Electricity has transformed human civilisation to the point that we could not imagine our lives without it, and yet, 150 years ago when Electrical Review was first published, electrical power was a promise for the future, rather than a present-day reality.

At that time, people could barely imagine electric light bulbs transforming the way we light our houses, businesses and streets, and yet now we use electricity for heating, transport, cooking and every task in between. The pace of innovation continues at speed, with electrical power likely to bring many more benefits long into the future.

Change is one of the greatest constants of humanity; after all, human civilisation has progressed astronomically in those 150 years. But one thing that has not changed is that Electrical Review has been there every step of the way to delve into how electrical power has transformed our lives. And while the magazine has changed throughout the years, the words that began that very first issue still form a key part of our mission.

“We need not dwell upon the importance of the applications of Electricity. It would be better to review the position that the chief branch—Telegraphy, a science itself—occupies in relation to the Public.”

While telegraphy is no longer a key part of what we cover at Electrical Review, our mission is still to ascertain how the electrical industry continues to change lives, even if it has become an ordinary part of day-to-day life.

That’s why we’ve put together the 150th Anniversary Edition, to highlight that mission statement and the work that we’ve done throughout the years to celebrate the electrical industry. But this is also an opportunity to celebrate our readers and contributors, as without them, the world could not be what it is today.

Throughout the years our readers and contributors have showcased their talents by developing new technologies, new standards and new practices that have quite literally changed the world. So, thank you.

Whether you have been reading for 50 years or this is your very first issue, the electrical industry has a bright future ahead thanks to all of you and we’ll continue to champion that future for many years ahead.

EDITOR

Jordan O’Brien

jordano@sjpbusinessmedia.com

CONTRIBUTING EDITOR

Kayleigh Hutchins

kayleigh@datacentrereview.com

DESIGN & PRODUCTION

Alex Gold

alexg@sjpbusinessmedia.com

GROUP ACCOUNT DIRECTOR

Sunny Nehru

+44 (0) 207 062 2539 sunnyn@sjpbusinessmedia.com

GROUP COMMERCIAL DIRECTOR

Fidi Neophytou

+44 (0) 7741 911302 fidin@sjpbusinessmedia.com

Printing by Buxton

Paid subscription enquiries: subscriptions@sjpbusinessmedia.com

SJP Business Media

2nd Floor, 123 Cannon Street London, EC4N 5AU

Electrical Review is a controlled circulation monthly magazine available free to selected personnel at the publisher’s discretion. If you wish to apply for regular free copies then please visit: www.electricalreview.co.uk/register

Electrical Review is published by

2nd

This 150th Anniversary Edition is a love letter to the last 150 years of Electrical Review. It highlights the ever-changing nature of the electrical industry, while showcasing Electrical Review’s role in reporting on it.

However, this isn’t just an opportunity to be nostalgic about the past, but also a continuation of Electrical Review’s role at looking to the future – as it’s clear that there’s an extremely bright future ahead for the industry.

Unlike other issues of Electrical Review, you can expect to see something completely different, as we highlight the past, the present and the future.

In this issue, the Past will showcase some of the technologies that have changed our lives during Electrical Review’s 150 year history. This includes everything from telegraphy to nuclear power, while also giving us an opportunity to showcase old articles from notable contributors –including none other than Nikola Tesla.

The smallest section of the issue will look at the Present, which gives us an opportunity to highlight some of the biggest news currently occurring within the electrical industry, while also giving our Gossage Gossip columnist an opportunity to showcase their latest words of wisdom.

Finally, this issue will finish with a look to the future – arguably the most important section. That’s because while we can be nostalgic about the past, Electrical Review will always have one eye on the future and the technologies that will unlock it.

As part of looking to the future, we’ve highlighted some key technologies that are in early development but are likely to transform the world. To showcase those technologies, we’ve asked some of the brightest minds from across the industry for their insights into the challenges involved with developing new technologies and how exactly they will transform humanity.

You can find out where to locate everything in the 150th Anniversary Edition in the Contents on the next page.

It’s been quite a year for the electrical industry and the UK as a whole — so let’s reminisce with the Top 10 news stories from the Electrical Review website in 2022.

Our columnist returns with some of the latest industry gossip.

The latest products that are on our radar.

To meet the looming challenges ahead, the industry needs to come together and collaborate, something Morten Weirod, President of ABB Electrification, is a big proponent of.

With the ban on fossil fuel cars just around the corner, electric vehicles continue to evolve, as Martin Boughtwood of DG Innovate discusses.

Sam Strivens, the Carbon Trust’s Floating Wind Senior Manager, highlights the important role floating wind will have on the decarbonisation of the electricity sector.

It may not be the fuel of choice for cars, but hydrogen could have a massive impact on helping data centres decarbonise, as Roberto Castaldini from Vertiv explains.

Damian Lewis, Market Development Manager, Enterprise at Inmarsat, describes why satellite-enabled IoT devices could have a large impact on the electrical industry.

The world is flipping the concept of a hydroelectric dam on its head, with pumped hydro energy storage. Find out how Sunshine Hydro puts the technology into practice.

How are DNOs keeping pace with decarbonisation efforts? Paul Jewell and Jonathan Berry from National Grid Electricity Distribution have the answers.

An autonomous grid is in our future thanks to the growing challenge of balancing unpredictable demand with variable supply, as Gavin Doyle from Cambridge Consultants explains.

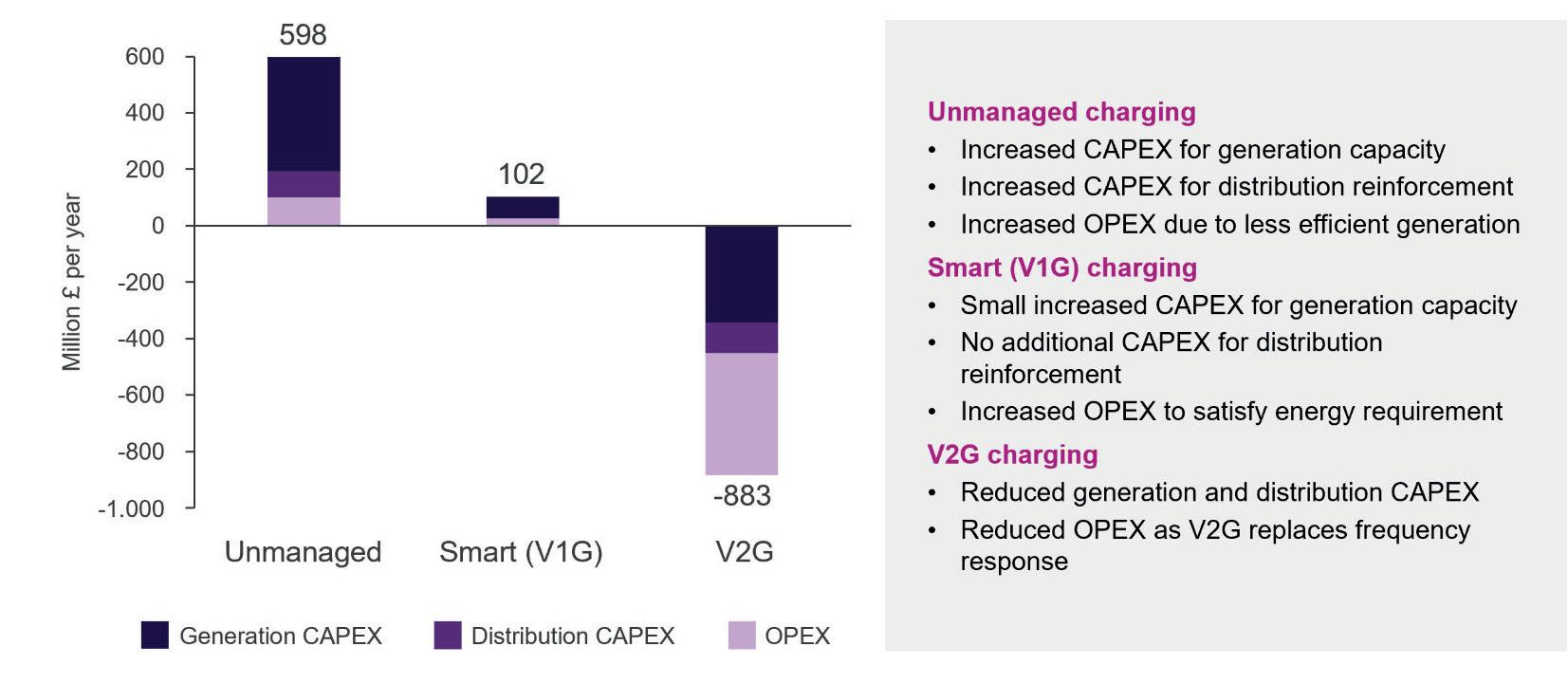

Could V2G technology actually help manage a grid reliant on renewables? The experts from Charles River Associates (CRA) weigh in.

