Are you a watcher or a participator? I ask because in this issue there are rallying calls for you to visit trade shows, attend conferences, take up eco schemes, and actively develop a crisis management plan for your business. The consensus seems to be act, act, act, so if you’re more of a thinker than doer you might feel you’re being somewhat chivvied along at an uncomfortable speed. But you know what they say about speed being of the essence, and perhaps the features herein will convince you to act sooner rather than later on certain issues.

I’m no Greta Thunberg, but let’s consider the urgency with which we need to make environmental change - as an industry and as individual companies. In all fairness there’s a fast-growing list of large-format digital and that of their clients. On p31, for instance, you can read about Rocket Graphics’ new print waste recycling scheme. But you can also read the BPIF’s and HP’s calls for more PSPs to get involved with what are now well-established but rather undersubscribed environmental schemes.

take more/faster actions than you currently are - read the Talking Point interview with organiser Frazer Chesterman on the aims and content of into how eco and supply chain issues are impacting large-format printer/ will colour your decision making when it comes to new kit purchases.

upcoming SDUK show, where the organisers are hoping for visitor numbers to return to pre-Covid levels. If you’re going I’ll hopefully see you there.

Hope we’re giving you food for thought, and action.

Editor LESLEY SIMPSONLESLEY.SIMPSON@IMAGEREPORTSMAG.CO.UK

TEL: 01932 707173

Editor: Lesley Simpson lesley.simpson@imagereportsmag.co.uk

Production / Design: Alex Gold

Publisher: Wayne Darroch wayned@sjpbusinessmedia.com

Advertising Manager: Carl Archer carl.archer@imagereportsmag.co.uk

Tel: 07723 079928

SJP Business Media, 2nd Floor, 123 Cannon Street, London, EC4N 5AU www.imagereportsmag.co.uk

For circulation enquiries contact: SJP Business Media

Email: subscriptions@sjpbusinessmedia.com

Image Reports is available free to printers based in the UK. Register at www.imagereportsmag.co.uk/register.

To purchase a subscription please visit www.imagereportsmag.co.uk/subscribe –UK £54, overseas £84

Printed in Great Britain. No part of this publication may be reproduced, stored in a retrieval system or transmitted by any means without the Publisher’s permission. The editorial content does not necessarily reflect the views of the Publisher. The Publisher accepts no responsibility for any errors contained within the publication.

REGULARS:

p7 News

Keeping you abreast of all the latest news in relation to digital wide-format print.

p10 Cover Story Advertorial

Liyu UK’s Platinum range combines style with substance.

p32 Forum

Digging below the surface with Industry Mole; Out and About events diary; Over to You interview; Vital Stats.

p34 Zeitgeist

Why it’s crucial to have a crisis management plan in place.

SECTIONS:

Special

p13 SDUK preview

A concise guide to the March show.

Business

p14 Talking Point

…with Frazer Chesterman on relaunching EcoPrint as a summit.

p17 Apprenticeships

Are we where we need to be in terms of funding?

p20 Top Tips

The Online Print Coach tells you how to better compete and win.

Technical

p23 What to Watch: Eco and supply chain issues

How are they impacting large-format kit manufacturing strategy?

Go to www.imagereportsmag.co.uk for all the wideformat sector’s industry news, updated regularly online. Image Reports can also send a twice weekly enews bulletin straight to your inbox – register at: www.imagereportsmag.co.uk/ newsletter

Environment

p27 Free and easy

HP’s Jane Rixon calls for PSPs to get more actively involved in no-cost eco schemes.

p29 Made to measure

A look at the ClimateCalc emissions calculator from Integraf.

p31 Rocket scheme launches Rocket Graphics’ new print waste recycling scheme lifts off.

Fespa unwraps WrapFest, 26-27 April, at Silverstone

Picon calls for wider industry involvement

FaberExposize UK creates dedicated exhibitions unit

CarbonQuota wins institutional investment

Screenbolaget gets Europe’s first ten-head VK300D-HS

Agfa showcases fastest Jeti Tauro H3300 at C!Print

BPIF introduces Supply Chain Practitioner Apprenticeship

Color-Logic certifies Ricoh flatbeds

Xaar opens inkjet lab in China

Durst P5 Tex iSub inks now Eco Passport certified

Printing Charity looking to fill its retirement homes

Onyx certified for HP Latex 2700 printer

Zund acquires Spanish sales partner

Spirit Displays merges with RTD Systems

Innotech stocking 2.2m Imagetech Polyprop Greyback

WOO Global Congress set for Lisbon June 2023

NUtec Digital Ink expands NVC-free UV inks offering

New hardware sales manager for Papergraphics

Made Smarter urges digital transformation among SMEs

New technical applications manager at Soyang

SAi appoints EnRoute product manager

Premier bolsters its carbon capture efforts

CMYUK to demo Mimaki JFX600-2513 at open house

RMC MD Nicole Spencer joins Fespa board

QPS moves to larger site

digitalprint.ie tests Brett Martin Foamalux substrate

UK Feather Flags commits to Innotech flag hardware

Epson sets up direct sales for industrial solutions

Canon launches A1+ desktop printer

MacroArt print and light installation turns heads in Soho

Screen clarifies Truepress printer positioning

Ottimo adds to print and cut arsenal

Pyramid Display Materials launches new web store

Fespa UK is forming a Next Generation youth committee to help formulate a training/ networking programme for 2023 and beyond. The move comes on the back of two Next Generation print training days held on 19 and 26 January, where the association aimed to find initial committee members.

The new youth group of 18-30-year-olds will be headed by Fespa UK’s creative coordinator Jay Burfield, and will aim to ensure that the next generation of print workers are represented fairly and able to bring new ideas to the businesses they work in.

Compass Business Finance, Vivid Laminating Technologies, HP UK and All Print Supplies have committed to supporting the youth scheme with various events and webinars throughout this year - schedule to be confirmed following the Next Generation committee members’ input.

“Having created many networking events for the industry over the years it stands to reason that most events are aimed at the more advanced members of a business, who have the most influence within a company. This got the team at Fespa UK thinking - when the people at the top retire will the next generation see the value of sharing information to develop their own careers and to help grow and support the industry as a community? With this in mind, we want to support the next generation in print to grow their confidence, develop their networking skills and be inspired,” said Fespa UK MD Suzie Ward.

“Following the two Next Generation training days, we will be forming a Next Generation committee, which will be small group of 18-30 year old’s working in print who want to contribute and make lasting changes for like-minded people in the same age group.”

Roland DG has published its annual ‘Substrate Index Report’, based on a survey of 140+ PSPs across the UK, Germany, France, Italy and Spain printing with UV technology. It shows that 68% of PSPs polled continue to print on plastic, having used it at least once in 2022.

64% said they print on metals, 60% onto PVC, and 58% onto wood. These same four materials came out top overall in last year’s report, with a small drop in popularity of plastic (-7%) and wood (-6%), while metal (+10%) appears to have gained in popularity.

Compass Business Finance has joined UK fraud prevention service Cifas, which manages the National Fraud Database (NFD). Compass will use the database to run checks on those seeking funding and will now provide data to Cifas for the NFD.

Compass director of Compass Mark Nelson

said of the move: “Fraud is becoming increasingly prevalent, and we believe, as does Cifas, that effective communication and collaboration is the way to push back against the perpetrators of this type of crime.

“Our customers will be checked against the NFD,

PressOn has installed a second HP Latex R2000 printer to enable it to take on more work in profitable markets, including transport livery, whilst helping it reduce its environmental impact and strengthen its eco print solutions offering.

The company - which has specialised in largeformat digital printing for indoor and outdoor advertising, with clients including Harrods, Dior, and Fendi - has worked with HP for more than 15 years. PressOn MD Andy Wilson has been an advocate of the eco benefits of HP technology for many years

and the company uses solely UL Ecologo and Greenguard-certified HP latex water-based inks. HP also influenced PressOn’s decision to move away from PVC as a primary substrate and switch to PVCfree vinyl and polyester PET materials.

