FORT WAYNE, Ind. The Fort Wayne Farm Show is back in full force for its 34th year Tradexpos will present the annual farm show Jan. 17-19 at the Allen County War Memorial Coliseum, located at 4000 Parnell Ave. in Fort Wayne.

Fort Wayne Farm Show exhibitors present the latest farm technology the industry has to offer along with the area’s largest variety of farm machinery equipment, all in one location.

“The Tradexpos team works diligently every year to meet the evolving needs of America’s livestock producers, row crop farmers and other agricultural professionals,” said Dan Slowinski, show director.

“The Fort Wayne Farm Show has been distinctively curated to provide real-time value and opportunity to the industry,” Slowinski said.

“Whether it’s your first time attending the Fort Wayne Farm

Show or your 30th, you’re certain to love the fantastic variety of exhibitors and educational seminars that the Fort Wayne Farm Show provides as Indiana’s

largest indoor agricultural expo. Together, we achieve the extraordinary.”

Attendees can expect to enjoy the innovations and wares of over 1,000 booths, as well as ample opportunities to attend seminars to learn more about current topics in agriculture from partners and trusted experts, Purdue Extension and Northeastern Indiana Soil and Water Conservation Districts

In support of Indiana’s FFA Scholarship Foundation, a fundraising auction will be held at 1 p.m. Jan. 17 and 18, featuring a variety of donated items. Last year’s auction raised more than $18,000 for scholarships.

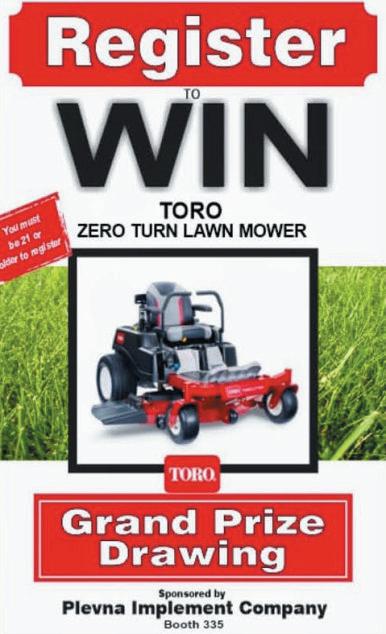

This year’s grand-prize drawing entrants must be 21 or older to register is for a Toro MyRIDE zero-turn lawn mower sponsored by Plevna Implement Co., located at 102 Peckhart Court in Auburn.

Find the business at Booth 335 during the farm show, as well as online at www.plevnaimplement.com.

Show hours are 9 a.m. to 5 p.m. Tuesday, Jan. 17; 9 a.m. to 8 p.m. Wednesday, Jan. 18; and 9 a.m. to 4 p.m. Thursday, Jan. 19.

“The Fort Wayne Farm Show is back and better than ever before,” Slowinski said.

Admission to the farm show is free, but there is a fee to park. The cost is $8 for the main lot, $12 for the preferred lot and $16 for buses or RVs. Cash, credit cards and debit cards are accepted, and this fee is valid for one entry.

In addition to the Fort Wayne Farm Show, Tradexpos produces the Topeka Farm Show in Topeka, Kansas; the North American Farm and Power Show in

Owatonna, Minnesota; the North Star Ag Expo in Medford, Minnesota; and the Wichita Farm and Ranch

Show in Mulvane, Kansas Visit the Tradexpos website at: www.tradexpos. com.

The Fort Wayne Farm Show, to be presented Jan. 17-19 by Tradexpos at the Allen County War Memorial Coliseum in Fort Wayne, Indiana, will feature daily educational seminars provided by Northeastern Indiana Soil and Water Conservation Districts and Purdue Extension.

All events will take place in Appleseed Room A, except for the luncheon program at 11:30 a.m. Wednesday in Appleseed Room B. Only 175 meals will be available for the luncheon, and they will be provided on a first-come, first-served basis.

TUESDAY, JANUARY 17

• 10 a.m.: “Midwest Ag Market Outlook” by Jon Cavanaugh, WOWO market analyst; David Kohli, WOWO market analyst; Ryan Martin, farm origination specialist, Louis Dreyfus Co.; and Rob Winters, farm director, News/ Talk 1190, WOWO.

• 11:30 a.m.: “Five Ways to Lose the Family Farm” by Dan Gordon, owner and attorney, Gordon Legal.

• 2:30 p.m.: “Distilling Down Digital Agriculture” by John Scott, digital agriculture specialist, Purdue Extension; and James Wolff, agriculture and natural resources educator, Purdue Extension, Allen County

WEDNESDAY, JANUARY 18

• 10 a.m.: “E-Z Farm Management Tools for 2023” by Jim Mintert, director, Center for Commercial Agriculture, Purdue University.

• 11:30 a.m.: “Farm Bill and Federal Policies” luncheon program in Appleseed Room B by Randy Kron, president, Indiana Farm Bureau. Sponsored by Indiana Farm Bureau and Adams, Allen, DeKalb, Huntington, LaGrange, Noble, Steuben, Wells and Whitley County Farm Bureaus.

• 2 p.m.: “Fertilizer & Commodity Outlook” by Josh Vollmar, director,

commodities and risk, The Andersons Inc.; “Making the Most of Manure Nutrients” by Theresa Dirksen, agriculture and natural resources director, Mercer County, Ohio; and “Maximizing Your Fertilizer Investment” by Ben Wicker, director, Indiana Agriculture Nutrient Alliance.

• 5:30 p.m.: “Innovative Ways To Tell Your Ag Story” by Aaron Chaflet, Chaflet Brothers Partnership; and Chris Steele, Steele Farms.

• 10 a.m.: “Market Outlook 2023” by Hugo Van Roessel, grain origination specialist, ADM; and “What Do The Numbers Say? PLC & SCO or ARC-CO” by Jason Williamson, vice chairman, Crop Insurance Professionals Association.

• 11 a.m.: “Farm Pond Fish & Weed Management” by Bill Horan, director, Purdue Extension, Allen County

• 12:30 p.m.: “Using Drones on Farms” by Purdue “Quad Squad” Drone Team.

