Sponsor Company: www.international-pharma.com Volume 14 Issue 3 Peer Reviewed Advances in Manufacturing and Processing Impacting Formulation Development Solid Form Services Bridging the Gap between Drug Substance and Drug Product Under Pressure Finding a More Sustainable Future for pMDIs What’s in Store for Aseptic Processing Technologies In 2022 and Beyond advanced liposomal technology

AUTOMATIC ENCAPSULATION MACHINE INTRODUCING THE NCF-45 A highly reliable encapsulator, producing up to 80% higher yields to typical hand-filling or semi-auto encapsulation machines. The smooth operation of the NCF-45 automates your encapsulation process to deliver up to 45,000 capsules per hour, making this Natoli machine ideal for medium-scale production. GMP & cGMP compliant I SCADA network compatible I 21 CFR part 11, CE Certified The solution to product loss. natoli .com

DIRECTOR: Mark A. Barker

BUSINESS DEVELOPMENT: Michael Hossain michael@senglobalcoms.com

EDITORIAL: Virginia Toteva virginia@senglobalcoms.com

DESIGN DIRECTOR: Jana Sukenikova www.fanahshapeless.com

FINANCE DEPARTMENT: Akash Shama accounts@senglobal.com

RESEARCH & CIRCULATION: Jessica Chapman jessica@senglobalcoms.com

COVER IMAGE: iStockphoto ©

PUBLISHED BY: Senglobal Ltd. Unit 5.02, E1 Studios, 7 Whitechapel Road, E1 1DU, United Kingdom

Tel: +44 (0) 2045417569 Email: info@senglobalcoms.com www.international-pharma.com

All rights reserved. No part of this publication may be reproduced, duplicated, stored in any retrieval system or transmitted in any form by any means without prior written permission of the Publishers.

The next issue of IPI will be published in Winter 2022. ISSN No.International Pharmaceutical Industry ISSN 1755-4578.

The opinions and views expressed by the authors in this journal are not necessarily those of the Editor or the Publisher. Please note that although care is taken in the preparation of this publication, the Editor and the Publisher are not responsible for opinions, views, and inaccuracies in the articles. Great care is taken concerning artwork supplied, but the Publisher cannot be held responsible for any loss or damage incurred. This publication is protected by copyright.

2022 Senglobal Ltd./Volume 14 Issue 3 – Autumn – 2022

REGULATORY

MARKETPLACE

08 A Prognosis of Sustainability in the Pharmaceutical Industry

The pharmaceutical sector is a key player in the race for a more sustainable future, and pharmaceutical companies are endeavouring to reduce their carbon footprint, eliminate pollution, conserve water, and use sustainable components. Suppliers and partners for drug delivery products are also working hard to ensure the entire supply chain improves its environmental, social and governance (ESG) standards. Pharmaceutical companies want to demonstrate action, and not just ambition, in moves towards greater sustainability. This Michael Earl at Owen Mumford Ltd will underline the achievements made to date as well as key areas for improvement.

12 Why We Recognise HIV Vaccine Awareness Day

May 18th is dedicated to HIV Vaccine Awareness Day. The significance of this recurrence is embedded in the years of research that have been dedicated to finding a reliable way for individuals to be protected against the virus. Research began shortly after the virus was discovered as being the cause of AIDS, with the first vaccine trial conducted in 1987. To this day, many clinical trials have been carried out, some with breakthrough results, yet no vaccines have been shown to be able to efficiently protect all individuals. Shameet Thakkar at Unimed Procurement Services, gives his expert opinion on the different factors that impact the effective delivery of vaccines and the power of prevention when it comes to global health crises such as HIV.

14 A Business Growth Tool: Patent Claiming Strategies

Developing a pharmaceutical product can take on the order of a decade from research to development, and finally to FDA approval. While Patent Term Extension can restore some time lost due to the regulatory approval process, the traditional strategy of relying on patents based on the drug itself or its general method of use will necessarily start – and stop – the protection clock much earlier. This limits the potential return on investment prior to generic copyists. Tom Irving, et al at Finnegan, discuss how additional strategies can be used to advance business growth with longer and stronger patents.

DRUG DISCOVERY, DEVELOPMENT & DELIVERY

18 Under Pressure: Finding a More Sustainable Future for pMDIs

The transition away from the use of ozone-damaging chlorofluorocarbon (CFC) gases has been one of the major environmental achievements of modern times. Today, hindsight affords us the ability to see how this transition enabled the Earth’s protective ozone layer to heal itself over several decades. An unintended consequence, however, was that the withdrawal of CFCs, ushered in greater use of hydrofluorocarbons, known as F-gases, which introduced their own environmental challenges. While this family of gases might not pose a risk to the atmospheric ozone layer, they were found to contribute to the greenhouse effect. Dr. John N. Pritchard, Dr. Jag Shur and Omar Usmani, explains why F-gases, compared to carbon dioxide (CO2) have a far higher global-warming potential, based on attributes including infrared radiation absorption and atmospheric lifetime.

22 Use of High-field NMR in Covid-19 Drug Development

The Covid-19 NMR Consortium, an international collaboration of NMR experts, is conducting research to determine the ribonucleic acid (RNA) structure of SARS-CoV-2 and its proteins using NMR spectroscopy. One of the consortium’s first discoveries, early in the pandemic, was that a protein within SARS-CoV-2 forms microdroplets with the RNA of the virus. Professor Markus Zweckstetter explains that in subsequent

wwww.international-pharma.com

INTERNATIONAL PHARMACEUTICAL INDUSTRY 1

Contents

06 Editor’s Letter

&

months, this discovery enabled scientists to set up experiments to study the interplay between the RNA and the protein, known as the nucleocapsid protein or N protein.

24 Virtual Screening in Modern Computational Chemistry

Virtual screening is a firmly established computational technique in computational drug design which has saved the pharmaceutical industry billions of dollars since its inception. The structure-based approach involves fitting potential small molecules to a protein target, to generate predicted ligand-protein interaction properties that can significantly reduce chemical search space. Scott Midgley and Mark Mackey at Cresset, discuss the technical and practical considerations for modern virtual screening to ensure projects are delivered efficiently, at optimal cost, and the time to get a drug to market is as short as possible.

30 The Pharma Drug Discovery Industry Should Look Towards Manufacturing as the Blueprint for Automation

Within the manufacturing sector – whether it’s transport, FMCGs, electronics or building materials – a modern approach to automation is already in place. Holistic, flexible, and automated processes are being used to carry out a wide range of tasks like formulation, blending, packaging, and cleaning – and enabling them to take place all at the same time. An industry that can also benefit from automation, is pharmaceutical drug discovery. Zoe Williams at Automata shows that by implementing a similar approach into laboratory spaces as is already happening in manufacturing, it will be possible to increase efficiencies, and ensure that wide scale, effective automation is in place, and for the long term.

CLINICAL & MEDICAL RESEARCH

32 The Use of Predictive Analytics to Improve Quality in Clinical Trials

The impact of poor quality in a clinical trial, often discovered late in the process, can not only add costs to addressing the re-work necessary, but in some cases can lead to rejection from a regulatory authority. Using predictive analytics and scorecards throughout the lifecycle of a study can, in many instances, prevent a quality issue occurring or mitigate the impact in other cases. Rose Kidd at ICON explains the need to apply this approach in Quality Assurance (QA) is becoming more important due to the increasing complexity of clinical research and the increased use of technology to capture patient data remotely, as is the case with decentralised and hybrid trials.

TECHNOLOGY

34 The Transformational Potential of Prioritising Data Today

Covid has spurred regulators towards a more agile and innovationsupporting future, paving the way for new opportunities for all. If life sciences companies embrace a data-driven approach to managing their product data now, they stand to reap the broadest benefits, including more robust and streamlined internal processes, supply continuity, and a level of transparency that really puts the patient first. Frits Stulp and Aida Demneri, partners at Deloitte, explore what’s possible.

