EssentialForkliftSafetyTipsforOperators

Summary

Comprehensive forklift safety tips guide covering essential practices to prevent workplace accidents and OSHA violations. Learn critical forklift pedestrian safety, inspection protocols, load handling techniques, and OSHA requirements to ensure operator protection and regulatory adherence.

OSHA reports approximately 85 fatal forklift accidents annually, with an additional 34,900 serious injuries requiring medical attention across American workplaces. These alarming statistics underscore the critical importance of implementing comprehensive forklift safety tips that go beyond basic training to create systematic accident prevention programs.

Forklift accident statistics reveal that 70% of all incidents could be prevented through proper training and adherence to established safety protocols. The financial impact extends far beyond immediate medical costs, with individual forklift accidents averaging $38,000 in direct expenses while indirect costs including downtime, legal exposure, and insurance increases can exceed $100,000 per serious incident.

OSHA Forklift Safety Rules

1. Fundamental Regulatory Requirements

OSHA forklift safety rules establish comprehensive requirements for powered industrial truck operations under 29 CFR 1910.178, mandating that operators must be trained and certified before equipment use. Certification requirements include formal instruction covering 22 specific safety topics, hands-on training

with qualified instructors, and workplace evaluation demonstrating competent operation.

2. OSHA Operator Certification (29 CFR 1910.178)

Training & Certification: Operators must be trained and certified before using powered industrial trucks

Certification process includes:

Formal instruction on 22 OSHA-mandated safety topics

Hands-on training with a qualified instructor

Workplace evaluation to demonstrate competent operation

Recertification: Required every 3 years to maintain compliance

Immediate retraining: Mandatory if an operator is involved in:

An accident or near miss

Unsafe behavior observations

Workplace condition changes (layout, equipment, materials, hazards)

Age restriction: No one under 18 may operate forklifts, regardless of training status

3. Equipment Standards & Modifications

Forklifts must comply with ANSI B56.1-1969 design and safety standards

Unauthorized modifications are prohibited – OSHA states:

“Modifications and additions that affect capacity and safe operation shall not be performed by the customer or user without the manufacturer’s prior written approval.”

Safety equipment requirements:

Overhead guards and load backrests must remain installed and functional

Drilling holes, removing guards, or disabling components violates OSHA regulations and compromises protection against falling loads

4. Maintenance & Inspection Standards

Daily pre-operation inspections: Mandatory before each shift

Defective equipment: Must be removed from service until repaired and safe to operate

Recordkeeping: Employers must maintain documentation of:

Daily inspection results

Operator training and certifications

Scheduled and completed maintenance activities

Authorized maintenance: Only qualified personnel familiar with forklift systems may perform repairs

Preventive maintenance intervals: Required to reduce breakdowns, prevent mechanical failures, and ensure regulatory compliance

Main Causes of Forklift Accidents

Understanding the primary factors contributing to forklift accidents enables organizations to develop targeted prevention strategies and comprehensive safety protocols. Recent analysis reveals consistent patterns that effective safety programs can address through systematic risk assessment and mitigation approaches.

Common Causes of Forklift Accidents

1. Lack of Proper Training

Inadequate training is a leading cause of forklift incidents, responsible for an estimated 25% of all accidents.

Training deficiencies: Poor understanding of forklift physics, load handling, and hazard recognition

Refresher gaps: Operators often miss required retraining every 3 years or

after incidents

Workplace-specific gaps: Training fails to address facility-unique hazards such as floor conditions, traffic patterns, and environmental challenges

Prevention potential: OSHA estimates 70% of operator-related accidents could be avoided with proper training

2. Overloading and Improper Load Handling

Load-related errors account for ~20% of forklift incidents.

Capacity violations: Exceeding manufacturer weight specifications or ignoring load center calculations

Unstable loads: Resulting from poor securing, uneven distribution, or lack of load assessment

Elevated load travel: Raises center of gravity, increasing tip-over risk

Load tilting violations: Cause material falls, endangering both operators and pedestrians

3. Speeding and Reckless Operation

Excessive speed is a critical factor in Forklift Tip-Overs, which cause 42% of fatal forklift accidents.