BAUGHMAN TILE CO. / DEALEY CHEMICALS 56

BEACHY WEALTH MANAGEMENT 901

BEACON AG GROUP C127

BECK’S SUPERIOR HYBRIDS C301

BELSTRA 284

BEST FORAGE LLC 1124

BEST ONE OF MONROE 841

BIG IRON AUCTION CO. C128

AGRO-CHEM INC. 135

AGROECOPOWER LLC 686

AGRONOMIC SOLUTIONS 928

AGVENTURE MCKILLIP SEEDS C106

AGWORKS H2 LLC 933

AGXPLORE 1105

ALLEN COUNTY SWCD / PURDUE UNIVERSITY 814

ALLIANCE FEED 1147

ALMOND GARTEN 720 AMERICAN NATIONAL INSURANCE 39

AQUA BLAST CORP. 1314 AQUA OTTER 954

BAMBAUER EQUIPMENT LLC 635

BARNYARD SUPPLY REPRESENTING CADMAN POWER 689

BATH FITTER C234

BATH PLANET 939

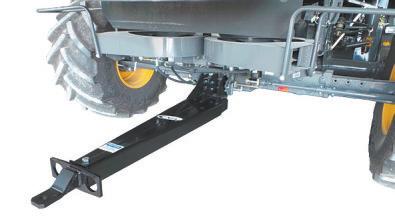

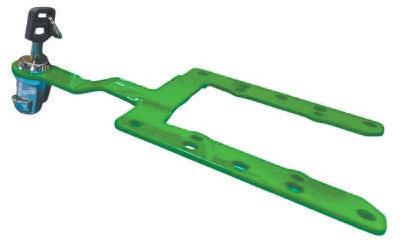

BOBCAT OF FORT WAYNE C201

BOHL EQUIPMENT, CRANE & MACHINE 1200

BORKHOLDER BUILDINGS & SUPPLY LLC 1102

BRECHBUHLER SCALES 228

BREVANT SEED / CORTEVA AGRISCIENCE C315

BROOKSIDE LABORATORIES C407

BROWN & SONS FUEL CO. 644

BUNGE NORTH AMERICA 535

BW-FUSION C421 C & J AGRI SERVICES LLC C327 C.C. SEAMLESS C322

CALMER CORN HEADS 1224

CAPELLO USA 571

CARBO-TECH AMERICA LLC C121

CASTLE CENTURION EXTERIORS 908

CENTRAL BOILER 1238

FENNIG EQUIPMENT 1014

FERTILIZER DEALER SUPPLY 503

FIBER BY PRODUCTS 829

FIRST BANK OF BERNE C219

FIRST FINANCIAL BANK — FARM & RANCH DIVISION C331

FIRST MERCHANTS BANK C115

FISHER AGRICULTURAL INSURANCE SERVICE LLC 70

FLAGPOLE SOLUTIONS 826

FLAGPOLES BY UNCOMMON USA INC. C343

FLEXXIFINGER USA INC. 243

FLYING EAGLE RENOVATIONS 684

FORE FRONT AG SOLUTIONS C430

FORT WAYNE CLUTCH & DRIVELINE 76

FRATCO C437

FREY MANUFACTURING & DISTRIBUTING 398

FRITSCH EQUIPMENT CO. 1225

G & H PETROLEUM ENCER LLC 842

GERBER AGRI SYSTEMS 23

GINGERICH CLEAN BURN INC 839

GOLDEN HARVEST SEEDS C200 GOLIATH AG 1053

GORDON & ASSOCIATES PC 55

GOSHERT INSURANCE LLC 290 GRABER LUMBER 251 GRASSHOPPER COMPANY 671

GREAT LAKES SCALE COMPANY 282

GREEN ACRES GROUP LLC / CUTLASS MOWER BLADES C123

GREEN LEAF TECHNOLOGIES INC. C134

GREENMARK EQUIPMENT C236

GROWERS MINERAL SOLUTIONS 549

GROWER’S SOURCE 1335

GUILD ASSOCIATES INC. 1339

HALDERMAN FARM MANAGEMENT & REAL ESTATE SERVICES 12

HARVEST SOLAR 1112

HAVILAND DRAINAGE PRODUCTS 18 HAYWARD DISTRIBUTING 526

HEADS UP PLANT PROTECTANTS C135

HEARING AIDS PLUS USA 63

HEARTWOOD PLANNING GROUP C323

HEAVY DUTY WORKBENCH 1241

HELENA AGRONOMIC CENTERS 324 HERDPRO 49 HIDOW C140

HILTY BUILDINGS LLC 165

HOCHSTETLER GRAIN EQUIPMENT 61 HOMAN INC. 207

HONEYVILLE METAL INC. 80 HOOSIER EQUIPMENT SERVICES 1208

HOOSIERS FEEDING THE HUNGRY 589 HULL LIFT TRUCK 1253

HUNTINGTON UNIVERSITY C131 HWY 20 TARPS 1111

HYTECH MARKETING 827

I M O AGRI SYSTEMS 68

I-BEAM SLIDING DOORS C133

INDIANA AGRABILITY / BREAKING NEW GROUND 919

INDIANA AGRINEWS 127

INDIANA AUTO AUCTION C428

INDIANA CONSERVATION OFFICERS E2

INDIANA FARM BUREAU INC. 77

INDIANA FFA LOBBY

INDIANA IRRIGATION CO. 225

INDIANA STATE CHEMIST 818

INDIANA STATE POLICE E1

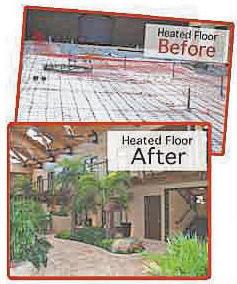

INDIANA WARM FLOORS INC. 1146

IRRIGATION SOLUTIONS C222

IVAN BUCKMASTER & SONS INC. 756

IVY TECH FORT WAYNE C220

J & J AG EQUIPMENT LLC 221

J & K COMMUNICATIONS INC. C126

J & M MANUFACTURING 259 JANITORS SUPPLY CO. 847

JOHNSON CONCRETE WATERERS 64

JONES FISH & LAKE MANAGEMENT 838

KAEB SALES 1114 KALE MARKETING 675 KASCO MANUFACTURING CO. 1121

KENN-FELD GROUP 301 KONGSKILDE INDUSTRIES 821

With first-hand farming experience, we know the stakes are high. That’s because farming isn’t just a business; it’s a lifestyle families want to pass down to the next generation—and generations to come We help families in the agricultural business to grow, preserve, and transition land and wealth to future generations. And we do it by cultivating a holistic, needs-based financial plan that aligns goals with actions for today and tomorrow

260.443.7653 matthew.henry@nm.com heartwood.nm.com

260.443.7662 ashley.stockwell@nm.com heartwood.nm.com

KOVIACK IRRIGATION 159 KUHN NORTH AMERICA 16

LAKE FRIENDLY AGRONOMY 1031 LANDLUVR 256 LEAFFILTER GUTTER PROTECTION 948 LG SEEDS 129

LIEBRECHT MANUFACTURING LLC 286

LINCOLN FINANCIAL C112

LOADER PARTS SOURCE C418

LOUIS DREYFUS COMMODITIES C309

LOUP ELECTRONICS INC. 1122 LOW MU TECH 35

LUTHERAN HOSPITAL TRAUMA SERVICES C326

M & W SEEDS 29

MACALLISTER MACHINERY 363

MACALLISTER TRANSPORTATION 1138

MAISCO LLC C426

MANCHESTER FARM CENTER 342

MANNIK SMITH GROUP 937

MARTIN INSURANCE C333

MARTIN TILL C434

MATSEN MINIATURE FARMS 809

MAX PROFIT AG 585

MEG-MO SYSTEMS 1006

MENSCH MANUFACTURING 183

MERCER LANDMARK INC. 658

MERCHANTS BANK OF INDIANA 1231

METZGER PROPERTY SERVICES 653

MEYER BUILDING LLC 11

MEYER MANUFACTURING 659

MICHIANA HARDWOODS LLC 1328

MICHIGAN VALLEY IRRIGATION C119

MICRO-TRAK SYSTEMS INC. 364

MID-OHIO CONSTRUCTION POST FRAME BUILDINGS 1315

MIDWEST BIO-TECH INC. 722

MILAN CENTER FEED & GRAIN INC. 1217

MILLER’S GRAIN ROASTING 66

MJC PRECISION DAIRY 371

MJK PURVEYORS 683

MODRESKE FENCE 1044

MONTY’S PLANT FOOD C110

MORE FARM STORE 519

MORTON BUILDINGS 213 MOSIER’S TARPS 1017

MSS ENGINEERING LLC 226

NAPA AUTO PARTS 151

NDY MANUFACTURING 944

NEVILL SUPPLY 21

NEXT GEN TUNING & DIAGNOSTICS 932

NICORR LLC 824

NIFF-TONE DISTRIBUTORS 1022

NINJA CRIMPER 1350

NORTHERN MINNESOTA MACHINERY SALES 265

NUEBERG MACHINERY SALES & SERVICE 1232

NUTRIEN AG SOLUTIONS INC. C237

OHIO VALLEY AG 902

OHLEMACHER WISCONSIN MEAT & CHEESE 1321

O’REILLY AUTO PARTS 370

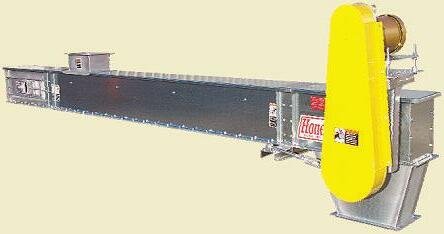

Bucket Elevators, up to 32,000 BPH

Bucket Elevator Support Towers

Catwalk and Support Towers

Distributors, Flat Back &Round

Horizontal Drag Conveyors (up to 26,000 BPH)

Incline Drag Conveyors (up to 20,000 BPH)

Bin Unloading Drag Conveyors (up to 6,350 BPH)

