their equipment and meet their team. Do they have the right equipment and the employee experience to manage the sites you award them?

Inquire about their workload. Do they realistically have the capacity to service your sites, too? Also ask if they are subcontracting for other companies that may further dilute their capacity.

• Less profit since the contractor is taking a cut

• Required to use the contractor’s software/ technologies for service documentation, billing, etc.

• Subject to slow payments from contractors

• Don’t have complete control of the contract

• Responsibility for your own taxes (federal, state, Social Security, etc.)

Does the subcontractor have safety standards and protocols in place?

Make sure they have the right type and amount of insurance. (See Page A3)

Only award what the subcontractor can handle; and don’t overwhelm them with a large portfolio. Start with a few sites and add more as you become comfortable with their capabilities.

There are three general tests that can be used to determine if you are following the guidelines for employee vs. subcontractor classification. It is vital that you follow the guidelines, or you could open yourself to significant penalties. Be prepared to “show your work” in the event of an audit because the government presumes that a worker is an employee unless proven otherwise.

The US Internal Revenue Service (IRS) classifies workers for federal employment tax purposes — income tax, FICA taxes for Social Security and Medicare, and federal unemployment taxes.

The IRS previously used a 20-factor Common Law Test to determine classification. They’ve streamlined the process, with those 20 factors falling into three general categories:

BEHAVIORAL CONTROL

These facts show whether there is a right to direct or control how the worker does the work.

Instructions: A company can provide subcontractors detailed guidelines on how the level of service and scope of work should be achieved. It cannot, however, provide extensive instructions on how, when and where the work is to be done; what tools or equipment to use; who they can hire; or where to purchase supplies and services.

Training: The contracting company cannot train the subcontractors on procedures and methods, which indicates that the business wants the work done in a certain way. It can orient subcontractors on company policies, regulations and service expectations.

Absence of control. The worker is free from the employer’s control or direction in performing the work.

Business of the worker. The worker performs tasks that are outside the usual course of the hiring entity’s business.

Customarily engaged. The worker is customarily engaged in an independent trade, profession, occupation or business of the same nature as the work performed by the hiring entity.

These facts show whether there is a right to direct or control the business part of the work.

Significant investment: If you have a significant financial investment in your work, you may be an independent contractor.

Expenses: If you are not reimbursed for some or all business expenses, you are likely an independent contractor.

Opportunity for profit or loss: If you can realize a profit or incur a loss, this suggests you are in business for yourself and may be an independent contractor.

RELATIONSHIPS OF THE PARTIES

These facts illustrate how the business and workers perceive their relationship.

Employee benefits: If a company provides benefits such as insurance, pension or paid leave, that worker will be classified as an employee.

Written contracts: A written contract may show what the company and the subcontracting company intend. Download a subcontractor agreement template at my.sima.org

Source: Internal Revenue Service Publication 1779 FINANCIAL CONTROL

Each state uses its own method to evaluate worker status, the most prevalent of which is the ABC Test. In the snowplowing industry, the “B” prong is often the most difficult to prove:

Some states use a modified ABC test, which disregards part B, so where the work takes place is no longer a consideration. This is beneficial for companies who work in multiple states.

Whichever test you choose to follow, make sure it meets the federal and state requirements for each state you do business in. If you aren’t sure, consult an attorney and/or accountant for guidance.

DID YOU KNOW? The Canada Revenue Agency establishes the rules for similar employee vs. subcontractor requirements. Learn more at canada.ca/en/revenue-agency.html

If you contract with subcontractors, keep these best practices in mind:

Do not allow subcontractors to perform services for you without executing a signed and written contract. The scope of the contract should, at minimum, specify what services are to be performed based on the contracted level of service. Getting in writing the contractual responsibility for site inspection and monitoring is crucial when confronted with litigation arising from a personal injury that occurred days after a snow event.

Legally you may be held liable for your subcontractors’ deficiencies; practically your customer will hold you at fault. Provide a written document outlining the specific job requirements for all locations the subcontractor is servicing. An unhappy customer could result in the loss of a contract.

Your agreement should reflect whether the subcontractor you hire can further subcontract the work. If you allow this, you should require the sub to also defend and indemnify your company from all claims and litigation arising out of their subcontractor’s performance or failure to perform required services. Some clients will not allow this practice, so you should also confirm this in the contract.

Have your insurance provider and attorney review your subcontractor contracts to ensure you’re protected.

ADDITIONAL RESOURCE: SIMA members can access subcontractor-specific contract clauses in the “Advanced Contract Clauses” document at my.sima.org.

Whether you’re hiring subs or working as a sub, make sure your I’s are dotted and your T’s are crossed when it comes to insurance coverage and documentation.

A COI is a summary of coverage issued by the subcontractor’s insurance company. It is recommended that companies only hire subcontractors that can produce a COI. Here are some COI best practices:

✔ Do not accept a COI directly from the subcontractor. It must come from the insurance company.

✔ Review all COIs for fraud. Examples may include missing contact information, poor quality/photocopies, inconsistent fonts, or information appears to have been whited out.

