Chairman

CEO

Welcome to the August issue of LA , and I hope it finds you well and happy.

Life in the aviation world is starting to take on a more ‘normal’ hue, we have even seen a few relatively low key fly-ins taking place and, by the time you read this, the Shuttleworth Collection should have run what I hope will have been a successful ‘Drive-in’ style airshow at Old Warden.

Visitors will have remained socially distanced by watching the show from their allotted parking area, I hope the musical backdrop included the Ronettes belting out Be my Baby and commentator Steve Slater wore his clip-on DA.

I know many of us are still very reticent about moving too quickly towards what now passes for the currently proposed ‘normal’, and with the latest membership survey (P18) reporting that the average age of respondents was 64.1 years, that’s perfectly understandable. It is important though that we do make a positive effort to support our industry if at all possible.

Airfields and equipment suppliers need all the help they can get, so if you can, don’t put off buying those parts for that project or upgrade, and if you fly, really make up for lost time and get out and about, visiting airfields, buying fuel and food and therefore helping the guys who provide the services we depend on retain their loyal staff so they are still available when a much more normal ‘normal’ finally arrives. We only succeed when we pull together.

Pulling together is something we can be proud of in the LAA, we have a deserved

reputation for helping each other with information and practical assistance. As editor I witness this every day, indeed I benefit from it because I have seen a positive effort by so many people to ensure that I have a regular flow of material for a packed issue every month. LA received a vote of confidence from the survey, which I hope the many people who contribute to it and help put it together every month will take justified pride in. Thank you one and all, for both supporting the magazine and for taking the time to comment on it. As ever we will endeavour to improve on its shortcomings.

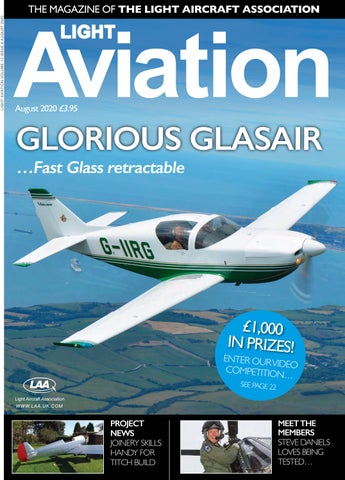

Cover story this month is the Glasair G-IIRG, based at Yeovilton and owned by a group of highly capable pilots. Popular in the early days of the kit revolution from the 1980s on, this was, and still is, a mightly impressive aircraft. Read Clive Davidson’s report on P40.

Enjoy the magazine, take pride in this wonderful pastime of recreational aviation, but above all be happy, be safe and try to make a stranger smile every day. And no, I’m not wearing hippie pink flares and a flower shirt – the trousers are pale blue and the shirt has butterflies on it.

Take care. Brian.

By Brian Hope

A potential new DIY aircraft security device is in the proof of concept stage. See P16.

By Brian Hope

A potential new DIY aircraft security device is in the proof of concept stage. See P16.

Well, clearly not, but I was wondering what the resumption back to what passes for normality might mean for our community.

Over the past few months, a lot of us have now experienced the ‘working from home’ situation. Once only the preserve of technologically enabled staff, anyone with a modest laptop, broadband subscription and Zoom can now be based at home and work effectively. In many cases this practice is set to continue for the foreseeable future for those who were previously office based, although it’s clearly not practical where your presence is needed.

Naturally the LAA has not been immune to the requirement to change the manner in which it operates in order to adapt to this new normal and, although there is a drift back into office life, none of us can expect things just to go back to where they were for some time to come – if at all in some instances. For example, the LAA Board has been meeting remotely since lockdown and, in all probability, Board members are likely to continue to want that facility, especially when weather makes flying into Turweston difficult. This is bound to hold true for a number of other gatherings. It has to be said that it works effectively and also saves costs.

But what might this remote and flexible working arrangement mean for LAA members? In my experience, committing to a working from home life needs discipline. However, with that discipline comes opportunity. Discipline is obviously required when it comes to getting the work done but flexibility in the exact shape and of the working day is also needed, as the normal working day tends to fray around the edges, allowing some scope into how you spend your time.

Need that crucial part, what about the insurance quote you’ve been after, need to research the latest avionics gizmos –

no problem! Even dare I say it, some mid-week flying, fettling or building; all now becomes possible because working from home has to be a quid pro quo, and to make it work you are now in charge of the office, the politics and chatting around the water cooler. Coupled with your reduced travelling to work they go a long way into making you more productive with your time. Suddenly, the new normal becomes a bit more appealing, doesn’t it?

I did read recently that an IT company has developed software that monitors the activity of a computer by remotely using the camera function, checking the time a user is present at the keyboard – no doubt LAA’ers will find a way around that!

You may recall that last month I raised the subject of airspace infringements after the lockdown. I was after a breakdown of the recorded infringements by aircraft type so that I could make the information more relevant to members, and I’m pleased to say that the CAA has responded to my enquiry. From mid-May, when solo flight was approved, until the end of June there were 107 airspace infringements nationally, although I think that means mainly England as the devolved administrations chose not to allow private flying.

Of these, the majority were certificated aircraft with a handful of LAA types. A pot of 39 miscellaneous GA aircraft needs further investigation however. The CAA cited these examples of reasons for the infringements 1) Skill fade 2) Pilot overload 3) Complacency including lack of planning 4) Over confidence. More details to follow…

In the meantime, I hope you and yours are safe and well, I’m sorry we won’t see you on what would have been the LAA Rally weekend but look forward to next year’s extra special 75th Anniversary celebrations.

06 NEWS

LAA art awards, Parts for Aircraft discounts, ADS-B Out systems

08 SUPERMARINE S.5

Project to build a full-scale replica of the Supermarine S.5 racer…

10 PROJECT NEWS

Taylor Titch, Pietenpol Air Camper, Just Superstol, Cleared to Fly and New Projects

16 GET ALARMED

LAA member Clifford Agius outlines the idea behind a new aircraft security system

18 MEMBER SURVEY

Steve Slater reports on a positive result, but services will continue to improve

22 VIDEO COMPETITION

LAA and Pooleys Flight Equipment launch video competition, with £1,000 in PRIZES!

24 SLING AFRICA: PART 2

Rod Wheeler and his fellow Sling aviators complete their African adventures

30 SPIRIT OF AYRE

Squadron Leader Chris Hives tells the moving, yet uplifting, story of Sgt Anthony Ayre’s Pitts S2A-E…

34 GIPSY LOM REPLACEMENT

Looking for a solution to the growing scarcity and cost of Gipsy Major spares…

38 GLASAIR IIS RG

Clive Davidson flies fast glass, which burst onto the kit building scene in 1980…

46 COACHING CORNER

Advice on flying with a Coach in these COVID-19 times

50 SAFETY SPOT

Malcolm looks at how to deal with an emergency ‘shortly after take-off’…

56 STRUTS4U

Anne Hughes profiles the activities of the Struts, making good use of social media

58 MEET THE MEMBERS

Meet Steve Daniels, ETPS helicopter test pilot instructor and VP-1 and Jodel owner

62 CEO THOUGHTS

‘Flying lightly’ and membership diversity

63 LANDING VOUCHERS

Your free landings, discounts and offers for September 2020

A spectacular painting entitled Griffin Ornithopter was the stand-out winner of the LAA’s ‘Kids at Home’ aviation art competition, organised for five to 15-year-olds in conjunction with the Shuttleworth Collection and the Guild of Aviation Artists. Produced by 15-year-old Nick Harder, the Griffin would be lifted to altitude by a helium balloon, with solar-rechargeable electric power providing lift and thrust via the flapping wings.

“The picture’s presentation and creativity made it stand apart,” said LAA CEO Steve Slater. “We were so impressed that in addition to the main prize of a family ticket for an Old Warden Air Show in 2021, we’ve made him an LAA member and invited him to join us for a day at LAA HQ, too. He’s got just the sort of inspiration we need for the future!”

First prize in the 5-8 aged category went to Bessie Revell, and first prize in the 9-12 age group went to Sebastian Wright. All showed real talent and imagination in their designs, as did many of the runners up.

Congratulations to all who entered and the LAA hopes that the diversion of an art competition during lockdown has helped to give some added interest to long days at home.

