Substation test solutions from Megger

Electric Vehicles

The Ordnance Survey gives an insight into how the UK’s EV infrastructure can be built to meet everyone’s needs.

Energy Storage, Standby Power & UPS

What are some of the key technologies that will fuel the energy transition?

& Sustainability

How Western Power Distribution, one of the UK’s largest DNOs, is cutting down its emissions.

Renewables

16 24 30 SUSTAINABILITY ISSUE 2022 Volume 256 | No 5 www.electricalreview.co.ukInforming the electrical industry for 150 years

Regulars

06

Comment

There’s no planet B, at least not yet.

08

12

38

sector.

Gossip

from our industry insider.

Talking Point

In this month’s Talking Point, Vattenfall Network Solutions maps out the top 10 reasons to upgrade your business’ HV electrical infrastructure.

40

Sponsored stories

All the products and industry news that you won’t want to miss.

Features

16

Electric Vehicles

Rollo Home, Head of Product at Ordnance Survey, explores how the UK can ensure that its EV infrastructure is built to meet the needs of everyone.

18

Energy Storage, Backup Power & UPS

Energy storage will be key in helping us transition to renewables, but Carlton Cummins from Aceleron discusses the importance of making sure that energy storage is more sustainable.

28

Renewables & Sustainability

What are some of the new technologies that optimise solar power generation? Griff Thomas from GTEC takes a look.

36

Smart Buildings

Pippa Boothman from Disruptive Technologies discusses the benefits of IoT sensors in making our buildings smarter than ever.

Contents 14 18 28 36 16 8

• Editor’s

• News Stories from the

• Gossage

The latest

•

•

•

•

•

•

+44 (0)

062

+44 (0)207 0622534

(0) 7741

Editor’s Comment

Welcome to the first ever Electrical Review Sustainability Issue. This is the first time we’ve dedicated an entire issue to all-things sustain ability and we couldn’t be happier with the support we’ve received from the industry.

Upon announcing the Electrical Review Sustainability Issue, we received huge interest from the industry, highlighting the importance of sustainability to the electrical sector in 2022. In fact, the two have become intrinsically linked, with the electrical industry set to play a major role in decarbonising the UK and the world as a whole.

In this issue, you will find tips on how to ensure an uninterruptible power supply is running efficiently, ways in which we can boost the EV charger rollout to meet the needs of all, and what the UK’s largest distribution network operator is doing to play its own part in achiev ing net zero. That’s not all, with contributors from the breadth of the electrical industry sharing their insights.

This year has brought the climate crisis into focus, with heatwaves across Europe and the worst drought for 500 years highlighting the need to act as soon as possible to limit global warming. While COP26 made good progress with promises, we’re hoping to see even more action at COP27 in Egypt later this year.

The electrical industry is uniquely placed to benefit from the world shifting to a more sustainable future, with the industry responsi ble for the installation of renewables, heat pumps, electric vehicle chargers, smart building technology, and so much more. This issue is a celebration of the unique role that our industry plays, and we really hope you enjoy it.

Plus, don’t forget that our next issue will officially celebrate Electri cal Review’s 150th Anniversary. For those of you subscribed to our digital edition, you may want to consider registering for a printed copy – as this will be a very special collector’s edition. More will be shared about this issue in due course, but we thought we’d just give you the heads up!

Jordan O’Brien,

Jordan O’Brien,

6 www.electricalreview.co.uk ????Electrical Review | July / August 2022

Editor EDITOR Jordan O’Brien jordano@sjpbusinessmedia.com CONTRIBUTING EDITOR Kayleigh Hutchins kayleigh@datacentrereview.com DESIGN & PRODUCTION Alex Gold alexg@sjpbusinessmedia.com GROUP ACCOUNT DIRECTOR Sunny Nehru

207

2539 sunnyn@sjpbusinessmedia.com ACCOUNT MANAGER Kelly Baker

kellyb@electricalreview.co.uk GROUP COMMERCIAL DIRECTOR Fidi Neophytou +44

911302 fidin@sjpbusinessmedia.com PUBLISHER Wayne Darroch Printing by Buxton Paid subscription enquiries: subscriptions@sjpbusinessmedia.com SJP Business Media 2nd Floor, 123 Cannon Street London, EC4N 5AU Electrical Review is a controlled circulation monthly magazine available free to selected personnel at the publisher’s discretion. If you wish to apply for regular free copies then please visit: www.electricalreview.co.uk/register Electrical Review is published by 2nd floor, 123 Cannon Street London, EC4N 5AU Any article in this journal represents the opinions of the author. This does not necessarily reflect the views of Electrical Review or its publisher – SJP Business Media ISSN 0013-4384 – All editorial contents © SJP Business Media Follow us on Twitter @elecreviewmag Join us on LinkedIn

Sweden overtakes France as Europe’s biggest net power exporter

Sweden was the biggest net exporter of power in Europe during the first half of 2022, overtaking France, according to a new report from EnAppSys.

France has long been a major exporter of power in the European market, with a fleet of nuclear power stations generating a stable surplus of electricity. However, that’s beginning to change, with France shifting from a net exporter earlier in the year to a net importer.

This fall from grace for France has, ironically, been blamed on its nuclear power station fleet, which is beginning to show signs of age and unreliability. In fact, the country has found several structural problems at its nuclear power stations, which means it’s had to plug a significant gap in its electricity supply with power generated elsewhere.

With France unlikely to be able to fix its nuclear fleet anytime soon, it’s also unlikely to make it to the top of the net power exporter list anytime soon either. Instead, the top honour goes to Sweden, which exported a total of 16 TWh during the first half of 2022. Most of that power, 7 TWh and 4 TWh, went to neighbours Finland and Denmark, respectively.

However, the real story for the European power export market is that Germany – a country com monly criticised for its energy policies due to an overreliance on Russian gas – was Europe’s second largest exporter in the first half of 2022. It exported 15.4 TWh, with France taking the lion’s share.

The UK also noticeably saw a change in its fortunes in the first half of 2022, with the country going from a reliable importer of electricity to a net exporter position, with power largely flowing back to France. However, the UK still ended the six month period as having imported 1.5% more power than exported.

Sizewell C gains final approval as Boris Johnson’s final act

Boris Johnson used one of his last acts as the UK’s Prime Minister to give final approval to the Sizewell C nuclear power plant.

There was no doubt that Sizewell C would receive final approval, with Business Secre tary Kwasi Kwarteng having already given his seal of approval in late July. However, the financial support package still needed to be signed off by the UK’s Prime Minister, which has now been done, with Sizewell C receiving £700 million in Government support.

That paves the way for Sizewell C to move onto the next step, which is the submission of a more detailed planning application and dealing with any appeals, before construction commences at some point ‘before 2024’, according to EDF.

Boris Johnson choosing to approve Sizewell C before leaving office is not exactly sur prising in itself, with the Prime Minister hoping to be remembered for his green policies. In fact, while his premiership has been heavily impacted by the Covid-19 pandemic and scandals, Johnson’s commitment to the green revolution has helped the UK climb two places on the Environmental Performance Index, with it now considered the second greenest country in the world.

Western Power Distribution has announced its intention to become the first electricity distribution network operator to approve all new connections of domestic EV chargers and heat pumps.

Dubbed the ‘connectability pledge’, Western Pow er Distribution is vowing to say ‘yes’ to customers seeking to install any electric vehicle chargers or heat pumps, noting that there will be no network obstacles blocking its eight million customers from adopting domestic low-carbon technologies.

Currently there are 10,759 heat pumps and 58,416 electric vehicle (EV) chargers connected to Western Power Distribution’s network. From 202328, it estimates it will connect 628,000 heat pumps and chargers for 1.5 million EVs.

Western Power Distribution pledges to approve all domestic EV charger, heat pump connections

???????? 8 Electrical Review | September / October 2022

NEWS News

Moto Medway, a motorway service station situated along the M2 near Gillingham, is un dergoing an electrical upgrade to make room for new EV charging stations.

UK Power Networks, the local electricity network operator, is upgrading power capacity for new EV charging infrastructure, including GRID SERVE’s high-power chargers, at the motorway services near J4 of the M2 in Rainham, Kent, as part of its £66 million Green Recovery Fund.

The company is halfway through a project to install 4km of new electrical cabling from a nearby substation to EV charging points locat ed in the car parks of the Moto Medway east and westbound motorway services. The work will enable the connection of a planned 48 new high-power charge-points (24 westbound and 24 eastbound) to support the growth in electric vehicles, reduce carbon emissions and improve air quality.

The ‘green recovery’ investment is deliver ing low carbon energy projects that will help achieve the Government’s Ten Point Plan towards Net Zero by 2050.

