Our Mission

Empowering the marine sector and beyond, towards a zero-emissions reality.

Shift is taking action on climate change now by providing customers around the world with a reliable, affordable way to electrify and reduce GHG’s, because reliance on fossil fuels, including in the maritime industry, is causing climate change. We need practical, cost-effective solutions.

Energy storage systems (ESS) and electrification are key to decarbonisation – delivering zero-emission power through electrification and unlocking the potential of new technologies with hybrid solutions.

We empower customers to Shift 2 Clean Energy with market-leading solutions. Our practical pay-as-you-go PwrSwäp service gives customers clean energy with more reliability but with less risk. Our unique innovations deliver quality ESS that can be used safely and efficiently for the lifespan of a vessel. Coupling this robust design and quality manufacturing, we have delivered remarkable returns on investment for our customers for over a decade.

Our clean energy solutions are good for the planet, and good for the bottom line.

From the first battery powered OSV, to the first fully replaceable cell systems, and now the PwrSwäp ecosystem service, our team has been at the forefront of marine battery innovation.

Core SPBES team delivers more than 70 ESS projects Started SPBES

2 1 5 2 1 4

CellCool Thermal

Runaway prevention

Tested and validated

World’s Safest Battery released

“ELF R IDA”

First Electric fish farm vessel launched in Norway

2 1 6

Elektra boat of the year

Gas Extraction Patent issued

Aurora joins Tycho Brahe to form the biggest tandem electric ferry route between Helsingor and Helsingborg

CellCool Technology Patent Issued 20 MWh ESS are deployed

Cell Nail Test passed first in world

First Electric Fish boat in Canada launched

First CellSwap System Deployed

Anda Lote Ferries launched first tandem fully Electric route in Norway

Tycho Brahe becomes world’s largest electric vehicle

Relaunch as Shift

2 2 3

Yinson GreenTech Increases Stake in Shift Clean Solutions

Intensifies Rollout of Battery Solutions for the Electrification of the Marine

Hydromover Launched Singapore’s first fully electric cargo vessel

POWERFUL ENERGY STORAGE

Shift systems use the industry’s most advanced cells, with the highest energy density in the market. Coupled with our CellCool ® system, enabling all cells to consistently operate at optimal conditions, our systems can achieve incredible power outputs, and operate at an average continuous rate of 300% to deliver power boosts. Our CellSwap® technology also allows for smaller system footprints, slashing the need for built in redundancy and making it simple and easy to update individual or groups of cells when necessary.

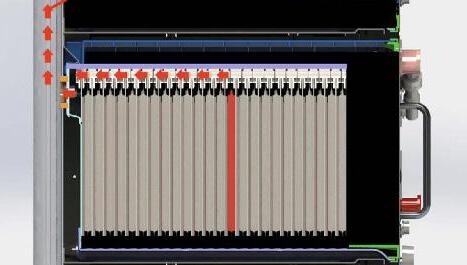

EVent - Venting System

Removes any harmful gasses from the battery.

Discharges them into a safe environment in the event of thermal runaway.

CellCool and

ThermalStop Liquid Cooling

Regulates temperatures throughout the entirety of the system’s cells.

Reverses thermal runaway incident within a cell or block of cells.

Racking System

Built one module at a time. Coolant plumbing safely embedded.

Designed for the space, built in a variety of arrangements.

CellSwap Battery Re-coring

Replace only the cells.

Cell stack easily separates, new stack is shipped to vessel.

Fractional cost compared to full system replacement. Allows for reduced system sizing.

Each cell encased in its own thermal shell, protected from the next cell, and externally.

POWERFUL ENERGY STORAGE

“More power. Less space.

Our ESS is manufactured and tested to the highest standards for safety, performance, and reliability, integrating several unique systems to deliver a superior level of quality, certified to the ISO 9001:2015 standard.

The Shift ESS has also received Type Approval from the DNV GL classification society for use in commercial marine, offshore oil & gas and renewable energy applications.

System Options:

Power 66 (P66) is designed for high discharge power applications requiring high C-rates and faster cycling. It provides up to 15,000 charge/discharge cycles at 80% DoD.

Power 75 (P75) also provides up to 15,000 charge/discharge cycles at 80% DoD but with an improved energy density of 14% for the same weight.

Energy 91 (E91) is for applications requiring lower discharge rates and greater energy density. A decrease in cost and weight provides the end user with a faster path to ROI and decreased footprint and weight.

Safe installation and maintenance using hardware and integrated software protocols.