36 New Technology and Automation in Labs: Data Risks and Privacy Compliance Issues

Within healthcare and life sciences, data science plays a major role in research and innovation. Improvements in computational speeds, storage capacity and connectivity across different platforms, systems and sampling equipment, mean that laboratories and research facilities are often the testing grounds for the use of advanced analytics including Big Data and Artificial Intelligence. Robert

Grosvenor, Managing Director with Alvarez & Marsal's Disputes and Investigations practice in London, points out that alongside the innovation and efficiency benefits of process automation, integrated workflow management, and collaborative research, comes increased exposure to data risks – some less obvious than others.

38 Why the Right Approach to Data Management Will Enable the Potential of Small-molecule RNA Modifiers as Drug Targets to be Fulfilled

Over the past 5 decades or so, the growing understanding that RNA can influence protein function through routes other than direct translation has opened the prospect of discovering small molecules for tackling diseases in novel ways. Using sources such as the UK Biobank, progress is now being made on using multi-omics data to derive mechanism of action (MoA) insights into the role of small molecules on RNA function, specifically the splice site selection process. However, such approaches are hindered by an approach to data management that is not designed to work with the large amount of interconnected, complex data in RNA splicing experiments. Zachary Pitluk, PhD., at Paradigm4, describes how a vector-based database approach can allow data to be managed, interrogated, processed, and shared much more effectively.

MANUFACTURING

42 Advances in Manufacturing and Processing Impacting Formulation Development

Achieving investigational new drug (IND) approval at an increasingly faster rate than competitor drugs is a widespread desire of biologics developers. This has been further amplified by the need for treatments and vaccines for the COVID-19 pandemic. As a result, the pressure to achieve speed in drug formulation development has escalated to new heights. Heonchang Lim of Samsung Biologics offers insight into the common hurdles that must be overcome in formulation development to meet these various requirements

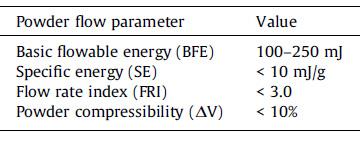

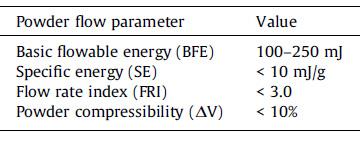

46 Testing Excipients for 3D Printed Pharmaceuticals

3D printing or additive manufacturing (AM) technology has considerable potential to align tablet manufacture more closely with modern requirements and is a growing area of focus for the pharmaceutical industry. A key challenge for pharmaceutical manufacturers looking to exploit 3D printing technology is to determine requirements for excipients. Jamie Clayton at Freeman Technology, consider the role of powder rheometry within this context. Industries leading the way in powder-based AM have already established the importance of powder flowability and the relevance of dynamic powder properties.

54 Flexible Manufacturing Environments are Vital for Today's Potent Oral Dose Forms

Driven by advances in oncology treatments and personalised precision medicine, two trends are converging to increasingly challenge pharma developers and their external contract manufacturing suppliers. Highly potent active pharmaceutical ingredients (HPAPIs) and small-batch manufacturing. Leveraging the end-to-end capabilities of a specialist CDMO can be a route to accessing the small batch facility flexibility to manufacture HPAPI oral products reliably and cost efficiently. Stephane Guisado at Recipharm, explains that with better production and production data control, we can efficiently and safely deliver finished HPAPI drug products to patients and markets.

58 Solid Form Services – Bridging the Gap Between Drug Substance and Drug Product

The solid form of a drug substance has a huge bearing on its formulation as a drug product. In an ideal world, every API would

2 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Contents

nature innovation + our reputation

We are Scientific Protein Laboratories.

over

years of expertise in development and cGMPcompliant manufacturing,

trusted global source for innovation, customization, and the manufacturing of high quality

process

have become

naturally derived pharmaceutical

INTERNATIONAL PHARMACEUTICAL INDUSTRY 3wwww.international-pharma.com

With

40

we

a

API’s and

products. • Custom

development and formulations • Traceable supply chain of natural ingredients • Scale up and cGMP production • Worldwide regulatory support • Decades of experience manufacturing naturally derived materials including heparin and pancreatic enzymes Put our quality team to work on your product solution. Visit us at CPhl Worldwide 2022 in November in Frankfurt. Booth #121A102splpharma.com 700 E. Main Street Waunakee, WI 53597 USA +1 (608) 849-5944 Scientific Protein Laboratories LLC part of Shenzhen Hepalink Pharmaceutical Group Co.,Ltd.

reliably form beautiful, homogeneous crystals on isolation that would be perfect for creating a dosage form with excellent bioavailability. But that in the real world, that is unusual. Abhijeet Sinha at Lonza discusses that significant amount of work is commonly required to bridge the gap between the bulk API that comes out of synthesis and a solid form with all the attributes required by formulation scientists to make a good drug product.

62 What’s in Store for Aseptic Processing Technologies in 2022 and Beyond?

By 2028, the global market for injectable drugs is set to reach $69.13 billion, growing at a CAGR of 8.9%. There are many reasons for this boom in demand, from the drive to develop innovative treatments for rare diseases to heightened demand for faster vaccine rollouts. As a result of this growth, there have been several innovations and techniques adopted to enhance efficiencies across aseptic processes. As these drug products are injected directly into the body and therefore bypass the body’s natural defences, Ben Wylie at ChargePoint explains that parenterals such as injectables and topicals used in ophthalmics require aseptic processing to ensure total sterility.

64 Modular Cleanroom Technologies Have Always Been the Answer to Biopharma’s Global Growth and Flexibility Needs

For the last three decades or more, biopharma’s growth has been nothing short of amazing. From life changing biologics and monoclonal antibodies (MAbs) to mRNA-based and now cell-based immunotherapy medicines to fight viruses, cancers, and previously incurable diseases elevating biopharma’s position to even greater prominence. Mitch Gonzales at AES discusses that regulatory guidance and approvals of Advanced Therapeutic Medicinal Products (ATMPs) also highlight the assimilation of these advancements in the biopharmaceutical sector.

68 PCI Pharma Services – Acquire, Invest, Grow

The biologic market has grown expediently over the past few years, driven not only by the pandemic but also by the increasing demand for innovative therapies, the continued rise in chronic disease areas such as oncology and the loss of patent exclusivity of leading biologic drugs. That has led to rapid growth of aseptic processing, which is expected to reach $24.36 billion by 2031, growing from $10.63 billion in 2020, witnessing a CAGR of 7.9% (2021–2031). Tom McGrath at PCI Pharma Services notes that with the pharmaceutical industry’s growing pipeline of biologics, the need for technically advanced manufacturing and specialized packaging support has grown considerably.

PACKAGING

70 How Product Inspection Drives Quality in Liquid Pharmaceuticals

In liquid pharmaceuticals, the stakes could not be higher. The correct dosage and usage can literally be a matter of life and death. Marco Pelka, Market Manager PCE of Mettler-Toledo, explains how manufacturers and packaging companies in this field can harness product inspection to ensure they produce high-quality liquid pharmaceutical products.

74 SMIs and Soft Mist Nasal Sprays – a Key Defence in the Fight Against the Next Pandemic?

The COVID-19 outbreak has provided several lessons for the pharmaceutical industry to consider for future pandemics. argues that one key takeaway must be to change the way vaccines are administered. Wilbur de Kruijf at at Resyca discusses if soft mist inhalers (SMIs), and soft mist nasal sprays hold the key to improved vaccine delivery?

HEALTH OUTCOMES

76 Choosing and Developing User-friendly Osmotic Laxatives for a More Patient-centric Portfolio

At least 1 in 10 people worldwide suffer from constipation at some point in their lives. It affects people of all ages and has many causes. The symptoms of constipation include pain in the lower abdomen and irregular and painful bowel movements. Laxatives are often needed in addition to dietary changes to treat constipation. There are many laxatives to choose from, each with different mechanisms of action and, consequently, different advantages and disadvantages. Here Dr. Martin Koeberle and Dr. Verena Garsuch at HERMES PHARMA look at the important role of osmotic laxatives and how they overcome many of the side effects and drawbacks of other constipation treatments.

