SU Shuoxuan

DOB: 01/01/1999 Mobile: +1 2812167959 E-mail: sshuoxuan@gmail.com

ACADEMIC QUALIFICATIONS

09/2017 – 06/2022

09/2017 – 06/2022

09/2014 – 06/2017

University of Pennsylvania

Master of Science in Design: Robotics and Autonomous Systems (MSD-RAS)

Zhejiang University of Technology

Bachelor of Architecture

Hangzhou Xuejun High School

EXTRACURRICULAR ACTIVITIES

09/2019

09/2017-06/2018

11/2017

Member of Study tour to Kitakyushu City University, participated in the exchange study tour for one month;

Minister of Physical Education Department of Zhejiang University of Technology, organized various school and college competitions;

Volunteer of Hangzhou International Marathon Activity, assisted the organizers in organizing the marathon, maintaining order on site and providing logistical support to the athletes.

HONOURS & AWARDS

05/2021

11/2020

10/2020

09/2020

Third Prize in the New Hangzhou Style House Design Competition;

Encouragement Award in Newcomer Cup National Student Design Competition;

First prize in the Community of the Future B.L.O.C.K. Neighbourhood Innovation Design Competition, Zhejiang University of Technology;

Best Popularity Award in the Professional Category of the Future Community B.L.O.C.K. Neighbourhood Innovation Design Competition.

IELTS 6.5

Mandarin

LANGUAGE SKILLS

Adobe: Photoshop Indesign

Illustrator

3D model: Rhino Grasshopper ZBrush

Rendering: Vray Keyshot Lumion

Programing: Python C#

Robot: Robot studio Machina Arduino

24/10/2020

01 TUNNELSCOPE

A telescope-based tunnel renovation project

NAME: Su Shuoxuan

INSTRUCTER: Adrian Friend(friend@arts.ac.uk)

LOCATION: London, UK

South Kensington Station is one of the most visited stations on the underground network. Today the reality of the experience of arriving at South Kensington Station and journeying through the tunnel is disappointing. It is very necessary to transform the tunnel.

The impression of tunnels is always "dark", "closed", and "unidirectional".In order for the tunnel to become "bright", "open", and "lively", the introduction of light is essential. The light is guided into a long tunnel through various optical lenses. Such a scene can not help but think of a telescope. The concept of tunnel-telescope came into being.

The tunnel is designed according to the principle of

the telescope. Many refracting lenses and mirrors are designed in the tunnel. They are not only accessories of the telescope, but can also be converted into other functional facilities during the day. Some of them are exhibit magnifiers, and some are giant screens.

At the same time, the renovation has also been extended to the street, which has solved the problem of light pollution.

The renovation project not only solves the lighting problem of the tunnel, but also creates a night sky holy land for citizens living in the city. This will definitely bring vitality to the tunnel and the community

02 THE TIDELAND

An environmentally friendly floating resort

NAME: Su Shuoxuan

INSTRUCTER: Hua Chenglin(huachengling@163.com)

LOCATION: Holbox, Mexio

It is located on a property on the coast of Isla Holbox, which is an island in the north of the Yucatán Peninsula of Mexico, in the state of Quintana Roo, in the Mexican Caribbean. It has unbeatable natural conditions as it has: beach, sea, mangroves and migratory birds.

However, the island's backward infrastructure can not cope with the increasing number of tourists, and the local drainage system and ecological environment are facing great challenges.

The FLOATING HOUSE, function as tourist accommo-

dation villas and is part of a complex on land that complements the services (which will not be screened).

It has the resort function of a hotel, which can enhance the image of the general building in the mangrove forest. At the same time, the automatic roof window that changes according to the change of the tide can achieve a comfortable environment where people and nature live in harmony. It functions as an independent element and can be formed into several units, adding value to the natural environment.

In the early morning, the sun has a low altitude angle, the sunshade windows are closed, and the sunshade canvas is opened.

In the afternoon, the sun has a high altitude angle, the sunshade windows are opened, and the sunshade canvas is closed.

In the early morning, the sun has a low altitude angle, the sunshade windows are closed, and the sunshade canvas is opened.