PressOn has recently used the HP Latex R2000 printer to wrap six electric London cabs in Metamark recyclable, self-adhesive vinyl as part of an ongoing sustainability project to showcase an eco-friendly printing practice. With the project continuing into 2023, PressOn aims to explore further recycling

Similarly, in terms of frequency of use, these materials are leading the pack, with almost a quarter (24%) of all respondents saying they print on both plastic and PVC at least once a week, 18% print on metals once a week, and 26% print on wood at least once a month.

Acrylic is also still very popular, with 53% of PSPs in the UK reporting using it at least once. Other geographical markets, such as Italy and France, saw glass and tiles rising in the ranks. Less than 3% of respondents claimed to have printed anything on concrete in the last year.

however, this is an entirely internal process and will not impact the ease or speed of delivery that we are known for providing. Having open and honest relationships with our customers is vital to us, and we’re confident that joining Cifas will help give further protection to everyone.”

possibilities across future projects

Wilson explained: “Our focus is to continue educating our customers on new and best printing practices with minimal environmental impact. We continue to invest in HP’s portfolio of latex printers as the devices have an incredible colour gamut and environmental credentials, helping us support our customers’ demand for environmentally sound supply chain without compromising on print quality.”

PressOn is signed up to HP’s Planet Partners recycling programme too.

The World Out of Home Organization is creating a Global Sustainability Task Force, to be led by blowUp media CEO and WOO board member Katrin Robertson.

“Sustainability is one of the most pressing issues facing advertisers and media owners and it’s important that ‘out of home’ (OOH), as such a visible and public medium, takes a proactive stance,” said Robertson. “The Task Force is designed to help the whole industry take the initiative on sustainability so it becomes an engine for growth rather than an impediment.”

Among the task force’s duties will be: positioning OOH (with a particular emphasis on DOOH) positively, including a database of constructive evidence and relevant information sources; sharing best practice on how companies and other WOO members can successfully implement sustainability into the heart of the business; advice on organising a sustainability team; advice on engaging appropriate consultants with recommendations by region and country; guidance on potential costs; collating real Net Zero Initiatives, mission statements, in-house activities and action

Premier Paper Group has acquired GPMI, a paper merchant established in the Irish market supplying both the commercial print and sign and display sectors. With warehouses and offices in Dublin and Belfast, GPMI has a turnover of around 28m Euro and 50 employees.

The move follows swiftly on from Premier Paper’s acquisition of retail display and packaging company

WBC as part of its mission to expand into further added value sectors. That in turn complements the group’s purchase of lamination film supplier Zulu Packaging (Now Premier Lamination Films) in July 2022.

Ireland-based WBC - which was established in 1989 and has a turnover of £18m - is a packaging and display product supplier to the speciality drinks

Fujifilm has officially opened Fujifilm House, its new UK headquarters in Bedford. Sustainability considerations were integral to the new building’s design, as underlined by the 2787m2 site’s BREEAM environmental rating.

In designing the new building - which is a short distance from where Fujifilm operations had been located since 1983 - Fujifilm worked with the Wildlife Trust for Bedfordshire, Cambridgeshire and Northamptonshire, one of its corporate charity partners, to keep the environment around the UK HQ site as habitable as possible for plants, wildlife and animals.

In addition, the site’s 80 rooftop solar panels are

able to generate up to 63,000 kW of electricity each year, saving 29 tonnes of CO2 emissions annually. On a sunny day, they collectively generate enough electricity to sustain the building without needing to draw energy from the grid.

Meanwhile, the site’s interior is fitted out with intelligent LED lights, which are triggered by motion sensors, turning on when they detect movement and remaining off when rooms are empty. The temperature in the main areas of the building is maintained with a centrally controlled comfort cooling system, which is turned off overnight.

To accommodate Fujifilm’s evolving company fleet, as well as anticipating the shift away from fossil fuel-

MacroArt has invested over £500,000 in a raft of new hardware and software solutions at its production hub in St. Neots, Cambridgeshire, to support its drive to deliver increased productivity and sustainability in 2023.

The company has added several key pieces of equipment to its plant list, including the UK’s first Durst P5 Tex iSub dye-sub machine, a Mimaki UCJV300 and a 1.6m-wide Canon 1650 UV gel printer. It has also invested in operational software that streamlines and optimises all areas of print production to maximise efficiency and minimise waste within the business.

Linking directly into the recently installed Durst Lift ERP system are a new Enfocus Switch Pitstop server and Tillia Labs Phoenix AI software systems

to deliver a host of efficiencies, from instant artwork checking/resolution and rapid, accurate proofing, to ganging up of print jobs, higher productivity, and reduced downtime.

The new software programmes are tied together using visual flows, allowing for a seamless processing of artwork files directly from MacroArt’s ERP system via an API set up through to the Rip stage of the production process, all without the need for manual intervention. The company said this bespoke system is already delivering positive results in many key areas of production.

MacroArt is seeing significant reductions in material, energy and ink wastage through the efficient ganging and collating of multiple projects, and in turn, this efficiency is reducing lead times

points; creating a regularly updated database of industry innovation; analysing and improving WOO’s own carbon footprint; and formulating a ‘Global Guidelines’ document for WOO members.

WOO’s own Sustainability Survey will also become an annual event canvassing views from all sides of the industry.

WOO President Tom Goddard said: “Sustainability is top of the agenda in all aspects of media and marketing right now and it’s vital that WOO helps its members make their case to advertisers and legislators.”

and food sectors. It will remain unchanged, with the current management team and all 55 employees retained to ensure the continuity of customer/ supplier relationships and to facilitate future growth.

The Premier Paper Group had a turnover of £187m in 2021 and is part of OVOL Japan Pulp and Paper Co. which operates in 21 countries with a turnover of $5bn.

powered vehicles, the car park at Fujifilm House has 16 charging points and there is capacity to provide double this number in the future as demand grows.

A continued part of operating sustainably at Fujifilm House involves reducing waste and recycling. A waste sorting system enables rubbish to be sorted into general waste, printer cartridges, plastics and cans, and paper and cardboard.

Fujifilm has also taken steps to keep its UK headquarters clean and tidy in an eco-friendly manner - the toilets are flushed with rainwater and toilet paper is made from recycled material. Even the toilet roll dispensers are made from recycled Tetra Pak packaging.

for clients, with increases in output by as much as 150% being regularly achieved, on top of the reduced wastage.

Mark Rose, MacroArt’s operations director, said: “At MacroArt, our forward planning is as much about delivering a truly sustainable result, as it is about enhancing productivity, and with these considerable technical additions in both our hardware and software capabilities, we are achieving both.”

This commitment to true, measurable enhancements in sustainability is supported by MacroArt’s recently announced initiative to provide, in conjunction with the services of its Waste Management Partner Prismm, a complete ‘end to end’ recycling service for all clients that order graphics for use at the ICE event at Excel in 2023.

Maybe you’ve heard the name Liyu UK, or indeed talk of the Platinum range, perhaps when talking to industry colleagues who have installed a Platinum solution, or passed a machine in action at a trade show, or even seen the team’s fun and engaging social media presence. If not, it was only a matter of time before you become better acquainted with what they offer. Liyu UK is the central component of the Ultimatum Group, an organisation built on the passion of expert Inca Digital, Oce Arizona and Durst engineers who truly believed in delivering outstanding service at a better value for customers. After much exploration and analysis, they decided that leading European manufacturer Liyu was the right technology to centre the business around.

Managing Director of Liyu UK Eddie Tucker explains: “We knew we could shake things up and do things differently, while ensuring that customers are still getting reliable, world-class print technology. We took the plunge and formed Liyu UK, it was absolutely the right decision. We’re transparent and real with our customers, supporting them from the beginning of their journey and making sure we’re available for whatever they need from that point forward. We’re delighted to be at the forefront of what we call ‘The Printer Revolution’!”

It’s been a busy few years for Liyu UK as they establish themselves as one of the major players in wide-format print in the UK market, but there is no denying that things are ramping up even further. A busy few days as part of the wider Liyu stand at FESPA Istanbul in December inspired a wider run of events as the standalone UK shows planned for the Autumn/Summer season. Hot on the heels of an outstanding Print Show in Birmingham in

September last year, Liyu has an impressive calendar line up for the NEC Print Show again Liyu UK plans exclusive Open House events, where visitors can see the printers and cutters live as well as connect with businesses who are already successful converts to the Platinum range. Tucker adds: “There’s a real buzz building around the Platinum range, so it’s the perfect time to invite people to see the equipment at work as well as enjoying a fantastic day out. We offer a fun, unique approach to business and so we will definitely make sure our visitors are wowed by our hospitality as well as our technology!”