80 Patient-Centric Clinical Trials: Turning Opportunities into Standard Procedures

Over the past year, the industry has heard often, and at length about patient-focused decentralized trials (DCTs), as vendors and some early adopters report their early experiences in an area that is still evolving. It’s important to remember that the industry is still at a very early stage in digital clinical trial development. Truly, patient-focused trials are a goal that we have yet to attain. We still use ePRO and eCOA, as we have for 20 years, only now we talk about these tools as if they are brand new and operate under a decentralized banner. We may be using eConsent, but still have patients come to sites to initiate the process. Richard Young at Veeva Systems analyses the fundamental challenges facing the industry in developing standards for sharing clinical data that will enable digital decentralized trials.

LOGISTICS & SUPPLY CHAIN MANAGEMENT

86 Supply Chain Disruptions Bring Short Notice Changes to Ingredients – But Can Your Labeling and Artwork Management System Cope?

Supply chain and procurement industry figures have called this the ‘era of the shortage’, with widespread disruption to supply chains, raw materials, and ingredient availability. Ingredients substitution is a viable tactic to avoid product shortages or ceasing production, but it unlocks a whole host of operational challenges, argues Bob Tilling at Kallik. With product packaging, labeling and artwork also requiring updates every time an ingredient changes, business leaders must embrace technology to ensure ingredient substitutions do not become a disruptive ‘chop and change’ tactic that overshadows other operations.

4 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Contents

the potential of

INTERNATIONAL PHARMACEUTICAL INDUSTRY 5wwww.international-pharma.com Unlock

active ingredients Contract Manufacturing R&D White Labelling Create your own liposomal supplements Speak to us at stand number 41H53 www.plantacorp.com

Editor's Letter

Pharmaceuticals is one of the world's most researchintensive industries, generating a continuing steam of new products that save lives and raise the quality of life. The discovery of new drugs has evolved over time from a decidedly empirical process to one based to a considerable degree upon fundamental scientific knowledge. Rich linkages have emerged between profit-seeking manufacturers and basic research performers such as universities and national laboratories. The safety and efficacy of new pharmaceutical products are stringently regulated in most industrialized nations, adding to clinical testing costs. Because of high expenditures on research, development, and clinical testing and because new products, once proven, might be imitated easily, patent protection is unusually important. The extension of patent protection to third-world nations under Uruguay Round Treaty mandates has precipitated vigorous policy debates. Patents, first-mover advantages, and the lack of good substitutes for significant new drugs often give rise to substantial monopoly power, against which many national governments have counterpoised a diverse panoply of price control mechanisms. When patents expire, however, generic substitutes often introduce vigorous price competition. The extent to which generics capture market share from the branded original drugs depends upon government regulatory policies, the reimbursement strategies of health care insurers, and the organization of health care provider institutions.

Rising research and development (R&D) expenditures by pharmaceutical companies are, in part, a consequence of changing industry structure, particularly the rise of the biotechnology sector. The creation of a market for biomedical science and increased vertical competition within the industry are likely to spur innovation and raise productivity, but they also could induce socially wasteful spending and weaken academic science. With innovation increasingly dependent on financially vulnerable firms and complex

Editorial Advisory Board

Bakhyt Sarymsakova, Head of Department of International Cooperation, National Research, Center of MCH, Astana, Kazakhstan

Catherine Lund, Vice Chairman, OnQ Consulting

Deborah A. Komlos, Principal Content Writer, Clarivate

Diana L. Anderson, Ph.D president and CEO of D. Anderson & Company

Franz Buchholzer, Director Regulatory Operations worldwide, PharmaNet development Group

Francis Crawley. Executive Director of the Good Clinical Practice Alliance – Europe (GCPA) and a World Health Organization (WHO) Expert in ethics

Rick Turner, Senior Scientific Director, Quintiles Cardiac Safety Services & Affiliate Clinical Associate Professor, University of Florida College of Pharmacy

contractual arrangements, R&D investment might be becoming more sensitive to price controls or other cost containment measures.

The pharmaceutical industry has produced many drugs that have benefited man. Political frameworks designed to govern the industry must maintain these benefits. However, regulation needs to be sufficiently robust to protect public health from drugs that are unsafe, ineffective, or unnecessary. The extent of industry influence over drug regulation, at the expense of other interested parties, suggests that the current system could be more robust.

One of the key influences on government is environmental policies.

In this edition Michael Earl at Owen Mumford Ltd gives a “Prognosis of Sustainability in the Pharmaceutical Industry” Pharmaceutical companies want to demonstrate action, and not just ambition, in moves towards greater sustainability. This will underline the achievements made to date as well as key areas for improvement, and Dr. John N. Pritchard, Dr. Jag Shur and Omar Usmani, explains why F-gases, compared to carbon dioxide

(CO2) have a far higher global-warming potential, based on attributes including infrared radiation absorption and atmospheric lifetime.

Heonchang Lim of Samsung Biologics within his article “Advances in Manufacturing and Processing Impacting Formulation Development” offers insight into the common hurdles that must be overcome in formulation development to meet these various requirements.

Our very popular “Health Outcomes” section features articles by Dr. Martin Koeberle and Dr. Verena Garsuch at HERMES PHARMA who looks at the important role of osmotic laxatives and how they overcome many of the side effects and drawbacks of other constipation treatments, and Richard Young at Veeva Systems analyses the fundamental challenges facing the industry in developing standards for sharing clinical data that will enable digital decentralized trials.

I hope you all enjoy this edition of IPI, and I look forward to meeting most of you at CPHI in Frankfurt.

Georg Mathis Founder and Managing Director, Appletree AG

Jagdish Unni, Vice President – Beroe Risk and Industry Delivery Lead – Healthcare, Beroe Inc.

Jeffrey Litwin, M.D., F.A.C.C. Executive Vice President and Chief Medical Officer of ERT

Jeffrey W. Sherman, Chief Medical Officer and Senior Vice President, IDM Pharma

Jim James DeSantihas, Chief Executive Officer, PharmaVigilant

Mark Goldberg, Chief Operating Officer, PAREXEL International Corporation

Maha Al-Farhan, Chair of the GCC Chapter of the ACRP

Stanley Tam, General Manager, Eurofins MEDINET

(Singapore, Shanghai)

Steve Heath, Head of EMEA – Medidata Solutions, Inc

Patrice Hugo, Chief Scientific Officer, Clearstone Central Laboratories

Heinrich Klech, Professor of Medicine, CEO and Executive Vice President, Vienna School of Clinical Research

Robert Reekie, Snr. Executive Vice President Operations, Europe, Asia-Pacific at PharmaNet Development Group

Sanjiv Kanwar, Managing Director, Polaris BioPharma Consulting

Stefan Astrom, Founder and CEO of Astrom Research International HB

T S Jaishankar, Managing Director, QUEST Life Sciences

6 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2

Virginia Toteva, Editorial Manager – IPI

wel-screen

A Prognosis of Sustainability in the Pharmaceutical Industry

The pharmaceutical sector is a key player in the race for a more sustainable future, and pharmaceutical companies are endeavouring to reduce their carbon footprint, eliminate pollution, conserve water, and use sustainable components. Suppliers and partners for drug delivery products are also working hard to ensure the entire supply chain improves its environmental, social and governance (ESG) standards. ESG credentials are becoming essential to pharmaceutical tenders at every step of the supply chain. Pharmaceutical companies want to demonstrate action, and not just ambition, in moves towards greater sustainability, to customers, policymakers and healthcare system stakeholders.

As a key delivery device partner for pharma companies, Owen Mumford Pharmaceutical Services has reviewed the current state of play on ESG compliance in the pharmaceutical industry among the top 25 companies reporting ESG scores. This article will underline the achievements made to date as well as key areas for improvement.

Outlining Targets

To really understand the progress of the pharmaceutical industry in its drive towards sustainability, it is valuable to begin by identifying what success would look like. Reports frequently focus on the same four main goals for achieving sustainability:

1. Reducing carbon emissions by improving energy use and setting net-zero targets.

2. Improving water sustainability by reducing manufacturing consumption and eliminating pharmaceutical waste from the water system.

3. Improving waste management by cutting down on excess packaging and more effectively recovering and disposing of used products.

4. Becoming more sustainable by design, through green chemistry initiatives,

chemical recovery and creating reuseable delivery devices.