✔ Make sure the COI is current and includes the policy expiration date. It is only valid from the date it was issued.

✔ Confirm your subs do not have exclusions on their policies (e.g., snow clearing services are not covered) and that the liability limits match yours. Some policies will not provide coverage if your sub’s limits are less than yours.

✔ At minimum, subcontractors should have liability and workers’ compensation coverage.

✔ Keep COIs organized and on file past the statutes of limitations for filing claims. These will be needed in the event of an insurance claim or audit.

When executing a contract with any subcontractors you plan to hire, follow these minimum insurance guidelines:

✔ Require the subcontractor to defend and indemnify your company from all claims and litigation arising out of the subcontractor’s performance or failure to perform required services.

✔ The agreement should expressly require the subcontractor to repair any damage caused by its employees.

✔ Require all subcontractors to identify your company as an additional insured.

ADDITIONAL RESOURCES: Learn more about these contract terms and conditions at sima.org/insurance. SIMA members can also download contract templates and advanced contract clauses at my.sima.org

Disclaimer: Work with your insurance agent to determine proper coverage, limits and endorsements for your business. Canadian readers should contact an agent to determine requirements in their province.

You have your subcontractor contracts signed and your certificates of insurance in hand. Just as important in the subcontracting process is quality control. If you are the hiring contractor, you ultimately answer to the client, so it’s imperative that your subs deliver on the promises that have been made. If you are a sub ready to take on work, you need to understand what you’ll be asked to do before committing to the work. Check out some best practices to ensure the subcontractor relationship is successful:

PRESEASON

Clearly set expectations for the season, including reliability; work quality; equipment, labor and materials commitments; safety requirements; service verification and documentation requirements; invoicing processes; and communication plans between your company, the subcontractor and the client.

While legal classifications prohibit you from telling a subcontractor how to perform the work, you should schedule a preseason meeting to review site maps and contract specifications and to document any pre-existing site damage. You don’t want to be sued because a subcontractor did not properly perform services because you failed to convey site-specific information or conduct a site visit to ensure everyone understood the site’s characteristics and potential hazards.

Make sure your contract outlines responsibilities and liability in the event of damage caused by the subcontractor, including responsibility for the costs of repair. Require your subs to report damage immediately using a detailed incident report.

IN-SEASON

Check in with subcontractors after the first and all major subsequent events to make sure standards are being met; share updates from the customer regarding service; and hear from the subcontractor about any challenges or concerns they may have about their sites.

POSTSEASON

When the season ends, meet to recap the season and provide feedback. Now is the time to look ahead and confirm they’re on board for next season and if there is an opportunity to add sites if they performed well.

TIP: PAY YOUR SUBS IN A TIMELY MANNER. Outline the process that must be met for them to be paid (e.g., documentation, timely invoicing, etc.). Never leave them hanging. It erodes trust, making them less likely to go the extra mile, which could result in less than stellar performance.

Where should you look for quality subcontractors?

• Referrals from your existing subcontractors.

• Seasonal businesses like roofing, paving, construction that have the equipment and employees but typically don’t work winters.

ADDITIONAL RESOURCES:

• Expanding Capacity Through Subcontracting

• Legal Hiring for the Snow Industry

• What You Need to Know about Snow Insurance

SIMA members can access these courses for free at train.sima.org

Mastering Commercial Snow & Ice Management

Mastering Commercial Snow & Ice Management has in-depth information on subcontractor management. Purchase it at sima.org/getcsp.

Some plows are built to get the job done. Others revolutionize the way you tackle work. The SnowEx® UTV plow line does both. Explore our full line of mid-duty and heavy-duty plows for your sport, recreational or full-size UTV—and start attacking work from a new angle.

MID-DUTY UTV STRAIGHT BLADE

The 5'6" and 6'0" Mid-Duty UTV Straight Blade Plows feature powerful hydraulics with a lightweight design and a weatherproof plow control. The patent-pending Sway-Frame™ allows the blade to shift side-to-side.

HEAVY-DUTY UTV STRAIGHT BLADE

Give your utility vehicle professional-grade plowing performance with the 6'0" Heavy-Duty UTV Straight Blade Plow. Its rugged design and durability with a full-trip moldboard protects

HEAVY-DUTY UTV V-PLOW

Take your sidewalk snow removal to the next level with the 6'0" Heavy-Duty UTV V-Plow. Designed to angle down to 5' wide— whether in straight, scoop, or V-mode—the

By MICHAEL WAGNER, CSP, ASM

Now that most snow and ice operations are underway, are you ensuring your organization and staff are delivering a quality service? As a leader, are you creating a culture that focuses on creating quality opportunities for employees, clients and the communities in which you operate? As you head deeper into the winter season it’s important to consider these elements of quality until the last snowfall.

We will work through four of the most important “quality” aspects of a snow and ice management organization and how they impact not only the bottom line, but all relevant stakeholders of the business. These are best practices for any organization involved in the industry no matter the size, whether 5 or 500 employees.

manner. Another important trait of quality leaders is supporting staff when the going gets tough!