In the afternoon, the sun has a high altitude angle, the sunshade windows are opened, and the sunshade canvas is closed.

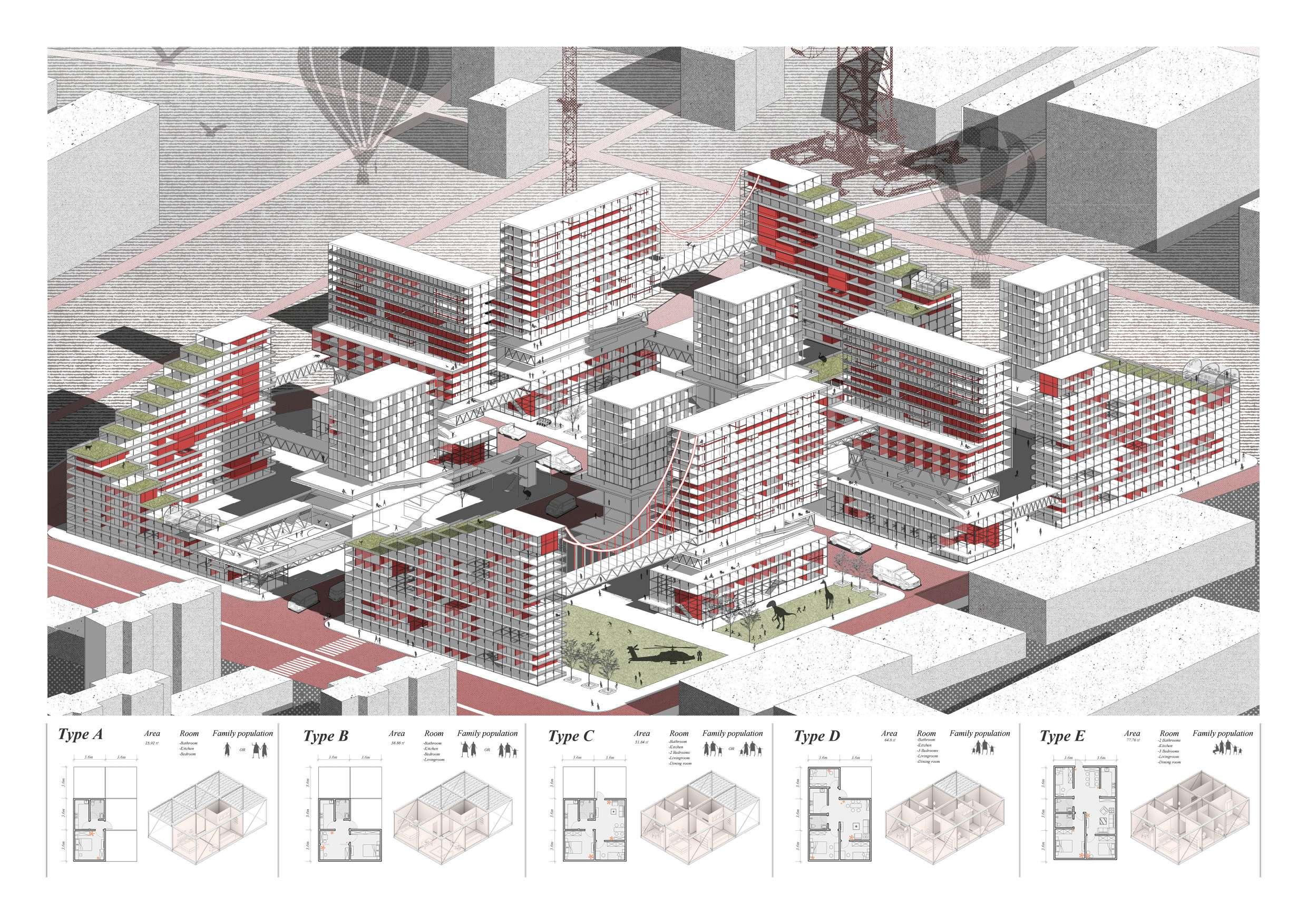

A community of new citizens

NAME: Su Shuoxuan

INSTRUCTER: Yang Jingxian/ He Wenmin(juliette117@163.com)

LOCATION: Hangzhou, China

In the context of rapid social changes, the identity of "new citizens" such as migrant workers and non-local college graduates in cities and urban adaptation issues have been concerned by many disciplines. The vague cognition of one's own identity prevents it from being well integrated into the city in terms of economy, society, and culture.