PastWhile former President Thomas Jefferson noted that he preferred the “dreams of the future better than the history of the past,” it’s important to know one’s history to ensure that we keep moving forward.

History has a lot to teach us – it’s a guide to the future, ensuring we learn from our mistakes and allowing us to ensure that the generations that come next benefit from the hard work that we’ve put in.

Without knowing our history, it’s possible that the rate of innovation would significantly slow – after all, many of the world’s greatest discoveries have often come off the back of something else.

That’s why while the future may be exciting, it’s important to keep one eye on the past and where we came from. For 150 years, Electrical Review has been at the forefront of the electrical industry, reporting on its highs and its lows. To celebrate this milestone anniversary, it’s time that we honour that history.

In this section, we will highlight some of the top technologies that have shaped the world that we currently live in, as well as report on Electrical Review’s role within the industry over the last 150 years.

From the beginning of Electrical Review and electrical engineering in 1872 to where we are today. Join us on this journey as we break down this very special history.

Communication has been key to the development of humanity since its very beginning. From early humans who leveraged cave drawings to get their message across, to the invention of the modern alphabet by the Phoenicians, human civilisation has been pushed forward through advancements in our ability to communicate.

While each advancement in communication had a major impact on the development of society, none had as large of an impact as the electrical telegraph. This was a technology that enabled communication across continents and oceans almost instantly, heralding a new era of globalisation.

However, the electrical telegraph did not only transform the way in which we communicated, but it also ushered in a new science that would change the world – electrical engineering.

The electrical telegraph was a simple concept – you could send messages over long distances by making and breaking an electrical connection, as long as you encoded that message in a way that could be decoded on the other end.

Of course, the code most commonly associated with electrical telegraphy is Morse code. You could make an electrical connection and quickly break it, making a dot, or make an electrical connection, leave it and then break it, making a dash. At the other end, those dots and dashes could then be converted into the alphabet, allowing the receiver to decode a message.

It was a revolutionary concept, although it required skilled operators on either side of the telegraph to ensure they could encode and decode the right message. An inexperienced operator could easily send or receive the incorrect message, which could have disastrous consequences.

Thankfully, innovations would make sending and receiving messages on the electrical telegraph easier than ever – but in order to share ideas and create these innovations, the industry needed a public platform. One they would soon receive.

In November 1872, The Telegraphic Journal would be published for the first time. In that very first issue, it detailed its surprise at the absence of a journal considering both the scientific and commercial aspects of telegraphy within the United Kingdom.

This surprise was not completely unfounded. In the nineteenth century, the United Kingdom had created the world’s first commercial telegraph company, with the country continuing to be dominant in the world of telegraphy well into the twentieth century. In fact, by the 1872 launch of The Telegraphic Journal, there would be electrical telegraph cables to almost all corners of the globe, including India, the United States, and even Australia.

And yet, while those in the United Kingdom would be regarded as the foremost experts in the manufacture of telegraphic lines and cables for the world – the global standard – the industry had no journal within the UK that would detail its development. Instead, many looked to foreign journals, which had to be translated to English.

Of course, with the creation of The Telegraphic Journal, the industry would finally find its voice within its home country. Eminent electricians and scientists would have a local platform in which to push the industry forward, as well as identify commercial opportunities.

While the industry within the United Kingdom was on an upward trajectory before the launch of The Telegraphic Journal, this new publication gave it a platform to share ideas and to push innovation to new heights. In fact, by 1896, there were 30 ships lying telegraphic cables across the globe, with 24 of them were owned by British companies

But it wasn’t just about laying new cables, as the industry also needed to make using the electrical telegraph more intuitive. While experienced operators were able to encode and decode Morse code at speed, those with less experience had limits on how quickly they could send or receive messages.

Innovations would improve the speed in which these messages were sent. Charles Wheatstone’s ABC system in 1840 was the first system that did not require skilled technicians to operate. Instead it relied on the alphabet arranged in a clock-face style, with a needle receiving the signal and rotating to the letter that was being sent. This system meant that the receiving operator need only write down each letter, rather than trying to decode the message that was being sent.

Charles Wheatstone’s ABC system meant that telegraphers could now receive as much as 15 words per minute, which while still slow by modern day standards, was much faster and simpler to use than what had come before.

The printing telegraph would be the next major development, as it allowed operators to simply type the message that they wanted to send using a 26 key keyboard. While this made it easier for the sending operator, the receiving end would be the biggest beneficiary as they had a fully automated recording process – meaning the receiving operator needn’t decode the message in realtime. This was the biggest problem associated with Wheatstone’s ABC system, and led to David Edward Hughes’ printing telegraph becoming the accepted standard around the world.

However, while the technology was advancing at pace; telegraphy was about to be transformed by a simple change that would resonate for generations to come.

While the technology behind the electrical telegraph was significant, it was made possible thanks to the invention of the Morse code. However, Morse code would later be replaced by the Baudot code.

The Morse code relied on dots and dashes for each letter, with the letter e, for instance, represented by using one simple dot. However, the Baudot code changed this by using binary – each letter would be represented by a series of five bits. The benefit of Baudot’s code was that it was a fixed length, whereas Morse was variable.

Baudot developed a machine for sending his code using a keyboard with five keys, with the operator simply pressing down the keys that would create the corresponding letter. Once the keys had been pressed, they were locked down until mechanical contacts in a distributor unit passed over the sector connected to that particular keyboard, at which time the keyboard was unlocked ready for the next character to be entered.

Using this method, operators could easily send messages, which included punctuation, numbers or letters. These were just encoded in a binary language, which would then need decoding.

12 Electrical Review | 150th Edition

translate

the following message from:

HOW TELEGRAPHY IS STILL WITH US TODAY

In the introduction to this issue of Electrical Review, I noted how electricity is something that we couldn’t imagine our lives without, but before the electrical telegraph, few knew of its potential. In fact, it was English scientist Francis Ronalds, the inventor of the first working electric telegraph over a substantial distance, who noted that the world could be transformed by electricity. How right he was.

Telegraphy created the industry of electrical engineering, and the technology would spur the development of other uses for electricity. The Telegraphic Journal was first published in 1872, but it wasn’t until 1882 that we would see Edison’s first large-scale electric power network that provided 110 volts, or 1888 until we’d see the radio, or even the television in 1931.

It’s hard to understate the role telegraphy has had on the development of electricity and how even in 1872, the very first contributors to The Telegraphic Journal had no idea what would come of the future of this simple invention.

ASCII, which is the code that most current-day devices use for text, is a descendant of Baudot.

In the 1800s, electrical engineering was just beginning to bear fruits for humanity, with the electrical telegraph having transformed the way in which we communicate. However, the fascination with electricity would only grow, with many who had tinkered in the telegraphic space, also discovering other uses for electricity.

People such as Charles Wheatstone and David Edward Hughes had improved upon the electric telegraph, but their fascination with electricity would lead them to experiment with other uses.

