Discover the Skid Pro Difference! From our humble roots in Central Minnesota, we have grown to become the largest family-owned, factory-direct skid steer attachment company in the USA. We know our success is fueled by our motto: Better Product. Better Service. Happier Customer.

Our 50 years of combined manufacturing experience and two decades of expertise in the attachment industry and an unwavering commitment to quality, guarantee you will get the best attachments available. We want to be the last attachment you’ll need to buy.

When you call with questions, we believe you should speak with a live person, no matter when you call. Customer service & product knowledge that exceeds your expectations is our standard! Our highly trained Product Gurus are here to cater to your needs and deliver worksite solutions. Call us anytime and experience the Skid Pro difference for yourself. We can’t wait to hear from you!

We only make and sell skid loader attachments. And above all, we’ve never waivered on our commitment to quality first. Unlike big brands, our sole focus is only skid loader attachments. It gets all our engineering, testing, passion and dedication. For us, it isn’t an afterthough…it’s our only thought!

Skid Pro is always pushing the limits of innovation. We focus on not only what works today but what will for years to come, ensuring that you will get the most value out of each and every attachment. We pioneered the industry’s first standard 2-year warranty across our entire line-up! We put our money where our mouth is on backing up our products.

At Skid Pro, our Product Gurus are more than just experts in their field – they’re your trusted advisors. When you call, they’ll guide you to the perfect attachment with precision and ease, ensuring you get it right the first time.

Our core values are simple yet effective. We strive to make great products, treat customers like friends, and make their experience with us easy and enjoyable. Our commitment to old-fashioned customer service ensures repeat business and customer satisfaction. Just like our customers, we’re blue-collar and believe in the power of customer success to drive company success.

While most companies prioritize online shopping and automation, we take a different approach. Our commitment to service means you’ll always speak to a Guru, no matter the time of day. Our team is always ready to make your experience with us exceptional from your first call to after delivery and during the life of our products.

At Skid Pro, customer service is a cornerstone of who we are. Time and again we talk about “customer service that would meet your Grandfather’s expectations.” There are a lot of good products out there, but no question the customer-focus is an absolute difference-maker in contributing to our high customer satisfaction and customer retention.

• Products built without dealer markup

• Parts are always in stock

• Always speak with a real person from the USA

• Product gururs are educated and informed

• Family run, family feel

• Largest collection of informative product resources

We go above and beyond to provide our customers with an exceptional experience. It is our belief that providing more than just a product is the key to building long-lasting relationships with our customers, and we can’t wait to hear from you and show you the Skid Pro difference.

“The snow blower that we purchased from Skid Pro exceeded expectations. We had no issues and with all the snow we had this past winter it was one of the most used pieces of equipment we have. Thanks again for a quality product. I know I made the correct choice in purchasing from Skid Pro.”

Jim C. Pennsylvania Kevin B. Maine“Wow! Mercy Sakes! Mercy Sakes! We got the rock bucket last week and man are we ever happy with it. It’s built like a tank and works like a charm. Thanks for the good deal and all your honesty and help. I hope we will be working on a brush cutter soon.”

“Our Industrial Brush Cutter w/ the open front is working great and we using it in some pretty extreme situations, taking down big trees and heavy brush. When we buy additional equipment it definitely will be with Skid Pro.”

Chris J. Maine Rick L. Kansas“I have to say, the mower exceeds all of my expectations. BEEFY! It is super rugged, it runs far more smoothly than I expected, it has a good coat of paint, and it mows perfectly. I am very happy with it and I will most definitely order from you folks again if I have a need. Your service is superb.”

“Finally got to use the Industrial Cutter, and it is fantastic! Of all the attachments I have ever purchased it has impressed me the most. It really eats up trees and whatever else is in front of it. It is an excellent value for the work that it is capable of doing. Thanks so much for your product advice and great customer service.”

James B. Kentucky“We have just used the bush hog, what a great piece of equipment! We have never seen one that performs like this one. Thanks.”

CLOSED FRONT INDUSTRIAL X4

OPEN FRONT INDUSTRIAL x4

HD3 BRUSH CUTTER

GB2 BRUSH MOWER

HD3 BRUSH CUTTER

GB2 BRUSH MOWER

Once you step up to the X4 brush cutter, you will never go back. This BEAST leads the indus try in cutting capacity, drive shaft, and standardized the direct drive motor on cutters. In the past, thick grasses and large trees were a bar rier to clearing land. With the X4 brush cutter, you no longer need to worry about those problems. This barrier busting attachment is our keystone product and has been the foundation of Skid Pro from the start. If you want to know what Skid Pro is truly about, you must try the legendary X4 Brush Cutter.