ORO AGRI INC. 900

ORTMAN DRILLING & WATER SERVICES 1242

OUTBACK GUIDANCE 227

OXBO INTERNATIONAL CORP. 277 P & L FERTILIZER 235

PACEMAKER BUILDINGS 74

PARKER & SONS EQUIPMENT 349

PARTNERS BRAND SEED C125

PEAK FORAGE SOLUTIONS INC. 46

PERFORMANCE AG INDIANA 1340

PIONEER 1039

PIVOT BIO 352

PLEVNA IMPLEMENT CO. 335 POET 41

POLY TECH INDUSTRIES INC. 1101

POMP’S TIRE SERVICE 910

POND SEED CO. C223

PORT INDUSTRIES C441

POST AGRI-SERVICE LLC 1026

POWELL SEEDS 925

PRAIRIE HYBRIDS SEEDS C328

PRECISION MANUFACTURING 692

PRECISION PLANTING 237

PRIBLE AG PRODUCTS 319

PROPEL SLIDING DOOR AUTOMATION C136

PROTEXIA 914

PUCK ENTERPRISES 24

PURDUE EXTENSION ALLEN COUNTY 808

QUALITY CRAFT TOOLS 1346

QUILLEN BROTHERS 822

RABER PATIO ENCLOSURES & FURNITURE LLC 187

RADIANT CRAFT 656

REDBRAND FENCE C139

REDLINE EQUIPMENT 353

RENEWABLE ENERGY SYSTEMS LLC C329

RENEWAL BY ANDERSEN 923

RENK SEED 1110

RICHMOND BROTHERS EQUIPMENT 30

RMH SELF PROPELLED FEED MIXERS 48

ROB-SEE CO. C235

RUPLEY FARM EQUIPMENT INC. 575

RYKER TOOLS / SID & SONS LLC 940

S I DISTRIBUTING INC. 760

S L PRECISION AG LLC C122

SCHAEFFER OIL & GREASE 1023

SCHRADER REAL ESTATE & AUCTION CO. 115

SCI LEASING GROUP 81

SCOULAR COMPANY 825

SEED CONSULTANTS 278

SEED GENETICS DIRECT 1019

SHELBY CROP INSURANCE INC. 1127

SHIPSHEWANA HARDWOODS — A PALLETONE COMPANY 1312

SHIVVERS MANUFACTURING INC. 220

SHOP HEAT BOILERS 157

SHOUP MANUFACTURING CO. 1001

SHUR-CO 1307

SHURWRAP 219

SIKKEMA EQUIPMENT 247

STEINHOFFER SCALE CO. 1048

STINE SEED COMPANY 78

STONEX FINANCIAL INC. — FCM DIVISION 1236

STOOPS FREIGHTLINER 931

STOR-LOC 1218

SUNSTAR HYBRIDS 15

SUPERIOR SLEEP EXPERIENCE 1233

SUPERIOR TURBO & INJECTION 1239

SWISS PERFECTION LLC 1045

SYNGENTA CROP PROTECTION C214

T. D. WALL INC. / WALLS TRAILER SALES 271

T.A.S. WELDING & GRAIN SERVICES C330

TERRAMAX INC. 836

THORNE INSURANCE AGENCY C335

TIMEWELL DRAINAGE PRODUCTS 662

TIMM SERVICES INC. C143

TIMPTE INC. 553

T-L IRRIGATION CO. 1326

T-MOBILE 844

TODD SCHAFFER EQUIPMENT LLC 563

TOPEKA NEW HOLLAND INC. 109

TRAVIS BURKHART FOUNDATION 58

TRI STATE LIGHTNING PROTECTION & PAINTING SERVICE 36

TRIPLE K IRRIGATION 1108

TRIPLE S REMODELING 652

TRI-STATES GRAIN CONDITIONING 551 TTG EQUIPMENT CO. 385

ULTRA CLEAR 65 USA INSULATION 832

U.S. DEPARTMENT OF AGRICULTURE NATIONAL AGRICULTURAL STATISTICS SERVICE 934

USED PRECISION AG 906

VALENT USA LLC 688

VALENTINE FEED & SUPPLY 1332

VALLEY TRUCK PARTS INC. 1141 VAN HORN BOLT SERVICE 1311

VETERINARY & POULTRY SUPPLY 14 VTF SUNRISE LLC 1247

VULCAN EQUIPMENT 625 WAGLER & ASSOCIATES 1322

WAKARUSA NUTRITIONAL SERVICES LLC / WAKARUSA AG LLC 375

WALINGA USA INC. 665

WATERS AGRICULTURAL LABORATORIES 1144 WAYNE-VAUGHN EQUIPMENT 171

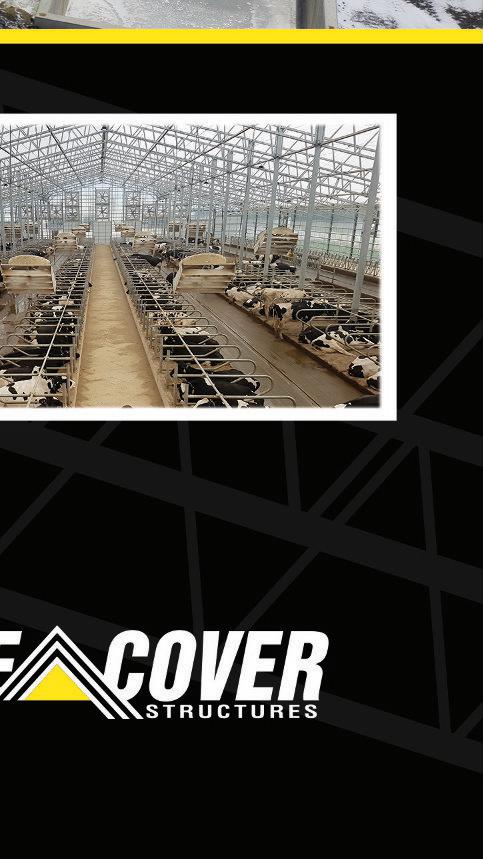

WECOVER STRUCTURES INC. 1248

CONTACT

ALLEN CO.

Bob Purlee, DSM (260) 414-2301

CASS CO. Brandon Beck, DSM (765) 431-0553

Larry Troyer (574) 721-0500

Joe Troyer (574) 721-0619

DECATUR CO. Cuskaden Seed Service (812) 593-1864

ELKHART CO. Doug Wenger (574) 535-5677

FAYETTE CO. Zach Glover (765) 309-1928

FULTON CO. DK Lash LLC (574) 551-7746

Larry Troyer (574) 721-0500

Joe Troyer (574) 721-0619

HUNTINGTON CO. Michael Thompson, DSM (260) 388-2862 Ryan Haupert (260) 358-6617

JASPER CO. Joe Klaus, DSM (812) 455-1006

KOSCIUSKO CO. DK Lash LLC (574) 551-7746

Ron Harter, DSM (260) 760-2480

MARSHALL CO. DK Lash LLC (574) 551-7746

MIAMI CO. DK Lash LLC (574) 551-7746

Jared Cordes (260) 571-2032

Larry Troyer (574) 721-0500

Joe Troyer (574) 721-0619

NEWTON CO. Scott Nelson (765) 490-0699

PULASKI CO. Niki Clemons (574) 242-0663

PUTNAM CO. Roger Rudolph, DSM (260) 908-3972

RUSH CO. Cuskaden Seed Service (812) 593-1864 Zach Glover (765) 309-1928

SHELBY CO. Cuskaden Seed Service (812) 593-1864

J.D. Kolkmeier (317) 625-4886

ST JOSEPH CO. Gary Freiburger, KAM (260) 433-5125

STEUBEN CO. Disbro Farms (419) 212-1746

WABASH CO. Jared Cordes (260) 571-2032

Ryan Haupert (260) 358-6617

By Martha Blum AGRINEWS PUBLICATIONS

By Martha Blum AGRINEWS PUBLICATIONS

LA SALLE, Ill The focus for AgriNews has remained the same for 45 years provide information important to farmers.

“Lou Lesniak was the idea guy, and the whole idea of AgriNews was to target the working farmer and farm families,” said Lynn Barker, who retired as publisher of Illinois AgriNews and Indiana AgriNews in December 2019. “The basis of AgriNews was built

around local news and local advertisers.”

Barker began his career at AgriNews in March 1978, one year after the paper began publishing.

The words “upstart,” “advertising” and “agriculture” intrigued Lynn Barker to apply for a job at AgriNews that resulted in a nearly 42-year career with the company.

“AgriNews was one of the few independent agricultural newspapers in the country,” Barker re-

called “There were ag newspapers in Wisconsin, Pennsylvania, North Dakota and Indiana at that time.”

AgriNews, which originally was owned by Miller Group Media, was purchased by Shaw Media in September 2019

“Shaw Media is the third oldest, continuously owned and operated family media company in the nation, founded in 1851,” said Dan Goetz, the current publisher of Illinois AgriNews and Indiana AgriNews “We have daily and weekly newspapers in northwest

Illinois and Iowa in addition to several niche magazines.”