For Wheatstone, he would be fascinated by the fact that sound was propagated by waves or oscillations of the atmosphere. It led him to believe that it was possible to transmit sound signals, music, or speech to long distances by this means. He conducted an experiment of his theory by using two slender rods, which conveyed mechanical vibrations to both ears – which he dubbed the microphone.

The only problem with Wheatstone’s invention is that the sounds would not exactly be accurate to what was being transmitted and would only convey a feeble sound. His experimentation also came before his fascination with electricity, so relied on mechanical means of transmission, rather than the use of electricity.

Thankfully, in 1878, David Edward Hughes would demonstrate an improvement upon Wheatstone’s theory using electricity.

It’s important to note that the invention of the microphone is a controversial one, and this publication documented this controversy in its July 1, 1878 edition. But before we get there, we should detail exactly how the microphone came to be.

In 1861, Johann Philipp Reis successfully designed and built a device to convert sound into electrical signals. These signals were then transmitted through a conductive wire to a similar device that converted them back into sound. If you want to be technical, you could note that the Reis telephone was the first microphone, as it converted mechanical wave energy into electrical energy to produce audio.

However, the Reis telephone was instrumental in helping develop Alexander Graham Bell’s telephone, which would represent the next major step in the development of a device to transmit audio. Bell had seen Reis’ telephone, but had noted its poor sound quality, as the voice transmission lacked clarity. He wanted to improve upon Reis’ design for his own telephone.

Bell was able to improve on the design by using a liquid transformer, also known as a water microphone. Essentially it was a metal clip filled with water and a small amount of sulphuric acid, with the acid key to making the liquid electrically conductive.

The water microphone was more technically advanced than the Reis telephone, as it enabled clear speech at the other end of the line, but there was one key problem identified by Thomas Edison – the use of water and sulphuric acid made the device commercially impractical.

So, like any great inventor, Edison got to work on his own alternative to the water microphone. Coincidentally, Edison wouldn’t be alone in coming up with an alternative, with David Edward Hughes also independently developing his own solution.

Both Edison and Hughes would turn to carbon to develop their microphone, which was dubbed the carbon microphone.

The carbon microphone is a variable resistance device that turns sound waves into electrical audio signals. It consists of two metal plates separated by carbon granules. One plate is thicker and stationary, while the other plate is very thin and acts as a diaphragm. Varying sound pressure (sound waves) at the diaphragm causes it to vibrate and exert varying pressure on the carbon granules. This, in turn, causes a changing electrical resistance between the plates.

A steady DC voltage is applied across the plates. The varying resistance between these plates causes modulation in the current that coincides with the diaphragm movement.

It was a genius invention and was much more commercially viable than previous designs, while also having far greater intelligibility. At one point Alexander Graham Bell bought the patent to the design for use within his telephone, which as we all know would go on to change the way we communicate once again.

The carbon microphone was so successful that it would be used by the majority of telephones until the 1980s, when electret microphones began to take over. But while the technology was revolutionary, as previously mentioned, it was beset with controversy.

Thomas Edison, David Edward Hughes and Emile Berliner all had a stake in the invention of the carbon microphone. Hughes had reportedly been working on his device in England completely independently of Edison and Berliner, who were working collaboratively on the carbon microphone in the United States.

However, things would turn ugly when the two different groups would reveal their technologies to the public, with Edison running a smear campaign against Hughes in the American press, accusing Hughes of stealing his and Berliner’s technology. Naturally, as the preeminent electrical journal of its time within the United Kingdom, Electrical Review leapt to the defence of David Edward Hughes.

The July 1, 1878, edition of The Telegraphic Journal and Electrical Review read:

“As soon as the details of the microphone of Professor Hughes were published to the world, it was seen by those who were familiar with Edison’s Carbon Telephone, that the two inventions were closely allied; and we are hardly surprised to learn that Mr. Edison has set up acclaim for priority of invention of the microphone.

“Following a practice of his country, one of those admirable institutions we are sometimes called upon to admire, but which we are happy to say is not yet introduced amongst us, he has rushed into the public press and made his complaint there.

“Starting with the assumption that the microphone is essentially identical with the carbon telephone, his case is that Mr. W. H. Preece has committed a breach of confidence, inasmuch as Mr. Edison, at the desire of Mr. Preece has kept the latter au courant with his inventions and experiments, including the carbon telephone, ever since they met in America last year.

“The Washington Star, of April 19, containing an account of his carbon telephone and thermopile, was sent by Mr. Edison to Mr. Preece, together with letters from time to time, and Mr. Edison has concluded that Mr. Preece betrayed his confidence to Professor Hughes, ‘I regard the conduct of Mr. Preece in this matter,’ says Edison in the New York Tribune, of June 8, ‘as not merely a violation of my rights as an inventor, but as a gross infringement of the confidence obtained under the guise of friendship.’

“Telegrams to a similar effect have also been sent by Edison to Sir William Thomson, and to Mr. Preece himself, calling upon him to set the matter right with details. We deplore the hastiness with which these communications have been made public by Mr. Edison, and take slight exception to the language in which they are couched.”

While it’s undeniable that Edison was working on a carbon microphone, Hughes had been entirely independent in his development. As highlighted in that edition of Electrical Review:

“It is no secret that Professor Hughes, after making the first articulating microphone, went on in a truly scientific manner, maturing the subject for three months more, ‘ere he communicated his results to anyone at all.

“The fact that no patent has been taken out, and no gain desired, is an argument in itself against the charge.”

David Edward Hughes himself would write to The Telegraphic Journal and Electrical Review disputing Edison’s charge, noting that Edison’s claims of completely inventing the technology from the ground-up were complete fabrications. In fact, much of the technology found within the carbon microphone was already widely spoken about within European circles.

He noted, “The use of carbon, as a varying resistance with varying pressure, is not original with Mr. Edison. Mr. Clerac, Electrician of the French Telegraph Department, supplied me with resistance tubes founded upon this principle in 1866, viz., a glass tube containing powdered carbon, the resistance of which was regulated by the varying pressure of a regulating screw pressing on the carbon.”

Ultimately history would prove that David Edward Hughes would be the first to demonstrate a working carbon microphone to the public, opting against filing a patent, noting it to be a ‘gift to the world’. However, Edison would later reap the rewards of the invention.

Emile Berliner would originally have the patent for the carbon microphone, which was later sold to Alexander Graham Bell for $50,000, which would be equivalent to almost $1.5 million today. However, Edison, unhappy with this, would challenge the patent in the US legal system, and in 1892 be awarded the patent by the United States Supreme Court in a controversial decision.

In the end, David Edward Hughes would move on to discovering other technologies, with many regarding him as an early pioneer in developing radio – some nine years before radio would even become a thing.

There’s a phrase that many of us are familiar with in today’s vernacular – ‘keeping the lights on’. It denotes the bare minimum effort that someone can put in to ensure that something continues running without great expense. It also showcases that when you cut away all the uses of electricity, arguably the most important for humanity is keeping the lights on.

While many in 2022 are worried about rising energy bills and the potential for blackouts threatening their ability to keep the lights on, when The Telegraphic Journal and Electrical Review first launched 150 years ago, electric lighting was yet to go mainstream.

In fact, when this publication was first published, it’s likely that the majority of homes and offices throughout the UK were still relying on oil lamps for their source of lighting – with some utilising gas lamps, like the newly-built Palace of Westminster that finished construction in 1876.

However, as electricity was beginning to transform the way we communicate with the electrical telegraph, it was also beginning to be thought of as a method for lighting. In fact, it had already been proved effective as a lighting tool as far back as the year 1800, when Humphry Davy showcased the arc lamp for the first time.

There would be some key problems associated with the arc lamp, however. When Davy showcased his electric lamp at the Royal Society in London, it would reach a brightness of over 10,000 lumens. To put that in perspective, the average light bulb today aims for around 1,600 lumens.

Additionally, while arc lighting would shine bright, it wouldn’t last very long. In fact, early arc lamps would last fewer than 100 hours, while also being messy, expensive, noisy and only capable of being used outdoors. Thus, the world wasn’t yet ready for electric lighting.

