BY

Ship Concept 2035

Connectivity

Function will still dictate form

— Stamatis Tsantanis, chairman and CEO of Seanergy Maritime

Regulatory pressures remain a dominant factor shaping operations

— Emanuele Grimaldi, chairman of the International Chamber of Shipping

I don’t think anybody, including myself, has that crystal ball to say, OK, which zero-carbon fuel is going to be the answer

— Eman Abdalla, global operations and supply chain director at Cargill Ocean Transportation

15

The ability to unlearn and relearn every few years will be crucial

— Janani Yagnamurthy, VP analytics, Marcura

The fundamental shipping business model has not changed since the 18th century

— Ben Palmer, president, Inmarsat Maritime

By 2035, full broadband will be a baseline expectation

— Manish Singh, the head of Aboutships

Navigating EU ETS and FuelEU Maritime

As a global leader in maritime solutions, the Synergy Marine Group is committed to helping shipowners navigate the complexities of the EU Emissions Trading System and FuelEU Maritime regulations. Our expertise in technical management, digitalisation and sustainable ship management practices ensures that your fleet remains compliant and efficient in an ever-evolving regulatory landscape.

Join us in shaping green shipping.

Discover more about our innovative solutions and sustainability efforts:

• Compliance with EU ETS and FuelEU Maritime

• Technical Management Expertise

• Advanced Digital Solutions

Through our innovative decarbonisation arm, Azolla, we offer cutting-edge solutions to reduce greenhouse gas emissions and enhance fuel efficiency. By integrating advanced technologies and sustainable practices, Azolla helps clients achieve their environmental targets while maintaining operational excellence. Scan

• Sustainable Ship Management Practices

SHIP CONCEPT 2035

The site for incisive, exclusive maritime news and views www.splash247.com

EDITORIAL DIRECTOR

Sam Chambers sam@asiashippingmedia.com

ASSOCIATE EDITOR:

Adis Adjin adis@asiashippingmedia.com

CORRESPONDENT

Bojan Lepic bojan@asiashippingmedia.com

All editorial material should be sent to sam@asiashippingmedia.com

COMMERCIAL DIRECTOR

Grant Rowles grant@asiashippingmedia.com

GENERAL MANAGER

Victor Halder victor@asiashippingmedia.com

Advertising agents are also based in Tokyo, Seoul and Oslo – to contact a local agent please email grant@ asiashippingmedia.com for details.

MEDIA KITS ARE AVAILABLE FOR DOWNLOAD AT WWW.SPLASH247.COM/ADVERTISING

All commercial material should be sent to grant@asiashippingmedia.com

DESIGN Belinda Printed in Hong Kong

Copyright © Asia Shipping Media Pte Ltd (ASM), 2025

Although every effort has been made to ensure that the information contained in this review is correct, the publishers accept no liability for any inaccuracies or omissions that may occur. All rights reserved. No part of the publication may be reproduced, stored in retrieval systems or transmitted in any form or by any means without prior written permission of the copyright owner. For reprints of specific articles contact grant@ asiashippingmedia.com. www.splash247.com

Our take on tomorrow’s ship

Nor-Shipping likes to think of itself as the maritime event in the calendar that addresses the future of our industry, and visitors to this year’s event will, no doubt, face a barrage of tech pronouncements on how ships will transform in the coming decade.

When compiling this magazine identifying how ships will operate and look like in 2035, which is being distributed at the Norwegian show, we wanted to seek the views of owners, operators, charterers, managers, specialist service providers, and, most importantly seafarers.

Too often the gizmos and hardware being installed on ships do not seek enough input and feedback from the folk who are actually going to have to use them. If you design in isolation, you create cost, resistance, and risk. I reckon future platform companies will differentiate themselves by embedding operational feedback loops — including from crew — into design. The seafarer viewpoint, often neglected, features very prominently with no apologies on most of the following pages.

We polled our readership on a huge range of topics to gauge opinion on how dramatically different ships coming out of shipyards in 10 years’ time will look like. The results? Frankly, you, dear reader, seem to think the exteriors of 2035 newbuilds will look mighty similar to today. Yes, there might be some large fuel tanks on deck, and some form of wind propulsion, but overall ships are

not set for a massive change in terms of overall shape. It is inside the vessel where everything is ready for a huge shake-up.

To assess the design of tomorrow’s ships we’ve factored in incoming regulations, the runners and riders in the future fuel race, changing seafarer skillsets, port constraints, shipyards, connectivity, and artificial intelligence. Your views on all these topics are carried on page 48. Our own conclusion? Ships of the future will still cross oceans—but they'll do it with some sails, and lots of sensors and software.

Sam Chambers Editor Splash

A PROMINENT PURE-PLAY CAPESIZE SHIPPING COMPANY LISTED IN THE U.S. CAPITAL MARKETS

How ships will look in 10 years’ time

Splash

reaches for its crystal ball

The smartest ships may look familiar from the quayside, but function entirely differently from within

The shipping industry is on the cusp of one of its most transformative decades. Driven by decarbonisation, digitalisation, and a shifting geopolitical landscape, the vessels that traverse our oceans in 2035 may look similar at first glance—but beneath the surface, they’ll be smarter, cleaner, and more efficient, shaped by technological innovation and regulatory pressure.

While hull shapes may remain largely familiar, function is set to redefine the form.

“Externally, we need to expect evolutionary, rather than revolutionary, change,” says Ajay Chaudhry, CEO of shipmanagement at Synergy Marine Group. “Constraints like port infrastructure and classification limits will inevitably curtail radical redesigns.”

Chaudhry says to expect visible additions like wind-assisted propulsion systems, air lubrication systems, larger and repositioned fuel tanks and some modifications to superstructures to reduce wind resistance.

As Stamatis Tsantanis, chairman and

CEO of Greek owner Seanergy Maritime, puts it: “Function will still dictate form, though sustainability demands will reshape certain visible elements over time.”

If the outside will evolve slowly, the inside will undergo a radical transformation, experts surveyed for this magazine suggest.

“In 10 years, the smartest ships may look familiar from the quayside, but function entirely differently from within,” says Chaudhry.

Digital control rooms, sensorintegrated systems, and AI-assisted operations will be standard, according to Shah Irani, chief technology officer at Fleet Management, who predicts a convergence of artificial intelligence for predictive safety and operational decisions, internet of things to enable real-time monitoring and diagnostics, big data analytics for route optimisation and predictive maintenance, and finally blockchain to secure and streamline logistics and compliance. These tools, Irani says, will reshape everything from navigation to fuel efficiency.

The strongest tailwind in shipping’s transformation is decarbonisation.

“The shipping industry stands at a pivotal transformative moment, driven by digitalisation and decarbonisation,” says Nick Copley, co-CEO of Ocean Technologies Group. “First movers who embrace innovation stand to gain a clear and lasting competitive advantage.”

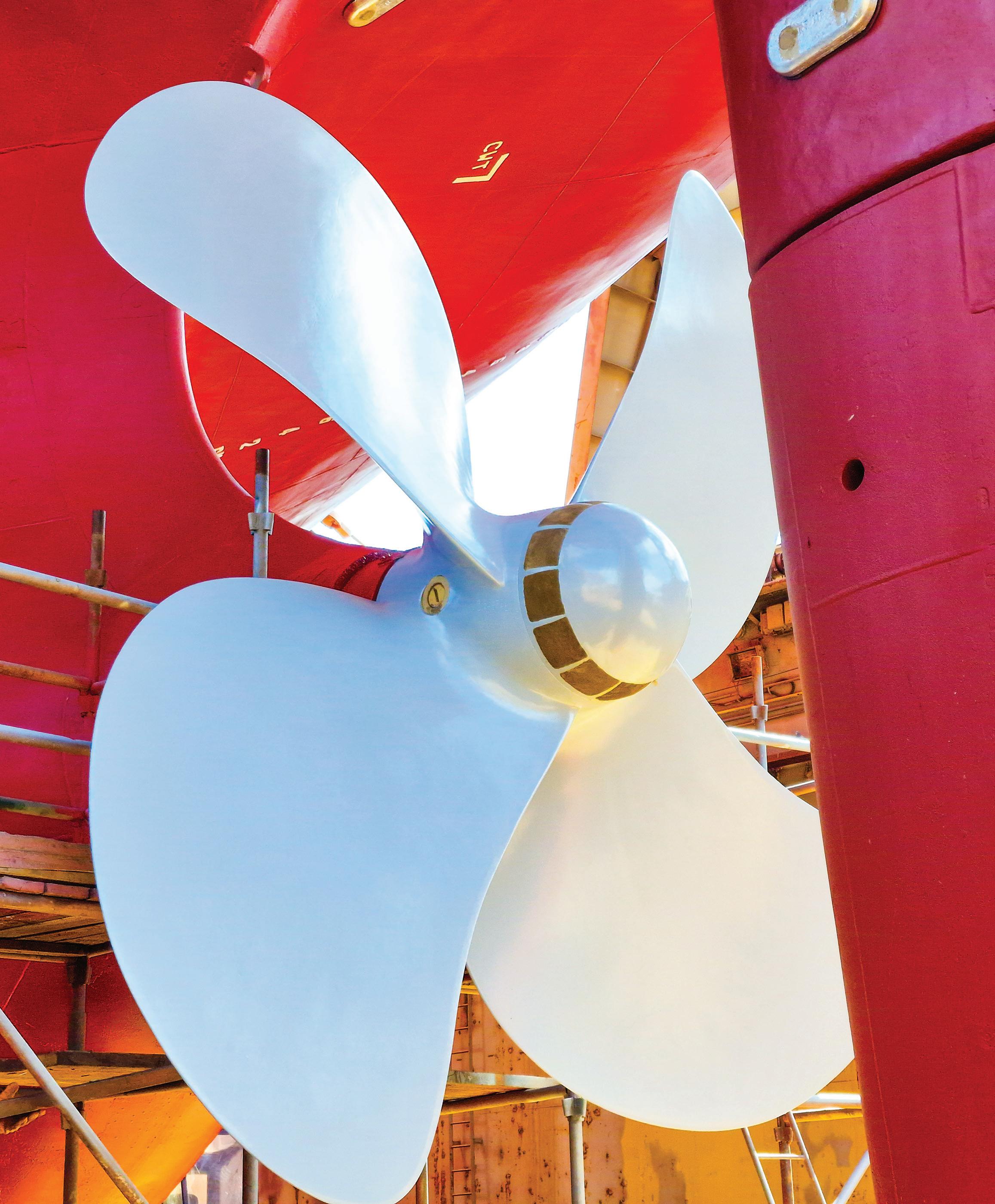

“Economy of scale, engine optimisation, and environmental pressures have historically driven design,” says Kristin Omholt-Jensen, the CEO of Maritime Optima, a shipping intelligence firm. “Now, carbon emissions will drive change—sails, propellers, dual fuels—all will influence the future.”