The analysis focuses on ESG targets specific to the pharmaceutical sector and its suppliers. Additionally, the report not only focuses on where ESG policies have been put in place, but also where corporations have publicly set themselves concrete targets.

Areas of Progress

The pharmaceutical industry has begun to make significant strides towards a more sustainable future, with the October 2021 Climate Reporting Performance report from Ecoact featuring three biopharmaceutical giants in the global top twenty companies for sustainability.1 As an industry, biopharma performed considerably better than many other industries in each of the key categories, which included ambition and targets, governance and achievement. We can see important improvements in four areas in particular. With regards to energy, water, waste, and air emissions there have been valuable steps taken across the industry.

Air emissions are the area where pharma companies are most focused on pursuing targets. Close to 70% of pharma companies have specific targets for lowering air emissions, focusing both on reducing carbon emissions and gaseous pollutants. Typical pollutants to be filtered are acid gases, dust and aerosols, pharmaceutical ‘actives’ and volatile organic compounds which can all cause harmful damage to the environment.

Secondly, the energy intensive sector has made steps to reduce usage. Most energy policies focus on a combination of renewable energy sources, self-generation and increasing energy efficiency by reducing energy requirements in the manufacturing process.2 Reducing energy use in the manufacturing process can be either production line or industrial building focused – in both cases, savings of 25% are typical and are often much higher.3

Next, moves to improve water usage not only focus on reducing consumption but also on cleaning and reprocessing water

– either for re use or putting back into the water grid. One international giant aims to achieve 100% water neutrality by 2025, meaning all wastewater will be recycled, re-used and captured from rainwater. Our review shows that around 50% of pharma companies have already set hard targets in this category.

Lastly, progress on waste is trending in the right direction with goals being set by a large number of companies. Over a quarter of pharmaceutical companies have already set targets to reduce their waste emissions by at least 25%. Companies are trying to avoid reliance on landfills for waste disposal, while others pursue a zero-waste approach. Moreover, commercial incentives may become a factor as waste becomes more expensive to dispose of.4

To address the controversial subject of disposable plastic components in drug delivery devices, alternatives such as degradable plastics are being debated and scrutinised, but for now immediate progress is being made by reducing the number of disposable components. An example of sustainable design is Auto which will help partners reduce plastic waste within their supply chain.

Areas for Improvement

While there are certainly improvements being made in the industry, areas remain that need change; the statistics can hide underlying issues that need addressing. For example, although the industry as a whole achieves an ESG score of 61% in the Ecoact review considered earlier – well above the all-industries average of 53% –the performance of individual companies varies massively.

Our study uncovered a variance of 40% between top performers and those who have a way to go. The industry must focus on narrowing this band of variance before big pharma as a whole can be considered firmly on the path to sustainability. Furthermore, it appears that neither geography nor size are important to whether a corporation has begun to make improvements. Top performing small firms are not far behind the most committed multi-nationals – implying

8 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Regulatory & Marketplace

Versatile design intuitive delivery

INTERNATIONAL PHARMACEUTICAL INDUSTRY 9wwww.international-pharma.com Want to know more? Find out more about our new innovative Aidaptus® auto-injector by scanning the QR code or visiting ompharmaservices.com/ipi-sept2022 *In addition to an air bubble and overfill Aidaptus® is a registered trademark of Owen Mumford Ltd, ©️2022 OMPS/ipi/ad/ob/0922 Available now Now in collaboration with Your fill volume may change, with Aidaptus® auto-adjust plunger technology your auto-injector doesn’t need to 0.3mL - 1mL* 0.5mL - 2.0mL* Accommodates both 1mL and 2.25mL glass syringes in the same device

Auto-adjust plunger technology Auto-adjust plunger technology 1mL 2.25mL

&

that corporate will and commitment are as important as bigger budgets in the race to improve ESG scores.

As well as the large differential in ESG scores between the best and worst performing firms in the pharmaceutical industries, there are some areas where improvement is required industry wide. One such area of concern is with contamination. While 84% of companies have a policy on Pharmaceuticals in the Environment (PiE) and 36% have a policy on the related issue of Anti-Microbial Resistance (AMR) there are very few concrete targets in these areas.

The AMR Alliance, an industry initiative to address anti-microbial resistances, states “Manufacturing emissions from both the production of active pharmaceutical ingredients (APIs) and their formulation into drugs is another source of environmental emissions... In countries where discharges are not well controlled some studies have found very high levels of active residues in the discharge vicinity of antibiotic factories.”5 Various studies share these findings, which is just one of several in safeguarding the environment from pharmaceutical contamination.6 Clearly there is much work to be done in the area of contamination.

Another area where the lack of progress is concerning is packaging. This is a much

less complex area in which to take action. In many other industries, we have seen efforts to alter packaging in the distribution phase in particular. While 76% of pharma companies have policies on packaging, only 13% have actually set concrete targets. Packaging could be converted to sustainable alternatives – where clinically acceptable – and reductions in weight and packing efficiency could help to reduce the resources used in the shipping process.

A few of the leading companies have set themselves specific targets – focussing heavily on converting from plastic to sustainable paper packaging. They have begun to assess where replacements bring the biggest net environmental gain and where original packaging should be retained. This area should begin to gain traction within the rest of the industry within the next few years and large-scale changes should begin to take place.

Conclusions

While a variety of studies have confirmed that the pharmaceutical industry is on the right track with regard to sustainability –and performing better than other industries – there is certainly still work to be done. Standards need to be adopted throughout the supply chain of the pharmaceutical industry to meet scope 3 emissions if further progress is to be made. A collaborative approach

between pharma companies and their suppliers, or between suppliers themselves, could help to speed up the rate of change and facilitate action. Areas such as contamination and packaging need concrete targets for real progress to be made; those that being to formulate initiatives now will pave the way for other businesses to follow suit.

REFERENCES

1. Ecoact, The Climate Reporting Performance of the DOW 30, EURO STOXX 50 and FTSE 100: 11th edition, 2021 https://info.eco-act.com/en/ climate-reporting-performance-research-2021

2. Fierce Pharma, The energy switch: Big Pharma harnesses sun, wind and water in quest for a low-carbon future, 15 October 2021 https://www. fiercepharma.com/pharma/solar-wind-waterpharma-go-planet-astrazeneca-novo-nordisknovartis-and-amgen-talk-renewable

3. PwC, Towards a Net Zero future in pharma – the role of continuous manufacturing, 17 February 2021 https://pwc.blogs.com/health_ matters/2021/02/towards-a-net-zero-future-inpharma-the-role-of-continuous-manufacturing. html%20

4. Let’s Recycle.com, Waste bills to rise as costs jump, 28th January 2020, https://www. letsrecycle.com/news/waste-bills-to-rise-ascosts-jump/

5. AMR Industry Alliance, Making antibiotics responsibly: A common manufacturing framework to tackle antimicrobial resistance https://www.amrindustryalliance.org/wpcontent/uploads/2019/11/Making-antibioticsresponsibly_A-common-manufacturingframework-to-tackle-AMR.pdf

6. See, for instance, Pharmaceutical waste and antimicrobial resistance, Ahmad, Akram et al. The Lancet Infectious Diseases, Volume 17, Issue 6, 578–579 https://www.thelancet.com/journals/ laninf/article/PIIS1473-3099(17)30268-2/fulltext

Michael Earl

Michael Earl joined Owen Mumford as Director of Pharmaceutical Services in November 2020. He was previously the Commercial VP at Bespak, leading the commercial team there to drive growth in their substantial medical devices business. Prior to that, he worked for a number of pharma, biotech and device companies. In a career spanning 35 years, he has been responsible for all aspects and stages of drug and device development and commercialisation. Michael has also completed a substantial number of commercial, licensing and M&A transactions.

10 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2

Regulatory

Marketplace

and Sterile

THE PCI WAY

www.pci.com talkfuture@pci.com YOUR BRIDGE BETWEEN LIFE-CHANGING THERAPIES AND PATIENTS OUR END-TO-END BIOLOGIC SOLUTIONS INCLUDE: • Sterile Formulation & Lyophilization Cycle Development • Lyophilization and Sterile Fill-Finish Manufacturing (including Complex Formulations) • Analytical Support • Clinical & Commercial Labeling & Packaging • Refrigerated/Frozen Storage & Distribution Lyophilization

Manufacturing

Specialist expertise and experience in driving development and connecting commercialization of sterile and lyophilized life-changing therapies, delivering peace of mind for our customers.