Forklifts average 9,000 pounds and require extended stopping distances at high speeds

Turning too quickly: Creates centrifugal forces that destabilize forklifts, especially with raised loads

Emergency maneuvers at speed: Frequently result in rollovers and loss of control

4. Poor Visibility and Obstructed View

Visibility limitations are linked to 36% of pedestrian-related forklift fatalities.

Forward vision blocked by large or elevated loads, forcing reverse travel

Intersection accidents: Occur when operators cannot see cross-traffic or pedestrians

Environmental factors: Low lighting, dust accumulation, glare, and weather conditions worsen visibility issues

Equipment deficiencies: Inadequate mirrors or lighting reduce situational awareness

5. Pedestrian Collisions

Pedestrian safety remains one of the highest-risk challenges in forklift operations.

Shared spaces: Forklifts and foot traffic often overlap without adequate barriers

Poor facility layout: Lack of marked pathways, insufficient separation, and blind corners

Human factors: Distracted pedestrians using headphones or mobile devices

Communication barriers: Multilingual workplaces limit hazard warnings and awareness

6. Mechanical Failures from Poor Maintenance

Neglected maintenance directly contributes to hazardous mechanical failures.

Common failures: Brake malfunctions, steering problems, and hydraulic leaks

Inspection failures: Allow defective forklifts to remain in service

Component wear: Tire deterioration, chain elongation, and low fluid levels reduce control and reliability

Essential Forklift Safety Tips to Prevent Accidents

1. Get Proper Training & Certification

OSHA requires that only certified operators handle forklifts (29 CFR 1910.178).

Training must include:

Formal instruction covering all 22 OSHA-mandated topics (operation, hazards, emergency procedures, etc.)

Hands-on training with a qualified instructor

Workplace evaluation demonstrating safe operation in real conditions

Documentation must include operator name, training/evaluation dates, and trainer identity.

Refresher training: Every 3 years, or immediately after accidents, nearmisses, or unsafe behavior.

Industry-specific training: Address facility layout, products, and environmental conditions.

2. Wear Appropriate Safety Gear

Mandatory PPE:

Hard hats – protection from overhead hazards

High-visibility vests – enhance pedestrian awareness

Steel-toe boots – protection from crushing/falling objects

Secure loose clothing and remove jewelry to prevent entanglement.

Use weather-appropriate gear for outdoor operations (e.g., slip-resistant footwear, protective outerwear).

3. Know Your Forklift Class & Capacity

Forklifts are classified into distinct types (e.g., Class I – Electric Rider, Class II – Narrow Aisle, Class III – Motor Hand/Rider), each with unique capabilities.

Always check the data plate for:

Rated capacity

Load center

Modifications/attachments affecting lifting ability

Follow stability triangle principles: never exceed safe capacity or shift the center of gravity.

4. Conduct Daily Inspections

Required before each shift by OSHA.

Key checks: brakes, steering, hydraulics, horn, lights, forks, tires, and structural components.

Defects: Must be tagged out and removed from service until repaired.

Maintain inspection records for compliance.

Monitor fluid levels (oil, coolant, hydraulic, electrolyte) to prevent failures.

5. Maintain 360° Visibility

Keep loads at minimum transport height with ground clearance.

Use reverse travel when loads obstruct forward vision.

Mirrors and spotters improve awareness in blind spots.

Follow intersection protocols: slow down, honk, and stop if vision is limited.

Ensure lighting meets OSHA’s 2 lumens/ft² minimum; backup alarms required.

6. Follow Floor Markings & Traffic Rules

Respect separated pathways for pedestrians and forklifts.

Obey speed limits and posted rules.

Use signage (stop signs, yield markers, one-way aisles) for predictable traffic flow.

Keep emergency exits and fire equipment accessible at all times.

7. Never Carry Extra Passengers

Passengers are prohibited unless the forklift is designed with an approved second seat.