Shaw Media, Goetz said, is dedicated to serving communities to provide local news and advertising.

“We’re going to continue the 45-year tradition of excellent coverage of agriculture to serve our farmers and also continue to provide a very strong print edition for our advertising partners,” he said “Along with that print edition, we can now reach our readers on many different platforms

with our website, newsletters, Facebook and Twitter.”

With resources at Shaw Media, Goetz said, advertisers have many ways to inform readers about their products and services.

“There are so many solutions like targeted email blasts,” he said “With those emails, we can go to different counties or down to ZIP codes to target different areas of the state.”

WELDY ENTERPRISES 1011

WELLMAN SEEDS 1004

WENZINGER FARMS THE PORTABLE SEED AUGER C415

WESTLAKE UNIFIED STEEL SHINGLES 1345

WILLIAMS EXPERT PIVOT C325 WILLIAMSON CROP INSURANCE 1205 WILSON TRAILER SALES OF INDIANA 634

WINDOW DOCTOR 1245

WINGFIELD MANUFACTURING LLC 629 WISCONSIN CHEESE & SAUSAGE CO. 835

WOLFE EQUIPMENT 926

WOODCHUCK BEDDING SPREADER 1222 WOODMASTER 1007

WOWO NEWSTALK 1190 82

YODER OIL CO. 67

ZERK ZAPPER TOOL / HORIZON PRODUCTS 1347 ZIMMERMAN MANUFACTURING 935

Technology provides readers information where they want to see it.

“Whether it’s a reader or an advertiser, we can provide people with the information they’re looking for in whichever way they’d like to see it,” Goetz said “If someone enjoys looking at the website, they can go there and see all the content, including the E-edition of the paper.”

Barker started as an advertising representative for AgriNews and held the position of national advertising manager prior to becoming the publisher of the newspaper.

Selling advertising for an upstart newspaper was not any easy task, Barker said, and he heard the word “no” quite often from many ag companies.

“When I started, I worked out of the Morton office, and I had a sales route in east-central Illinois,” Barker said.

“We always wanted to make at least 13 sales calls per day,” he said

“After being told ‘no’ the entire day, I pulled off on the city square to reflect and I told myself I had to find another job,” he recalled about a day early in his career “After 15 minutes of reflection, I made my last stop of the day and sold a two-column by 5-inch ad.”

Advancements in technology had a significant impact on how Barker completed his work for the AgriNews.

Once an advertisement was sold, AgriNews salespeople used grid paper to design an ad and sent film to the home office in La Salle to be developed for pictures that were included in the ads.

“All our work was packaged and put on Greyhound or Trailways buses on Friday nights,” Barker said “One of the tricks of the trade was finding a phone booth to call clients with a calling card while you were on the road or to call the home office.”

Now, advertising sales representatives submit ads for AgriNews through the internet,

“Technology has made our jobs easier because sales people can show spec ads or previous ads on their tablet while visiting a customer,” Barker said.

AgriNews employees attended all kinds of agricultural events to introduce the paper to as many potential readers and advertisers as possible during the initial years.

“I would go to the consignment auction at Martin Auction Company, set up a card table and hawk newspapers,” Barker said “The Martins recognized early on that

this publication had potential, so they welcomed me there.”

Among Barker’s fondest memories of his work at the AgriNews is the day an equipment jockey from Mexico walked into the office.

“He had found our newspaper at the Martin consignment sale a couple months before,” Barker said “He was back in the U.S. and he traveled to La Salle, Illinois, to pick up the AgriNews.”

As websites on the internet became important for companies and organizations to provide information, the Chicago Board of Trade contacted AgriNews Publications for some assistance,

Barker said.

“One of the traders who was on the CBOT board asked us to be a content provider for the CBOT website,” he said. “So, we worked out a system to provide content every week to the CBOT, and we probably did that for a year before they started doing that work themselves

“The AgriNews is successful because it is all encompassing we don’t just concentrate on row crops or raising livestock,” Barker said. “And we don’t only include the business of farming, but also the lifestyle, as well as youth activities like 4-H, FFA and county fairs.”

“We will continue to provide the agricultural community with the information they need and our advertising partners the solutions they need for marketing,” Goetz said “We’re always looking ahead to see what’s next to serve our readers and advertisers.”

Martha Blum can be reached at 815-410-2254, or mblum@shawmedia.com. Follow her on Twitter at: @AgNews_Blum.

“We’re going to continue the 45year tradition of excellent coverage of agriculture to serve our farmers and also continue to provide a very strong print edition for our advertising partners.”

Dan Goetz, publisher ILLINOIS AGRINEWS AND INDIANA AGRINEWS

DWIGHT, Ill. The 1970s was a pivotal decade for agriculture, not only for the economic struggles that would follow, but also for concerted efforts to step-up soil conservation efforts

Commodity prices spiked in 1973 after the Soviet Union signed a substantial three-year trade agreement to purchase U.S. grain. Grain exports doubled from 1972 to 1973.

In response to crop prices increasing, then-USDA Secretary Earl Butz encouraged farmers to “plant fencerow to fencerow.” It more or less discouraged conservation practices and the moldboard plow was part of the regular management

Butz also released production controls, including the annual set-aside acres, to encourage more acres of cash crops.

Environmental groups took notice as reports of increased soil erosion spread Environmentalists and allies in Congress questioned the effectiveness of existing soil conservation programs in light of the fencerow-to-fencerow trend.

As a result, the Soil and Water Resources Conservation Act was signed into law 45 years ago. The law provides the U.S. Department of Agriculture broad strategic assessment and planning authority for the conservation, protection and enhancement of soil, water and related natural resources

It also called for USDA to “develop a national soil and water conservation program to give direction to USDA soil and water conservation activities.”

Since the fencerow-to-fencerow days, U.S. conservation tillage acres have increased from 44 million in 1973 to about 202 million

acres in 2021, 104 million of which are no-till

Lee Bunting, a fifth-generation farmer from Dwight, joined the Livingston County Soil and Water Conservation District board a year after the resources conservation legislation. He has served the district for 44 years, now as county SWCD chairman.

Bunting noted the changes in conservation efforts in his farming career and the proactive role area producers have played in improving soil and water quality.

“Back in the 1970s when I got on the board, everybody was moldboard plowing their cornstalks and even plowing some soybean stubble,” Bunting said.

There weren’t a number of incentives four decades ago to implement conservation practices compared to today, and it was up to farmers to apply those practices on their own.

However, there was an indirect incentive by way of the 1979 oil crisis that moved farmers to rethink their tillage practices

The energy crisis in 1979 caused a drop in oil production in the wake of the Iranian Revolution.

Although the global oil supply only decreased by about 4%, the oil markets’ reaction raised crude oil drastically over the next 12 months, more than doubling to $39.5 per barrel, equivalent to $143.58 today. The price spike resulted in fuel shortages and long lines at U.S. gas stations.

“In the late 1970s and early 1980s there was an issue getting diesel fuel and I think that helped

us along as far as doing more chisel plowing or not plowing the stalks You needed less diesel fuel if you chisel-plowed rather than plowing. It saved on time and fuel and that helped a lot, and it kept the soil erosion down, too,” Bunting noted.

“The first thing was to put the moldboard plow away and then we got into no-tilling. I think Allis-Chalmers was one of the first to make a no-till soybean and corn planter with the coulters in the front.

“Someone in Livingston County had one and I used it on a few no-till acres of corn and soybean stubble.

“Technology hadn’t really caught up with no-tilling because you’d use a lot more herbicide and different herbicides rather than tillage to keep the weeds down.”

FROM

During his early years with SWCD, Bunting said the county was awarded an Illinois Environmental Protection Agency grant to set up monitoring stations to test for wind erosion.

“We did that for three or four years and made comparisons between the fields that were plowed and the fields that were left untilled or chisel-plowed,” he added.

Like many other county SWCDs across Illinois, Livingston County has been a focus of several research efforts focusing on soil health and water quality.

“Livingston County is in a unique situation. We have the Vermilion River going through the county and that’s a drinking water supply for Pontiac and Streator It then goes to the Illinois and Mississippi rivers and down to the Gulf of Mexico where the problems are with the pollution is in the Gulf,” Bunting said.

“We are very important as far as keeping the water safe for the people of Pontiac and Streator and also maintaining productivity. We have some good soils, too. We need to maintain that productivity plus also watch what we use so we don’t lose it going down the streams.”