“Vessel design will continue to evolve; to address regulatory requirements in particular around emissions and to promote improving operational efficiency,” says Gareth Burton, senior vice president of global engineering at ABS.

Yet, challenges abound. As Dr Kanghyun Song, a senior vice president at Korean Register, points out, there are four key uncertainties, namely fuel

The tide may bring not only compliance, but competitive advantage

price volatility, regulatory ambiguity, technological immaturity where the likes of fuel cells and carbon capture are still unproven at scale, and finally infrastructure gaps with many ports lacking bunkering for alternative fuels.

To address this, Song says new vessels will need flexible fuel systems and modular configurations that can evolve as regulations and fuels mature.

For all the promise of technology, adoption must consider real-world usability.

“Technologies should be employed such that they are not only technically sound but also practical and usable in real-world maritime environments,” says Eric Van Der Horn, ABS's manager of technology.

“It is important to understand and listen to the challenges that shipowners and crew face when adopting new technologies,” says Patrick Wadden, marketing and communications manager at coatings specialist GIT.

Stefan Schindler, general manager of

BestShip, a joint venture of Wilhelmsen Ship Management and MPC Capital, adds: “A common challenge lies in the lack of accurate onboard measurement mechanisms to validate the business case for new technologies. For crewmembers, the biggest concern is often the complexity of maintenance associated with these solutions.”

Manufacturers must incorporate seafarer feedback in design to ensure safety, efficiency, and practicality.

The move toward smarter, greener ships demands capital. But finally more shipowners are realising the long-term payoff.

“The decarbonisation agenda is now forcing a spend-to-save mindset,” says Manish Singh, who heads up UKbased advisory Aboutships. “Owners increasingly see digital investments and predictive tools as ways to manage opex, not just capex.”

As fuel prices fluctuate and carbon pricing tightens, digital optimisation becomes a strategic necessity, not a

luxury.

One barrier to rapid tech adoption is the inherent diversity of the shipping industry.

“Shipping is a uniquely complex industry. Unlike land transport or aviation, vessels vary significantly in design, type, and operational profile,” says BestShip’s Schindler. “This lack of standardisation makes it difficult for technology vendors to develop solutions that are universally applicable.”

Tailored, modular solutions will likely become the norm, allowing for fleetspecific customisation while maintaining core technology platforms.

The next decade will not completely reshape the silhouette of ships, but it will redefine their soul. From AIdriven decision-making to cleaner propulsion, shipping is entering an era of intelligence, efficiency, and accountability. And for those who invest early and wisely, the tide may bring not only compliance—but competitive advantage.

The best-written rules don’t seem to change much at sea

Can global legislation keep up?

Splash identifies where regulators are enforcing change and where they are not

In global shipping, we often talk about regulation as a good thing – and rightly so. Rules are meant to protect the environment, improve safety and support fair labour conditions. The International Maritime Organization (IMO) and other bodies have spent decades creating systems to guide our industry toward higher standards.

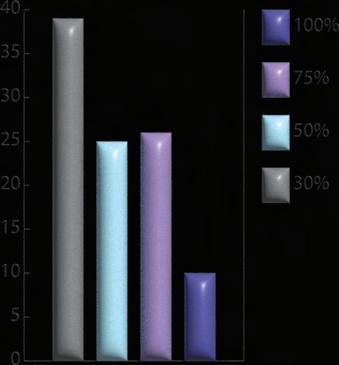

However, progress comes way too slowly, something our reader poll clearly backs up (see page 48) with around three-quarters of readers believing global legislation will fail to keep up with technological innovation through to 2035.

Over the past decade, the failure to enforce global shipping regulations has seen regional bodies - led by the European Union - increasingly take matters into their own hands.

“Enforcement appears uneven. The playing field unlevel. And the best-written rules don’t seem to change much at sea,”

Darren Shelton, a well known shipping commentator, wrote in a recent article for Splash, adding: “So we must ask the harder question: what if the real issue isn’t the quality of regulation but the quiet preference for keeping it ineffective?”

“Regulatory pressures remain a dominant factor shaping operations,” Emanuele Grimaldi, the chairman of the International Chamber of Shipping, tells Splash, adding: “They demand significant investment and innovation, something that requires clear signals from policymakers to enable businesses to make the longterm investment decisions needed.”

Technological innovations and regulations are inseparable and have always evolved together, influencing each other, argues Dr Kanghyun Song, a senior vice president at Korean Register.

“Regulations are designed to encourage technological advancements while maintaining flexibility, allowing

for gradual implementation when technological progress is slow,” Song says.

Bjorn Hojgaard, who heads up shipmanager Anglo-Eastern, says he expects regulations to evolve but legislation will still move slowly relative to actions being taken, especially when trying to strive for uniformity across regions.

“We expect regulations to follow the industry and for key players to take on responsibility to lead in a sustainable and ethical manner alongside evolving societal expectations,” Hojgaard says.

Concluding, Vikas Pandey, founder and CEO of ShipFinex, a ship finance specialist, suggests that with global regulators behind the curve it will be up to private initiatives and industry consortiums to lead by example, with blockchain providing traceability and accountability to push regulatory bodies forward.

Key new laws coming into force in the coming years

What will be powering ships in the 2030s?

Our survey suggests the phase-out of traditional bunker fuel is a way off still We do not envision a one-size-fits-all fuel

Realistic, pragmatic, or jaded?

Splash readers are a funny bunch. Despite the huge amount of articles and columns carried every week on decarbonisation, 49% of respondents to our survey for this magazine (see page 48) reckon that the majority of the global fleet come 2035 will still be using traditional bunker fuel.

Arguably no single facet will shape what ships look like in 2035 more than fuel, so one in two readers are inferring vessels will not have changed much in appearance 10 years from now, even if recent regulations do genuinely mean ships using traditional bunker fuel will be charged a lot more to move cargoes by 2035.

Shipping’s long path to decarbonise received a kick earlier this year when member states of the International Maritime Organization agreed on a so-called Net Zero Framework. From 2028, when the measures will come into effect, use of very low sulphur fuel oil and compliance via the purchase of socalled remedial units - essentially carbon credits - could lead to costs of $2,500 a day for a non-eco capesize, rising to $15,000 a day by 2035 as standards tighten, according to calculations from Clarksons Research.

British consultancy Maritime Strategies International (MSI) has also given an early indication of the impact that the Net Zero Framework will have on

the bunker market.

By extending the annual fuel consumption estimates calculated for 2024 through to 2035, and applying MSI’s forecasts for bunker prices, it is possible to project the future fuel costs for conventionally-fuelled ships alongside the projected IMO penalties. By this approach, the IMO’s penalties would be equivalent to an 82% premium on top of the fleet bunker costs by 2035 – almost $100bn for the 30,000 ships tracked in MSI’s database.

From another perspective, this also highlights the opportunity for the shipping bunker market – an annual pot directed towards drop-in biofuels and low carbon alternatives that could rise to

The new fuel levy will only lead to more expensive freight and not to actual decarbonisation

$100bn per year within the next decade.

Eman Abdalla, global operations and supply chain director at Cargill Ocean Transportation, says of the IMO’s new green rules, “There isn’t necessarily a well-defined business case for anybody to go and immediately order ships for specific zero-carbon fuels, but at least it has definitely planted the right seeds so that we can start ordering dual fuel vessels or dual fuel capable vessels.”

