Curriculum WORK EXPERIENCE

March 2017 – Present

Costume organization Dutch Garrison 501st Legion.

Charity work

August 2015 – Present

Toys XL/Intertoys/ToyChamp Breda Sales Assistant

Part-time job

February 2016 - June 2016

Engie Cofley, electrical services in Amphia Hospital, Molengracht Breda

Internship

December 2016 - April 2017

Amgen Europe B.V. Breda

Maintenance Work Preparation

Internship

December 2017 - April 2018

& January 2019 - June 2019

VDL Steelweld B.V. Breda

Parking Systems Department

Maintenance Work Preparation

Internship

February 2022 - June 2022

Promea Industrial Design Breda

All-around Product Designer

Internship

Hobbies

- Working with computers

- DIY (Do It Yourself)

- Costume making/Cosplay

- Model building

- 3D drawing/printing

siebefoesenek@outlook.com

CurriculumVitae EDUCATION

2019 – Present

Rotterdam University of Applied Sciences

Bachelor of Industrial Product Design (IPO), Full-time

2015 – 2019

Radius College/Curio Breda

Intermediate Vocational Education in Engineering, Technician track, Level 4

2011 – 2015

Foesenek

14/10/1998

32 84 79

siebefoesenek@outlook.com

VMBO-GT (preparatory secondary vocational education)

Newman College Breda

Technical subjects including history and visual & audio arts

Skills

Adobe Illustrator

Adobe Photoshop

Arduino

Autodesk Autocad

Autodesk Inventor

Autodesk MeshMixer

KeyShot

Paint.net

SolidWorks

Sony Vegas Pro

Ultimaker Cura

Languages

Dutch (native)

English (advanced)

Sketches & Renders

SKILLS

GENERATING IDEAS

RENDER SKETCHING

SOLIDWORKS

KEYSHOT

Sketching

An important aspect of Industrial Product Design is the ability to quickly and clearly convey ideas, to visualize them effectively, and make them presentable. That's why, since the beginning of my studies, I've had the ambition to improve my sketching skills and even delve into the world of anatomy. I've already made significant progress, but I still have a lot to learn.

Rendering

In the past, I created renders manually or using SolidWorks, but during my third year and my internship at Promea Industrial Design, I discovered the world of KeyShot and graphic drawing.

Idea & Concept Sketches

Sketch Renders

Artery Line

For over 60 years, nurses at Erasmus MC in Rotterdam have been using the same laborintensive system to adjust their artery lines in height. The artery line always needs to be at the same level as the patient's heart. Since the patient's bed needs to be adjusted multiple times a day to prevent muscle weakness, this task needs to be performed repeatedly, which takes up a lot of time. There must be a better solution for this. Hence the request from Create4Care to develop a system that simplifies this task.

After exploring multiple adjustment methods, I came up with three concepts focused on userfriendliness. The people at Create4Care saw benefits in each concept. We then decided to combine the positive features of each concept into one design.

Tests showed that a button would provide a better user experience. I further developed this concept.

However, when the model was ready and could be tested in a physical prototype, the button mechanism did not work properly. Although it felt comfortable in the hand, I had to reconsider. After redesigning, I arrived at a simplified product that functioned well without the button. Personally, I found the design with the button more aesthetically pleasing, and given more time, I might have made it work. However, to have a functioning design within the given timeframe for this project, I had to make a compromise.

Foldable Workstation

Dataflex is a company specialized in creating ergonomically sound computer workstations for both home and office use. Currently, Dataflex has more demand from businesses than from individual consumers. They have asked us to design a product for the consumer market.

My vision was to create a product that could easily transform a workstation into a more home-like space. I wanted to establish a clearer distinction between work and home environments. Especially now, with more people working from home, the line between work and home is becoming increasingly blurred, and I believe people have a need for a clear separation. After generating multiple ideas, I presented three concepts to the team at Dataflex, who then selected one idea to be further developed.

To get a better understanding of how to transition effectively from Setup A to Setup B, I asked as many people as possible to send me photos of their home workstations. I replicated the most common objects using cardboard and incorporated them into a mock-up of a home and work setup.

Next, I made considerations regarding the space needed to hide and reveal certain objects and how to achieve this transformation effect. My solution came in the form of the parallelogram effect.

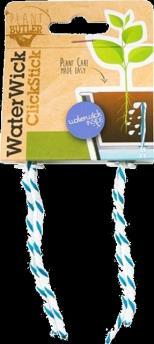

WaterWick Cultivation PRO 22

2nd year – 3rd semester

WaterWick Cultivation Table

WaterWick strings are designed to draw water from a reservoir in the decorative pot to the cultivation pot. Viscon Airfresh already produces ready-made pots that keep space between the cultivation pot and the decorative pot for storing water. Unfortunately, many people prefer to use their existing decorative pots. Therefore, they asked us to come up with a solution that could create this space without the need to purchase a new pot and be usable for multiple pot sizes.