The Liyu Platinum flatbed pairs sleek aesthetics with highproductivity, and is available in two sizes; the KC2512 and the KC3020 XL pro. The Platinum KC builds on existing Platinum architecture to add even more efficiency and functionality through additional upgraded features including the maskless bed, reducing the need to use masking tape, the reverse vacuum for easily removing heavy or awkward materials from the flatbed, and electronic vacuum zoning. The beltless drive and LED UV liquid cooling ensures the Platinum KC is speedy upto a whopping 350 Ssm/ hr, sustainable, and affordable to run, and the choice of Konica Minolta or Ricoh Gen6 printheads means highquality prints are par for the course.

Owners of Gocre8 in Liverpool opted for the KC2512. Having explored the ‘usual suspects’ in terms of leading flatbed solutions, they found that the Platinum KC ticked all the boxes for their requirements: “After doing extensive research for our next flatbed printer we decided on the Platinum KC2512 with Varnish, what a superb

AFTER DOING EXTENSIVE RESEARCH FOR OUR NEXT FLATBED PRINTER WE DECIDED ON THE PLATINUM KC2512 WITH VARNISH, WHAT A SUPERB CHOICE AND SO AFFORDABLE TO RUN

choice and so affordable to run.

We do a lot of fine artwork as well as high production boards, this ticks all the boxes for us. The Maskless vacuum is so powerful which is ideal for awkward cardboard.”

Elsewhere in Liverpool, the larger version of the Platinum KC flatbed is also making a big impression. Peter Wilson, Managing Director of LWV Printworks, Liverpool, says: “We’ve taken delivery of the massive KC3020 Flatbed and its phenomenal in quality and speed, I didn’t know this type of flatbed was available at such a good price, we would highly recommend one.”

If a roll-to-roll solution is what’s needed, the Liyu Platinum range doesn’t disappoint. The Platinum PCT roll-to-roll printer is available with either UV LED or eco-solvent ink sets for environmentally responsible production. Once again putting operators at the heart of the design, the core Platinum technology has been upgraded with a range of user-friendly functionalities including an automatic media measuring system, LCD control panel, LED lighted printing area, and automatic pinch roller control.

The Platinum superfast QR3 XL Pro & QR5 are roll-toroll UV LED printers that incorporate the familiar polished Platinum design with state-of-the-art technology. For businesses looking to explore new markets and revenue streams, the application possibilities of the Platinum QR combined with its production capabilities make it an attractive contender. The QR’s versatility handles materials such as leather (or vegan leather) and canvas, as well as being suitable for backlit applications, signage, adhesive vinyl and window stickers, and even packaging and prototypes.

On the hybrid front, the Platinum Q2 brings the ‘wow’ factor. It’s hybrid status means it’s a highly versatile machine, capable of printing on to a huge range of flat medias Including Foamex, Di-bond, glass, wood, and many more up to 50mm in height. Described as the ideal ‘all-rounder’, the Platinum Q2 boasts a heavy duty roll and take-up unit, Automatic head cleaning, Quadro vacuum ring motors for extra flatness for those awkward medias, and liquid cooled LED UV units. For an even more impactful solution, see the Platinum Q3 – this wider version accommodates larger media such as 3 metre boards.

Growth in the textile market continues, following a drop in demand during COVID, exhibitions and other events are back with a bang, making textile printing an attractive prospect for print service providers. Liyu’s Platinum FH Textile printer delivers a wealth of opportunities in the sector, offering a 3200mm print width and print speeds of up to 210 m2/h with 2880 dpi resolution and 3.5-13 picolitre droplet size, it’s possible to print with photographic quality on many types of fabrics such as bed covers, curtains, wall coverings, seat covers, flags, table clothes, and T-shirts.

On the finishing side, the Platinum Q Cut is a range of high-precision, flexible and automated cutters equipped with an intelligent conveyor, automatic camera registration, a double beam cutting system, and speeds of up to 1.5m/s. The range consists of the Q Cut 3521, Q Cut 2516, BQ Cut 2516, Q Cut Offset, and DF Plotter. Platinum printer operators will find a match made in heaven with the razor-sharp accuracy of the Platinum Q Cut range.

It’s important to highlight the fact that sustainability is a driving force underpinning Liyu’s Platinum technology. As businesses across all sectors are aiming to work with print and signage partners that help them meet their sustainability targets, the Platinum UV printing inks are GREENGUARD GOLD certified, a prestigious certification that is awarded to products meeting some of the most exacting chemical emissions standards.

Tucker concludes: “It’s great to be expanding our presence in the market and showing PSPs what our equipment can do. We definitely encourage anyone with an interest in cutting-edge wide-format technology, particularly those that are looking for better value and more focus on their needs than they might be getting with their traditional manufacturer partners, just get in touch –we’re waiting to host you at our showroom!”

With more exciting news, Liyu UK will be adding some long term familiar faces from the industry to its sales and technical team but these will be announced officially shortly.

WE’RE DELIGHTED TO BE AT THE FOREFRONT OF WHAT WE CALL ‘THE PRINTER REVOLUTION’!

from FuturePrint, talking about sustainability and the drive to use recycled PVC in signage; Marcus Timson, also from FuturePrint, on the importance of adaptability for signmakers and print providers; and Alex Liggett from The Vinyl Guys, who will be looking at the huge diversity in wide-format printing media and advising business owners on taking advantage of this versatility while keeping focused on their core applications. The full schedule will be posted on the show website closer to its opening.

The Sign Surgery - which will take place alongside the Explains Lounge - will be an informal environment where visitors can put questions to ISA-UK directors.

Craig Brown, CEO of the ISA UK, says: “The Sign Surgery will be a vibrant and welcoming place where sign-makers, graphics designers and digital print providers can come to discuss the issues and challenges most important to them. ISA directors with decades of experience in all areas of sign-making will be available throughout the show to answer questions and discuss real business issues. We have seen and lived it all in signage as a group, and this is a rare opportunity to share this knowledge with fellow sign-makers and print service providers.”

Almost 4,000 attended SDUK’s return to the trade exhibitions stage last year, somewhat underwhelming but a number that the show’s organisers are confident of overtaking with the 2023 event.

“Last year, it felt so great to be back after a three-year break. However, the country was still very much in the grip of the pandemic and the show week saw the highest numbers on record testing positive. We expect to return to pre-pandemic numbers and exceed 5,000 this year,” says event director Jenny Matthew, pointing out that more than 70 companies have confirmed stands. These include Epson UK, Roland DG, swissQprint, Premier, Hexis UK and Vivid Laminating Technologies, but not (at the time of going to press) other notables for large-format focussed visitors, such as Agfa, Canon, Fujifilm, HP and InkTec, though many will have a presence on other exhibitor’s stands.

As you’ve come to know over the course of this long-running show, exhibitor stands are only part of its attraction anyway, and other show features this year include the Explains Lounge, Sign Surgery and Studio, Hexis UK Wrap Battle and Sustainability Trail.

The International Sign Association UK (ISA-UK) is back to host the SDUK Explains Lounge and a brand-new feature, the Sign Surgery.

The Explains Lounge will host presentations designed to engage, inform and inspire. All of the sessions are free to attend and there’s no need to book. At the time of going to press confirmed speakers included: Frazer Chesterman

Where:

Hall 2, NEC, Birmingham

When: 21 - 23 March, 2023

Times: 10am - 5pm, Tuesday - Wednesday, 10am - 4.30pm, Thursday

Cost:

Free. Pre-register online at: www.signuk.com/visit

The Sign Studio will run daily, with live demonstrations and practical workshops hosted by sign-maker Paul Hughes. These sessions will allow visitors to learn more about the basics of vinyl application, vehicle livery, wall coverings and more. “I will give practical, hands-on demonstrations designed to inform people looking to take their first steps in vinyl application and those wanting to add to and develop their skills. There will even be something for more seasoned pros on the hunt for the latest tips and tricks,” says Hughes.