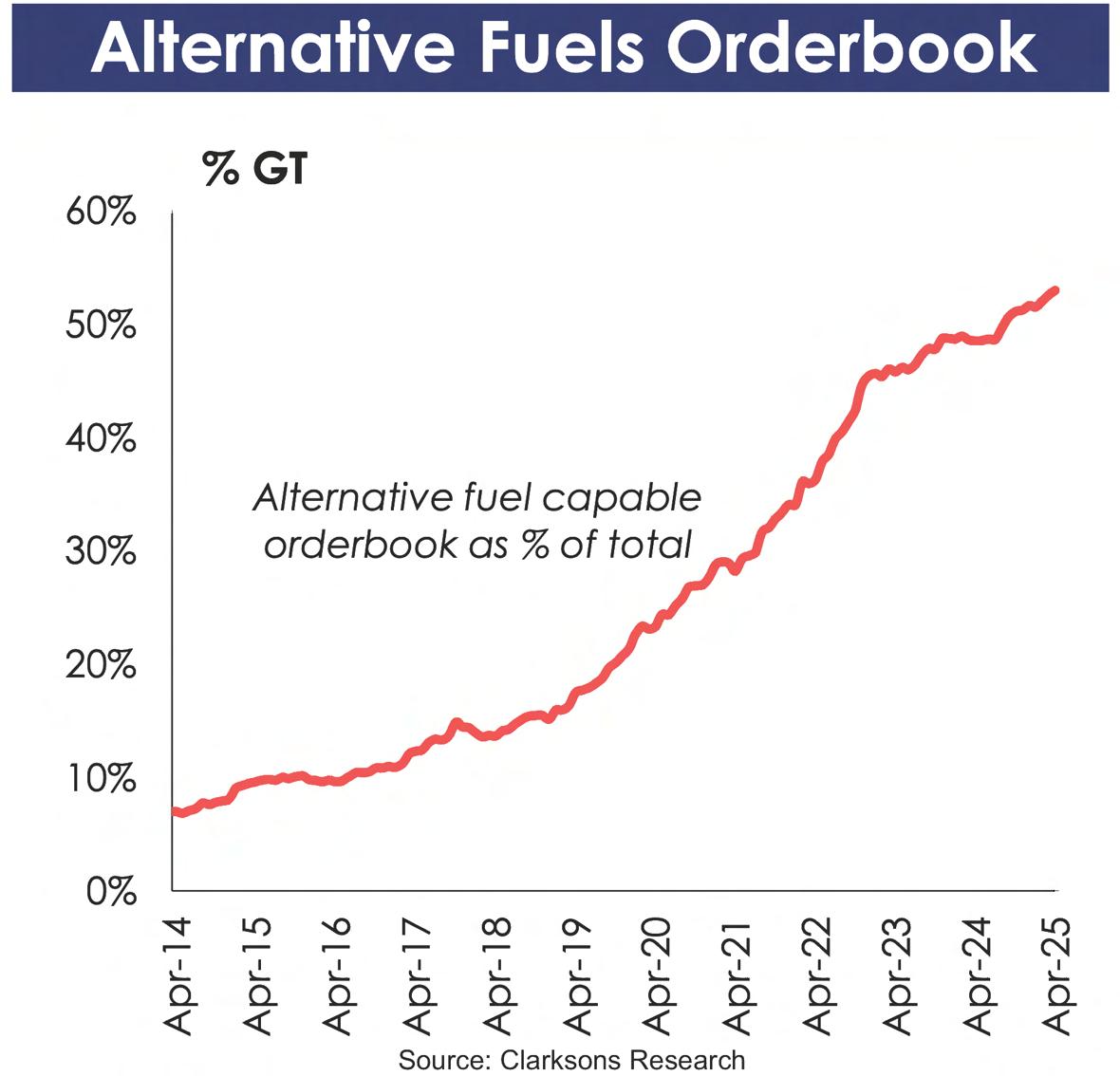

Data from Clarksons Research shows that less than 8% of the global merchant fleet in gt terms today is alternative fuel capable, although more than half of all ships on order will be able to use alternative fuels, a quintupling over the past decade. However, it is important to note that most dual-fuel ships coming out of yards today tend to use traditional bunker fuel most of the time.

“I don’t think anybody, including myself, has that crystal ball to say, OK, which zero-carbon fuel is going to be the answer,” Abdalla admits.

Putting his own spin on the Net Zero Framework, Splash columnist Pierre Aury has some inconvenient truths for shipping, which he shares with readers.

“There is simply no solution deployable at scale which can produce

a carbon-neutral, whatever that means, shipping industry within a time frame consistent with preventing global warming turning from a runaway train to a slow-motion train wreck,” he says, adding: “We will not be able to power any meaningful number of ships with either kites, sails, batteries, biofuel, hydrogen or nuclear fuel quickly enough so, whatever its level and its formula, the new fuel levy will only lead to more expensive freight and not to actual decarbonisation. This extra cost will drive some marginal efficiency improvements, which by the way will probably be offset by the growth of the fleet.”

Dr Kanghyun Song, who heads up

decarbonisation for the Korean Register, tells Splash: “We believe that the era of multi-fuel usage in shipping will persist for quite some time.”

“While a few leading fuel-types will likely garner wider uptake we do not envision a one-size-fits-all fuel,” agrees Bjorn Hojgaard, the CEO of AngloEastern, the world’s largest shipmanager. “There will still be a need to consider wider alternatives taking into account available resources and risk mitigation through diversification.”

Factors affecting relevant fuel choice, according to Hojgaard, will include route distance, port infrastructure, ship size, ship type and regulations that may also differ region to region.

Depending on vessel type and trading routes, LNG, methanol, and biofuels will likely be the main initial options, KR’s Song reckons. Once the production of green ammonia begins in earnest, ammonia is also tipped by Song to be adopted more widely.

“For existing vessels, biofuels may be the only viable alternative, but they will face a severe supply shortage due to limited production,” Song adds.

The key factor determining the production of green fuels is the availability of clean energy sources, which means that the generation of renewable power—such as wind and solar—will be critical. Song says countries with strong potential for wind and solar power—such as the US, China, Australia, and those in the Middle East— are expected to become major production

The era of multi-fuel usage in shipping will persist for quite some time

hubs.

Other countries such as India, Colombia, Chile, and Egypt are also emerging as potential hubs for green fuel production, according to Prakash Chandra, a director at Fleet Management. “Their efforts will be vital in creating a robust infrastructure,” he says.

Nuclear power is also under consideration, KR’s Song says, but he warns there are still too many issues to resolve before it can be applied to commercial shipping, making near-term adoption unlikely.

In terms of what will the fuel infrastructure will look like come 2035,

Vikas Pandey, founder and CEO of ShipFinex, a ship finance specialist, reckons we will see a hybrid network of retrofitted terminals, floating energy storage units, and AI-optimised fuel distribution networks powered by realtime data analytics.

Concluding, Nick Brown, the CEO of Lloyd’s Register, tells Splash: “The next decade will determine the shape of the industry’s long-term sustainability, demanding not just technological advancements but also greater investment in seafarers and human capital, which remain fundamental to creating the longterm change we need.”

27,000+ seafarers

www.fleetship.com

Are we turning a ship into a micromanaged hell?

Crewing in the digital age

Splash reports from a recent, pertinent workshop at Geneva Dry, the world’s premier commodities shipping conference

Kicking off the 2025 edition of the world’s leading commodities shipping event, Geneva Dry, was a specialist workshop sponsored by Inmarsat exploring how connectivity at sea drives digitalisation, decarbonisation and particularly crew welfare.

Hosting the panel, prior to the main conference at the Hotel President Wilson in the Swiss city of Geneva, Richard Watts, managing director of HR Maritime, tasked a stellar lineup of speakers with giving a rundown on the subject of how crewing and operations have changed in the digital age and how different areas of shipping and shipmanagement are being impacted.

The first panellist to address the room was Audra Drablos, strategy director at maritime connectivity specialist Inmarsat, describing vessels in the past as remote islands compared to connection hubs or remote offices that they are today.

Drablos argued that things have really changed for crews in terms of

connecting back home and having less feeling of isolation, as well as operationally, because they don't have to make decisions on their own, but also she noted that although massive changes are taking place, this is far from universal.

“I was shocked to hear that 13% of vessels still don't provide connectivity to their crew,” she said, "but things are changing rapidly; there's been a lot of disruption in terms of connectivity and how it's delivered."

From the perspective of Silje Moan, chief commercial officer of Norwegian maritime software developer Dualog, changes in connectivity onboard ships over the last 10 years have been moving towards a high- or office-like bandwidth, low-latency situation.

“We can move from focusing on saving costs on bits and bytes and compressing absolutely everything to focusing more on what kind of value we can bring to the end user onboard and also in the office. Now we don't have to

take into account how much data this will require,” she said.

Moving a little bit sideways, the discussion turned to ESG and how connectivity is helping the increasing requirement for collecting data and reporting.

Peter Schellenberger, founder of maritime consultancy Novamaxis, highlighted that, while there are positive and negative impacts of connectivity increasing, it is “the first real disruptor” that we see on a technology basis in the maritime sector that could hopefully be followed by many others if put in the right frame.

“Now we can start thinking about what we are going to do with it meaningfully,” he said.

Schellenberger noted that “surprisingly or not”, connectivity is still the number one driver for the crew.

“If, as a company, you want to be relevant and retain and win new people, then these are the tools that you have to provide almost no matter what the cost

is,” he said, adding that a move to declare connectivity a basic human right for a seafarer is something worth pursuing.

Speaking of challenges that come along with better connectivity, Schellenberger called attention to loneliness onboard when people disappear in their bunks, a lack of team building and onshore offices pushing more work for their colleagues at sea.

“It's not an enablement of the vessel; it's an overload of bureaucracy,” he stressed.

The microphone was then handed to Shubpreet Singh, senior managing director of strategy delivery at shipmanager V.Ships, who emphasised that the company has a standard of what it wants as a minimum connectivity, but that not all vessels are at the same level.

“I have to admit that there are vessels that are more progressive. Vessels that are delivered new from the yard come with certain packages for monitoring the main engines or the systems onboard, and we, as managers, see the benefit of it.”

Still, he observed that “the needle and the drivers” for most of the vessels are pointing to having better and more

connectivity as an enabler, not just for the commercial work, but also for the crew.

“So, going forward, I think the shift would be towards having more enabled vessels,” he said.

The panel was put on the spot again with the moderator’s question on whether a move towards more connectivity is seen as all positive or if it is a little bit more nuanced than that.

Singh argued for the latter, saying that if connectivity is not used properly, the crew onboard could actually get disabled.

“As we are getting more connectivity, we have to unlearn some of the things that we used to do in the past and, you know, relearn,” he said, explaining that for the masters onboard, the idea is not to always take their autonomy away and that managers as well as owners also have to be mindful and have checks and balances put in place for the mental health of the seafarers.

Inmarsat’s Drablos shared that the company is seeing a lot of customers asking whether they can control the amount of internet that's provided.

“We are getting a lot of requests about

restricting time so that they can manage fatigue. Basically, they don't want the crew to be on the internet for such long periods of time,” she said.