With environmental concerns growing across the nation, there have been farmer-led groups proactive in finding solutions.

The Five-mile Creek Project in the 1990s focused on nutrient loss into the creek that eventually flows into the Vermilion River.

The Indian Creek Watershed Project through the Conservation Technology Information Center began in 2012 and was then rolled into the larger Vermilion Headwaters Project in 2018 that is now ongoing in multiple central Illinois counties

The programs have provided boots on the ground to assist farmers in implementing conservation practices and seeing the end-results.

“We’ve had very good support with those programs We’ve put in wetlands, bioreactors and

other conservation practices and set up test programs so they can monitor and see how they’re actually working and tell the story of how these projects do help,” Bunting explained.

In the midst of those ongoing watershed projects, the Illinois Nutrient Loss Reduction Strategy was released in 2015 that includes a 10-year plan to reduce nitrate losses by 15% and total phosphorus loss by 25% by 2025 with a final goal of reducing losses by 45% for both.

“We’re getting close to 2025 and it depends on who you talk to, but I don’t think we’re really mak-

ing the progress as far as getting down to reducing those amounts of nitrogen and phosphorus that we need to be, but we’re still working on it,” Bunting said.

“There are a lot of different groups and districts that are promoting nutrient loss strategies and promoting cover crops. Soil health is a big thing now.

“This last year, the state came up with $3.5 million in new funding for Soil and Water Conservation Districts to help with implementing the Nutrient Loss Reduction Strategy. I haven’t seen anything on what the opportunities are as far as applying for those dollars to get those programs to the local level. That’s

kind of a work in progress yet.”

Bunting reflected on the changes he’s seen in the rural landscape and the transition to cover crops and other efforts to improve soil and keep the nutrients out of the streams and rivers.

“Back in the 1960s, everyone had few cows and had some hay ground and pasture ground Then corn and soybeans took over and we lost a lot of that pasture ground and hayfields,” he said.

“Now we’re not only reducing soil erosion, but getting healthier soils by keeping cover crops in place. That ties up the nitrogen and other fertilizers and keeps them in place for the next crop.

“We have to maintain productivity. We have to grow a crop and provide feed and fiber for the United States and the world, but it’s doing it in a way that maintains our soil productivity, too.”

Tom C. Doran can be reached at 815-410-2256 or tdoran@shawmedia.com. Follow him on Twitter at: @AgNews_Doran.

PONTIAC, Ill. Over most of the past 100 years, there were step-changes in farming technological advancements. But that rate increased exponentially the past few decades, transitioning from the Green Revolution to the Digital Revolution.

Jason Webster, Precision Planting commercial agronomist and Precision Technology Institute director, has seen this growth both from the prospective of his family farm and on the research side.

As a youngster, Webster worked with his grandfather and father on the family farm and had the opportunity to farm his own ground in 1988 as a junior at Tri-Point High School in Cullom. He has since ridden the tidal wave of change.

“My grandfather saw it all with horses and look where we are

now with a whole different form of horsepower,” Webster said

His family used a John Deere 7000 planter with only the basics that were available in 1988.

“There was a spring to keep the thing downforce-wise, there’s like no control at all. There was an old monitor that didn’t even show population. There was just an orange little light saying if it was planting or not,” he said

“Wow, have we come a long way since then. I remember running that planter when I was a junior in high school planting my corn I knew with the lights it was dropping seeds in the seed tube in the ground, but I knew nothing else that was going on behind me.

“Now, I know population by row, I know how much fertilizer I’m putting on the row, I have the ability to put fertilizer in five different bands on each row. I can change hybrid on the fly if I want to

“What does the soil that I’m

in right now need, and I can address fertility, seeding rate and the actual germplasm that we’re planting in that area. Talk about taking control and saying, here’s what we’ve been given for soil, this is what we’ve been given for weather, now react, take control, do something different so you don’t lose as much yield or, even better yet, you make yield and make more dollars per acre.”

In today’s planters, down-force control and electric row units have replaced a chain-drive drive shaft.

“Also, the sensing, that monitor that monitor in the cab showing me everything I wish my grandfather could still be here to watch everything on that monitor. It would just blow him away,” Webster continued.

“It’s us learning more as we plant. It’s measuring, reacting and taking control. Measuring, know you have a problem, go fix it and keep it from happening

again. Those are the things right now that have changed and we’re doing it.”

Real time kinematic, or RTK, autosteer technology using the global positioning system was first put into a tractor in 1999 Webster was skeptical of its success. Not any more “When it first came out I didn’t think anyone would buy it. There are too many farmers that like to drive They want to do it themselves. I was totally wrong. It’s efficiency It’s less passes in the field, less overlap with tillage and things like that,” Webster said.

“The biggest thing for me with autosteer is I don’t have to worry about driving the tractor. It’ll just drive a straight line and I can see how the planter is actually performing. Even for those who don’t think they’re making any money on it, there’s convenience there that everybody wants it and

is going to take advantage of it.”

Advancements in technology the past several decades extend beyond iron and software into how seed genetics have improved farming.

The breakthrough in genetically modified technology came in 1973 The first field trials of GMO plants were in 1986 with tobacco plants engineered to be resistant to herbicides The following year saw the first genetically engineered insect-resistant plants

The Webster farm saw firsthand the benefits of these scientific developments.

Corn rootworm was first found in Illinois in 1987 in a Ford County field near where the Websters farmed and by the 1990s there were large populations in Illinois and Indiana.

FROM

In 2003, the first Bt corn rootworm trait products were introduced for hybrids.

“When I started farming, we were just getting into the rootworm problems. We were kind of the epicenter of corn rootworm problems Corn was falling down We didn’t have any traits at that point and that when we started putting liquid on the planter, putting the tanks and the pumps on to put liquid insecticide on the planter. It absolutely failed It didn’t give us the control that we really wanted,” Webster said.

“That was the first time of dealing with liquid on the planter and trying to go after it that way. That was the first time we put technology on the planter and trying to address that issue. Then the traited corn came out and it kind of took care of the problem for the most part.”

After graduating from college, Webster’s career path led

him smack-dab in the middle of new technological advancements.

For 11 years beginning in 1996 he was farm manager at then-Pontiac National Bank where much of his time was working with absentee landowners.

“I quickly noticed that the landowners asked why we are spending money on this seed trait, this technology, and I had to explain it to them I said wouldn’t it be easier if we just did it in the field and showed it to them that way. So, we show them the data or if they want to come to come out to the field and they can look at it,” Webster noted.

He began hosting field days with side-by-side trials, showcasing new technologies and providing learning opportunities for farmers.

“We started doing field days and that’s where we starting doing all these side-by-sides, bringing the technology out, learning, and farmers loved it,” Webster said.

FROM

“They would come out and say this is great, this is what we want to learn about, and we tried to keep it new and fresh, and the stuff that wasn’t even available yet we’d try to keep it out there and learn. That was a big part of what we did, explaining why we are doing some of the things we’re doing,” he added.

His move on to Beck’s Hybrids as director of the then-new Practical Farm Research facility near Downs expanded the opportunity to deliver research that focused on new genetics on a larger scale.

His work there led to a focus on planting the right genetics for a variety of soil, including the notion of a multi-genetic planter.

“I still remember making a phone call to an equipment dealer in Milford, Indiana, and I said I wanted to build a planter

that can change corn hybrids or soybean varieties on the fly. He said, ‘you’re crazy that will never happen.’ As we got talking about it he said maybe it can work,” Webster said

“We went to John Deere, Case IH, all of the big planter companies and asked if I could buy a multi-hybrid planter. They said there’s no such thing available, and so we made it We created one and did it so it would change the hybrids where the management zone change and then we ask if we made money, and we did.”

Webster used a modified Kinze twin toolbar planter to plant trials in 2012 and 2013. Multi-hybrid planters were available on a limited basis for the 2015 planting.

“Now that’s a product being sold by not only Precision Planting, but there are others who are offering that, too,” he continued

“It makes total sense on fields that are variable. If you’re flat, black and beautiful, you don’t

Jason Webster PRECISION PLANTINGneed it, but if you’re variable like a lot of farms are, it makes a lot of sense.”

Of all of the technology that’s been rolled out over the past several decades, Webster said the biggest game changer were advancements on the breeding side with better hybrids and varieties and the planter itself. Farmers are no longer limited to watching the orange light indicating if it was or was not planting.