A total of 86 schemes are being fasttracked by the electricity company across a range of sites including electric vehicle charging hubs at motorway service stations, fleets of electric buses, community energy schemes and heat pumps.

Siemens Gamesa’s RecyclableBlade is now available for onshore wind projects

Siemens Gamesa pushed the renewables in dustry forward with the introduction of its RecylableBlade for wind turbines, although at launch it was only available for offshore wind power projects. Now, the company is making the technology available to onshore projects too.

The RecylableBlade is exactly what it says on the tin, it’s a wind turbine blade that is recyclable, making the carbon footprint of a wind turbine lower than ever. While it’s taken a lot of work to get to this stage, Siemens Gamesa was able to prove the technology’s worth in just 10 months, having launched the product in September 2021 before it was

finally installed at RWE’s Kaskasi project in Germany in July 2022.

Of course, the RecyclableBlade should enjoy a long life before it’s sent for recycling, it’s still positive to know that the next generation of wind blades won’t head for landfill and will instead go on to have additional uses. However, that was only the case for offshore wind farms, until now.

A new onshore solution is now ready for customers to employ at their onshore wind sites. Further development by Siemens Gamesa and partners ensure full compatibili ty with the product and process requirements for onshore blades.

Moto Medway to receive 48 new EV chargers thanks to electrical upgrade

Moto Medway to receive 48 new EV chargers thanks to electrical upgrade

10 Electrical Review | September / October 2022 NEWS

Gossage Gossip

Spendthrifts at Ofgem

There I was, foolishly thinking that expenditure on installing a couple of display panels in a meeting room would be a matter simply for petty cash. Well, it might be for you and I, but not for those grand people at the nation’s energy regulatory body, Ofgem.

In September, the regulators had some graphic display panels installed at their plush offices in London’s Canary Wharf. These panels cost the Ofgem purchaser, one Alfie Ellis, some £22,740. And which local East End installers actually undertook the work? Er, none.

The installation was undertaken by a firm based in High Wycombe, in leafy Buckinghamshire. So, not local at all. That company’s name is withheld, apparently ‘for commercial reasons’. But we are permitted to know they have over 500 employees, so not a small outfit either. One thing we can all recognise – these installers can easily spot a very over-generous purchaser over one hundred miles away.

Ladies who lunch

Ever wondered how come the big energy companies managed to persuade Liz ‘no handouts’ Truss into a complete U-turn? A U-turn which just happened to provide them with precisely the residential bills subsidy scheme they were seeking? Look no further than the two ladies who recently joined the main boards of Scottish Power and Centrica.

Their names are Claire Perry and Amber Rudd. What do these ladies have in common? The answer is that both left Parliament at the last election, having been in succession the Conservative minister in charge of energy policy. And both remain most definitely very close members of the sorority around Liz Truss.

Cameron was anti-nuclear

Grammar lessons for Jacob

Much has been written about the appropriateness of appointing Jacob ReesMogg as the Cabinet Minister in charge of energy policy. Because of the rotundity of the language he deploys, he has frequently been described as “just visiting from the eighteenth century.” Long immaculately dressed in clothes of his great grandfather’s time, he has always been meticulous in the precision with which he uses erudite English words, avoiding colloquial slang on all occasions.

So, what are we to make of his contribution to a press release issued by Number 10 concerning the decision to make future taxpayers pay large chunks of your and my home fuel bill this winter. In it, Mr ReesMogg is quoted accusing Russian President Putin of ‘weaponising’ the supply of energy.

Weaponising? Weaponising? In no dictionary of the English language can this improbably vulgar new ‘noun-into-verb’ word be found. What could have happened to Mr ReesMogg? Is he changing his famous precise use of vocabulary overnight, to celebrate running energy policy? Or are No 10 simply putting the new-fangled words that Liz Truss might choose to deploy into her colleague’s mouth? If so, what sort of dangerous precedent is this new Prime Minister setting?

Bombing out with hydrogen

It is currently Government policy that, within a couple of years, no new buildings will have gas boilers installed. And that by 2035 all gas boilers will be illegal. Even though Liz Truss is anxious to encourage as much gas extraction as possible from the North Sea, and is studiously ignoring the specific commitment in the Conservative manifesto at the 2019 election that “we will not support fracking.”

Even so, the threat of elimination within the next decade or so is causing some consternation amongst companies that make these gas boilers – of which well over two million are currently sold each year.

What to do? Simple. Just pretend your boiler is not fuelled by natural gas. Recently I was at a trade show at the National Exhibition Centre near Birmingham, where two of the largest British manufacturers, Worcester Bosch and Vaillant, were marketing 100% hydrogen boilers. In Worcester Bosch’s case, the label, inevitably coloured green, described the same ‘hydrogen ready’ boiler as being ‘zero carbon’.

But were you to install such a ‘zero carbon’ boiler today, you would find that it would still mostly run on natural gas – even if hydrogen was available. If and when green hydrogen was to be injected into existing gas grids on any large scale, ‘blended boilers’ would still only run on 20% hydrogen. Leaving them reliant on natural gas to provide 80% of the power to heat buildings.

Those who, like the new Prime Minister, bemoan the failure of past Labour governments to promote masses of new nuclear power stations, may care to consider these prophetic words from her Conservative predecessor, David Cameron, uttered just before the Conservatives regained power in 2010: “Where the [Brown] Government sees nuclear power as the first choice, under our framework it would become a last resort. We need to think in an entirely new way about energy. The future of energy is not top-down, it’s not centralised – it’s bottom-up and decentralised.”

12 Electrical Review | September / October 2022

Work safer on medium voltage systems

When you work on medium voltage switchgear, your first and overriding priority will always be to maximise safety. But what can you do to protect yourself against hidden hazards that are not readily apparent? Sandy Woodley of Megger looks into this issue and offers some useful suggestions.

If you’re professionally involved with MV switchgear, you’ll know that there are many ways in which it can fail. You’ll also know that the most common failure is insulation breakdown, and that the results can be catastrophic. Even a modest fault in an MV installation releases enough energy to wreck equipment and, if the circumstances are truly unfortunate, to kill. Which means that when you’re working with or even near MV equipment, you want to be as sure as you possibly can that such a fault is not likely to occur.

Unfortunately, equipment that’s about to fail rarely gives you an ad vance warning. Or does it? In fact, insulation breakdowns are very often preceded by partial discharge (PD) events. If you can detect and monitor these events, you will, therefore, have a strong indication of equipment and cables that may soon fail. You can then investigate further and, if necessary, take the equipment out of service before a really serious problem develops.

At the very least, you’ll know that it’s a good idea to keep your distance from the suspect equipment if you want to stay safe. That’s reason enough for owners and operators of MV systems to insist that PD checks are always carried out on their equipment before any work takes place on or near it.

That’s all very well, but how do you carry out these surveys? Equip ment to detect PD is nothing new but, for the most part, it has been designed not only to detect PD but also to investigate and characterise it. That’s excellent in its place, but the consequence of all this functionality is that the equipment requires skill to operate and to correctly interpret the results. Also, if you invest in this equipment, it will undoubtedly serve you well in demanding applications, but if you only intend to use it for MV switchgear surveys, you’ll be paying for a lot of features you’ll never use.

What you really need is a compact instrument – ideally handheld – that is very easy to use and that provides clear, unambiguous go/no-go results. You’ll need an instrument that works in a live environment, so that you don’t need to take equipment out of service to carry out your surveys. You won’t, however, need sophisticated functionality – you can always bring in other equipment when you want to investigate potential problems in more detail –but you will need versatility, so that you can deploy the widest possible range of PD detection techniques. A PD detector can offer the versatility you need by employing multiple sensors – both internal and external – so let’s take a look at some of the possibilities.

14 Electrical Review | September / October 2022 SPONSORED FEATURE

You will find an internal acoustic sensor – essentially a microphone that listens for the characteristic noise produced by partial discharges – is a good choice for PD testing on air-insulated MV switchgear and equipment that’s in direct line of sight. If you need more flexibility in where you can place the sensor, you can achieve this by using an external acoustic sensor that connects to the detector via a cable.

For fully enclosed switchgear, you’ll want a contact probe that is sen sitive to vibrations produced by partial discharge, while for switchgear where the components are not visually accessible – mostly vacuum and GIS equipment – an internal TEV (transient earth voltage) sensor will pick up RF radiation from the PD via the switchgear’s metallic enclosure. An external TEV sensor performs a similar function but will also help you to localise the PD source.

If you have a PD detector that allows you to connect an HFCT (high-frequency current transformer) sensor, this will usefully extend its functionality to include simple on-line PD surveying of MV cables. Finally, a parabolic acoustic sensor will let you carry out outdoor surveys to detect, for example, corona and surface discharge in terminations, CTs, PTs and isolators.