• 8” Cutting capacity

• Heavily guesseted

• Direct drive motor

• Oversized solid 3 ¾” drive shaft

• 4 double-edge, swing-away blades

• Unique extra-tall 10” deck

• 2-year warranty

Options

Rear roller

Mulcher flywheel

High Flow

Options

Rear Roller

Mulcher Flywheel

High Flow

• 6” Cutting capacity

• Direct drive motor

• Oversized solid 3 ¾” drive shaft

• 4 double-edge, swing-away blades

• Unique extra-tall 10” deck

• Front push bar and integrated bumper

The X4 Brush Cutter is the heart and soul of Skid Pro Attachments. We engineered every detail of this MONSTER with you in mind. Cutting through brush and trees is a high impact sport, and you need the steel to do so. To start, we loaded the flywheel with 467 lbs of 1” thick steel, delivering the punch you need, combined with a direct drive motor to give you premier recovery time. Looking at the deck, we heavily gusseted every inch of this attachment. If you really want to feed the beast, we have optional High Flow or Piston Drive Motors. In short, we didn’t think of most things, we thought of everything.

• 4” cutting capacity

• Direct drive

• 9” tall deck

• 1/4″ steel Rigi-Deck design

• Class leading construction

• 3 ¾” solid drive shaft

• XL 262 lbs. flywheel

• 3 swing-away, drop-down blades

All new over engineered design!

• Heavily gusseted deck

• Bottom side rail skid runners

• Deck cross-sectional gusseting front to back

• Precisely timed gearbox

• 3” cutting capacity

• Double updraft blades

Forestry Mulchers Log Splitters

Stump Bucket Grapple

Tree Shear

Tree Puller

Stump Bucket

Wood Chipper

Tree Saw

Forestry Mulchers Log Splitters

Stump Bucket Grapple

Tree Shear

Tree Puller

Stump Bucket

Wood Chipper

Tree Saw

• High Flow

• Flow motor match

• HD Frame & push bar

• Ultra HD drive train

• Dynamically balanced rotor

• Carbide faced teeth

• High-carbon tooth holders

• Visible pressure gauge allows easy monitoring

• High flotation skid shoes

The Skid Pro forestry mulcher is a beastly machine designed for conquering the toughest land clearing and forestry tasks. Boasting a high-speed cutting drum and industrial-strength teeth, the Skid Pro forestry mulcher can pulverize trees, brush, and thick vegetation in record time. With your choice of devastating single or dual stage high flow motor, this mulcher is built to withstand even the most demanding of conditions. If you need to tame unruly vegetation and take charge of your land clearing projects, the Skid Pro forestry mulcher is the ultimate weapon of choice.

• High flow or standard flow

• Flow motor match

• HD Frame & push bar

• Ultra HD drive train

• Dynamically balanced rotor

• Carbide faced teeth

• High-carbon tooth holders

• Visible pressure gauge

• High flotation skid shoes

• Standard Flow

• Flow motor match

• HD Frame & push bar

• Ultra HD drive train

• Dynamically balanced rotor

• Carbide faced teeth

• High-carbon tooth holders

• Visible pressure gauge

• High flotation skid shoes

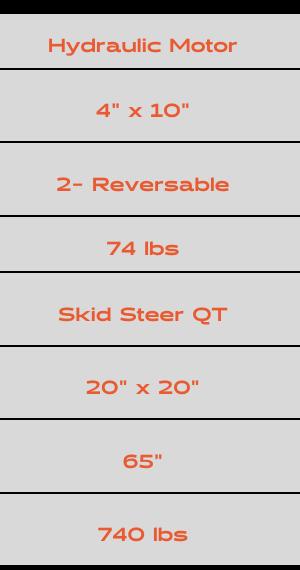

• Heavily gusseted bottom frame and skid shoe base

• Extra thick 5/8” rotor

• Self-feeding hopper constructed of 7-gauge steel

• XL ¾” hydraulic hoses with check valve for built in pressure relief

• Dual 4” greaseable bearings

• 360° rotation on discharge chute

• XL 20” x 20” self-feeding hopper opening

• XL 25” rotor

HD LOG SPLITTER

HD LOG SPLITTER

• 4.5” inch industrial cylinder

• Extra heavy duty, I-beam frame

• 30” long cylinder stroke allows for a 30” opening

• Impressive 30 tons of splitting force

• Angle mounted design

1” thick beveled head splays out to a whopping 8” wide for quicker more efficient splits

4-way or 2-way splitting

Bolt on inverted plate

Skid Pro Difference

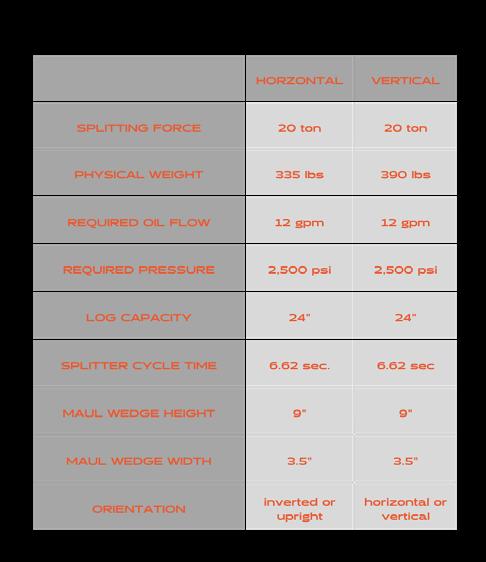

• Heavily gusseted

• Reinforced XL 24” log opening

• 4” diameter cylinders

• 1.50” hardened steel rod diameter

• Extra wide maul-style wedge

• HD I-beam

• Bolt-on plate of HD splitter allows for inverted or regular upright position options