Fork riding/pallet riding is strictly forbidden due to fall and crush hazards.

Lifting personnel requires certified work platforms with fall protection in compliance with OSHA standards.

8. Ensure Load Stability & Secure Handling

Center loads on forks for even distribution.

Tilt mast back slightly during travel for added stability.

Use straps/binders for unstable loads.

Maintain low travel height for stability and ground clearance.

Account for load composition (e.g., loose materials requiring extra securing).

9. Operate at Safe Speeds & Distances

Recommended speed limits:

8 mph in open/clear areas

3 mph in pedestrian zones

Reduce speed for wet, uneven, or debris-covered surfaces.

Maintain three forklift lengths of following distance.

Slow down when turning to avoid tip-overs.

Brake smoothly to prevent load shifting.

10. Avoid Hazardous Areas of the Forklift

Stay clear of mast chains, hydraulics, and moving mechanisms.

Maintain awareness of overhead clearance for raised forks or loads.

Be mindful of the rear swing radius during turns.

Enter/exit using three-point contact; avoid rushing.

11. Parking & Shutdown Procedures

Lower forks to the ground, set parking brake, neutralize controls, and remove key.

Park only in designated areas, away from exits, fire lanes, or pedestrian paths.

On inclines, chock wheels in addition to engaging the brake.

A forklift is considered unattended if:

Operator is >25 feet away, OR

Out of visual contact → requires full shutdown.

Benefits of Following Forklift Safety Tips

1.Accident Prevention and Worker Protection

Implementing comprehensive forklift safety tips delivers measurable accident reduction through systematic risk elimination and proactive hazard management. Organizations following structured safety protocols achieve accident reduction rates of 25-70%, with some facilities maintaining zero incident records over extended periods.

Worker protection extends beyond physical injury prevention to encompass psychological benefits including increased job satisfaction, reduced workplace stress, and enhanced organizational trust. Long-term health preservation prevents life-altering consequences including permanent disability and chronic pain that affect workers throughout their careers.

2. Financial Benefits and Cost Reduction

Insurance premium reductions of 15-20% result from demonstrated safety performance and proactive risk management. Workers' compensation savings accumulate through reduced claim frequency and severity, while operational continuity prevents costly disruptions.

Equipment protection through safe operating practices extends machinery lifespan, reduces maintenance costs, and prevents premature replacement expenses. Productivity improvements result from confident operators, reduced downtime, and streamlined operations.

3. Regulatory Compliance and Legal Protection

OSHA compliance prevents citation penalties ranging from $16,131 for serious violations to $161,323 for willful or repeated infractions. Legal protection improves through demonstrated good faith safety efforts and comprehensive documentation protocols.

Industry reputation benefits from safety leadership, while customer confidence increases with suppliers demonstrating operational reliability and risk management capabilities.

Forklift Pedestrian Safety

1.Operator Responsibilities

Forklift pedestrian safety requires operators to yield right-of-way to foot traffic in all circumstances. Horn usage at intersections, blind corners, and during reversing operations provides audible warnings that allow pedestrians adequate reaction time.

Eye contact establishment confirms pedestrian awareness before proceeding, while hand signals communicate intentions clearly. Speed

reduction in pedestrian areas prevents accidents when unexpected encounters occur.

Spotter utilization in congested areas provides additional safety coverage, particularly during backing operations and tight maneuvering.

2. Pedestrian Guidelines

Pedestrian awareness training must emphasize that forklifts cannot stop suddenly due to their substantial weight and momentum. Walkway designation keeps foot traffic separated from forklift operating areas.

Visual awareness requires attention to wide rear swing radius during forklift turning operations. Prohibited areas include spaces under lifted loads and within forklift travel paths.

Communication protocols ensure pedestrians signal their presence and intentions when crossing forklift routes.

Conclusion

Essential forklift safety tips represent comprehensive commitments to worker protection, operational excellence, and regulatory compliance that extend far beyond basic training requirements. The evidence consistently demonstrates that systematic safety approaches combining rigorous operator education, advanced technology integration, and proactive risk management deliver measurable improvements in accident prevention and operational efficiency.

