2DFAB Two Dimensional Fabrication

Tessellation

Activity - Create a tessellation

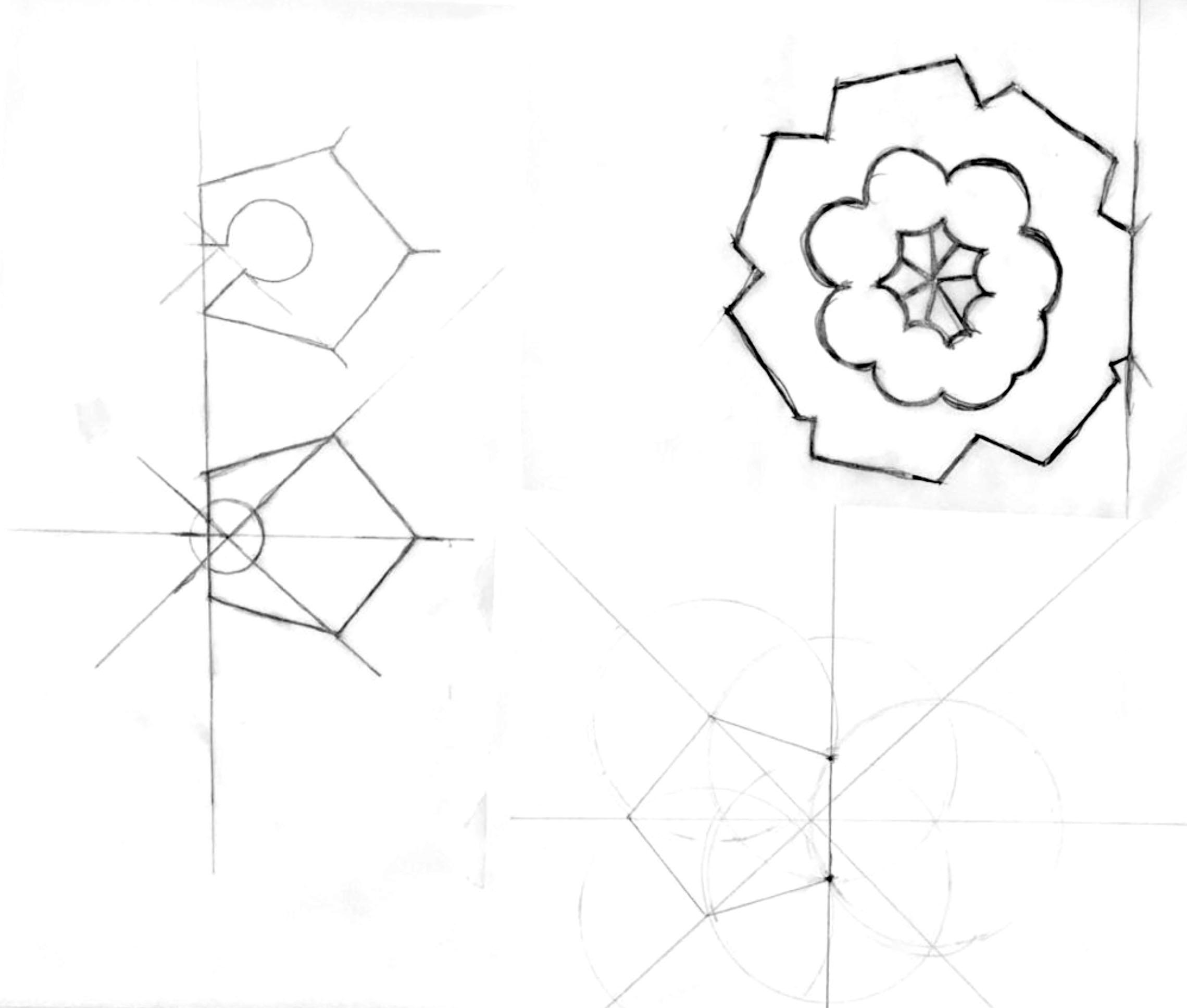

I wanted to try to make a tessellation based on a pentagon. I cut a shape out and attached it to another side.

I tried some iterations with this pentagon shape and arrived at one where I rotated it around a center point.

The flower shape was asymmetrical and finding a logical manner for a repeating pattern was a challenge.

KEY TAKEAWAYS

Shape looks like a flower Without the center part, the shape is less interesting Three together look good 3D shape is less effective Pentagons are challenging