• Horizontal in cab operation

• Fast cycle times

• Manual outside the cab controls

• Operate in vertical or horizontal

• Extra large table

Hydraulic rotation option

Machine specific wire harness or universal toggle available

• Extra thick push bar

• High visability 5/16” steel mesh

• Oversized hardened steel pivot pins

• Massive 5” x 12” cylinder w/ 2.5” rod

• XL 14” jaw opening

• 12” tree cutting capacity

• 90 degree rotation

• Near flush ground cutting

• Aggressive holding teeth

• Huge 8” tree capacity

• Extra wide and deep jaw opening

• XL double jaws

• Heavy duty square tubing main frame

• Industrial strength cylinder

• 360 degree, fully-boxed cylinder cover

• Heavily gusseted jaws

• XL steel deflector

• XHD direct drive motor

• Powerful direct drive motor

• Built-in pressure relief

• 34 carbide, removable and replaceable teeth

• 24” cutting wheel

• Unique design cuts 10” below ground

High flow options available

• Heavily gusseted boom, blade, & grapple

• Extra large 48” opening down to 3” close

• 1” hardened stainless steel greaseable pins

• Industrial-grade 2.5” hydraulic cylinder

• Unique interlocking serrated grapple

• Slip resistant design

• Cantilever cradle controls long logs

• 9,400 lb grip force

• Rotator and pivot rating of 6,750 lbs.

180° Manual spring rotation or 360° fully hydraulic rotation available

• Double-layer, 1” thick plate utilized in wear area near bucket teeth

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• HD Grapple option utilizes an industrial cylinder with 1 ¼” greaseable pivot pins

• Serrated side saw-teeth

• Curved bottom for better digging leverage

• 3 replaceable excavator style cast teeth

• Over 60” long design

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• Heavily gusseted QT plate and frame

• 3 replaceable excavator-style cast teeth

• Curved bottom for better digging leverage and break-out force

• Serrated side saw-teeth

• Over 60” long design

• 4 drain holes in bottom of bucket

• Aggressive tooth chain and 5,000 RPMs

• High-gloss, powder-coat paint

• Extension arm made of high-strength, double-walled steel tubing

• Quick hookup directly to your loader bucket with quick hitch bracket

• Extra-long reach can trim limbs 18-20 ft in the air on most carriers

• Light and maneuverable to take on/off

• 20” titanium alloy steel bar

• 5,000 RPM motor

• Self-oiling system utilizes carrriers hydraulic oil

Industrial Grapple

Rake Log Grapple

Pallet Fork Grapple

Rock Grapple

Scrap Grapple

Skeleton Grapple

Tine Grapple

Industrial Grapple

Rake Log Grapple

Pallet Fork Grapple

Rock Grapple

Scrap Grapple

Skeleton Grapple

Tine Grapple

Skid Pro Difference

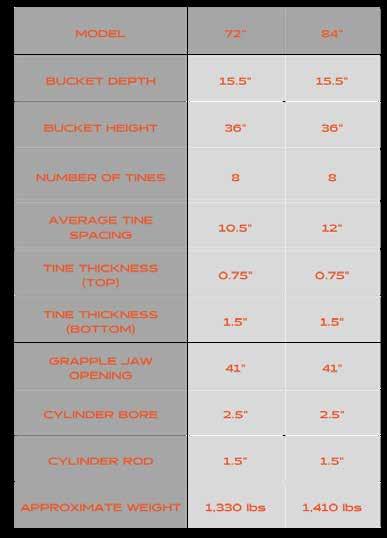

• Industrial cylinders for max clamping force

• Replaceable 1 ½” thick bottom tines

• ¾” top tines

• Back-plate & heavily gusseted lower grapple frame

• Top and middle brush guard

• Protected cylinders and hose routing

• Oversized, hardened pins with greaseable pivot points

• Heavily gusseted boom, blade, & grapple

• Extra large 48” opening down to 3” close

• 1” hardened stainless steel greaseable pins

• Industrial-grade 2.5” hydraulic cylinder

• Unique interlocking serrated grapple

• Slip resistant design

• Cantilever cradle controls long logs

• 9,400 lb grip force

• Rotator and pivot rating of 6,750 lbs.

180° Manual spring rotation or 360° fully hydraulic rotation available

42″, 48″, or 60″ tine lengths

Dual, independent grapple option

• Lifting capacity of 7,000 lbs.