Let’s remember now that if you’re going to be routinely carrying out quick pre-work safety surveys, your PD detector must be fast and easy to use, so what should you need to do to configure it appropriately for the type of sensor in use? The answer is nothing! The detector should automatically set itself up for the type of internal sensor you select, or for the type of external sensor you plug in. This not only saves you time and trouble, but also makes it near impossible for you to make mistakes that might produce misleading results.

And what about those results? You may have heard – or even know from your own experience – that PD results can sometimes require skill and expe rience to interpret. But you don’t need that level of detail for a safety survey. So how about an instrument that provides you with “traffic light” results? Green for all is OK, amber for caution – consider investigating further, and

red for danger – further investigation definitely needed.

Of course, as you gain experience, you may well want to be able to al ter the thresholds for amber and red indications to suit your own specific requirements, and you’ll almost definitely want a little more detail in the results so you can record and trend them. A phase-pattern PD display option will also be useful, as it provides a very useful way to distinguish between true partial discharge effects and random noise.

Hopefully by now you’re convinced of the benefits of routinely carry ing out PD surveys on MV equipment, especially before you start work on or near it, and so you’ll be interested to know that a PD survey instru ment that meets all of the requirements we’ve discussed has recently been introduced to the market. This is the new PD Scan from Megger.

In fact, this innovative device does rather more. It includes, for exam ple, a camera that allows photographs to be easily attached to test reports, and which can also be used to read QR codes to identify equipment and documentation. It has a humidity and temperature sensor so that you can easily add these key parameters to your data, and there’s provision for you to download your results easily into a PC and quickly generate comprehensive reports.

For all of its versatility and functionality, this instrument is as simple to use as a smartphone. It has just three buttons, and a large colour touchscreen that is intuitive in use and shows only those options you need to deal with the current operation, rather than forcing you to plough through a rat’s nest of complicated menus.

Every one of us in the electrical sector is constantly aware of the need for safe working, which is why many safety precautions are “baked” into our routines: locking out circuits under test, for example, and grounding equipment that’s being worked on. Now the easy-to-use equipment dis cussed in this article provides us with the opportunity to adopt another safety routine: that of carrying out PD surveys before working on MV equipment. The process is fast, easy and non-disruptive; the results can save not just money, but lives.

www.electricalreview.co.uk 15 SPONSORED FEATURE

How to build national EV infrastructure that works for all

Rollo Home, Head of Product at Ordnance Survey, explores how the UK can ensure that its EV infrastructure is built to meet the needs of everyone.

16 Electrical Review | September / October 2022 ELECTRIC VEHICLES

There’s a buzz – or at least a gentle whir – at the moment around electric vehicles. Following commitments on climate change and reducing the nation’s carbon emissions, greener transport options are firmly on the agenda for increased in vestment and initiatives that will help the UK Government with its Net Zero Strategy. So much so that it has set an ambitious zero emissions target for 2035 to eliminate the sale of internal combustion (ICE) vehi cles from the UK’s roads. With 27% of the UK’s total emissions coming from the transport sector, it’s a logical area to focus on.

planning on-street charge points.

Solving the challenges of EV infrastructure will therefore require intelligent data aggregation and integration, with geospatial data being the vital thread that connects places and people, creating the true picture of local, regional, and national demand. This will require organisations across industries, and the public and private sectors, to collaborate and enable innovation. Thankfully, those with the technical skills to work with this data are increasingly interested in sustainability-focused pro jects – and there are many opportunities in this rapidly growing industry.

Supporting EV infrastructure

Of course, a key component in the strategy to reduce the amount of ICE vehicles is encouraging the growth and adoption of more sustain able options. Though not the only piece of the net zero puzzle, EVs will certainly help us transition to a more sustainable transport paradigm. But before we can reach those greener sunlit uplands, there are a number of barriers that must be overcome.

Enabling EV infrastructure

Making the UK truly EV-ready is a massive undertaking. While many of the negative perceptions associated with EVs are addressable, there are many challenges to overcome when it comes to creating the national infrastructure that will enable their mass rollout and adoption. Think of the current refuelling infrastructure that supports ICE vehicles; the development of the fuel station network and infrastructure has taken the best part of 100 years. If we are to meet the 2030 Government targets, that network will need to be overhauled in less than a decade.

To achieve this, we can’t let normal market dynamics work their way through – we need to provide assistive tools that accelerate the arrival of this infrastructure. The Government has committed to raising the number of EV charging stations to 300,000 by 2030, which is more than an 800% increase on current facilities. Today, the majority of charging stations are concentrated in more populated areas, such as London. But if widespread adoption is to occur, an equitable EV infrastructure must be in place nationwide. In short, we have to place EV facilities where they will have the most impact, and thereby accelerate adoption.

A key component of this endeavour will be a reliance on geospatial data to pinpoint optimal charge locations across the country. As with any large infrastructure projects, however, optimal locations will be deter mined by a number of factors.

Data around accessibility, pavement widths, disruption to road users, and the current and projected distribution of EV owners across the country are factors that must be reconciled to determine optimal locations. However, land is the UK’s most valuable asset – estimated to be worth over £5.4 trillion in 2017 – and practically every Government department has its own stake in securing the land that will help them meet policy commitments, putting land in short supply. Therefore, consideration of wider concerns around town planning, the environment and social welfare, for example, must all be considered when it comes to

Enabling EV infrastructure and ensuring the vehicles and drivers are suf ficiently supported will require a significant amount of development and energy. It’s not just about placing charging stations; it’s essential that the energy infrastructure is in place to support increased energy demands. It’s also important to create solutions that improve the experience of EV drivers, such as apps that connect them to EV facilities, services, and appropriate charging locations, taking into account individual preferenc es around accessibility and safety.

When it comes to the energy infrastructure, geospatial data will again be invaluable, and there should be an increased focus on renewable en ergy resources to power the growth of EVs. Ultimately, there’s no use in creating infrastructure that supports sustainable transport if it’s entirely powered by fossil fuels.

There are many examples of the ways in which geospatial data can be used to create this infrastructure. In the Netherlands, mapping information and aerial imagery has been combined with artificial intelligence to identify the amount of roof space that can accommodate solar panels. Closer to home, the ParkPower initiative in Scotland has used data on green and blue spaces in urban areas to identify the optimal locations for installing ground source heat pumps which can supply energy to buildings in these areas.

Ordnance Survey has long supported the utility sector with accurate mapping and addressing data. Today, utility companies, including electric ity, water, gas and telcos, rely on OS data and data from other providers to support their operations and keep homes and businesses connected.

Across the sector, geospatial data is used by companies to provide detail on road networks, terrain, rivers and every building and address across the country, enabling them to manage their energy networks with more informed asset planning, efficient maintenance operations and improved customer service. With up-to-date and detailed geospatial data, utility providers, and their third-party contractors, can plan and maintain assets and networks more effectively.

In much the same way, geospatial data can be used to accurately plan and position EV infrastructure and more sustainable energy infrastruc ture across the nation in a way that meets the growing and projected demands of users and encourages motorists to shift into a more environ mentally-friendly gear.

It’s not just about placing charging stations; it’s essential that the energy infrastructure is in place to support increased energy demands

Geospatial data can be used to accurately plan and position EV infrastructure and more sustainable energy infrastructure across the nation

www.electricalreview.co.uk 17 ELECTRIC VEHICLES

Why energy storage needs to be sustainable

Carlton Cummins, CTO and Co-Founder of clean tech firm Aceleron, discusses the importance of making energy storage more sustainable.

18 Electrical Review | September / October 2022 ENERGY STORAGE, STANDBY POWER & UPS

Energy storage will undoubtedly be powering our lives in the near future so, as we build a renewable energy infrastructure to meet today’s needs, it is vital that we create a sustainable, resilient system that will stand the test of time.

The transition to renewable energy is already underway, with increas ing urgency and focus being placed upon this transition thanks to the se rious and obvious signs of climate change, coupled with Russia’s invasion of Ukraine earlier this year.

A large part of this new renewable energy infrastructure will rely on energy storage. It is absolutely essential, therefore, that the technologies we use will be sustainable and built to last – first and foremost to reduce the impact on the environment but also, because replacing large-scale energy storage entirely will be an extremely costly and wasteful process.

serious contender for automotive batteries due to the lack of cobalt and long duration.

There has been a lot of interest in recent years in pushing the boundaries of LFP and this has resulted in a gradual improvement in energy density.