As well as a broad and diverse range of exhibitors, SDUK is running a series of features designed to educate and inform sign-makers of all shapes, sizes and experience levels. The UK Wrap Battle 2023, hosted by Hexis, will run throughout the show, giving visitors a chance to see the very best vehicle wrappers demonstrate their skills in a battle of speed and accuracy in a bid to claim the title of ‘Best UK Installer 2023’.

This has become a popular feature of the show according to the organiser, who says it will include even more exhibitors this year, though specific products and services are yet to be announced - but, it will include signposting to the Explains Lounge and Sign Surgery where there will be regular features on sustainability.

Matthew, concludes: “We are so excited about the show this year. We want everyone who joins us to get real value from their time, so we are doing our best to ensure there is something for everyone, from industry newcomers to seasoned veterans. The schedule will be jam-packed with fantastic exhibitors, exciting features and thousands of networking opportunities to ensure that visitors will be informed and inspired by everything they find at SDUK 2023.”

The first print industry focussed EcoPrint summit will take place in Geneva on 6-7 June this year and right now this sector’s input and collaboration is being sought to help ensure it hits the mark. I talked with Frazer Chesterman from organiser FM Future on the subject.

This EcoPrint summit comes more than a decade after the first EcoPrint, which ran as a tradeshow and conference in Berlin at the end of 2012. It hasn’t run since. Why was that, why the relaunch now, and why have you changed the format?

In 2012 we - myself and Marcus Timson, now of FM Future - launched the original EcoPrint event in a converted rail station in Berlin, attracting around 1,000 people from across Europe. In the intervening decade, sustainability has gone beyond a ‘nice to have’ talking point to become the defining issue of our age, with retailers, brands, and other organisations committed to ambitious net zero targets. Despite this, there remains insufficient correspondence in the print supply chain.

This has prompted FM Future to build on the foundation of the first event and create an EcoPrint movement that encourages the community to ‘be the change’.

The popular elements of the event in Berlin were the cause and the community, and in truth it wasn’t about machines and technology. We feel the time is right again, 10 years later, to create a focal point for our industry as a summit for ideas and conversation that will bring the industry together.

We’re calling on the industry to help us unravel and clarify what sustainability means, as well as how to integrate best practice into business and gain inspiration from digital print technology that can help our sustainable performance.

Now in 2023, many leading printers have sustainability managers, net zero goals, and a genuine concern for their people and their impact on the planet. Sure, this is not yet wholesale, but even at this early stage in our launch there is a noticeable difference compared with EcoPrint the first time around.

In 2011/12 when we were attempting to gain support for the original EcoPrint, we had to spend a huge amount of time finding people who genuinely believed in sustainability. This is no longer the case. Now, the industry is eager to be involved. They are contacting us as they want to be part of a movement that is created to be a force for good.

The goal is to showcase what is possible with new technology, create a dialogue about how the industry can improve, provide access to guidance on best practice, and maybe even discuss the idea of governmental and industry standards. To achieve this, industry unification is

needed. Collaboration is crucial. We cannot afford to sit on our own islands, exist in our own silos, and not work together. The water is rising and the planet is getting warmer. We can all improve by simply collaborating, communicating, forging new ideas and taking action.

When you announced the summit you said the aim was “to showcase the technological possibilities of sustainable print production and discuss how the print industry can collectively make a difference for planet, people and profit.” How are you defining ‘sustainable print production’ in this instance?

That’s a good question and I have always felt that sustainability is about creating a ‘sustainable business model’, not just about being ‘green’. Key to the discussion will be the ‘why’ and the ‘how’ - insight, innovations, ideas, and actions. EcoPrint will focus on showcasing technology that makes a difference with our Eco Innovations awards, as well creating straightforward action plans to help businesses move in the right direction.

You have made it clear that you need the print industry to play a part in ensuring the summit content is right. Have you had much feedback so far, and what are proving to be the biggest concerns?

It’s clear that people are keen to get involved, and like the idea of being part of a movement that is created to be a force for good. As our recent sustainability survey underlines, anxiety about climate change and its increasingly prevalent effects is the key concern driving this change in attitude.

Since we ran the first EcoPrint in 2012, so much has changed. The climate change deniers have all but disappeared into the background. There are net zero targets publicly proclaimed by retailers, brands, and governments. There will be continued legislation, and there is now a whole new generation of professionals who are gracing the stage, a generation that is far more action oriented, more committed, less tolerant of false proclamations. And business leaders are recognising that sustainability is not a trend that will fade away.

We already have a fantastic number of ‘eco ambassadors’ who have joined our EcoPrint advisory group to help shape the event. They represent all the key touchpoints for our industry - not just printers, packaging

converters and print manufacturers, but brands, retailers, designers, government, research analysts, sustainability professionals, NGOs - all who are driving the agenda.

The Geneva event agenda is now taking shape, and input from the growing EcoPrint community plays an essential role in bringing a valuable, actionable content programme to life.

The wide-format digital inkjet sector has quite specific eco issues. Are you in collaboration with players in this space, and do you want more?

It’s important to reiterate that the EcoPrint movement needs collaboration and participation from every corner of our industry, and wide-format digital inkjet is certainly an important focus. We are already working with a number of players in this space, and we are of course open to working with anyone else in the sector who wants to be involved.

PVC-free wide-format materials provider Kavalan will serve as a headline sponsor of the Geneva event. Nova Abbott, chief marketing officer, Kavalan, says “sustainability is about preserving the future for all of us, and the print industry is certainly one of many sectors having a significant negative impact on the planet through its waste and emissions. As a business we have a mission to significantly reduce the environmental impact of signage materials by replacing high impact products such as PVC and textile signage with low impact materials - this is where EcoPrint aligns perfectly with our mission.”

Kavalan continues to lead the market in terms of the manufacture of environmentally positive signage, banner, POP and out of home advertising materials, and as such we believe being a part of the EcoPrint Summit is absolutely vital.

Probo, Europe’s largest wide-format print business, is also committed to the vision and the concept of the event with its Sign Again product. Other companies committed include HP , Xanita, Antalis, Epson, HelloPrint, Boxmaker, Northernflags, highcon, HH Global, Fujifilm, Alchemie Technology, Sun Chemical, Agfa, Siegwerk and Kao Chimigraf Swatch amongst others.

identify topics for discussion?

Part of the reason for choosing a summit format is to invite the key associations such as IPIA, Intergraf, POPAI,

BPIF, VIGC, Print Power etc. to participate. However, to be honest, we know that the key leadership on this issue is coming from the brands - the likes of P&G, Unilever, Walmart, L’Oreal, Diageo - as they are the ones demanding change in all areas of ESG. We are not talking just about the processes FSC, Nordic Swan, Blauer Angel, EU FLower, PEFC - we want to talk about what impacts on business.

That said, organisations like the IPIA have been doing some amazing things with members and I expect them to be sharing best practice, as well as Ulbe Jelluma from Print Power who has some great stories to tell.

How can you ensure that the summit focusses on what needs to be discussed, rather than on what speakers want to talk about?

The EcoPrint advisory group will be vetting the presentations to ensure we don’t have manufacturers delivering ‘greenwash’. We expect the morning of both days to be full of amazing content to get people thinkingit certainly will not be a selections of sales pitches.

How is the content programme shaping up so far?

Isabelle De Wolf from Hello Print, Elsie Hargate from Bluetree group, Beate Van Loo Born from Climate Ark, Henning Ohlsson from Epson, Jenny May from CarbonQuota, Steve Lister from HH Global, Kristi Duvall from Boxmaker, Fred Lil of Lil Packaging, and Nathan Swinson-Bullough from ImageCo are already on board.

What do you hope attendees from this event will take away with them?

We will have high value content to inspire on both mornings, then a selection of one-hour workshops from sustainability professionals to offer learning for delegates, followed by roundtable COP style discussion groups to ensure action. Finally at the end of the day the EcoPrint Innovation Awards will recognise best practice and great innovations in sustainability in print.

