2024 Annual Sustainability Report

“Infrastructure is the fabric of civilization”

As builders of safe and reliable infrastructure, we know that what we do matters. Infrastructure is the fabric of civilization. It is the shelter, facilities, networks, and assets needed to thrive.

We prioritize safety – for workers and users. We understand that through industry, innovation and infrastructure we help build sustainable cities and communities, deliver affordable, clean energy, and empower economic growth and opportunity.

Thank You

Jim McNelis Chief Executive Officer of S&B USA Construction

Lucas Lahitou Chief Executive Officer of S&B USA Concessions

Self-performing construction

P3 construction (Fargo-Moorhead Area)

P3 construction (PennDOT Major Bridges)

About Us

• In the past decade, S&B USA has achieved unprecedented growth, allowing us to tackle bigger projects than ever before. As the US operations of our global parent company, Shikun & Binui, Ltd, we leverage over a century of experience and collective knowledge while prioritizing local autonomy.

• S&B USA is supported by our Construction and Concessions arms, which work together to bridge knowledge gaps and foster innovative infrastructure solutions. We offer a diverse portfolio of large-scale infrastructure projects and mega P3 projects.

• Our work combines the local self-performing construction expertise of Fay, S&B USA Construction and the resources of S&B USA.

Our Growth

• In the five years since establishing the US headquarters in Pittsburgh, S&B USA has grown substantially by winning $3.8B of Private-PublicPartnership projects (P3s) and several other large construction projects.

• After winning the Virginia Passenger Rail Authority (VPRA) Long Bridge South package in a joint venture with two other major construction companies, S&B USA's total backlog of work reached at an all-time record.

One Company: Comprehensive Expertise

Did you know?

• S&B USA is a national leader and full-service partner helping public agencies and private owners solve complex infrastructure challenges. With deep expertise across both concessions and construction, we are among the few firms equipped to deliver the full spectrum of alternative delivery solutions, including P3, design-build, progressive design build, and construction manager at-risk.

Want to know more?

See our website

• We go beyond general contracting by offering innovative strategies in financing, construction management, and longterm operations and maintenance—supporting infrastructure throughout its lifecycle. From P3 megaprojects to accelerated design-builds, our seamless, end-to-end approach ensures safe, on-time, and on-budget delivery.

SelfPerforming Construction

Did you know?

• As a Mid-Atlantic contractor with over 75 years of experience, Fay, S&B USA Construction is our self-performing construction company and focuses on regional construction in Pennsylvania, Maryland, Virginia, and beyond.

• We deliver safe, resilient and quality infrastructure. Our team specializes in design-build, value engineering, and accelerated construction delivery methods. Our innovative solutions, combined with a customer-focused approach, enable us to excel in completing complex projects on tight schedules and delivering our clients with exceptional value.

Want to know more?

See our construction management overview

Alternative Delivery

Did you know?

• Alternative Delivery approaches to the structure, design and delivery of projects can find more resilient, greater value solutions for owners and operators of infrastructure. Through allowing providers to be closely involved in design (from initial plans through to iterative value engineering), room for innovation, efficiency and optimization can be created.

• Alternative Delivery can include bid-build best value or design-build, and showcases our ability to provide novel, customized solutions based on our capability and experience.

Want to know more?

See our introduction to alternative delivery

Did you know?

PublicPrivatePartnerships for All

• Led by S&B USA Concessions, our P3 model enables the delivery of complex infrastructure by combining public oversight with private sector expertise, capital, and efficiency. This approach expands capacity beyond public funding constraints and ensures long-term value for stakeholders.

• By embedding sustainability considerations into project design and delivery, we help public agencies meet regulatory expectations while advancing broader environmental and social outcomes.

Want to know more?

See our concessions overview

P3: Delivering Resilience at Scale

Long-Term Flood Protection and Resiliency for the Fargo-Moorhead Area

This flood management project represents one of the first largescale, sustainability-focused P3 transactions in the US. The protected area includes billions of dollars in infrastructure, including the region’s only Level 1 trauma center which serves a broad rural population across multiple states (North Dakota, South Dakota and Minnesota), and more than 55 schools (including 20%+ of all North Dakota educational facilities).

With a construction value of $1.2 billion, the project includes the design, construction, financing, maintenance and operation of a 30mile-long diversion channel, 19 bridges, 2 aqueducts, 14 drain inlets, and 2 drop structures.

The first green-financed, split delivery, large-scale flood protection resiliency P3 (Fargo-Moorhead Stormwater Diversion Channel).

P3: Delivering Resilience at Scale

The Largest Bundled-Bridge Project Delivered in the US Under a P3 Agreement

The PennDOT Major Bridge Project, with a single $1.5 billion construction contract, is an ambitious P3 addressing essential bridges in Pennsylvania’s intra and interstate transportation system in need of replacement and contemporary safety designs.

Delivered through a progressive Design-Build-Finance-OperateMaintain method (‘DBFOM’) which incorporates flood, rock and mudslide mitigation into the designs, this project will rehabilitate, reconstruct and replace interstate bridges at six locations across the Commonwealth of Pennsylvania to ensure the long-term resiliency and dependability of the state’s transportation infrastructure.