This gradual improvement in energy density is worth bearing in mind when searching for the right energy storage solution for a larger applica tion. There are serviceable, repairable and upgradeable battery technol ogies available, where individual parts can be removed independently for repair or to be replaced with a newer, more energy-dense material as technology evolves over time. Replaced parts that still have use can be repurposed into second-life products, creating a circular economy – the gold standard of sustainability.

Meanwhile, the service and upgradability of such a system works to extend its lifespan which reduces its total cost of ownership and retains usefulness as energy storage technology improves. This combination of clean energy compatibility and future-proof longevity work together to make it a worthwhile investment.

This is what will provide the renewable energy infrastructures we build today with the ability to keep going for as long as possible, making the most use of the materials used to build the product in the first place.

Battery waste across the board is going to become an increasingly serious concern –if it isn’t already. The majority are made using raw materials that the Earth has a finite amount of, so making sure that we get maximum use before recycling or safely disposing of them is crucial from a sustainability point of view.

‘Layering up’ the power

Large-scale installations – for grid deployment or data centres, for ex ample – require a resilient, constant and vast power supply, which means that investing in several ‘layers’ of power source is unavoidable. Not only is the equipment and energy itself far from cheap, but using diesel-pow ered generators as a backup – although reliable – will not help us on the road to net zero and will eventually become obsolete.

The direct integration of solar panels combined with energy storage not only allows for backup power via renewable energy, but excess ener gy – on a sunny day for instance – can be sold onto the grid, transform ing this operational expense into a revenue generator, and helping to decarbonise the grid at the same time.

Many of these larger facilities already use batteries as a form of backup power, but often buy the cheapest lead-acid batteries available. There are several drawbacks to these types of batteries. They do not last long, don’t store as much energy as other batteries, can be temperamental due to their chemistry and are highly toxic when being broken down at the end-of-life stage. For a facility that needs reliability and resilience, these batteries are far from ideal.

Now is the time to research more long-lasting, high-density and safe long-term energy storage solutions.

Finding a reliable, long-life energy storage solution

Currently, the most widely referenced battery materials sit within the Lithium-ion family. Lithium iron phosphate (LFP) has no cobalt (which is costly and comes with geopolitical concerns), is amongst the least vol atile, with the highest safety ratings, and benefits from one of the longest lifespans in the family, which makes it very popular for renewable energy storage – particularly for stationary applications. It has also become a

Questions to ask when making the purchase decision

Although cost will be a significant factor, there are longer-term risks in going for the least expensive. Taking the following into consideration will make all the difference to the legacy that our generation leaves behind:

• How will the product be serviced and supported? Loss of power may well happen from time to time; making sure there is locally based support available will be key to safeguarding continuity. This includes access to replacement parts. Having to wait while they’re shipped in from overseas for instance is a headache we can all do without.

• What are the safety standards? There are a number of internationally recognised safety standards that must be met. As a minimum, the product needs to meet the UL 1973 (standard testing for stationary applications) and IEC 62619 and/or IEC 62620 (which means that any secondary cells have been tested for industrial application.)

• What is the overall environmental impact? It’s important to look at the entire life cycle of the product, starting with: how much carbon was produced during the build process, what materials were used and where it will be shipped from. This is also where the expected lifespan comes into consideration – the longer it lasts, the better for the envi ronment and budget.

We’re all under pressure to transition to 100% renewable energy, so it’s an exciting time for innovation. We now have a unique opportunity to create a clean and robust energy infrastructure for future generations to build on – so we have to get this right the first time. This means avoiding the temptation to source cheaper, short-term options based on current requirements – longevity will be the key to our success.

Replacing large-scale energy storage entirely will be an extremely costly and wasteful process

Although cost will be a significant factor, there are longer-term risks in going for the least expensive

www.electricalreview.co.uk 19 ENERGY STORAGE, STANDBY POWER & UPS

How to save money and reduce the environmental impact of a UPS

Louis McGarry, Sales and Marketing Director at CENTIEL UK, discusses improving the efficiency of an uninterruptible power supply to reduce its power consumption and its impact on the environment.

UPS systems are known for protecting critical loads in data centres. However, power protection is essential throughout most sectors. Examples can range from medical to banking and finance to defence applications. Whatever the use, if a UPS is ageing and/or incorrectly sized they can literally be ‘power hungry beasts’.

UPS and their associated infrastructure consume energy and if this is the case, the running costs alone can add up to hundreds of thousands of pounds over the years for some organisations.

A system working at its optimum efficiency will ensure it is cost effective and the impact on the environment will also be minimised with a reduction in power consumption. With energy costs at an all time high, now is the perfect opportunity to re-evaluate and review assets to reima gine and re-manage UPS installations to maximise efficiency.

Right sizing

The biggest step change with iPhones was between the iPhone 8 and 10. Screen size and processing speed was improved dramatically, and facial

20 Electrical Review | September / October 2022 ENERGY STORAGE, STANDBY POWER & UPS

recognition added. We may not see enhancements on this scale again. It’s the same with UPS technology. In reality it is unlikely that a UPS will ever be 100% efficient, and with today’s technology offering <3% of losses, any enhancements will be minor. We have already reached the iPhone 10 stage. So, to continue to make advances in efficiency we need to consider other aspects of the whole set up.

The vast majority of UPS installations we are called to evaluate are oversized. There are many reasons for this including the need at the time of installation to ‘spend all the budget’. It could also be that the client wants to avoid the risk of under sizing, they may be asked to add head room which can be anything from 10 – 50% to the design consideration ‘just in case’.

Have you ever looked into how much energy an oversized UPS can waste? It is standard practice for my team to compare the running costs of oversized, legacy systems with a replacement right-sized UPS. The To tal Cost of Ownership (TCO) calculations can be impressive. Regularly I see new systems paying for themselves within three years through energy savings alone.

The key point to evaluating the efficiency of any existing UPS is to look at the loading. Below 25% load, a UPS is less efficient. Even with no load, a UPS consumes energy simply to stay on, so it pays to run a UPS at the sweet spot of its efficiency curve. This can vary between systems; this information should always be made available by the manufacturer.

Repair or replace

Legacy kit will obviously be less efficient than a correctly sized new UPS. However, the cost of energy used to power a legacy UPS over five years is actually huge. It is generally more than the cost of a new system.

We are making TCO calculations on a daily basis to help clients understand how much they will save from day one, at what point in time the new system will have paid for itself, and the ongoing savings over the longer term. Making these calculations and choosing to replace legacy systems could save thousands of pounds on running costs, not to mention the associated benefits of increased availability of deploying true modular UPS technology.

Battery banks

It is important to consider right-sizing of the entire UPS system includ ing its associated battery bank. Larger battery banks will demand more energy from the grid to trickle charge and recharge, so be careful not to oversize or overspend on batteries that you don’t need.

Another consideration when re-evaluating batteries is their location in relation to the UPS and other heat sources. Lead-acid batteries need to be kept at 200C to optimise design life. Separating the batteries in a dedicated room, away from the UPS, means only the area housing the batteries needs environmental consideration. The batteries can now

operate in an ambient room temperature, which on average is between 20-220C, needing very little or even zero environmental control. That’s another cost saving.

Future growth

Don’t ever buy more UPS equipment than you need to. I’ll repeat that: don’t ever buy more UPS equipment than you need to! Whether that’s batteries or UPS. That may sound strange coming from a UPS manufac turer – however, our goal is to optimise system design and minimise the energy required to run the system for the best outcome for our valued clients. This means we nurture long-term relationships and work with organisations over many years as trusted advisors to design the best solu tions for installations. We are experts at saving clients’ money.

The ‘what if’ question frequently comes up. What if the load chang es? What if demand increases or decreases and the UPS system we’ve purchased becomes overloaded? The answer is that true modular technology is designed for a pay-as-you-grow approach, simply adding (or removing) more UPS modules ensures consistent rightsizing. This is achieved by ensuring there is sufficient physical infrastructure, or racks, to accommodate the changing nature of the organisation.

For clients to buy into this concept, UPS providers must work with clients to help them understand the facts and figures.

So, instead of saying ‘we need a like-for-like UPS replacement’, the question to ask is: ‘what is my actual load and do we really need a UPS that big? By looking at the alternatives, right sizing and managing room layout, it is possible to minimise energy and running costs and tame the power-hungry beast.

It is unlikely that a UPS will ever be 100% efficient, and with today’s technology offering <3% of losses, any enhancements will be minor

Don’t ever buy more UPS equipment than you need to

www.electricalreview.co.uk 21 ENERGY STORAGE, STANDBY POWER & UPS

Why there’s never been a better time to invest in battery energy storage

to some positives – namely, electric car sales and renewable electricity deployment. However, renewable energy is still inflexible and potentially unstable, while electricity demands are growing exponentially in a da ta-driven world, and with the significant demands of EV charging.