Tessellation 02

Activity - Continue development of tessellation

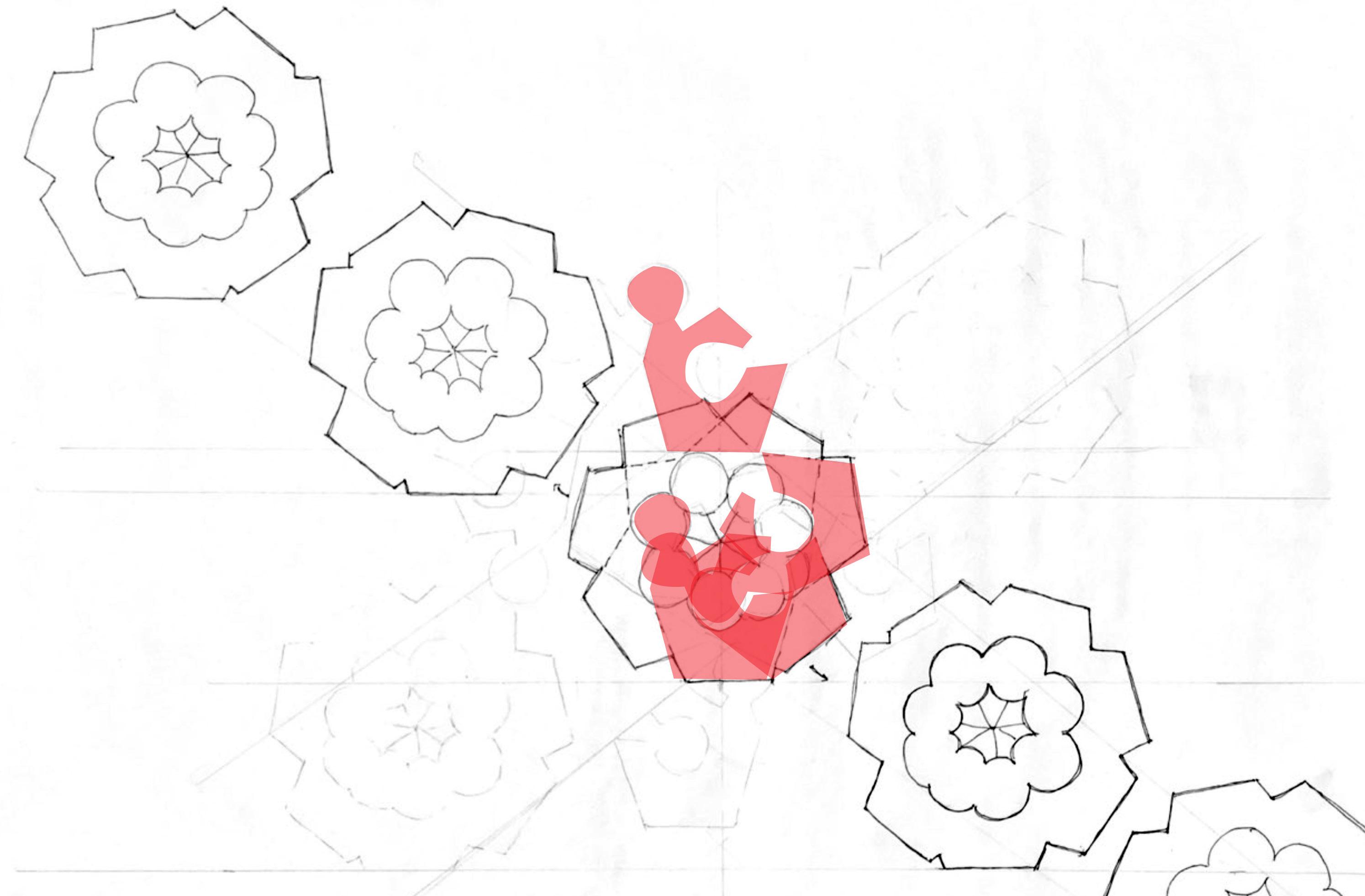

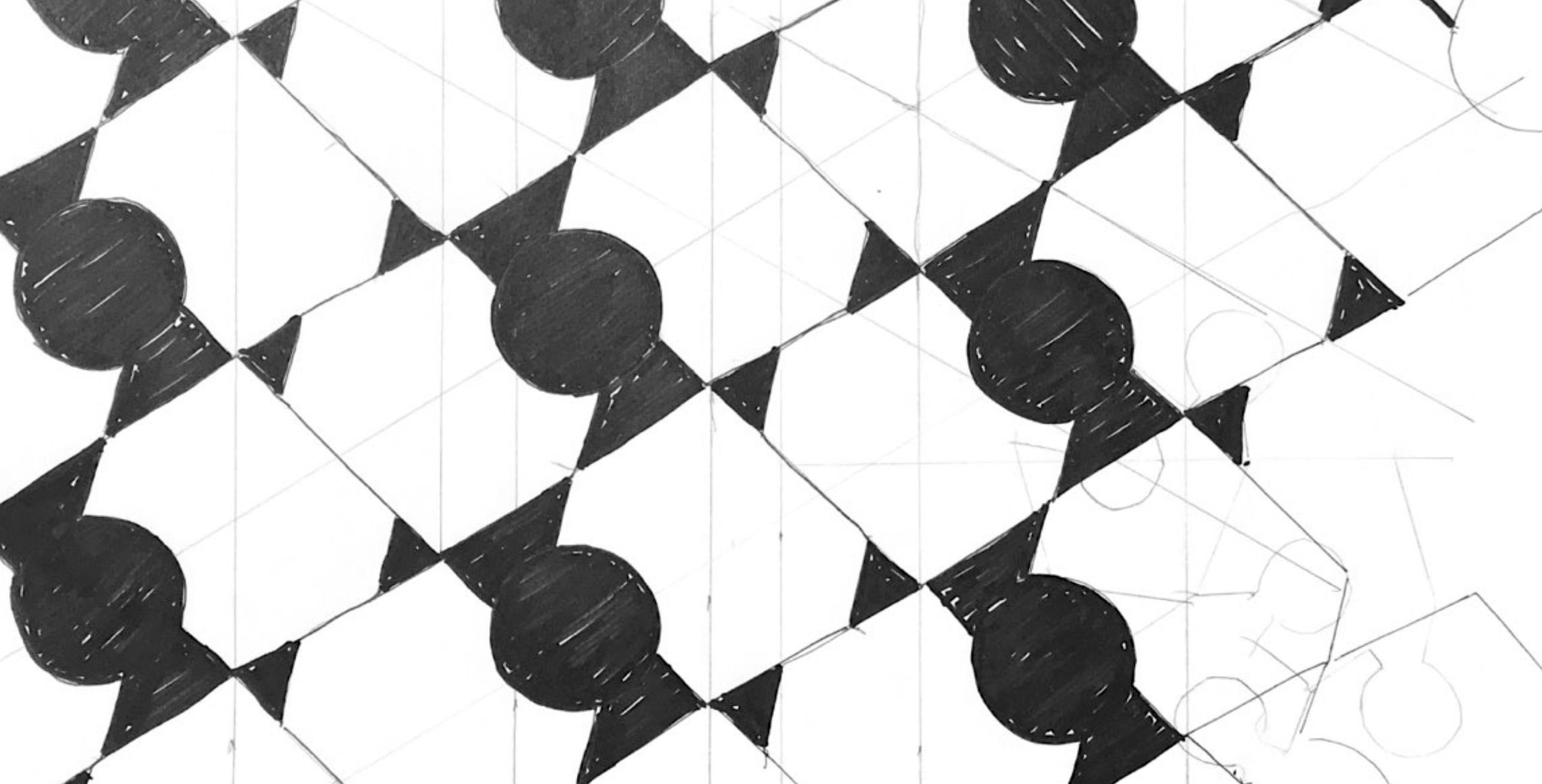

Initial flower shape abandoned for new direction.

A shape based on a hexagon with a cut-out on one side. Various attempts at a 3D version did not yield success.

