Informing the electrical industry for over 140 years

January / February 2018 Volume 252 | No 1 www.electricalreview.co.uk

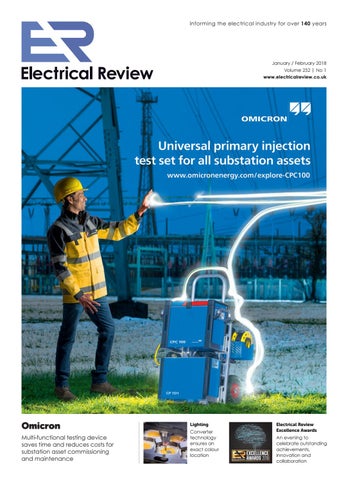

Omicron Multi-functional testing device saves time and reduces costs for substation asset commissioning and maintenance

Lighting Converter technology ensures an exact colour location

Electrical Review Excellence Awards An evening to celebrate outstanding achievements, innovation and collaboration