Why We Recognise HIV Vaccine Awareness Day

May 18th is dedicated to HIV Vaccine Awareness Day. The significance of this recurrence is embedded in the years of research that have been dedicated to finding a reliable way for individuals to be protected against the virus.

Research began shortly after the virus was discovered as being the cause of AIDS, with the first vaccine trial being conducted in 1987.1 To this day, many clinical trials have been carried out, some with breakthrough results, yet no vaccines have been shown to be able to efficiently protect all individuals.

While people worldwide are infected with HIV, those living in sub-Saharan Africa have the highest rates with Eswatini, Lesotho and Botswana being the three countries with the highest prevalence of the virus almost consistently between 2000 and 2020.2

Without a reliable vaccine being available, reducing the risk of transmission by providing assistance and resources to countries who struggle with accessing them should therefore be the main point of focus in the battle against HIV.

In this piece Shameet Thakkar, founder and managing director of leading healthcare procurement services organisation Unimed, gives his expert opinion on the different factors that impact the effective delivery of vaccines and the power of prevention when

it comes to global health crises such as HIV.

The Importance of Prevention

What the above stats tell us is that there are deep-rooted issues with individuals in certain countries being unable to limit their exposure to the risk factors that can lead to becoming infected with HIV.

In this regard, Shameet aims to highlights the importance of prevention. He says:

“What we really need to focus on is developing reliable preventative measures and services. By helping more individuals access vaccines and other forms of prevention such as contraception, we can solve the problem at the root and efficiently assist individuals affected by life-threatening illnesses.

What many don’t realise is that there is a lot that goes into supplying vaccines to populations or groups of individuals. There is an entire supply chain at the forefront of vaccine operations, which must provide the right equipment at the right time in order to be effective.” he continues.

Vaccines therefore play a fundamental role in prevention, but vaccine projects require a lot more than just syringes and the vaccines themselves. In order for vaccine delivery missions to be effective, the right shipment services and equipment must be provided.

These programmes require appropriate ultra-low freezers, vaccine carriers, alcoholic wipes, sharps containers and immunisation cards, and even one item missing or being damaged could compromise the whole operation. That is why using effective procurement services is key.

Using the right equipment can have a life-changing impact. A vital example of this is auto-disable syringes, which play a vital role in prevention, as they are designed to automatically lock after every use, meaning they cannot be reused.

Given the fact that sharing contaminated syringes or needles is one of the main ways in which individuals contract HIV, this type of equipment should be used as much as possible when administering any vaccine.

This is because it is a safe and effective way to save lives without accidentally contributing to the spread of HIV and other blood-borne viruses.

Reducing Waste by Using the Right Equipment

When it comes to providing medical services, reducing waste should be at the forefront of people’s minds. Considering the life-saving impact vaccines can have on preventing the spread of viruses such as HIV, wasting even a small amount of vaccine can be incredibly harmful.

12 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Regulatory & Marketplace

This is precisely where using the right equipment can make a difference. A relevant example is low dead-volume syringes, which can minimise waste by reducing the amount of liquid left in a syringe after an injection.

This equipment plays a vital role in increasing the amount of people vaccinated, which is particularly relevant in the context of worldwide healthcare crises such as Covid-19, as the use of low dead-volume syringes was proven to increase Covid-19 vaccine supply by providing an extra dose per vial.3

These syringes can also reduce the risk of spreading viruses like HIV due to the fact that less dead volume means there is less space for potentially contaminated blood to be left in the syringe.

Medical procurement services are therefore crucial in the battle against viruses such as HIV, as medical professionals – and those in need of a vaccine – have to rely on these providers to deliver efficient equipment and develop the right solutions to distribute it, once ready.

In the context of distribution services, tracking performance KPIs such as OTIF (On Time in Full) can guarantee more control and efficiency in the delivery of products, helping organisations meet their targets effectively.

Maximising OTIF scores is then a great way to optimise operations and identify issues within a supply chain, potentially avoiding detrimental and wasteful time delays.

Thinking About the Future

Unimed’s mission revolves around staying ahead of evolving needs within the healthcare industry in order to be prepared to provide imminent aid to individuals globally as and when required, no matter the circumstances.

Although there is a long road ahead for medical researchers when it comes to developing a vaccine, HIV vaccine awareness day should be dedicated to recognising the vaccine development journey so far and the clinical trials that have brought us a step closer to our goal.

Unimed’s sustainable procurement efforts will continue to be directed towards

supporting research and contributing to the fight against global health issues such as HIV.

REFERENCES

1. https://www.niaid.nih.gov/diseases-conditions/ hiv-vaccine-research-history

2. https://www.statista.com/statistics/270209/ countries-with-the-highest-global-hiv-prevalence/

3. https://www.ncbi.nlm.nih.gov/pmc/articles/ PMC8418643/

Shameet S. Thakkar

Shameet S. Thakkar is the Founder and Managing Director of Unimed Procurement Services, an MHRA licensed healthcare procurement company. With over 10 years of experience, Shameet has successfully delivered healthcare projects to global clients in over 25 countries.Shameet is an expert in harnessing procurement activity to engage supply markets in innovative ways, reduce costs and maximise commercial benefits.

HIGH PURITY. HIGH DEMANDS.

High

Safety valves

traps

INTERNATIONAL PHARMACEUTICAL INDUSTRY 13

Pressure regulators Control valves Pipeline ancillaries Special equipment Steam

purity equipment for clean steam adca@valsteam.pt www.valsteam.com +351 236 959 060 Zona Ind. da Guia, Pav. 14 - Brejo 3105-467, Guia PBL PORTUGAL PRODUCTS MANUFACTURED IN PORTUGAL AV 001 AP EN 01.20

Regulatory & Marketplace

A Business Growth Tool: Patent Claiming Strategies

Developing a pharmaceutical product can take on the order of a decade from research (first inventing the drug) to development, and finally to FDA approval. While Patent Term Extension can restore some time lost due to the regulatory approval process, the traditional strategy of relying on patents based on the drug itself or its general method of use will necessarily start – and stop – the protection clock much earlier. This limits the potential return on investment prior to generic copyists. But, if one is creative and coordinated, additional strategies can be used to advance business growth with longer and stronger patents.

While each and every product presents new and unique facts that must be separately evaluated, creative strategies such as coordinating patent claims with the product label, claiming unexpected discoveries from later product development, and using the oft overlooked “means plus function” claiming format have each been shown to provide opportunities for valuable patent protection.

I. Coordinating the Claims and the Label

With some exceptions, a generic or bio-similar manufacturer must copy the innovator’s FDA approved package insert (“label”). This makes innovations reflected in and recommended on the label – such as from pivotal Phase III clinical trials – a potentially valuable source for additional patent protection.

The successful use of clinical trial results in this way was affirmed in Sanofi v. Watson, 875 F.3d 636 (Fed. Cir. 2017), in relation to Sanofi’s antiarrhythmic dronedarone product, marketed as Multaq®. The net result for Sanofi was achieving 10 more years of patent exclusivity for Multaq® compared to the dronedarone composition of matter patent.

Prior to the approval of Multaq®, a Phase III clinical trial conducted by Sanofi showed decreased cardiovascular hospitalisation and death in a particular high-risk patient population, specifically patients at least age 75 or those having hypertension, diabetes,

or other cardiovascular risk factors. Sanofi’s patent in the case relied on the Phase III data to claim a method of administering dronedarone to decrease a risk of cardiovascular hospitalisation in these patients. Once approved, the Multaq® label included the same Phase III results with all the relevant details in its “Clinical Studies” section, which was also cross-referenced from the label’s “Indications and Usage” section.

