,QIRUPLQJ WKH HOHFWULFDO LQGXVWU\ IRU RYHU 140 \HDUV

October 2016 Volume 249 | No 10 www.electricalreview.co.uk

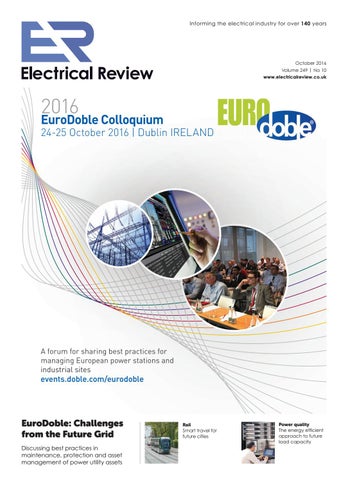

2016

EuroDoble Colloquium

24-25 October 2016 | Dublin IRELAND

A forum for sharing best practices for managing European power stations and industrial sites

events.doble.com/eurodoble

EuroDoble: Challenges from the Future Grid 'LVFXVVLQJ EHVW SUDFWLFHV LQ PDLQWHQDQFH SURWHFWLRQ DQG DVVHW PDQDJHPHQW RI SRZHU XWLOLW\ DVVHWV

Rail Smart travel for IXWXUH FLWLHV

Power quality 7KH HQHUJ\ HIÀ FLHQW approach to future ORDG FDSDFLW\