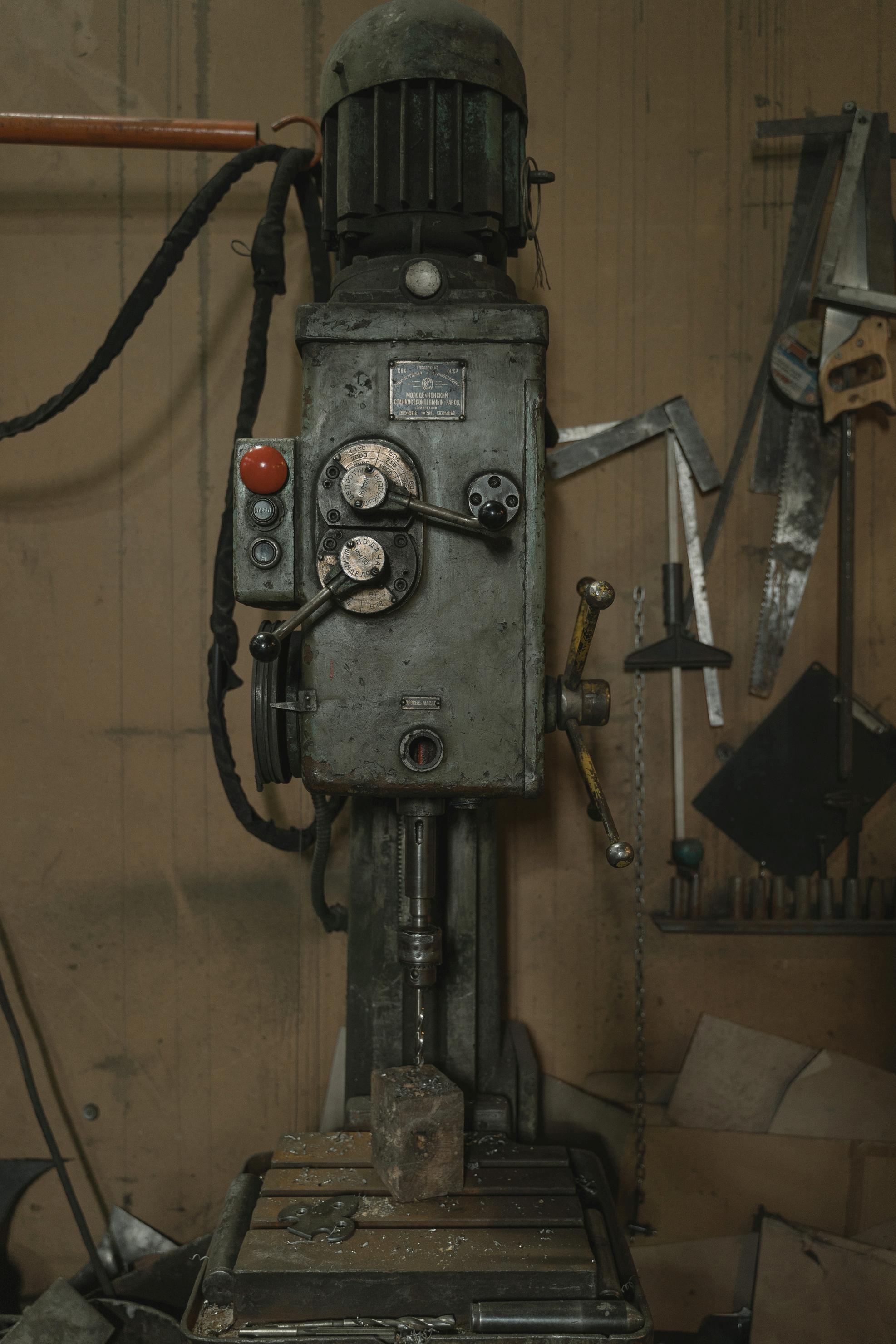

Large and hard materials, such as structural steel or metal beams, are a real struggle for traditional drills. The Magnetic Drilling Machine takes the game to a whole new level. Its magnetic base anchors firmly to the metal surface, providing rock-solid stability that enables users to drill perfectly aligned holes in any direction-vertical, horizontal, or upside down-without vibration or misalignment.