This would begin to change as the 1800s ticked by, with Paris becoming one of the first cities in the world to experiment with electric lighting. The problem with the implementation, however, came from cities’ inability to reliably produce enough electricity for these lights. After all, there would be no purpose-built power stations until at least the latter half of the 1800s.

Thankfully, when power stations began to be built, there was a new lighting solution available on the market.

When it comes to having bright ideas, it’s often regarded as a ‘light bulb’ moment. Well, that light bulb moment came for Joseph Swan in 1879, when he would reveal a new type of lighting solution – the incandescent light bulb. This used a carbon filament as opposed to relying on an electrical arc.

Ironically, in the US, Thomas Edison was also looking at creating this kind of technology. Thankfully, unlike the bitter battle Edison had with his fellow inventors when it came to the carbon microphone, Edison would later work with Swan, creating the Edison and Swan Electric Light Company.

Newcastle would become one of the first cities in the world to benefit from this new invention, with Swan demonstrating the technology by lighting up one of the city’s streets in 1879. However, like the arc lighting that came before it, the incandescent light bulb suffered from a serious issue – the filament would only last 40 hours.

The technology would later become more reliable and become a new standard for how people would light their homes and businesses. However, it would also spark the need for one of the most important developments in the proliferation of technology – power stations.

Edison knew that if electric lighting was going to take off, people needed to be connected to a source of electricity, as homes and businesses couldn’t be expected to produce all their own power. Not everyone could build a hydro-electric power station on their country estate in Cragside like William, Lord Armstrong, after all.

To meet this need, Edison built the world’s first public power station, which was located in London. It was dubbed the Holborn Viaduct power station, or as it was otherwise known, the Edison Electric Light Station. It officially began running January 12, 1882, burning coal to drive a steam turbine which drove a 27-tonne, 125 horsepower (93 kW) generator, producing direct current electricity at 110 volts.

This station was necessary in London as the city had installed electric street lighting in the form of 968 16-candle incandescent lamps, which lit up the street from Holborn Circus to St Martin’s Le Grand. The installation of the power station was so successful, that the project was later expanded to 3,000 lamps.

However, despite the success, the power station could not be expanded due to it being located on property owned by Queen Victoria. Without expansion, the generator could only produce so much power, and it ended up costing more to run that it was making. While it had proven that the concept of generating power on a large scale was possible, the project would be closed in September 1886 owing to financial difficulties, with the street lights converted back to gas.

But while the Holborn Viaduct power station would fail due to financial issues, it would receive a sister power station across the pond in New York City, dubbed the Pearl Street Station. Pearl Street Station was fired by coal; it began with six dynamos, and it started generating electricity on September 4, 1882, serving an initial load of 400 lamps at 82 customers. However, unlike its London counterpart, Pearl Street had room to grow.

The station was originally powered by custom-made Porter-Allen high-speed steam engines designed to provide 175 horsepower at 700 rpm, slightly more than the Holborn Viaduct, but these proved to be unreliable with their sensitive governors. They were removed and replaced with new engines from Armington & Sims that proved to be much more suitable for Edison’s dynamos.

This enabled Pearl Street to serve 508 customers with 10,164 lamps by 1884, and while the Pearl Street project was not an immediate financial success, it conclusively proved that Edison’s system worked and demonstrated the enormous benefits of comprehensive electrification.

Towns and cities across the world began licensing the technology that Edison had demonstrated at his Holborn Viaduct and Pearl Street power stations, which would lead to proliferation of electricity on a local level. However, to truly go global, George Westinghouse’s approach to using alternating current and a transformer would prove far more successful. However, we’ll discuss that in another article.

While Edison had pioneered a new type of electric lighting that would endure until this very day, nearly 150 years later, his technology is unlikely to last much longer. That’s due to the world’s push for efficiency, something that was not on the agenda back in 1879 – especially considering that incandescent bulbs waste 90% of the energy inputted through heat, with just 10% being converted to visible light.

Thankfully Oleg Losev, a Russian scientist, would come up with a solution in 1927. He is often credited as the inventor of the light-emitting diode, also known as LED, although found no practical use for it in the 1920s. It wouldn’t be until 1962 that Nick Holonyak, Jr. would invent the first LED that produced visible, red light while working at General Electric. However, red light was still not a replacement for the incandescent light bulb, requiring more development.

The beginnings of the LED lamps we know today came in 1994, when Shuji Nakamura of Nichia Corporation demonstrated the first high-brightness blue LED. This directly led to the development of ‘white LED’, utilising a phosphor coating to partially convert the emitted blue light to red and green frequencies, creating a light that appears white. A discovery that would eventually lead to a Nobel Prize in Physics in 2014.

And yet, 1994 was still too early for LEDs to go mainstream, with the first examples of early adopters not happening until after the turn of the millennium. A factory in Wisconsin would convert in 2008, albeit at an initial cost that was three times that of a traditional mix of incandescent and fluorescent lamps.

“

While Edison had pioneered a new type of electric lighting that would endure until this very day, nearly 150 years later, his technology is unlikely to last much longer

However, thanks to the change, the factory estimated that it would make the initial cost back within two years via electricity savings, and the lamps would not need replacing for 20 years. That’s because LED lights are capable of converting 90% of the consumed energy into light, significantly more than incandescent bulbs.

While it’s crazy to think that nearly 150 years have passed and we’re only now beginning to fully phase out Edison and Swan’s invention, it also demonstrates the impact these early technol-

ogies had on humanity. After all, the carbon microphone stuck around until the 1980s, while the world’s last commercial electric telegraph system, India’s state-run Bharat Sanchar Nigam, Ltd, shut down in 2013.

Here you will find an unedited article from Nikola Tesla from the March 6, 1891 edition of The Telegraphic Journal and Electrical Review.

In the Electrical Engineer of June 10th, I have noted the description of some experiments of Prof. J. J. Thomson, on the “Electric Discharge in Vacuum Tubes,” and in your issue of June 24th, Prof. Elihu Thomson describes an experiment of the same kind. The fundamental idea in these experiments is to set up an electromotive force in a vacuum tube – preferably devoid of any electrodes – by means of electro-magnetic induction, and to excite the tube in this manner.

As I view the subject, I should think that to any experimenter who has carefully studied the problem confronting us and who has attempted to find a solution of it, this idea must present itself as naturally, as, for instance, the idea of replacing the tinfoil coatings of a Leyden jar by rarefied gas and exciting luminosity in the condenser thus obtained by repeatedly charging and discharging it.

The idea being obvious, whatever merit there is in this line of investigation must depend upon the completeness of the study of the subject and the correctness of the observations.

The following lines are not penned with any desire on my part to put myself on record as one who has performed similar experiments, but with a desire to assist other experimenters by pointing out certain peculiarities of the phenomena observed, which, to all appearances, have not been noted by Prof. J. J. Thomson, who, however, seems to have gone about systematically in his investigations and who has been the first to make his results known.

These peculiarities noted by me would seem to be at variance with the views of Prof. J. J. Thomson, and present the phenomena in a different light.

My investigations in this line occupied me principally during the winter and spring of the past year. During this time many different experiments were performed, and in my exchanges of ideas on this subject with Mr. Alfred S. Brown, of the Western Union Telegraph Company, various different dispositions were suggested which were carried out by me in practice.

Fig. 1 may serve as an example of one of the many forms of apparatus used. This consisted of a large glass tube sealed at one end and projecting into an ordinary incandescent lamp bulb. The primary, usually consisting of a few turns of thick, well-insulated

copper sheet was inserted within the tube, the inside space of the bulb furnishing the secondary.

This form of apparatus was arrived at after some experimenting and was used principally with the view of enabling me to place a polished reflecting surface in the inside of the tube, and for this purpose the last turn of the primary was covered with a thin silver sheet.

Fig. 1.