Examples of quality leaders in the snow and ice management industry:

• Understanding the physical and emotional toll of an extended work shift or long-duration storm, and supporting staff where necessary.

• Learning the current and most valuable leadership tools and practices through continuous education and webinars/seminars.

• Devoting time to developing more leaders throughout the organization, and supporting idea generation and creativity.

attention when necessary, so you don’t miss details such as nonverbal communication cues, the “big” and the “small” picture of the issues being described, and clues as to the root causes of problems.

Examples of quality communication in the snow and ice management industry:

• Developing a company-wide communications plan that includes hierarchy, points of contact for specific tasks and responsibilities, and process/ procedure specifics.

• A culture of trust and respect that comes from leaders and staff listening and responding to the concerns and ideas of others.

As the first best practice, quality leadership in any organization is a key to success. Leadership personnel should complete leadership seminars and third-party trainings, and they should consume a mixed bag of leadership-related content including blogs, magazine articles, podcasts and books.

Another great development tool is utilizing peer networks and mentorship programs to learn from other's experiences and be able to share ideas and thoughts with similar professionals.

Quality leaders help provide vision and direction to employees as they work to carry out company-wide goals and the company’s mission. Also, true leaders are talented in developing strong teams that can complete required tasks and projects in an efficient and timely

The next characteristic of quality within an organization is quality communication, which rivals leadership for No. 1! Developing a system of successful and effortless communication is vital to providing timely and professional service, as well as building respect and trustworthiness throughout the company.

Communication can involve showing empathy and attentiveness to employee needs/wants and problems/stresses, as well as effectively conveying company objectives, goals, values and the mission.

One of the greatest ways to create quality communications within your organization is to be an active listener. This means giving people your undivided

• Providing communications training opportunities for leaders and staff.

The next best practice is to acquire and maintain quality tools for getting the job done; and this goes beyond basic hand tools. This can include quality trucks, plows and spreaders, as well as snowblowers, shovels and loaders. These tools should be ready to use and be dependable for the winter weather season.

Other important tools include quality and reliable computers, cell phones, cellular and internet service providers, weather reporting platforms and enterprise management software systems. All of these are important

tools in influencing increased capabilities for all company personnel; malfunctioning or ill-prepared tooling can cause stress, lost time/revenue and many other problems.

Examples of quality tools in the snow and ice management industry:

• Snowplows, trucks, spreaders, snowblowers, loaders and more that have gone through preseason preventive maintenance programs.

• Operating capabilities of cellular and computer devices to handle a variety of data needs, with contingency plans for interrupted service.

• Software that enables streamlined processes within administrative and operating business units for proper job tracking, costing and billing.

this characteristic unique is that if you achieve quality leadership, communications and tools, you are well on your way to providing a quality service.

This includes developing the proper site specifications and requirements, completing the proper pre- and midseason training activities, and carrying out an exceptional service. Such things as job-specific training and expertise can be taught and must be integrated, and the experience of your talented staff will certainly influence this as well. Remember that the effort you put into the system directly influences the output or the service provided!

Examples of quality services in the snow and ice management industry:

• Managing minimal service complaints and reducing insurance claim counts and costs.

clients that see the value in your service.

With these four elements of quality in mind, you should be able to guide your team and the organization in the right direction. Whether it’s improving processes or services, quality must be one of your top business and personal values to be successful.

As a representative of the industry, you can provide a necessary emergency service when the stakes are high because things are usually stressful for employees, clients and those within the community that may be visiting sites on which you operate. Be creative, diligent and always keep an open mind regarding organizational improvements.

Finally, ensuring quality service is key to organizational success. What makes

• Providing a dependable and timely service for every snow event throughout the season.

• Retaining and adding long-term

Michael Wagner, CSP, ASM, is fleet and safety manager at Designscapes Colorado Inc. Contact him at 303-328-5554 or mwagner@designscapes.org.

By CHERYL HIGLEY

Internships are commonplace in many industries, like medical, business and engineering. Students receive practical, supervised experience and often the company can get a head start on identifying candidates that would be great team additions. While uncommon in the snow industry, some SIMA members have launched programs in their green divi-

sions to tap into a new candidate pool.

Level Green Landscaping, which services clients in Maryland, Washington DC and Virginia, has worked with interns for 20 years; and founder and managing partner Doug Delano says a comprehensive internship program can help make a company a more attractive landing place for students upon graduation.

“That’s a big issue right now because there aren’t as many people going into landscaping as there were years ago,” he says.

Making the right connections in the educational space is key to establishing a foundation for an internship program. Identifying college landscape programs, local vocational schools and high schools, and building relationships with key advisors will open the door to possibilities for your company and intern candidates.

Level Green Landscaping has had interns from the University of West Virginia, Penn State University, Texas A&M and University of Maryland. Grunder Landscaping ventured far and wide as well, seeking candidates from BYU, Auburn and Ball State before shifting its focus to the Midwest — most notably Michigan State University.