“Equipment-wise this measuring ability of knowing what’s happening on the planter is incredible. It’s changing they way we’re farming and guys are doing a better job. We’re not guessing anymore,” Webster said.

“Yes, we’re Precision Plant-

ing and we sell stuff for the planter, but it’s still the most important pass a grower makes. Yes, you have to pick the right seed out and that’s important, but it’s so much more. You have to get it in the right depth, you’ve got to get it into moisture, you’ve got to have the right downforce to keep the depth and you have to close on the back side properly, remove the sidewall smear and remove the air pockets.

“You want that beautiful stand, that consistent, uniform emergence, and how do you get it, and I don’t think we were getting it before, but it’s a heck of a lot easier now. Now we have the tools. We have eyeballs in the trench, if you will, to get that measurement and if it’s not right we can fix it on the fly without even stopping.”

A third game-changer is “figuring out how to feed these plants,” Webster said.

“Once you get the uniform even emergence, now we’ve got to feed them right to get full yield and full profit. The tools we have

right now in the toolbox are just tremendous,” he said.

Looking ahead to the next 20 years of technological advancements, Webster said what he would like to see fixed in farming is crop scouting

“Crop scouting is probably our number one problem in the industry Once the crop is up, we make that last herbicide pass, that last shot of nitrogen, we’re done, it’s vacation time and guys will say it’s up to the good Lord now,” he said

“I don’t want to give up I don’t know what’s happening in the field I can’t listen to a corn crop and ask it what it needs.”

Webster said crop scouting could utilize autonomous technology that would go though the rows, monitor the plants and gauge what they need so it can be addressed immediately.

Tom C. Doran can be reached at 815-410-2256 or tdoran@shawmedia.com. Follow him on Twitter at: @AgNews_Doran

“The tools we have right now in the toolbox are just tremendous.”

CHAMPAIGN, Ill. What began as an agricultural boom in the early 1970s created the perfect storm that led to the 1980s farm crisis that forever changed the rural landscape.

“The 1970s were a very good time in agriculture. It all started in the 1973, 1974 time period with new export markets and the Soviet Union grain deal,” said Gary Schnitkey, University of Illinois Extension farm management specialist.

The Soviet Union entered into a three-year contact and in July and August 1972, the U.S. sold 440 million bushels of wheat to the Soviets, more than the total U.S. commercial wheat exports for the marketing year. The sales represented 30% of the average annual U.S. wheat production during the previous five years.

The demand resulted in nearly

tripling wheat prices during the marketing year ending in August 1973 to $4.45 per bushel Corn prices rose from $1.51 per bushels in August 1972 to $2.68 12 months later, and soybeans increased from $3.36 per bushel to $8.99 during that same time frame. Prices for steers, hogs and broilers rose 55%, 102% and 153%, respectively.

“We had much higher corn and soybean prices that led to good returns in agriculture but mainly what it did as well is led farmers to buy a lot of farmland and use debt to buy that farmland,” Schnitkey said.

“Farmland prices were going up and going up and we got some petty high debt-to-asset ratios on these farms because we’d buy farmland which we always believed was going to keep going up. We had to have it right now, so we bought it and bought it, and got some pretty high debt levels. That set this all up.”

Unfortunately, the perfect storm was about to unleash.

Inflation was also gripping the nation and around 1979, 1980, policymakers wanted to address the issue and bring inflation back in line

“The way they decided to do that was the Federal Reserve raised interest rates,” Schnitkey said.

“So, we had increases in interest rates (reaching 21.5% in 1981). We had a lot of debt on farms. Those higher interest rates then caused an increase in interest costs and then that led to a lot of financial difficulty, bankruptcies,

and everything. That fighting inflation, high interest rates, and lower commodity prices (but not all that much lower) sort of burst this bubble. It was a tough time.”

In January 1984, the Federal Reserve Board issued a report estimating that one-third of all U.S. farmers had nearly two-thirds of the nation’s total farm debt

Farmland values dropped 60% in some parts of the Midwest from 1981 to 1985 Record crop production combined with a 20% decline in exports between 1981 and 1983 (following the 1979 Soviet Union grain embargo), caused farm debt to hit $215 billion by 1984, double the 1978 debt

The crisis led to foreclosures and also an exodus from rural America and the number of farms dropped from 3.711 million in 1960 to 2.2 million by the mid1980s.

The U.S. Congress got involved in developing policies in the mid1980s to assist farmers.

The 1985 Food Security Act (farm bill) allowed for lower commodity price income supports and created several conservation programs. Then in 1986, Congress introduced Chapter 12 Bankruptcy which allowed family farmers to restructure their finances and avoid liquidation or foreclosure In 1987, the Agriculture Credit Act authorized a $4 billion financial assistance package for financially vulnerable institutions of the Farm Credit System

It was said that Congress did too little too late It took an act of nature to finally solve the farm crisis.

“Ironically, the 1987-1988 drought sort of cleared it up. We had higher commodity prices after that,” Schnitkey said.

Tom C. Doran can be reached at 815-410-2256 or tdoran@shawmedia.com. Follow him on Twitter at: @AgNews_Doran

“The 1970s were a very good time in agriculture.”

Gary Schnitkey UNIVERSITY OF ILLINOIS EXTENSION

KIRKWOOD, Ill. No matter what part of agriculture you mention, Wendell Shauman has been there and done that Growing corn?

“If you track the yield of corn from the early 1900s, it was reasonably flat until about the early 1970s, when it just turned upward and has continued upward on a pretty nice increase. I pointed out to my old classmates that was about the time I got into the business of corn breeding,” said Shauman, tongue firmly in cheek.

He worked for Funk’s Seeds as a corn breeder, starting with the company while still in graduate school and continuing with them after he received his Ph.D Livestock? That, too.

“We raised pigs We farrowed them in A houses out in an open

pasture. In winter, you were out there trying to thaw out hog waterers when it was cold as the devil,” Shauman said Cattle, as well

“I got rid of my last cow in September last year. We had cows get out a month or two before that and they were five miles away before we found them. There were no fences in their way,” Shauman said

He also understands what it’s like to be a farm kid and want to return to farming. A 1967 graduate of Monmouth College and a recipient of the college’s Distinguished Alumnus award last year, Shauman was working for Funk’s Seeds as a corn breeder.

“I was working as a corn breeder and I went to Iowa to look at some plots. My wife stayed with my parents. My dad asked her, ‘Do you think Wendell would ever want to come back?’

My wife said, ‘Yes,’ and that was

all it took. It was a done deal and I was back on the farm the next spring,” he said.

Shauman also knows what it is like to endure hard times.

“We bought our first farm in 1978. I remember my grandmother, she just shook her head and said, ‘I sure hope you can pay for it.’ My wife went back to work as a high school math teacher and kept us going through there. It took everything you had and we managed to make the mort-

gage payments, but, boy, it was ugly, income-wise,” he said

His vast experience also extends to the policy and legislature side Shauman has been involved in leadership positions at the local level, starting as a member of the Warren County Farm Bureau board, the Illinois Farm Bureau board, the Illinois Soybean Association board and the Illinois Corn Marketing Board. He served as chairman of the U.S. Grains Council.

His work with those different organizations has taken him around the world.

“My first trip, they said, ‘You’re new on the board and we work with this group called the U.S. Grains Council. We’re doing a trip to Russia. We think you ought to go.’ I said, ‘OK, but what is the U.S. Grains Council? I want to go to Russia?’ What an experience that was,” he said

When he isn’t running the farm with wife Janet, with whom he will celebrate 55 years of marriage in August, Shauman continues to promote and speak about and cheerlead for U.S. agriculture. He and Janet have three children and six grandchildren.

Speaking from the Commodity Classic, Shauman talked to AgriNews about some of his experiences and some of the issues, challenges and opportunities he sees in the industry to which he has devoted his life.

“I think U.S. agriculture has every reason to be proud of what it does and to promote the message that, ‘Hey, we really do a good job,’” he said

Jeannine Otto can be reached at 815-410-2258, or jotto@shawmedia.com. Follow her on Twitter at: @AgNews_Otto.

“I think U.S. agriculture has every reason to be proud of what it does.”

Wendell Shauman

KIRKWOOD, Ill. His journey started on a farm in rural western Illinois. Seven decades later, he has traveled to various foreign countries, has been in the room at some of the most momentous times in agriculture and has seen some of the best and most difficult years in U.S. agriculture in modern times.

Wendell Shauman looks back on his career in agriculture with the awe of that farm kid.