•Contractor in each module

•Voltage isolation

•Motorized breaker

•Automated BMS checks

SYSTEM SPECIFICATIONS

CONTAINERIZEDESS

Pre-Engineered. Standardized ESS.

Shift Containerized ESS is an end to end Microgrid, containing DC Energy Storage and all of the AC power equipment needed to power your application. It delivers 100% uptime and has been engineered to exceed the extreme operating conditions and demanding standards of commercial marine, ports and industrial grid applications.

This fully mobile solution is easily transported by truck, rail or ship to virtually any location. It is available for sale or lease with a 10 year 100% replacement warranty, and is remotely monitored around the clock by the Shift data analysis system for management and performance.

Containerized ESS Microgrids are available in 2040’ containers. Container is designed to DNV 2.7.3.

System Example Standard

Container - All ESS Capacity

System Example High Cube

Inclusive of Power Electronics

CONTAINER SPECIFICATIONS

CONTAINER SPECIFICATIONS

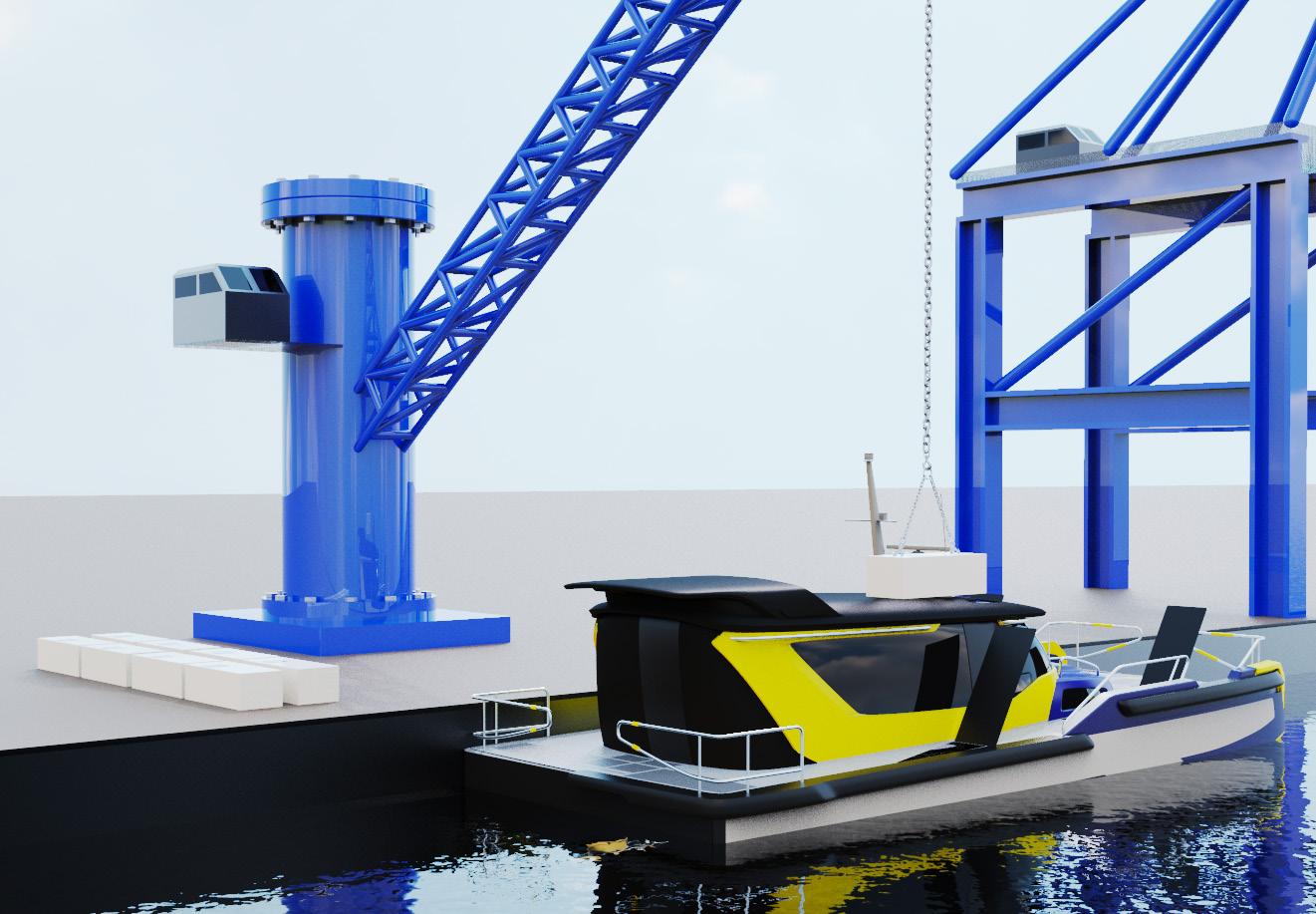

Pwr Swäp

A first of it’s kind - Pay-As-You-Go Service.