“It took a few years to gain traction. We work with the advisors to understand the curriculum and the expected outcomes and tailor the internship to meet them,” explains Director of Production/Operations Dalton Yates, who adds that establishing name recognition is important. “We’ve sponsored collegiate events and MSU’s career service network. Being present is

GAINING TRACTION: Visibility in a variety of spaces like career fairs and building relationships with advisors, students and even parents can showcase the industry as a place to build a career.

huge. It’s getting your name out and getting students talking. I ran into an intern from 2 years ago and he’s still telling people about our program.”

With over 30 years in the industry, Environmental Enhancements’ HR Manager Carmen Kesteven has developed a passion for encouraging students who haven’t been given the opportunity to look beyond high school graduation. It is her

goal to help students who may not think they have options to find their way.

By building relationships with the Loudon County Workforce Center and Loudoun County Public Schools counseling department, EE is invited to participate in career fairs or visit the schools — and sometimes they are the only landscaping company represented.

“I focus on schools with students who

Offering a well-rounded experience across the company’s different departments is a great opportunity for students to get a holistic view of the industry.

At Environmental Enhancements, Inc. in Sterling, VA, the internship program started right before the pandemic. The program, although young, is full of great opportunities for the students. Believing in being innovative, the program is all about hands-on experience from the beginning. That view means gaining on-the-job experience in every level of the organization, including production, sales, estimating, management, design and administration.

“Our internship program provides a great opportunity for learning more about the landscape industry by getting hands-on experience. After being exposed to all the areas

of services provided, our students can really see where they want to concentrate their efforts in the future, whether it is account management, project management, design, etc.,” says EE HR Manager Carmen Kesteven. “A silver lining from the pandemic was that it proved our industry is considered essential. That

will help makes this industry very important and provide great career opportunities.”

Grunder Landscaping in Dayton, OH, has had interns for 15-20 years but formalized its program in 2018 after seeing what other companies were providing. Interns experience all

Continued on page 22

don’t know what to do after high school. My number one school is low income, with a lot of Hispanic students,” she says. “I get them to think about what’s happening after high school and to realize that they have the right to feel they can reach their goals.”

Educational connections are just one piece of the puzzle. Yates says sometimes winning over parents and dispelling the myths about the industry is more difficult.

“There is a huge misconception about the landscape and snow industries. People think it’s just rough guys pushing snow or dirty lawn work. Our interns know it’s so much more, and the advisors and professors do a good job showing that,” he says. “When we’re going to a technical school and we’re meeting with parents and students, we target the parents in our pitch. We bring job site photos and show that you can make a good living and that it’s a professional industry. That communication piece is huge.”

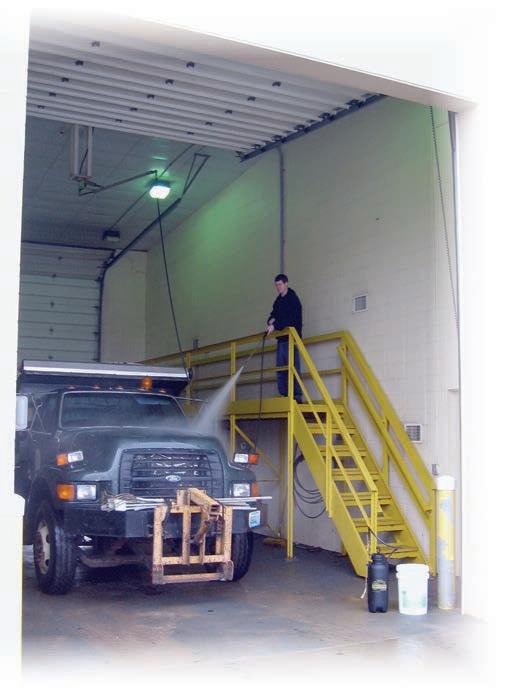

Easily remove the corrosive salt contamination from your entire fleet.

Works where soaps fail – because soaps chemically cannot break the carbonic bond that salt and liquid deicers have when attached to your fleet.

Prevents rust and corrosion damage to your fleet – by removing the salt contamination from your frames, wiring harnesses, radiators, paint jobs and more.

Extremely economical protection – dilutes 1 to 8 with cold water and only takes a few gallons of diluted product to treat a tandem axel truck.

No added workload for your staff – it just take 2 to 3 minutes to neutralize the salt so you can rinse it away.

Stop high-moisture content snow from sticking to your equipment.

Snow slides right out – of your truck beds, loader buckets and blower chutes.

Eliminates the need for manual removal – no more popping the hydraulics or using a backhoe to remove the sticky snow.

Easy application – with RHOMAR’S 25-gallon powered sprayer.

Saves you time – less time idling means more roads cleared.

Continued from page 21

major aspects of the company during a 12-week structured program where they shadow and work alongside team members and managers.

“Seeing the whole company allows the intern to see how the different departments work together,” says Director of Production/Operations Dalton Yates. “Sometimes they learn what they don’t want to do when they grow up. Sometimes that’s the easier question.”