The generic party (Watson) copied the Multaq® label, including the “Clinical Studies” section with the Phase III results and the “Indications and Usage” section. Watson argued, however, that this did not induce the claimed method in part because its “Indications and Usage” did not specify treating the claimed high-risk patients. The courts – district court and Federal Circuit – disagreed. They found that the generic label induced infringement by encouraging the claimed treatment of the claimed highrisk patients. Id. at 646. Relying in part on the fact Watson’s “Indications and Usage” section also cross referenced to the “Clinical Studies” section, the courts found that Watson’s label “directs medical providers to information identifying the desired benefit for only patients with the patent-claimed risk factors.” Id. at 645.

The strategy of protecting non-obvious innovations developed from late-phase clinical trials included on the product label has proved successful in other cases as well. For instance, Vanda Pharmaceuticals obtained stronger patent exclusivity by developing, claiming, and including on its product label a method of using iloperidone to treat patients suffering from schizophrenia, where the dose was adjusted based on determining whether the patient was a poor CYP2D6 metaboliser.1

There are several key considerations to successfully rely on late-developed clinical innovations included in the label. For example, a patent application based on later clinical trials is best filed before the product is approved and before such results are published. Otherwise, the product label or publication could become prior art, as set out under 35 U.S.C. § 102(a)(1), in the absence of any 35 U.S.C.

§ 102(b)(1) exceptions. Importantly, with timing being everything, IP teams should coordinate early and frequently with clinical and regulatory teams to implement this strategy.

Another important consideration is whether the specific information included in the label and covered by the claims can be carved out by the generic or biosimilar manufacturer. In general, label information related to safety, dosage adjustments, and references to the clinical studies section in the “Indication and Usage” section must be copied, such that they are particularly suitable when considering how to best protect the product. In addition, the relied-upon clinical trial results should be recommended or encouraged by the label, such as the population to be treated or the dose to be used to minimise the effect of drug-drug interactions.

II. Claiming Unexpected Discoveries

Unexpected discoveries from late-stage pharmaceutical development can also be relied upon for novel and non-obvious inventions that provide additional protection. A good example of this is addressed in Teva Pharms. USA, Inc. v. Corcept Therapeutics, Inc., 18 F.4th 1377 (Fed. Cir. 2021), where the Federal Circuit affirmed that Teva failed to show that Corcept’s patent was obvious in a Post Grant Review (“PGR”) before the Patent Trial and Appeal Board (“the Board”).

Corcept markets Korlym®, mifepristone— an old drug – in a 300 mg tablet for the treatment of Cushing's syndrome. In approving Corcept’s New Drug Application (“NDA”) for Korlym®, the U.S. Food and Drug Administration (“FDA”) required Corcept to conduct a post-marketing (Phase IV) drug-drug interaction clinical trial of mifepristone and ketoconazole (a strong CYP3A inhibitor). Id. at 1379. The FDA also provided a memorandum (the “Lee Memorandum”) explaining that the drug-drug interaction study was necessary to determine whether there was a safety risk in co-administration of CYP3A inhibitors and mifepristone. Id.

Corcept’s original Korlym® label recommended a starting dose of 300 mg once daily up to a maximum of 1200 mg

14 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Regulatory & Marketplace

INTERNATIONAL PHARMACEUTICAL INDUSTRY 15wwww.international-pharma.com www.lifescienceaustria.at Advancing Austrian life science at the heart of Europe www.lifesciencesdirectory.at Find your right partner in Austria Find out more about our excellence

once daily, but with a warning to limit the mifepristone dose to 300 mg once daily when used with strong CYP3A inhibitors. Id. Based on the post-marketing drug-drug interaction study, Corcept unexpectedly discovered that doses higher than 300 mg could be used with concomitant administration of a strong CYP3A inhibitor. Based on this, Corcept applied for and received U.S. Pat. No. 10,195,214 (“the ’214 patent”), claiming the use of up to 600 mg of mifepristone in combination with a strong inhibitor.

In the PGR, Teva argued that the claims of the ’214 patent were obvious based on the original Korlym® label, the Lee Memorandum, and other references. Id. at 1380. The Board disagreed, finding that Teva failed to show “a reasonable expectation of success for safe co-administration of more than 300 mg of mifepristone” – the limit set by the original Korlym® label – "with a strong CYP3A inhibitor.” Id. The Board relied on, among other evidence, an admission from Teva’s expert’s testimony that the skill artisan “would have no expectation as to whether the co-administration of 600 mg of mifepristone with ketoconazole would be safe.” Id. at 1381-82. (emphasis in original). The Federal Circuit affirmed based on precedent that that “reasonableexpectation-of-success requirement is not satisfied when the skilled artisan would have had no expectation of success.” Id.

Claiming late-developed unexpected discoveries has been successful for other companies as well. For example, Cumberland Pharmaceuticals obtained and successfully enforced a patent based on its unexpected discovery – also based on a Phase IV study –that its Acetadote® (acetylcysteine) Injection for the treatment of acetaminophen poisoning could be formulated as a stable product without a chelating agent (EDTA) that been used in all prior commercial acetylcysteine formulations.2

As these cases illustrate, claiming an unexpected discovery helps the patent owner bolster its defense against obviousness challenges since showing obviousness requires a reasonable expectation of success in arriving at the claimed invention. The claims are no longer simply dosage and formulations of specific amounts, but dosage and formulations with specific and important properties that could not have been expected.

III. Means-Plus-Function

Means-plus-function (“MPF”) claims define

an element, in a combination claim, by its function instead of its structure:

35 U.S.C. §112(f) ELEMENT IN CLAIM FOR A COMBINATION. – An element in a claim for a combination may be expressed as a means or step for performing a specified function without the recital of structure, material, or acts in support thereof, and such claim shall be construed to cover the corresponding structure, material, or acts described in the specification and equivalents thereof.

MPF claims, often thought of as very narrow and only for use in the mechanical or electrical arts, can in fact provide greater protection than can other types of claims, including for claims drawn to pharmaceutical subject matter.3 That is because the statutory term “equivalents” does not reference the doctrine of equivalents, but rather refers to literal equivalents of structure, material, or acts that perform the same function. By encompassing literal equivalents, an inventor’s claims can better protect an inventor’s rights. MPF claims can also better prevent competitors from drafting around the literal scope compared to claims that recite particular elements, as MPF claims can encompass alternatives that provide the same function as claimed. MPF claim language may also provide more accuracy and clarity than purely structural characterisation and may avoid written description and enablement issues.

Overall, MPF language can be a powerful tool in drafting pharmaceutical claims to encompass broader claim scope and thus more fully protect an inventor’s rights and provide greater protection against infringement. Practitioners are cautioned, however, that 35 U.S.C. § 112(b) also applies. If one of ordinary skill in the art would be unable to recognize the structure, material, or acts in the specification that is clearly linked to the means plus function element, the claim will be invalid as indefinite under §112(b)!

IV. Applying These Creative Claiming Strategies for Business Growth

Using creative patenting strategies to advance business growth means, by definition, not simply relying on routine patents and claim formats. Making the most of one’s innovations requires looking deeper, such as considering all the potential claimable subject matter:

• Actives

• Formulations

• Delivery systems

• Drug-device combos

• Methods of treatment

• Methods of making

• Diagnostic, personalised medicine

If you have access to pivotal clinical trial data, try a Sanofi v. Watson application with narrow claims that capture the clinical trial results recommended in the drug product label, e.g., specific indication, dosing, specified target patient population, contraindicated symptoms, warnings and risk factors. Consider, in particular, safety signals, dosing regimens, and other disclosures that are difficult or impossible to carve out of a label.

If you make unexpected discoveries that lead to novel methods or formulations, protect these too. As described above, they can be the basis for particularly strong patent protection.

In addition to capturing innovations with other claim styles, consider meansplus-function claiming such as:

A composition comprising:

• component A and means for [achieving some desirable outcome]

• possibly effective against an ANDA applicant; or

A composition comprising:

• means for [achieving some desirable outcome]; and a pharmaceutically acceptable carrier

• possibly effective against an 505(b) (2) applicant.

Draft the specification to cover all the embodiments that you want to cover with this language (include alternatives). Link the function recited by the “means for” in your claim to the specification’s description of the structure(s), materials or acts of that function. This can be done in a preliminary amendment if not explicit in the specification. In other words, be intentional and thorough in your decision to use MPF claims.