In this context, the energy security and storage capabilities of a BESS make it a compelling technology choice for companies needing to protect digital assets, maintain an undisrupted workflow, and work towards their own net zero targets.

Why opt for battery energy storage?

Progress is lagging behind ambition, and it is a significant issue in the transition to net zero, as highlighted in the latest Progress Report from the Climate Change Committee (CCC). Couple these policy problems with an energy crisis, and the difficulty of balancing the agendas of energy security and sustainability is clear.

In his foreword to the CCC’s latest Progress Report, Lord Deben was explicit, observing that, despite the UK being a world leader for net zero am bitions, implementation is severely lacking across key themes and sectors. He pinpoints “sharply rising fuel costs (which) should have given added impetus to improving energy efficiency, yet the necessary programmes are not in place…” With targets of 95% low-carbon electricity generation by 2030 and a fully decarbonised sector by 2035, the CCC is now focused on scrutinising delivery of these legally binding goals.

While policy is vague on implementation, UK companies are increas ingly taking it into their own hands to address the energy crisis – the spiralling costs and the insecurity of supply – through investment in Battery Energy Storage (BESS). And, alongside these commercially press ing imperatives, BESS technology is helping companies work towards their own net zero commitments, harnessing on-site renewable power generation and reducing carbon emissions.

Considering long-term energy management strategies, the current en ergy crisis is not a one-off, and energy prices and supplies will be volatile for the foreseeable future. The transition to renewables can’t be a simple switch from coal and gas to solar and wind. Rather, it means changing energy transmission, distribution and energy storage.

Given the infrastructure implications, capitalising on the opportu nities of a shift to renewables while pre-empting supply issues will be a balancing act for many years to come. The CCC Progress Report points

In terms of power resilience, the benefits of a BESS in comparison to a traditional uninterruptible power supply are well-established. Although a UPS will protect specific equipment during any interruption to power supply, the unit remains idle most of the time, with a loss of capaci ty – generally between 10 and 15% – meaning continual costs and the associated unnecessary carbon emissions.

In comparison, a BESS offers site-wide protection, with an energy loss of around 1%. In commercial terms, the cheapest unit of energy is the one you don’t use. It’s also the greenest.

BESS technology offers the flexibility to use stored electricity as and when required. Using the appropriate control software this process can be auto mated, with AI determining what generation and usage to prioritise.

The commercial application of BESS for Behind the Meter (BtM) scenarios provides an integrated energy management and microgrid solution for the greater flexibility and control of energy usage that are vital during an energy crisis.

In addition to resilience for security of supply during any power disruption, energy storage allows companies to shift the times when grid-supplied electricity is used and provides the capability to buffer large loads so that these can be more easily and more cheaply connected. This is particularly pertinent while EV charging remains a significant issue, as highlighted by the CCC Report.

How policy is falling behind decarbonisation

Security of supply and sustainability are two arms of the Energy Trilemma, and the UK ranks highly – currently fourth – on the World Energy Council’s latest Energy Trilemma Index. However, the third arm of the Trilemma –energy affordability – is the UK’s Achilles’ heel. It is also the aspect which brings together the agendas of security and sustainability in the current economic landscape, demonstrating what are, arguably, the greatest benefits

Alastair Morris, Chief Commercial Officer at Powerstar, considers how Battery Energy Storage (BESS) technology can help companies to profitably manage energy security and net zero targets in volatile times.

22 Electrical Review | September / October 2022 ENERGY STORAGE, STANDBY POWER & UPS

of BESS as a means for companies to balance competing priorities.

The UK’s Review of Electricity Markets Arrangements proposals, outlining plans to minimise exposure to wholesale natural gas prices, is highly relevant here. Linking power supply to gas prices is illogical and untenable in an increasingly decarbonised energy sector and decoupling the two – as tabled in the proposals – would be the biggest shakeup of the UK electricity market this century.

Policy falling behind ambition and implementation is problematic –but solving the UK’s baseload generation issues won’t be quickly resolved by nuclear technology, where the timeframe could span decades.

Successful decoupling of gas and energy prices would require flexibili ty, and this approach is evident in policy terms, including National Grid’s proposals to incentivise end-users to minimise electricity demand during peak times, with new proposals from BEIS to offer cheaper electricity rates when demand is low and renewable generation is good.

Using BESS for financial gain

For BESS users, there are opportunities – income generation through the UK’s Capacity Market, as well as potential financial savings for compa nies that can take advantage of fluctuating energy costs through storage.

As the UK’s energy generation moves further to renewables, these are still inherently inflexible and even though electricity prices would seem likely to reduce if decoupled from gas prices, this inflexibility may well mean short-term variance in electricity costs.

BESS technology allows companies to mitigate against such volatil ity by purchasing and storing electricity when prices are lower to then be used at peak times when prices are higher – maintaining power resilience in cases of disruption and assisting with budgeting in times of great cost fluctuations.

Perhaps the most financially compelling opportunity for BESS users, though, is the ability to take advantage of income generation – where battery technology really comes into its own.

Businesses who can engage with National Grid on demand side response (DSR) are operating at the forefront of the shift away from the old model of centralised energy dispatch and towards more distributed power generation.

DSR works for the grid as a cost-effective mechanism to manage supply and demand. For BESS users, there are revenue-generating opportunities either through a direct contract with the grid, with the local distribution network operator or, at a smaller scale, via an aggregator service.

In essence, battery storage enables end-users to fulfil DSR contract obligations by turning up, turning down or offsetting their own demand in real-time, helping the grid to smooth out peaks and troughs in overall demand. With a BESS, companies can secure a better price for surplus power by storing and selling when demand peaks and prices are highest.

As a mechanism to ensure supply meets demand, the Capacity Market has many critics, not least because of its descending clock format which, effectively, has subsidised fossil fuel generation – the lowest bidders at auction – to stay on standby. However, the Elec tricity Market Review includes a proposal to use more low carbon flexibility technologies to provide for the Capacity Market, which may well see further incentives for BESS users and new opportunities as government policy develops.

It is in this context – an energy crisis at the time when net zero targets are most pressing – that resilient power generation and storage capabilities provide a compelling case for companies to make profitable investment in BESS technology.

With a BESS, companies can secure a better price for surplus power by storing and selling when demand peaks and prices are highest.

www.electricalreview.co.uk 23 ENERGY STORAGE, STANDBY POWER & UPS

How we can fuel the future

From heat waves and wildfires in the headlines, to longer term concerns about climate change putting greater pressure on ecosystems and communi ties, there is no doubt that sustainability is the defining issue of our times.

Global demand for energy continues to increase exponentially, yet climate change demands lower emissions. As we look to COP27’s ambition to move from pledges to action in the context of an increasingly uncertain geopolitical landscape, there will be an even greater onus on how utilities and industry can tackle both challenges.

This will see an accelerated shift towards not just clean and renewa ble fuel sources but innovative solutions which enable decarbonisation strategies, as we continue to redefine how we produce, distribute, manage and consume electrical energy.

Add to the equation growing concerns about the cost and availability of energy which is exposing the vulnerability of economies that rely on global fossil fuel supplies – coupled with soaring energy demand – and it’s clear that the world needs a swift and broad transition to sustainable energy.

The wide consensus is that national and international focus on climate must take a definitive shift from optimism and ambition to decisive action. For many of the world’s biggest economies and carbon emitters it is time to take action to ensure promises made at last year’s COP26 are delivered at speed.

The good news is that we already have many of the tools we need to solve these challenges. The task now lies in deploying and scaling up the key technologies which could play a focal role in slashing emissions and realising a low-carbon society.

Morten Wierod, President of Electrification at ABB, looks at some of the key technologies which will fuel the energy transition.

ENERGY STORAGE, STANDBY POWER & UPS

24 Electrical Review | September / October 2022

Why energy storage is a key enabler of the energy transition

One of the most important climate change relevant innovations is one of the oldest – the humble battery. To understand why, we must first look at renewables. Science suggests solar and wind deployments are the cheapest ways to cut over a third of the required emissions reductions by 2030. But integrating these new energy producers to the existing mix is complex.

This is because most of the existing grid infrastructure is decades old and was only ever designed to manage a steady, reliable supply of energy under the assumption that the amount of energy fed into the grid is al ways roughly equal to the amount consumed. The inherent variability of wind, solar and hydroelectric, including potential imbalances in supply and demand and changes in transmission flow patterns, make balancing the grid more problematic. Without some form of backup, utilities run the risk of instability or even a blackout.