The largest bundled bridge project delivered under a P3 agreement (PennDOT Major Bridges)

What’s in This Report

This Annual Sustainability Report summarizes our strategic efforts in 2024 and since our last annual report.

Demonstration of Our Progress

S&B USA has always conducted responsible business. This report showcases our continued progress over the course of the last year.

Commitment to Continuous Improvement

Building for a Safe, Sustainable Future

At S&B USA, we are proud to prioritize safety in everything we do. As creators of safe and innovative infrastructure solutions, we seek to improve our projects through safe working conditions and innovative ideas that save time, money, and resources.

Our sustainability initiatives are a direct reflection of our commitment to safety which is a pillar of our sustainable business philosophy.

We reflect on our operations’ impact on the environment and its financial optimization and efficiency. in partnership with:

Our team is comprised of people who deliver projects, and those who support them.

As our business grows, our need for talent grows with it. As we offer more complex and expanded services, with an emphasis on P3s, alternative funding and alternative delivery (from designbuild to bid-build best value), the sophistication of our talent increases.

This report will showcase our people and projects in the context of delivering resilient infrastructure in a sustainable world.

• Amtrak Susquehanna River Rail Bridge Project.

Amtrak. Perryville and Havre de Grace, MD.

• Beaver River Bridge Replacement Project.

Pennsylvania Turnpike Commission. Beaver, PA.

• CSX Howard Street Tunnel Clearance Project.

CSX. Baltimore, MD.

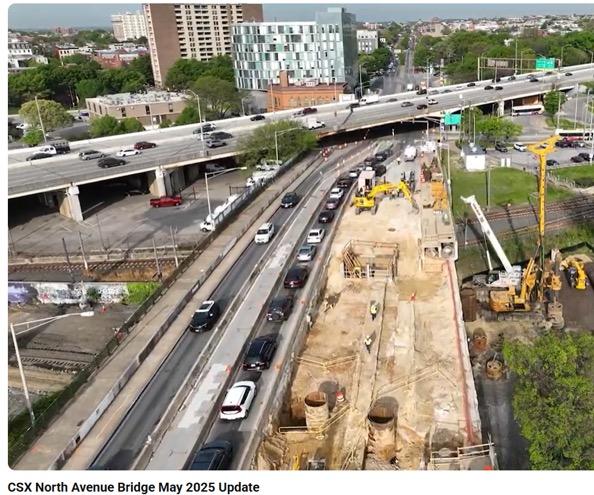

• CSX North Avenue Bridge Project.

CSX. Baltimore, MD.

• Fargo-Moorhead Stormwater Diversion Channel P3.

Metro Flood Diversion Authority, US Army Corps of Engineers. Fargo, ND and Moorhead, MN.

• Monongahela River Locks and Dam No.3 Demolition.

US Army Corps of Engineers. Elizabeth, PA.

• Pittsburgh International Airport – Roads & Bridges Project. Allegheny County Airport Authority. Pittsburgh, PA.

• PennDOT Major Bridges P3 Project.

o I-80 North Fork Bridges.

o I-81 Susquehanna River Bridges.

Notable Projects Underway in 2024

Notable Projects Won in 2024

• I-376 Commercial Street Bridge Replacement. PennDOT. Pittsburgh, PA.

• I-64 and I-464 Interchange Exit 291 Ramp Improvements (Design-Build).

VDOT. Chesapeake, VA.

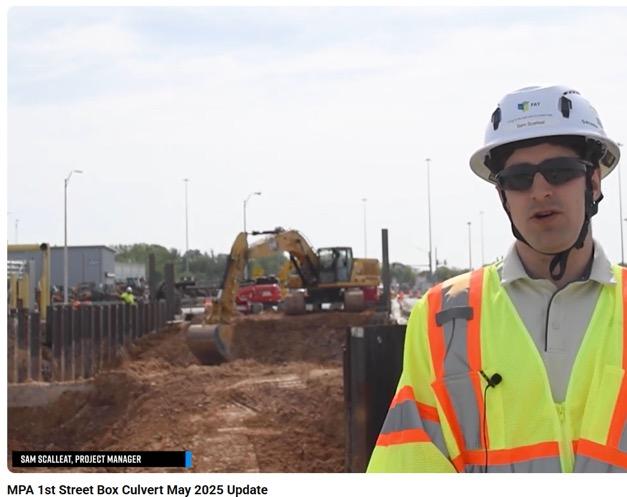

• Maryland Port Administration First Street Box Culvert (BidBuild Best Value). Maryland Port Administration. Dundalk, MD.

• Virginia Passenger Rail Authority Long Bridge South (Design-Build).

Virginia Passenger Rail Authority. Arlington, VA and Washington, DC.

Project Sustainability and Resiliency

• Our projects deliver resiliency, and must be resilient in and of themselves to be on time, on budget, and on specification.