However, she also maintained that this is done due to the sense of camaraderie on vessels, because, in the past, most people spent their time in mess rooms.

"So, bringing the crew back into the mess room, I think, is also another important thing that we need to think about now that we have so much internet connectivity,” she argued.

In terms of regulating the crew, Singh reminded delegates that back when the master used to sail out without connectivity, ships still worked. "It's not as if we had a disaster every day," he said, adding, "Internet connectivity onboard for crew is like a kid in a candy shop and if you try to control it, you will have challenging conversations."

Meanwhile, Drablos said that a lot of the crew, when they're deciding whether to join, the first question they ask is about the internet onboard.

"I don't know anyone on land asking that question in a recruitment process," she said, noting that it also has to do with the new population coming onto the

LESS MORE IS

We help reduce your carbon footprint.

BSM‘s emission management services include:

• Enhancing vessel performance

• Ensuring compliance with CII, EU ETS, FuelEU Maritime and more

• Reducing OPEX and emission costs

Want to find out more? www.bs-shipmanagement.com/footprint

vessels that are used to having internet all the time. "So, you know, the concept of a floating home and a floating office is something that they think is a basic need."

Dualog's Moan reckoned limiting internet use is a bit of a minefield but also revealed that certain companies have been working to create a sense of belonging for the new generation of seafarers by giving them their company identity.

Speaking from the audience, Manish Singh from Aboutships and a thirdgeneration seafarer, observed that some of the language used during the panel, if seafarers were in the room, they would find it "borderline patronising, if not offensive".

"So we are trusting them with our ships, with our cargo, with the safety of life and the marine environment, but we can't trust them with connectivity? Try having that conversation with your children at home. That will tell you where this rhetoric needs to move on," he said.

He further stressed that shipmanagers need to stop taking ships that don't have the basic levels of connectivity and welfare and that the conversation has to move to digitalisation and decarbonisation.

Singh from V.Ships agreed that seafarers don't need to be patronised and that the company is already preparing them for the new types of vessels, but that in this mass of the seafaring community that's not really linked to owners or managers, at some time they could lose people, and that there have to be many other solutions that have to be reasons for the seafarers to stay with that company.

"There are a lot of intangible things that need to be done, and it's really a battle of hearts and minds. We are very much at the mercy of making sure that

we treat our seafarers equitably, rightly," he divulged.

Adding to the discussion, Dimitris Monioudis, chairman of the technical committee of INTERCARGO, reminded the panel of the necessity of all stakeholders to take part.

"Rather than just putting all the focus on the crew or the shipmanager, we should take into account the obligations that other stakeholders, such as ports, fuel suppliers, and charterers have. So, everybody has to play their part," he asserted.

The final question from the audience came from Graeme Somerville-Ryan, founder of Eyesea, asking, "Are we turning a ship into a micromanaged hell?"

Coming from the manager's perspective, Singh told delegates that there's a lot of "instant gratification" wanted from ships these days, which was not the case in the past.

"From a very commercial perspective,

it's about getting the information right here, right now. From a shipmanager's perspective, it's about getting things right all the time," he said.

Discussion drew to a close with remarks on autonomous ships, with Inmarsat's Drablos saying that with the levels of connectivity that the industry is seeing, "it could leapfrog us, but regulation is going to be a burden there for sure".

Dualog's Moan believed it is not about having autonomous ships as the goal but instead about running an efficient ship. "I don't think the goal should be to remove the crew but rather to find the correct balance of using IT and the digital to run it efficiently," she said.

Schellenberger closed the session by saying, "What is quite clear is that as long as we don't have standardisation of the technology, we will always have people onboard. So, I will reassure the seafarers who want to join the trade; we will need them for a long time."

Aligned with the IMO's Hong Kong Convention

Scan the QR for more information about our program

Digital efficiency drivers on land

make sure ships spend less time in port

navigate that change.

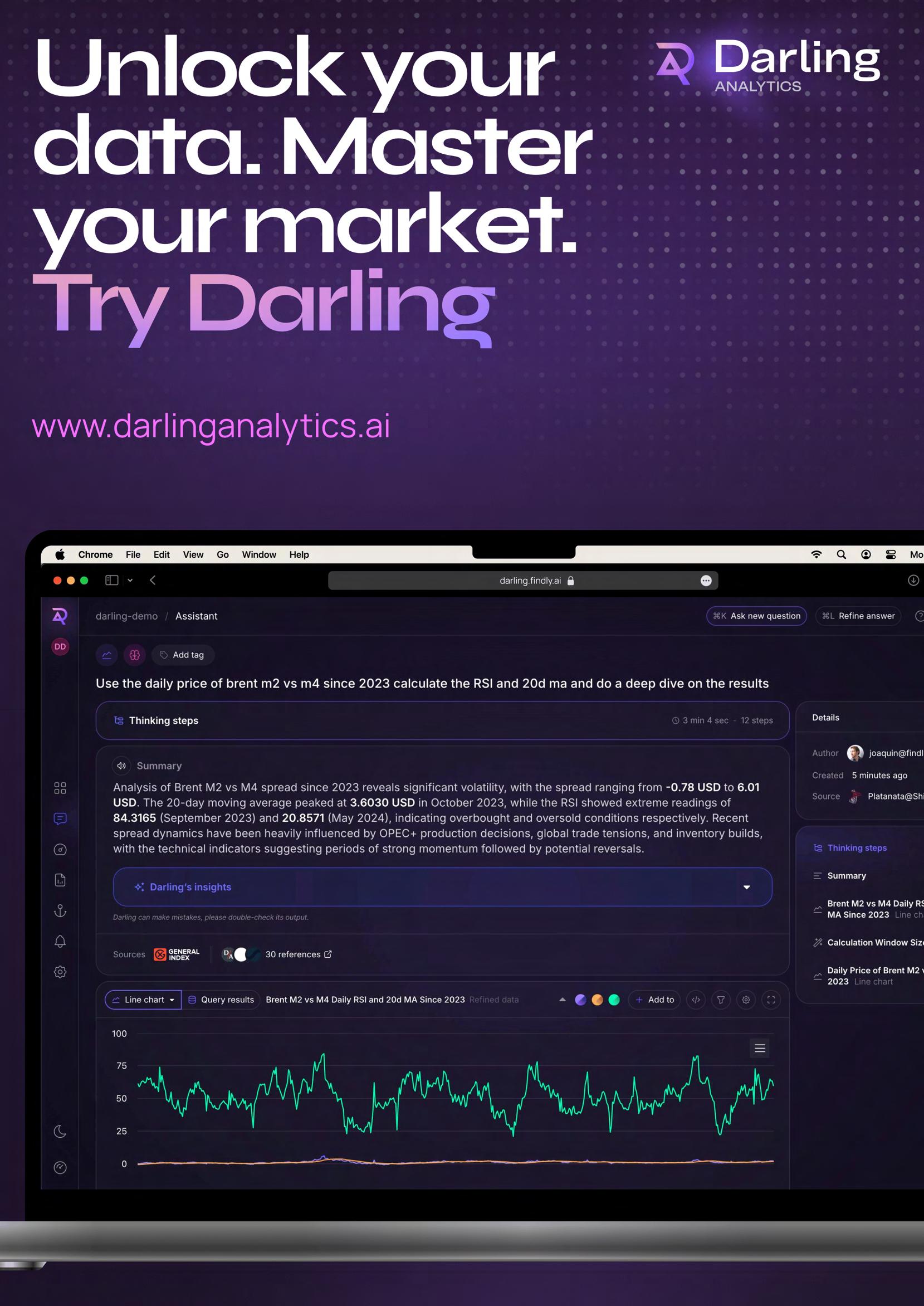

Kicking off the session, moderator Cynthia Worley, vice president of strategic accounts at UK-based technology firm Sedna, underscored the overwhelming pace of digitalisation, with AI tools like ChatGPT dominating conversations, yet many professionals remain unsure about where to begin or what questions to ask.

have finally provided the infrastructure necessary for widespread innovation. However, cultural conservatism and resistance to change still hamper adoption.

world’s premier commodities shipping conference, where delegates were given a glimpse of the technology driving change on land.

The central theme revolved around transforming talk of innovation into actionable strategies, real-world examples, and measurable results. With a panel of seasoned professionals across maritime technology and analytics, the session explored the digital transformation sweeping ports and terminals globally, and how to practically

Ben Palmer, president of Inmarsat Maritime, emphasised that reliable, realtime connectivity is essential for ports and terminals to function efficiently. He drew parallels between the shipping industry and manufacturing facilities, explaining that while the maritime sector is inherently interconnected, it suffers from a lack of true digital integration.

Palmer highlighted the need for always-on, global, secure connectivity— likening it to oxygen for digitalisation. He noted that recent advances in satellite-based, multi-band connectivity

Janani Yagnamurthy, vice president of analytics at maritime tech firm Marcura, built on Palmer’s points by identifying mindset, fear of dark data, and integration complexity as key barriers. She emphasised that legacy systems, while functional, often discourage experimentation and that many ports are paralysed by the sheer volume of data.

She shared the example of the Port of Gijón in Spain, which successfully adopted a modular, non-disruptive digital approach. Rather than replacing systems outright, they layered sensors over existing infrastructure to start small and scale progressively. This phased model respected financial and operational constraints and allowed data maturity to grow organically.

CELEBRATING 15 YEARS of GREAT SERVICE !

Our staff experience covers some 80 bulk vessels ranging in size from small multipurpose bulkers through Handysize, Supramax, Ultramax, Panamax to Capesize vessels trading regionally and worldwide.

NEWBUILDING SUPERVISION

Our newbuild team project experience is based on various shipping and offshore newbuild projects over a 7 year track record.

