Informing the electrical industry for over 140 years

Jan / Feb 2017 Volume 250 | No 1 www.electricalreview.co.uk

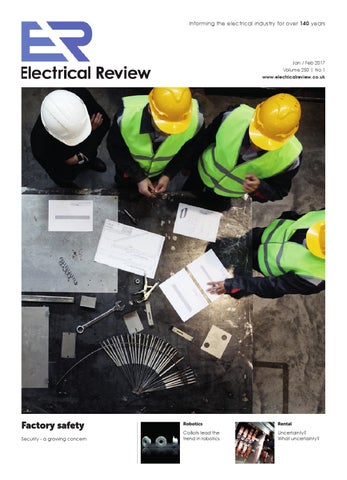

Factory safety Security - a growing concern

Robotics

Rental

CoBots lead the trend in robotics

Uncertainty? What uncertainty?

Informing the electrical industry for over 140 years

Jan / Feb 2017 Volume 250 | No 1 www.electricalreview.co.uk

Factory safety Security - a growing concern

Robotics

Rental

CoBots lead the trend in robotics

Uncertainty? What uncertainty?