FAI Art – International Friendship: The Association also continues to work with the Royal Aero Club to facilitate UK entries for the FAI International Aviation Art Contest, with the 2021 theme recently being announced as A Friendlier World with Air

Due to the impact of COVID-19, the operating hours of the Solent CTA (Control Areas) and Southampton CTR (Control Zone) have varied considerably from published information, which has caused some confusion among General Aviation pilots using aerodromes in the vicinity, such as Lee-on-Solent, Popham, Blackbushe, Goodwood, Shoreham, Bembridge, Sandown, Old Sarum, Compton Abbas, White Waltham and Fairoaks.

However, until at least 30 August, a more consistent programme is planned with the

controlled airspace around Southampton Airport active from (local) 0700-1900 daily (except Saturday 0700-1500). Any change to these times will be subject to Notam as per normal procedure so pilots should always check and also maintain a listening watch on 120.230 MHz when flying in the vicinity.

This is a timely reminder that other airfields are similarly amending their operating hours in line with different demand profiles, so if your flight takes you through airspace that would normally be closed, do not assume it will be – check Notams.

Sports to encourage participants to create a picture to illustrate how friendships are made via aviation across the world. The UK competition will close on 31 January 2021. For details, please contact: office@laa.uk.com

The latest infringement update from Southend Airport Air Traffic Control sets out tips for avoiding infringements of their Controlled Airspace. In 2019 there were 33 reported infringements into the Southend CTR/CTA, and it has been identified that a large percentage of these occurred because pilots made a late request for a transit while close to, or already having crossed, the CAS boundary. Read the advice available in https://airspacesafety.com/updates and avoid becoming an infringement statistic.

MGL Avionics’ UK dealer, Parts For Aircraft Ltd., has been busy during lockdown producing a new website for its customers. Owner Paul Sistern said, “We needed a fresh look, one that better reflects the product range and is easy for our customers to

Although the UK’s Financial Conduct Authority has postponed the enforcement of PSD2, which requires online merchants to comply with new SCA (Strong Customer Authentication) requirements, the LAA will be compliant from August.

We are changing our provider to PayPal, but the only change you will see is that when making online payments via the Shop or Members Area the new merchant will be PayPal, and you will be redirected to the PayPal site when confirming payment. Please note you DO NOT have to create a PayPal account. You will also still have the option of paying by Credit/Debit card.

Direct Debit changes: The LAA is also moving its direct debit transactions to a third party, GoCardless, which is a BACS approved bureau. This ensures the LAA continues to be GDPR compliant and also means our members, current and new, can set up their own direct debit, thus removing the need for paper mandates. We will be writing to all our members currently on a direct debit with more information, but you will not need to take any action.

The CAA has launched a six month Stay in Control safety campaign designed to combat the significant impact that Loss of Control accidents have on GA – in the last five years, 20% of accidents, 44% of fatalities and 55% of all serious injuries have been because of LoC incidents.

Specific aspects of loss of control will be explored over the coming months and material will be posted on the dedicated Stay in Control website: www.caa.co.uk/ stay-in-control

The first advice on ‘Loss of Control in the Circuit’ is available now and other topics due to be covered include angle of attack and weight and balance.

navigate. We’re MGL’s largest dealer in Europe and I’m keen to hold onto that position as we exit the EU. Making the buying process as easy as possible should help us achieve that goal.”

To celebrate the new website, Parts For

LAA Engineering has updated TL 3.03 to introduce an approval path for higher performance ADS-B Out systems, so that owners of LAA aircraft can benefit from this more sophisticated equipment and the improved conspicuity that it allows, knowing that their flight data isn’t going to be summarily filtered out by other airspace users as ‘uncertified’ or ‘unreliable’.

Aircraft Ltd. is offering LAA members a 10% discount until the end of September. Visit www.parts4aircraft.com and use code laa10 at the checkout. The discount is available across the product range and can be used in combination with other online special offers.

Since these systems use the transponder frequency which is used by air traffic control, commercial air transport and military identification systems, and are claiming a high degree of accuracy/integrity, it’s important that they are installed and operated against appropriate requirements.

Following successful trials coordinated by NATS back in 2015 and supported by LAA, we’ve been able to approve installations of uncertified GPS units with certified transponders to provide ADS-B Out transmissions for a number of years.

In these installations, the ‘SIL’ (Source Integrity Level) and ‘SDA’ (System Design Assurance level) settings in the transponder have had to be set to ‘zero’. This transmits to other airspace users the fact that the system claims no certificated level of accuracy and some receivers automatically discount these transmissions.

Certified ADS-B Out systems transmit higher SIL and SDA values, which correspond with specific probabilities that the data being transmitted is accurate. It’s worth noting that these values aren’t associated with the transponder alone – the SIL value is related to the performance of the GPS source and the SDA value is related to the performance of the system as a whole, including antenna performance.

The updated LAA Technical Leaflet includes a table of acceptable combinations of equipment, and in order to get an installation approved, the system must be one of the listed configurations.

As with regular avionics fit, applying for

approval is done using a special LAA form, in this case LAA/MOD 17, which can be downloaded from the website. The installation must then be checked by an LAA Inspector to ensure that the equipment configuration is one of those listed in the table in the Technical Leaflet and that the physical installation is satisfactory.

Once signed off on the form by the LAA inspector, the aircraft may be flown to a licensed avionics engineer with the appropriate ground test equipment to check that the system is correctly configured and transmitting the right information.

The application form is then sent to LAA Engineering for review and approval – thanks to the guidance provided on the form, the degree of technical appraisal is minimised and this has allowed us to keep the cost of the approval process down so that the charge made by LAA has been able to be kept to just £30.

One question that has been asked is, “Why can’t an LAA Inspector sign off this installation as with a transponder fit?”

With SIL/SDA>1 you’re transmitting the fact that the installation is operating to fully certified levels – not just that the boxes are appropriately installed, but the installation is meeting the stated performance, information transmission and power requirements. We therefore have to demonstrate a comparable level of oversight to the certificated world. At this stage the most logical route is to require that they are signed off by appropriate avionics facilities who have the specialist equipment and knowledge.

The British nation owes a great deal to the dedication, aeronautical skill and foresight of R J Mitchell CBE, for his masterpiece fighter, the Spitfire. He worked as a designer at Supermarine Aviation, becoming Chief Designer at the age of 25, and Technical Director aged 32. However, many people do not realise that during his short career he designed 24 aircraft, including the Supermarine S.4, S.5 and S.6 racing seaplanes. His life was tragically cut short when he succumbed to cancer in June 1937, aged only 42.

The S.5 was designed as a ‘nocompromises racer’ specifically to win the 1927 Schneider Trophy, which was to be held in Venice. It evolved from the earlier S.4, itself a world air speed record breaker, retaining the wooden wings and empennage of the earlier aircraft, but adopting duralumin monocoque fuselage and floats. Powered by the Napier Lion engine of 875-900hp, of the

Above R J Mitchell, centre in light trousers, Supermarine S.5 N219, and the victorious team at Venice in 1927.

Photovia

John WightonBelow S.5 CAD model development based on the original three-view and detail drawings. Credit: John Wighton

three aircraft that were built, two reigned supreme in Venice, gaining first and second places, with Flight Lieutenant S N Webster winning at an average speed of 281.66mph (453.28km/h). The third aircraft was unfortunately lost while attempting a new air speed record in 1928.

The passion for the S.5 was rekindled in the 1970s when Ray Hilborne was commissioned to design and oversee the construction of a replica S.5, based on serial No N220, the

winning machine in Venice in 1927. His design, drafted between 1973 and 1975, was built with an all-wood primary structure and powered by a 210hp Continental six-cylinder engine. It was registered G-BDFF and was operated by a leisure company at Thorpe Park as a key feature of the Schneider Trophy exhibit. The airworthiness compliance checks were conducted by Eric Smith at the CAA, who’s office issued the Permit to Fly.

The aircraft flew for less than 40 hours before being damaged and rebuilt in the mid1980s. In 1987, while being operated in Cornwall, the rebuilt replica S.5 suffered a total loss and fatality following a flutter-induced structural failure.

Winding the clock forward to today, Capt. William Hosie (the son of the pilot who

perished in the 1987 accident) has launched a project to celebrate the centenary of the S.5 Trophy win. The S.5 build follows closely the design created by Ray Hilborne, albeit with modifications designed to improve safety and to comply with modern design regulations, and with LAA Engineering overseeing the construction.