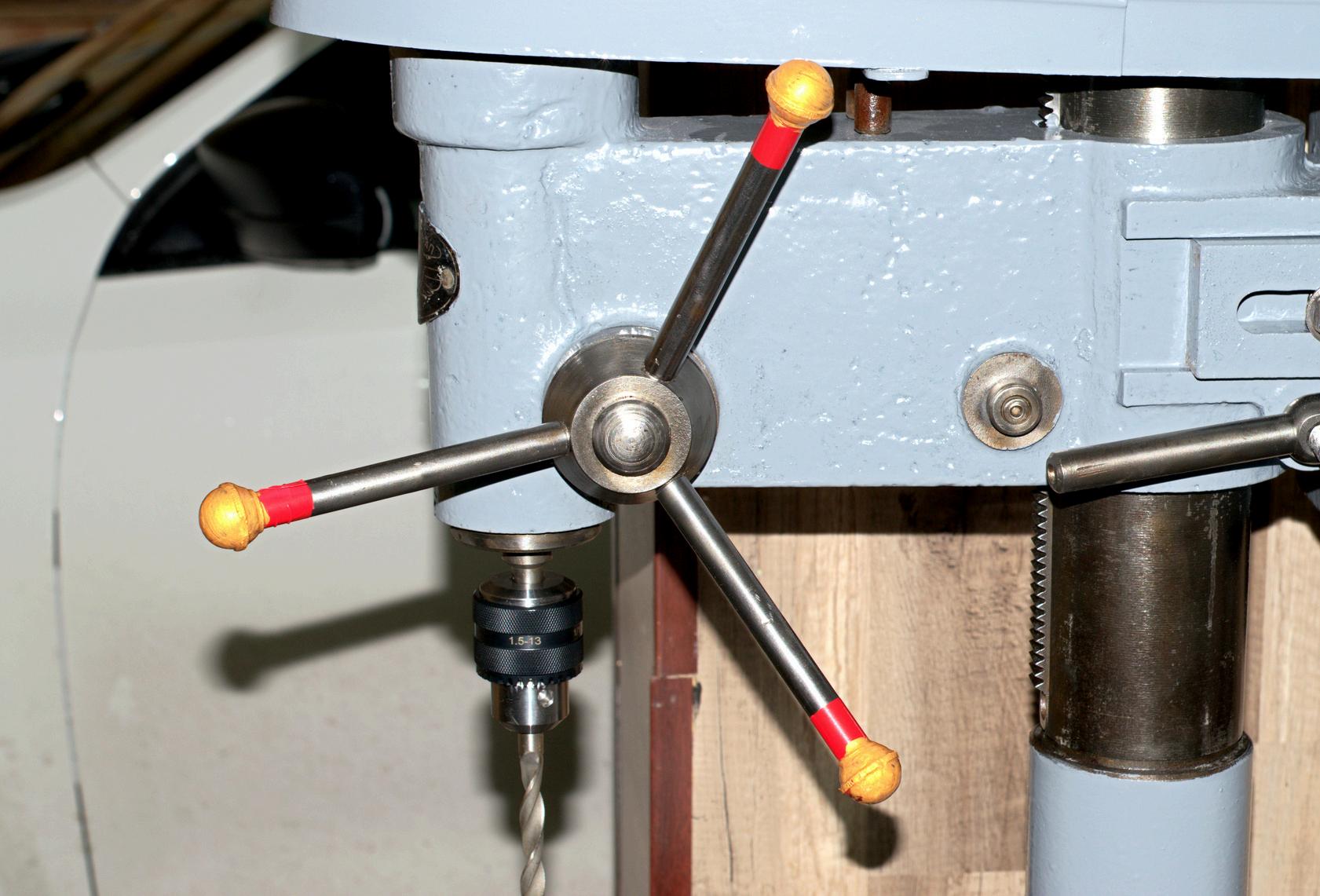

Accurate positioning of every hole for bolt, rivet, and fastener placement is absolutely crucial in every structure made of steel. Therefore, the Magnetic Drilling Machine makes sure that each hole is perfectly aligned, even at difficult angles or heights.

BDS drilling machines have earned a reputation for their superior holding power and stable operation, hence, the preferred choice for fabricators who require reliability on site. A BDS Magnetic Drilling Machine will ensure that thick plates and beams are drilled smoothly without deviation, which is essential for the maintenance of alignment in large frameworks.

Unlike stationary drills, a magnetic drill can go wherever the job takes you-on scaffolding, high beams, or confined spaces-and attach securely to perform consistent drilling.

That is why it is considered mobile by construction professionals; it does not require them to transfer huge components to the workstation. The Magnetic Drilling Machine comes to the material, saving hours of lifting, setup, and adjustment time.

Preciseness and safety are everything in infrastructure development. BDS Magnetic Drilling Machines are used in critical installations by engineers because of their steady magnetic adhesion and ability to operate even in awkward positions. When the steel is heavy and the stakes are high, these machines keep the work steady and accurate cut after cut, hole after hole.

Very often, factories and plants have to make modifications, retrofits, or repairs on existing machinery and steel platforms. That’s where the magnetic drill proves its versatility.

Maintenance engineers find Magnetic Drilling Machines valuable for their quick, precise work without disassembling large structures. Their portability allows direct drilling on installed equipment, reducing downtime and keeping production running smoothly.

There are few environments that test the tools like marine construction does: salt, moisture, and vibration can push machines to their limits. Yet the BDS Magnetic Drilling Machine stands firm-quite literally. It features a corrosion-resistant design with a powerful magnet that enables reliable drilling on hulls, decks, and large steel frames both in shipyards and offshore rigs. This combination of precision with endurance makes it a trusted companion for shipbuilders who cannot afford inaccuracies.

The BDS Magnetic Drilling Machine stands apart not just for its engineering but for its purposebuilt design to meet industrial demands: compact, powerful motors with increased torque and stable magnetic adhesion all in a balance that professionals rely on, whether working in heavy-duty drilling or fine detailing.

Our goal at SFTC is to work closely with industries all over the KSA to ensure each operation has just the right machine for the job.

When projects demand accuracy and mobility, combined with durability, it is time to switch to a smarter way of working. The Magnetic Drilling Machine brings precision from the workstation directly to the site without any compromise or slowdown.

Get in touch with SFTC today-your trusted BDS Distributor in KSA-and explore an array of BDS Magnetic Drilling Machines that are redefining drilling performance. Let's help you build stronger, faster, and more confidently.