KEY TAKEAWAYS

Hexagon based pattern still requires additional shapes

Circles and curves are challenging to fold with precision

Uneven hex shape is working

Round cut out is not working T2 REPEATING PATTERN

Tessellation 03

Activity -develop tessellation in 3D

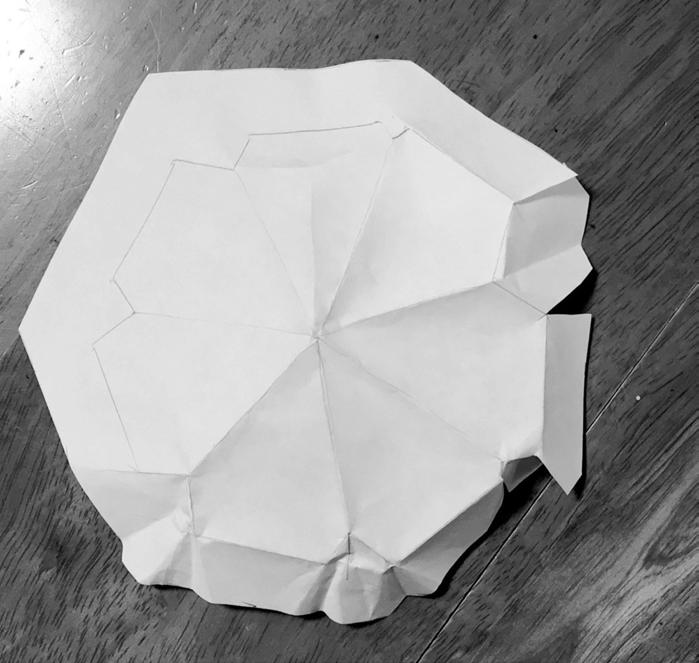

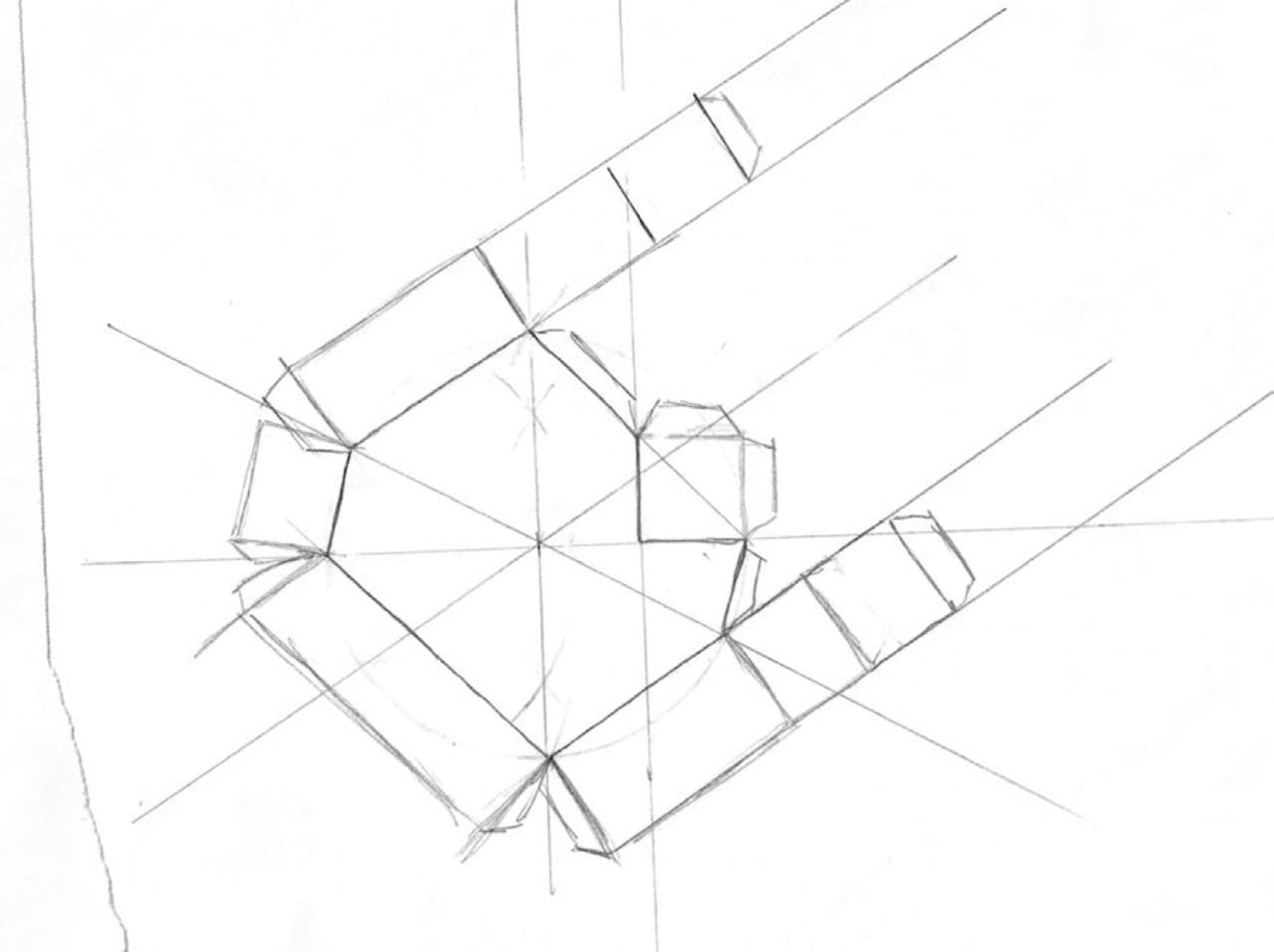

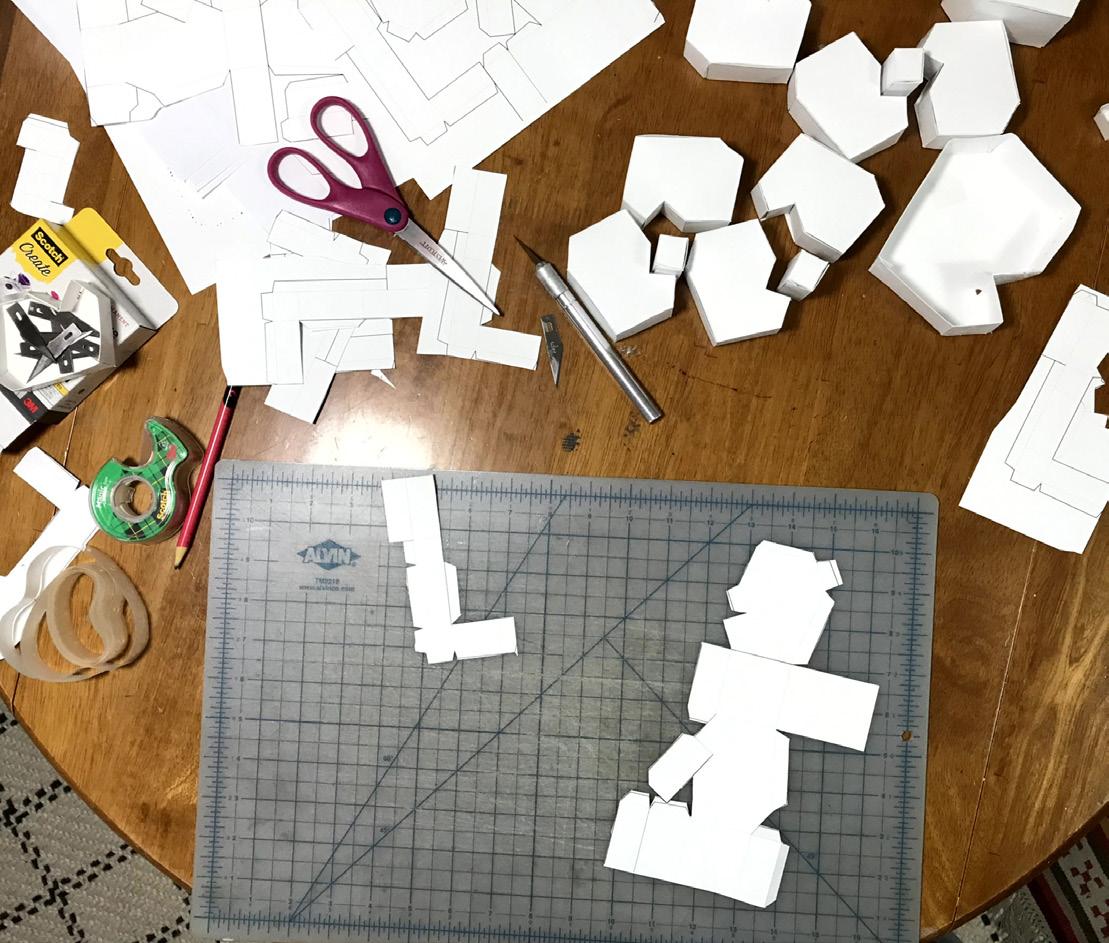

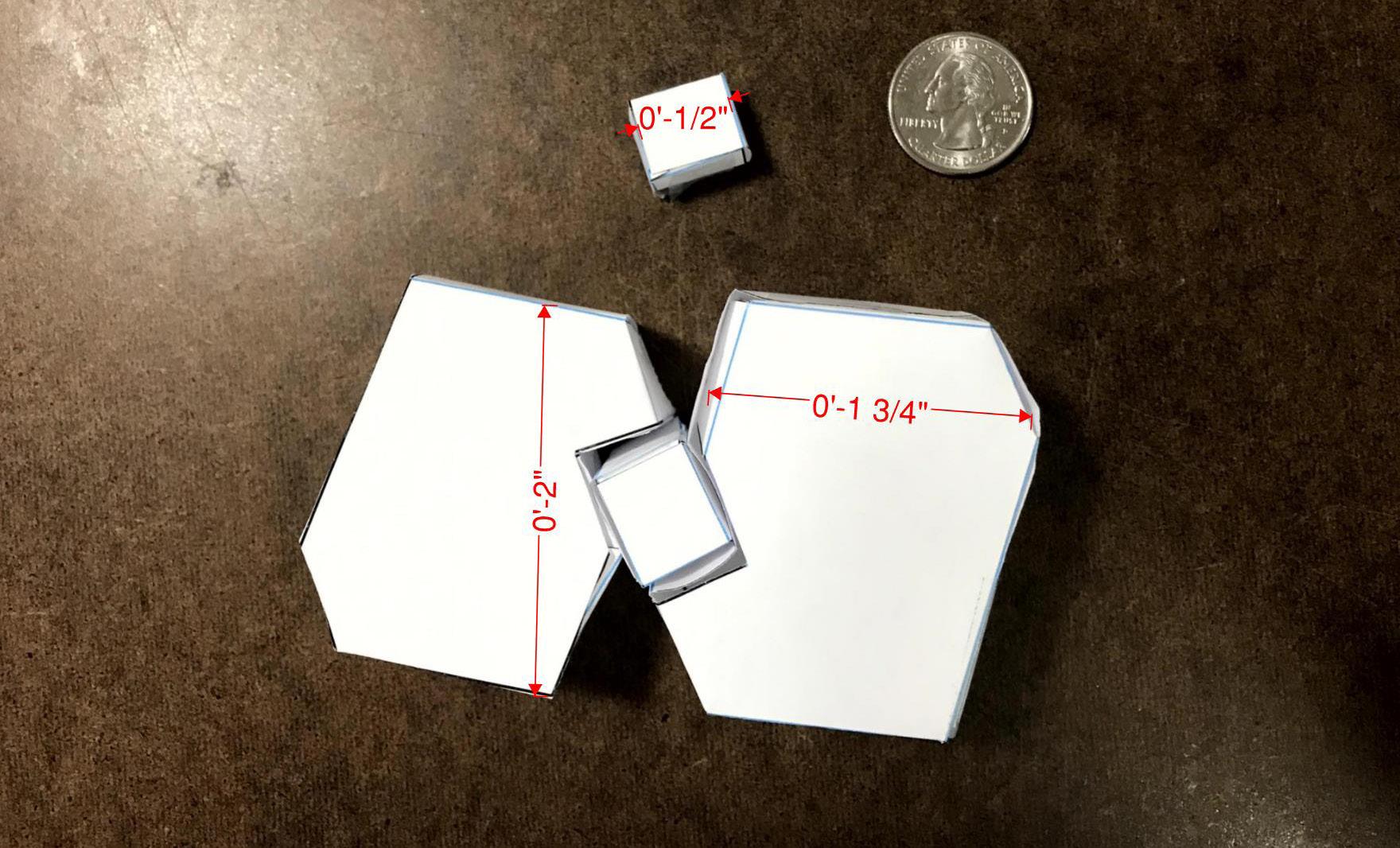

Created a template for scoring and folding to produce a 3D version of my shape. I included tabs to receive glue.

I made a standard version, a taller version of the standard, and a 1.5 scale version. Using tracing paper, I transferred the shape to cardstock and cut them out with an exacto. I enlisted my husband to help me assemble- he was so careful and he used a lot of glue.