• XL grapple opening to 50.5”

• Adjustable top grapple

• Fully boxed cylinder guard

• Greaseable pivot points

• Protected hose routing

• Fully gusseted

• ¾” thick front cutting edge

• Gusseted tines

• Robust independent top grapples

• Industrial cylinders

• Laser cut 80,000 psi rated steel tines

• Oversized pins and greaseable bushings

• HD cylinder guards

4 different width options, 66”, 72”, 78” & 84” available

HD Rock Grapple also available in 3/8” bottom tines and 3/8” top grapples

HD Rock Grapple comes in same configurations above, 72” most popular

• Independent grapples

• Industrial cylinders

• Heavy-duty cylinder guards

• Heavily gusseted

• Oversized 1 ¼” pins

• Protected hydraulic hose routing

• Unique side plate design

• Best in class clamping force

Four different widths ranging from 66″ – 84″

• Independent grapples

• Industrial cylinders

• Heavy-duty cylinder guards

• HD high-capacity frame

• Serrated bottom grapple

• Fully gusseted tines

• 80,000 psi rated steel

• Designed for load security

• Protected hydraulic hose routing

• Best in class clamping force

Four different widths ranging from 66” - 84”

• Independent grapples with industrial cylinders

• Oversized 1 ¼” pins

• HD cylinder guards

• Completely protected hydraulic hose routing

• Clamping force up to 85% more strength

• Individual tines are bolt-in removable and replaceable

• 1” thick plate utilized in wear area near bucket teeth

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• Utilizes an industrial cylinder

• 1 ¼” greaseable pivot pins

• Serrated side saw-teeth

• Curved bottom for better digging leverage

• 3 replaceable excavator style cast teeth

• Over 60” long design

• Cold rollled steel moldboard

• Heavily gusseted

• Industrial cylinders

• Protected angle cylinder

• 6-way tilt

• HD reinforced backing

• Oversized 4” x 11” adjustable skid shoes

• Reversable and replaceable cutting edge

• Oversized safety step

• 3” vertical pivot pin

• HD cradle on frame supports auger drive

• Class leading planetary drive

• Produces over 3,000 ft. lbs. of torque

• Handles bits up to 36” diameter

• Self leveling, dual pivoting design

• Protected drive and motor housing

• Reliable 4-year warranty

• Oversized safety step

• Bi-directional motor

• Integrated pressure relief

Multitude of auger bit designs and sizes available ranging from 6″ up to 36″

Bit types include tree-style, HD, and rock augers

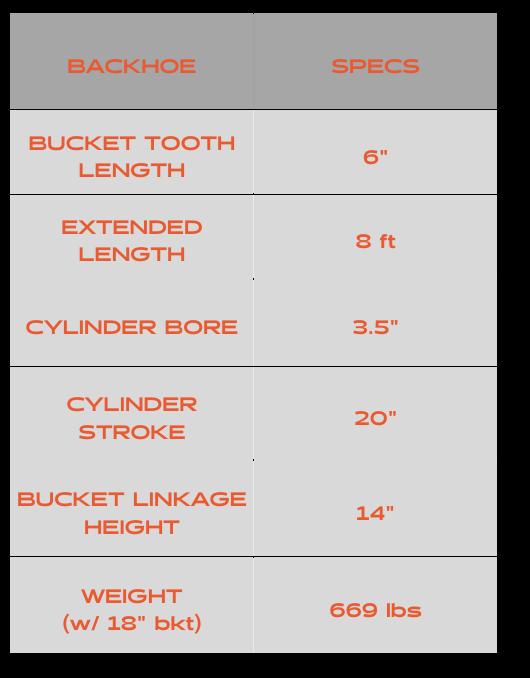

• Fully-boxed I-beam design

• HD bucket design

• ½” wear bars

• 6” long cutting edge

• Replaceable excavator teeth

• Greaseable pivot points

• Extra-tall bucket linkage geometry

• 8 ft of digging depth

• HD thumb option

12”, 18” & 24” HD bucket widths available

3 Settings allow for a Available

• Industrial strength chain links and hardware

• Planetary drive system for maximum torque

• XL 26” x 6” skid shoe

• Built in HD crumber

• Removable oversized spoil auger

• Manual side shift standard

• 50/50 mix of tungsten “hammer” teeth and standard scoop teeth

• Low maintence roller bearing and MT sprocket

consistent digging depth of 24”, 30” & 36” on 3’ boom, and 32” 40” & 48” on the 4’ boom