We believe 2023 is the perfect opportunity to create real, sustainable change within our industry and the sectors it touches, and with the focal point of the growing EcoPrint community being the summit held in Geneva, Switzerland, the ‘home of summits’, European HQ of the UN, and many other important NGOs, it is the perfect location.

WE CANNOT AFFORD TO SIT ON OUR OWN ISLANDS, EXIST IN OUR OWN SILOS, AND NOT WORK TOGETHER

WE NEED MORE APPRENTICES IN PRINT, BUT IS THE FUNDING THERE TO ALLOW US TO BRING MORE YOUNG TALENT INTO THE INDUSTRY? THE BPIF AND PRINT SCOTLAND, BOTH KEY TRAINING PROVIDERS, EXPLORE THE ISSUE.

Apprenticeship funding can be a minefield in the UK, particularly when the different nations have different sets of funding sources and requirements for funding apprenticeship delivery. That, paired with an aging workforce and a growing skills gap in the print sector, makes it critical but somewhat difficult to ensure everyone fully understands and has access to the right levels of funding and support to make sure this industry continues to thrive. So says Karly Lattimore, MD of training at the BPIF - and who can argue?

BPIF training continues to try and navigate all the above in order to support apprenticeship delivery for business that operate in the print and graphic communications sectors in England, Wales, Scotland, and Northern Ireland. Print Scotland has a handle on the situation there - and together they paint a somewhat jarring picture of current apprenticeship funding across the UK nations.

If you’re based in England you actually have it quite good!

As Lattimore points out, and as most will be aware by now, in 2017 the Government introduced the apprenticeship levy. This levy is a 0.5% tax paid by all UK employers with a wage bill of more than £3m. This tax is then ring fenced for these organisations to fund apprenticeship training in their business, but only for businesses in England. Where a business is not an apprenticeship levy payer, in England, they

can still access funding to support apprenticeship training whereby the Government will contribute 95% of the funding required for the apprenticeship, with the employer being responsible for the remaining 5%. For example, should a non-levy paying business wish to support an apprentice on the print technician apprenticeship standard, the employer is responsible for £600 whilst the Government will fund the remaining £11,400. Furthermore, for micro businesses employing an apprentice aged 16-18, there are additional grants to support apprenticeship training.

“For BPIF Training, delivering apprenticeships in England, this funding has allowed us to support around 250 apprentices each year starting an apprenticeship from across a range of programmes including the print technician and operative standards, lean manufacturing and business skills, customer service, business administrations and leadership and management. 97% of apprentices who complete one of these programmes remain in employment, in the industryand without the appropriate level of funding this would not be possible.”

Lattimore continues: “In England, whilst there are some rules around the eligibility of apprentices such as their prior qualifications and learning, access to funding is readily available to employers to support apprentices at any age. But, with the apprenticeship levy funds only being able to be used on apprenticeship training in England, what happens to the funds for business in the rest of the UK, and how is apprenticeship training funded for the smaller organisations?

“Scotland, Northern Ireland, and Wales manage their own apprenticeship programmes independently of England, and therefore the money raised by the apprenticeship levy from businesses in these areas are transferred to central government to choose how they use the funds for training based on local, economical, and regional need - and not necessarily apprenticeship training.”

Apprenticeships in Wales are fully funded by the Welsh Government for apprentices over the age of 16 with employer incentive payments available to support

97% OF APPRENTICES WHO COMPLETE ONE OF THESE PROGRAMMES REMAIN IN EMPLOYMENT, IN THE INDUSTRYAND WITHOUT THE APPROPRIATE LEVEL OF FUNDING THIS WOULD NOT BE POSSIBLE BPIF

recruitment of apprentices with a disability.

“Whilst BPIF Training does not hold a direct contract with the Welsh Government to fund apprenticeship delivery in Wales, we do partner with ACT, a provider based in Cardiff,” explains Lattimore. “Through our sub-contract with ACT Training Group we offer the full range of printing apprenticeships. There are twelve different printing pathways, ranging in specification from print finishing to digital print production, and over 120 different NVQ units covering the huge variety of printing techniques. Over the past year we have seen update in apprenticeships in Wales double and participation in Wales is still growing.”

In Northern Ireland apprenticeship funding is provided by the Department for the Economy (DfE) with full funds being provided for those apprentices aged 16-24 and 50% funding provided for those apprentices aged 25 and over.

An employer incentive payment is also available to employers whose employees successfully complete their Level 2 and/or Level 3 apprenticeship framework. Level 2 and 3 print related apprenticeship are available in Northern Ireland across a range of disciplines including pre-press, packaging, press, print administration and postpress. Lattimore points out that whilst BPIF training has no direct contract with the DfE, nor a current sub-contract to deliver training, it is seeking partnerships to be able to further support the industry in apprenticeship training in Northern Ireland.

For those based in Scotland, apprenticeships are funded through the Skills Development Scotland (SDS), with the level of funding contribution dependent on the age of the apprentice, the qualification level, and the apprenticeship sector - with additional funding contributions for those apprentices who are disabled and care-experienced, up to the age of 29.

Print Scotland is the voice of Scotland’s graphics industry and as an approved training provider for modern apprenticeships in print occupations it is leading the lobbying of the Scottish Government to prevent further cuts and to seek a review of funding for apprenticeship frameworks.

“The grants for training an apprentice are much less in Scotland than those in England and have not been increased for several years. There is little doubt that gaining improvements in funding will be necessary for the long-term survival of some training providers that don’t have a diverse training portfolio,” says Garry Richmond, MD Print Scotland.

He points out that print in Scotland is centuries old and that by the 1990/2 had become the fifth largest employer. “However, the main challenge the industry faces now is that the baby boomer generation, who took skilled manual jobs, are set to be retired by 2030 causing a skills shortage of up to 5% across the general labour force. It is therefore difficult to recruit and excite school leavers to consider a career working in the print industry.

“We have shown that with modern apprenticeship training that a career in print can be sustainable, enjoyable and with many progression opportunities.”

Last year, Ultimate Learning Solutions developed an online Learning Platform branded for Print Scotland. “This enables

Print Scotland

our apprentices to access their SVQ training modules as well as other supplementary training material to enhance their learning experience,” says Richmond.

“The delivery of the programme is now fully modernised, with each apprentice not only able to access the relevant material digitally but also to communicate more efficiently with the course assessor during and after each module. Progress is monitored more easily by both the mentor and the assessor which helps keep the apprentices on track using both handheld digital devices and desktop. Feedback from the apprentices has been positive and all our cohort is now signed up and using the platform.”

Susan Graham, president of Print Scotland, adds: “We have spent a lot of time and effort on the apprenticeship scheme, and I am pleased with the progress and the professionalism of Jim McKenzie our assessor. We are competing in a recruitment pool where demand is high and candidates few. Print is not just ink on paper - it’s a creative craft that needs to be appealing and attractive to a very different generation.”

THERE IS LITTLE DOUBT THAT GAINING IMPROVEMENTS IN FUNDING WILL BE NECESSARY FOR THE LONG-TERM SURVIVAL OF SOME TRAINING PROVIDERS

Here, print industry coach Colin Sinclair McDermott talks you through some of the basics that can be so easily forgotten in the day-to-day operational scramble.

IF YOU’RE STILL OPERATING YOUR PRINT COMPANY AFTER ALL THE LAST COUPLE OF YEARS HAVE THROWN AT US YOU MAY THINK YOU’VE LEARNED ALL THE LESSONS THERE ARE TO LEARN ABOUT RUNNING A COMPETITIVE BUSINESS. BUT COULD THESE NUGGETS OF ADVICE FROM COLIN SINCLAIR MCDERMOTT, CREATOR OF THE PRINT GROWTH ACADEMY AND PERHAPS BETTER KNOWN AS THE ONLINE PRINT COACH, HELP YOU DO BETTER?

It’s important for any business to have a strong culture that breeds the overall mission of the company. A good mission statement is something that is often overlooked, yet it is key to showing your customers what makes you different from the other print suppliers and why they should buy from you. It should also help provide a clear and concise direction for your company and help give your employees defined objectives.

