OTTO

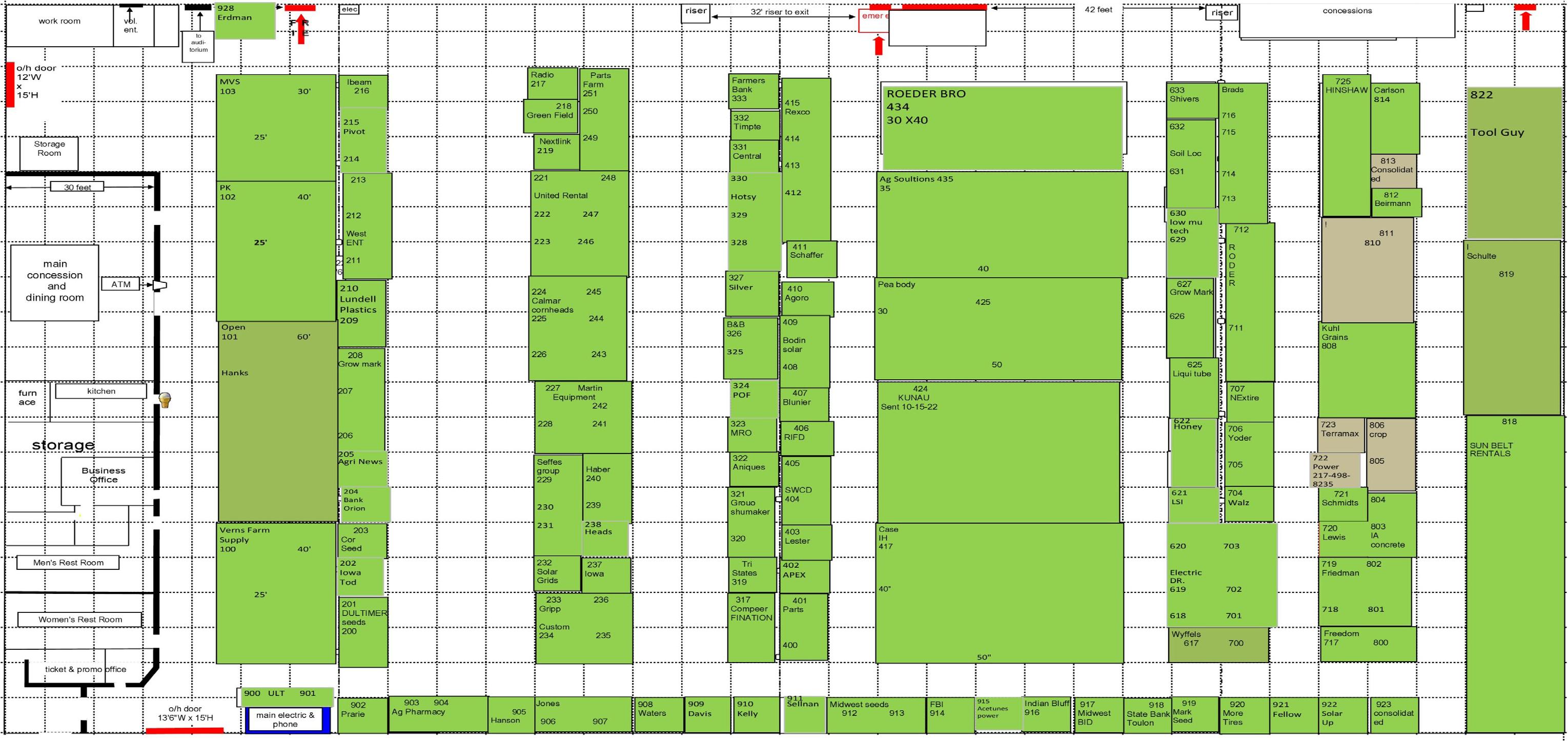

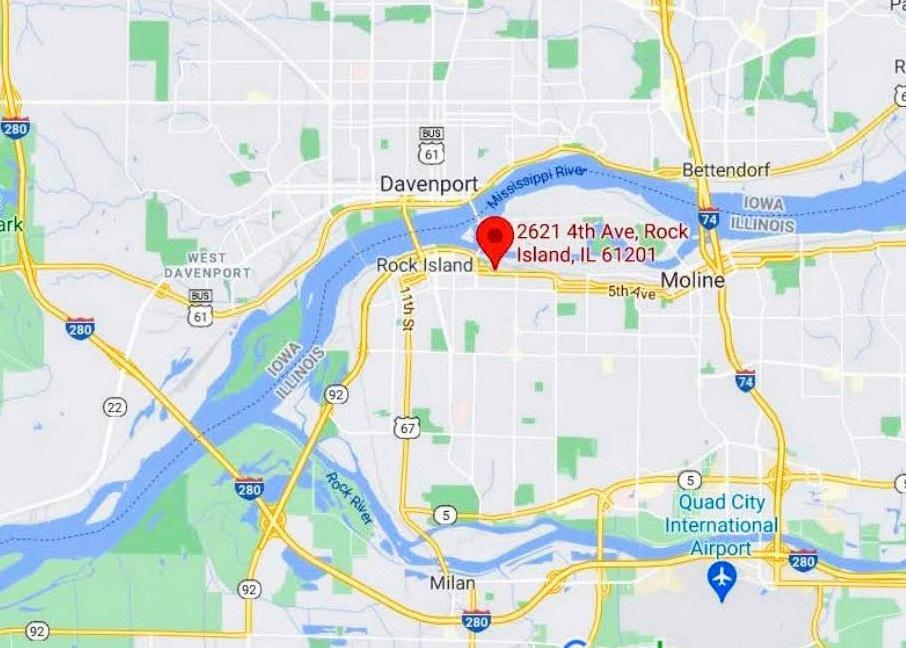

The 32nd annual Quad Cities Farm Equipment Show is scheduled Jan. 15-17 at the QCCA Expo Center in Rock Island, Illinois.

The 32nd annual Quad Cities Farm Equipment Show is scheduled Jan. 15-17 at the QCCA Expo Center in Rock Island, Illinois.

The QCCA Expo Center in Rock Island is extremely pleased to once again host the Quad Cities Farm Equipment Show.

Hours for the show Jan. 15-17 are 10 a.m. to 5 p.m. Sunday, 9 a.m. to 5 p.m. Monday, and 9 a.m. to 3 p.m.

Tuesday. See 60,000 square feet of new equipment, products and services designed for today’s farmer and farming operations plus the latest in supply and livestock equipment. Discover new technologies

that are so vital to profit for full- and part-time farmers. Free admission and free parking. For more information, go to qccaexpocenter.com/ farmshow.

Rob Junker, farm show director QCCA EXPO CENTER

SHEFFIELD, Ill. — Gripp Custom Farming has full ag retail locations in Sheffield and Wyanet.

“We do fertilizer, chemical, full service, wholesale and our big thing is drone applications. We do drone applications for fungicide and some herbicide applications, as well,” said Bill Winter, sales representative.

“Last year we did 30,000 acres of fungicide applications with drones. This year we’re going to have 12 drones available for in-season fungicide applications.”

Winter: It’s all coming down to precision agriculture. We have precision ag at the planter. We have precision ag and sustainable agriculture. So, we want to be more precise with our applications per acre.

With the drone, especially with

obstructions like windmills, power lines, tree lines, creeks, everything involved, we can get more precise with a drone instead of an airplane or helicopter flying 50 feet in the air.

We can be 12 feet in the air going about 20 miles per hour across the field, which makes a more precise application for fungicide.

You don’t lose chemical moving away, and you don’t have a big scary plane out there making neighbors nervous, people in town nervous with planes or helicopters buzzing their house and getting an off-target application of product.

How many acres per load can be covered with a drone?

Winter: We ran four smaller T30 drones last year. They have about an 8-gallon tank. This year we have upgraded to the T40 with a 10.5-gallon tank. So, we’re going to get anywhere from 8 to 10 acres per load. It takes about 10