• To showcase how sustainability and resiliency are ingrained in how our projects operate; look out for this symbol (from ‘Provide Solutions’ in Our Values) throughout this report denoting case studies:

Keys to Sustainable Infrastructure Practices

• Aligned Stakeholders: collaboration with partners on shared targets.

• Climate Resilient: infrastructure that withstands extreme weather.

• Sustainable Materials: use of recycled and low-carbon materials

• Waste Reduction: circular economy strategies for material reuse.

• Talent & Community Engagement: mutual development.

• Technological Advances: smart infrastructure, data-driven decisions.

• Energy Efficiency: renewable energy, optimized resource utilization.

• Efficient Delivery: focus on cost efficiency, minimizing waste.

Case Study: UNECE P3 certified finalist project (Fargo-Moorhead

Where

• Fargo, ND, USA.

Stormwater Diversion Channel)

The comprehensive FM Area Diversion

• Protects 260,000 people, their homes, businesses, and property.

Why

• Designed to withstand 100-year flood and provide resiliency up to a 500-year flood.

• Property owners will save tens of millions of dollars annually on flood insurance.

What

The P3 portion will deliver a 30-mile stormwater diversion channel, 19 bridges, 2 aqueducts, 14 drain inlets, and 2 drop structures.

• Brings permanent, reliable flood protection to the Fargo-Moorhead communities and surrounding areas, reducing the area impacted by flooding.

• Four major components of the project are the southern embankment, stormwater diversion channel, mitigation projects, and in-town features.

• The project is committed to The Envision® Rating System for Sustainable Infrastructure and is part funded by a green bond (Sustainalytics evaluated).

• Want to know more? See our update video here

Case Study: Notable Updates

This annual sustainability report provides select project updates throughout this document as case studies; for video updates on other select projects please click the thumbnails below

• I-81 Susquehanna River Bridge (part of PennDOT Major Bridges P3).

• CSX North Avenue Bridge, Baltimore, MD.

• Maryland Port Administration First Street Box Culvert.

Case Study: Notable Updates

This annual sustainability report provides select project updates throughout this document as case studies; for video updates on other select projects please click the thumbnails below

• I-80 North Fork Bridge (part of PennDOT Major Bridges P3).

• CSX Howard Street Tunnel, Baltimore, MD.

• I-64 and I-464 Interchange Exit 291 Ramp Improvements Design-Build.

Want to know more about PennDOT Major Bridges P3? See our project video update here

Governance

Our Leadership

Jim McNelis

Chief Executive Officer

S&B USA Construction Lucas Lahitou

Chief Executive Officer

S&B USA Concessions

Learn

S&B USA Jessica Cicali EVP. Chief Legal Officer, Chief Compliance Officer S&B USA Amir Zion Interim Chief Financial Officer

S&B USA

Laurie Roy EVP. Chief Human Resources Officer

Surrena

Headon

Mehmet Akinci

Strong Governance, Strong Foundations

Rigorous oversight and strong management controls are mission critical, foundational capabilities. Our public and private partners of resilient infrastructure place their highest trust in our integrity.

Formalized board management and oversight, robust reporting cadence and controls

S&B USA leadership of industry veterans, dedicated roles for compliance, safety, and more

Specialized committees on mission-critical topics (such as safety, sustainability, and vendors)

Best practice standard operating procedures and policies (operations to corporate ethics)

Sophisticated risk management (Cybersecurity & Data Breach Plan, Crisis Management Plan)

Contract and project level commitments, oversight, and governance across the business

Our Vision, Our Values

Work Safely Deliver Return Value People Act with Integrity Provide Solutions

Safety is our culture Earning a fair profit increases our longterm value Take care of employees and they will take care of clients and stakeholders Honesty builds trust Better solutions yield greater satisfaction

• Vision: Creators of Safe and Innovative Infrastructure Solutions.

• Value Proposition: Think Globally. Act Locally.

Work Safely

Safety is critical for our resiliency

At S&B USA, our employees are our most valuable resource. We have established a culture of caring for our people, and we encourage our employees to prioritize safety and work in a manner that is safe and accident free . We adhere to the best safety practices to:

• Provide a safe workplace for employees, subcontractors and the general public.

• Strive for the highest safety standards on our jobsites.

• Train and educate our employees to ensure they are knowledgeable of safety rules and standards.

Case Study: Work Safely Highlights

Employees Act Quickly in Time of Need

Recently, the quick thinking of two of our employees (together with subcontractor employees) on the Frederick Douglass Memorial Bridge Pier E Demo project helped rescue an individual from the Anacostia River in Washington, DC. They witnessed a person drop from the South Capitol Street Bridge, and without hesitation, they boarded one of the vessels on site to reach the individual and pull them out of the water. The employees performed CPR and flagged down first responders, who then transferred the person to an ambulance.

Shawn Sparks (center left of the picture below) and Milton Herrera (center right of the picture below) were honored with a gift from Fay, certificates from the office of Mayor Muriel Bowser, and were recognized by the District Department of Transportation for their bravery and composure in a critical moment. Mehmet Akinci, VP and Chief Operations Officer traveled to DC to personally recognize them.