As Technical Director of the Supermarine S.5 ‘A British Legend Reborn’ project, I am tasked with ensuring that sufficient design data, drawings and technical resources are made available, and ensuring compliance during construction. Fortunately, whether due to extraordinary foresight or just plain luck, many of the Hilborne drawings (designated HD8) have been found and our first task has been to evaluate the many paper copies into a set from which a component based bill-of-materials (BOM) could be derived.

The project is currently only partially funded, hence we are focused on the wings and floats, and Bill Penaluna and Rod Bellamy have agreed to manage the build of these components, their expertise being gained from a vast back-catalogue of projects.

Although steeped in history, and with a largely complete technical library of data, we are utilising modern design methodologies,

Above The S.5 General Arrangement drawings: Plan and side views.

Credit: John Wighton

and some sympathetic modifications, to minimise weight. Clearly there is a need to mitigate any risk of flutter, although there is increasing evidence that the empennage and/or aft fuselage structure (post-1980 rebuild) was compromised. We have created an external CAD model and will utilise finite element methods (FEM) where appropriate to incorporate any modifications that are deemed necessary.

We have received tremendous interest in the project so far, and with the LAA membership encompassing such a wide range of skills, commercial as well as technical, we are hopeful we will receive additional support in the form of time, materials and funding.

We hope to be able to provide periodic build reports, perhaps via the Project News pages of this magazine, or more in-depth articles (warts and all), showing progress as we approach the completion of the project, which is scheduled for 2023.

For more details of the project go to www. supermarineseaplane.co.uk, where branded items can be purchased and the current funding status can be viewed. All contributions will be gratefully received! ■

It cannot be denied that the Van’s aircraft are popular with LAA members, and by way of confirmation, four of the five designs on the New Projects list are from Van’s. By contrast, the Cleared to Fly list is very varied with half-a-dozen different types reaching that major milestone and being granted their test Permit.

An approved type for only a couple of years and with just five on the register, there were two of the unusual Just Superstol aircraft in the Cleared to Fly listing last month. Eric Marsh’s G-CLDI was one of them and the first customer-built example that we’ve seen here in Project News

There was a very comprehensive article on the type in the January 2018 edition of Light Aviation – it is definitely worth excavating your pile of back issues to have a read again. Eric is a compulsive builder, with several Van’s passing through his workshop, so the tube and fabric approach of the Superstol was a

new constructional method to him. Clearly not daunted by the change in building technique, he has produced a very exciting looking aircraft.

I’m always a sucker for an Air Camper, and John Comfort’s is a lovely example with some real insights into the ingenuity neede d to scratch build any type. As with many such projects, the member completing it was not the one who started it, and I understand from Pietenpol builder Mark Bowler, that there is believed to b e a sizable number of Camper projects ‘sleeping’ out there. If you are aware of an inactive Air Camper, then Mark would be interested in hearing from you, in an effort to unite it with eager active bu ilders.

You can make contact via braywood@hotmail.co.uk or through Project News

To get in touch with Project News , and tell your story, report a milestone or just to send a picture, email: projectnews@laaarchive.org.uk . Please share your story!

Interested in aircraft for most of his life, Tony Wyatt was keen to build his own aeroplane. As a retired joiner and cabinet maker used to working from drawings, a plans-built wooden aircraft seemed the perfect choice, but which one?

The Corby Starlet and Colibri MB-2 were contenders, but it was another 1960s low-wing single seater, the Taylor J.T.2 Titch, that Tony decided to build – not least because he has a friend who has built one, so first-hand advice and guidance would be on hand.

Below Tony’s cabinet making skills are clearly evident in the beautifully made wings. Photo: Tony Wyatt

Further, and much-valued support, has come from his Inspector, Duncan McFadyen, who has always brought clarity and simplicity to what was confusing and intimidating.

Started in July 2014, Tony has now largely completed the woodwork, and comments that with his 71st birthday imminent, the project keeps him busy and active.

The Titch is an interesting type and there is a lovely Pathé-style video of the prototype’s birth here: http:// tinyurl.com/taylortitch

Iacquired the project in 2012 when I was working at Classic Flight in Coventry. After reading an article about an Air Camper in LA magazine I decided ‘I want one of those!’ – but thought it best to acquire a part-built one.

I asked my Inspector, Steve Evans, to look the project over before buying it as it had been stored for a while, although hadn’t quite reached the stage where ivy was growing all over it.

The owner had sold the engine and it had been robbed of its lift struts, however, it had its LAA blue build record book which was signed off up-to-date and most of the remainder was there, including a beautiful mahogany prop made by Alan James.

David Slaughter, who started the project back in the 1990s, had covered the wings and tail but the fuselage

was still varnished wood – and on examination it was clear that David’s woodwork was top class. The project was shipped back to mine and my neighbour’s garages in order that work could carry on on the fuselage.

At about this time Classic Flight morphed into Heritage Air Services and they invited me to bring the project to Coventry, where they encouraged me to get on with it, which was an offer I could not refuse. At this time Martin Slater carried on with the inspecting. In the meantime, they also found me some quite interesting jobs to do as well, one of note was to help replace the lower main spar fittings on a DH Dove. A less involved job was to re-fabric its rudder.

Initially I thought about obtaining a Rotax engine, but I ultimately decided it was rather out of character and subsequently a C-90 was recovered from a damaged aircraft and put to one side. In the interim, I had become a member of the Pietenpol Club and joined its lift strut scheme, so this accounted for most of the important bits that were missing.

The project’s time in storage had not been kind to the fuselage metalwork, so everything had to be cleaned and repainted. I had help painting the wings but covered and painted the fuselage myself. The engine frame turned out to be hopeless so I made a jig, prepared the metalwork, and had Tim Mashford weld it together for me. The result fitted the jig and the fuselage perfectly.

The next job was to put enough of the aircraft together so as to assess the weight and balance.

One aspect of an Air Camper that can spoil the appearance is the cowl, so I was very fortunate to be introduced to Owen Watts, who made the cowl for me. I had already been warned that if I fitted the project with a ‘tombstone front’ the aircraft would be kicked out of the hangar. With the help of David Phillips, cardboard mock-ups were made to assess the profile and the end result is very pleasing.

During 2019, I carried on with the almost endless ‘finishing off’ jobs under the watchful eyes of Martin Slater

and Ben Cox. The prospect of a finished project encouraged me to put in more effort, but even so, things seemed to take forever… Magnetos were overhauled and timed, cylinder bores were examined, the oil system was primed, and the engine started second blade after a long period of inactivity. Compressions were checked and found to be good. It had a brief taxi run before the winter and was put back in the hangar to continue finishing off.

Typical of the snags that you find at this stage was a small amount of lost motion between the control columns and the torque tube, which affected the aileron control. So, the columns and torque tube were taken out, bushes reamed, new spindles made and the whole lot put back together.

Plans for the Pietenpol leave something to be desired in many areas, requiring builders to come up with numerous modifications. This makes the LAA’s job more difficult and resulted in a visit from them to see how we had dealt with the elevator control. We bribed them with chocolate biscuits and a CAD drawing of what we had done, and they seemed to go away happy.

Considerable thanks are due to Martin Slater and Ben Cox at Heritage Air Services and to the many other people who have helped.

Above Only minor touches left, but what a cracker – ’FS shares some esteemed company in Heritage Air Services’ hangar.

Right Plenty of exquisitely detailed touches on John’s superb Air Camper. Photo:

Ileft school in 1960 age 16 wanting to be an engineer like my dad, but was not clever enough. Three O-Levels got me into hospitality and, after a classic hotelier training, I secured the tenancy of The Cavendish Hotel in the Peak District in 1975. By chance, the following year I was given a ride in an aeroplane, and in 1981 I gained my PPL – a SLOW learner!

I was also a very timid pilot, I still am, but to overcome this, my CFI recommended aerobatics, and I would likewise recommend that to any pilot, timid or not – it demonstrates just what an aeroplane can and cannot do in absolute safety.

I was privileged to be introduced to, and then taught by, the renowned Alan Wade (sadly recently deceased) at Netherthorpe.

Initially in the 1980s we shared a Slingsby T67, then I acquired a Steen Skybolt in which I competed in the British Aerobatic Association contests with modest success; no wins, second place was my best result.

Unfortunately, I pranged the Skybolt at a strip en route to a contest, but bought another at Oshkosh later that same year, which I sold a few years later.