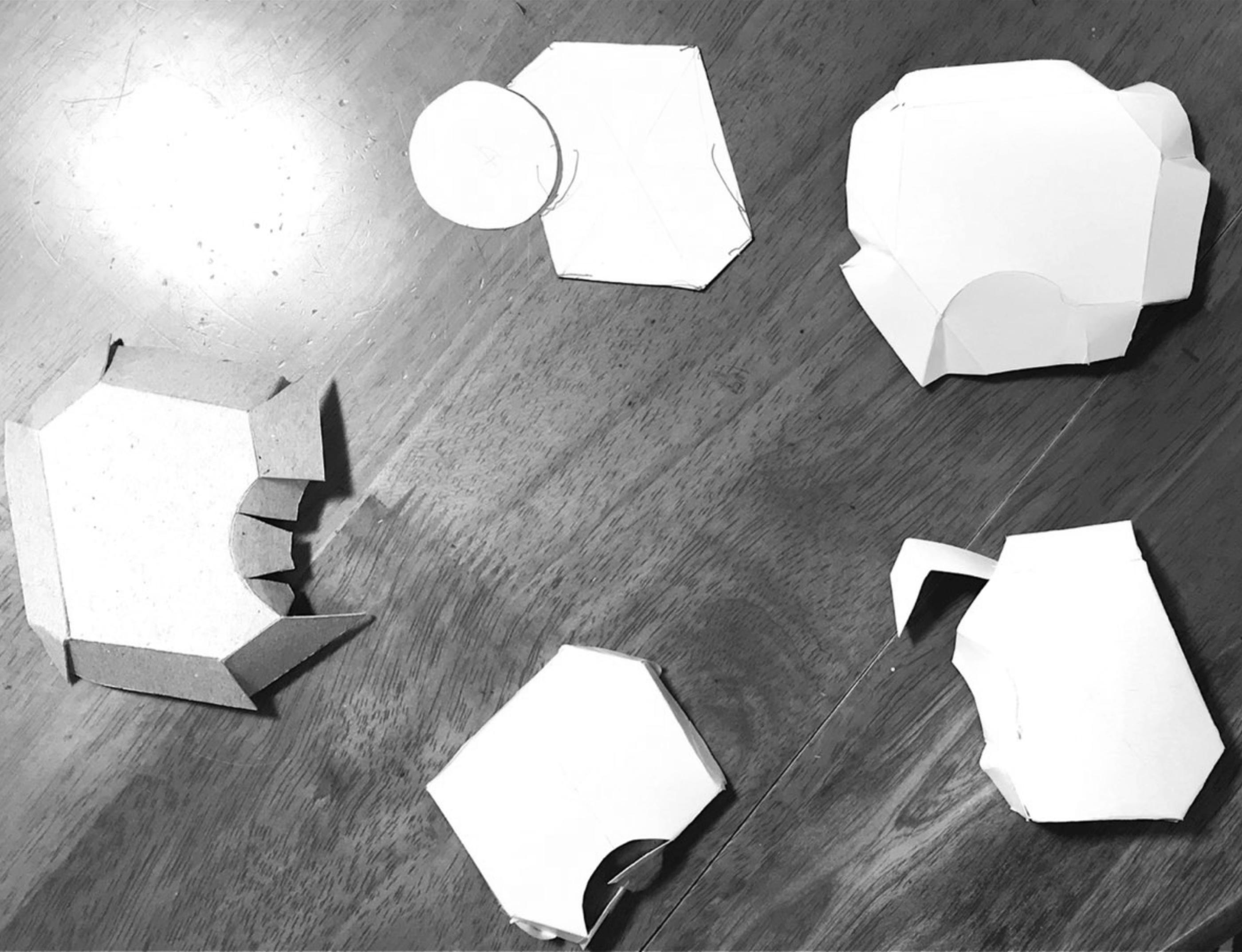

Variations

Activity -develop tessellation in 3D

KEY

TAKE AWAYS

Straight sides fold neatly

Tracing paper not precise enough

1.5 scale pieces disrupted the pattern

Add a bottom plane for stability

Make pieces as large as possible

Add square piece in between

“Box” folding method works

T3 THREE VARIATIONS

Tessellation 03

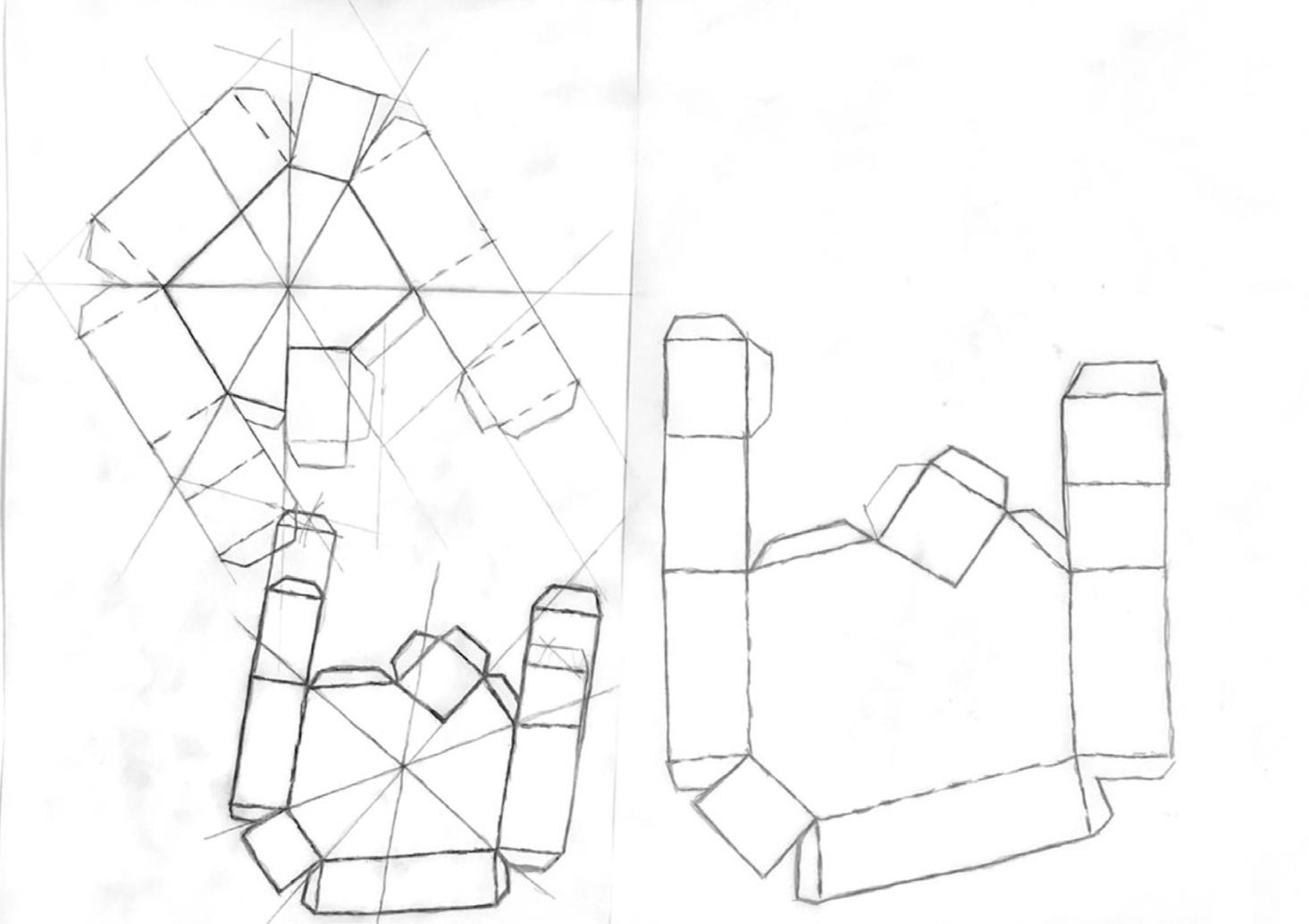

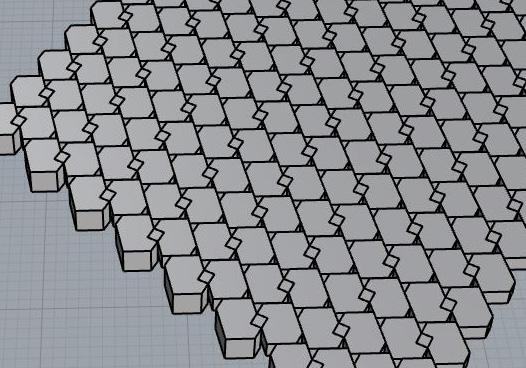