Winners of the MDAGC Zero Lost Time Incidents, Injury Rate 100% Below the National Average and Safety Improvement awards

Eight employees were selected as Safe Supervisors by the MTBMA, and Perry Sparks won the Ed Tracey Distinguished Supervisor Award

Winner of a Workforce Safety Award from LECET/LiUNA

Case Study: Work Safely Highlights

Beaver River Bridge Work Safely Case Study: Data for Dynamic Readiness

• This project is building dual cast-in-place segmental bridges on the historic Pennsylvania Turnpike in western Pennsylvania to replace the current steel deck truss bridge built in 1953.

• We are replacing the existing, single 60-ft.-wide bridge with two 70-ft.-wide bridges in each direction and widening the adjacent highway.

Our team actively monitors river levels (upstream and downstream) of our project using National Oceanic and Atmospheric Administration (NOAA) tides and current data and has pre-planned response procedures at differing water levels to keep our people, our equipment and our progress safe and secure.

Financial Summit

In July 2024, we held our inaugural ‘Financial Partners Summit’ Our executive team sharing details on our strategic vision, our integrated infrastructure platform, concessions and construction, talent strategy, sustainability accomplishments and goals, financial performance, and a project site tour.

Our strong growth and success safely delivering innovative infrastructure solutions would not be possible without our invaluable financial partners.

Employee Conference

In May 2025, we held our third annual all-employee conference

We believe it is vital to create opportunities for conversation and celebration with our talented team. This exciting, two-day in-person event, included curated panels, guest speakers and awards. As a testament to the importance of the US operations, special guests included Amit Birman, CEO of Shikun & Binui Ltd. and board members

Naty Saidoff (Chairman) and Shawn Evenhaim (Vice Chairman).

Employee Conference 2025

Employee Conference 2025

Laurie Roy Executive Vice President and Chief Human Resources Officer

Team members including: Derek Vargo, Logan Glace, Joe Martincic, Tyson Hicks, Bryce Firestone and Roberta Madoni

Jim McNelis

Chief Executive Officer of S&B USA Construction

Amit Berman Chief Executive Officer of Shikun & Binui Ltd

Innovation Awards

In May 2025, we held our third Innovation Awards, to recognize the incredible achievements of our people

The S&B USA Innovation Awards are designed to encourage and reward pioneering solutions to project scale challenges across the company’s construction activities, including:

• Construction means or methods

• Materials utilization

• Engineering solutions

• Improved efficiency

• Technology and automation

Training Highlights

• Safety: training classes, annual summit, stand-ups, regular communications.

• Standard Operating Procedures (SOPs): ongoing project led by members of our management team to continuously publish and improve digital access to our SOPs.

• Leadership: delivered by our own Learning & Development specialist, a series of curated and crafted leadership training sessions.

• Building Smarter series: developed and executed by our Operational leaders, this multi-part series of in-person and online forums on technical construction topics.

• Ongoing: corporate training and lunch & learns across our regions.

Act With Integrity

Rigorous oversight and strong management controls are mission critical, foundational capabilities. Our public and private partners of resilient infrastructure place their highest trust in our integrity.

Ethics & Compliance

S&B USA's Ethics & Compliance framework focuses on teaching employees how to identify ethical dilemmas and properly navigate them.

Our Code of Business Ethics and Conduct outlines the highest standards of ethics and compliance. We utilize yearly training and toolbox talks that provide real-life examples and promote problem solving through the guidance of an EEO Officer or our Ethics & Compliance hotline. We ensure every employee has the contact information for our Compliance Officer to voice issues if and when they arise. Additionally, upper management in the company is thoroughly trained on crisis management.

Anti-Bribery and Anti-Corruption

S&B USA has a zero-tolerance policy for bribery and corruption. Every aspect of our business is subject to our Anti-Bribery and Anti-Corruption compliance program.

• Officers implement and assimilate the compliance program

• All employees are informed of our Anti-Bribery and AntiCorruption policy

• Our contracts adopt Anti-Bribery and Anti- Corruption language

• We hold an annual training for all employees on the AntiBribery and Anti-Corruption program

• We ensure proper documentation and bookkeeping

• We perform due diligence as necessary

Environmental

Carbon is Cost

• True of any organization, particularly in civil infrastructure, our activity levels drive our carbon footprint.

• Our use of energy, fuel, materials and more are integral to delivery of resilient projects.

• These categories also represent some of our largest cost centers, so the use of technology, insights and alternatives to increase efficiency can reduce cost and our carbon footprint to benefit our clients, our communities and our environment.

Yellow Iron Activities

Infrastructure projects produce emissions that vary based on the type of activities involved. Any given project can be a combination of activity type and project type, especially on our mega projects. At S&B USA, we strive to balance between building lasting projects and managing our carbon footprint.

The spectrum on the right demonstrates how the emissions generated by our work can vary based on activity type (above the line) and project type (below the line).

We are always exploring new ways to lower emissions—on every project and in every activity.

Scope 1 & 2 Emissions: Own Operations

The Greenhouse Gas Protocol outlines three main groups (or ‘scopes’) of emission producing activities. Scope 1 and 2 emissions are those arising from direct use (such as fuels) and indirect energy-use (such as electricity).