Battery energy storage systems (BESS) offer the obvious solution. Put simply, utility-scale BESS enables power generators to store excess energy and redeploy during periods of reduced energy generation, such as when the sun isn’t shining, or the wind isn’t blowing, to help balance the grid and ensure reliability. Amid increased pressure to deliver green energy at volume, this approach offers an economical route to renewable integration while us ing existing infrastructure in the space of grid modernisation programmes.

When partnered with digital capabilities, BESS also makes it easier to man age growing demand – including the impact of transport electrification.

But it isn’t just about utility-scale BESS. As more industrial and commercial operators pivot to self-generation to reduce energy costs and emissions, and gain energy security, energy storage offers a more effec tive way to manage energy by leveraging peak shaving, load shifting and maximisation of self-consumption. It can also provide critical backup power, preventing revenue impact in the event of a grid failure.

In line with the wider rate of digitalisation, the emergence of Artificial Intelligence (AI) enabled BESS is shifting the decarbonisation dial further. By harnessing the power of data analytics and machine learning, AI-enabled BESS can provide an accurate prediction of future supply and demand requirements ahead of time.

Amid an unpredictable energy picture, the insight afforded by this technology is a game-changer. Through predictive analytics, it will allow energy generators at all levels to store and distribute resources far better to make sure that every single kilowatt of clean energy is used to maxi mum effect – genuine energy efficiency in operation. Further opportuni ties in predictive maintenance and asset optimisation also ensures each renewable investment offers the maximum performance.

SF6-free – preparing for a more certain future Alongside the adoption of clean energy sources, reaching climate neu trality, of course, also requires the reduction of greenhouse gases.

This was seen earlier this year as the European Commission an nounced progressive plans to tighten limits on human-made fluorinated greenhouse gases (F-gases) and ozone depleting substances (ODS). This includes proposals to ban SF6 – a synthetic, high-polluting gas widely used as an insulating medium in switchgear – from new MV electrical equipment up to 24 kV by 2026, and up to 52 kV by 2030.

This means power system operators will soon have little choice but to begin their migration to more eco-friendly alternatives.

Now or never

As we look ahead to COP27, there can be no question that it is ‘now or never’. Action has to overtake ambition if we are to achieve a low carbon future and the targets set. With many of the technologies already on hand to power the journey, governments, utilities and industry need to leverage these today, and commit to the necessary investments, to make the biggest impact to our future, where ‘survival of the greenest’ is the reality.

One of the most important climate change relevant innovations is one of the oldest – the humble battery

Action has to overtake ambition if we are to achieve a low carbon future and the targets set

www.electricalreview.co.uk 25 ENERGY STORAGE, STANDBY POWER & UPS

Mastering the art of UHF partial discharge measurements

2,000 MHz on gas-insulated switchgear and lines, oil-filled power trans formers, and high-voltage power cable terminations.

Tunable bandwidth filters ensure an optimal signal-to-noise ratio for reliable analysis, even in noisy onsite testing environments.

The system’s portable and flexible modular design enables fast and easy setup during type and routine testing in HV laboratories or test bays, onsite commissioning, and troubleshooting in the field.

Single-channel or multi-channel testing

One UHF 800 measurement device is used to detect PD activity in the UHF range of each measurement channel. Up to 12 measurement devic es can be connected via fibre optic cables in a daisy chain for simultane ous, multi-channel PD measurement and analysis.

Each UHF 800 measurement device is powered with our RPB1 re chargeable external battery for hours of uninterrupted testing.

Powerful software for PD measurements and analysis

The UHF 800 is used with our MPD suite software and includes the latest, time-saving PD measurement and analysis features. These features include recording and replaying PD measurements, user-definable test ing profiles, and customised reporting.

Use it with or without MPD 800

OMICRON’s new UHF 800 offers you an optimal signalto-noise ratio

Partial discharge (PD) testing is a highly effective tool for medium-volt age (MV) and high-voltage (HV) devices that assesses their insulation condition and detects critical defects in them.

Conventional on-site PD measurements, such as those specified by the IEC 60270 standard, are often affected by noise in the surrounding environment.

Measurement alternative for noisy environments

Unconventional PD measurements performed in the ultra-high fre quency (UHF) range of 100 to 2,000 MHz are a reliable measurement alternative. These measurements are especially useful for PD testing on gas-insulated switchgear and lines, oil-filled power transformers, and HV power cable terminations.

This is because numerous noise sources, such as mobile communi cations, radar signals, and corona discharges, predominantly transmit in lower or narrow frequency ranges. By comparison, measurements performed in the UHF range result in a very high signal-to-noise ratio. That means optimal PD measurement sensitivity is ensured with little or no interference from external noise.

Reliable UHF PD testing with UHF 800

The portable UHF 800 PD measurement system is our latest solution for performing off-line and on-line UHF PD measurements from 100 to

The UHF 800 can be used as a standalone UHF PD measurement and analysis system. It can also be easily used with our MPD 800 universal PD measurement and analysis system. This allows you to combine con ventional PD measurements using the MPD 800 with UHF PD measure ments when the UHF 800 is in the same measurement setup.

The combination of UHF 800 and MPD 800 PD measurement devices – up to 12 measurement devices in total – can be connected via fibre optic cables in a daisy chain for simultaneous, multi-channel PD meas urement and analysis using the MPD suite software.

26 Electrical Review | September / October 2022 SPONSORED FEATURE

This November, Electrical Review is turning 150 years old!

To celebrate this renowned title and its past 150 years serving the electrical industry, we are publishing a special, one-off 150th Anniversary Commemorative Edition, and would like to offer you the unique opportunity to be part of it.

This publication, due in December 2022, will be unlike anything else you’ve seen before from Electrical Review, ever since its very first issue as The Telegraphic Journal and Electrical Review published on 15th November 1872.

A premium, 120-page, souvenir-style publication designed to be at home in any boardroom or executive lounge, it will focus on the milestones and highlights from our archive, tracing our coverage alongside the developments in the electrical industry across the decades.

The content will be laid out in a timeline style, blending our early coverage of the invention of the microphone, telephotography (which eventually evolved into the fax machine) and the light bulb, that time when Nikola Tesla wrote for ER in 1888, through to developments in solar and nuclear power, energy storage and the creation of the National Grid, concluding in the present day and the future with features on offshore wind, electric vehicles, IoT and the Metaverse among others.

We will also bring back the best of iconic columns such as Gossage and Letters to the Editor, with a healthy dose of nostalgia which, we are sure, will be appreciated by our many long-time, loyal readers.

If you would like to explore this more with us, please contact:

• Sunny Nehru on sunnyn@sjpbusinessmedia.com / (+44) 7741 911 296

• Kelly Baker on kellyb@electricalreview.co.uk / (+44) 7741 911 373

www.electricalreview.co.uk

www.electricalreview.co.uk 27 SPONSORED FEATURE

What is needed to enable a transition to renewables?

To meet the momentous challenge of net zero, we need creative thinking and innovative engineering surrounding renewable energy generation and usage.

Solar energy is one of the most powerful resources we have as we head towards net zero 2050. The related technology is well-estab lished, producing clean electricity that is critical for decarbonising key sectors, including transport and heating. To remain on track to deliver net zero by 2050, some experts think the UK will need to triple the amount of electricity produced by solar during the 2020s.

To this end, scientists, manufacturers and researchers have been taking

huge steps forward to expand solar capacity and power the future. New approaches include floating solar panels, or ‘floatovoltaics’, which have been shown to be 11% more efficient than land panels due to the cooling properties of the water, and improvements to the panels themselves.

Meanwhile, Oxford University spin-off Oxford PV has developed a perovskite-on-silicon cell that set a new world record in 2020 at 29.52% efficiency.

But generating more solar energy is just one side of the coin, we also need to use this renewable energy more efficiently to optimise produc tion and ensure the grid can balance supply and demand – a complex process – made more challenging by the use of energy sources that are highly influenced by the weather and seasons, which can essentially drop-off at a moment’s notice.

Electric Vehicles (Smart Charge Points) Regulations 2021

The electrification of the transport sector brings both challenges and opportunities for innovation surrounding solar energy usage. We must be clever about how we use energy generated from renewable sources because increasing demand for EV charging could cause a surge on the

Griff Thomas from GTEC looks at some of the new technologies that optimise solar power generation, making it more valuable for businesses, reducing carbon footprints and helping to balance the grid as demand grows.

28 Electrical Review | September / October 2022 RENEWABLES & SUSTAINABILITY

grid if it is not properly managed.

This year, the Electric Vehicles (Smart Charge Points) Regulations 2021 were introduced to ensure that EV charge points sold for domes tic or workplace use have smart functionality. These regulations were designed to help even out spikes in demand, while enabling renewable energy to be allocated in a controlled way to keep carbon emissions to a minimum and prevent power outages.