OSHA forklift safety rules provide regulatory frameworks, but industryleading organizations achieve superior safety performance through integrated programs addressing human factors, environmental conditions, and forklift safety solutions. Investment in comprehensive safety protocols generates substantial returns through reduced accident costs, improved productivity, and enhanced insurance relationships.

FAQ

1.Why is forklift safety important?

Forklift accidents lead to serious injuries, fatalities, and costly OSHA violations that can exceed $16,131 per violation. Proper safety measures protect operators, pedestrians, and workplace property while ensuring regulatory compliance and operational continuity.

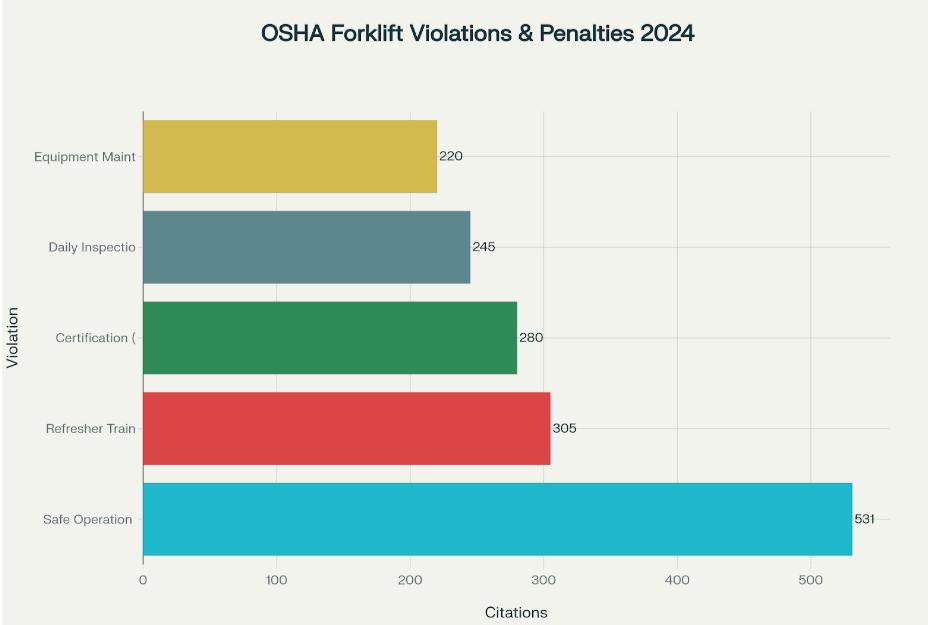

2. What are the most common OSHA violations related to forklifts?

Common violations include operating without proper certification (531 citations in 2024), failing to provide refresher training (305 citations), inadequate daily inspections, overloading equipment, and ignoring pedestrian safety zones.

3. What should a pre-operation forklift inspection include?

Forklift inspection checklist must check tires and wheels for damage, fluid levels (oil, hydraulic, coolant), brakes and steering, forks and lifting mechanisms, and lights, horn, and warning devices.

4. How can forklift operators avoid tip-overs?

Tip-over prevention requires seatbelt use, keeping loads low and tilted back during travel, driving slowly around corners, avoiding sudden stops, and maintaining proper load distribution within the stability triangle.

5. What are the key Forklift load capacity rules?

Load handling rules include never exceeding rated capacity, ensuring loads are stable and properly secured, lifting and lowering smoothly, and keeping forks low while transporting materials.

6. How should forklift operators handle pedestrians in the workplace?

Pedestrian safety requires horn use at intersections, yielding right-of-way, maintaining clear visibility, following designated pathways, and prohibiting unauthorized riders unless forklifts have approved passenger seats.

7. What are the basic safety tips for forklifts?

Basic safety principles include completing proper training and certification, conducting thorough pre-use inspections, following load limits, maintaining stability while driving, and obeying all workplace safety rules for pedestrian protection and traffic management.