Available in 3’ and 4’ boom depths & high-flow models available

Available in 4”, 6” & 8” widths

Other tooth configurations available

• Industry leading push/pull design

• HD reinforced ½” frame

• Spring loaded, 16” diameter coulter

• XL 2” x 8” greaseable pivot pins

• Adjustable rear pivot has 90 degrees of swing

• Plow can install silt fence from 6” deep to 20” deep

• Replaceable 2” hardened plow point

• 1” thick moldboard

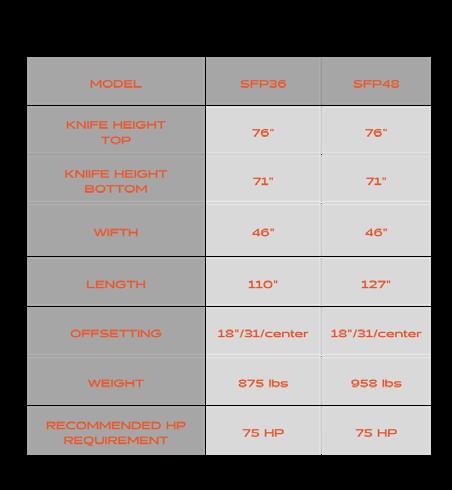

HD 36” and HD 48” available

Push/pull option

Wire un-roller option for wire-backed silt fence

Seeder

Telescopic Boom

Tree Spade

Land Leveler

Seeder

Telescopic Boom

Tree Spade

Land Leveler

• Ultra-rugged frame

• 6 x 6 inch heavy wall square tubing

• Direct drive motor

• XL pivot pins

• Integrated hydraulic pressure relief

• HD axle beam

• Durable walking tandem axle

• Full-length carbide teeth

• Bi-directional motor

Wing kit option

High Flow

Hydraulic angle option allows full angle range

When it comes to getting the most of your attachment, it’s the little things that truly matter. To start, we equipped a bi-directional direct drive motor. This provides less maintenance, more power, and unmatched versatility. Our massive wingkit keeps your soil in line and provides a leveling effect during the process. The walking tandem axel in the front gives you a perfect level without making adjustments. While other companies skimp on their teeth, ours are full length carbide to ensure longevity and performance. All these “little things” add up to creating the best engineered soil conditioner on the market.

• Tills up to 6” deep

• Direct drive motor

• HD Planetary worm gear drive

• XL 3.5” wide forged, heat-treated tines

• 7 gauge hood cover

• 3/8” side panels

• Heavily gusseted

• 900 lb. operating weight

• Low maintenance

• 2 year warranty

• Over-built main frame

• 1,550 lbs. operating weight

• Up to 30” root ball

• Easily moves trees with trunks up to 3’

• Functional blade design

• Truncated blades

• Swing open blade design

• Industrial hydraulic cylinders with 70” stroke

• Blade towers are heavily gusseted

SP440 – 4 blade, dual hydraulic swing, 40” root ball model available

Multitude of spade control options

Tractor 3 point and tractor loader retro kits available

Skid Pro Difference

• All steel design

• 1,250 lbs. operating weight!

• Rugged main frame construction

• Proven time-tested design

• XL 9” cast front and rear rollers

• Heavy duty 2” hardened steel axle

• 72” working width, 84” overall width

• Oversized 4 bushels capacity hopper

• Shroud covered chain drive

• Adjustable depth and pressure on slicing discs

• Forward and reverse operation

• Best in class edges

• Oversized cylinder

• Extruded screen

• Full length steel gussets

• 3/4 x 6” high carbon steel weld-on cutting edges

• Forward operation scarifier teeth

2 widths available, 78” & 84”

Hydraulic scarifier teeth

Optional screen kit

Skid Pro Difference

• Pounds T-posts up to railroad ties

• Doubles as a tree and post puller

• Thick-walled square tubing main-frame

• Industrial oversized cylinders

• Oversized, greasable pivot pins

• Commercial grade engineering

• 100% payback in 1-2 miles of fence

• Rubber noise dampening pads

• 275 lb. hammer

• True one person operation

• High tensile tube steel

• 72” hydraulic stroke optional

• Longest manual extension at 270”

• Up to 32’ reach with most skid steers

• 1,750 lbs. rated operating capacity

Available in manual or hydraulic extensions

• 10 gauge steel bristle hood

• HD reinforced ½” frame

• Durable motor guard

• Extra-large, commercial-grade 32″ bristles

• Auto-float broom head

• Bi-directional direct drive motor

• Oversized, greaseable bearing

Poly, poly/steel, Full Poly, 50/50 poly/steel

bristle options

Hydraulic angling (EH control harness needed)

Broom width options of 72”, 84”, & 96”

with leaving innovative features choice sweeping. gle capabilities, Broom nook with rable ity materials performance. Broom the standard

The Skid Pro Angle Broom with its unparalleled performance, leaving competitors in the dust. Its innovative design and advanced features make it the ultimate choice for efficient and thorough sweeping. With its adjustable ancapabilities, the Skid Pro Angle Broom effortlessly reaches every nook and cranny, eliminating debris with precision and speed. Its durable construction and high-qualmaterials ensure long-lasting performance. The Skid Pro Angle Broom is simply sweeping away competition, setting a new standard in the industry.