Activity - Refine tessalation in Rhino

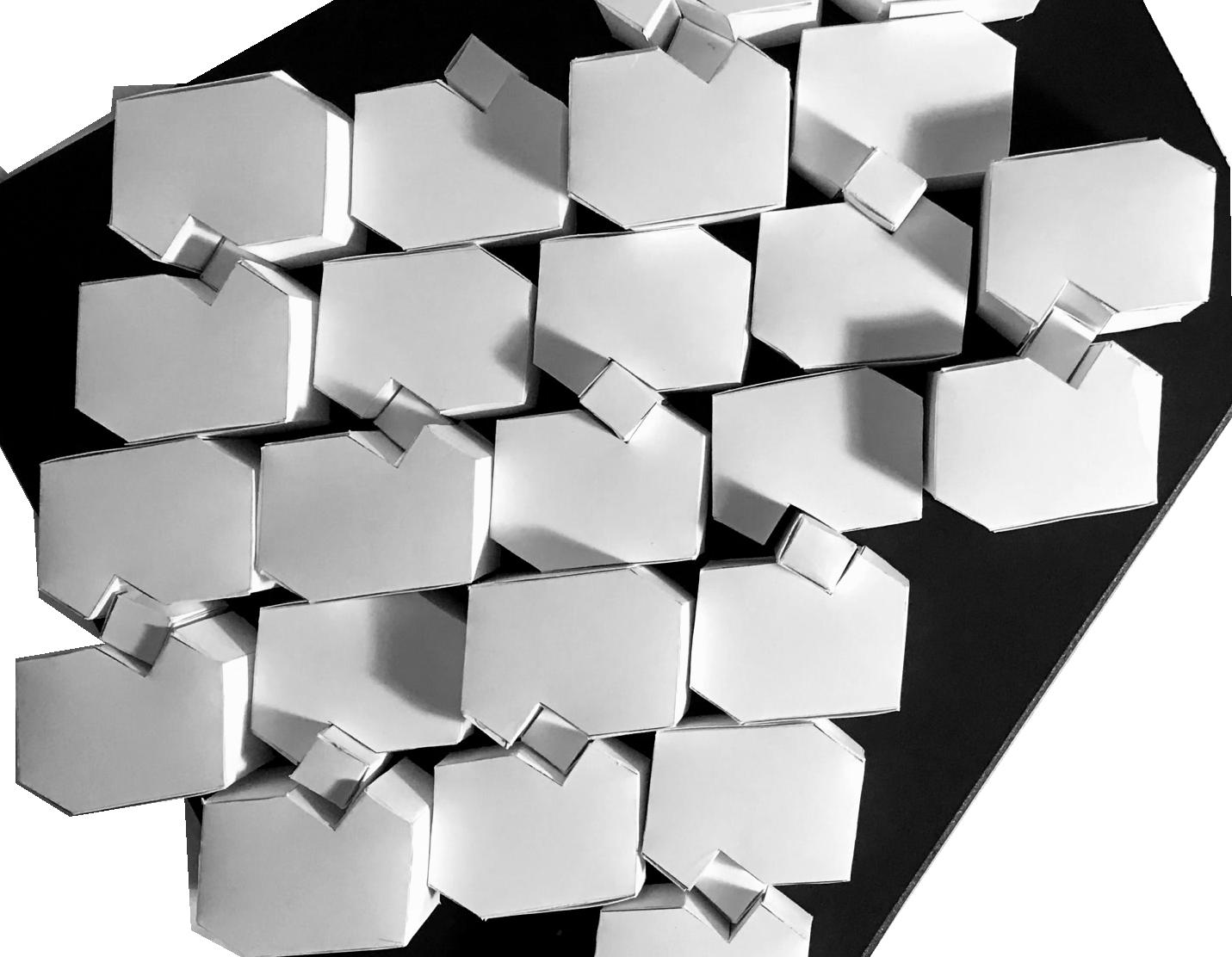

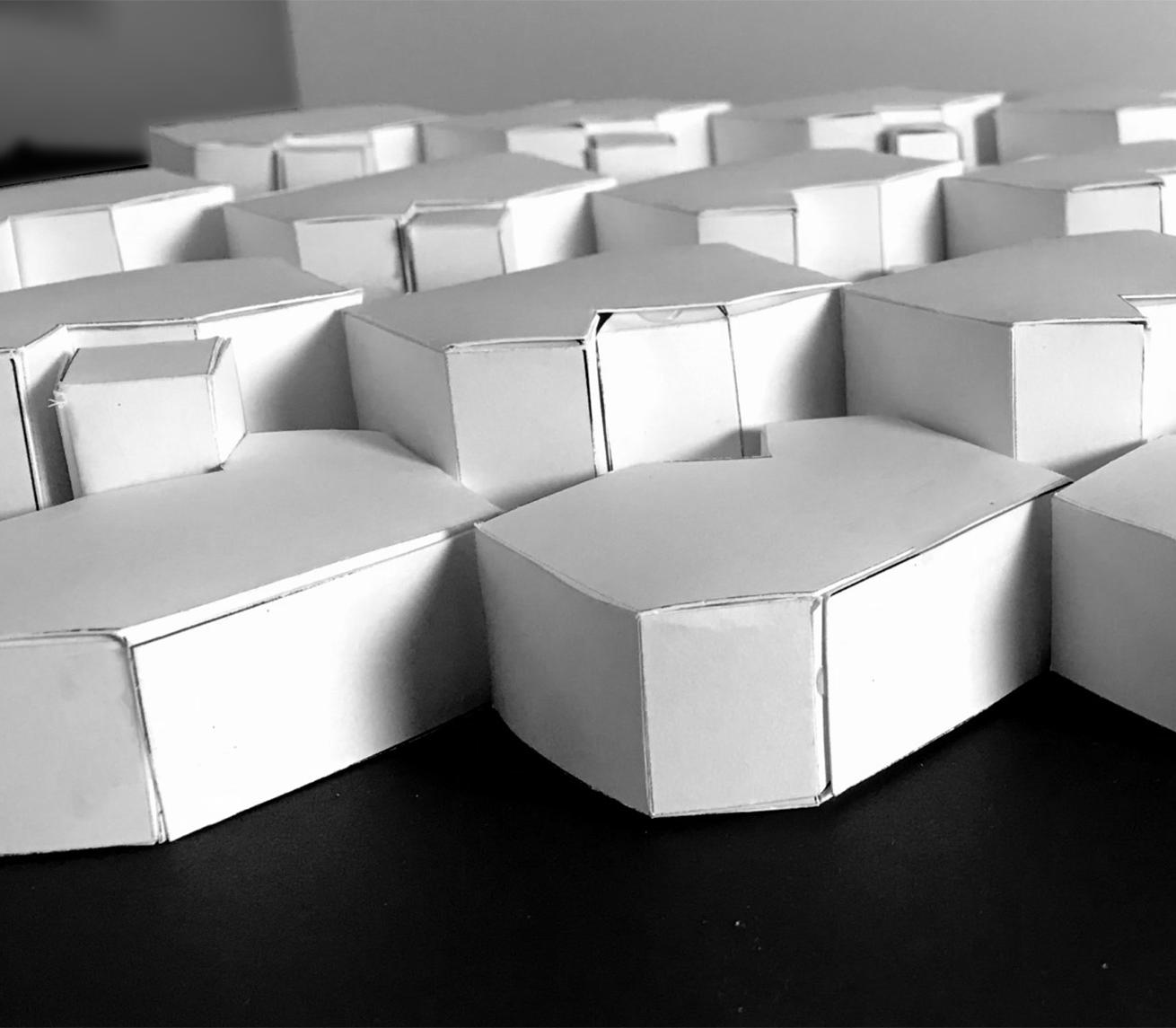

Layout in Rhino provided more precision in the individual units. Assembly was more efficient with printed stencils and some adhesive dots I found in my craft supplies.

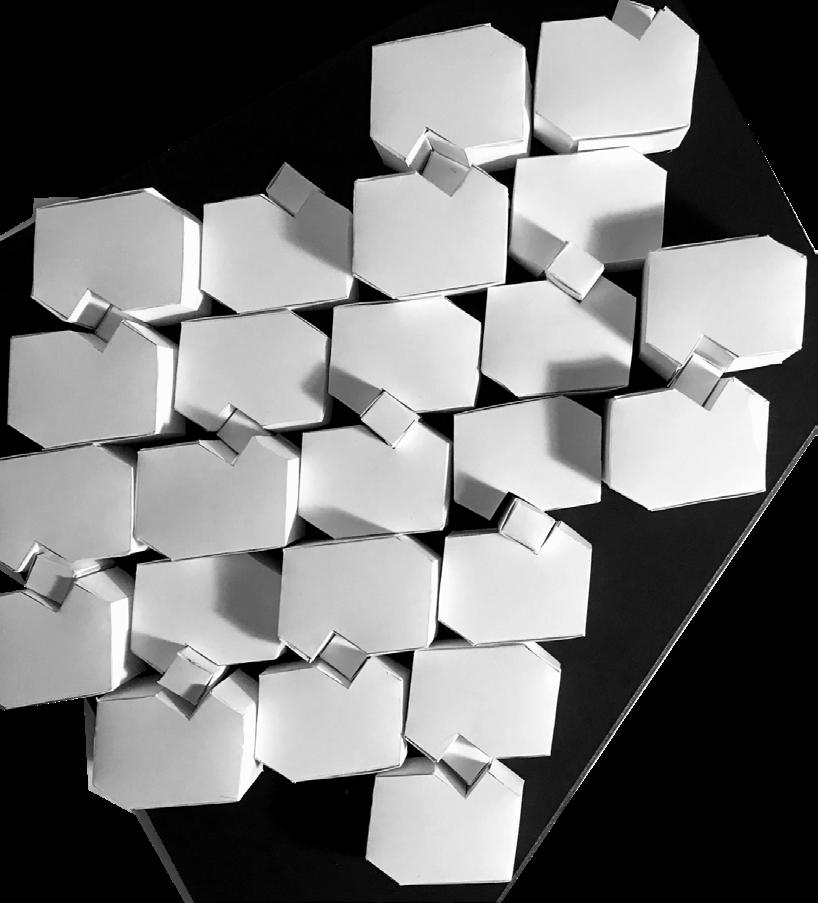

This was a more successful iteration. The combination of the 2 shapes is working and the height variations are enough to look intentional.