minutes to runoff a load.

The drone comes back, lands, it’s filled and a new battery put in and it’s off in one minute and back out spraying. We have to keep four batteries per drone in a constant rotation, making sure we are charging them every 8 to 10 minutes.

So, it is four people to a trailer. Each of our trailers has two drones and we have four people manning those two drones at all times.

What are some of Gripp’s new offerings?

Winter: One of our new products is Full Feed that we get from Meristem Crop Performance. That is a stalk digester with the same biologicals that are used in oil spills that eat carbon.

We spray that in the fall and the spring, and it eats the carbon off your stalks and releases it back into the soil for more NPK, more carbon in the soil.

There are other products out there that require UAN or ATS to activate the breakdown of stalks, but then you have what’s called a gassing off effect where the nutrients and the carbon go into the atmosphere. Full Feed has the biologicals excreted back down into the soil.

Another product we’re really excited about that’s new this year is Revline Hopper Throttle. It is a starter in a bottle.

So, it is a full starter in a talc-graphite formulation as your lubricant with the equivalent of one quart per acre of zinc, a plant growth regulator, iron and manganese, nitrogen-fixing bacteria, and bacteria that help release potash and phosphorous, as well.

Winter: Chad Gripp started

Gripp Custom Farming in Sheffield about 20 years ago. Chad is a sixth-generation farmer. He just wanted to expand the business and do more to help his neighbors and offer another option for chemical and fertilizer applications. He bought a sprayer and did some spraying for local co-ops.

He decided to go out on his own and run his own custom business. So, he and his wife started out small, spraying a few acres for neighbors. Over the last five years we’ve grown into a full fertilizer and chemical operation.

We recently purchased Morton Fertilizer Service facility in Wyanet. We also bought another location just outside of Wyanet, the Rediger Auction facility, that we will be expanding to in December. So, we are growing and we offer the full line of retail offers.

Tom C. Doran can be reached at tdoran@shawmedia.com.

GENESEO, Ill. — The first confirmations of tar spot in the United States were in Illinois and Indiana in 2015 and the corn disease has since spread across the Corn Belt.