Due to the fact it outlines why your business operates, your mission statement acts as a framework for decision-making. Rewarding your staff for following these guidelines at the highest level will ensure peak performance and help you rise above the competition.

- NETWORKING EVENTS OR MEMBERSHIP ORGANISATIONS

By becoming the expert in your field, you very quickly become the ‘go to’ person when someone requires the products or services your offer.

There are a couple of different ways to explore this. The first could be to look for speaking opportunities - networking events or membership organisations are always a great place to start.

The second would be to become somewhat of an influencer, by providing comment either in publications your target audience is likely to read, or perhaps by creating your own blog. Blog posting is wonderful for search engine optimisation purposes and can also be a great source for attracting new customers.

Don’t be afraid to check the elasticity of your pricing and charge what you are worth. It’s not uncommon in the print industry to see many companies fight it out at the bottom of a low-cost leadership pricing battle. It’s a model that works for some printers who have vastly high volumes of throughput to justify such low pricing but for the majority it’s just not sustainable and in some cases can put some buyers off. We’ve all heard the saying “You get what you pay for”.

Advice worth considering is to work more with a high value differentiation pricing model. Look to increase your prices by as little as 5-10%. Many of your customers will likely not bat an eyelid because they do value the service you provide. Typically, the customers who do push back are the ones who give you the most challenges and in fact, you would likely have much more time on your hands were they to go elsewhere. The thing is, with the extra give to ten percent extra you are now charging, you will probably still be making the same profit, but you don’t have the same challenging customers giving you a headache so you can spend your time servicing the customers who do truly value you.

ARE ALWAYS A GREAT PLACE TO START

After I trained to be a corporate coach, I was strongly advised to open myself up to work with people outside of the printing industry and spread myself about more. The problem with that was that I was setting myself up to compete with the other hundreds of thousands of other coaches in the marketplace. By niching down, I’ve crafted out a career with a lot less competition. Being a corporate coach who has run his own print company makes it more appealing to someone in the industry versus someone with no experience in print. The same rules apply when customers are looking for new print suppliers. If a customer is looking for a fleet of vehicles to be wrapped, are they more likely to order from a generic print company or a specific wrapping specialist who focuses on that area of the industry on a daily basis? It will increase your chances of converting quite considerably.

Every business should have something called a customer value journey. What it does is represent the different phases each of your customers should go through whilst dealing with your business. It should cover every aspect of communication from when they first heard about you all the way through to becoming a raving fan. These are the best types of customers. The ones who regularly order from you but not only this, they should about your business from the rooftops and refer you to others.

Your customer value journey is all about sequence and you should be able to look and any individual customer, know where they are currently at in that sequence and identify if they are on track to the next stage or whether there is a call to action in place to help get them back on track.

Speaking to all your customers in the same way can be harming your business. It’s why it’s so important to build profiles for each of the customer types you service - customer avatars if you will.

A customer avatar is essentially the profile of your perfect customer. The ones you make the best margins on, the ones who give you the least challenges and take up less of your time. It’s what they look like, what their habits are, their interests, what challenges they face each day, what their aspirations are for their business. Once you know all this, it makes marketing to them far more effective for your business and you can show them how dealing with you will make their lives better.

Many businesses I come across don’t initially have a process like this in place and as a result have low retention rates. Implementing a system like a Customer Value Journey can often not only help new customers get to where you want them to get quicker, but it can also help you improve the average lifetime value of your current customers.

Following on from building your customer avatars, you are now able to segment your audience. Something we can be guilty of is trying to be everything to everything and therefore our marketing message may not be relatable directly to each customer. By having your customer base broken down into business sectors, you can target them specifically based on what you know about them, addressing what concerns they might have and promoting products relevant to their needs.

Likewise, if you can track customer’s or said sector’s spending patterns, you can create targeted campaigns based on products they are interested in or at times of the year they typically order.

It’s important that you know who your competition is. It can often be the case that they can provide alternative solutions to your customers that you are missing out on. Are they offering print products or services that you don’t? Are they targeting specific industries and having success that you had overlooked?

Analysing competitors regularly can also help identify things like what value propositions are they focusing on? Is it a free next-day delivery service? Dedicated account managers? Free artwork checks? Credit accounts? Discount on the first order?

Lastly, take some time to check out their reviews. Most businesses these days will use the likes of Google Reviews or Trust Pilot and within there, you’ll find plenty of golden nuggets. Reviews can highlight opportunities where your competitors are falling short and show you how you can gain an advantage and plug those holes in their business.

WORK MORE WITH A HIGH VALUE DIFFERENTIATION PRICING MODEL. LOOK TO INCREASE YOUR PRICES BY AS LITTLE AS 5-10%.

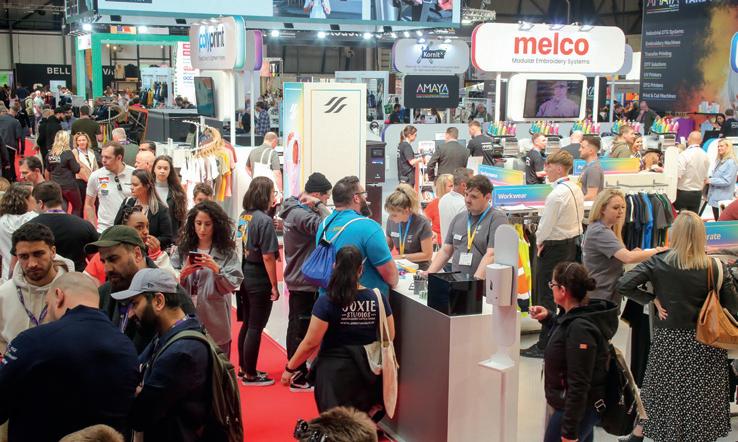

THE UK’S ONLY NATIONAL EXHIBITION FOR GARMENT AND PROMOTIONAL PRODUCT DECORATORS RETURNS TO HALL 20 AT THE NEC IN BIRMINGHAM THIS MONTH – ARE YOU READY TO DISCOVER MORE ABOUT THIS THRIVING INDUSTRY?

stand (F40) and four new direct to film printer models from Resolute DTF (B20).

Plus, you can learn from the experts and gain all the essential knowledge you need to expand your business in 2023 in our two Seminar Suites.

The ever-popular Decoration Advice Suite returns in 2023 with some familiar faces, along with some new ones. Andy Rogers of Target Transfers returns to help transfer printers save both time and money in 2023, while Phil Oakley of Kornit Digital will be explaining how digital printers can achieve retail certified quality, high throughput and low cost per print. And, following the rapid introduction of direct to film printing in 2022, Colin Marsh of Resolute DTF will explore all there is to know about the process, covering both the pitfalls and the benefits.

Printwear & Promotion LIVE! 2023 will provide an excellent opportunity for sign makers and print service providers to discover how garment decoration and personalisation could be a beneficial and profitable addition to their business.

A vibrant and interactive environment awaits. Whether you’re looking to branch out into garment decoration or are one of our regular visitors, the exhibition presents an unrivalled opportunity to meet all of the key suppliers from within the industry.

As Nova Chrome UK’s technical manager, Ian McDowell, says: “Printwear & Promotion LIVE! provides one of the longest serving, most widely known platforms for equipment, consumables, networking and knowledge transfer in the UK. The offerings go far beyond the name, with every year delivering something new to see. The benefit here doesn’t need explaining – whatever you’re visiting the show for, you’re bound to find it.”

Over in The Knowledge Centre, we are pleased to see the return of Instagram expert Estelle Keeber following her debut in 2022. This year she will be informing attendees how they can make more impact and sales using Instagram. Javan Bramhall of Digital Glue also returns to explain how you can market your business on a shoestring, and in what is expected to be a fun yet informative session, Alex Liggett of The Vinyl Guys will be presenting his print business cookbook covering all the essential ingredients you need to run a successful business. Speaking for the first time is Alex Hall of Shire Leasing, who will be exploring how you can invest in capital equipment in this current economic climate. Register today and discover ways to enhance and expand your business in 2023!