KEY TAKEAWAYS:

• Short squares need to be taller

• Bottom plane requires sequenced assembly

• Adhesive dots are handy

• Addition of squares is worthwhile

Unroll command in Rhino produced difficult shapes to fold up in paper

Expolded and reassembled in shapes similar to previous iteration

3D Model Development

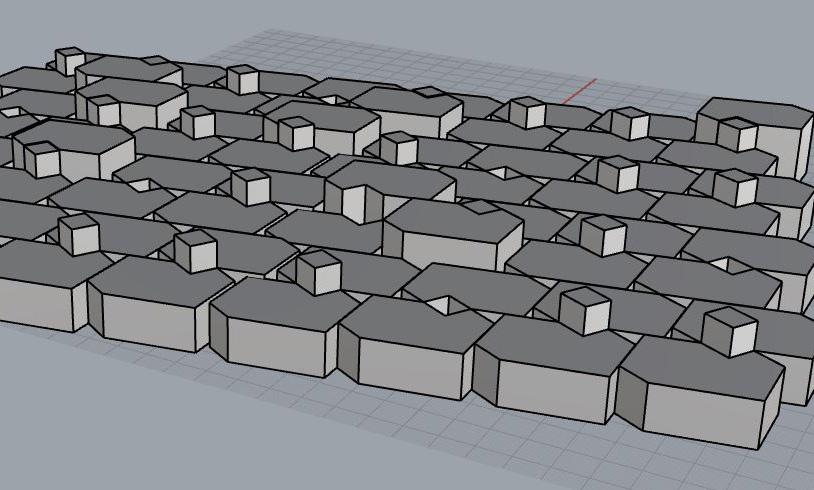

Activity - Refining the pattern in Rhino in preparation for laser cut

Further refine the tessellation in Rhino with greater precision in layout. Tile the design to observe the overall pattern.

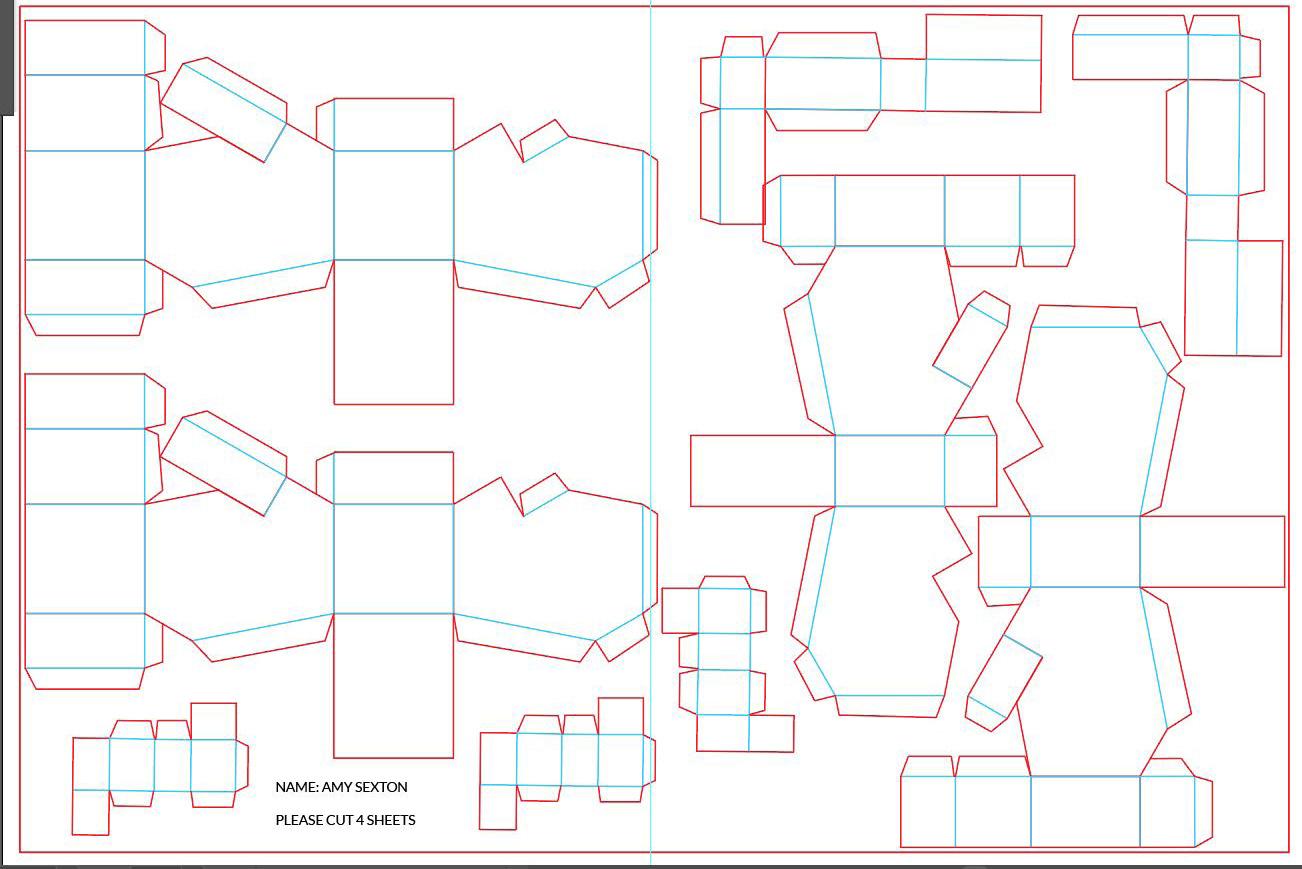

Refine chosen variations. Unroll the solids used in the pattern and refine for constructibility. Export the Rhino file for editing in Illustrator. Edit line styles, add tabs for assembly and verify print size.

KEY TAKEAWAYS:

• Precision improved

• Height variations working

• Scale was so small, assembly was challenging

• Make as large as possible- split on 2 pages

Printer paper is too thin for models- print on thicker stock

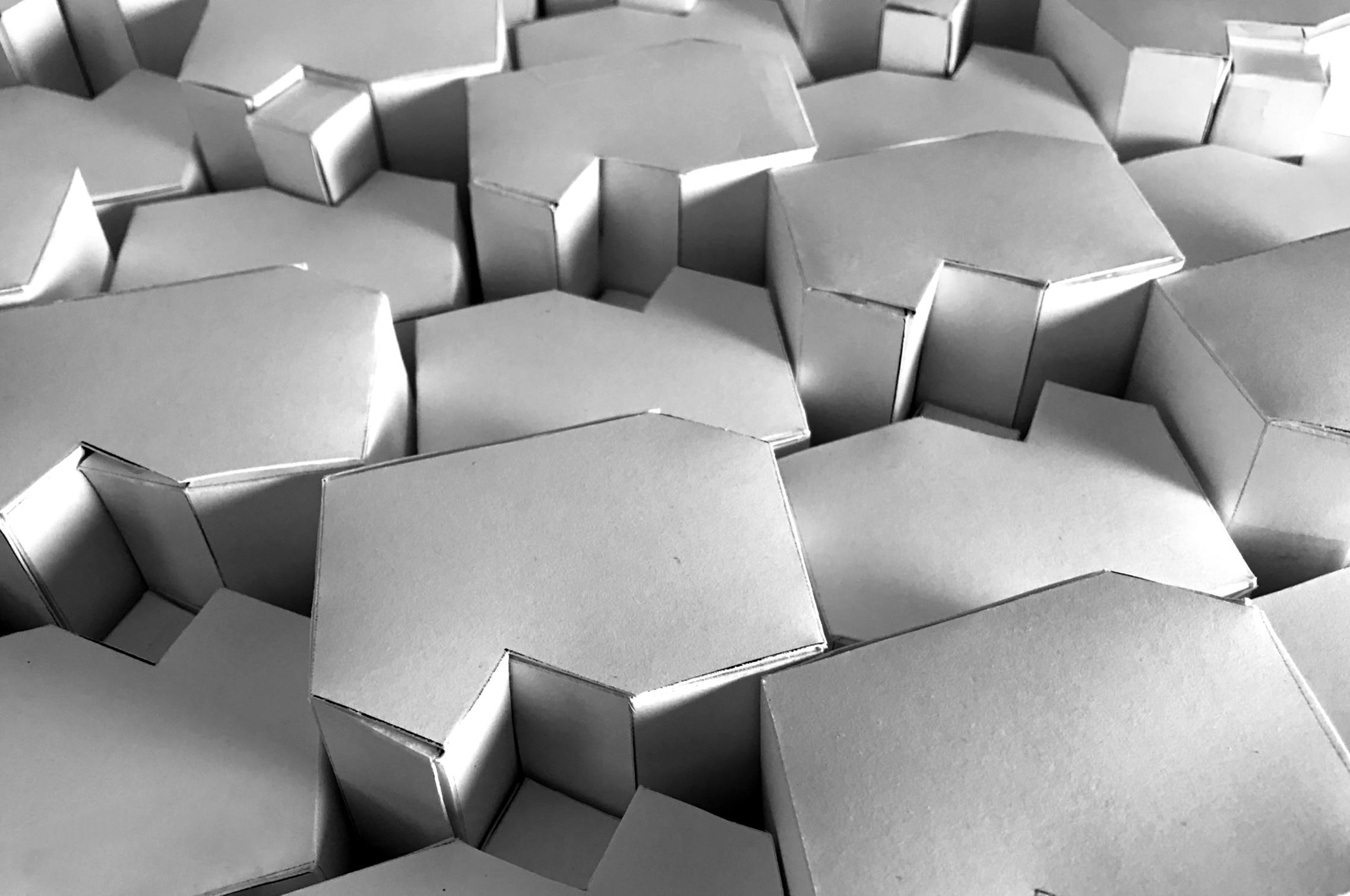

Architectural Wall Finish

Activity - Further refine model, print and assemble

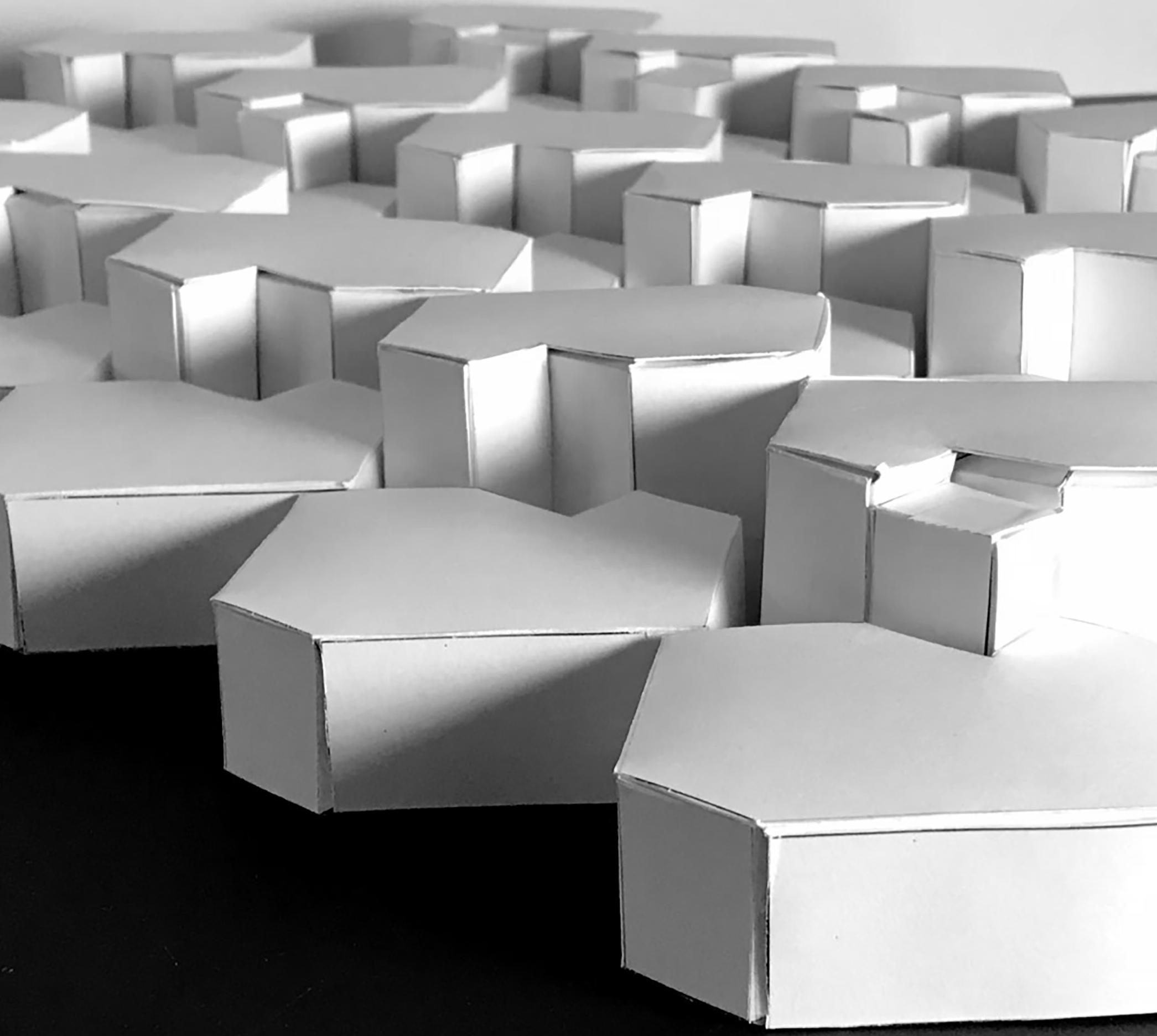

A slight increase in scale to fit on a legal sized sheet and heavier stock were the improvements that had the most impact.

A printed template copied on to cardstock on the copier at work facilitated multiple copies. Each sheet contained 2 hex shapes and 2 cube shapes.

Forms were hand cut and assembled using adhesive dots and tape. The random arrangement of high/low is imntentional to show variation.

KET TAKEAWAYS

Height variation works

Short cubes still too short?

Random arrangement not working

Shadows across the sides are interesting

Laser Cut Preparation

Activity - Edit unrolled Rhino model in Illustrator for laser cutting

Export Rhino file for editing in Illustrator. Edit line styles using color to indicate cut and score locations. Red lines are cut lines and blue lines are score lines.

Print the edited file and assemble to test for constructibility. Add or omit tabs as needed to aid assembly.