CONTAINER / MPP

Our staff experience covers some 30 vessels ranging in size from 1,100teu to 3,500teu, geared and gearless, reefer fitted, running on intensive scheduled services regionally within Asia, North/South America, Europe, Australia and New Zealand

STS/LIGHTERING

Our staff experience includes full management of STS/Lightering vessel / Terminal for eight years. Offloading Capesize, Panamax and Ultramax vessels with the industrial high-cycling Tsuji cranes, then transferring from storage holds via EMS-TECH high spread conveyor and 75meter boom to shallow draft tug & barge trains.

Our staff experience covers some 26 units including Dive/ROV Support vessels, AHTS, Heavy Lift Shear Leg barges, Jack-ups, Drillships, SemiSubmersible Drilling units and FSO projects. OFFSHORE

RORO / ROPAX

Our staff experience covers several RoRo, Pure Car Carrier and RoPax vessels supported by long experienced colleagues in Europe, China and Japan, RoRo and RoPax sectors.

Ingrid Kylstad, managing director of Norwegian solutions provider Klaveness Digital, stressed the importance of not just acquiring digital tools, but also integrating them strategically into workflows. The real value, she argued, comes from transforming how teams operate—not merely digitising existing inefficiencies.

Kylstad warned against buying highpotential tools without internal process redesign, drawing a vivid analogy of buying a Ferrari and driving it like a Fiat. Without adapting workflows and ensuring integration, the true ROI remains untapped, leading to eventual disillusionment, she told delegates.

Evangelos Efstathiou, CEO of Burmester & Vogel, a laytime and demurrage software company, noted that historical resistance to automation stemmed from fragmented tools and a lack of standardisation. However, with the advent of SaaS platforms and APIs, seamless integration is now more attainable than ever. He advocated for incremental wins to build momentum— starting with small, demonstrable benefits to encourage internal buy-in.

Yuriy Kizlevych, co-founder of Overhorn Swiss, a port management specialist, supported this by highlighting the global disparity in terminal performance. He advocated for sharing AIdriven operational data transparently with stakeholders to drive optimisation and competitive advantage. This multi-model, data-sharing environment, he argued, could significantly reshape trade patterns.

The panel agreed that while technology enables transformation, trust is what sustains it. Digital adoption is as much a human challenge as a technical one. Tools must empower employees rather than replace them, with training, clarity, and inclusion key to overcoming scepticism.

An audience member shared a success story of cloud migration followed by a deliberate pause to let employees catch up. Rather than pushing for continuous upgrades, they emphasised empowerment

The industry must adopt new tools and embrace a new mindset

and ownership, resulting in increased internal innovation.

The discussion turned toward the untapped potential of operational data. Kylstad stressed that while many systems now promote transparency and efficiency, the real opportunity lies in using that data to develop new business models— not just for cost savings, but for revenue generation.

Efstathiou echoed this by citing an example where a client requested dashboards to prioritise only high-risk voyages, streamlining focus. Aggregating such data could help all stakeholders benchmark performance and identify gaps.

Port documentation remains a bottleneck in many operations delegates were told. Yagnamurthy from Marcura addressed the inconsistencies in format, language, and metadata in critical documents like statements of facts (SOFs), notices of readiness, and bills of lading. She recommended robust master data management, data governance, and the use of AI to extract, standardise, and interpret such data—ultimately turning it into an asset rather than a liability.

Kylstad suggested that the rise of tools like ChatGPT and intelligent automation will increasingly simplify and democratize access to complex documents, making

industry-wide standardisation less critical than it once was.

Efstathiou and Inmarsat’s Palmer agreed that while different segments face unique challenges, shared-value ecosystems can offer immense benefits. They encouraged open communication, shared KPIs, and collaborative platforms as a future model.

Yagnamurthy foresaw a need to “unlearn every five years” due to rapid changes in AI models and workforce expectations.

“As AI and digital ecosystems evolve, the ability to unlearn and relearn every few years will be crucial. Maritime operations are shifting fast, performance metrics are changing, IT is becoming operational, and digital agility will be a defining capability. To stay relevant, the industry must adopt new tools and embrace a new mindset,” Yagnamurthy said.

In his closing remarks, Burmester & Vogel’s Efstathiou advised the audience to take an active role—don’t wait for vendors to deliver a perfect solution. Engage, experiment, and drive collaboration between stakeholders, he said, advising that the technology gap between consumer and enterprise tools is narrowing quickly, and those who move fast and smart will win the competitive edge.

NexusWave Fully managed bonded connectivity service

Multi-orbit, multi-band network: globally reliable Ka-band, low-latency high speed LEO, coastal LTE and resilient L-band

Multiple high-speed networks: future ViaSat-3 upgrade bringing additional high speed bandwidth when and where it’s needed most, even in hotspots

Seamless network bonding: unique SD-WAN technology aggregating available capacity to maximise throughput and enable ‘always-on’ connectivity with unlimited data

Connected confidence inmarsat.com/NexusWave

*ViaSat-3 – Coming soon Connected

A special report Connectivity With Inmarsat

‘The opportunity to transform is fantastic’

Splash sits down with Ben Palmer, the president of Inmarsat Maritime, to discuss the challenges and opportunities for change in shipping over the coming decade

Shipping is entering an exciting, potentially transformative era over the coming decade, reckons Ben Palmer, the president of Inmarsat Maritime. The question he has though is whether the industry will be able to grab all the opportunities out there, or will its conservative, fragmented nature hold it back?

“The fundamental shipping business model has not changed since the 18th century,” Palmer tells Splash. “Over the last 50 years, ships have got fatter, faster and longer but they still look pretty much like they did after World War II.”

With connectivity growing exponentially, ships and their operations are set for change, Palmer says. This started with crew welfare, and is now moving towards “office-like” connectedness.

“There’s a huge amount of tech innovation going on, too. The opportunity to transform is fantastic,” Palmer says touching on decarbonisation, the cloud, artificial intelligence, and big data.

“Ships can be less manpower intensive

The absence of really muscular standardisation and regulation will be a brake on progress

with more monitoring and all kinds of applications,” he says, while cautioning:

“I do have a concern. There is clearly a huge opportunity, lots of drivers to do this, but will shipping have the gumption, the ambition to do this? Shipping has historically not been the earliest adopter, so I would say the jury is still out.”

Palmer insists today’s more forward thinking players are seeing the business case for tech-enabled ships, others in this fragmented business less so.

“I see a lot more doing, but there’s still a lot of talking,” Palmer says.

Palmer became president of Inmarsat Maritime in late 2021, moving across from defence contractor Northrop Grumman. Maritime featured in his career earlier on with BAE Systems, which was his first posting in the private sector having started his career with the UK’s Ministry of Defence.

Palmer sees shipping’s appetite for

innovation as weakened by fragmentation - whether by geography, scale, or flagas well as its relatively under regulated nature.

“The absence of really muscular standardisation and regulation will be a brake on progress,” he says.

The other issue that needs addressing if shipping is to make genuine tech strides in the coming decade surrounds recruitment.

“The industry has an interesting challenge - attracting people to it, young people, tech savvy people at sea and on shore,” Palmer says.

Different skillsets will be required by shipping’s next generation. The next generation want to believe in what they are doing, to work for a sustainable business and to use tech, Palmer says.

“Shipping has to get better at telling its story. The fierce war for talent is visceral,” Palmer concludes.

Free for all?

The so-called office onboard will be achieved by full broadband internet free for all for how much of the fleet by 2035?

Connected ships are all the rage these days, discussed at length at myriad shipping conferences and at boardrooms across the world. Improved bandwidth is changing the business of shipping and how vessels and crews operate far out at sea, all happening at astonishing speed and yet Splash readers do not believe this advance will spread across all ships in the years ahead. Just 10% of readers in our survey (see results on page 48) believe so-called office onboard will be achieved for 100% of the global merchant fleet by full free broadband internet by 2035.

It’s unlikely that full internet broadband will be free for all onboard by 2035 or later, says Tore Morten Olsen, president of maritime at Marlink, a digital solutions provider.

“As we have seen in other areas of life and business, users pay one way or the other and remote communication at sea requires more than the average deployment of hardware and software,” Olsen explains, predicting greater competition as new low Earth orbit (LEO) providers offer services and a tiered market in terms of solutions provided at multiple price points.

It’s unlikely to be free for all anytime soon, concurs Andrew Airey, who heads up Thai shipmanager Highland Maritime,

By

2035, full broadband will be a baseline expectation

thanks to the sheer growth in data collection, analysis, action, and CCTV monitoring and interaction requirements outstripping capacity growth.

More optimistic is Stamatis Tsantanis, chairman and CEO of Greek owner Seanergy Maritime.

“Thanks to falling satellite costs and rising demand for crew welfare and operational connectivity, a large portion - say 75% - of the fleet will likely have free, full broadband access—though full coverage across all vessels may take longer,” Tsantanis tells Splash.

Peter Schellenberger, founder of Novomaxis, a shipping consultancy, sees a minimum of 95% having free full broadband in 10 years time, citing the 2027 launch of Amazon’s Kuiper service as a “game changer”.

“By 2035, full broadband will be a baseline expectation, especially for vessels over 20,000 dwt,” argues Manish Singh, the head of Aboutships, a maritime advisory.

The bigger shift for Singh will be how this connectivity enables truly integrated fleet operations — where ship and shore are in constant sync, making decisions together in real time.

“The cost/benefit of equipping ships with terrestrial levels of connectivity is so attractive that laggards will find it difficult to compete with connected fleets,” Singh maintains.

Turning to the office onboard part of the question posed to readers, Ajay Chaudhry, CEO of shipmanagement at Synergy Marine Group, says this will mean cultural and working practice shifts as it will involve more digital workflow, cross-functional meetings, and real-time owner access.

“Connectivity must be paired with capability—the ability to conduct critical operations, access documents, and interact with experts without bandwidth barriers,” says Chaudhry, adding: “By 2035, this will be a standard expectation, rather than an innovation.”

