The Role of Rubber Pressure Rollers in High-Precision Industrial Printing

Introduction

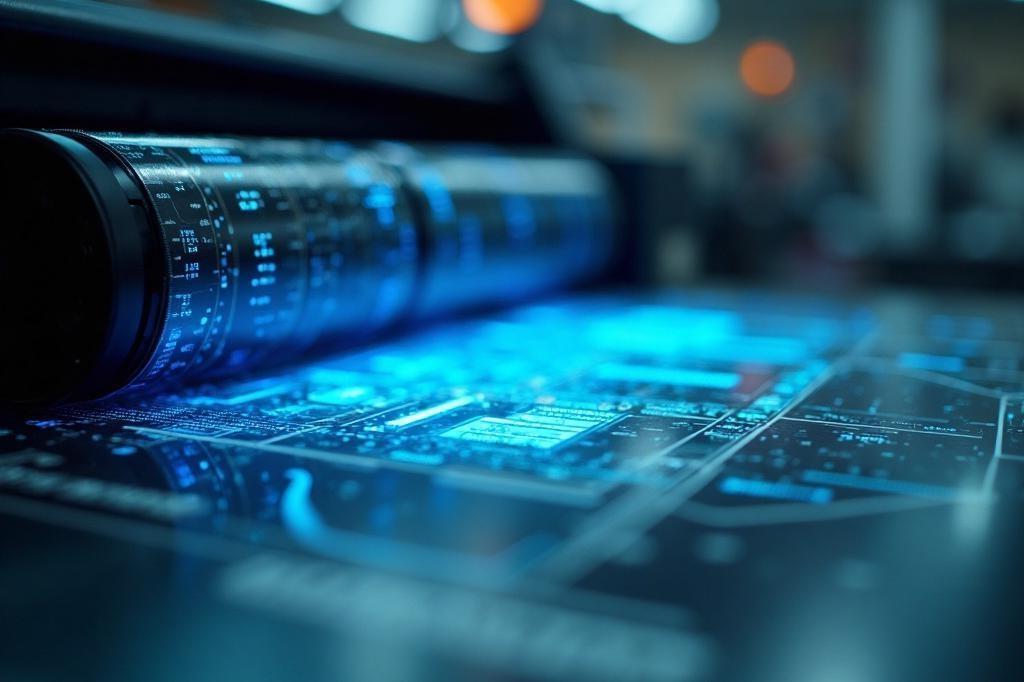

In the world of industrial printing, precision and consistency are crucial. One of the key components that ensure high-quality output in various printing systems is the rubber pressure roller. These rollers are responsible for applying uniform pressure across substrates, allowing for consistent ink distribution, smooth feed movement, and enhanced printing accuracy.

From packaging to publishing, rubber pressure rollers have become indispensable for modern printing technology.

Understanding Rubber Pressure Rollers

Rubber pressure rollers are cylindrical components coated with durable rubber compounds. They work in conjunction with other rollers in a printer or press to maintain contact with the material being printed. Their function is not limited to applying pressure alone—they also aid in guiding the material and controlling the feed speed. What sets them apart from other rollers is their ability to maintain even pressure across the substrate, which is essential in preventing smudging, misalignment, or uneven ink application. The softness, resilience, and chemical resistance of the rubber coating make these rollers highly efficient and long-lasting.

Applications in Industrial Printing

Rubber pressure rollers play a critical role in various highprecision printing processes, including flexographic, gravure, offset, and digital printing. Each of these methods relies on the roller’s ability to apply balanced pressure over large surface areas, often at high speeds. In digital and offset printers, printer rubber rollers work to stabilize the paper feed and help in consistent ink transfer.

They are particularly vital in multi-color printing where perfect registration is required. In large-format printing and packaging industries, these rollers also interact with rubber covered conveyor rollers to ensure the continuous and smooth transport of printing materials.

Importance of Precision

High-precision printing demands tight tolerances. Even the slightest inconsistency in pressure can result in blurred images, off-centered prints, or wasted materials. Rubber pressure rollers are engineered to deliver consistent compression without deforming under stress. Their shock-absorbing properties allow them to handle high-speed operations while maintaining print clarity and color accuracy.

Moreover, advanced rubber compounds and customized hardness levels (measured in durometers) can be chosen depending on the printing substrate—whether it's paper, film, plastic, or fabric. This customization makes them suitable for a wide range of industrial applications.

Rubber Rollers in India: A Growing Market

India has emerged as a significant player in the global rubber roller market.

With advancements in manufacturing and rising demand for high-speed printing solutions, several manufacturers now offer high-quality rubber rollers in India. These companies produce both standard and custom rollers used in textile printing, laminating machines, packaging equipment, and commercial presses.

Many Indian manufacturers are now competing on a global level by offering cost-effective solutions without compromising quality. They use advanced materials like EPDM, silicone, nitrile, and polyurethane to meet industryspecific requirements.

Integration with Conveyor Systems

In large-scale printing setups, rubber covered conveyor work in tandem with rubber pressure rollers to ensure seamless material handling. These conveyor rollers are essential in automated printing and packaging lines where speed and synchronization are critical. The rubber covering on the conveyor rollers provides the necessary grip to prevent slippage, while the pressure rollers manage the print fidelity.

Conclusion

Rubber pressure rollers are the backbone of industrial printing systems. Their role in maintaining pressure consistency, improving material handling, and ensuring print quality cannot be overstated. As printing technologies continue to evolve, the demand for precision-engineered rubber rollers will only increase.

With a growing number of manufacturers producing reliable rubber rollers in India, businesses now have access to affordable and high-performance components that support a wide range of printing applications. Whether it's a printer rubber roller or a rubber covered conveyor roller, investing in the right type of roller can significantly enhance operational efficiency and print quality.