On a subsequent trip to Oshkosh I discovered Van’s, and in 1992 I bought an RV-4 kit, which I completed in five years and 5,000 hours. I continued competing in aerobatic competitions with it, and still didn’t win anything! But, that notwithstanding, it was certainly the best aeroplane of the dozen or so I have owned over 40-plus years.

In due course I thought an RV-6 would suit me better, so in 1999 I bought and built one (four years, 3,600 hours), but disliked it, so I sold it and kept the RV-4.

Below

Photo: Eric MarshWhen the RV-8 came out it seemed an obvious successor, so I bought the kit in 2005 (3½ years, 3,300 hours) and in anticipation of flying it sold the RV-4. Of those I have built, I guess the RV-8 was the finest, so much so that I had an immediate offer to sell, so for me it was back to the drawing board. Now without an aircraft, and my son having started his PPL, I bought two of the comparatively inexpensive and easy to build RV-12s, one for an ageing dad and potentially one for a prospective pilot son. Alas, neither worked as such, so it ended our aviation futures for both of us. Again both RV-12s were sold, each having taken about 15 months and 1,300 hours – they were so easy to build as to be marginally boring.

I thought that would be the end of my building days, except I still had a large-ish, well-equipped workshop and the free time which retirement provides, when I heard of the Just Superstol being marketed by my old friend Bob Pooler at Sleap. I was intrigued by the unique STOL performance and had never built a steel-tubeand-fabric aeroplane.

I started the kit in August 2016 and finished it last November after 2,483 hours. I cannot say it was an easy build, for neither the manual nor the drawings are very good, although inevitably I am comparing them with Van’s material, which although now is exemplary was, in the early days, not dissimilar to what Just provides.

Covering was new to me, so I had some assistance there, although it was a lot easier than I had feared. Similarly, rigging control cables instead of tubes was wholly outside my ability, so in the true spirit of LAA support a colleague from Netherthorpe, Richard Eaton,

arrived every Monday evening to help me. He was totally invaluable, and without his generosity I could not have completed the project. Painting (plain white) was comparatively simple, the materials I used not requiring the complex breathing apparatus some materials need.

On completion I was obliged by my landlord to move from my garden shed workshop of 30 years and, wings folded, the Superstol was trucked to its new home of Bradwell, a private strip in the Peak District near Ashbourne. LAA Inspector and engineer Neil France, effectively took over there, with careful checking of everything, including engine runs, instruments and control surfaces etc. Himself a Kitfox owner, he was

approved to test fly by the LAA and had already flown Bob Poolers demonstrator Superstol at Sleap.

After the inevitable delays – instrument supplier problems, bad weather and coronavirus – Neil made the initial test flight on Friday 29 May. The only snag was high oil temperature, attributed to the absence of an adequate vent in the front cowl, which was easily corrected the next day.

At the time of writing Neil is continuing the test flight process with completion expected later in June, upon which he will be in a better position than me to report on the experience. It will then be offered for sale at what will, as usual, be virtually its cost price – my reward is in the fabrication.

If your aircraft has been featured in the New Projects list, please let Project News know of your progress at: projectnews@laa-archive.org.uk

n Van’s RV-8 (LAA 303-15706) 18/6/2020

If your aircraft has featured recently in the magazine and has subsequently completed its maiden flight, Project News would like to hear from you at: projectnews@laa-archive.org.uk

n G-CJNL Replica Jodel DR1050M (LAA 304-15103) 19/6/2020

Mr Michael Dolphin, 311 Harlaxton Road, Grantham, NG31 7JP

n G-CDBC Magnum (s/n 001) 2/6/2020

Name & Address held by LAA Engineering

Mr I S Smith, Old School House, Tattershall, Lincoln, Lincolnshire, LN4 4LR

n Van’s RV-8 (LAA 303-15705) 17/6/2020

Name & Address held by LAA Engineering

n Van’s RV-14 (LAA 393-15704) 11/6/2020

Name & Address held by LAA Engineering

n G-OELZ Wassmer WA52 (s/n 66) 29/6/2020

Name & Address held by LAA Engineering

n G-ORUN Sherwood Scout (LAA 34515129) 23/6/2020

Name & Address held by LAA Engineering

n G-OWGC Slingsby T61F Venture T MK2 (s/n 1875) 4/6/2020

Name & Address held by LAA Engineering

n G-YAKX YAK-52 (s/n 9111307) 15/6/2020

Name & Address held by LAA Engineering

n Van’s RV-8 (LAA 303-15703) 8/6/2020

Name & Address held by LAA Engineering

n Aeroprakt A32 Vixxen (LAA 411-15702) 1/6/2020

Name & Address held by LAA Engineering

Following our response to the recent call in the magazine for security solutions to counter the continuing spate of Rotax engine thefts, we at CA Software have been working on an alarm system that protects the individual aircraft. A prime consideration is that it should be equally effective on an unserviced farm strip, a busy airfield hangar or even when the aircraft is parked outside. It represents the last line of defence after building security devices have been breached.

We work with many clients producing mobile and web application solutions to solve problems such as tracking devices, consequently we have extensive experience in the areas required for this project. We are in the embryonic stage of building a (Rotax-powered) TAF Sling 4TSi, and the issue of security is something that concerns us as well.

We have looked at communication issues as well as those concerning raising the alarm, when it comes to an engine or other equipment being stolen. First we need to detect that someone is tampering with the aircraft. This needs to be achieved in such a way that the unit can be removed before flight, therefore negating the need for engineering approval. We have decided that the best solutions would be those outlined below.

The unit will house a solar/battery panel in the top half, which will attach to the inside of the front windscreen of the aircraft in a way that has yet to be decided – but velcro or clips could work. Alternatively, the unit can use an external power bank, similar to an Anker power brick, or be connected to the aircraft battery as the connection is simply a USB connector.

The solar cell is optional, but even in a hangar it may generate a little power to extend the battery life by a day or two. The sensor box hangs from this mounted solar panel and can pivot so that it points in the correct direction with the front housing the camera, and the back housing a PIR sensor.

The PIR sensors can detect movement and are there to detect if someone tries to break into the aircraft and remove the unit or steal that fancy headset you left behind while you went to get your £200 burger and pay the landing fee…

The camera will take a still image periodically and will detect if an object is seen in this image. We use object

Above The proof of concept main unit, no case, with USB attached power brick.

Right General arrangement of the device installed in the aircraft.

detection, as facial recognition technology can be thwarted with a balaclava, but if it detects an object it will send the images and raise the alarm.

If there is no local Wi-Fi available, in order to raise the alarm the aircraft unit will connect to the cloud via an internal 2G/3G communications module. Once the signal has been sent to the cloud, even if the unit is destroyed, it is already too late – the alarm will have been raised.

To protect against the aircraft unit being damaged or the battery going flat, a heartbeat signal will be sent at a given interval. If this check fails then a signal is also sent to the owners so that they can investigate. Also, ‘battery low’ warnings will be included to indicate when the batteries are running low. The unit’s case will be 3D printed for ease of build and prototyping, so the design can be refined to fit each aircraft required.

For this project we would use Microsoft Azure for the computer, and the Twilio service for SMS/WhatsApp messaging. In the cloud when an alarm is received, it will send either SMS/WhatsApp messages to the preprogrammed numbers of the aircraft owners, or the local farmer/airfield security to raise the alarm. A push notification will also be sent to the mobile application to back up the SMS/WhatsApp, and with this it will also allow the users to view the image/video that was received from the aircraft unit, which means you can decide if it’s a valid alarm (and call the police), or just another owner who forgot to turn off the alarm.

The mobile application will connect to the system with Bluetooth when in range, to check the system is configured correctly, change settings and show a live camera feed so that the owner can adjust where the camera is pointing.

The owner will also use the app to configure the mobile numbers for alarm messages and this list can be as long or short as needed. Owners will be able set up a number in order that the farmer/airfield security gets an alert.

Within the app you will also be able to set ‘quiet times’, which means that if the aircraft is moved during the day to get another aircraft out for instance, you won’t be alerted, and you can also use the app to arm the system when you hop out after landing, therefore protecting that expensive GPS/iPad/headset, etc.

The project will be designed in the open and all the hardware designs and a bill of materials made freely available so that owners can do what LAA owners do best – build their own. 3D printed designs will be included, or they can be ordered from CA Software for a small fee, but all the components are available from UK suppliers HobbyTronics and Amazon. The parts list is currently about £80, plus £10 for a Wi-Fi only solution and approximately £50-£70 extra for the 3G/4G solution.