In all forms of apparatus used there was no special difficulty in exciting a luminous circle or cylinder in proximity to the primary.

As to the number of turns, I cannot quite understand why Prof. J. J. Thomson should think that a few turns were “quite sufficient,” but lest I should impute to him an opinion he may not have, I will add that I have gained this impression from the reading of the published abstracts of his lecture. Clearly, the number of turns which gives the best result in any case, is dependent on the dimensions of the apparatus, and, were it not for various considerations, one turn would always give the best result.

I have found that it is preferable to use in these experiments an alternate current machine giving a moderate number of alternations per second to excite the induction coil for charging the Leyden jar which discharges through the primary—shown diagrammatically in fig. 2—as in such case, before the disruptive discharge takes place the tube or bulb is slightly excited and the formation of the luminous circle is decidedly facilitated. But I have also used a Wimshurst machine in some experiments.

Fig. 2.

Prof. J. J. Thomson’s view of the phenomena under consideration seems to be that they are wholly due to electromagnetic action. I was, at one time, of the same opinion, but upon carefully investigating the subject I was led to the conviction that they are more of an electrostatic nature. It must be remembered that in these experiments we have to deal with primary currents of an enormous frequency or rate of change and of a high potential, and that the secondary conductor consists of a rarefied gas, and that under such conditions electrostatic effects must play an important part.

In support of my view I will describe a few experiments made by me. To excite luminosity in the tube it is not absolutely necessary that the conductor should be closed. For instance, if an ordinary exhausted tube (preferably of large diameter), be surrounded by a spiral of thick copper wire serving as the primary, a freely luminous spiral may be induced in the tube, roughly shown in fig. 3.

In one of these experiments a curious phenomenon was observed; namely, two intensely luminous circles, each of them close to a turn of the primary spiral, were formed inside of the tube, and I attributed this phenomenon to the existence of nodes on the primary.

The circles were connected by a faint luminous spiral parallel to the primary and in close proximity to it. To produce this effect I have found it necessary to strain the jar to the utmost. The turns of the spiral tend to close and form circles, but this, of course, would be expected, and does not necessarily indicate an electro-magnetic effect; whereas the fact that a glow can be produced along the primary in the form of an open spiral argues for an electrostatic effect.

In using Dr. Lodge’s recoil circuit, the electrostatic action is likewise apparent. The arrangement is illustrated in Fig. 4. In his experiments two hollow exhausted tubes H H were slipped over the wires of the recoil circuit and upon discharging the jar in the usual manner luminosity was excited in the tubes.

Fig. 3.

Fig. 4.

Another experiment performed is illustrated in Fig. 5. In this case an ordinary lamp-bulb was surrounded by one or two turns of thick copper wire P and the luminous circle L excited in the bulb by discharging the jar through the primary. The lamp-bulb was provided with a tinfoil coating on the side opposite to the primary and each time the tinfoil coating was connected to the ground or to a large object the luminosity of the circle was considerably increased. This was evidently due to electrostatic action.

In other experiments I have noted that when the primary touches the glass the luminous circle is easier produced and is more sharply defined; but I have not noted that, generally speaking, the circles induced were very sharply defined, as Prof. J. J. Thomson has observed; on the contrary, in my experiments they were broad and often the whole of the bulb or tube was illuminated; and in one ease I have observed an intensely purplish glow, to which Prof. J. J. Thomson refers. But the circles were always in close proximity to the primary and were considerably easier produced when the latter was very close to the glass, much more so than would be expected assuming the action to be electromagnetic and considering the distance; and these facts speak for an electrostatic effect.

Furthermore I have observed that there is a molecular bombardment in the plane of the luminous circle at right angles to the glass – supposing the circle to be in the plane of the primary – this bombardment being evident from the rapid heating of the glass near the primary. Were the bombardment not at right angles to the glass the heating could not be so rapid. If there is a circumferential movement of the molecules constituting the luminous circle, I have thought that it might be rendered manifest by placing within the tube or bulb, radially to the circle, a thin plate of mica coated with some phosphorescent material, and another such plate tangentially to the circle. If the molecules would move circumferentially, the former plate would be rendered more intensely phosphorescent. For want of time I have, however, not been able to perform the experiment.

Another observation made by me was that when the specific inductive capacity of the medium between the primary and secondary is increased, the inductive effect is augmented. This is roughly illustrated in Fig. 6. In this case luminosity was excited in an exhausted tube or bulb B and a glass tube T slipped between the primary and the bulb, when the effect pointed out was noted. Were the action wholly electromagnetic no change could possibly have been observed.

I have likewise noted that when a bulb is surrounded by a wire closed upon itself and in the plane of the primary, the formation of the luminous circle within the bulb is not prevented. But if instead of the wire a broad strip of tinfoil is glued upon the bulb, the formation of the luminous band was prevented, because then the action was distributed over a greater surface. The effect of the closed tinfoil was no doubt of an electrostatic nature, for it presented a much greater resistance than the closed wire and produced therefore a much smaller electromagnetic effect.

Some of the experiments of Prof. J. J. Thomson also would seem to show some electrostatic action. For instance, in the experiment with the bulb enclosed in a bell jar, I should think that when the latter is exhausted so far that the gas enclosed reaches the maximum conductivity, the formation of the circle in the bulb and jar is prevented because of the space surrounding the primary being highly conducting; when the jar is further exhausted the conductivity of the space around the primary diminishes and the circles appear necessarily first in the bell jar as the rarefied gas is nearer to the primary. But were the inductive effect very powerful they would probably appear in the bulb also. If, however, the bell jar were exhausted to the highest degree they would very likely show themselves in the bulb only, that is, supposing the vacuous space to be non-conducting. On the assumption that in these phenomena electrostatic actions are concerned we find it easily explicable why the introduction of mercury or the heating of the bulb prevents the formation of the luminous band or shorten the after-glow; and also why in some cases a platinum wire may prevent the excitation of the tube. Nevertheless some of the experiments of Prof. J. J. Thomson would seem to indicate an electro-magnetic effect. I may add that in one of my experiments in which a vacuum was produced in the Torricellian method, I was unable to produce the luminous band, but this may have been due to the weak exciting current employed.

Fig. 5.

Fig. 6.

My principal argument is the following: I have experimentally proved that if the same discharge which is barely sufficient to excite a luminous band in the bulb when passed through the primary circuit be so directed as to exalt the electrostatic inductive effect — namely, by converting upwards — an exhausted tube, devoid of electrodes, may be excited at a distance of several feet.

Here’s something not many people know: Megger has been driving innovation in the electrical measurement sector for almost as long as Electrical Review has been published. Evershed & Vignoles, the company that became Megger, was founded in 1895, when Electrical Review was just 23 years old, and the Megger trademark was registered in 1903.

Right from the start, Megger was renowned for innovation. In the 1890s, electricity was starting to become widely adopted and there was an urgent need to ensure that installations were safe and reliable. That meant measuring insulation resistance – however up until this point it could only be done under laboratory conditions and with low voltages. Sidney Evershed discovered a better way, using a portable hand-cranked generator that could produce high test voltages in the field and a measuring instrument that was unaffected by external influences. This was the first Megger insulation resistance tester, and it laid the foundations for all modern insulation testing.

The first instruments had the measuring device and generator in separate boxes so that they could be spaced far enough apart to avoid the generator influencing the sensitive meter but, by 1903 the design had improved to the extent that only one box was needed. Hand-cranked Meggers were accurate, reliable and convenient – so much so that, even after almost 120 years, they’re still in production at the Megger factory in Dover to this day. The main market now is countries where batteries for modern electronic instruments may not be easy to obtain.

The Megger factory was originally located in London, but a new factory on the present site in Dover was built during the early 1960s. Initially, this was a satellite factory for the London operations but, after it had been substantially extended, almost all work transferred there in 1966. The extended factory was officially opened by Admiral of the Fleet, the Earl Mountbatten of Burma on 24th October 1966. Although it has undergone significant redevelopment and further extension, this factory is still in use today. The Dover site is also Megger’s world headquarters for low-voltage instrument development and design.