“I’ve been to 38 countries. I started out in a one-room schoolhouse. Who does that?” he said

Shauman acknowledges the effort and hard work it took all along the way, along with what he calls “dumb luck.”

“I have just been incredibly lucky in my life, of having the right people in the right place at the right time,” he said.

Wendell and his wife, Janet,

returned to farm with his parents in 1975.

To mark 45 years of AgriNews, Wendell took us on a journey through his career in farming, agriculture and ag organizations and talked about the past, present and future of U.S. agriculture.

“The way we farm started changing drastically. Back then, we were all pulling moldboard plows and chisel plows were just starting to become popular. When I came home to farm in 1975, we were plowing everything

“You worked the ground, you disked stalks in, then you disked or field cultivated in the spring. We did all this tillage. I was a little slow to come to it, but I am all no-till now.

“Herbicides have become more

and more important. Part of all that tillage we did was to kill weeds. There weren’t a lot of herbicide options available then, probably atrazine and 2,4-D, but that had limits, too.

“When other herbicides started coming in, that was a revolution in how you controlled weeds. If you could control weeds, you could increase yield.

“We had cows. We had hogs. You had pasture. Only half your farm was row crops. You had some oats. You had some hay. That has totally changed.”

What have been two of the most significant drivers of U.S. agriculture in your career?

“World trade really opened up. I went from the Illinois Corn Marketing Board onto U.S. Grains Council and I have stayed involved with them

“Our job is to promote corn, barley, sorghum and, now, ethanol and DDG, exports around

the world. That was all just developing in the 1970s. Developing those markets helped get rid of some of the surpluses of grain

“In the 1990s, we went out to Washington, D.C., and lobbied for the North American Free Trade Agreement. We were in the West Wing of the White House and we all had our pins on promoting NAFTA. We were visiting senators’ and congressmen’s offices. But the increase in trade was a big deal, that really got us out of a hole.

“The other thing is the development of ethanol and the people who had the foresight to create the ethanol industry Forty percent of our corn crop now goes into ethanol.

“We needed a new demand We needed a new market. The price of corn was just too low for anybody to make any money.

“’What would the price of corn be if that market went away?’ That is my comment to (Presi-

dent Joe) Biden and these guys who say everything is going to be electric I don’t think that is totally going to happen, but it certainly is going to hurt us if there’s a real big drop in demand for ethanol because that is a huge market for us.

“The ethanol industry is a big development that happened during my career and it happened over decades it wasn’t overnight.”

Speaking of ethanol, you were literally in the room when one major event happened, related to trade and ethanol and DDGS?

“When we started out, DDGS was a byproduct and nobody knew what to do with it. Then somebody figured out this stuff had a decent protein level, maybe we can sell it as livestock feed, and that market really took off

FROM PAGE 40

“The sales of DDGS to China increased year after year Then the Chinese decided they were going to file a WTO suit against us We were on a trip abroad when the Chinese informed the U.S. that they were going to file the WTO complaint, claiming the U.S. was selling DDGS below the cost of production.

“We were in India at the time, so a group of the officers, including myself, diverted to China. We were sitting in the room in China with Chinese economists and diplomats when they filed the complaint against the U.S. That was a surreal experience.”

How did you get involved in farm organizations? Where did you start?

“I started out on my county Farm Bureau board. I enjoyed it Then a Farm Bureau district director retired and I asked some friends, ‘Should I try that?’ and they said, ‘Sure.’ I won a slightly contested election. From then on,

one thing led to another.

“What I always mention to young people in leadership classes is just say yes. There are a lot of people who turn down opportunities and they will never know what they missed.”

Looking to regulation and the regulatory side of things, what do you see as the major issues facing U.S. agriculture in the future?

“It would probably be easier to look backward than forward. U.S. agriculture has been incredibly effective at protecting itself. For no bigger percentage of the population than we are, we have been very lucky in getting politicians to support us.

“Maintaining those relationships is going to tell a whole lot of the tale. One of the things you have to do to maintain that relationship is you have to educate the population. We need to get people out on farms.

“I got an award from Monmouth College this past fall and a lot of my friends from college came back Before they left, I got them all in the combine and they all got a chance to drive the com-

bine, husbands and wives.

“Before they left, I went down in the basement every farmer has a collection of hats and gave them all a hand and I told them, ‘You’re all ag investors now.’ We really need to do that, get people out and show them what we do, show them how we treat the land right and how we treat livestock right. That will make it a lot easier to keep these regulations under control.”

How do we get young people back to the farm and back to rural communities and how do we keep young people interested in agriculture and farming?

“I don’t think that’s the problem. I think there are plenty of people wanting to come back. How you introduce them is the challenge, with the price of land and the price of machinery. There are a lot of people who want to come back and farm, but there is just no economic way for them to make the transition or get it done.

“The other problem you’ve got I’m 76 years old and I’m still farming. I should have retired 20 years ago and somebody else

should have been in there. Farmers are staying around longer.

“It’s easier now to keep going and there’s a whole generation almost that’s being squeezed out. Now, instead of every farm having a couple kids, we rely on our grandkids to come out and farm.”

Looking at the high prices that farmers are getting now for different commodities, from your experience, is it a good thing, a bad thing or a little bit of both?

“We can price ourselves out of markets, too. The particular situation we are in now, we are enjoying these high prices, but nothing cures high prices like high prices There is going to be some pain coming to us over the next two or three years probably.

“These prices are too high. How in the world can you afford to feed cattle now? That has to be a challenge for them. There still is a demand for beef and people will pay for it, but how many people will pay for it and how many people even can? What effect is that going to have on the livestock market over the next two or three or five years?

“What effect is it going to have on those ranchers who rely on livestock for their livelihood? How are they going to manage and struggle through the next two or three years until the price of grain gets back down? The price of grain will come down quicker than that, but you have to rebuild your herd and that takes a couple of years.”

Are we in the golden era of U.S. agriculture? Was there a golden era of U.S. agriculture?

“Things ebb and flow. There have been a lot of good years. There have been a lot of bad years. We remember the bad years more than the good

“There is a lot more trauma in trying to make it through when times are tough than there is when yields are good and prices are high and it’s easy to make payments and it’s easy to buy something new.”

Jeannine Otto can be reached at 815-410-2258, or jotto@shawmedia.com. Follow her on Twitter at: @AgNews_Otto.

ovo® soybean herbicide is setting a new preemergence standard. It combines unprecedented weed control and crop safety to deliver higher potential yield in soybeans. Compatible with any soybean production system and soil type, Tendovo provides a sound defense against more than 70 yield-robbing weeds See how Tendovo delivers weed control without compromise at SyngentaUS.com/Tendovo.

HOOPESTON, Ill Robert

Fraley has received numerous prestigious accolades for his contributions to agriculture worldwide, yet his roots remain deeply planted in his local farming community

Fraley was born in 1953 and raised on his family’s grain and livestock farm between Hoopeston and Wellington in east-central Illinois.

“Grew up on small farm and did all of the things that a normal farm kid experiences,” said Fraley, who would go on to lead the successful introduction of genetically engineered glyphosate herbicide-resistant soybeans and other biotechnologies.

His experiences and observations on the farm of his youth and his love of science set the path toward game-changing developments in food production

Fraley recalled experiences on the family farm that guided his direction to do what he could to improve farming.

“The one I talk about a lot that’s so vivid in my memory banks is my dad looking out the window and the big thunderstorm passes us by when our crops are thirsty. The impact of drought and how important the weather is on crop production has always been key,” he said.

“And, of course, we had our share of issues with corn rootworm and corn borers and some of the fungal diseases It left a real impression on me that the risk in farming due to environmental and pest problems was enormous.”

Fraley attended Wellington High School where he had “a great science teacher who convinced me that’s where I wanted to spend my time. So, I went to the University of Illinois and started

studying biology and things kept moving forward.

It was an exciting time to be in biology with an interest in agriculture because the science was changing and moving so fast.”

He remained at U of I after earning a degree in biology. He worked with Professor Samuel Kaplan in the Department of Microbiology for his doctoral degree, focusing on microbiology and biochemistry.

He accepted a post-doctorate position at the University of California-San Francisco.