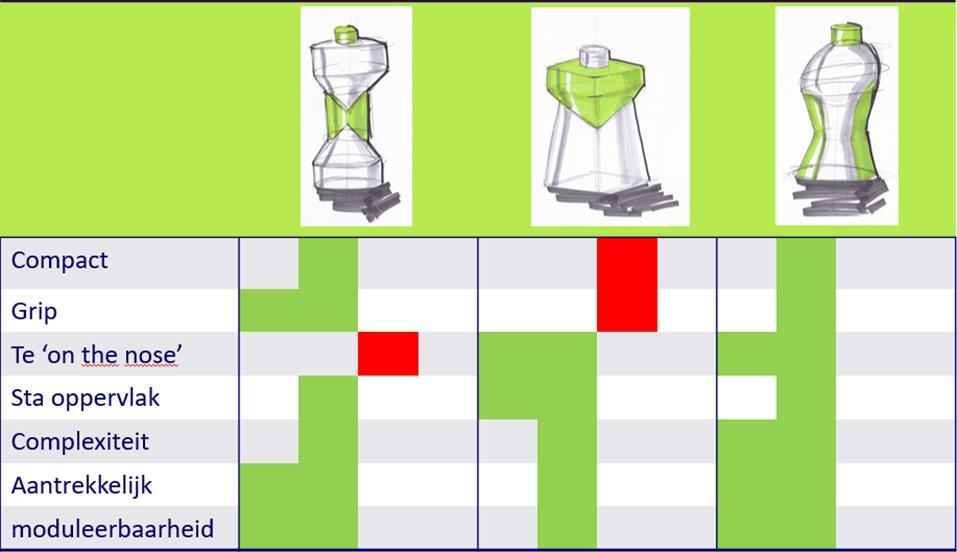

For the concept presentation, I presented three concept designs. The team at Viscon selected two concepts and expressed interest in having a concept that combined the positive features of both into one product.

I divided the two concepts into three sub-functions: height adjustment, surface adjustment, and surface shape. I tested and refined these sub-functions and then incorporated them into the final design.

Too complex and too many components

Balance light

A fictional company requested a ceiling lamp that can be positioned in multiple angles using the principle of balance.

First, I started sketching ideas for the type of lamp I wanted to create. Then, I translated my idea into a cardboard prototype to see if it was feasible in practice.

To calculate this balance, I applied the data from SolidWorks into an Excel calculation to automatically determine whether the lamp would remain balanced or not.

Bottle

For this assignment, I had to design a bottle for a random beverage and target audience. The design had to be suitable for both the specific target audience and the beverage itself. The target audience and beverage assigned to me were "apple juice for athletes". The main objective of this assignment was to generate ideas, select the best ones, and then develop them into a presentable design that would appeal to this target audience.

3rd year – 7th semester

SKILLS

MECHANICAL ENGINEERING SOLIDWORKS

Minor Influential Design & Creative Engineering

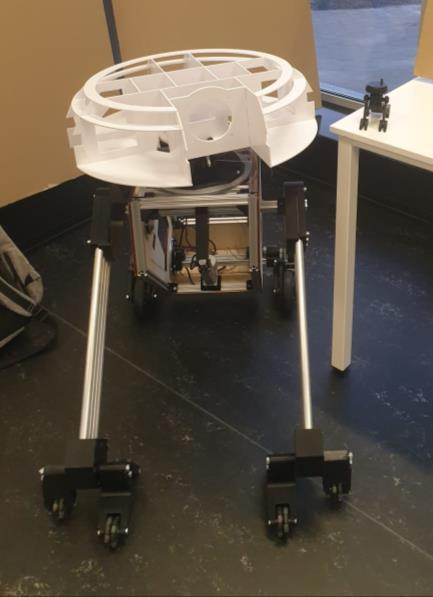

During the minor Influential Design & Creative Engineering at IPO Rotterdam, we were given the freedom to choose our own design assignment as long as it challenged us to learn new skills.

For a long time, I had the ambition to build a robot similar to R2-D2 from Star Wars. Eventually, I chose a design from a video game from 2003 because I saw many challenges in it.

Over a period of 5 months, I designed multiple mechanisms to make the robot's mechanical functions work, including the ability to lean forward and backward, drive the rear wheels, and have a head that can tilt and rotate in 3 axes. The robot stands at a height of 87 cm (when not tilted) and has been showcased twice at an IPO exhibition upon request.

Typically, most robot builders take 24 months to complete a similar robot. Although my robot is not fully finished yet, what I have achieved in 5 months is a breakthrough in terms of efficiency and speed.

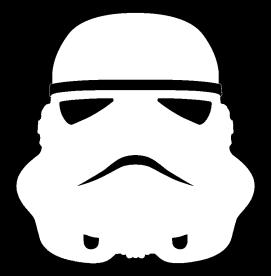

Costumes & props

Costumes & props

The 501st Legion is an international charity organization that focuses on creating and wearing costume replicas from Star Wars. Members of the 501st Legion often attend events for charitable causes and organizations while wearing these costumes.

The admission requirements to join the 501st Legion are very high and primarily focus on the quality and likeness of the costumes, but that didn't deter me from becoming a member. So far, I have designed three costumes that have been approved. Creating these costumes involves many requirements, details, and techniques such as vacuum forming, 3D printing, painting, and weathering.

Due to the high standard of our costumes, the organization is frequently invited to participate in charity and entertainment events such as hospital visits, TV shows, and fan films.