If the LAA member decides that ‘playing’ with electronics and 3D printer is not for them, we will offer pre-built units for sale. As we are not set up for this and it could take a while to get them built initially.

There will be three parts to this: the aircraft unit, Azure cloud and mobile app. The aircraft unit’s software will be available under licence from us for free.

The mobile app will be made available via the various app stores and will carry a small annual fee to cover the costs of the Azure cloud infrastructure, the app maintenance and app store charges.

The idea of charging a fee for the software is to cover the time and costs of developing the system, yet leaving the LAA member with the ability to build the units themselves, plus edit the designs to fit the needs of the aircraft they are trying to protect. We expect that if this system is proven then it may not just be used by Rotax-engined aircraft but also by others who wish to protect their ‘pride and joy’.

The plans are that this is just to be used as a security system, but as it has a camera mounted and ability to record/store this feed onboard, the unit could be used in a secondary role. If we use the included GPS part of the mobile comms unit and added an IMU (Inertial Measurement Unit) it could measure the aircraft position and its bank/pitch/yaw, as well as speed and altitude along with images/video, and therefore potentially be used as a crude form of a flight data recorder.

The unit could record the data for the past 20 minutes and allow the owner to see what happened during the flight, maybe view the data of a poor landing to see what went wrong and what they could do better next time. In the case of an incident/accident, AAIB investigators could retrieve the data and use it as part of their investigation.

This is currently only an idea, as the tech is already there, but it would need some thought and help from the LAA Engineering team, as the aircraft unit would then need to be powered from the aircraft’s USB power, as well as the mounting needing deeper thought as it will need to be hard-mounted rather than removable. Think of this as being very much like those cameras mounted on the rear-view mirrors of cars – but with added inertial/GPS data.

As mentioned above, this is a proof of concept idea, which means that along the journey of building it there will be parts we may wish to change and adapt.

This design started as a fun paper exercise based on work we have completed in the past using some of the self-components, but we have cobbled together some parts on the bench and have a working system of sorts.

Just to be sure there is no misunderstanding, this design will just raise the alert with the owner(s) and/or local farmer/airfield staff, it will not make any noise or flash lights etc. However, if this should be required then it can be added.

We have tried to cover eventualities where any perpetrators could fool the system or disable it, but not being security experts we may have missed something. Consequently, we can’t guarantee that this system will protect the user’s aircraft, only that we intend to raise the alarm and allow the owner(s) to decide on the best course of action with the given data.

Also, as an owner, if you have read this far and are interested, then please send ideas and comments to us and we will endeavour to include them in the project. We were aiming for the LAA Rally where we could ‘show off’ a working prototype, but as that is cancelled we are looking to have a follow up article in a few months with a production version, and then move on to showing members how to build their own. For details, contact: CliffordAgius@CA-Software.co.uk ■

high with an average of 82% satisfaction across all areas, up from 78% in 2016. Engineering service satisfaction also improved, from a rating of 82% in 2016 to 85% in 2020. Permit renewals continue to score exceptionally highly at 91% satisfaction, however, modifcations and repairs scored, at 76%, lower than other areas, with 10% marking the area as poor – principally complaining at the lack of timely responses. Generally, however, speed and completeness of responses from Engineering was well received with an 82% approval rating.

Our editor will no doubt be delighted to see continuing member satisfaction with the LAA Light Aviation magazine, refected in an overall satisfaction rating of 88%, up from 85% in the 2016 survey. Magazine content appears to generally meet member aspirations, but we can always do better. The preference for more technical articles is noted. We also noted a number of members want more detailed ‘how to’ articles on build techniques and general aircraft maintenance. We’ll also brief our designers that many members commented on there being too much small print and too much print on colour, making it harder to read.

The survey looked at our two prime training offerings, the Pilot Coaching Scheme and the LAA Training Courses.

The PCS has a relatively low take-up in terms of numbers but is deemed highly important by all members. Just 6% of respondents used the PCS in the past two years, down from 8% in 2016 and 11% in 2011. The majority of these, 45%, used the PCS for their biennial fight review. As in previous years, around 75% of those surveyed regarded the PCS as ‘worthwhile’, but an increasing proportion identifed it as being either of limited use or needing improvement. This therefore endorses the recent activities by a new Head of Training and Chief Coach to refresh the scheme.

LAA Member Training Activities are demonstrating the initial benefts of our investment in training with 23% (up from 12%) of members having reported attending courses in the past two years, and a similar drop in members stating they were disinterested.

Until the COVID-19 lockdown, the level of interest in the existing courses was being maintained (they were all fully booked) and the survey question on future courses indicates a clear wish for routine owner maintenance and specifc engine and airframe maintenance as future subjects as we expand the offering.

The fnal questions of the 2020 survey asked for opinions on the Association as a whole, and how well it serves its members. It is gratifying to note that in excess of 75% satisfaction was noted in all areas surveyed and that in some areas, such as the value of

membership, feeling like a real community, modern and forward looking, have all exhibited improvement since 2016.

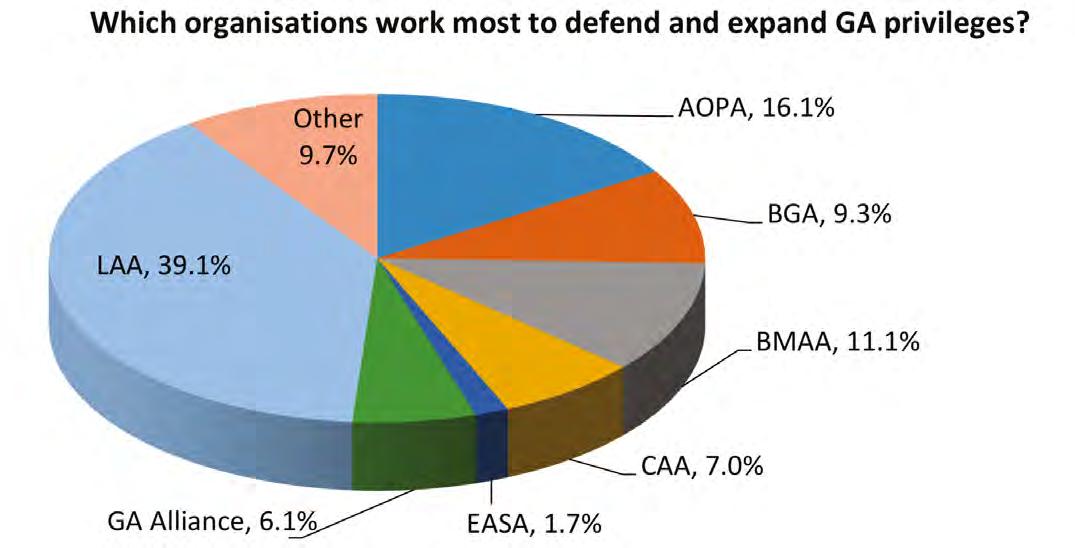

A new survey point on advocacy was added for 2020 and the question asking whether “the LAA responds effectively on my behalf” , gained a high 82% approval rating. The LAA headed the list of associations seen as working most to defend and expand GA privileges, with 39% of the total.

Finally, we asked members “ if there was one thing you would suggest to improve the LAA... ”, which elicited 800 responses. They are too numerous to list here, but there are some great suggestions which we’ll work on,

BGA,

BMAA,

including encouraging easier access for new members, and inclusivity. Encouraging young members and PPL trainees, and development of a stronger regional presence with more LAA events and training courses in Scotland, Wales and the regions.

Other ideas included initiatives for ‘retired’ pilots, to motivate those who have sold their aircraft to stay involved, greater legal support including member advice and magazine articles on new legislation and staying out of trouble.

It was good though to see almost a quarter of comments say, “It ain’t broke, don’t fx it, we’re happy with the LAA.”

Thank you for that, but we will continue to work on the improvements! ■

Having launched our own YouTube channel earlier this year (access via the website homepage www.laa.uk.com), what better way to populate it than with videos from our own highly individualistic and talented membership!

We have therefore teamed up with Pooleys Flight Equipment to launch a sport flying video competition, which allows members to share their passion in a competition to submit a video of their aircraft or their flying. It could be a documentary discussing your build or restoration project, or a fast-moving, action-packed film with multiple shots showing your hot ship or vintage biplane dancing among the clouds, edited to a voiceover or dramatic music.