Successfully implementing any of these strategies also requires making sure the specification provides adequate written

16 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Regulatory & Marketplace

description support for the claim, such as the results of the clinical study or other relevant (unexpected) discoveries, and the MPF support. And coordination between the clinical, regulatory, and IP teams is critical.

There are necessarily multiple moving parts to track to implement advanced patenting strategies for pharmaceutical products. But, if properly considered, they can be leveraged to advance business growth and increase return on investment.4

REFERENCES

1. See Vanda Pharms. Inc. v. West-Ward Pharms. Int'l Ltd., 887 F.3d 1117 (Fed. Cir. 2018), US Patent No. 8,586,610 (FANAPT®); see also AstraZeneca AB v. Macleods Pharmaceuticals Ltd., No. 1-20cv-01180 (D.DEL.), US Patent No. 10,300,065 (BRILINTA®).

2. See U.S. Patent No. 8,399,445; Cumberland Pharm. Inc. v. Mylan Institutional LLC, 846 F.3d 1213, 1214 (Fed. Cir. 2017).

3. Examples of issued MPF bio/pharm claims can be found in U.S. 8,722,872; U.S. 10,413,611; U.S. 9,149,464; U.S. 7,579,380; U.S. 7,670,617; U.S. 9,446,076; U.S. 10,335,405; and U.S. 6,974,595 (note, successfully enforced in Nautilus Neurosciences, Inc. v. Wockhardt, United States LLC, 2:11-cv-01997 (D. NJ Feb. 27, 2013) (not for publication). See also Examples 5 and 6 in the USPTO Training Materials at https://www. uspto.gov/patents/laws/examination-policy/ examination-guidance-and-training-materials

4. These materials have been prepared solely for educational and entertainment purposes to contribute to the understanding of U.S. intellectual property law. These materials reflect only the personal views of the authors and are not individualised legal advice. It is understood that each case is fact specific, and that the appropriate solution in any case will vary. Therefore, these materials may or may not be relevant to any particular situation. Thus, the authors and FINNEGAN, HENDERSON,

Regulatory & Marketplace Tom Irving

Tom Irving is a partner at Finnegan and has some 45 years of experience in intellectual property law. His U.S. pharma practice includes America Invents Act (AIA) post-grant proceedings, due diligence, counselling, patent prosecution, reissue, and re-examination.

In addition to advising on procuring strong U.S. patents, Tom counsels clients on a wide range of mainly pharmaceutical matters, including pre-litigation, Orange Book listings of patents covering FDA-approved drugs, infringement issues, enforceability, supplemental examination, and validity analysis.

Email: tom.irving@finnegan.com

Stacy Lewis

Stacy Lewis is called to the bar in New York and has worked as a law clerk at Finnegan since 1995. She focuses on research and writing, particularly in the life sciences. She is the coordinating editor of the books Global Patent Litigation: How and Where to Win and Design Patent Law, as well as the coursebook Chemical Patent Practice. Stacy sits on the AIPLA Quarterly Journal and IPO Law Journal editorial boards.

Email:

FARABOW, GARRETT & DUNNER, LLP (including Finnegan Europe LLP, and Fei Han Foreign Legal Affairs Law Firm), cannot be bound either philosophically or as representatives of their various present and future clients to the comments expressed in these materials. The presentation of these materials does not establish any form of attorney-client relationship with these authors or FINNEGAN, HENDERSON, FARABOW, GARRETT & DUNNER, LLP (including Finnegan Europe LLP, and Fei Han Foreign Legal Affairs Law Firm). While every attempt was made to ensure that these materials are accurate, errors or omissions may be contained therein, for which any liability is disclaimed.

Mark Feldstein

Mark Feldstein, Ph.D. is a partner at Finnegan. His practice focuses on U.S. district court litigation, primarily concerning the enforcement of U.S. patent rights and trade secret issues, and postgrant trial proceedings at the USPTO.

His experience encompasses a range of technologies, including pharmaceuticals, chemicals, biochemistry, polymers, small molecule chemistry, nanotechnology, optics, and medical and analytic devices.

Mark has particular experience with litigations arising from Abbreviated New Drug Applications (ANDAs) under the Hatch-Waxman Act.

Email: mark.feldstein@finnegan.com

Adriana Burgy

Adriana Burgy is a partner at Finnegan. Her practice focuses on opinion work, client counselling, patent prosecution and management, and litigation in the chemical, pharmaceutical, and biotechnology arts. Recognised by The Legal 500 U.S. for patent prosecution, re-examinations, and post-grant proceedings, Adriana counsels her clients on a diverse range of patent issues. She has managed the prosecution of hundreds of patent applications domestically and internationally directed to consumer products, pharmaceuticals, and small molecules.

Email: adriana.burgy@finnegan.com

INTERNATIONAL PHARMACEUTICAL INDUSTRY 17wwww.international-pharma.com

stacy.lewis@finnegan.com

Drug

Development & Delivery

Under Pressure: Finding a More Sustainable Future for pMDIs

The transition away from the use of ozone-damaging chlorofluorocarbon (CFC) gases has been one of the major environmental achievements of modern times.

Today, hindsight affords us the ability to see how this transition enabled the Earth’s protective ozone layer to heal itself over several decades. An unintended consequence, however, was that the withdrawal of CFCs (Chlorofluorocarbons) ushered in greater use of hydrofluorocarbons, known as F-gases, which introduced their own environmental challenges.

While this family of gases might not pose a risk to the atmospheric ozone layer, they were found to contribute to the greenhouse effect. Compared with carbon dioxide (CO2), F-gases have a far higher global-warming potential (GWP), based on attributes including infrared radiation absorption and atmospheric lifetime. These characteristics mean F-gases are now also subject to a phasing down, impacting a variety of processes and applications where they currently play an essential role.1

In medicine, the use of F-gases is widespread across the globe, with HFC134a and HFC-227ea relied upon as safe and effective propellants within inhalation devices, helping millions of patients manage respiratory conditions such as asthma and chronic obstructive pulmonary disease (COPD). As the negative environmental impact of these gases becomes more understood, there are implications for every stakeholder in the chain, from device manufacturers and pharmaceutical companies to healthcare professionals (HCPs) and patients.

The phasing down of F-gases is already well underway, with global efforts falling in line with the Montreal Protocol of the Vienna Convention on Substances that Deplete the Ozone Layer. The Montreal Protocol has provided a framework for safeguarding the ozone layer since it went into effect in 1989 to define the transition away from CFCs.2 This framework was expanded on January 1,

2019, through the Kigali Amendment, which binds all 198 signatories to also take action to reduce the production and use of F-gases, including the HFCs used in medical devices.

Of all territories across the world, Europe has historically implemented the most stringent targets for HFC reduction. On April 5, 2022, The European Commission set out proposals for two new regulations that would strengthen F-gas legislation and pave the way for a series of changes to accelerate the phasing down process. In announcing the proposals, Frans Timmermans, Executive Vice-President for the European Green Deal, said that while the EU’s current ambitious policies have been successful, “science urges us to go further and faster now”.3

Currently, F-gases account for 2.5% of total greenhouse gas emissions across Europe. The European Commission (EC) said the proposals to accelerate their phasing down would contribute to reducing these emissions by at least 55% by 2030 and support the continent’s overarching plan to be climate-neutral by 2050.

In the United States, the world’s largest market for pressurised metered dose inhalers (pMDIs), the phase-down programme is scheduled to follow behind Europe through the American Innovation and Manufacturing Act, which came into effect in December 2020. While pMDIs are encompassed within ‘set-aside’ allocations to ease the transition in the region, these are only in place for a period of five years and the US is expected to achieve a phasedown level of 15% by 2035. Other territories across the rest of the world, including India

and countries across the Middle East, are expected to follow behind the US by a period of around 15 years.

Although these robust environmental targets are fixed in place, less certainty surrounds the knock-on effects of meeting them. Of primary concern here are patients, whose ongoing needs must be met in terms of consistent access to relief and prevention medication – something that can only be achieved through the transition either to alternative inhalation devices with lower GWP, such as dry powder inhalers (DPIs), or to pMDIs using lower GWP propellants.