Building an internship program is time consuming. Creating the program internally, building relationships with school advisors and marketing the program are all essential … Most importantly, though, is getting the team to commit to what will be required to make it a success.

“You have to follow through. What I have seen is everyone gets excited and then they realize they’re busy.

MANAGEMENT MATERIAL: Level Green Landscaping's trainee program gives employees the chance to climb the career ladder.

Besides its internship program, Level Green Landscaping operates a twotier management trainee program: The first tier involves identifying and selecting motivated crew members for a one- to six-month program in which they receive training to help them become operations managers. “We can promote our people internally that way,” explains company owner and managing partner Doug Delano. The second program is geared more toward the sales and customer service side of the business and targets college students

who are interested in the sales profession but who might not realize the career options available in the landscape industry.

“We want to try to expose them to what Level Green is like; like the internship program they are going to spend a little bit of time in each of these sectors of the business. But we also try to do some fun outings with them,” Delano explains, “because, really, the long-term goal is if the kids are good, you want to try to get them to come back to work for you after they graduate.”

— Patrick White

Who’s mentoring the trainees? Who’s going to work with them? You have to be realistic about what you want to do and how many people you can handle,” Kesteven says.

Grunder Landscaping has 2-3 interns a year, and Dalton agrees team buy-in is key: “We ask our team members to pay special attention to interns to focus on their learning and growth. We can share our company’s culture and why it is a great place to work. Even if we do not get a full-time employee, hopefully the interns share their experiences with others that we may be able to recruit.”

Looking at an internship program as a conduit for cheap labor is a shortsighted approach, particularly if you want to show candidates that the industry is one where they can build a career and make a good living doing so. The key is to have interns working with you … not for you.

Level Green, Grunder Landscaping and EE interns are paid, and some offer travel stipends and housing assistance for students who aren’t local to the area.

Since most internship programs take place in the spring or summer, none of the companies has hosted interns during the winter; but Kesteven isn’t ruling out the possibility as EE’s internship program grows.

“We have not had winter interns yet, but anything is possible as we are very innovative and want to be able to provide the student the opportunity to learn about the industry. We tailor the program based on the students’ needs and following the school’s requirements,” she says.

Few of the companies interviewed have seen much of a direct return on hiring interns into full-time positions,

but that isn’t a sign that the program isn’t successful.

Dalton says Grunder Landscaping has recruited full-time employees out of college that can be linked to the relationships the company has built with college advisors and students who continue to spread the word about their experience.

Kesteven also sees a bright future for EE’s program.

“Young people are the future, and they have so much to give. We need to educate people that there is so much to do in the industry,” she says. “School is important, but there are so many kids who can’t afford to go to college, or the college experience isn’t for them. We give them the opportunity to realize that they have the right to be successful and that no one is more than or less than … we are all important.”

Cheryl Higley is Director of Education & Content for SIMA. Email her at cheryl@sima.org or call 262-236-9972.

By MIKE RORIE

Like many of you, I’ve had to navigate bad weather, labor shortages, supply chain issues, and the daily challenges facing a snow and ice management business. During the pandemic, we learned on the fly how to equip our businesses to accommodate remote workers and safety concerns. But what if we knew how to solidify our operations – and stay prepared in any economic crisis?

Knowing how to shepherd your business through downturns and maintain or even increase growth even under those conditions will ensure you keep your company and team thriving for years to come. Here’s how you can keep your snow business moving forward.

Knowing where your company stands at the present moment is key to planning for economic downturns.

Look at your position in the market, your pipeline, and how you’re tracking against your financial targets. If you’re not in a dominant market position, then your best course of action is to go into containment mode and prioritize risk mitigation to secure your sustainability. This might mean pausing growth activities and focusing on shoring up gaps in areas that were neglected when growth was the focus.

On the other hand, perhaps you’re one of the lucky operators in a dominant market position, meaning you have low debt and a lot of cash on hand. In that case, you’re in a position to go and grow, meaning you can pursue aggressive growth through new customers, new markets, or new acquisitions.

Look at your current book of clients. Where do they stand as far as satisfaction and renewals? If they’re at risk, ensure your account managers are in contact with those clients and that they have a strategy to secure renewal agreements and address any outstanding quality control concerns.

If your client retention is strong, ensure your pricing is accurate since inflation has been significant.

When your revenue targets are covered, check your renewal-to-lost client ratio to understand how much you need to make up. For example, if you’re planning for 90% renewals, is your pipeline ready to replace those lost customers?

To keep a healthy pipeline, your team must identify the right prospects to meet your dollar goals for each of your customer types. Whether you’re planning for expansion or containment, ensure your pipeline is ready to meet or exceed your goals.

To keep a healthy pipeline, your team must identify the right prospects to meet your dollar goals for each of your customer types.

There are two things you are always certain to need in this business: equipment and product. Assessing your equipment’s condition will help you get ahead of any significant purchases.

Likewise, understanding your supply needs will help you prepare for any bottlenecks to obtaining your materials. When in doubt, buy early and buy extra. Not being able to get equipment or product can be disastrous.