KEY TAKEAWAYS

Plenty of tabs for assembly

Cannot fit many on sheet

1 cube for 2 shapes

Illustrator allowed control of line weights, colors

Needed to verify if lines are doubled

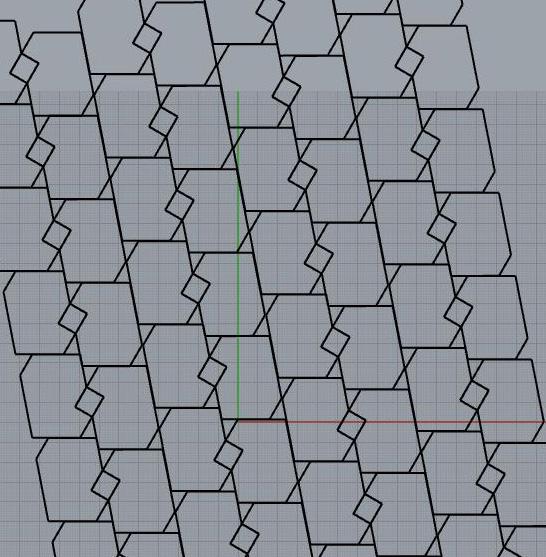

Exploded Tessellation 03.1

Activity - Assemble the laser-cut model pieces

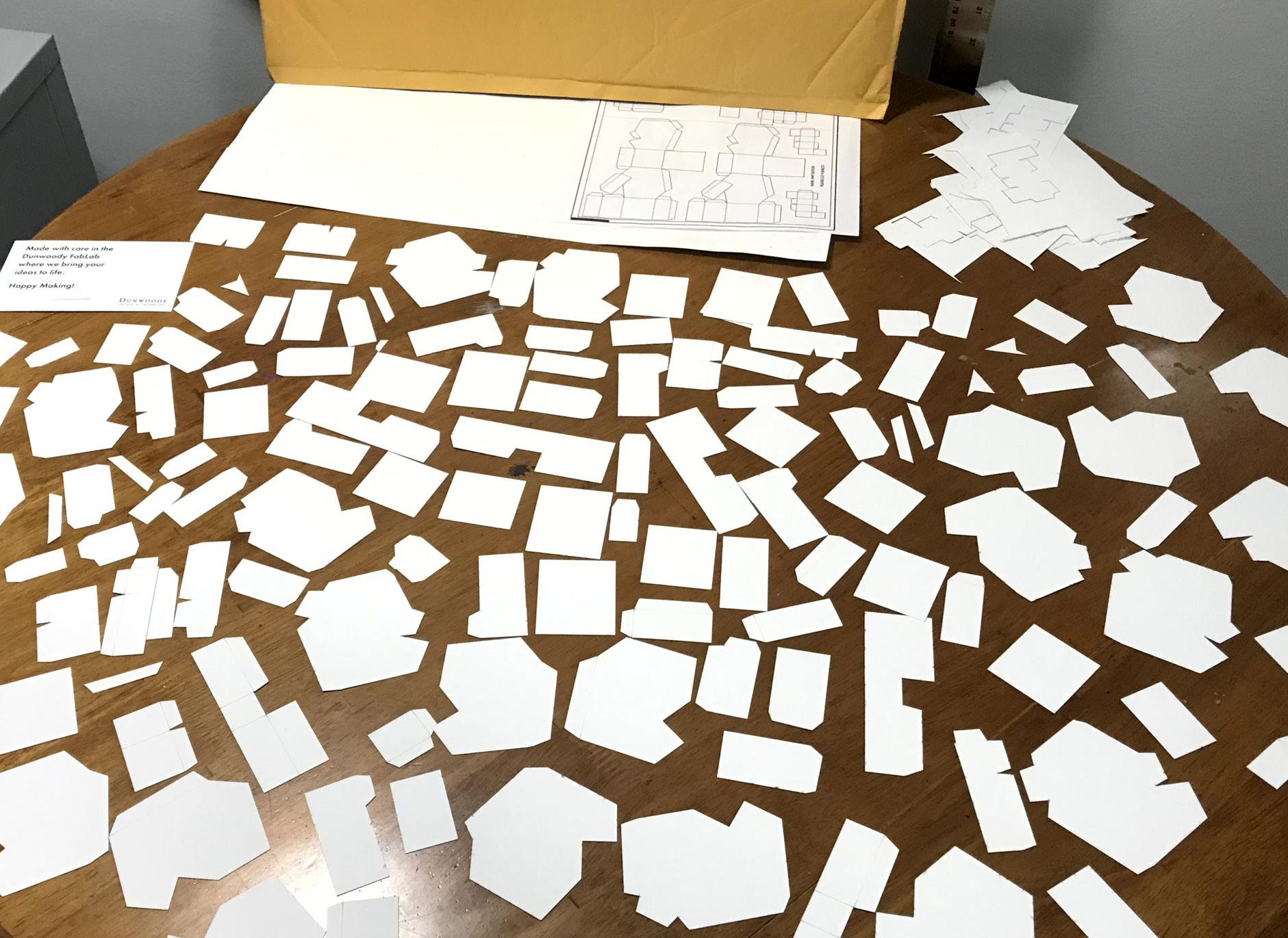

The envelope from the Dunwoody Fabrication lab contained pieces of the forms broken up into separate planes. Some pieces were less than 1/8” w.

In translating the physical model into Rhino and further into Illustrator, some lines were overlaid, resulting in cuts that should have been scores.

Tiny brown marks on the cut pieces suggest the laser going back and forth over certain spots and heating the paper.

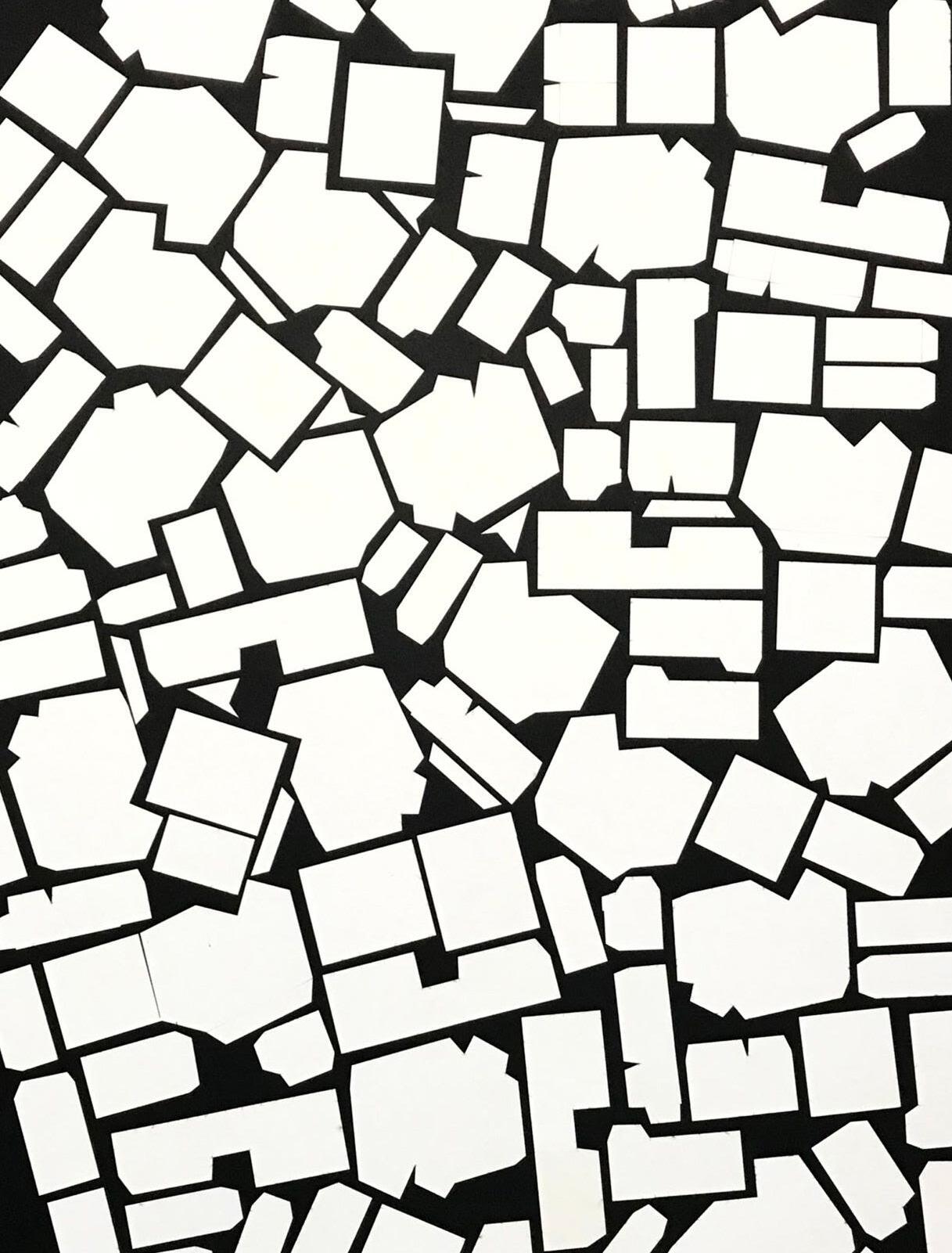

Image at right shows the pieces laid out on a black matboard to form a random pattern.

KEY TAKEAWAYS

Lines were doubled

Impossible to tell which pieces went together

Use pieces in 2D instead Arrange on black background to make an overall pattern

Tile pattern in Photoshop (for wallpaper image)

Final Products

Outcome - Two complementary finishes

The exercise using a tessillation as the inspiration for an architectural wall finish was successful.

Producing numerous iterations throughout the process kept improving and evolving the results.

The 3 dimensional finish incorporates stylized hex shapes with cuboids that repeat with height variations. From certain views, the finish suggests repeating building facades.

The play of shadow and light off the various sides adds visual interest and texture.

The 2 dimensional pattern design was an unexpected outcome. The various cut pieces from the laser cutter laid out on the table looked like terrazo - which lead to the development of the complementary wallpaper and textile pattern.

Below - Exploded Tessellation WallpaperAvailable soon