Pradeep Chawla, the founder of MarinePALS, a training specialist, concludes by telling Splash how he is very much against the whole office onboard thinking.

“Seafarers have reached their limits with the number of tasks that they have to do. Yes, we need to give broadband onboard, but not for pushing more tasks to the ship’s staff,” Chawla says.

Prolonging a career at sea

Can improved connectivity onboard lead to more seafarers extending their time onboard before pursuing a career ashore?

Shipping faces a shortage of qualified staff at sea, a problem that risks becoming more acute over the next 10 years.

One way to help fix the problem is to ensure people stay longer in their jobs at sea with many experts saying for this to happen connectivity must improve. The availability of internet access is now a critical factor in seafarers' career decisions, something that will only become more important in the years ahead.

“Improved connectivity is an essential expectation for people coming out to sea,” says Pradeep Chawla, the CEO of training specialist MarinePALS. “You cannot explain to an 18-year-old who is used to connectivity of one gbps to accept a VSAT connection of two or four mbps.”

“New entrants may not even join the industry if the comms plans are not conducive,” warns Peter Schellenberger,

Improved connectivity is an essential expectation for people coming out to sea

who runs Novamaxis, a consultancy.

By 2028, Schellenberger predicts that 90% of quality vessels will have a LEO type comms plan.

“By staying connected with family and accessing digital resources, seafarers can enjoy a better quality of life, which can positively impact their wellbeing and job satisfaction. This, in turn, may lead to longer tenures at sea,” says Stamatis Tsantanis, chairman and CEO of Greek owner Seanergy Maritime.

Improved internet access can significantly reduce feelings of loneliness and isolation amongst seafarers. The ability to stay connected with family and friends via video calls, messaging, and social media can help seafarers remain a part of family milestones and important life events in

real-time, and maintain a connection with the outside world, which can reduce the emotional distance between shore and sea, alleviate feelings of being alone during long ocean voyages, boost morale, and create a more positive and motivated work environment.

By enhancing work efficiency and providing access to a wealth of online options in their free time, a more rewarding work-life balance can be achieved. From communicating with family and friends, managing personal matters, and following the latest news to watching sports, movies, and listening to music, a reliable internet connection opens up a world of opportunities to seafarers, allowing them to relax and enjoy their free time as they wish, which is essential for their overall wellbeing.

We have to stop waving connectivity as a magic wand

“The work-life balance can make a career at sea more sustainable,” says Niraj Nanda, chief commercial officer of shipmanagement giant Anglo-Eastern.

“Connectivity helps facilitate meaningful social interaction with friends and family ashore and supports recreational engagement like browsing and streaming—both of which ease the psychological burden of long voyages,” says Ajay Chaudhry, CEO of shipmanagement at Synergy Marine Group.

“By prioritising safety, improved connectivity onboard can positively impact seafarers to extend their careers at sea,” Nanda says. “Better connectivity can help improve operational efficiency and the well-being of seafarers onboard, thereby contributing to a more fulfilling and secure work environment,” he says.

“Improved connectivity allows seafarers to access news, digital banking and services, entertainment, and

educational resources. Staying informed and entertained can make their time onboard more fulfilling,” says Shah Irani, chief technology officer at Fleet Management.

Moreover, as Nanda points out access to online medical and mental healthcare services, therapy, and video consultations by trained professionals can help reduce the distance between specialists and the seafarers who may require their services. This can positively impact the physical and psychological wellbeing of seafarers by improving medical care onboard, thus reducing the need for port visits, medical sign-offs and diversions, and the relevant costs.

With access to online courses and studies, seafarers can further their knowledge, training, and qualifications during their free time onboard. This enables seafarers to enhance their skills and advance in their careers in

the industry, which can be a strong motivator for extending their time at sea.

Manish Singh, a former seafarer and shipmanager who now runs advisory Aboutships, cautions readers that connectivity by itself is not a panacea to the seafarer shortage issue.

“We have to stop waving connectivity as a magic wand,” he says, predicting that even “laggard” fleets will have fast, reliable and cheap internet soon.

“Longer term crew retention has more to do with a sense of inclusion, purpose and through-career visibility,” Singh argues.

Better connectivity helps with wellbeing and continuity, he concedes, but retention also needs recognition, upskilling, and agency for colleagues onboard.

“I envisage seafarers will feel more connected into the overall workflow as we embrace a connected and data-driven ecosystem,” Singh concludes.

Bandwidth bonus

Will improved connectivity onboard improve competence in shipping?

Improved onboard connectivity significantly enhances competence in shipping, according to many people surveyed for this magazine.

Enhanced connectivity facilitates real-time communication between onboard crews and shore-based teams. Through video conferencing and collaborative platforms, seafarers can receive immediate guidance, partake in virtual training sessions, and engage in knowledge sharing, thereby improving operational efficiency and decisionmaking.

Andrew Airey, who heads up Thai shipmanager Highland Maritime, argues that if connectivity brings true assistance to shipboard personnel in more efficiently handling their duties and reducing their workload and stress levels then it can clearly improve the industry.

“Enhanced bandwidth enables realtime training, remote mentoring, and

We’ve seen best results when connectivity enables, not replaces, professional development

smoother digital operations. Competence increases as crews can access updated safety protocols, predictive maintenance alerts, and decision support tools,” says Shah Irani, chief technology officer of Fleet Management.

Tore Morten Olsen, president of maritime at Marlink, questions whether accessing training remotely between work and sleep is the right environment.

“Training that builds competence - whether in person, remote or virtual - needs to be delivered in the right environment to encourage learning and teamwork,” Olsen says.

Pradeep Chawla, the founder of MarinePALS, a training specialist, has statistics that back up how online training directly leads to better safety and

better performance in vetting and port state control inspections.

Ajay Chaudhry, the CEO of shipmanagement at Synergy Marine Group, maintains that real-time access to simulators, troubleshooting support and feedback on performance all transform learning into what he describes as a “continuous loop”. However, the tech must be complemented by human systems, Chaudhry argues.

“Leadership, feedback culture, and accountability. We’ve seen best results when connectivity enables, not replaces, professional development,” Chaudhry says. “With the right infrastructure, even vessels that are far out to sea become floating learning environments that empower crew to solve problems in real

Real-time performance feedback, shore-based support, and system diagnostics become possible with connected ships

time.”

Connectivity is only the toolbox or enabler, argues Peter Schellenberger, the head of Novomaxis, a consultancy.

“It is now up to the industry to find correct use cases and applications to maximise efficiency,” he says, stressing the importance of training for both shore and seagoing staff. "Applications are live faster than regulations so it is up to the companies to work with their learning providers to cover the ground,” Schellenberger says.

Quite so, agrees Nicholas Goubert, co-CEO of online learning giant Ocean Technologies Group.

Improved connectivity onboard promises massive gains in the speed of deployment whereby as soon as a solution is ready it can be consumed by seafarers wherever they are located, Goubert says.

“This makes the process of building

competency much more agile especially when regulations are moving fast and people want to respond to dynamic threats,” Goubert says.

Improved connectively also opens up the possibility of richer learning experiences such as cloud simulation, virtual reality, and gamification, he adds.

In terms of operations, connectivity is crucial in facilitating technology deployment and digitalisation of the maritime industry.

“Reliable connectivity allows for real-time monitoring and management of vessel operations, including navigation and maintenance. This leads to optimised fuel consumption, reduced downtime, and improved safety,” says Niraj Nanda, chief commercial officer of Anglo-Eastern.

Reliable connectivity is also essential for driving innovation in the maritime industry. Anglo-Eastern, for instance, continues to explore

innovative technologies, including drone deliveries, augmented reality, and AI, to further drive efficiency and sustainability. A notable example is the company’s remote maintenance support, which revolutionises equipment troubleshooting and enables swift issue resolution without requiring on-site specialists.

It’s not just competence, per se, that will improve, according to Manish Singh, the founder of British advisory Aboutships. Decision making will change massively, he says.

“Real-time performance feedback, shore-based support, and system diagnostics become possible with connected ships,” Singh says, discussing the rise of embedded training, remote decision support, and automated compliance — all of which he believes will raise technical competence and reduce human error.

How the daily routines of seafarers will evolve

How much of daily manual operations at sea will be made redundant by 2035?

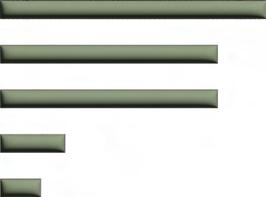

How has your job changed over the past 10 years? Is the workload similar? That’s the kind of thoughts we asked Splash readers to contemplate in our survey with one of the key questions posed asking how much of daily manual operations at sea will be made redundant by 2035.

For all the hype about tech’s ability to streamline every facet of work, most respondents felt that the vast majority of manual operations would still be performed by seafarers 10 years from now (see results on page 48).

“We see technology as an enabler that will remove a lot of the mundane repetitive tasks allowing maritime professionals at sea and ashore to focus on the parts of the operation where they can add more value,” says Nick Copley, co-CEO of Ocean Technologies Group, a training specialist.

Advancements in automation will change the way work is performed, and possibly where those jobs are performed, according to Copley, but seafaring knowledge and skills will still be needed to ensure safe, reliable and responsible shipping for many years to come.

“Enhanced connectivity facilitates

training, remote support, and realtime data exchange, contributing to better decision-making and operational competence,” says Masaki Matsunaga, executive vice president at ClassNK, who, like Copley, sees seafarers continuing to carry out the majority of manual operations.

Routine monitoring, reporting, and maintenance diagnostics will be automated or shifted ashore by 2035, predicts Ajay Chaudhry, who heads up shipmanagement at Synergy Marine Group.

“We anticipate up to 40% automation of current manual tasks over the next decade, but also a commensurate rise in new skill demands for those going out to sea,” Chaudhry tells Splash.