However, the change and identification of identity is not only a change in the household registration system and living environment, but also a change in the psychological and behavioral levels. Today's cities are still too weak to help new citizens in supporting them to complete this series of transformations, and the negative impact of the resulting social and psychological problems

on the entire society should not be underestimated. Appropriate architecture can create a new environment, not only to improve physiological materials, but also to guide psychologically.

The "Future Communities" designed for new citizens will face this practical problem, starting from assisting new citizens to realize their identity and urban adaptation in the city, and propose architectural ideas based on the real conditions and practical needs of new citizens. We aim to help the new citizen through this difficult periodthis process will also determine his future life: whether to follow the trend in frustration, or to put hope in life and achieve a better self.

04 Robot Hot-wire Cutting

Hot-wire cut EPS form ceiling prototype

NAME: Su Shuoxuan, Shunta, Wu Renhu, Luo Jingyu

INSTRUCTER: Andrew Saunders(asaun@design.upenn.edu)

TAs: Riley Studebaker and Claire Moriarty

LOCATION: Philadelphia, US

This is a robotic fabraication project. Firstly, we explored the geometric qualities of two sculptures by Naum Gabo and Antonie Pevsner, and used them to create a 900 square feet speculative ceiling for the Upper Gallery of Meyerson Hall. The project involved digitally reproducing the ruled surface forms of the sculptures and extracting specific geometric qualities, which were then fed into a Convolutional Neural Network to generate 3D outcomes. The 3D outcomes were then used to create a multi-axis robotic hotwire cutting routine to prototype the ceiling in high-density Styrofoam. The resulting

ceiling scape features a series of hierarchical variations in the depths of the lilies and peaks that form different zones resembling an infinite mushroom forest. Two forms of light sources were introduced to create a more hierarchical distribution of light, with the brightness of the linear lights increasing and more holes lighting up as the number of people in the gallery increases. The resulting effect is a space that stimulates wanderlust and a feeling of Deja vu.

RULED GEOMETRY DEEP LEARNING

The exploration started with the analysis of pieces in the Linear Construction series by Naum Gabo and Antonie Pevsner’s Construction of Developable Surface series. The sculptures were carefully analyzed to digitally reproduce their ruled surface forms and model specific geometric qualities.

Two geometric qualities were chosen to focus on: Gabo's cone-shaped forms and Pevsner's twisted tear-shaped holes. The ruled surfaces were transposed into volumetric implications of rulings in space to deconstruct the geometric moves made by the sculptures and input into neural networks to depict the geometry in light and shadow.

After identifying specific geometric qualities from sculptures and depicting them in light and shadow, the images were fed into a Convolutional Neural Network (CNN) to generate an outline for extracting three-dimensional geometric ceiling arrangements.

However, CNN struggles to generate impeccable 3D outcomes that can be constructed, so we used our understanding of distinct elements and their hierarchy to model explicit CNN outcome images for multi-axis robotic hotwire cutting routines to prototype the design.

Cutting Diagram

Constructivist Sculpture Study

CNN Generative Design

Cutting Diagram

Constructivist Sculpture Study

CNN Generative Design

Ceiling Protype Design Robot Fabrication

We created prototypes using resin and 3D prints before using a 6-axis robotic arm to realize the chosen geometry in high-density Styrofoam. We faced limitations in generating the tool direction, target plane, and wire position, so we custom-modified the script to gain more control.

The modified script used a graph as input to adjust values along the timeline of the cutting sequence. As a result, we proposed a 900 square feet speculative ceiling for the Upper Gallery of Meyerson Hall.