Our scopes 1 & 2 emissions calculations for our ‘Own Operations’ (as defined in the Appendixes) covers the uses shown above.

Scope 1 & 2 Emissions: Own Operations

* Updated prior years for revised emissions factor for canister gas only

As previously noted, emissions from our Own Operations are driven primarily by off-road diesel as a direct result of our project activities. Since 2022, we have seen significant growth in large scale projects that have required enormous earth moving activities as part of the contractual requirements (including some of the case studies shown herein).

Journey Ahead

Off-road diesel is by far the biggest constituent of our scope 1 & scope 2 ‘own operations’, driven by the stage and scope of our projects.

In years where large earth moving activities are necessary, this will drive our fuels use. That said, we look at all aspects in our control:

• Accelerating fleet replacement – moving truck and other vehicle replacements to 4 years (instead of 10 years) for modernization

• Moving on-road fuel selections towards gasoline and greater efficiency engines

• Using fleet and equipment telemetry data and AI for optimization and efficiency

• Piloting alternative fuels for yellow iron

Case Study: Electrification in Action

Less noise, less emissions, greater efficiency

Our teams seek continuous improvement, utilizing new technologies and new approaches in our projects. Since our last report we have:

• Installed Electric Vehicle (EV) chargers at sites including at 33rd St, Pittsburgh, PA.

• Used EV Ford Lightings in the field as part of an ongoing pilot.

• Conducted a study with Duquesne Light and partners on EV fleet options.

• Utilized electric excavators at project sites including Howard St, Baltimore, MD.

• Reviewed electrified construction equipment options with our providers.

• Introduced our first green energy mobile field office (see next page).

Case Study: First Green Energy Field Office

The Utilities and Demolition Group recently introduced our first 100% green energy mobile field office trailer, known as T-151.

This trailer started as a basic 7-ft by 16-ft cargo mode trailer, typically powered by loud Honda 1000w generators. However, the group opted for a quieter rechargeable battery bank and upgraded with two solar panels.

The cost of the battery bank and solar panels is cheaper than the typical cost of a Honda 1000w generator and T-151 is expected to pay for itself within six months due to the energy cost savings.

T-151 can run four electrical outlets and two USB charging ports for up to 10 hours. The two solar panels keep the battery fully charged during the day.

The trailer is expected to last between 10 to 20 years, with the battery alone having a 10-year guarantee. T-151 has already traveled to various locations throughout the region.

The Utilities and Demolition Group added solar panels to trailer T-151 in order to make it 100% green energy and carbon free

Material World

• Our teams have an incredible track record of optimizing our projects to save materials, cost and carbon.

• Materials reclamation is a standard capability for us; from asphalt milling, metals reclamation, re-use of stone, crushing of aggregates for site use and more.

• We work closely with project owners and environmental agencies, with strict adherence to the highest standards to put quality and resiliency first for win-win outcomes.

• In our work with ports, we perform a significant amount of demolition of old structures to make way for the new.

• In a recent port project example, we utilized ~70,000 tons of aggregate from recycled concrete demolition as new subbase and sub-slab for new structures.

Beaver River Bridge Replacement (Pennsylvania Turnpike Commission)

Want to know more? See our project video update here

Case Study: No Stone Unturned

• The project team collaborated with the client to redesign access and excavation haul roads for safety, cost and materials optimization.

The Beaver River Bridge Replacement project is the largest contract in Pennsylvania Turnpike Commission history - a solution to efficiently replace a steel-deck bridge with two modern, wider bridge structures to carry traffic over the Beaver River and adjacent railroad lines.

• Furthermore, the team showed excellent materials management, including re-purpose of road cover millings (use and stockpile), crushing aggregate for access roads, the permanent reclamation of more than 1,800 tons of stone, reuse of traffic barriers in retaining wall solutions, and sourced local solutions for around 800,000 tons of excess dirt and fill.

The Statue of Liberty without the pedestal, weighs ~225 tons including:

Case Study: Iconic Scale

Some of the S&B USA case study examples in this report:

• Copper: 62,000 pounds (31 tons)

• Steel: 250,000 pounds (125 tons)

• Typical medium-sized dozers used for construction weigh: ~21 tons

The massive pedestal and foundation adds ~54,000 tons including:

• Concrete: 54 million pounds (27,000 tons)

• Reclaimed stone in our Beaver River Bridge example: ~ 1,800 tons

• Recycled concrete in our recent port example: ~ 70,000 tons

• Removed excess fill and dirt in our Beaver River Bridge example: ~800,000 tons

Extensive earthworks mean that the landscape of the project is ever-changing.

To keep track of the excavation and backfill progression, surveying is an important yet time critical process.

Case Study: Higher Standards

• AI and drone technology is revolutionizing surveying in earthwork projects, reducing the process from days to mere hours.

Drones take up to 2,500 photos biweekly, capturing 1.5 million points to create accurate 2D and 3D maps. These maps are used by supervisors on iPads to measure and take off quantities, and identify design flaws.