However, tasks requiring immediate judgment, evaluation, or coordination, and any form of emergency response, will always need people onboard, he stresses.

As an example, Chaudhry sites how the first law of the sea is to help those in peril, saying it is hard to see how an autonomous vessel could undertake even the most basic of the search and rescue operations that seafarers perform every

day.

That said, Chaudhry does admit machinery reliability also needs to evolve.

“Systems such as ballast water treatment and exhaust scrubbers continue to demand significant manual intervention across the fleet—highlighting that automation must be paired with robust design and ongoing technical support,” he points out.

Manish Singh, who leads Aboutships, a UK maritime advisory, sees up to half of repetitive tasks disappearing from seafarer daily routines come 2035.

“Some maintenance activities will shift from done while at sea to done while in port and involve in-port crew,” he says.

Retained roles will focus on watchkeeping, critical safety and compliance, mooring, cargo care, repairs and maintenance, Singh reckons while a lot of the onboard workflow will be digitally assisted in areas such as reporting, routing, and documentation.

"With better connectivity and extensive sensors onboard, decision support systems, and AI tools, much of the manual monitoring and form-filling will go,” Singh predicts.

A lifeline to home and increased productivity

Internet use is now a critical factor in seafarer satisfaction, something that will only accelerate in the years ahead

An in-depth Inmarsat survey of nearly 400 seafarers working on merchant ships, offshore support vessels or high-end fishing vessels across the globe shows that seafarers are increasingly experiencing a sense of a ‘floating home’ when it comes to their time onboard, a portent of what’s to come over the next decade.

Seafarers spend an average 8% of their annual salary on internet connectivity, the survey found, with the cost split equally between their usage at home and onboard their vessels.

When at sea, video calling, voice calling, and messaging family and friends were the most popular uses for the internet, with a huge majority saying the connections positively impacted their mental wellbeing.

During long voyages, seafarers said they were 23 times more likely to feel positive effects from these personal interactions, rather than negatives.

Staying in touch with friends and family were the main reasons given for needing connectivity, although seafarers also cited managing work-related tasks as important, as ships increasingly depend

on real-time data for both compliance and competitive advantage.

Around two-thirds of respondents put personal video or voice calls and text messaging in their top three uses for connectivity. Less critical, but still pronounced, were top three preferences for social media (51%), web browsing (34%) and watching movies, TV shows, sports or other streamed content (29%). A small proportion identified shopping (11%) and gaming (8%) as top three online activities.

However, while 97% of these seafarers actively manage their own data usage at sea, more than four out of five said they exceeded their limit – with more than a third saying it happened often. Furthermore, a mixed picture emerged regarding satisfaction with connectivity at sea.

Of those surveyed, 28% said they were dissatisfied with the cost, while more than half said they would be willing to

pay more for better connections.

Overall, internet usage among seafarers increases while they are in port, with 61% reporting higher usage and only 15% using it less. On average, seafarers use the internet 18% more while in port compared to when they are at sea. Although those who use their mobile phone plans often find it cheaper than vessel connectivity, the majority of the survey respondents (52%) indicated a preference for ship connectivity over their mobile plans or port wifi.

In a remarkable finding, 83% of the surveyed seafarers expressed concern about security and privacy while using a vessel's internet – with one in nine of the seafarers reporting a data security issue, such as hacking or data loss, while connected to a vessel’s internet.

Clearly, for this seafaring constituency, work remains to be done on security before a ship can truly merit the comfort of a floating home.

Seafarers spend an average 8% of their annual salary on internet connectivity

Coming to a shipyard near you soon?

Some yards are pushing the innovation envelope. Most are not

Sporting jeans and a rollneck rather than the standard overalls and helmet of his peers, Kisun Chung, the third generation of the Chung family at the helm of HD Hyundai, South Korea’s largest shipbuilder, has for the past few years trekked out to Nevada once a year to speak and exhibit at CES, a high-profile Las Vegas tech event where his company likes to pitch itself as a “future builder”.

The yard is one of shipping’s leaders when it comes to artificial intelligence and autonomous technology. It is far ahead of most of its competitors around the world in developing a smart shipyard.

As a very visible sign of how the business of shipbuilding is changing, HD Hyundai has just signed a deal with an American company to get humanoids welding, helping to alleviate ongoing workforce shortages.

Senior vice president Dong-ju Lee said: “Our goal is a smart shipyard where humans and intelligent robots collaborate seamlessly.”

However, it is important to bear in

mind, HD Hyundai is a bit of an outlier, few yards match it in the world for its appetite for innovation.

In Splash’s poll for this magazine, most readers felt shipyards could be doing more to foster innovation and new designs.

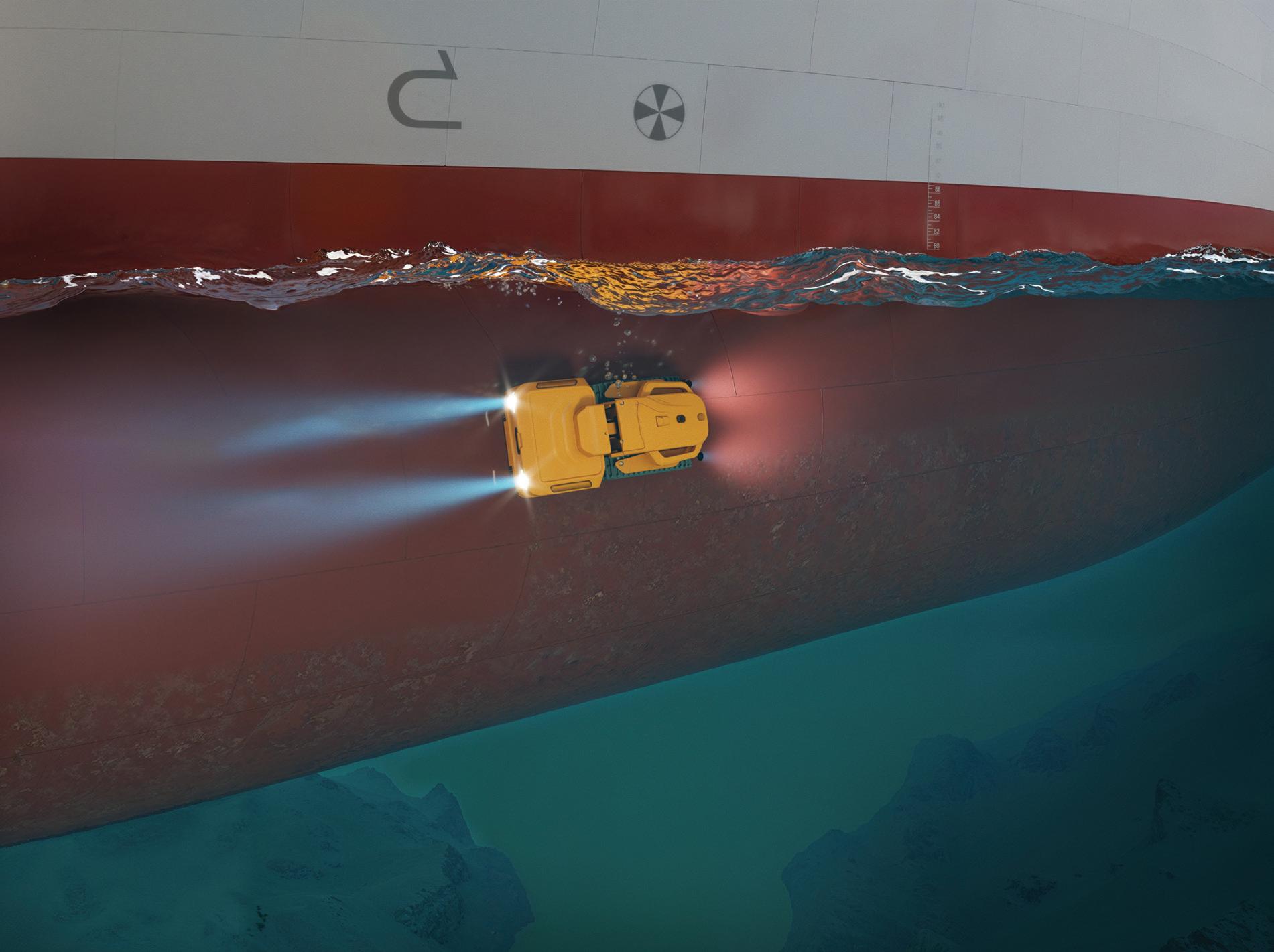

Andrew Airey, who heads up Thai shipmanager Highland Maritime, says simple immediate things yards could address include improving the steelwork and paint protection systems to significantly reduce lifetime steelwork maintenance as well as improving machinery design and reliability to significantly reduce the lifetime maintenance requirements necessary for semi/fully autonomous vessels.

Craig Tulk, a product business analyst at the Sustainable Shipping Initiative, tells Splash: “Our industry is conservative, and owners will always be the ones who drive the latest innovations in vessel design.”

However, Tulk did say that increasingly, shipyards are working with owners as partners to achieve “loftier” goals.

Progress is visible, but again it is not standard across the industry, according to Ajay Chaudhry, the CEO of shipmanagement at Synergy Marine Group.

“While a few advanced shipbuilding nations are pushing boundaries— particularly in areas like LNG, ammonia, and dual-fuel readiness—design cycles remain heavily owner-driven,” Chaudhry says.

For real innovation, he is calling for tighter shipyard-designer-operator loops, and stronger incentives.

“A shared commitment to lifecycle outcomes—and specifically addressing fuel flexibility, emissions profile, and digital readiness—can turn yards into innovation partners, rather than just builders,” Chaudhry says.

Design cycles remain heavily owner-driven

Manish Singh, the CEO of Aboutships, a maritime transaction advisory, says pressure is building on yards to deliver more.