FIND THE PERFECT DECORATION PROCESS FOR YOU

Venue: Hall 20, NEC, Birmingham

Dates: Sunday, February 26 to Tuesday, February 28, 2023

Times: Sunday and Monday, 10am to 5pm and Tuesday, 10am to 4pm

This year’s tagline of EXPLORE · DISCOVER · EXPAND, captures the very essence of the show, which will once again showcase all that is new in garment decoration from over 100 suppliers! Direct to film printing was undoubtedly the main attraction at P&P LIVE! 2022 and a year on, further advancements in DTF will be on display, together with many other exciting product launches.

For those looking to get started in the garment decoration industry, equipment launches that may be of interest include the Texjet NG range of direct to garment printers which can be viewed on the Amaya Sales UK

With over 100 exhibitors, Printwear & Promotion LIVE! features the leading names in garment decoration – so no matter the decoration route you take, whether that’s direct to garment printing or dye sublimation, you’ll be able to find the ideal solution at the show.

Many sign makers and print service providers have already made the move into this exciting market and reaped the rewards. Come along to the show to find out just how quick, easy and cost-effective it can be for your business to get your add-on up and running.

What are you waiting for? Register to attend Printwear & Promotion LIVE! today!

To find out more about Printwear & Promotion LIVE! and how it can benefit your business, visit www.printwearandpromotionlive.co.uk

ECO AND SUPPLY CHAIN ISSUES - HOW ARE THEY IMPACTING LARGE-FORMAT PRINTER/FINISHING MACHINE MANUFACTURING AND DISTRIBUTION STRATEGIES? WE ASKED THE COMPANIES THAT MAKE THEM TO BRING YOU UP TO SPEED.

We hear a lot about how ‘green’ large-format printers are in terms of their running efficiencies, inks, and output capabilities etc., and as we run up to the major trade shows we’ll no doubt hear a lot more, but PSPs still have very little information on the whole cradle-to-grave eco aspects of what they are buying. In an attempt to shed more light on that we asked all the major manufacturers for their take. Perhaps it was just a timing thing, but you may be unsurprised to learn that even some of those singing loudly to the eco tune fell quiet when it came to commenting on how increasing environmental concerns - and supply issues - are impacting and changing their parts sourcing, manufacturing/assembly locations and methods, shipment distances etc. But some were vocal, providing what’s at least a starting point for deeper conversations that need to be had if, as a sector, if we are serious about reducing our overall carbon footprint.

Mike Horsten, global press and PR manager (digital print/inkjet) spoke for Agfa, pointing out that “changing locations is not easy as it involves staff and buildings. We believe in our people so there are no changes there. To produce more ecologically we have implemented many things like solar arrays, the reduction of energy consumption and the use of recycling. We use electric vehicles on the sites. We are doing everything possible to reduce our footprint but exact examples are complicated as they affect many things, but we work on this every day.

He continues: “As all of Agfa has issues with the supply chain, getting parts for our hardware is not as easy as in pre-Covid times. The sourcing of parts, that come from around the world, has made it more critical that we look at all the chain and how we can improve logistics. Also, the lockdowns in China and Asia in general have made it more difficult to source parts - even if they are being made they haven’t been able to transport them out due to Covid restrictions.

“Agfa has a good position as we do manufacture many of the components ourselves, and we manufacture all inks in Belgium so we can control the supply a bit easier on that

side, but even there the prices of ground/raw materials have gone up as a result of the war in Ukraine and Covid. Although we have worked hard to maintain the pricing as it was, there are too many extra financial impacts like energy and salary cost that has driven the manufacturing cost of these goods up.”

Mathew Faulkner, director marketing and innovation wide-format group at Canon EMEA, says that “as with all manufacturers, we continually monitor our supply chain to anticipate and prepare for any potential disruption and take steps to deal with the situation, such as adjusting product designs and placing orders with different suppliers. An example of an area where we have had to adapt is the well-documented global shortage of semiconductors. In response Canon is building a new semiconductor equipment plant in eastern Japan, which will begin operating in the spring of 2025.

“We benefit from having manufacturing plants both in the Far East and in Europe - manufacturing in multiple regions has allowed us to both lower our carbon footprint through shorter shipping routes, as well as increasing the efficiency of our maintenance and installation services. In addition, our product portfolio is built with serviceability and field upgradeability in mind.”

Faulkner reiterates: “Canon’s corporate philosophy ‘Kyosei’ - living and working together for the common good - means that the principles of sustainability and responsibility are etched into our innovations. We always consider the environment when producing, transporting, using and recycling our solutions. We’re also committed to contributing to Canon Inc.’s target to achieve net zero by 2050 by reducing CO2 emissions across our corporate operations and throughout our product lifecycles.

“This includes innovating in areas such as product design to take into account the environmental impacts at each stage of the product lifecycle - and working to reduce them. We are also committed to expanding the use of renewable energy, improving energy efficiency, and cutting CO2 emissions from logistics through the use of more environmentally friendly transport methods. Where possible, we also design our products to help save space and improve efficiency during transport.

“Our wide-format graphics solutions are developed with durability, longevity and sustainability in mind. We have strong systems and processes in place to responsibly manage environmental impacts across our operations and supply

DURING THE DESIGN STAGES, R&D IS ACTIVELY WORKING TOWARDS A TARGET OF CUTTING LIFECYCLE CO2 EMISSIONS BY 3% YEAR-ON-YEAR

Faulkner

chains. This is reflected in the product lifecycle of our Arizona family of flatbed UV printers and our UVgel Colorado roll-to-roll printers. During the design stages, R&D is actively working towards a target of cutting lifecycle CO2 emissions by 3% year-on-year. Additionally, we work with our manufacturing sites to lower their energy consumption with a target of 1.2% per year - we also endeavour to bring down waste discharge, water consumption and chemical substance emissions. Our Canon production printing manufacturing site in Germany also uses 100% renewable electricity.

“It’s our ambition to become a circular business, meaning that every single product and material is designed, created, reused, repaired and recycled in a closed loop. We’re working towards this by creating and delivering refurbished and remanufactured devices and growing our portfolio of products suitable for remanufacturing and with improved upgrade, service and repairability. For example, the latest Colorado range of models are upgradeable in the field to add new innovations such as FLXfinish+ matte and gloss printing, double-sided printing and additional media drawers. This not only allows the technology capabilities to develop in line with our customers business needs but is also a much more sustainable way to get access to new innovations than buying a replacement printer.

“When our print devices reach end of life, they can be returned to Canon, where they will be refurbished, remanufactured, or parts reused depending on their condition. We have been remanufacturing devices for more than 20 years to help extend the lifetime of our products and we currently remanufacture products at centres in Venlo, The Netherlands and in Giessen, Germany.

“We’re also expanding our recycling and refilling programmes across the EMEA region and reducing the amount of single-use plastic used in product packaging materials and at operational sites.”

Joey Kim, managing director of Korea-based InkTec, whose European operations in Oxfordshire was established in 2006, points out that “in 2022, InkTec expanded its European operation by having a base located on the mainland in the Netherlands. This means it can now rapidly bulk distribute its inks across Europe, while offering faster delivery options and no duties or taxes within the European distribution zones.”

He adds: “With a significant number of Jetrix printers operating across Europe, InkTec continues to invest in its support team, in order to maintain and extend the lifetime of all its kit. This even includes supporting some of the original printers, such as the Jetrix 2513 which was launched in 2008. Equally, where printers are looking to invest in the latest technology, we are working with them to look at options for part exchange and re-sale of their existing machines, therefore avoiding scrapping them prematurely. This is opening up the options for smaller businesses or for those wanting to enter the large-format printing arena.”

On the supplies side Kim says that while the current economic climate is proving challenging, InkTec has taken several steps to mitigate this. “We are in the fortunate position of manufacturing our own inks and media so we produce to order. This ensures we manage the whole process, the result of which is that from an environmental perspective any ink wastage is minimised, with very limited supply stock going out of date.”