Inventing the first insulation tester is by no means Megger’s only early achievement; it is also responsible for the now ubiquitous multimeter. Until 1923, electrical engineers had to carry around a bag of separate instruments to enable them to measure current, voltage and resistance. Then Donald Macadie, a Post Office engineer, came up with the idea of a combination instrument – a multimeter – that would measure Amps, Volts and Ohms. The initial letters of these units gave the instrument its name – the AVO meter. A new company was formed to make these instruments, which ultimately became part of today’s Megger Group.

Instruments based on Macadie’s original design were still being manufactured in the Dover site until early in this century, when rising costs and falling demand ultimately made production uneconomic. During this long production life, many special-purpose AVO meters were produced but one in particular stands out: the Braille AVO meter for blind users. There must have been a demand for these instruments, or they wouldn’t have been made, but it’s interesting to speculate how users would have attached the test leads to the equipment under test…

Specialised instruments based on Megger insulation testers have also been produced, possibly one of the most memorable being the ‘pork resistance meter’ or, to give it its official name, the Meg Salinity Tester. Complete with a hand-cranked generator, just like a normal Megger, this instrument was used to measure the resistance of brined pork joints to determine whether the brine had penetrated sufficiently for the meat to be properly cured. Let no one say that Megger instruments aren’t versatile.

Over the years, other unusual products that have emerged from Megger’s Dover site have included photographic light meters, thermionic valve testers, signal generators for radio and television testing, and an extensive range of instruments for use in the nuclear industry. Today, however, the focus is firmly on instruments for low-voltage electrical applications, including the remarkable new MFT-X1 multifunction installation tester which was developed and is being manufactured in Dover.

Megger in Dover, and at its locations around the world, remains true to its history as an innovator in electrical testing, and the company holds a plethora of patents for developments in the testing of cables, circuit breakers, electrical installations, protective relay systems and more. It seems that some things definitely do get better with age, and two shining examples of this are undoubtedly Megger and Electrical Review!

Throughout this 150th Anniversary edition, we have spoken about Electrical Review’s role in reporting on major events within the electrical industry. It has helped usher in new technologies and was the journal of record for many of the world’s finest electrical engineers. Given Electrical Review’s stature within the industry, it’s not all too surprising to see the publication’s name come up in some important debates within the UK’s Houses of Parliament. We’ve collated some of the most interesting namedrops here.

One of Electrical Review’s first mentions in the Houses of Parliament would come from none other than future Prime Minister, Ramsay MacDonald. It occurred during a debate of the Coal Mines (Minimum Wage) Act of 1912.

This was an important bill that the Government reluctantly brought before Parliament due to the 1912 Miner’s Strike, which began at the end of February 1912. This was the first time miners in the UK had taken national strike action and it caused significant disruption, with almost one million miners taking part.

They ended up achieving their end goal of receiving a minimum wage due to the Coal Mines (Minimum Wage) Act 1912. However, during this debate, Ramsay MacDonald noted, “A six weeks’ partial strike – according to the Noble Lord’s own admission – on English railways would be such a very serious matter that if you could not stop it you could not boast very much of the legislation that failed. Those who read the ‘Times’ will see an interesting article, a column in length, on the fifth page this morning, regarding the failure of compulsory arbitration in New Zealand.

The United Kingdom Government recognised in the early 1960s that there were a number of agencies responsible for conducting civil scientific research, yet these were fragmented and responsibilities were divided. This was despite scientific research growing in importance for nations across the world.

The United Kingdom wanted to improve its focus on the development of science and technology, and thus proposed the Science Research Council and the Natural Environment Research Council. It would also establish a new Ministry of Technology, giving powers that were fragmented across multiple departments to the new Minister of Technology.

During the debate James Boyden, the Junior Minister for Education and Science, noted Electrical Review’s support for the proposals. He said, “I thought that the right hon. and learned Gentleman was not as comfortable as he looked.

“Certainly, this is a difficult problem. It is one which the Bill will do a good deal to remedy.

“I intended to give more elaboration of the support that we have found for the Bill. I give just one more instance, from a technical journal, the Electrical Review:

“‘It is clear that Mr. Cousins and his principal colleagues are not now wasting any time and they exhibit an impressive grasp of what is required of them in guiding and stimulating a major national effort to bring advanced technology and new processes to British industry.’”

The Electricity Act of 1989 introduced a brand-new levy paid by suppliers of electricity from non-renewable energy sources in the United Kingdom. Upon its introduction in 1990, the levy was set at 10.6%, but before it would reach Royal Assent, the levy was heavily debated upon in Parliament.

Rhodri Morgan, the soon-to-be First Minister of Wales, challenged the Conservative Government’s proposed fossil fuel levy, noting that it could be confusing for consumers. He commented, “An issue of Electrical Review that came out over Christmas carried the headline ‘Proposed Contracts are Riskless’. The description that the Minister has given is a perfect description of a contract that is riskless for the private sector. The electricity consumer will now have to pay the private generator to build private generating stations. If that is the purpose of the Bill, it is about time the consumer knew it.

“My hon. Friend the Member for Aberdeen, South (Mr. Doran) and I spent a long time examining Government amendments Nos. 36 to 43, and concluded that they showed that the nuclear levy is in serious trouble. The Government and the electricity companies do not know, and the consumer and the House certainly do not know, how the nuclear levy will work. It has been devised at a Sir Humphrey’s mad hatter’s tea party and the amendments show us all just how much trouble the levy is in and just how short a time the Government have left to get it right.

“The area boards do not know how the nuclear levy will be collected. They know only that the additional costs of nuclear production over coal production – which John Baker, the chief executive, told us would be 42 per cent. in the financial year that has just started – will be distributed in some way. The proposal cuts completely across the concept at the heart of the Bill and the Idea of direct contracts between generators and suppliers. It looks to us as though the Government are beginning to admit that they have devised a wholly unworkable system for collecting the levy.”

Electrical Review may have its eye on the electrical industry, but that doesn’t mean it hasn’t kept current with the happenings in its sister industry – gas. That’s why it’s no surprise that the publication was name dropped in a debate regarding the establishment of the British Gas Corporation.

The British Gas Corporation would replace the Gas Council, centralising control away from individual gas boards across the numerous regions across the UK. This was prior to privatisation, and would simply see a new Government Corporation take responsibility for the development and maintenance of the supply of gas to Great Britain.

Arthur Palmer, a Labour politician, was opposed to the creation of the British Gas Corporation, and he took to quoting Electrical Review’s editorial to make a point during a debate. He noted, “Many arguments have been used against this change. Even if one ignores the ever useful Mr. Kelf-Cohen –like Shakespeare, he is always quotable – one can turn to the Electrical Review, which might be thought a little biased but which has a strong point here. It has expressed the hope that this system will not be used for electricity supply. One of its reasons for deploring this change in the sister industry was:

“‘A loss will be that the Department of Trade and Industry will no longer have official contacts at the ‘grass roots’ or Board level, and instead of establishing its views on how the industry is being managed and operated from an amalgam of a wide range of opinions it will have to be content with a single industry view…’”

“We suggest that a little could be done in this way to maintain the local interest.

“This new organisation is likely to be too big for effective central management, and it will remove to a great extent local influences on policy and make the work of the consumer councils much more difficult. We suggest that the Amendment goes some way to removing the greatest objection to the legislation’s present form – that it over-centralises.”

Electrical Review was last quoted in the House of Commons in 2008 by none other than Colin Challen, a Labour politician who has said that “catastrophic destabilisation of global climate represents the greatest threat that humanity faces.”

During a debate on the Energy Bill, which would later become the Energy Act of 2008, another Labour politician had men-

tioned how Patrick Moore, the co-founder of Greenpeace, had changed his views on nuclear energy, remarking that “nuclear energy may just be the energy source that can save our planet from another possible disaster: catastrophic climate change.”

