Informing the electrical industry for over 140 years

October 2018 Volume 252| No 10 www.electricalreview.co.uk

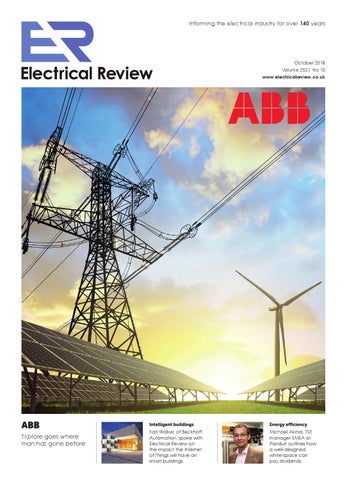

ABB TXplore goes where man has gone before

Intelligent buildings

Energy efficiency

Karl Walker, of Beckhoff Automation, spoke with Electrical Review on the impact the Internet of Things will have on smart buildings

Michael Akinla, TSE manager EMEA at Panduit outlines how a well-designed white-space can pay dividends