The format and content of the video is entirely up to the participant – as long as it is between 1.5 minutes and 15 minutes in length, and demonstrates the fun that can be had with an LAA permit aircraft.

A £1,000 prize fund will allow winners to choose up to £500 of Pooleys flight equipment and merchandise, and the top three entrants will have FREE LAA membership for 2021. The competition is only open to LAA members, but everyone will be able to enjoy the results, via the LAA YouTube channel and Facebook page at www. facebook.com/lightaircraftassociation

The competition concept was the brainchild of LAA engineers Mike Roberts and Joe Hadley, who are keen to point out that any member can contribute.

“With over 7,700 members and 2,800 active aircraft of different shapes, sizes and capabilities on the LAA fleet, we are all united in our love for flying,” says Mike Roberts. “You don’t need an expensive camera, suitably edited mobile phone footage will do. In addition, older footage can also be used. The aim of this competition is for members to share the enjoyment of their aircraft with families and friends, and to capture that fun in an engaging, exciting manner. We’re really looking forward to seeing the results.”

Once the final edit is complete, the video should be uploaded to YouTube where a link should be made to the LAA YouTube channel. Entrants must then send a copy of the link, with their name and membership number to office@laa.uk.com headed Video Competition plus the title of the film. We recommend that it depicts the video accurately – Long-EZ Cloud Chasing Fun or A Taylor Monoplane Build Diary for example, as well as something about you and your featured aircraft.

The deadline for video submissions is 31 October 2020

Each submission will be required to comply with the following criteria:

■ It must be made by an LAA member with help from family, friends or colleagues.

■ It should be no shorter than 1.5 minutes and no longer than 15 minutes.

■ It must include either the LAA logo and/or watermark at some point in the video.

It must only include footage, images or music either owned by the member submitting the video or allowed to use the media under an appropriate creative commons license (royalty free) with credit for royalty free media given to the artist in the YouTube video description.

To complete any flying sequences, it is likely to require camera(s) to be mounted on your aircraft. Before any flying footage is captured, all camera installations must be approved by your inspector. LAA Technical Leaflet TL 3.24 (available via the Aircraft and Technical / Data Library tabs on the LAA website homepage) details the installation requirements for mounting small cameras on your aircraft.

As mentioned, the aim of this competition is for the LAA members to capture and enjoy the process of creating an exciting action or factual video of their particular aircraft type.

It cannot be stressed enough that any video submission demonstrating reckless or dangerous flying will be immediately disqualified.

Three prizes will be available for the top three submissions.

First: £500 Pooleys Flight Equipment merchandise voucher, plus a year’s free LAA membership.

Second: £300 Pooleys merchandise voucher, plus a year’s free LAA membership.

Third: £200 Pooleys merchandise voucher, plus a year’s free LAA membership.

All prizes must be redeemed between December 2020 and December 2021.

Each video will be judged by members of the LAA team and invited external judges. The judging criteria will be based on how engaging we found the video, the visual impact, production quality and the video accurately depicting LAA permit aircraft and flying.

The three winning entries will be announced on 1 December 2020

For further information please contact office@laa.uk.com

To offer some inspiration, here are some examples of what can be done. Look out for more on the LAA YouTube Channel

■ Sling 7-Day Aircraft Build at the 2016 LAA Rally

https://tinyurl.com/Sling-7

■ Hugh Scrope: The 80th Anniversary of the Chilton Monoplane

https://tinyurl.com/Hugh-Scrope

■ Flight with Trevor! 1946 Auster from Coventry to Staverton

https://tinyurl.com/Auster-Trevor ■

In Part 2 of North by Northeast to Zanzibar, Rod Wheeler and his fellow Sling aviators complete their African adventures before saying their goodbyes and journeying to their respective home airfields…

The leg to Zanzibar was extraordinary.

Maintaining our trusted groupings and tight formations, we simply followed the stunning coastline north, some flying this way and that at low altitude, others taking the more direct route higher up. All the while exclamations resounded on the chat frequency, pointing out beautiful beaches and lakes. Off the coast, sand-fringed islands delineated the line of a hidden reef that had confounded so many sailing vessels down the centuries.

“Tango Alpha Delta cleared to land Runway 18, you are number four, please keep speed up as there is an Emirates Airbus on an 18 mile final” … The hint of Kiswahili patois in the slightly agitated reply to my downwind call confirming our destination.

By now we were becoming experts in ‘formation’ landings and happily followed the other three Slings on base and short final at less than a mile from the threshold, with two more close behind us. Three others were already safely landed as we started our own

Main Rod Wheeler and the Sling ‘caravan’ continue their trip to Zanzibar and back to South Africa.

descending turn from base to final, the nose of our Sling dipping to reveal the outskirts of Stonetown, with its Medieval fort a commanding presence overlooking the turquoise water of the port and islands beyond. Three hours and 40 minutes after leaving the wide concrete of Pemba Airport, we touched down at the Spice Island’s Abeid Amani Karume International Airport, marking the midpoint of our Johannesburg to Zanzibar flying safari. All that stood between us and our shoreline resort hotel was the refuelling truck and Tanzanian immigration –suffice to say the beer we were handed five hours later tasted very special.

Despite the challenges of getting through the airport, Zanzibar itself turned out to be everything it had promised. The tangible excitement shown by Lucien on returning to his homeland meant we had a fantastic and willing guide. Full of stories about navigating the intricate back streets of Stonetown to visit an early girlfriend, jostling in the noisy and smelly meat and fish markets, he made us feel justifiably proud that we were not just ordinary tourists. Having arrived in our own little aeroplanes we somehow felt more akin to those intrepid

travellers who had made Zanzibar historically one of the most influential trading hubs. A crossroads for traders voyaging between the African Great Lakes, the Somalian and Arabian peninsulas, Iran, and the Indian subcontinent. A melting pot of people and identities, fusing the ancient cultures of Arabia, East Africa and India with the more recent European colonial powers, it appeared to have safeguarded its exotic past with an air of sleepy indifference. But as a gateway to the supposed untapped mineral and gas deposits promised in the countries over which we had just flown, the influence of new Russian and Chinese money was already starting to show.

After two glorious days of sightseeing, which included a memorable visit to a local spice village and snorkelling in mangrove lagoons from a fishing dhow, we geared ourselves up for the second half of our trip.

Sadly, Trevor and Lizzie had to head directly back to the UK, due to a family illness, and this meant Tim took captaincy of their Sling 2, kindly offering my son Nick

Top Schools out for the youngsters in a spice village in Zanzibar.

Above The group enjoy a boat trip to Pamunda Island, Zanzibar, to go snorkelling in the mangrove lagoons

Right Banana leaf hats for son Nick and Lucien d’Sa, mementos from exotic Zanzibar.

the P2 seat, which left James solo in ZU-TSI. Another couple, Graham and Stella flying their own Sling 2, now joined our merry band. Originally part of the earlier group headed by Essie, they had been abandoned due the previously mentioned battery problem. As the only Sling in that earlier group, they seemed pleased to have found kindred spirits and we welcomed them warmly.

So efficient was our formation start-up and departure from Zanzibar International early in the morning, that all 11 aircraft in their three groups were closely spaced as we once again headed out over the sea direct to our first waypoint on the mainland at Ras Kutani. Almost exactly as we reached the point of no return, a calm radio call from Sling 4 pilot Mthandeni, up ahead flying with his wife Thembi in ZU-KRA, jolted us out of our quiet reverie. “James, my voltage is low and dropping.” A beat of silence and James responds “Turn off all non-essential electrics but keep the radio on for now. Try resetting the Alternator circuit breaker.” “OK.”

Ten minutes passed and our little formation was nearing the coast, -KRA was just visible in the group ahead and the call came: “James, I am going to land as soon as possible.” Serendipitously, the dirt strip of Ras Kutani was dead ahead and only a mile or so inland. A quick call from James requested that we follow Mthandeni down, with him following close behind. Chris executed an extraordinarily neat, short field landing on the sloping dirt runway cut deep into the acacia forest. The rest of the group continued on south towards Pemba while we assessed the situation.