However, Challen disagreed with the suggestion that Moore be taken as an expert, quoting Electrical Review as a source. In his retort, he noted, “Patrick Moore’s name was prayed in aid last week, during the statement. Somebody kindly sent me a copy of the Electrical Review, volume 240, No. 4. An article in it states that Dr. Moore “wrote last year to the Royal Society arguing there was no ‘scientific proof’ that mankind was causing global warming”.

“Was that the kind of statement to which my hon. Friend referred?”

Some 50 years after the first issue of Electrical Review hit shelves, one man’s curiosity about the behaviour of electrical currents would spark the creation of a family legacy that would be placed firmly at the heart of the energy industry for generations to come – Socomec.

In 2022, Socomec, which was founded by Joseph Siat in 1922, celebrates its centenary – joining the inner circle of century-old French businesses. Ivan Steyert, the fourth-generation CEO of the company founded by his great-grandfather, shares his unique insight into the company’s heritage and its future direction.

Our story begins in the Alsace countryside in the spring of 1922, where my great-grandfather – textile engineer, Joseph Siat – experimented endlessly with electrical accessories in his rural workshop in the Bas-Rhin village of Benfeld. His curiosity was ignited by the unpredictability of electrical currents and his attention soon turned to switches, circuit breakers and other fuse-based solutions as he tried to reduce the variations in what was, at that time, still a poorly controlled current.

Socomec is now a young centenarian. This is a source of great pride because few companies reach this age with such demonstrable stability and with continued family shareholding. In the last 100 years, we have experienced war, with economic and political crises on a global scale, as well as facing new challenges in terms of the environment and our impact upon it, but we have been able to adapt and reinvent ourselves whilst retaining our values of independence, innovation and responsibility.

Our customers are our greatest inspiration – across the entire business. Our customers inform the way that we work across departments and, in turn, our development work draws on that in the widest possible sense.

Whether smart switches, modular measurement systems or UPS, the most sophisticated electrical and electronic equipment has been developed over the course of the last century to meet the security and continuity needs of critical installations, such as data centres, airports, healthcare settings and industrial infrastructure.

In more recent years, we have been developing progressive energy storage solutions to support the energy transition and the increasing use of renewable energies. In every critical setting – whether providing power, light or guaranteeing continuity of activity – Socomec provides truly innovative solutions that are adapted specifically for these vital installations.

How do you maintain such a strong sense of tradition whilst constantly innovating in a shifting landscape?

The political and economic landscape has altered beyond measure over the last century – and continues to change rapidly today.

Part of Socomec’s success lies in its combination of strong and stable foundations and its ability to be the master of its own destiny, whereby adaptability and innovation are part of the very fabric of the organisation.

What is the secret of such longevity? Above all, how can we make it last so that we can continue this wonderful adventure? There is no miracle or mystery ingredient.

Our stable and solid foundations allow us to move forward, to renew ourselves, to adapt to the transformation of our environment, of our markets, to differentiate ourselves through our expertise and through innovation. This is even more the case in the period we are going through now. Innovation will be the key to continuing this great adventure, both in our products and in our ways of working. Because energy matters and, together, we have plenty of it.

With a century of proven innovation to draw upon, and a culture of exploration and invention, it’s no surprise that Socomec continued to up the ante during what was a uniquely challenging year for every organisation around the world.

Driving innovation forward is one aspect of the process – but looking back is vital. By running a retrospective of innovation launched during 2021, for example, and reflecting on our work in this way we are able to help teams learn and adapt. It means that we can better understand what works well and what might need to change. Reviewing how we have innovated in the past helps us to innovate better for tomorrow.

Our customers are truly embedded in our ideation and development processes. It’s a really collaborative approach that ensures that we are delivering exactly what the customer needs – whilst also de-risking the development and speeding up time to market.

What’s more, we challenge everything in order to exceed expectations, whether that is process or strategy; by rigorously interrogating every aspect we are able to drive performance that much further.

Sometimes that means starting with a blank sheet of paper and sometimes it’s about taking a relatively simple and proven concept and introducing incremental changes that ultimately deliver something completely new. When these are changes that resolve your customers’ greatest issues, it’s possible to deliver unprecedented value.

Socomec’s centenary is a reflection of what has made us successful so far – strong values that have been shared by successive generations and working in the spirit of conviviality and sharing. We are driven by a common vision; one of mastering electrical energy by demonstrating responsibility, openness and commitment.

For a century, thanks to our employees, customers and partners, we have been able to meet our most critical technological challenges, standing the test of time and becoming a major player in the world of energy, today and tomorrow.

Socomec has celebrated throughout this exceptional year, marking the anniversary by giving employees the opportunity to complete 100 challenges that will unlock donations to charity.

Individual and team challenges united participants from across the business – and around the world, covering themes including, ‘knowing the company’, committing to more ecological and social practices, ‘moving your body’ to sporting challenges, ‘meeting and sharing’ to encourage working beyond borders and

‘celebrating’ to highlight the business’ accomplishments. In the UK one such event was a cycling challenge that took place over eight days between June 18th and 25th, with teams made up of both employees, as well as partner organisations including Arup, Durata, Paktronic, Yuasa, Lloyd Morris and Waldeck Consulting.

Research and development is in our DNA: we are always learning, always discovering and always innovating. Our AC and DC equipment combines our expertise in energy switching, measurement, conversion and storage, for energy that’s ever more available, secure, flexible and efficient – for example, our Diris Digiware DC range makes the metering, measurement and monitoring of DC electrical energy quality simpler than it’s ever been before.

Diris Digiware is a unique, fully digital, multi-circuit plug and play measurement concept that brings together groundbreaking digital electrical measuring technology – from sensors to software - to deliver an unrivalled degree of flexibility to installations.

In 1992, a young engineer tasked with launching electronic development within Socomec’s then switchgear division focused his research on electrical multi-measurement. The vision of that young engineer – Michel Krumenacker, who is now Deputy CEO at Socomec – opened an entirely new market for Socomec, setting the industry benchmark.

Over 20 years after having revolutionised the electrical multi-measurement market with our Diris meter, Socomec once again set the precedent in leading-edge power monitoring systems with the launch of the new Diris Digiware.

We know, however, that one size does not fit all, which is why our standard offer can be adapted to create tailor-made solutions. That’s also why we have created modular ranges of UPS equipment, for example.

With more than 20 years of experience in developing and supplying modular solutions, Socomec’s Modulys solutions provide the ultimate availability, scalability and extended lifetime to critical applications in IT infrastructures.

Based on proven technology – with several thousand modular systems in the field – the range has been described as the gold standard in terms of power scalability and risk-free maintenance in a truly online modular format.

By removing most of the risk and uncertainty often associated with new developments, and starting with the intrinsic value of products within our current range – combined with insight and expertise from the market – it has been possible to deliver something exceptional.

Because we include our customers in the development process – at every step along the way – we have been able to take all the knowledge of our big data centre technology and democratise that technology – making it accessible and relevant for every application.

For 100 years, our family-owned, independent group has been dedicated to the development of innovative solutions – solutions that we then adapt to our partners’ specific and most critical needs. We are resolute in that commitment – and we will be working side by side today and for the next 100 years.

Increasingly, we are deploying our resources to help our partners accelerate their energy transitions – to take advantage of all that renewable energy has to offer and to help find simple and pragmatic solutions to what can feel like complex challenges. We do this by combining our know-how and technologies – along with the sustainability of our products – to contribute to a more responsible world.

Leveraging strong historical expertise in both AC and DC power monitoring, power switching and conversion, Socomec has invested in energy storage applications since the early 2010s and has participated in a number of progressive experiments with major utilities, battery manufacturers, energy management software editors and pioneering energy storage system integra tors. The result is a range of innovative and proven solutions

for commercial and industrial buildings, isolated and resilient microgrids, renewable energy integration, mobile energy storage and electric vehicle charging infrastructure.