Responsive Lighting Effects

Ceiling Protype Photos

05 CERAMIC FOREST

A robotic-crafted ceramic facade

NAME: Su Shuoxuan, Bentian Wang, Haohan Tang, Jingyu Luo, Pouria Vakhshouri. INSTRUCTER: Robert Stuart-Smith(rssmith@design.upenn.edu

TAs: Hadi El Kebbi, Matt White, Sophia O‘Neill LOCATION: Philadelphia, US

Architectural ceramics have evolved in building facades, merging traditional extrusion ceramics with modern robotic fabrication. Our goal is to optimize building component production by combining the versatility of robotic manufacturing with the advantages of traditional extrusion. Through customized robot extrusion experiments, we enhance the production process.

Our design approach focuses on studying clay material characteristics and utilizes air extrusion and robot movement to optimize production. We prioritize architectural aesthetics and assembly characteristics, creating a modular, self-organizing, and adaptive method for designing facades. This approach surpasses geometric limitations, efficiently producing customized

ceramic modules on an industrial scale. We document the integration of traditional craftsmanship with cutting-edge technology.

Our insights, creative solutions, and transformative impact on the architectural landscape are shared to inspire architects, designers, and researchers. We encourage exploration of the intersection between robotic fabrication and architectural ceramics, unlocking new possibilities for architectural expression and construction.

Robotic Tool

Optimizing Extrusion Methods

Alignment with the main direction provides control and efficiency, while rotating with the TCP accommodates curves. Air pressure and robot speed are controlled separately during extrusion. Speed adjusts based on curve radius, ensuring accurate alignment. These measures optimize the process, ensuring consistent and high-quality results.

Automated Clay Tube Cutting Process

Computer vision techniques were used to detect and remove imperfections in clay tubes resulting from the extrusion process. By capturing images and employing algorithms, the precise position and boundaries were determined. Using point cloud data, the targeted region was digitally simulated for the robot arm to cut and remove the imperfections.

The use of interchangeable dies expanded customization possibilities and improved precision in the fabrication process. Switching between dies enabled adaptation to specific design requirements, allowing for varying tube thicknesses and profiles. Texture-enabled dies added aesthetic richness and tactile appeal, enhancing the ceramic components.

By leveraging the cutting end effector, we were able to explore alternative design possibilities while maintaining structural integrity. The ability to create varied cuts on the tubes not only resulted in reduced weight but also allowed for the exhibition of the intricate inner textures, adding an element of visual interest to the final ceramic components.

Experiments in Clay Extrusion

In the pursuit of achieving optimal extrusion results, the comprehensive robot extrusion tests were conducted to identify the most suitable parameters for successful outcomes. Through a systematic exploration, different robot motion modes were explored, and careful adjustments were made to key variables, including extrusion speed, robot movement speed, height, and angle.

By methodically varying these parameters, the objective was to uncover the ideal combination that would yield desirable extrusion results, particularly in scenarios involving bending with different angles and radii. This iterative process allowed for the refinement and fine-tuning of the extrusion parameters, ensuring precise control over the fabrication process and consistent achievement of the desired outcomes.

Experiments in Clay Cutting

Extensive testing was done to address discrepancies between actual cutting and digital simulations. Factors such as robot paths, speeds, and clay moisture were examined. The goal was to understand their interplay and reduce deviations. Through analysis, we refined our approach for closer alignment between simulations and cutting outcomes.

CUTTING TEST CUTTING

Overall Facade Form-Finding logic

The growth logic of the growth network is based on a hexagonal grid. In the planar space of hexagonal tiling, different growth patterns are executed according to the step number between the starting point and the endpoint. When the step size is 0 or 1, pattern “loop” is executed. When the step size is 2 or 3, a smooth curve is generated. When the step size is too large, a discontinuous short tube is generated. We only need to input the starting point grid and the endpoint grid, and we can generate density-controlled free-standing forms.

Physical Prototypes

Within the curated collection of ceramic tubes, we present an ensemble of 20 distinct examples that collectively compose a captivating panel for the facade. These tubes, originating from the same extrusion process and sharing an identical section profile, manifest their uniqueness through a variety of bending angles and individualized cuts.

Theatre Design

Residential District Design

Digital sculpture renderings

Model photos and renderings

Digital sculpture renderings

Model photos and renderings