Operators must set up ground control points (GCPs), create flight plans, and acquire licenses and permits at each site before surveying.

Picture taken by drone at an S&B USA project (2024)

Environmental Protection in Action

In building safe and resilient infrastructure, we help protect communities from the effects of extreme weather – including stormwater management, flood diversion, renewable energy production and more. We operate in highly regulated areas (which vary by region) and our full and transparent compliance with all environmental protection regulations is our upmost priority.

water protection plans project and permit specific activities project delivery and community engagement project tracking, reporting and reviews environmental protection plans agency, regulator and stakeholder management environmental permits and approvals

Case Study: Environmental Protections

• Our I-64 and I-464 Interchange Exit 291 Ramp Improvements Design-Build Project reconstructs a total of 1.62 miles of roadway and will install ~67,000 sf of noise barrier walls throughout the interchange to protect local residents and nearby wildlife populations.

• Located in Chesapeake, VA which is centrally located in the 64,000 square mile Chesapeake Bay watershed area.

• Our project team includes full-time environmental compliance managers and dedicated permitting personnel.

Comprehensive project plans include:

• Environmental Compliance: Measures such as noise barrier studies, adherence to noise requirements, and regular environmental inspections, emphasizing a collaborative process.

• Water Management: Stormwater management plans, erosion and sediment control practices, turbidity monitoring, emergency spill kits, and custom environmental training for water quality and site safety.

• Wetland Protection: Measures include wetland delineation with fencing and mitigation via a wetland mitigation bank, underscoring the ecological benefits of wetlands.

Community and Social

Our People

2024 was the 100th anniversary celebration of our parent company; in a century of success one constant is true – our people are our purpose.

Behind every hard hat, every safety glass, every computer, every project site are problem solvers. We are the team profoundly impacting communities across America. We solve problems. We move fast. We think ahead.

Concessions, construction, enterprise shared services. One team. We build, we finance, we deliver together. Different roles, one vision… we're building more than infrastructure. We're building one team, one vision, one goal.

Belonging, Purpose and Wellbeing

As a talent-led organization, we seek to attract, develop, celebrate and reward industry-best people.

In addition to the annual S&B USA Innovation Awards, we create opportunities and moments of recognition and reward throughout the year:

• Industry engagement and support (CAWP, APC, DBIA, VCA, MdQI).

• Employee picnics, breakfast lunch & learns.

• Volunteering opportunities, sponsorship.

• 100th anniversary celebrations.

• Training, coaching and certifications.

Case Study: Women in Construction

Did you know? women make up 14% of the construction industry workforce in the United States.

“for every 5 trades people that retire, only 2 people replace them… for 12 years this trend has continued…” (Mike Rowe)

We know how crucial it is to support and attract all available talent – S&B USA has continued its ardent support of Women in Construction sponsoring many notable events and engagements.

Case Study: Strengthening Our Supply Chain

We gather top industry talent from far and wide to ensure strength in our supply chain. Whether the Disadvantaged Business Enterprise (DBE) is a Minority or Women-owned Business Enterprise (MWBE), Veteran-Owned Business Enterprise (VBE), or any other, we believe in uplifting the expertise of historically-disenfranchised business owners in our communities.

By the Numbers

442

DBE partners in our supplier database

14.5% of database partners are DBEs

100% of projects achieve DBE compliance

Sustaining Diversity in Construction at Pittsburgh International Airport

We are committed to providing DBEs with ample opportunities to succeed within our industry. One way we do this is by meeting and exceeding minority participation goals set by project Owners.

Supporting DBEs is a cornerstone of our philosophy. No project better exemplifies this than the Pittsburgh International Airport Terminal Modernization Program Roads & Bridges.

We are on track to provide DBEs with 14% of our contract value—that’s more than $23 million!

“S&B USA is devoted to working closely with DBEs in the construction industry. We not only meet DBE goals; we strive to exceed them. We work side by side with all of our DBE partners to get them actively involved in our projects from the day of project advertising until project closeout.”

Sylvia Wolfe, P.E. Manager of Estimating Systems

Case Study: Corporate Social Responsibility

Did you know?

S&B USA supported over 20 company endorsed community engagement initiatives last year.

S&B USA CSR Strategy is built on three pillars: Time, Talent and Treasure. Time, or the ability to volunteer and be present with communitybased organizations. Talent, or the ability to provide volunteer impact utilizing the skills of S&B employees. Finally, Treasure, or financial investments through direct giving, or leveraging tax credit investment strategies.

Want to know more?

See our community news page

Case Study: CSR in Action

• We connect our Giving and volunteer investments with our industry and purpose (i.e. STEM education, employee selected initiatives, local environmental efforts).

• We create shared investment opportunities across regions & offices (MD, VA, PA) (i.e. Chesapeake Bay Foundation, Food Banks, March of Dimes, Cystic Fibrosis).

• We collaborate with major foundations in our community (Pittsburgh Foundation, Jewish Federation of Pittsburgh).

Case Study: CSR in Action

Did you know?