Reducing reliance on the grid

Ideally, in this new electric landscape, commercial and domestic build ings would combine rooftop solar with battery storage and an electric vehicle. Using generated electricity is always the most cost-effective option, as export rates under the Smart Export Guarantee (SEG) are far lower than what it costs to buy.

If consumers and businesses can make use of time-of-use tariffs, there are further savings to be made. These new models allow energy providers to better balance supply and demand and prevent surges. End-users can benefit from cheap energy, as low as 7.5p/kWh at the time of writing, if they charge their EV during certain hours of the night, utilising smart technology to help them optimise the process.

The ability to create and store electricity, independent of the grid, is an appealing prospect in the face of rising energy costs and concern about security of supply. However, add in the option to sell cheap energy back to the grid at peak time from an EV battery and it gets really interesting.

Vehicle to Grid (V2G) and Vehicle to Home (V2H) charging

Electric vehicles have large batteries which can be up to 10 times more powerful than a standard home battery. As the number of EVs on UK roads continues to rise, our capacity to store surplus and off-peak renewable energy increases. This has led to research into how EVs could be used to store excess power, feed energy back into the grid and even power people’s homes.

Going one step further, bi-directional vehicle chargers are an emerging technology that allows surplus energy to power homes and buildings, known as V2H. Initial trials by British smart energy technology compa ny, Indra, indicate that V2H technology can generate significant savings of up to £200 per month on an average household energy bill.

Indra is running a larger trial this year with 500 participants over a 12-month period to further develop the technology, which holds real promise for consumers looking to play a role in a sustainable future and make a savvy investment.

Driving a skills revolution

The important ingredient in making solar, or any renewable technology, work is skilled installers. We need a qualified workforce to help roll out

these technologies and educate consumers about the benefits of going green. As an electrician, this presents exciting business opportunities and cements your chosen career as a future-proof one.

Solar PV installation, battery storage and EV charging point installa tion courses are all designed for existing electrical installers, providing an ideal ‘next-step’ for anyone with an eye to expanding markets.

A different path to power

Change is happening, and, in the not too distant future, our reliance on fossil fuels will come to an end. We need a new approach to the way we power our buildings, for the environment and also the pockets of end-users, who are increasingly hammered by rising fuel bills. The cur rent situation is just not viable.

Electricians have an important part to play in helping consumers find a different path to power, one which offers more security while making an important contribution to reducing the UK’s carbon footprint.