“That was pivotal for me because in many ways that’s the institution that started the biotech revolution. One of the researchers there, Herb Boyer,

and some of his colleagues, Stan Cohen and Paul Berg, were the first ever to introduce a new gene into another organism Within a few years it was already pretty obvious that this technology was going to have a big effect on health care,” Fraley said

“By the time I had moved out to U of C in 1978, some of the new biotech healthcare companies had already cloned the human insulin gene, the tissue plasminogen activator (for treating blood clots), and growth hormone. So, the use of this technology in human health was already being established, but at that point in time no one had been able to apply these tools to improve crop plants.

“I looked around for places that had an interest in this new technology I talked to a couple of universities and some companies but what really struck me about Monsanto was they were really committed to this new field They

were looking for something to go beyond the traditional crop chemical industry.

“I realized this was going to take a real team effort at Monsanto both on the science side and the business side to make it happen They convinced me that they had the stamina and the resources to make it happen and I think it was a pretty darn good decision.”

A team was formed at Monsanto with members that had expertise in different areas: Fraley in gene delivery, Steve Rogers in gene cloning and Rob Horsch in tissue culture.

The team of researchers began with the petunia due to its ability to regenerate plants from single cells and flower color genetics that helped identify the location of the inserted gene

FROM PAGE 44

At the same time, several other labs were also working to develop gene transfer techniques in plants

In 1982, Monsanto’s team was successful in inserting a kanamycin antibiotic resistance gene into a petunia cell and generating plants that were fertile, with the inserted trait being stable. Once gene transfer was demonstrated, the company moved to developing Roundup resistance in commercial crops, including soybeans, cotton and corn, and insect protection in cotton and corn.

Roundup Ready soybeans and Bollgard Bt cotton were both commercially launched in 1996. Bt corn to manage rootworms was released commercially in 2006.

“Thinking about it through the lens of an Illinois farmer, obviously the Roundup Ready soybeans and then subsequently the technology for insect control for caterpillars and rootworm in

corn were hugely impactful products for farmers,” Fraley said.

Fraley has been a long-time advocate for using GMO products to help address global food insecurity while reducing agriculture’s environmental footprint.

Norman Borlaug, often called the father of the Green Revolution, had a strong influence on Fraley’s career and refers to Borlaug as his personal hero.

“I met Norm actually a few years before the first biotechnology products, Roundup Ready soybeans or Bollgard cotton were released. Norm was already interested in how biotechnology could be applied to food production and crop productivity in developing countries,” Fraley noted.

They worked together to help create the International Service for the Acquisition of Agri-biotech Applications organization which is still very much involved in tech transfer to developing countries.

“It was clear to me in understanding Norm’s experience and

passion with the Green Revolution that technology that helps farmers can help farmers everywhere. That technology that we’re developing to protect crops from insects and weeds in the U.S. or South America can be enormously beneficial to small holder farmers in India or in Africa,” he said

“So, I was really proud of the efforts that Monsanto made to share technology with small holder farmers around the world. It’s been a real win both from a food productivity perspective but when you think about it globally, a big percentage of the world’s poor are farmers. So, it not only addressed good security but it really helps address poverty if a farmer can get higher yields or more production.”

Fraley believes the environmental side of biotechnology is as important as the production side.

“Those have really helped farmers increase their productivity and, at the same time, reduced some of the chemical inputs or

provide for better solutions. The technologies have a strong impact not only on increasing food production and food security, but I think helping to enhance the environment and give farmers more sustainable solutions,” he added.

“The other piece that ties into it is these advanced biotechnology tools for sequencing genes and mapping genomes have basically during this time frame revolutionized plant breeding.

“Early on we recognized that these mapping tools would dramatically help corn and soybean breeders produce better varieties and better hybrids. That led us down the path of acquiring some of the seed companies like DeKalb, Holden and Asgrow, and using these tools to greatly accelerate the rate of gain.

“It’s been remarkable for me to step back and see how important these tools have been.”

“As we look to the future, the breeding tools are getting better and more sophisticated. A whole new class of biotechnology tools based on the gene editing and

the mRNA technology that’s been used to produce some of the COVID vaccines, all create incredible opportunity for the future.”

Going up on the family farm, Fraley noted what he learned.

“Farming is a really challenging and risky business, and farmers are really smart business folks who understand and are always looking to adopt new technology So, in many ways the success of the science has been really based on farming and farmer interest in adopting these new tools,” he said.

“Everywhere where we’ve seen the technology have a big impact has been a place where farmers really understood and supported the technology, and in many ways that has enabled the rapid adoptions.”

Tom C. Doran can be reached at 815-410-2256 or tdoran@shawmedia.com. Follow him on Twitter at: @AgNews_Doran

ELLISVILLE, Mo. Ethanol has been used as an energy source for nearly 200 years, but when the oil crisis hit in the 1970s it took interest in the corn-based product to the next level

The concentration of oil power in the 1970s shifted from the U.S. and its close allies to the Middle East.

In October 1973, members of the Organization of Arab Petroleum Exporting Countries proclaimed an oil embargo “in response to the U.S. decision to re-supply the Israeli military” during the Yom Kippur War. OAPEC declared it would limit or stop oil shipments to the U.S. and other countries if they supported Israel in the conflict.

The embargo was lifted in March 1974, but it immediately sparked the notion of blending ethanol with gasoline.

The embargoes and ongoing uncertainties in the global oil

market led to pressure on the U.S. Environmental Protection Agency to address energy security The agency agreed to allow a 10% ethanol blend in gasoline in 1978 That same year, the Energy Tax Act was passed, providing a partial exemption for ethanol from federal motor fuel taxes.

One may say ethanol went mainstream when television viewers saw Bob Hope’s 1979 commercial promoting Texaco’s gasohol, a mixture of 90% unleaded gasoline and 10% ethanol “made from renewable crops like corn Gasohol can’t replace our gasoline, but it can help stretch our available supply.”

The ethanol industry produced 500 million to 700 million gallons per year in the 1980s and expanded to 2 billion to 3 billion in the 1990s. With a boost from state and federal policies, the 21st century saw production rise even more dramatically, reaching 15.02 billion gallons last year.

Here are among other import-

ant developments in the ethanol industry the past four-plus decades:

• 1984 — Congress includes a 6-cent per gallon federal tax exemption for ethanol fuels.

• 1990 — Clean Air Act Amendments establish reformulated and oxygenate gasoline programs for metro areas with air-quality issues.

• 1993 Annual ethanol production surpasses 1 billion gallons, and the average ethanol blend tops 1% for the first time

• 1995 — National reformulated gasoline program begins in onethird of the U.S. fuel market, opening new markets for ethanol as an additive to help clean the air

• 1996 U.S. automakers begin mass production of flex-fuel vehicles capable of running on up to 85% ethanol.

• 1998 — States begin banning the use of MTBE, which was found to be contaminating groundwater.

• 2005 — President George W.

Bush signs the Energy Policy Act into law, creating the first-ever Renewable Fuel Standard. The RFS required increasing the amounts of biofuel to be blended into the fuel supply up to 7.5 billion gallons in 2012. The ethanol tax exemption transformed into the Volumetric Ethanol Excise Tax Credit

• 2007 RFS is expanded with the signing of the Energy Independence and Security Act. With the addition of the advanced and cellulosic biofuels, the RFS was raised to 36 billion gallons of renewable fuel by 2022, including 15 billion gallons of corn-based ethanol production The average ethanol blend rate hits 5%.

• 2011 EPA approves blends of 15% ethanol in gasoline for use in model year 2001 and new passenger cars and light trucks The U.S. ethanol industry becomes a net exporter as exports top 1 billion gallons for the first time

• 2016 — Ethanol consumption breaks the “blend wall,” com-

prising of more than 10% of the nation’s gasoline

• 2018 — U.S. ethanol production reaches 16.1 billion gallons.

• 2020 — At the peak of the global COVID-19 pandemic lockdowns, over half of the ethanol industry’s capacity was shuttered and roughly three-fourths of ethanol plans were offline or generating at reduced capacities

• 2021 — U.S. Energy Information Administration data found that ethanol comprised a record share of America’s gasoline in 2021, averaging 10.34% of every gallon sold. The U.S. ethanol industry produced 15.02 billion gallons in 2021, an 8% increase over 2020 and the largest annual volume growth since 2010. Domestic ethanol consumption grew even faster, jumping 1.26 billion gallons over 2020 levels a 10% increase. Meanwhile, U.S. ethanol exports dipped slightly from 2020 levels, but still registered as the fifth highest on record.

aring stays tight double-roller bearing and withstands the abuse, unlike the OEM threaded bushings.