Delivering clean and reliable renewable energy with no risk. Typical energy storage barriers of cost, size, weight and charging times are all drastically reduced.

We bring together proven technologies and provide something no one else has: a clean energy ecosystem of swapable batteries that deliver power when and where customers need it. This integrated approach can electrify ports, terminals, inland waterways, ship fleets, industrial sites and even entire isolated communities.

Shift covers the cost which means customers don’t have to invest in expensive up-front capital costs.

Pwr Swäp

wrSwäp SPECIFICATIONS

PwrSwäp offers fully charged ePod battery cartridges which are connected through cloud-based service and management centres.

It’s simple: use energy from the ePods to power your ship or equipment, then exchange them for new, fully charged ones. ESS is sized per trip, not for the life of the vessel.

Customers save money from day one, while meeting climate action goals through electrification.

PwrSteer

Maintaining steering in the event of a BLACK OUT

Shift PwrSteer is a solution to prevent the loss of operational control in the event of a blackout or power disaster. The easily mounted battery cartridge(s) provide a low CAPEX solution to deliver the power needed to remain in control of a container ship in the event of a blackout.

How container ships — with their huge demand for power — respond in an emergency can make or break the situation.

With limited power reserves, most container ships will have only minimal capabilities from backup lead-acid batteries while backup generators come online. The recent incident in the Suez Canal has shown just how dangerous a loss of steering can be, and how vulnerable the chokepoint in global trade are to events which stem from a failure on a single vessel.

After a blackout, the emergency generators will take at least 45 seconds to start, during which time the ability to steer the vessel is lost, and wind, currents, or waves are in control. These seconds are when control of a ship can be lost, and can make the difference between a collision or a safe response.

In the event of any kind of loss of generator ensure your vessel is neither run aground nor faces a collision.

SYSTEM SPECIFICATIONS

An easily installed ePod battery solution

The solution benefits from rapid retrofit, which can be implemented without operational interference. Put simply: no vessel downtime. The transferable cartridges can be moved from asset to asset for charter ships.

Unlike lead-acid batteries, Shift’s liquid-cooled lithium-ion batteries can supply the power needed to enable the crew to maintain steering and control of the emergency switchboard regardless of the situation — enabling full control of your vessel at all times.

Accidents resulting from loss of power not only put your crew, vessel, and surrounding ships in danger. They also result in increased insurance costs and compensation as a result of losses inflicted to other ships or a canal authority.

OnWatch SOFTWARE

In real time see how much fuel and emissions were saved today or drill into system performance.

The all-in-one platform analyzes and supervises key battery performance indicators 24/7 to give you a visual map of performance for your entire fleet. OnWatch enables proactive maintenance, enhanced battery life and conserves reliability of every single module. It also advises on how new or altered operating profiles will affect the ESS system life and performance.

WE KEEP YOUR PROPELLERS TURNING

Service. Guaranteed.

Lifetime Performance Agreement

With over a decade in the marine energy storage industry and over 20MWh of installed systems, Shift has the depth of knowledge and expertise required to help any shipowner throughout the design, installation, and operation of an electric or hybrid solution.

This is backed up by our lifetime performance guaranteed and our global network of experts and engineers who ensure the highest standards of support across North America, Europe, South Asia, and Oceania – backed by the global network of Sterling and Wilson.

LPA OVERVIEW

Installation Training The LPA includes training of installer to install the ESS, thus reducing costs and increasing flexibility.

Software Updates Remote or on site - Shift provides support updates as-needed.

• Scheduled maintenance and updates for optimal system performance and life.

• Direct support of any maintenance completed by customer.

Maintenance

Shift OnPoint™ Remote Active Monitoring:

• Preventative maintenance whereby Shift replaces all parts to be serviced at 90% of their design life.

• Shift system safety certification of customer service staff via Shift training.

• Shift monitors the safety and state of health of the ESS.

• Confirms the system is running as programmed.

• Alerts if there are potential variations.

• Advises on how new operating profiles affect the ESS system.

• Provides SOC and SOH reports every six months for the first year with annual frequency thereafter

We warrant our system to perform as defined in the project engineering documentation for the life of the system.