Before our departure, Sean Russell had commented, “There will be two things that will ruin your day on this trip. One will be a puncture and other will be the failure of the voltage regulator.” Well we quickly identified that we had fallen foul of the latter curse. Knowing that our ZU-TAD had both the engine driven alternator that utilises the same regulator as Mthandeni’s Sling 4, as well as the second alternator mounted at the front of the Rotax with its own inbuilt regulator, James had cleverly diverted us in as the ‘spares’ machine.

Peter to fix Paul’ at Ras Kutani when the voltage regulator failed on one of the Sling 4 aircraft.

All it required was a 10mm spanner. While James headed off down the dirt track to the nearest village, Thembi miraculously appeared with just such an item – somehow procured from a young Tanzanian lad who had appeared out of the bush. I quickly set to work freeing up both regulators, which on a Sling involves a good deal of one-handed dexterity with one’s head deep into the footwell and legs dangling over the door sill. James reappeared just in time to help the reinstallation, swapping the units around in each aircraft.

Fortuitously, Mthandeni had packed a small battery charger and after a 10-minute boost, his engine roared into life, charging light out. Incredibly, after just 45 minutes we were ready to go. James planned to get us airborne so we could radio Dar Es Salaam and re-activate our international flight plan. Easy! But just as we were making ready, a safari vehicle bounced through the gate and waived us to a halt. It seemed the owner of the game reserve was not happy that we had arrived unannounced and refused to allow us to leave until he had received clearance from the Tanzanian CAA.

With mobile connection only possible while standing on a specific anthill two metres into the edge of the bush, this proved to be a tortuous process. With the afternoon wearing on, every minute of lost time meant our chance of making it to Pemba before official night time started to dwindle. Eventually it was too late, and we were given two options – fly the 30nm north-west up to Dar Es Salaam to re-clear customs, or head back over the water to Zanzibar. After a short debate, all five of us decided that despite the original challenges and longer leg, it was a case of ‘better the devil you know’.

Heading back to Pemba

Retracing our route, tired and slightly depressed, we were welcomed by the manager of the airport like long-lost brethren, and he generously waived any landing fees and the $300 international arrival fee. It was at this point that Mthandeni mentioned he had a business contact in Stonetown and, after a quick phone call, we found ourselves sipping iced tea in the infinity pool of the five-star Verde Hotel.

Sometime during all the palaver, Chris and I had remembered that we not only had all of Nick’s luggage but also his passport and phone. I was too tired to ring my wife Sandy and tell her that I had managed to misplace one of my sons and leave him stranded identity-less and impecunious, airside at a strange airfield in Mozambique. Unbelievably, given our earlier experiences, and despite the previous requirements to complete visas and forms in triplicate, he apparently just explained his predicament and was waved through at Pemba Airport to join Tim and the others!

Having enjoyed what we hoped would really be our last supper in Stonetown, the five of us headed back for an early night with alarms set for 0500.

In order to make our final destination in Mozambique at Vilanculos, nearly six hours on from Pemba, we calculated we would need to depart at sunrise. Even then it would be tight since the Windy app indicated some strong headwinds of 20-30kt below 5,000ft, but interestingly it hinted at a slight tailwind if we could get up to 7,500ft. If all went to plan, we would land just as the rest of the group would be preparing to depart Pemba late morning. If we could refuel and clear customs quickly, we should be able to follow them down and arrive before sunset.

All did go to plan, and after an uneventful flight south, we braced for the administrative hurdle at Pemba International. Scarily it felt as if Will Smith had recently passed through with his Neuralyzer, as it became apparent that no one remembered anything about us or the rest of the group being there just a few days earlier…

A missing landing fee book and our nearly lunchtime arrival meant almost two hours of toing and froing between one official’s office and another. Miraculously Nick had strolled through the departure gate and now joined me in -TAD, with Chris settling into ZU-SNG with his new captain, Tim. I am still not sure whether Tim spotted this change of surrogate son…

Vilanculos

Polokwane

Tedderfield

Top As the reg suggests, ZU-TSI is the 141hp Rotax 915iS powered Sling 4TSI demonstrator. Its performance with the additional power was impressive.

Kruger International

After much cajoling and pleading, we eventually started our take-off roll spaced behind Lucien and Colin in ZU-YAY, the rest of the group having departed safely ahead.

Seconds after take-off, the dulcet English tones of Colin caused us to take evasive action to the right. “Engine running rough, we are aborting”. James was also airborne and calmly followed -YAY around the circuit, instructing the rest of us to continue. After a thorough engine inspection and ground run it was deemed that vapour lock had caused the rough running, and we were later relieved to hear them on the radio, both safely on their way, throttles fully advanced.

If I had any lingering doubts about the decision to build a Sling 4, these were categorically dispelled on this epic day. Two legs totalling 885nm and over nine

hours of flying between sunrise and sunset, along one of the most uninhabited and gorgeous coastlines in the world, demonstrated just what a remarkable design Mike Blyth and his team at TAF have produced. Short, dirt strip departures, hot and high, fully loaded – tick Beautifully harmonised controls requiring only fingertip touch – no problem. Ultra-long distance in maximum comfort at a healthy average 120kt ground speed –absolutely. Panoramic views forward, up, down and backwards – yes, siree. State-of-the-art avionics and a two-axis auto-pilot (if required!) – why not? And all the while sipping just 24 litres of mogas or avgas an hour –yes please! Surely one of the most comprehensive acceptance flights ever…

With James, Colin and Lucien making up for lost time some 30 minutes behind us, I had taken on the role of primary navigator and radio man for our now diminished three-ship formation. With so many GPS systems across our aircraft the first part was ludicrously easy. While our G3 provided easy access to the varied local frequencies, it required a bit of care to ensure I was using the single radio correctly. A few times I caused much hilarity, as having just completed a rather long-winded position report and request for transit, Nick kindly pointed out we were still on the chat frequency. I maintained I was just practicing for the real thing!

As we transited south out of his airspace, and still not fully acclimatised to all the local dialects, I was surprised by the request from Nampula Tower to report on the hour, “Ops normal.” It soon became apparent that, with over three hours to go until our next waypoint, we would be transiting over even wilder and uninhabited terrain. Any technical challenges that might befall us now, would require some careful but expedient management.

With the G3 constantly updating us on our estimated time of arrival at Vilanculos, I was able to use the rubber band facility on the touch screen display to create an arcing dog leg that would keep us well east of Beira

Below Lucien and Colin arrive at Vilanculos at sunset following their engine problem at Pemba.

airspace, while maintaining a decent distance from the coastline in case of an emergency. Beira had been battered by several seasonal typhoons earlier in the year and the international airport seemed eerily quiet, the controller just asking us to confirm we had cleared her airspace.

Cruising at FL95 at a comfortable 127kt ground speed, and with Nick needing a rest from the controls, I set up an automated descent on the autopilot. Having selected a desired descent rate of 350fpm and wishing to arrive overhead the airfield at 1,000ft, we watched as the VNAV controller kicked in with 45 miles to go. With only small reductions in manifold power required as we descended, the electric prop controller maintained our cruise setting of 5,250rpm. -TSI and -YAY had closed the gap behind us but had stayed lower down round the bay, but we were able to convert our higher energy into an extra 10kt of speed and easily pulled ahead again.

Having listened to the rest of the group making their final approaches some 20 minutes ahead, we were delighted to hear the welcoming call of South African Chris on the Tower frequency. It seemed he had already made friends with the resident fire crew and, with the sun just touching the western horizon, he vectored us in for a low-level circuit over the sea and a squeaky landing on the northerly runway. Popping open the gull wing doors we were greeted by nine sleek Slings parked line abreast in the last of the golden sunlight, their animated crews with beers in hand. James, Colin and Lucien touched down exactly on official night time. What an extraordinary 24 hours…

The website claims it is a family run business and introducing himself as the duty manager, Alberto Nhamtumbo, welcomed us to his sparkling new terminal. Where Pemba and Zanzibar had been all ‘pole pole’ (slowly slowly) and countless forms in triplicate, Alberto whisked us through and out into a waiting minibus without so much as a glance at our passport. What a star!

While Zanzibar had promised to be the spice in our African smorgasbord of delights, Vilanculos turned out to be the unexpected fine cheese and glass of port to round the whole thing off. Nick, Chris and I were allocated the Presidential suite, a vast reed-thatched chalet with a spectacular view of the ocean. In fact, it could have accommodated the entire group.