While it would be hoped that such a transition would follow some of the precedent set by the move away from CFCs, it is clear that the phasing down of F-gases must overcome a different set of complex hurdles to ensure device and drug are optimised in a way that satisfies patient need.

In the most acute circumstances, patient need can manifest itself as the administration of life-saving medicine to a potentially incapacitated individual who might not have the respiratory force required to deliver the necessary dose via a DPI. Over decades, pMDIs have proved their worth in this scenario, with the force of a propellant driving successful drug deposition and, therefore, patient outcomes when used in tandem with a spacer or nebuliser. As an indication of their importance to patients, pMDIs account for 77% of inhaled device doses in the world’s top 15 markets.

Dry powder inhalers, while highly effective, do not represent a like-for-like ‘swap’

18 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2

Discovery,

Drug Discovery, Development & Delivery

in this regard. For elderly populations, drug delivery can be impaired when respiratory muscle weakness limits a patient’s inhalation action, while younger children can struggle to comply with the technique required for optimal dose delivery. As such, the use of DPIs as a rescue medication remains limited, accounting for only 3% of prescriptions containing a short-acting beta-agonist (SABA).

Running in parallel with the requirement to answer patient need is the need to consider limiting the disruption to the current economic models that successfully underpin pMDI use. It cannot be ignored that delivering medication via HFC-based pMDIs is both highly efficient and highly cost-effective, with the average cost per dose of salbutamol estimated at $0.06.

However, analysis of the global economic impact of switching from pMDIs to DPIs, using prescribing data sourced from the IQVIA database, has revealed that in all the world’s top 15 markets for respiratory drugs by value, costs would rise if SABA pMDIs were replaced with DPIs. The only exception is Brazil, where there is no equivalent DPI registered.4

That is not to say that the economics for existing pMDIs are fixed. As regulations drive down volumes of industrial-grade F-gases, from which medical-grade propellants are manufactured, prices are likely to increase. Indeed, the market has already experienced this dynamic in recent years, with escalating propellant cost pressures only eased by the allowance of imports under the ‘exempted’ classification.

The answer to providing patients with device continuity therefore rests on the development of a new era of pMDIs using propellants with lower GWP than existing options. Of the candidate gases being evaluated across the sector, HFA152a and HFO-1234ze show promise in terms of balancing high performance and environmental credentials with low toxicity.

Simply switching to these new propellants might be an appealing notion, but, of course, their potential must first be fully evaluated via an assessment of their characteristics to ensure device performance, clinical efficacy, toxicology and patient safety are all satisfied. Nanopharm, an Aptar Pharma company, has conducted extensive testing in this area, revealing the influence of variable propellant attributes, such as solubility, and their interaction with the drug formulation. During their research, Nanopharm has uncovered, for example, that the electrostatic charge for HFA-152a is comparatively higher than HFO-1234ze, and that the two gases impact on particle dynamics differently, with higher oropharyngeal deposition observed for HFO1234ze.

As well as overcoming any formulation and aerosolisation challenges for devices using new propellants, regulatory hurdles must also be cleared to ensure patient safety is guaranteed in the final marketed product. As urgency builds around the accelerated phase down of F-gases, any transition will require stakeholders to engage closely with regulatory bodies to facilitate approval with the requisite clinical data. Pathways may be available to expedite this process. The

US Food & Drug Administration (FDA), for example, points to section 505(b)(2) of the Federal Food, Drug, and Cosmetic Act as an option for providing an abbreviated route for approval, potentially opening the door to applications being augmented with data from bioequivalence studies.

Particularly in light of the compressed development timeframe presented by the EU’s recent proposals, the emphasis on accelerating the transition to low-GWP propellants has intensified. It could also be said, however, that this has constricted the potential for wider reflection and innovation around inhalation devices. Tighter controls on imports and the removal of exemptions for medical use mean that by 2027, F-gas levels are projected to be at just 10% lower than the baseline and, without significant change, almost all that allowance would be consumed by MDIs.

Considering these figures, it is understandable that healthcare professionals (HCPs) are being encouraged to move patients to DPIs. However, there is also the risk that such an isolated switch does not take into account the realities of human behaviours and therefore does not fit into a holistic healthcare strategy for controlling the serious risks associated with respiratory conditions.

For example, if patients have difficulty in self-managing their condition, it is possible that they will require additional support within primary or secondary care settings. Aside from the health risk involved, this places an unnecessary burden on the health system while also carrying an additional carbon cost.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 19wwww.international-pharma.com

& Delivery

Data from the SABINA CARBON UK study found that excess greenhouse gas emissions per capita were eight times higher for patients with uncontrolled asthma (as defined by one or more exacerbations in the past 12 months or being prescribed three or more SABA inhalers per year) compared with patients with controlled asthma (defined by no exacerbations and being prescribed up to two SABA inhalers per year).5 In addition, a single hospitalisation for a respiratory patient has been found to have a larger carbon footprint than 1.5 years of daily pMDI use.6

Findings like the above show that there is a wider picture to be considered when tackling the global challenge of climate

change. It is essential that the use of F-gases is controlled, but it is also critical that this process is managed within a holistic approach to the future of pMDIs, and that the contribution of associated factors such as dose efficiency, adherence and compliance are all equally considered. Within a managed transition to low-GWP alternatives, pMDI devices can not only continue to fulfil their vital purpose in delivering rescue and relief medication for patients with respiratory conditions, but they can also fulfil their potential in areas such as nasal drug delivery and as a platform for sensitive biologics, where low-GWP propellants show promise in supporting formulation stability and the delivery of high payloads.

Within the EU in particular, the drive to phase down F-gases and switch to DPIs means opportunities for more holistic reflection and innovation might be limited. In other territories, however, the elongated phase-down schedule could allow companies in these regions to leverage their position, using the introduction of low-GWP propellants to also usher in complementary device innovation.

One of the important lessons from the phasing out of CFCs via the Montreal Protocol was collaboration: all stakeholders were aligned on a singular vision, taking action to support a common goal. Today, however, we are faced with different circumstances in the challenge to deliver a sustainable strategy for the future of managing respiratory conditions. Converging on a collective vision must involve a comprehensive assessment of the changing role of different device formats within a multi-layered ecosystem over time.

Simpler strategies might hold more immediate appeal, but arguably come with risk attached.

Targets to reduce greenhouse gas emissions are of immediate interest to many across the globe but trying to make progress by exclusively focusing efforts on certain directions may carry consequences that are not immediately visible. From policymakers to healthcare providers, drug companies and device manufacturers, it is incumbent to find the right balance on the path to delivering better outcomes for patients and the planet long into the future.

REFERENCES

https://ec.europa.eu/clima/eu-action/ fluorinated-greenhouse-gases_en

https://ozone.unep.org/treaties/montrealprotocol

https://ec.europa.eu/commission/ presscorner/detail/e%20n/ip_22_2189

https://www.dovepress.com/the-climate-ischanging-for-metered-dose-inhalers-and-

20 INTERNATIONAL PHARMACEUTICAL INDUSTRY Summer 2022 Volume 14 Issue 2 Drug Discovery, Development

1.

2.

3.

4.

Drug Discovery, Development & Delivery

action-is-needed-peer-reviewed-fulltextarticle-DDDT#T0002

https://www.astrazeneca.com/media-centre/ medical-releases/carbon-studies-showeduncontrolled-asthma-is-associated-with-an-

increased-carbon-footprint-of-asthma-care.html

https://www.astrazeneca.com/media-centre/ articles/2020/investing-in-a-sustainablefuture-for-patients-with-respiratory-disease.

Omar Usmani

Dr. Jag Shur

Dr. Jag Shur, Vice-President, Science & Technology, Nanopharm, an Aptar Pharma company, and Co-Founder of Nanopharm is an internationally recognised expert in the investigation of bioequivalence of OINDPs. Holding a BSc (Hons) in Chemistry, he completed his PhD entitled ‘Formulated Muco-Regulatory Agents in the Airways of Patients with Cystic Fibrosis’ from Portsmouth School of Pharmacy in the UK. Dr. Shur is also a post-doctoral fellow at the London School of Pharmacy, having investigated the fabrication of micro particles for vaccine delivery using supercritical fluid technology.

Dr. John N. Pritchard