S&B USA has a generous Volunteer Time Off (VTO) policy to support employee paid time off to volunteer for the causes our people care about!

Food, Fun, Learning and Volunteering

Throughout the year, our Pittsburgh headquarters hosts regular breakfast events to bring employees together to learn about nonprofits that make our community a better place to live and work. Organizations that have shared their stories with us include Humane Animal Rescue of Pittsburgh, Reading is Fundamental, Animal Friends and Special Olympics Pennsylvania.

Member

Case Study: CSR in Action

The Challenge Program

Did you know?

S&B USA has major partnerships with the Challenge Program and the Pittsburgh Parks Conservancy to support education

S&B USA, The Challenge Program, and four schools (Jeff Tech, Brookville, Brockway and DuBois) are partnering in a workforce development effort to help alleviate this problem by introducing students to career opportunities in the construction trades. Our $50,000 contribution to The Challenge Program enables us to inspire and support high school students by introducing them to the exciting opportunities in construction, while equipping them with the knowledge and skills needed to pursue a rewarding career in the industry.

Case Study: CSR in Action

Did you know?

S&B USA has major partnerships with the Challenge Program and the Pittsburgh Parks Conservancy to support education

Want to know more?

See our project video here

Pittsburgh Parks Conservancy

We expanded our partnership with the Pittsburgh Parks Conservancy through a $50,000 investment to three of their school environmental education programs!

Through site visits to our Commercial Street Bridge

Replacement project site, students will explore the intersection of infrastructure and the environment—

seeing and learning how our talented employees are not only building a new, innovative bridge that will be slid into place when completed, but also the steps we’re taking to protect and restore Frick Park and Nine Mile Run Trail beneath the bridge.

Case Study: CSR in Action

Polar Plunge Special Olympics

Together, our Pittsburgh and Maryland offices raised $27,765 benefiting the Special Olympics.

Did you know?

S&B USA employees get really active in their volunteering!

Pittsburgh Marathon

S&B USA had six teams participating in the 2025 Pittsburgh Marathon Relay. This premier running event is known for its hills and elevation gain!

Great Strides

Great Strides is the Cystic Fibrosis Foundation's largest national fundraising event, which supports our mission to cure cystic fibrosis.

PA Polar Plunge team

MD Polar Plunge team Marathon team

Great Strides team

Case Study: Sustainable Community

Did you know?

S&B USA is a major sponsor of green community efforts and seminars

Case Study: Sustainable Community

Panel Speaker: Laurie Roy, Executive Vice

President and Chief Human Resources Officer, S&B

USA

Did you know?

S&B USA champions women in our industry

To bridge the talent gap our industry needs to tap into underrepresented demographics, including women.

Increasing talent attraction starts with education, where women make up only 21% of tenured civil engineering faculty, then awareness, with companies like S&B USA partnering with communities to highlight career opportunities.

Case Study: Higher Education

Higher thinking

Industry experts in construction and engineering report that 41% of the current U.S. construction workforce is expected to retire by 2031, resulting in the industry experiencing a massive generational shift. S&B USA partners and collaborates with many colleges and universities in our communities, including on efforts such as fellowships, interns, class presentations, seminars and more with esteemed providers including:

Geneva College ASCE student visit to Beaver River Bridge

Mercyhurst University student event with S&B USA

Case Study: Higher Education

Higher thinking

In the last year, we signed a Memorandum of Understanding with the University of Pittsburgh that establishes areas of collaboration including: student recruitment (undergraduate and graduate/doctorate); experience-based student learning; business and engineering integration opportunities; direct participation with student groups; presenting and sharing educational insights and industry trends; and access to S&B USA’s regional and global infrastructure projects.

This MoU builds upon the collaborative successes we have had to date, including the Mascaro Center for Sustainable Innovation, and the Center of Sustainable Business.

Did you know?

We have major partnerships with many colleges and universities including the University of Pittsburgh

APPENDICES

Our Emissions by Scope

Calculations

Overall, our Own Operations CO2e tons are calculated as shown, no other fuels or activities have been identified for our current scope 1 or scope 2 activities. We reserve the right to add additional activities and activities (either in these scopes or scope 3) as appropriate.

Our Emissions Calculations

Own Operations: Our Own Operations emissions calculations include S&B USA, S&B USA Construction, Fay S&B USA Construction, and - in prior years - Fay Southeast S&B USA Construction, which are our primary activity centers in the US. We do not include construction joint ventures. S&B Energy – a related entity that owns and operates renewable energy across the US – is also not included.

Scopes

Scopes as per the Greenhouse Gas Protocol. In our reporting only the following are included:

• Scope 1 includes on-road and off-road diesel and gasoline, natural gas, propane and acetylene.

• Scope 2 includes purchased electricity, steam and chilled water.

Our emissions calculations do not yet calculate scope 3 (e.g., steel, cement, asphalt, lubricants and other aspects) from the upstream or downstream value chain.

Methods

Calculations are volumes based and are in reasonable accordance with Greenhouse Gas Protocol and GWP Fifth Assessment Report (AR5), with estimations for non-material locations and missing data.