Deep sea fishing experts Morne and Amanda had cleverly pre-booked a day for snorkelling, so after a full night’s sleep we congregated on the beach. Dividing ourselves between two small motorboats we were soon speeding towards the nearest of the golden islands that had been formed on the reef just two miles offshore. Within minutes of setting off we were joined by a pod of dolphins, which cavorted alongside the boats and then, unbelievably, a humpback whale broke the surface not far away. Concerned that it seemed to be too close

inshore, our boat captains wisely kept a good distance and we soon left it to continue its display as it headed north up the coast.

For those that have snorkelled here or in other parts of the world, it will be no surprise to hear that trying to describe the wonders of life on and around a reef is nigh on impossible. Words cannot describe the sheer variety of fish, their colours and shapes. The sunlight dappled coral swaying in the gentle swell gleamed with every hue of red, purple, blue and green. It truly was the perfect end to our spectacular adventure.

A final night of singing and dancing gave our now close-knit group of aviators a chance to celebrate and say goodbyes. Tomorrow would see us complete two final legs homeward bound, with the nearly five hours’ of flying now seeming only a short hop. Dropping into Kruger International to clear customs back into South Africa, the group disbanded and headed to their various home airfields.

It seemed there was just one little moment of hilarity to come though; as the last group to depart, and climbing steeply to crest the hills at the departure end, Kruger Tower were heard to ask whether we had meant to leave a pair of boots on the parking area. A quick call established these belonged to my co-pilot Nick. While I was happy to leave them as a memento, he declared that they were rather expensive RAF fare and he needed them once back in the UK.

James once again had a chance to demonstrate the TSI at its best, wheeling around he landed downwind and still managed to vacate off the first exit. Chris leapt out, grabbed the boots and they were off again much to the bemusement of the Airlink Avro J85

Above Rod and his twin sons enjoyed the Presidential suite at Vilanculos, typical of much of the accommodation.

Below The happy band who enjoyed each others’ company on the Sling adventure from South Africa to Zanzibar and return.

waiting to take off. And somehow, they still managed to beat us all home!

Sean was there to greet us Tedderfield-bound Slingers, and as the sun set for a final time on our happy band, Rotax engines quietly tinkling away in the cool evening air, we knew it would take some time for it all to really sink in.

A huge thank you to all at The Airplane Factory for letting us fly its beautiful aircraft, to Tim for persuading us to join, to James for his joyous leadership and the whole team for all their friendship and laughs along the way.

But most especially to Nick and Chris for keeping dad on the straight and narrow – keep calm and carry on… ■

One of Sgt Anthony Ayre’s favourite passages came from the book Jonathan Livingston Seagull by Richard Bach. It reads: “Don't believe what your eyes are telling you. All they show is limitation. Look with your understanding, find out what you already know, and you’ll see the way to fly.”

A talented engineering technician by trade, and truly ‘blue to the cut’, Anthony completed 29 years of exemplary service in the RAF, specialising on many aircraft types, and later in his career was selected to fly as an airborne technician onboard the Sentry E-3D (AWACS).

Throughout his service life Anthony was an avid light aircraft builder and pilot, and clearly related to the sentiment of Bach’s evocative words, which inspire us to take hope and faith in our own abilities. Such inspiration will surely be appreciated by anyone embarking upon an aircraft build – and that includes those who may find themselves, rather unexpectedly, asked to complete one!

Living his life ‘to the max’, Anthony worked hard – but played even harder. An active member of many RAF sport associations, including the RAF Flying Clubs’ Association (RAFFCA) and the RAF Motocross Association, 'challenge and achievement' was his mantra for life. Having gained his Private Pilot Licence with the RAF Akrotiri (Cyprus) Flying Club in 2003, he had immersed himself in the world of GA, serving on many RAF Flying Club committees. His selfless commitment to ensuring that aircraft were serviced and maintained, ultimately allowed many others, namely Junior Ranks (JRs), to experience the joy of flight at very little personal cost.

Featuring in the February 2011 edition of LA, Anthony’s abilities as an aircraft engineer and restorer were further showcased through his own Jodel D117 (G-ATIN) project. A complete top-to-bottom rebuild spanning six years of hard graft, his skill and attention to detail were evidenced by the end product – an authentic aircraft completed to a very high standard, exuding buckets of gallic character.

While sourcing a suitable propeller for G-ATIN, Anthony’s search had led him to Wickenby Airfield, one of the many WWII airfields scattered across the Lincolnshire countryside – and only a few miles from RAF Waddington where he was based. Little did he realise that his visit would serve to offer much more than just a propeller.

A rare Pitts S2A-E kit (E for Experimental) had been imported into the UK in January 2009 and, for various reasons, was now up for sale at Wickenby. Without batting so much as an eyelid, Anthony knew that this was the project he yearned for – an advanced aerobatic aircraft with history, provenance, character, and moreover, raw power. Furthermore, as a permit aircraft, he could build and maintain the aircraft himself, what more could he ask?

In March 2009 Anthony purchased the kit and all associated items, which then became build number LAA-009A-14904 on 7 August 2009. The foreword now complete, chapter one of a remarkable story took shape.

Rather like a child wanting to see what their Airfix model may look like when complete, Anthony returned to RAF Waddington and set out the Pitts’ upper wings on a large oak dining room table in the Sgts’ Mess. Using RAF crockery (mugs) as spacers and placing his Sunday roast in what would be the cockpit, he could not be happier.

Clearly hoping to immerse himself in the thrill of aerobatic G, he applied for a rather apt and subtle registration – G-PULR (G Puller).

Over the next five years, Anthony meticulously inventoried all components and focused his work on the fuselage and wings. He was ever grateful for the support and help of a good friend, John Worthington, whose carpentry skills were invaluable.

It was clear from his email traffic to Aviat and the LAA that Anthony intended to build his Pitts to an exceptionally high specification and was steadily working towards the option of a modified high-power engine… to the max!

Tragically, on 21 July 2014, while returning from a week of summer leave spent with his mother at his house near RAF Leuchars, Anthony lost his life in a road traffic accident. A few days before, he had become the first RAFFCA Beginners’ Aerobatic Champion. Scoring an incredible 81.86%, he had specifically requested to compete in, of course, a Pitts S2A. A much-loved son and extremely popular serviceman, the loss of Anthony is still proving difficult to accept for those who knew him.

In memory of Anthony

It was shortly after Anthony’s passing that his mother, Mrs Joan Drinkel, and uncle, Ian Cogdon, asked me, a close friend and RAFFCA Exec, if the Association could complete the project and operate the aircraft in Anthony’s memory. Honoured to do so, yet in much need of inspiration akin to that found through Richard Bach’s words, the request was accepted.

Little did anyone know at the time just how much work lay ahead. However, it was obvious that the project would need the help of many friends and supporters if it was to succeed. Thinking caps on and time to pen a few letters –as a starter-for-10 we needed an engine and a propeller, thoughts anyone?

To ensure the delivery and operation of the aircraft in accordance with the wishes of Anthony's family, it was decided to formally name G-PULR as the Spirit of Ayre and establish the Ayre to Air Charitable Incorporated Organisation (CIO). I, together with Air Commodore Alistair Seymour and Wing Commander Gary Coleman (both fellow RAFFCA Execs and friends of Anthony), were appointed trustees of the charity which would own and eventually operate the aircraft.

Testament to Anthony’s character and standing, as the trustees we were not surprised to receive so many kind offers of voluntary assistance and financial support to progress the aircraft build. Of particular note was the unwavering support of Paul Ford, a talented aircraft builder who offered to locate the project in his hangar at Derby Aerodrome and oversee the work efforts and contributions

of the many volunteers, friends and family. While it was clearly going to take considerable time and effort, the team was confident that the final objective, being to deliver a very special aircraft of which Anthony would have been proud and made available for the benefit of others, was indeed achievable.

By June 2018, it was time to emblazon the aircraft with a unique and striking livery, designed by Anthony’s mother and uncle. A skilled aircraft painter, Andrew Brydon completed the work at RAF Marham in July – supported by his colleagues and the kind assistance of SERCO. A RAF roundel, modified with a red heart at its centre, envelops the underside via both pairs of wings. When viewed in the vertical or from beneath, the roundel design comes together and will surely be a top shot for aviation photographers to catch. The roundel was developed further to become the charity's logo by adding a motocross bike in the very centre – as a nod to Anthony’s other great passion.

With her fresh paint, and an opportunity too good to miss, it was decided to display G-PULR at the Royal