Many yards remain capex-focused, not lifecycle-optimised

“The regulatory clock and new fuels are forcing change, but inertia is high,” Singh says, adding: “Many yards remain capex-focused, not lifecycle-optimised.”

Peter Schellenberger, founder of Novamaxis, a maritime consultancy, hits out at the lack of standardised systems hindering progress at yards around the world.

“Compared, for example, to the airline industry, the varieties of execution and components used in shipbuilding are totally not aligned and far from standardisation, even for same vessel types. Even sister vessels built in the same yards may not have the same equipment list, which in effect is a real hindrance to speed up the standardisation which is necessary to propel forward more autonomous shipping,” Schellenberger argues.

While some yards actively invest in R&D and innovate, others continue to rely on standardised designs instead of adopting new ideas, concedes Arunava Sengupta, managing director of AngloEastern Technical Services.

What has changed, according to SSI’s Tulk, is that shipyards now have the tools to work with the owner earlier and with less friction.

“We’re seeing shipyards partner with owners earlier in the concept

design process and use a shared source of truth to manage the project from earlier in its lifecycle,” Tulk says, while reminding readers that it remains the owners who tend to initiate this conversation.

The maritime AI market nearly tripled in size in just one year

The coming force

Whatever industry you may be in, odds are that it is being invaded in a multitude of ways by artificial intelligence. Shipping is no exception, but how it will all look in the years to come is still vague due to AI developing at blistering speeds.

You could say that AI is seemingly everywhere. But most likely you’d be wrong. It is everywhere. ChatGPT, Gemini, Copilot, and different image and video editing apps are just the tip of the iceberg that is the application of AI.

The burst of AI, however, is only a recent thing for the mainstream. In industrial and academic purposes, it has been around for a long time. If you needed to analyse particle data from CERN’s Large Hadron Collider or find a potentially hazardous asteroid that might one day collide with Earth, you could use AI to do it because it would take whole teams of people to do it in way more

time.

Both of those things have already been done by AI, as well as guiding your robot vacuum cleaner to clean your house and making an image of you in the style of Japanese anime.

AI is the buzzword of today. There is no two ways about it. Advances are being reported on very often, and new applications are seemingly found daily. All this is precisely why the future for AI in general, and in the maritime sector in particular, is a bit of a guessing game due to the almost quantum leaps it is making.

Regardless, it is partially the present but surely the future for the world and with it the maritime industry. And Splash readers agree.

A survey carried out by Splash for this magazine, in association with Inmarsat, suggests that AI will have the most significant impact on maritime

Splash readers are adamant that AI will impact ship operations more than any other tech in the coming decade. Splash explains why and how

operations in the coming decade. AI came on top of other tech making waves in the shipping sector, such as Internet of Things, Big Data analytics, and blockchain.

British consultancy Thetius reported in September last year that the maritime AI market had nearly tripled in size in just one year and was valued at $4.13bn, with a projected five-year compound annual growth rate of 23%.

The application of AI also showed positive results. McKinsey reported that AI implementation can reduce forecast errors by 50% and logistics costs by 15%, while companies using AI have seen inventory levels decrease by 35% and service levels improve by 65%.

McKinsey’s senior partner Kweilin Ellingrud even stated that AI alone could automate almost 10% of tasks in the entire US economy.

It is important to understand what

kind of work AI can do and is doing for the maritime industry. Automation is probably the number one use of AI algorithms.

Routes can be optimised based on real-time data, enabling timely adjustments to unexpected events while maintaining the most cost-effective alternative. This, in turn, makes vessel operations energy efficient and reduces carbon emissions. Companies and crews can also be assisted by AI providing real-time data analytics, predictive maintenance insights, and risk assessments.

This is where Splash readers agree once again. When asked about the average crew numbers onboard in 2035, an overwhelming 74% said that it would be less than today. Also, over half of our readers voted in the survey that at least 25% of daily manual operations at sea would be made redundant by 2035, while 21% said 50% or more would become redundant.

If everyday tasks are taken over by AI, it would stand to reason that vessels would operate with smaller crews and that certain tasks or even jobs would fade out of existence. On the other hand, if AI can handle routine and repetitive tasks, it frees up time for individuals to learn new skills or take on new responsibilities. As for particular roles that could be most affected by automation by 2035, navigation was voted the most likely to be affected, followed by engine room operations and maintenance.

In the, probably not so distant, future we will also be looking at the most extreme version of autonomous ships – ones in which the operating system of the ship is making decisions and determining actions by itself. This would require a fully developed AI, similar to the ones in self-driving cars, which would do all the tasks needed to get from point A to point B.

On the matter of how the adoption of

autonomous vessels, in any form, will affect shipping costs by 2035, Splash readers were quite indecisive, with an almost even split between decreasing, increasing, or staying on par with today.

What is very clear from the survey, though, is that the sectors which will be most affected by automation are containerships and short-sea shipping. The two sectors together account for 90% of the answers.

Safety is another area where AI can shine by identifying crucial safety and security events in real time. However, Splash readers are not so convinced that AI-powered safety would bring considerable improvement. In an almost split decision, 49% of readers stated that the number of incidents would remain the same or increase, while 51% believed that things would improve. It is alarming that 28% of those surveyed believed that incidents would increase.

With automation and AI, just like with any other technology, come safety concerns and cybersecurity, along with

equipment malfunction and human error in oversight, were the biggest ones identified in the survey.

To best see how much work can be done by AI, global logistics provider C.H. Robinson announced it has performed over 3m shipping tasks with its fleet of generative AI agents. The company also hit 1m orders processed by AI in March.

Maritime companies know this, and some have been spending big bucks to get enough AI tools in their toolbox.

For example, CMA CGM's contract with Mistral AI, signed in April, has brought its AI-related tally to over half a billion US dollars, and it will surely only keep rising.

The future for AI is looking very bright, and as its applications become more and more prevalent, shipping will fall in line like all other facets of life because, as futurist and technophilosopher Gray Scott once said: “There is no reason and no way that a human mind can keep up with an artificial intelligence machine by 2035."

Enhance vessel performance with our sustainable graphene-based hull and propeller coatings

Applied on 400+ Vessels

AI, automation and the future of maritime jobs

Mark Charman, CEO and founder of Faststream Recruitment, on why human skills still matter

AI is reshaping the maritime industry at an unprecedented pace. From predictive maintenance and autonomous shipping to AI-driven recruitment and workforce optimisation, technology is making operations smarter, safer, and more efficient. But as AI takes on more tasks, one question remains:

What does this mean for human talent in maritime? For C-suite leaders, the challenge isn’t whether to adopt AI, it is how to integrate it effectively while ensuring that human skills remain at the heart of the industry.

AI is excellent at processing vast amounts of data, automating repetitive tasks, and optimising decision-making. However, the core of maritime leadership, things like strategic thinking, relationship management, and crisis navigation remains uniquely human.

AI can generate insights, but leaders must interpret them, foresee risks, and adapt strategies in real-time. Maritime operations are unpredictable, requiring a level of human judgement that no algorithm can replicate, well certainly not yet…

Whether negotiating contracts, managing diverse crews, or making highstakes decisions, human intuition and empathy are irreplaceable. The maritime industry thrives on trust, collaboration, and leadership, all of which depend on strong interpersonal skills.

AI can suggest solutions, but it

doesn’t understand company culture, values, or the wider economic and regulatory landscape. Leaders must balance AI-driven insights with ethical considerations, long-term vision, and business strategy.

As AI adoption accelerates, maritime C-suite executives and HR leaders must rethink their workforce strategies. The most successful maritime organisations will be those that:

● Invest in upskilling and reskilling

● Equip employees with the digital literacy and problem-solving skills needed to work alongside AI

● Prioritise soft skills like adaptability, collaboration, and strategic thinking alongside technical knowledge.

● Balance automation with human expertise

Using AI to handle data-heavy tasks while empowering people to focus on high-value leadership and decisionmaking.

AI is a tool, not a replacement for human ingenuity. The leaders who thrive in this new era will be those who can leverage AI while championing the human skills that drive maritime success.

As automation evolves, maritime professionals will need to adapt to hybrid roles. Digital literacy, data analysis, and AI-assisted decision-making will become essential, but so will leadership, resilience, and problem-solving. The most future-proof employees will be those who can seamlessly integrate technical

expertise with human-centric skills.

As AI takes over routine and dataheavy tasks, professionals will have more capacity to focus on high-value activities, such as strategic planning, innovation, and customer relationship management. The ability to problem-solve, think creatively, and lead with vision will be more valuable than ever.

AI can process vast amounts of data and present recommendations, but it is up to human professionals to make final decisions. In high-stakes situations, maritime professionals will need to use AI-driven insights to enhance their judgment rather than replace it.

One of the biggest challenges maritime leaders face is managing concerns over AI adoption. Some employees fear job displacement, while others worry about AI’s impact on workplace culture.

To successfully integrate AI while maintaining a motivated workforce, maritime leaders must prioritise clear and transparent communication. The best organisations will proactively address concerns by explaining how AI will support roles rather than replace them. Providing real-world examples of AI augmenting rather than eliminating jobs can go a long way in helping ease uncertainty.

Transparent communication, clear career development pathways, and ongoing training will be critical in ensuring AI is viewed as an enabler, not a threat.

Why high-quality data demands the right foundations

The trend towards high-frequency sensor data is increasing, writes Christian Rae

Holm, the CEO of Coach Solutions

The welter of information that high frequency sensors can provide creates an opportunity for applications that can work at this cadence. For the majority of the fleet, however, the emphasis is still on the ability to capture high-quality, lowfrequency data and blend the two into a robust combination.

Low-frequency data is not just for simple analysis tasks. Used in conjunction with complex digital vessel models, it can provide high-quality insights that reflect the specifics of the ship being analysed.