“It’s here and we’re going to have to learn how to deal with it,” said Ryan Gentle, Wyffels Hybrids agronomy manager, in a webinar.

The severity of yield reduction will depend on the timing of the infection, weather favoring the spread after the infection, and management practices such as fungicide.

“The earlier it infects the corn plant, the more yield it can take out. If it’s infected in the dough or dent stage, yield loss is 40% to 50%. It would lose 12% yield if infected at half milk line,” Gentle noted.

“We want to keep it as healthy

and happy to black layer as we can. It can be controlled if we get the application timing right and use the right fungicide to protect yield.”

Here are Gentle’s tar spot observations and recommendations:

Tar spot appears as black raised bumps resembling tar or black paint and can be present on both sides of leaves, as well as on husk and tassel tissues in severe cases, and cannot easily be scraped off of leaf surfaces using your finger or fingernail.

Spots can appear as a raised black bump on otherwise green healthy plant tissue, or it can be surrounded by a brown to tan halo lesion resulting in a “fisheye” appearance. Lesions can coalesce during later development and areas between spots will show a water-soaked appearance and subsequently dry out.

Spores can come from residue or be windblown. There’s the notion that rotating to soybeans or doing tillage will eliminate tar spot. However, that’s not the case as wind-borne spores can travel from a field miles away. Rotating to soybeans or tillage might help a little, but it’s not going to be a key management factor.

The pathogen completes its lifecycle in 14 days. Once it gets started, it can literally overwhelm a plant in 10 days to two weeks. That’s why we’ve got to be proactive scouting and spraying.

The environment is probably the wildcard every year. It’s going to be up to the environment if tar spot is going to be a problem for us or not every year.

Tar spot loves cool, prolonged periods of leaf wetness over seven hours a day. It likes 60 to 70 degrees. We have that a lot of nights, at least in central Illinois in July and August. It loves relative humidity of 75% or greater.

I’ve also read one of keys is 10 to 20 foggy days per month in the summer. If you think back, at least in Illinois, we had the smoke from wildfires out west last summer and had a lot of foggy days where it didn’t dry out until after noon or 1 p.m. The canopy stayed soaked.

I’ve also read that about 6 inches of rain per month is kind of the magic number to watch for. Irrigation is highly susceptible. I saw several fields last year where the dry corners out-yielded the irrigated part of the field and the irrigated part was even sprayed, but it had the leaf wetness and probably higher humidity out there.

Another factor why it was so bad in 2021 was there was tar spot

plus other diseases. It puts more stress on the plant and it’s just going to take the plant out sooner in the fall.

We had a lot of crown rot in central and southern Illinois last year; you throw the tar spot on and we had early death in a lot of plants, and affected yield and test weight.

Wyffels will not have hybrid ratings for tar spot in 2022. You cannot inoculate tar spot in a field like you can with several other diseases to get a consistent rating environment.

For example, we can set up replicated plots for gray leaf spot, we can inoculate all of the plants with GLS, we can get a uniform look at different hybrids and how resistant they are to that disease.

For tar spot, no one has been able to figure out how to inoculate.

University of Illinois and several other universities are looking at it and trying to figure that out, but right now it’s not possible.

We don’t want to give a false sense of security, either. There’s absolutely no inbred or hybrid out there right now that is 100% resistant to tar spot. Companies are now saying they’re either susceptible or very susceptible.

We’re going to need to use fungicide as our tool for a while until we get farther down the road with plant breeding.

Tar spot susceptibility shouldn’t dictate hybrid selection, and tar spot tolerance levels should not influence management tar spot decisions.

Start scouting for tar spot lesions at V8 to V10. If you find lesions, apply a fungicide as soon as possible.

At minimum, we recommend a VT-R2 fungicide application re -

gardless of lesion presence. Due to the speed of development and risk of significant yield loss, a fungicide application is worth the investment.

If you have tar spot at VT, I would pull the trigger at VT. If your leaves are clean, you’re not seeing a lot of tar spot, I think waiting until R2 or R3 is OK, probably late R2 timeframe.

After the VT-R2 application, continue to scout. A second application may be necessary up to dent stage, R-5, if disease continues to progress.

The University of Wisconsin has done extensive research on different fungicides and application timings, and researchers at Purdue, Michigan State, Illinois and Iowa State are pretty much in agreement. The double and

triple modes of action fungicides consistently perform the best. Wisconsin also did field research on application timing and found VT-R1 application consistently turned out to be the best combined with using a double or triple mode of action fungicide.

Multiple universities in the Midwest participate in the Crop Protection Network which publishes ratings for tar spot efficacy based on field trials on many common fungicides.

The University of Wisconsin has developed a free app to help predict the upcoming risk of tar spot based on local information inputted by the user.

The “Tarspotter” app along with scouting has shown to help make timely decisions on fungicide applications the last two growing seasons. Tarspotter uses GPS coordinates to determine if weather has been favorable for the development of tar spot in a specific field.

Tom C. Doran can be reached at tdoran@shawmedia.com.