One such solution is Socomec’s SUNSYS – a native outdoor system that merges proven technologies to create an all-in-one solution that is greater than the sum of its parts. Safe and compliant, this system sets a new standard when it comes to safety. Whether peak shaving or load shifting, SUNSYS will deliver optimised savings plus a rapid return on investment while maximising renewable energy production.

The fact that we are an independent group means that we guarantee the control of all of our strategic and operational decisions – which are in keeping with the values forged by our family shareholding and members of staff. Our assets and approach allow us to create lasting value and sustainable growth for our shareholders, employees, customers and partners – as well as in relation to our wider society and the environment. We firmly believe that by taking control of all aspects of design and operation – as well as energy usage – it is possible to create reliable, sustainable solutions and build a better future for us all, starting now.

Most of us take for granted that a flick of a switch or press of a button turns on the lights, starts up a computer, or engages the EV charger, without ever thinking about where this electricity comes from, or how it is delivered.

The circuit breaker plays a critical role in energy distribution networks globally — mainly used in utilities, power generation and renewable applications, or substations in cities — because it protects electrical systems from damage by interrupting and safely re-establishing a disrupted current flow.

By way of example, medium voltage circuit breakers are installed in data centers around the world to ensure the highest data availability — and in a typical facility hosting 130,000 servers, a minimum of five circuit breakers protect the network.

If a power interruption occurs, a circuit breaker isolates the section of the network at risk within milliseconds — which is 10 times faster than the blink of an eye — to safeguard the energy flow. When this happens, the breaker is exposed to intense heat ranging from 5,000 degrees to 6,000 degrees Celsius, temperatures capable of melting rocks.

So, next time you settle down to watch your favorite TV show without any interruption, spare a thought for medium voltage circuit breakers, which are providing optimal power flow.

An early form of circuit breaker was described by Thomas Edison in an 1879 patent application, although his commercial power distribution system used fuses. Its purpose was to protect lighting circuit wiring from accidental short circuits and overloads.

In 1924, a miniature circuit breaker — similar to the ones now in use — was patented by a Swiss group of electrical engineering companies, Brown, Boveri and Cie (BBC), which in the intervening years became ABB.

However, it was German engineer Hugo Stotz — who sold his company to BBC in 1918 — and his chief engineer, Heinrich Schachtner, that were generally recognised as the inventors. Stotz and Schachtner’s version made the rapidly increasing electrification of private homes safer and more efficient and was the forerunner of the modern thermal-magnetic breaker commonly used in load centres to this day.

Incidentally, it’s Schachtner’s name that appears on the U.S. patent — No. 1,629,640 — for the miniature circuit breaker, issued May 24, 1927.

“My invention relates to automatic electric circuit breakers of the kind in which two contact pieces normally pressed together by springs are separated by the interposition of an insulating slide,” Schachtner wrote, according to the U.S. Patent Office document.

“When the overload in the apparatus ceases, switching-on can be affected by the mere pressure of the finger without the necessity of unscrewing the apparatus from its socket.”

Prior to circuit breakers, fuse technology was considered cutting-edge — where a metal wire melts when too much current flows through it — when it came to shielding buildings from electrical fires. The problem was the fuse had to be replaced every time there was a fault. Here’s where Stotz and Schachtner produced a revolution by combining thermal and magnetic trips into a single, reusable unit capable of switching off high currents without requiring devices to be replaced repeatedly.

The first serial production of the miniature circuit breaker began in 1928 at the Stotz facility in southern Germany and was met with immediate success, as its device could easily be screwed into the existing fuse base and no changes to the electrical installation were required.

Today, nearly every household is equipped with miniature circuit breakers to stop the flow of electricity, protecting people and equipment from electrical fire.

A small but essential piece of equipment — the humble circuit breaker — has long had the power to make a big impact across the electrification industry and to energy management in general, explains Sami Raitakoski, Global Head of ABB’s Control & Protection Products.

Being an inventor, Stotz and his team continued to push circuit technology further. In 1928 they developed a special circuit breaker for coping with loads of higher starting currents, including motor applications. This opened the door for industrial applications that nowadays can withstand the harshest of environments, such as dust, humidity and condensation.

Over the years ABB has produced more than a billion circuit breakers and continues to pioneer its evolution through commercial and industrial applications and digital technology. There are versions for an extensive range of requirements, including heavy industries like Oil and Gas plus Marine, as well as large switchgear designed to protect high voltage circuits feeding an entire city.

intelligent insight and data. Original equipment manufacturers and panel builders can now take advantage of smarter integrated and digitally enhanced circuit breakers — complete with Industry 4.0 level sensing technology — without having to completely change installations, make substantial investments or transform operations.

In today’s increasingly challenging times though, it must be about plug and play solutions that make switching to digital operations seamless, simple and cost effective — without having to completely change installations, make substantial investments or transform operations.

One of the first new generation circuit breakers is the VD4 evo, launched September 2022. Its design incorporates sensor enhancements for all thermal, mechanical and electrical parameters along with an advanced Central Monitoring Unit for 24/7, real-time analytics.

With key information delivered via a simple, intuitive dashboard, this approach enables improved visibility of equipment data, status and condition from anywhere in the world — and is completed with diagnostics reports and alarm notifications.

In fact, the MV VD4 circuit breaker has been the market benchmark for more than 35 years and today, with over 2 million units installed in 100+ countries, helps to bring secure power and energy to homes, businesses, and the infrastructure that keeps the world running.

It’s the model of choice for most modern electricity distribution applications, but since the mid-1980s this little, often overlooked gem, has been leading the way in power distribution for control and protection of cables, overhead lines, transformer and distribution substations, plus motors.

However, with demand for resilient power 24/7 accelerating at breakneck speed, even the small but perfectly formed circuit breaker has some limits in today’s world. Unfortunately, such is the demand for power, outages and supply shutdowns are still a concern for operators of medium and low voltage switchgear. Such scenarios are not only financially costly, but potentially damaging to corporate reputation too. And for many of these unwanted incidents, the origins are often unknown to the users and operators.

This is where circuit breaker technology has taken another leap into the 21st century through digitalisation, helping end users and system integrators unlock the value of their assets through

“ With demand for resilient power 24/7 accelerating at breakneck speed, even the small but perfectly formed circuit breaker has some limits in today’s world.

Alongside this, through technological enhancements it becomes easier to predict wear and tear and increase overall lifespan and output, helping to save thousands of dollars per solution when compared to traditional MV switchgear.

The result is a series of significant operational and financial benefits for end users, such as Utilities and Industries. Thanks to the ability to detect issue signals ahead of time, which reduces the risk of power outages by 30%, it is possible to achieve savings in the range of $10,000, depending on the application. It also increases operation and maintenance efficiency by as much as 60%, minimising Opex expenses.

While safety has been the critical driver behind circuit breaker technology since its invention, today, businesses of all sizes are also challenged with adopting sustainable operations. Taking the VD4 evo as an example, its ultra-compact design and energy efficient operation is fully Environmental Product Declaration (EPD) certified. It is 15% smaller and around 30% lighter compared to traditional MV breakers with consequent saving of more than $3,500 per switchgear on footprint square metre cost by itself.

As an essential component of digital switchgear, it also plays its part in helping to save up to 150 tons of CO2 emissions over a 30-year lifetime of a 14-panel unit — the equivalent to a million km in long haul economy flights.

Equally, the ability to make better decisions in all aspects of installation and repair work ensures advanced safety and protection for personnel and maintenance staff.

So, the humble but constantly evolving circuit breaker is now unlocking a more resilient, efficient, safer and environmentally sustainable power distribution network — by facilitating the transition to a brighter digital future.

In the modern smart grid concept, the role of the MV circuit breaker has evolved from a simple protection device to an active apparatus, able to interact directly with the main installation-specific electrical quantities and coordinate operations. Advancements in sensor technologies have paved the way for making the power grid more reliable, robust, and intelligent, while integration of the new generation of IoT sensor and control electronics is tangibly extending quality and operational performance of the apparatus, as well as opening up new business models.