To determine your purchasing needs, you should be able to access historical purchasing information quickly and be confident your data is accurate. This

is where integrated business management software that connects job costing to purchases really pays off.

When materials like salt increase significantly in price, inform your customers as soon as possible that the bid they receive will reflect this price hike. Keeping a close eye on these costs before and throughout the snow season will help you remain profitable with competitive bids and ample materials on hand.

Changes in subcontractor costs will drastically affect your profitability, so it’s important to discuss these agreements before the season and revisit them as circumstances require. With the labor shortage, many subcontractors have increased their hourly rates. If that’s the case, it’s better to come armed with today’s competitive rates to support how much you’re willing to pay for their services. With good data, the conversation should be less contentious.

Identify gaps in your subcontractor agreements, particularly with your most significant contributors. Knowing where they stand will ensure you do not have to walk away from your largest subcontractor before you need them.

Your pipeline is also a concern when it comes to having enough subcontractors to perform the job. If you’re always recruiting, you’ll be able to ensure enough labor to meet your clients’ demands, even when you must part ways with a contractor.

If labor prices have gone up, communicate that to your clients. Be prepared to show them the trends over the last few years. Discuss material, fuel, equipment, and how demand in other industries, like the construction industry, affect your rental costs and ability to obtain equipment.

Again, this is where technology and detailed reporting are critical to accessing accurate labor and material costs to support any price increases or surcharges in real time.

Instability in the economy or the supply chain shouldn’t discourage you from staying engaged with colleagues and friends – and even your competitors – in the industry. Remaining connected to local and national associations like SIMA keeps you ahead of the curve. Plus, you’ll be using your resources to keep informed about any cost/ availability changes or innovations in equipment or materials.

Best of luck this snow season and beyond.

Mike Rorie has been a participant in the snow and ice industry for over four decades. He sold his company GIS Dynamics, creators of Go iLawn and Go iPave, to Aspire Software in 2021 to continue evolving both products for contractors. He remains an active participant and leader in the industry, and is a board member for GroundSystems, Inc. in Cincinnati.

By MIKE McCARRON

Winter is finally here! And so are the clients that signed contracts late or decided last minute to switch providers. I don’t know about your market, but here on the East Coast we are noticing a trend of contracts being returned later and later; this creates a serious issue for contractors trying to properly plan.

By this point in the season, you should have already made any changes to existing clients’ scopes of work and prepped operations accordingly. However, new clients are more of a challenge since they

are coming on board when winter operations are in full swing and time is of the essence. That doesn’t mean, however, that you should skip steps as you add them to your routes before the next snowfall.

Following are a few reminders to consider as you prepare to add or renew clients mid-season:

1 Has the client sent back an updated signed contract? If service levels were changed, did you document them in your system?

2 Do all account managers and production staff have the latest scope of work details for each site? Have all maps and measurements been updated for supervisors, foremen and laborers to review prior to their first event at each property?

3 Have you updated your records to reflect new pricing or fuel surcharges, and have you notified your clients of such changes so invoicing expectations are managed?

4 Have all locations been inspected ahead of time and reviewed by production staff?

5 Were properties marked and staked for fire and rescue services, concrete curb edges, etc.? Were speed bumps marked to avoid damage caused by your plow trucks?

6 Were low-hanging tree limbs and leaning trees on contracted properties identified and addressed? Wet and heavy snow may bring them down, possibly blocking access for your team or causing damage to property, such as client vehicles.

7 Did you conduct a full

Continued on page 28

Whether it is an HOA board waiting until the fourth quarter to make decisions or customers with an “Amazon” mentality that one click and the product ends up on your doorstep (sometimes in less than 24 hours), the professional snow industry needs to continue to elevate expectations and educate prospects and customers on why awarding contracts earlier is vital to their contractor’s ability to deliver exceptional service. Share the following with them, or include them in the next contract renewal. All are available at my.sima.org.

The 52-week procurement timeline illustrates by season what should take place when, both from a contractor’s and a client’s perspective.

SIMA’s risk meter shows how late contract awards jeopardize the snow professional’s ability to properly prepare to service their sites.

Use the Standard Practice for Procuring and Planning Snow and Ice Management to identify areas where your company can improve and to share best practices with clients.

Continued from page 26

walkthrough video of parking lots, sidewalks, buildings, curbs and other features to document what the property looks like before an event? This pre-event footage will be valuable evidence should a client claim that your company damaged property.

8 When staging equipment and materials on properties, have they been stored in safe and secure locations? Mark off these areas with cones and tape to ensure you have easy access when the event occurs. This will also help to prevent any parking issues for your crews.

Our fleet of interchangeable truck bodies and WorkReady™ subframes will transform your truck from season to season in just 3 minutes.

• One Truck, Multiple Bodies

• Multi-Seasonal Use

• Non-CDL Trucks

switchngo.com/snow

It’s always the little details that seem to get missed and that ultimately bother clients, causing you and your team unnecessary heartache and stress.

prepared

Covering these details and communicating them to your team quickly before an event can be difficult. Create a checklist for your team to make sure nothing gets missed. Do it NOW! Not next week or when you “get to it.” After the fact, you don’t want to play “would have, could have, should have.”