Fuels: gasoline variants and diesel variants are based on fuel CO2 factors plus GWP conversions for CH4 and NO2 factors only (at the vehicle category/use type e.g. Construction EquipmentDiesel Fuel); together these are stated as CO2e.

Utilities: electric uses location-based method i.e., emissions factors at the State level for CO2e (combined generation and transmission & distribution figures based on EIA e-grids data). Natural gas uses EIA national emissions factors. The primary input across these calculations is usage volumes for the associated utilities, estimated from spend or square footage data where usage is not available. Steam and chilled water on vendor provided emissions factors. Note: in 2024 volumes for steam and chilled water were not available, therefore emissions were estimated based on the increased square footage occupied in the applicable building compared to the prior year.

As our emissions capability matures we may seek additional boundaries, scopes and methods and are currently reviewing the applicability of targets and commitments. Emissions calculations are provided for indicative purposes and have not yet been independently assured or audited.

About this report

This S&B USA Sustainability Report ("Report") extends to Shikun & Binui – America Inc. (“SBA”) and of all of SBA’s U.S. subsidiaries and affiliates, including, without limitation, Shikun & Binui Concessions USA LLC, S&B USA Construction, and Joseph B. Fay Co. (collectively, “Company"). Except as otherwise expressly stated, it does not address Shikun & Binui, Ltd.; S&B USA Energy; applicable joint ventures; the operations of our suppliers; our channel partners; our contractors; or other business partners. To the extent the Report includes financial information, it is presented in US dollars.

As Corporate Social Responsibility (CSR), Environmental, Social and Governance (ESG), Sustainability, and similarly known topics are rapidly evolving, the reporting methods and/or metrics used in preparing the Report may also continue to evolve. The Company’s current reporting methods and/or metrics are based on, among other things, Company management’s assumptions believed to be reasonable at the time the Report was prepared.

Statements of intention or aspiration contained in the Report speak only as of the date of the Report unless otherwise expressly noted. The Company undertakes no obligation to update publicly any statements in this report.

The Report may also include forward-looking statements regarding the Company that are based on management’s current expectations or projections about our products, markets, associates, and programs. These statements are no guarantee of future performance, conduct, or policy and are subject to various factors, many of which are beyond the Company’s control. Therefore, the actual conduct of our activities discussed in the Report may differ materially in the future, and actual results may vary as well.

The information in the presentation is basic and concise while the public reports of the Company contain more detailed information which may be different from, or additional to, the information contained in this presentation. In the event of any contradiction or discrepancy between the presentation and the public reports, the information in the public reports prevails. Thus, the presentation is not intended to serve as a substitute to reading and of the Company’s public reports.

Cautionary Statement Regarding Forward-Looking Statements

Unless otherwise indicated, information contained in this presentation concerning our industry, competitive position and the markets in which we operate is based on information from independent industry and research organizations, other third-party sources and management estimates. Management estimates are derived from publicly available information released by independent industry analysts and other third-party sources, as well as data from our internal research, and are based on assumptions made by us upon reviewing such data, and our experience in, and knowledge of, such industry and markets, which we believe to be reasonable. In addition, projections, assumptions and estimates of the future performance of the industry in which we operate and our future performance are necessarily subject to uncertainty and risk due to a variety of factors, including those described above.

These and other factors could cause results to differ materially from those expressed in the estimates made by independent parties and by us.

Unless otherwise indicated, information contained in this presentation concerning our industry, competitive position and the markets in which we operate is based on information from independent industry and research organizations, other third-party sources and management estimates. Management estimates are derived from publicly available information released by independent industry analysts and other third-party sources, as well as data from our internal research, and are based on assumptions made by us upon reviewing such data, and our experience in, and knowledge of, such industry and markets, which we believe to be reasonable. In addition, projections, assumptions and estimates of the future performance of the industry in which we operate and our future performance are necessarily subject to uncertainty and risk due to a variety of factors, including those described above. These and other factors could cause results to differ materially from those expressed in the estimates made by independent parties and by us.

Except for historical information, certain matters discussed in this Report may be “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements include, but are not limited to, all projections and anticipated levels of future performance, future opportunities, and any other statements about managements’ future expectations, beliefs, goals, plans, or prospects. Words or phrases such as “anticipates,” “expects,” “intends,” “plans,” “targets,” “forecasts,” “projects,” “believes,” “seeks,” “schedules,” “estimates,” “positions,” “pursues,” “may,” “could,” “should,” “will,” “budgets,” “outlook,” “trends,” “guidance,” “focus,” “on schedule,” “on track,” “is slated,” “goals,” “objectives,” “strategies,” “opportunities,” “poised,” and similar expressions are intended to identify such forward-looking statements. Forward looking statements involve risks, uncertainties, and other factors that may cause actual results to differ materially from those discussed herein and may not align with historical performance and events due to a number of factors. Although we believe that the expectations reflected in the forward-looking statements are reasonable, we cannot guarantee future results, levels of activity, performance or achievements, and caution should be exercised against placing undue reliance upon such statements. We are under no duty to update publicly any of the forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.