Each Owner/Operator can choose to take any element of the LPA or not – it is discounted in an up front decision or charged at current rates during the life of the vessel.

We work with you to manage your budget and service protocols, so that no matter your structure our team is available to support the system.

Technical Hot-line

Customer Service Response

Recycling - When the system reaches end of life

• 24/7 Communications

• 1hr response time

• Deploy service personnel within defined time as outlined in the LPA.

• Provide engineering update when needed.

• Document the issue and any action taken.

• Follow up with crew and add to service log.

• Shift will supply options for CellSwapTM re-coring the system.

• Shift decommissions the system and arranges for recycling facilities.

• Decommissioning to be quoted in the cost of the LPA.

OUR PROJECTS

“

After 4 years with over 15000 charging cycles/year we just passed the latest SOH test with excellent results and much less aging than expected. A remarkable result far beyond expectations.

Christian Andersson, Senior Chief Engineer ForSea Ferries

Ferries

Melshorn, Norway, 520 kWh, Hybrid Ferry

Elektra, Finland, 1040 kWh, Electric/Hybrid Ferry

Aurora ForSea, Denmark, 4160 kWh, Electric Ferry

Selbjørnsfjord, Norway, 585 kWh, Hybrid Ferry

Gloppefjord, Norway, 1040 kWh, Hybrid Ferry

Vardehorn, Norway, 520 kWh, Hybrid Ferry

Eidsfjord, Norway, 1040 kWh, Hybrid Ferry

Thyboron, Denmark, 156 kWh, Hybrid Ferry

Yxlan Ferry Finland, 136 kWh, Hybrid Ferry

Alutasi, Canada, 26 kWh, Hybrid Ferry

Arrow Park, Canada, 246 kWh, Electric Cable Ferry

Aveiro, Portugal, 910 kWh, Electric Ferry

GRSE, India, 246 kWh, Electric Ferry, Delivery Q1 2024

Super Yachts

Damen, 130 kwh, Hybrid Super Yacht

Feadship, 422 kWh, Hybrid Super Yacht

Eidsfjord

Melshorn

Vardehorn

Aurora Gloppefjord

Yxlan

Arrow Park

GRSE

OUR PROJECTS

Workboats

Elfrida, Norway, 156 kWh, Electric Fish Farm Vessel

Vitol, Singapore, 542 kWh, Hybrid Bulk Fuel Carrier x 2

Canaletto, Netherlands, 157.5 kWh, Hybrid Electric Tanker

Kotug/Cargill, Netherlands, 281 kWh, Electric Barge x4

Hydromover, Singapore, 70kWh x6 PwrSwäp, Electric Cargo Vessel

LandBased

CCCC, China, 91 kWh, Hybrid Port Crane Malahat Nation, Canada, 280kWh, Microgrid

Vitol Canaletto

Elfrida

Malahat Nation

CCCC

Hydromover

FORSEA ELECTRIC FERRY

All Electric. 8,414 Tonnes.

The Aurora is a fully electric passenger ferry. It measures 111 m and weighs 8,414 tonnes. It operates on a 4 km ferry route between Helsingborg (Sweden) and Helsingör (Denmark). The massive ship carries 7.4 million passengers and 1.9 million vehicles annually.

The system is comprised of 640 6.6 kWh batteries installed on top of each ferry in containers. Cables run from the containers to connecting points at each end of the ship.

Charging: All pre-docking procedures are based on 3D laser scanning and wireless communication between ship and shore. During the last 400 mm of the ferry’s approach the robot will reach out and pull the shore cable

from the ship. The cable reel releases the cable and the robot moves the connectors to the corresponding connectors below the robot. After the connection is made, the robot moves back to the home position and the rollup doors closes. The robot will reside inside its own building when not in use.

ZERO EMISSIONS

ForSea Ferries have chosen to charge their batteries with “green electricity”, from non-fossil fuel sources such as wind, water and solar energy. This means that there are no emissions from the battery-operated vessel.

The system is comprised of 640 6.6 kWh batteries installed on top of each ferry in containers. Cables run from the containers to connecting points at each end of the ship.

Client FinnFerries

Project Date Completed in 2017

Project Information

Category: Ferry

System: 4160 kWh Country: Sweden

STUDYCASE

FINNFERRIES HYBRID FERRY

3 Power Modes - Electric, Hybrid, Diesel Electric

This double-ended ferry has paved the way for a new type of ship, the hybrid/electric ro-ro. Finnish stateowned ferry operator FinFerries is only the second operator in the world to build such a vessel but remains the first of its kind to recharge its batteries at each end directly from the domestic power grid; Norwegian Ampere was the first however it draws its power from banks of batteries at each terminal. In June 2017, the Elektra began regular operation between Nauvo and Parainen in the Turku archipelago. Designed to be a 24/7 workhorse, it travels this route every 15 minutes during peak hours and once an hour over overnight.