It’s always the little details that seem to get missed and that ultimately bother clients, causing you and your team unnecessary heartache and stress.

Think about going to a restaurant and ordering a meal only to find that your favorite sauce, the one you specifically requested, was not delivered with the meal. Was the server not paying attention to your order or did the kitchen miss something? Either way, you may be a bit disappointed, and certainly not wowed.

Remember, “wow” usually wins in today’s tough and competitive customer care market. Why not make all of your winter engagements “wow” moments? It just takes a little upfront planning to pave the way for exceptional customer service experiences.

Mike McCarron is president and founder of Image Works Landscape Management, a commercial landscape maintenance and snow removal firm in the Northern Virginia market. He has 24 years of industry experience. Email him at mike@ imageworkslandscaping.com.

TBy JASON OSTRANDER, CSP

here is no shortage of articles and presentations written on the importance of preparing your team and your equipment in advance of the winter’s first snowflake.

Recently there has been a greater importance placed on how we close the winter season by taking a more proactive approach to truck and equipment maintenance, client communication and service evaluations. (Which is great for the industry!) In fact, we’ve done such a good job at winter preparations and spring postmortems that it can be easy to lose sight of what we should be doing during the season.

Here are some things to keep in mind for you and your team as the snow begins to accumulate.

In the lead-up to any snow season, a ton of communication is happening – both with the clients and your team members. Discussions about routes, equipment, scopes of work and documentation are pivotal conversations, but beware of the radio silence that sometimes occurs when the work actually needs to get done. If you can approach every storm like you approached fall preparation, you’ll be ahead of the pack for sure.

Communicating with clients after every storm and asking them to rate your performance will ensure against the need for major midseason course corrections. Likewise, constantly polling your team and asking them how they’re doing throughout the winter will give you an insider’s view of their mental and physical capacities.

High quality snow contractors will work year-round to equip their

teams and solidify snow and ice best practices. In fact, most snow training occurs in the heat of summer when no one else is really thinking about snow. Yet the most overlooked time for training is in the heat of the battle.

Rather than taking the time to reiterate proper snow removal principles and staffing issues after every storm, business owners will wait until spring to address key in-season problems. The best time to course correct, or to celebrate quality workmanship, is right after a storm. You will never regret planning post-storm debriefs after every event, giving your team a chance to tackle performance-related issues early and often.

Don’t forget that clients need continuous training, too! If you had an ice-only event, or a storm with higher-than-average accumulation, you might need to train your client on how to handle the potentially abnormal invoice that they’re about to receive.

If you have more than 3-5 trucks going out for a storm, you probably spent time during the preseason preparing routes for your team. While this is a significant component to proper snow

and ice management, the one thing that becomes obvious as the storms roll in is that no route is set in stone.

It is important during the winter to constantly evaluate your routes. Do you have the right vehicle on each route? Do your routes need to be reordered to better accommodate clients?

Are your staff showing up for every storm? If not, which vehicles and equipment are easier for new people to hop into? Consider adding to your staff or fleet mid-season (or utilize subcontractors) if you realize you have overestimated your team’s capability. Better to take a small financial hit during the winter than to lose the contract outright when it comes up for renewal.

The current usage of technology in the snow industry is at an all-time high. One pass through the trade show floor at the Snow & Ice Symposium this past summer tells you all you need to know about the importance of mobile service verification and documentation.

As an owner or manager, you can probably list the benefits of documentation quicker than you can snap a picture of a salted parking lot; but can your team do the same? Of all the things they need to understand about the future of the industry, documentation and service verification should be priority #1.

Not only does documentation support you from a legal perspective, but it also keeps your team’s production in check. Creating an ecosystem where pictures and data abound will help every facet of your operation (especially accounts receivable)! Take the valuable time to constantly monitor your team’s use of your documentation strategy and course correct as soon as you can.

Jason Ostrander, CSP, is chief operating officer for East End Group, and a member of the Snow Business Editorial Advisory Committee. Email him at jason@ eastendgroup.net.

Don’t go through another snow season without resources and support. Joining SIMA has never been easier!

Spend 5 minutes giving us a little info … we’ll set up your account and invoice you.

Pay $20 to get started and automatically be billed $40 per month.

The WESTERN® mild-steel MVP 3 V-plow outfits the Sauers managers’ trucks for ultimate performance and efficiency.

WESTERN MVP 3 Snow Plow https://tinyurl.com/WESTERNMVP3

When the snow flies and the ice hardens, time is of the essence. Property managers expect their sites to be clear and safe for patrons. This leaves little room for error for snow and ice contractors.

For Sauers Snow and Ice Management in Warminster, PA, the WESTERN® MVP 3 V-plow with flared wings is truly a most valuable player. Their fleet of manager trucks is outfitted with MVP 3 plows to ensure all properties are serviced to the Sauers service standard.