Skid Pro Difference

• HD motor cover and inset motor

• XL, commercial grade 26″ bristles

• Optional direct drive gutter Brush

• Variable speed controlled

• Oveersized, rubber-composit skirt

• Dual-directional motor

• Quick set hood and bristle adjustment

• Low maintenance

Options

Poly, poly/steel, or all steel bristle options

Optional gutter brush

Water kit available to reduce dust

Three different widths; 60”, 72” & 84”

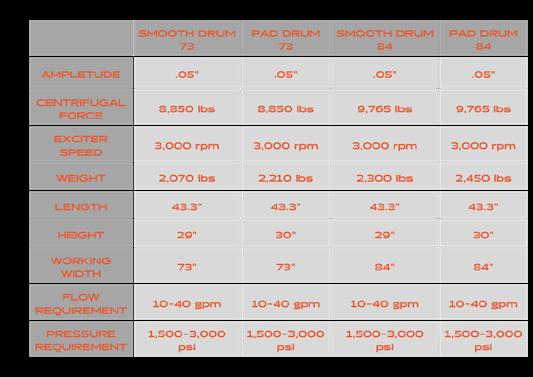

Vibratory Roller

Concrete Breaker

Cold Planer

High Flow

Cold Planer

Standard Flow

Concrete Bucket

Hydraulic/Manual

Road Saw

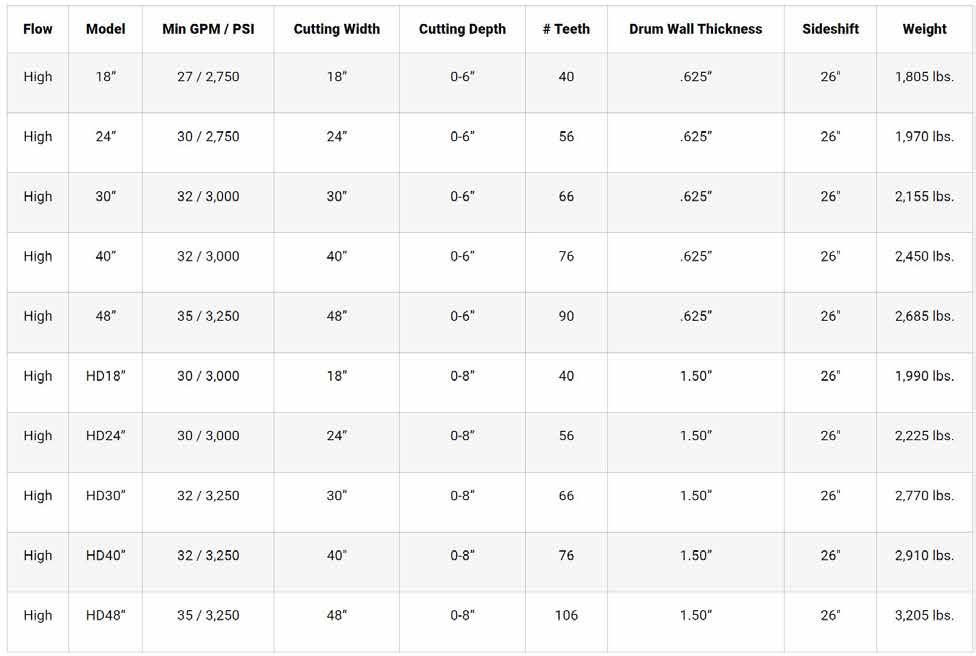

• Operating weights up to 3,205 lbs

• Planetary gear isolates motor

• Kennametal 20mm teeth

• Strategic double V wrap tooth positioning and cut arc

• Ultra-smooth hydraulic depth control

• XL safety steps with aggressive tread

• Incredible torque and robust durability

• Best-in-class drive train

40-gallon, gravity-fed, ROPs-mounted water kit available

OSHA-approved dust suppression on the jobsite

• Operating weights up to 1,250 lbs

• Ground-engaging frame mitigates vibration

• Direct drive motor

• 1” thick drum

• Manual depth and tilt

• Adjustable depth of cut up to 5”

• XL 3” main frame pivot pin

• 26” hydraulic side shift with valve block

Water Kit Option

40-gallon, gravity-fed, ROPs-mounted water kit

Increases tooth life by 25%

• Heaviest steel body in class

• Industry leading QT plate

• Commercial rated

• Heat-treated steel

• Machined internal drive components

• N2 accumulator delivers power and efficiency

• 750 ft. lbs. of force

• Delivers up to 1,400 BPM

Quad-tapered moil point or double beveled chisel point options

• 1/2 yard hopper capacity

• Industrial-grade cylinder

• High tensil 3/16” wrapper

• XL industry leading 28” chute

• 28” spout is easily removable

• Economical, non-hydraulic option available

• Industrial design yields operating weights up to 2,500 lbs.