www.electricalreview.co.uk 29 RENEWABLES & SUSTAINABILITY

Switching gears to a circular, sustainable approach to modern power management

30 Electrical Review | September / October 2022 RENEWABLES & SUSTAINABILITY

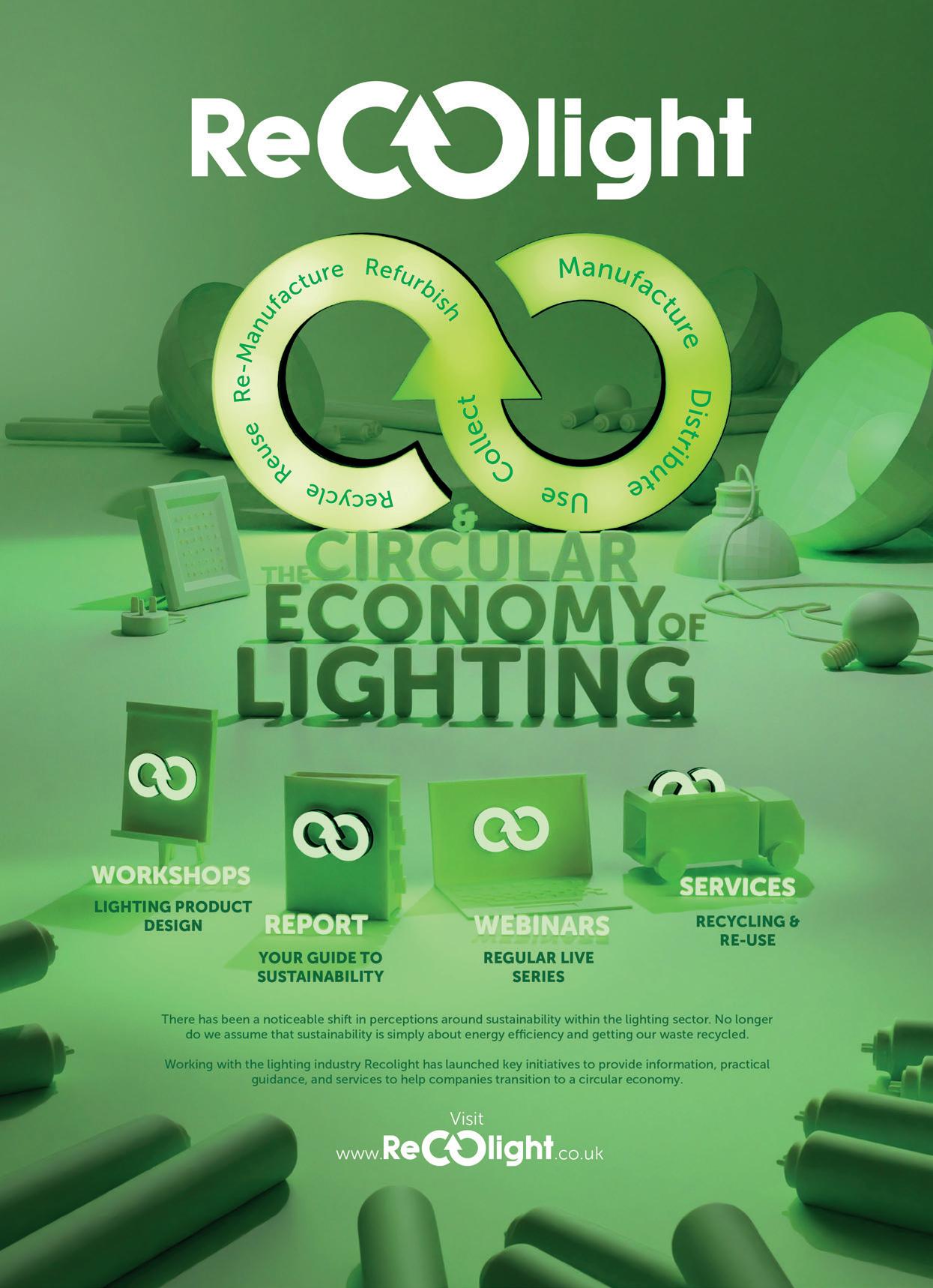

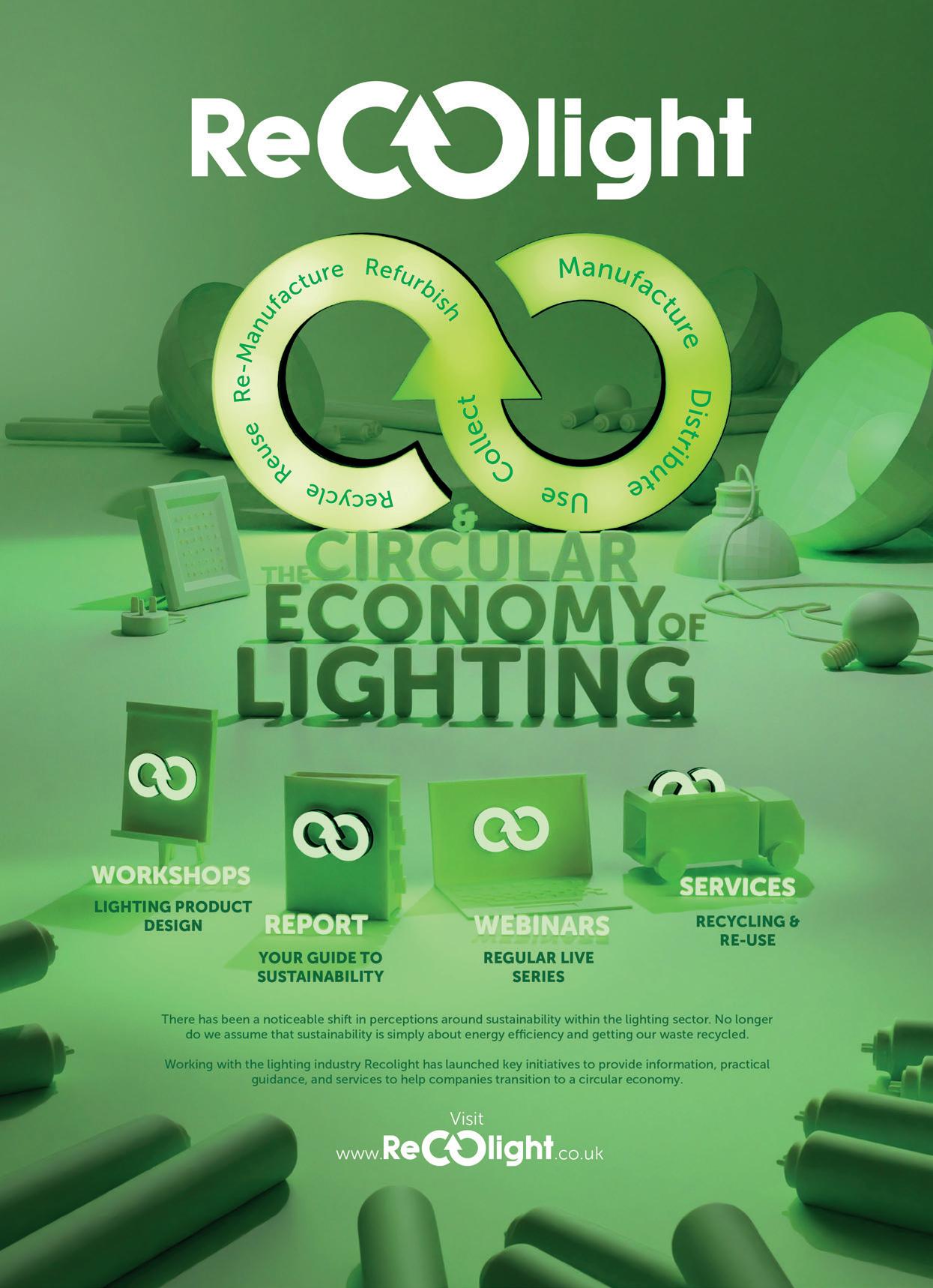

In the face of climate change, biodiversity loss, and resource scarcity, the need for a green revolution to reduce waste is fundamental to a sustainable future.

In recent years, there has been a growing awareness of the circular economy as a way of tackling the industry’s waste challenge. This traditional linear model of production and consumption, often referred to as ‘take-make-waste,’ is simply not sustainable in the long term.

In circular economies, sharing, reusing, repairing, remanufactur ing, and recycling are key. By extending the life cycles of products and materials, manufacturers can reduce overall waste, while realising other business-critical benefits, such as lowering costs and increasing uptime.

equipment, fewer waste materials must be processed compared to a com plete replacement. For example, retrofitting a circuit breaker unit inside the switchgear avoids manufacturing new cubicles, busbars, cables, and accessories in electrical distribution.

Retrofitting practices can include reusing switchgear housings and accessories, such as plugs, lights, LV switches, and extra LV cabinets and preserving viable cables and wires. Where components are obsolete, they can be refurbished or recycled. Retrofits minimise and simplify construction work resulting in faster installation, less human error, and fewer hours of costly production downtime. Compared to installing new equipment, retrofitting switchgear can result in environmental and cost savings of between 40% and 65%.

Circular-inspired modernisation; why now?

Our urgent need to address climate change is just one of the convinc ing reasons manufacturing must favour such circular approaches. The likelihood of unplanned and costly downtime increases daily as internal electrical systems are put through their paces. In addition, as the global utility power supply becomes more unstable, internal electrical systems are subjected to more wear and tear. Alongside issues such as equipment phase-outs, rising maintenance costs and new regulatory requirements, modernisation is more often a question of when – not if.

Solutions that fit the scale of the problems

The benefits of moving to a circular economy are numerous, including reducing environmental pollution, creating jobs, boosting the economy, and saving resources. For many manufacturers, the benefits of it are com ing to life within vital electrical distribution system upgrades. Tradition ally costly and disruptive to operations, by adopting circular economy principles, manufacturers are increasingly retrofitting low-voltage (LV) and medium-voltage (MV) electrical distribution switchgear to ensure the longevity of equipment while also reducing waste.

Innovative approaches now allow manufacturers to replace ageing and obsolete MV/LV switchgear components more easily (e.g., power circuit breakers, contactors, protection relays, and fuse devices) with modern upgrades while maintaining aspects of the original design. Since retrofitting solutions replace only a portion of the existing electrical

In this drive to modernisation, facility owners and managers must juggle competing priorities; the need for cost-effectiveness, optimum uptime, health and safety, and sustainability. All these aspects are rele vant when it comes to electrical distribution, the lifeblood of the facility. Malfunctions in the system rupture processes with unplanned downtime, resulting in higher costs and sometimes even threats to safety.

Helping the business with sustainable prevention

Prevention is always better than cure. Modernising electrical systems is part of a healthy, preventative strategy that delivers holistic benefits. For example, modernisation should include the digitalisation of assets when retrofitting systems. Equipment upgrades now mean the integration of low-cost sensors connected to the cloud. Feeding equipment data into analytics programmes delivers rich insights that improve performance and efficiency, decrease energy costs, and reduce CO2 emissions.

Crucially, digitalisation as part of a modernisation programme ensures manufacturers can evidence the impact of their efforts, both in terms of sustainability gains and to ensure cost-savings and efficiencies are genuinely being realised.

Manufacturers can realise multifaceted benefits by modernising power systems underpinned by an appreciation of the circular economy. Indus trial leaders now view sustainability as an investment. They can realise short and long-term advantages and are hungry to embrace innovative programmes that support waste reduction in all its forms. They are looking for expert partners to bring these ambitious programmes to life in pragmatic and practical ways.

Stewart Gregory, VP, Power Products at Schneider Electric, explains how modern power management technology can benefit from adopting a circular economy.

Retrofits minimise and simplify construction work resulting in faster installation, less human error, and fewer hours of costly production downtime

Digitalisation as part of a modernisation programme ensures manufacturers can evidence the impact of their efforts

www.electricalreview.co.uk 31 RENEWABLES & SUSTAINABILITY

How Western Power Distribution is working towards a net zero future

Western Power Distribution is playing a key role in helping the UK achieve net zero. One of the main aims of the company is to enable stakeholders to achieve net zero in line with their own ambitious aspirations.

To achieve this, Western Power Distribution is rewiring our network to provide the capacity required for the connection of low carbon technologies, such as electric vehicle charging points, heat pumps and more localised renewable generation.

But in order to deliver a low carbon network for our customers, it is impor tant that WPD leads the way in improving its own carbon footprint, which in turn will ensure that we as a business can prosper in a net zero society. Only by committing to internal sustainability targets, can we realistically support local communities in achieving their own goals.

Over the past decade, we have made significant strides to be recognised as a leader in tackling climate change, but we will not rest on our laurels and continue to push our sustainability plans further than ever before.

Reaching the Government’s 2050 net zero target will require investment. In our RIIO-ED2 Business Plan we outlined £6.7 billion of investment into our network. This investment will drive sustainability across the communities we serve and within WPD as a company.

Earlier this year we published our sustainability strategy, which builds on

Mark Shaw, ED Transformation Lead, at Western Power Distribution describes the role the distribution network operator is playing to reduce its own carbon emissions.

32 Electrical Review | September / October 2022 RENEWABLES & SUSTAINABILITY

We also have major plans for waste. By 2028, WPD will no longer send waste to landfills. Overall, we will be cutting the tonnage of waste we produce by 30% over a five-year period, and our starting point will be to avoid creating waste in the first place. We are working with manufacturers and suppliers to cut the environmental impact and waste of products and services we use. This will include sourcing more goods made from recycled plastics and eliminat ing non-recyclable plastic. Ultimately, we are aiming to reduce both the use of raw materials and carbon emissions.

By improving our internal business practices we can effectively increase sus tainability across the network. Our plans include collaborating and forecasting to support local authorities in reaching their own climate targets. Our RIIOED2 Business Plan shows how we have pledged to help accelerate the adoption of EVs, heat pumps, and other LCTs through helping to co-create, with local authorities, robust and challenging Local Area Energy Plans. We are also ap pointing dedicated WPD community Energy Engineers and Local Authority Engagement Engineers to help communities navigate the road to net zero.

At WPD, our belief is that sustainability should not be limited to the envi ronment and can be applied to the energy network as a whole. This is where flexibility comes in, as it allows network operators like WPD to manage the peak load without having to invest in additional costly infrastructure to meet a temporary spike in demand.

This recognition that the network needs to be future-proofed led to Flexi ble Power, which is a portal that allows DNOs to publish flexibility require ments which can then be accessed by flexibility providers. While it started as a WPD innovation project, it is now used by five out of the six DNOs and will only become more vital in ensuring that our customers can make sustainable choices, connecting their own low carbon technologies with capacity never being a barrier.