The System: The two lithium-ion battery packs each have a capacity of 530 kWh (1MWh total storage), one in the forward and one in the aft machinery space. Both banks are

charged simultaneously but each is dedicated to one of the thrusters. Each trip uses about 15% of the batteries’ capacity, which must be replaced during each brief port call. This energy storage system was design for a 10-year lifetime.

The engine room is equipped with a pair of 900kW, Z-drive, azimuthing thrusters from Rolls-Royce, and three diesel generators –divided between two engine rooms, each deliver 420 kWh when needed.

CHARGING IN 5 MINUTES

Because of the harsh winter conditions in Finland, the ferry can use diesel engines to support the onboard batteries, which serve as an extra boost travelling through ice. This gives three power modes: pure battery; diesel-battery hybrid and dieselelectric. And to add to her eco-friendly profile, just below the bridge, rows of photovoltaic cells from Activesol of Poland, provide enough power during summer months to run the air conditioning and other hotel loads.

The value of energy storage compared with the existing conventional ship on the route, Sterna, Elektra carries 40% more vehicles but with 60% less emissions and the electricity cost is trivial: just €5 (US$6) of electricity per crossing.

Charging in 5 Minutes: The fast-turnaround pattern for the ferry means that it only leaves a minimal, five minutes at the quay for recharging. The ferry docks with a Cavotec vacuum auto-mooring system which holds the vessel in the right position,a laser sensor guides the connector that opens from the side of the vessel where it connects to the ship’s battery to begin charging.

Client

SalMar ASA

Project Date

Completed in 2017

Project Information

Category: Workboat

System: 156 kWh

Country: Norway

HYBRID AQUACULTURE SHIP

The Elfrida electric boat, the world’s first electrically powered ship for fish farming, is in operation off the coast of Central Norway. The work boat is used to transport feed and equipment, to repair or relocate fish cages, check anchorages, and make inspections.

It requires around 50 minutes for its daily trip to the fish hatchery, which lies 12km off the coast. During the normal working day of about eight hours the ship is powered by 100% battery power.

The system is made up of 24 6.5kWh Power batteries for a total of 156kWh.

Salmar Elfrida

Client

Torghatten

Project Date

Completed in 2016

Project Information

Category: Ferry

System: 520 kWh

Country: Norway

STUDYCASE

TORGHATTEN HYBRID FERRIES

Retrofit hybrid ships

Melshorn and Vardehorn low-emissions ferries are part of the ongoing push for zero/low emission public transportation in Norway.

Each 102m vessel can carry 120 automobiles and 350 passengers. The Melshorn operates on the 25-minute crossing on E6, Bogenes to Skarberget and Vardehorn runs the 45-minute crossing R827, Drag to Kjøpsvik. Identical ships, each vessel contains 520kWh of Shift Power 65 batteries providing 1000V to the DC bus.

The ships now use two of the four motors, which can now run on optimal load. The crew also has access to immediate extra power from the battery system if necessary.

The two 18-year-old ferries now see a 20% savings in fuel with battery power. The project has been so successful that the ferries are soon to be upgraded from hybrid to fully electric propulsion

OUR MISSION TO ZERO EMISSIONS

“

Excellence through expertise , teamwork and action .

The world is undergoing a period of significant change unlike anything in human history. Climate change is making a real impact, and our customers want solutions.

The pioneering spirit is embodied in our values - it takes courage, excellence and passion to make an impact. Courage to create, challenge and innovate. Excellence through expertise, teamwork and action. Passion for the environment, our customers, our people and our work.

Join us in our mission to zero emissions.

REFERENCE CLIENTS

Gloppefjord fully battery-operated ferry, which operate on the Anda-Lote route Nordfjord on the west coast of Norway.

LOCATIONS WORLDWIDE

SHIFT

Vancouver, Canada

HQ R&D and Product Development

Rhode Island, USA Solutions

Trondheim, Norway Service Center

Copenhagen, Denmark Solutions

Kolkata, India Solutions UAE Solutions

MANUFACTURING

GTC, Gustrow Germany Manufacturing

STERLING WILSON

Mumbai, India Solutions

Perth, Australia Solutions

Backed by a global network of energy storage experts

Yxlan - Sweden’s first hybrid ice-going passenger ferry