• Ground-engaging frame

• Strategic tooth positioning and cut arc

• Cut widths ranging from 2.5” to 6”

• Ultra-smooth hydraulic depth control

• 26” hydraulic side-shift from the cab

• XL foot and greaseless rear rollers

• 10” or 18” cut depth & 2.5” to 6” cut widths

Water Kit Option

40-gallon, gravity-fed, ROPs-mounted water kit available

OSHA-approved dust suppression on the jobsite

• Double-layer, 1” thick plate utilized in wear area

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• Industrial cylinder with 1 ¼” greaseable pivot pins

• Serrated side saw-teeth

• Curved bottom for digging leverage

• 3 replaceable excavator style cast teeth

• Over 60” long design

• Adjustable drum scrapers

• 9,765 ft. lbs. centrifugal force

• Self-oiled system

• Single piece drum

• 12 HD rubber shock mounts

• Industrial grade build

• Integrated dozer blade

• XHD frame adds to downforce

• Patented exciter shaft

Available in widths of 72” and 84”

Available in padded (sheep’s foot) or smooth drum

• Reinforced brick guard

• Unique walk-through design

• HD frame with XL side and brick guard gussets

• Extra HD 1 1/2” x 4” forged solid tines

• 4,000 lbs. rated lift capacity

• Adjustable tines slide on HD rail

• Tines are removeable and replaceable

48” tine length is standard, 42” and 60” length tines are available

Hydraulically-adjustable-tine pallet forks available

Traditional frame/brick-guard design available

Additional 55” wide and 5,000 lbs. plus rated options

42″, 48″, or 60″ tine lengths

Dual, independent grapple option

• Lifting capacity of 7,000 lbs.

• XL grapple opening to 50.49”

• HD top grapple has three adjustment settings

• Industrial cylinder with fully boxed cylinder guard

• Greaseable pivot points

• Protected hose routing

• Heavily gusseted

• Double-layer, 1” thick plate utilized in wear area near bucket teeth

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• Industrial cylinder with 1 ¼” greaseable pivot pins

• Serrated side saw-teeth

• Curved bottom for better digging leverage

• 3 replaceable excavator style cast teeth

• Over 60” long design

• Heavily gusseted

• High-strength steel bucket body

• 3/4″ x 6″ HD front and back cutting edges

• Reversable and replaceable cutting edge

• Tooth bar and bolt-on edge options available

• Oversized hardened steel pins

• Protected industrial cylinders

• Serrated teeth on side of bucket

Four widths ranging from 66″ – 84″

• High tensile tube steel

• 72” hydraulic stroke optional

• Longest manual extension at 270”

• Up to 32’ reach with most skid steers

• 1,750 lbs. rated operating capacity

Available in manual or hydraulic extensions

• 60,000 psi rated steel tines

• Flat-bottom design

• Tough cross member supports

• Heavily gusseted teeth

• Open bucket design

• Unique design holds rocks while digging

• Engineered for large loaders

• Serrated front cutting edge

66”, 72”, 78” & 84” widths available

• Weld-on shank

• Bolt-on, reversible cutting edge option

• High-carbon 3/4” x 6” weld on cutting edge

• Reinforced floor and back wrapper

• Power crimp construction

• HD 1/2” side wear bars

Multiple options, sizes and designs to fit any skid steer or track loader

• High-strength, high-carbon 1″ x 8″ steel cutting edge

• Heavily gusseted QT plate and frame

• 3 replaceable excavator-style cast teeth

• Curved bottom for better digging leverage and break-out force

• Serrated side saw-teeth

• Over 60” long design

• 4 drain holes in bottom of bucket

• High volume

• Power-crimped back

• Vertical stiffeners

• Oversized wear bars

• High-carbon steel cutting edge

Mega bucket option available

Bolt-on cutting edge optional for all model widths

Special order backhoe & pay loader buckets available

• Our HD forged spears are rated to carry up to 3,500 pounds

• Tubular steel frame

• 2 spear configurations for big squares or round bales

• All spears and stabilizers are replaceable and removable

• Dual, non-slip safety tabs for easier cab access

• See-through design gives great operator visibility

• Custom mounts available other than skid steer universal

Smooth inside jaws is gentle on wrapped bales

Custom mounts available for tractor loaders

• Strong, simple design with heavily reinforced universal attach plate

• HD cross frame gussets for strength & durability

• Side & bottom supports tie into lateral gussets

• Accepts standard 2” receiver hitch (not included)

• Receiver hitch has side & bottom reinforcements

• Extended receiver hitch gives operator great visibility when hooking onto trailers

• Handles small boat & atv trailers, up to large-framed 5th wheel trailers

• Skid hitch does not include hitch plug, trailer ball or receiver pin

• Hardened steel pads, pins & links

• Rubber pad gives the most protection to asphalt and sensitive surfaces

• Rubber pad tracks delivers:

• Less vibration

• Less noise

• Less wear

• Max flotation

• Max tire durability

OTT systems available in popular cross bar or rubber pad options

No flat tires available in standard 10x16.5 and 12x16.5 sizes

Oversized 13”, 14”, and 17.5” tire options with different widths also available

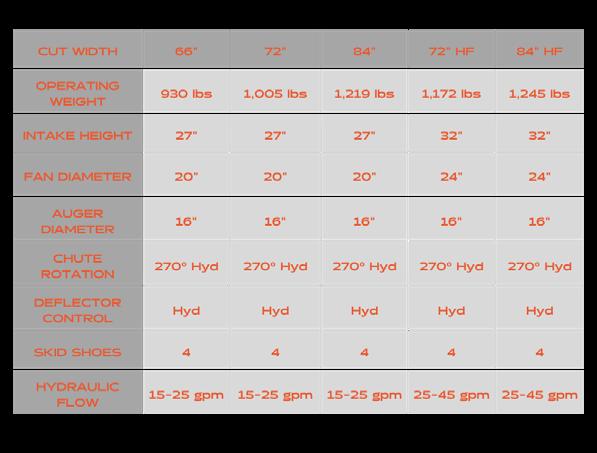

Double

High Flow

Auger

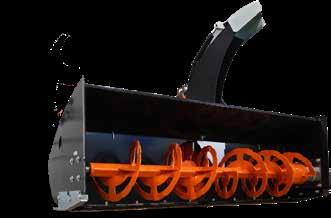

Snow Blower

Single Auger

Snow Blower

Snow Blade

Snow Bucket

Snow Pusher

Hydraulic Snow Blade/Pusher Combo

Auger

Snow Blower

Single Auger

Snow Blower

Snow Blade

Snow Bucket

Snow Pusher

Hydraulic Snow Blade/Pusher Combo

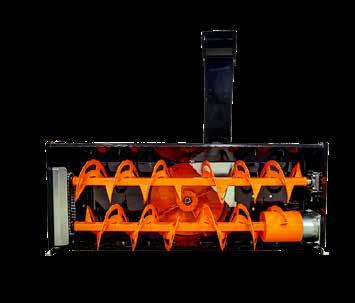

• Protected hydraulics, solenoids, and hoses routing

• Steel cutting edge is bolt-on replaceable

• Heavily gusseted

• No freeze up chute design

• Extra tall and deep design

• Direct drive 6,000-class motor fan

4 blade fan is cupped and reinforced

Custom electrical options include 8-Pin, 14-Pin

Recommended to have at least 30 gpm for optimal performance

Three different widths: 66”, 72” or 84”

Standard flow & high flow options available

Mid & large tractor 3 point blowers available

• Heavy duty industrial frame

• Fully protected hydraulics

• Steel cutting edge is bolt on replaceable

• Heavily gusseted

• Extra tall and deep design

• Direct drive hydraulic fan and auger

• 1/4” thick spiral auger

• No freeze up chute design

• 10 gauge steel bristle hood

• HD reinforced ½” frame

• Durable motor guard

• Extra-large, commercial-grade 32″ bristles

• Auto-float broom head

• Bi-directional direct drive motor

• Oversized, greaseable bearing

Poly, poly/steel, Full Poly, 50/50 poly/steel

bristle options

Hydraulic angling (EH control harness needed)

Broom width options of 72”, 84”, & 96”

with leaving innovative features choice sweeping. gle capabilities, Broom nook with rable ity materials performance. Broom the standard

The Skid Pro Angle Broom with its unparalleled performance, leaving competitors in the dust. Its innovative design and advanced features make it the ultimate choice for efficient and thorough sweeping. With its adjustable ancapabilities, the Skid Pro Angle Broom effortlessly reaches every nook and cranny, eliminating debris with precision and speed. Its durable construction and high-qualmaterials ensure long-lasting performance. The Skid Pro Angle Broom is simply sweeping away competition, setting a new standard in the industry.

• Fully reinforced frame

• 2 angle cylinders

• Oversized skid shoes

• Spring adjustment on trip edge

• Quick change lock switches from snow to dirt blading

• Strong curved moldboard

• Heaviest snow blade in the industry

Four different widths: 72”, 84”, 96”, 108” Optional HD wing kit

• High volume

• Power-crimped back

• Vertical stiffeners

• Oversized wear bars

• High-carbon steel cutting edge

Mega bucket option available

Bolt-on cutting edge optional for all model widths

Special order backhoe & pay loader buckets available

• Industrial cylinders

• Built with a thicker steel blade

• XL cutting edges

• Reversible and replaceable bolt-on wear edge

• Cutting edges deliver 5 ½” of total wear

• Individual trip edge springs

• Floating frame

• Independent wing operation

• Heavy duty construction

• High strength 3/8” thick side plates

• Three 4” steel channels on back side of moldboard

• Engineered for commercial durability

• Optional bolt-on pullback system

• Precision rolled moldboard

• XL 1.4” thick rubber cutting edge

Options

8’ and 10’ sizes

Optional bolt-on pullback system

Optional pullback system cutting edge is bolt-on adjustable and replaceable

Skid Pro Difference

• XHD steel moldboard

• Floating frame

• Optimized moldboard curvature

• Industrial cylinders

• Unique corrosion-resistance rods

• Thick steel blade,

• XL cutting edges

• Additional structural support

• Up to 5 1/2” cutting edge wear

• Engineered for 5 different angles