Rob Goleniowski, head of sales at Rolad DG stresses that “in a world increasingly aware of the impact of environmental concerns, businesses are under pressure to print responsibly and establish environmentally sound business practices. In light of this, Roland DG has adopted various ways to cater to the needs of its customer base. Our cloud-based Roland DG Connect app includes new features for accurate fault logs and diagnosis, helping increase first-time fix rates and engineer mileage. Moreover, our proprietary ink dot control technology limits ink use while maintaining high-definition print quality. And our move to a pouch-type design compared to plastic cartridges makes sorting and disposal of used inks easier. Additionally, all Roland DG printers feature sleep mode to minimise power consumption when on standby, leading to lower costs.

“In fact, we comply with the Waste Electrical and Electronic Equipment regulations (WEEE) to reduce energy and resources during each stage of our products lifecycle - from using recyclable boxes through to product size packaging design for optimal loading during transportation and disposal. And unlike some manufacturers, we do not advocate a throw-away culture by managing the lifespan and support of older products with a new lease of life from another owner.”

He continues: “Even by simply moving our engineering fleet over to hybrid alternatives, and our Japanese headquarters relocating to a ZEB (Zero Energy Building) certified building, we can make huge leaps forward to reduce our CO2 footprint.”

At swissQprint chief sales and marketing officer Carmen Eicher, says “we are dependent on global structures and feel the bottlenecks in procurement. That’s a fact. However, there are circumstances benefiting us at swissQprint. We are sourcing from Switzerland - and locally - to the greatest extent possible. There is hardly anything we can improve. Some things, like inks or printheads, are simply unavailable in Switzerland, but we have long-standing partnerships with suppliers.

“Our purchasing and logistics teams know the machine parts inside out. If delivery problems become apparent, they quickly initiate measures to find a solution with suppliers, or a temporary change to internal work processes. We have everything under one roof at our HQ in Switzerland which makes us flexible. So, if the only and last option is to use an alternative product, our development teams perform the necessary technical adjustments.

Eicher points out that the company’s building in Kriessern is heated and cooled via groundwater heat exchangers, making it independent of fossil fuels. “That far-sighted investment of yesteryear is now helping us to avoid the global energy squeeze. Also, by adopting small measures, each and every one of our staff contributes to reducing electricity consumption.”

Asked if swissQprint is considering any ‘take-back’ and recycle programme for large-format kit Eicher says simply: “There is no such programme as there is currently no need for it, given that all of our machines are still operating. What is more, there is a big demand for our secondhand (and even third-hand) machines. We offer spare parts for as long as we can to keep these machines running. The longevity of our machines keeps their overall carbon footprint small.”

WE COMPLY WITH THE WEEE REGULATIONS TO REDUCE ENERGY AND RESOURCES DURING EACH STAGE OF OUR PRODUCTS LIFECYCLE

Goleniowski

IT’S WELL KNOWN THAT TO SOME, FREE MEANS WORTHLESS. PERHAPS THAT’S WHY UK LARGE-FORMAT PSPS ARE PROVING SLOW TO TAKE UP SOME ENVIRONMENTAL SCHEMES OFFERED FREE OF CHARGE.

JANE RIXON, BUSINESS DEVELOPMENT MANAGER AT HP LARGE FORMAT PRODUCTION UK AND IRELAND, EXPLORES THE ISSUE AND CALLS FOR MORE ACTIVE PARTICIPATION.

As the world’s desire for sustainability grows to help combat climate change, commercial printing professionals are proactively looking to explore ways to embed sustainable and regenerative practices into their designs, processes, and services. That said, making the large-format print sector more sustainable will be one of the most ambitious transformations the industry has ever undertaken. There are many existing green initiatives that can help bolster a company’s environmental credentials, but they are still being underutilised.

For large-format printing companies, creating a truly sustainable business is both a social good and an economic opportunity, which can drive cost efficiencies, stimulate the development of circular services, and win business from eco-conscious brands. That’s not just my say so - there’s a lot to be learned from those that have already seen that’s the case.

Take East Yorkshire-based Greens the Signmakers, which recently invested in a HP Latex R2000 printer to expand into new markets and boost its environmental credentials. The new machine has helped the business significantly enhance its environmental USPs, off the back of demand for solutions from customers proactively looking to explore ways to embed sustainable and environmentally friendly practices into their designs, processes, and services.

Managing director Lawrence Green is the third generation of the family to lead the business. Inspired by Charlotte, his eight-year-old daughter, Green sought out ways for the company to grow while improving its environmental credentials at the same time. A key part of his strategy for 2022 was to invest in new technology that enables the business to become more environmentally friendly.

It also makes use of the HP Media Locator. One of the most obvious environmental challenges facing largeformat PSPs is to find greener alternatives to materials such as PVC, and this directory lists well over 50 media that have been identified as an eco-conscious to help in this mission.

Now, when receiving an inbound request for a project,

Greens the Signmakers has adopted a new approach to customer service - it sends the customer two quotes, one offering them the chance to have their project designed with sustainability in mind via the use of more eco-friendly materials for instance.

As a leader of a large-format PSP you may still be wondering where to start your company’s environmental transformation given so many are rather cynical about what is said and done in the name of sustainability. The most effective way of countering the cynicism is to be completely transparent about - and to share hard evidence of - your changing practices.

It’s important to start small with simple initiatives that might be deemed as ‘low-hanging fruit’ but that often have a big impact.

Schemes like HP Planet Partners can help make the world a greener place through initiatives including its ‘Return and Recycle’ programme, which allows for the simple recycling of HP printer supplies, any brand of computer hardware and rechargeable batteries. HP customers can either order postage-paid envelopes or labels to return their cartridges by post or have the box collected from their premises when full. This free of charge return and recycle scheme was responsible for over 764,800 tonnes of recycled hardware and supplies throughout last year, so using it really does make a substantial difference.

It’s worth reiterating the importance of transparency. Many companies claim to have a ‘take back’ policy, but where are products being taken to? If there’s no transparency, no data, and no proof, then there is no trust.

To date, HP has recycled more than 875m cartridges and eco cartons since the initiative launched in 1992, yet it remains underutilised by many of its print partners. Currently, only half of HP’s UK customers are enrolled on its Planet Partners scheme, though using it is one sure-fire way for a PSP to reduce its potential plastic waste.

Like any ambitious company programme, creating a truly environmentally sustainable large-format print business inevitably brings challenges. When momentum has slowed, unexpected obstacles emerge and new regulations bring plans into question, it pays to remember why you are doing this - it is good for the planet, good for your conscience, and good for business.

With that in mind, and in the knowledge that there are underused environmental enhancing schemes already in existence out there, I am calling on all commercial printing businesses to sign up for ink and toner cartridge recycling programmes. It’s a small, but effective move that means old cartridges can become new products and don’t end up in oceans or landfills. An easy way for companies to reduce their environmental impact.

ONLY HALF OF HP’S UK CUSTOMERS ARE ENROLLED ON ITS PLANET PARTNERS SCHEME

If you’ve not heard of ClimateCalc you’re not alone. It’s an online carbon footprinting tool that’s for the whole of the graphics industry, covers 95% of all measurable emissions and doesn’t cost the earth. The BPIF jointly developed the software with its European sister print federations a number of years ago but take-up in the UK has been slow, though there are now 22 UK sites using it. Should your business be another?

Based on the recommendations from Intergraf, the European umbrella body for graphic associations, ClimateCalc covers 13 crucial parameters and allows a graphics company to offer its customers a carbon footprint for each job.

The tool complies with ISO14064-1 and comes in two forms - the ‘basic’ model, which is simple to use, and the ‘full’ model, which requires more input but gives a more company specific measurement. Both models allow a PSP to input the emissions factors for the substrates they actually use, rather than generic factors.

Taking its emissions factors from the Ecoinvent website and university research, the ClimateCalc software covers areas such as inks, varnishes and IPA, uncommon in many other calculators.

In the basic form, a PSP simply has to input the number of employees it has, its annual consumption of energy, the annual amount of substrate purchased and sent to waste and the tool will give it a site carbon footprint split between Scopes 1,2 and 3. It will also allow a PSP to offer its customers a carbon footprint for each job by inputting the weight of substrate used on the job and the distance the job has to travel to the customer.

The full model allows for far more bespoke data inclusion, with a PSP able to add the raw materials used, such as inks and varnishes, as well as packing material and transportation, including employee commuting.