“We have over 20 WESTERN MVP 3 plows,” said Zach Kelley, CSP, Director of Operations for Sauers. “They are reliable and stand up to wear and tear. They allow for interchangeability when we have issues in a storm.”

The FLEET FLEX Electrical system allows for true fleet interchangeability. The same FLEET FLEX CabCommand handheld or joystick control can operate any UltraMount® 2 plows. The UltraMount 2 system makes plow installation and removal easy. This allows Sauers to remove the plows when they aren’t needed and quickly mobilize their fleet when snow is in the forecast. For Kelley, this is one less thing to worry about when preparing for a storm. He knows that his service team can quickly prepare the fleet to handle the winter weather.

At Sauers, their site managers are tasked with closing out the services at each property at the end of the storm. Each site undergoes a 12-point inspection before the winter services are marked as complete. The efficiency provided by the MVP 3 and its ability to operate in straight, scoop and V-blade mode has saved Sauers thousands of dollars in payroll by making their managers more efficient due to the versatility of the WESTERN MVP 3 V-plow.

And at the end of the storm, there is nothing more motivating than getting out of the cold. The efficiency of the V-plow boosts morale, which is worth a lot to Sauers.

In addition to handling the snow, Western Products also knows a thing or two about handling ice. The WESTERN Striker™ stainless steel hoppers are reliable hoppers that provide spread widths up to 40 feet. Chuck Lantzman, President and CEO of Snow and Ice Management Co. (SIMCO), has used Western hoppers for over 20 years.

The MVP 3 is the Swiss Army Knife of plows. My managers fight over the V-plows because they get everyone home and warm that much faster.” — Zach Kelley, Director of Operations / Sauers Snow and Ice Management

The WESTERN® MVP 3™ plow is a true Swiss Army Knife that gets the job done faster.

Reliability and durability of equipment means a lot to SIMCO. When equipment functions as it’s supposed to, Lantzman’s team can focus on closing out properties and verifying service levels. SIMCO operates with a small team of direct employees, so when equipment goes down, someone has to work on the unit in the field or come to the shop for troubleshooting.

This winter season, SIMCO will be using the pre-wet system accessory for each of its hoppers. This system will allow the operator to pre-wet the deicing material with liquid brine solution before it hits the spinner. This activates the material to

The WESTERN® Striker stainless steel hopper has a spread width of 40 feet and a variety of optional accessories for maximum performance.

WESTERN Pre-Wet System for Hopper Spreaders https://tinyurl.com/HopperSpreader

accelerate ice melting and reduces the bounce of the granules when they hit the pavement for greater control and less waste. Studies show that salt application rates can be reduced by up to 30%. SIMCO hopes to reduce the amount of salt that they use during the season with the pre-wet system.

“When I make an investment,” said Lantzman, “I’m looking for equipment that is reliable and isn’t going to break. I prefer simple equipment with limited electronics. The simplified functions do better in harsh environments and work well for my team.”

Jennifer Walth is Advertising Manager for Douglas Dynamics CSI. Email her at jwalth@douglasdynamics.com.

Adapt to whatever the weather throws your way with the WESTERN® WIDE-OUT™ and WIDE-OUT™ XL adjustable wing snowplows. The WIDE-OUT XL model extends to 11' in straight blade position, making it the widest WESTERN plow yet. Both models feature 31" tall moldboards with independently-controlled flared wings that retract at the push of a button to easily maneuver smaller and tighter areas. Cross jobs off your list over 30% faster with WESTERN WIDE-OUT snowplows.

MORE JOBS. DONE FASTER.

WIDE-OUT™ | WIDE-OUT™ XL ADJUSTABLE WING SNOWPLOWS

The Live Edge Sno Pusher features industry-leading Live Edge Technology and an all-new floating coupler design, ensuring superior surface outcome. The efficiency and productivity of the Live Edge Technology is matched with Pro-Tech’s durability and ease of use. Users will find themselves with an all-around superior snow removal tool for a more efficient operation. www.snopusher.com

The Doosan DL220-7 wheel loader offers the durability and maneuverability needed for pushing and loading snow. The heavy-duty axles offer impressive lift capacities, and an optional larger counterweight further enhances performance. The box frame boasts added strength, while an articulating design ensures excellent load distribution and rigidity. na.doosanequipment.com

The Holms SL Sweeper has an innovative design for working at higher speeds and on more difficult surfaces. The SL features a 28” diameter brush for high-performance sweeping; and the suspended design ensures a proper sweeping position for managing ground contours without adjustment. Brush and spray options are available. www.holms.com

The PILE DRIVER lineup of pusher plows – available in 8’, 10’, 12’, 14’ and 16’ widths – come with three heights and a common carrier attachment system, making them compatible with skid steers, wheel loaders, tractors and backhoe loaders. Patent-pending TRACE (terrain response advanced cutting edge) technology is made up of independent 2’ sections that oscillate, move vertically, and trip to accommodate contours and obstacles in the plowable surface. www.westernplows.com